Influence of Hot Deformation on the Precipitation Hardening of High-Strength Aluminum AA7075 during Thermo-Mechanical Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Testing Procedures

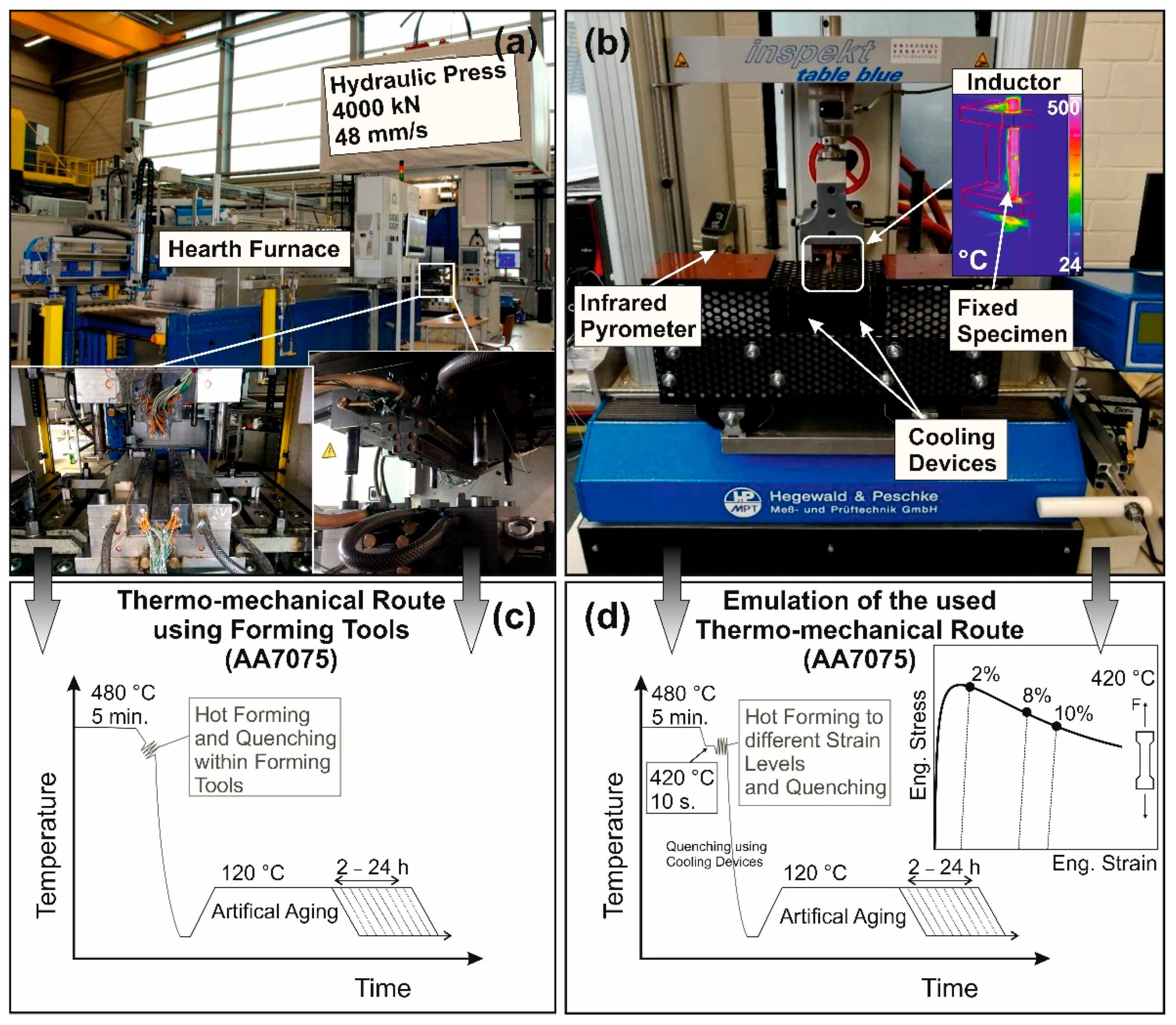

2.2. Experimental Setup and Program

3. Results

3.1. Forming Behavior at Elevated Temperature

3.2. As-Received Microstructure and Mechanical Properties

3.3. Effect of Hot Deformation under As-Quench Condition

3.4. Effect of Hot Deformation on the Strengthening Behavior after Artifical Aging

3.5. Effect of Hot Deformation on Microstructure

4. Discussion

5. Conclusions

- The formation of a high-strength aluminum alloy at a high temperature of 420 °C led to a higher formability compared to room-temperature forming due to the activated softening mechanisms.

- The response of artificial aging to the hot deformation represented only a low influence on mechanical properties due to dynamic recrystallization and recovery, leading to a decrease in dislocation density.

- Almost the same microstructure with the nucleation of fine precipitates, which act as effective barriers to dislocation motion, as well as few coarse particles, were obtained at hot deformations of 2% and 10%, confirming the low effect of the deformation degree.

- Nonetheless, further microstructural investigations are needed to clarify the complex precipitation–dislocation behavior during artificial aging.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Starke, E.A.; Staleyt, J.T. Application of Modern Aluminum Alloys to Aircraft. Prog. Aerosp. Sci. 1996, 32, 131–172. [Google Scholar] [CrossRef]

- Hornbogen, E.; Starke, E.A. Overview no. 102 Theory assisted design of high strength low alloy aluminum. Acta Metall. Mater. 1993, 41, 1–16. [Google Scholar] [CrossRef]

- Peng, X.; Fan, J.; Yang, Y.; Chen, Y.; Yin, Y. Investigations to the effect of heating-rate on the mechanical properties of aluminum alloy LY12. Int. J. Solids Struct. 2003, 40, 7385–7397. [Google Scholar] [CrossRef]

- Garrett, R.P.; Lin, J.; Dean, T.A. An investigation of the effects of solution heat treatment on mechanical properties for AA 6xxx alloys: Experimentation and modelling. Int. J. Plast. 2005, 21, 1640–1657. [Google Scholar] [CrossRef]

- Krajewski, P. Overview of Quick Plastic Forming Technology. Mater. Sci. Forum 2007, 551–552, 3–12. [Google Scholar] [CrossRef]

- Bay, N. Cold forming of aluminium-state of the art. J. Mater. Process. Technol. 2000, 71, 76–90. [Google Scholar] [CrossRef]

- Lin, J.; Balint, D.S.; Wang, L.; Trevor, A.D.; Foster, A.D. Method of Forming A Component of Complex Shape from Sheet Material. U.S. Patent No. 9,950,355, 24 April 2018. [Google Scholar]

- El Fakir, O.; Wang, L.; Balint, D.; Dear, J.P.; Lin, J.; Dean, T.A. Numerical study of the solution heat treatment, forming, and in-die quenching (HFQ) process on AA5754. Int. J. Mach. Tools Manuf. 2014, 87, 39–48. [Google Scholar] [CrossRef] [Green Version]

- Scharifi, E.; Knoth, R.; Weidig, U. Thermo-mechanical forming procedure of high strength Aluminum sheet with improved mechanical properties and process efficiency. Procedia Manuf. 2019, 29, 481–489. [Google Scholar] [CrossRef]

- Zheng, K.; Dong, Y.; Zheng, J.H.; Foster, A.; Lin, J.; Dong, H.; Dean, T.A. The effect of hot form quench (HFQ®) conditions on precipitation and mechanical properties of aluminium alloys. Mater. Sci. Eng. A 2019, 761, 138017. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.J.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex—Shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Moeini, G.; Scharifi, E.; Lauhoff, C.; Böhm, S.; Niendorf, T. On the Effect of Quenching on Postweld Heat Treatment of Friction-Stir-Welded Aluminum 7075 Alloy. J. Mater. Eng. Perform. 2019, 28. [Google Scholar] [CrossRef]

- Liu, J.; Gao, H.; El Fakir, O.; Wang, L.; Lin, J. HFQ forming of AA6082 tailor welded blanks. MATEC Web Conf. 2015, 21, 05006. [Google Scholar] [CrossRef] [Green Version]

- Li, N.; Mohamed, M.S.; Cai, J.; Lin, J.; Balint, D.; Dean, T.A. Experimental and numerical studies on the formability of materials in hot stamping and cold die quenching processes. AIP Conf. Proc. 2011, 1353, 1555–1561. [Google Scholar] [CrossRef] [Green Version]

- Garrett, R.P.; Lin, J.; Dean, T.A. Solution Heat Treatment and Cold Die Quenching in Forming AA 6xxx Sheet Components: Feasibility Study. Adv. Mater. Res. 2005, 6–8, 673–680. [Google Scholar] [CrossRef]

- Wang, L.; Strangwood, M.; Balint, D.; Lin, J.; Dean, T.A. Formability and failure mechanisms of AA2024 under hot forming conditions. Mater. Sci. Eng. A 2011, 528, 2648–2656. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Scharifi, E.; Weidig, U.; Steinhoff, K.; Niendorf, T. Performance of Thermo-Mechanically Processed AA7075 Alloy at Elevated Temperatures—From Microstructure to Mechanical Properties. Metals 2020, 10, 884. [Google Scholar] [CrossRef]

- Xiao, W.; Wang, B.; Wu, Y.; Yang, X. Constitutive modeling of flow behavior and microstructure evolution of AA7075 in hot tensile deformation. Mater. Sci. Eng. A 2018, 712, 704–713. [Google Scholar] [CrossRef]

- Gupta, R.K.; Anil Kumar, V.; Sarath Krishnan, A.; Niteshraj, J. Hot Deformation Behavior of Aluminum Alloys AA7010 and AA7075. J. Mater. Eng. Perform. 2019, 28, 5021–5036. [Google Scholar] [CrossRef]

- Shojaei, K.; Sajadifar, S.V.; Yapici, G.G. On the mechanical behavior of cold deformed aluminum 7075 alloy at elevated temperatures. Mater. Sci. Eng. A 2016, 670, 81–89. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.M. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Sakai, T.; Belyakov, A.; Kaibyshev, R.; Miura, H.; Jonas, J.J. Progress in Materials Science Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog. Mater. Sci. 2014, 60, 130–207. [Google Scholar] [CrossRef] [Green Version]

- Hornbogen, E. Hundred years of precipitation hardening. J. Light Met. 2001, 1, 127–132. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation Reactions in Age-Hardenable Alloys during Laser Additive Manufacturing. JOM 2016, 68, 943–949. [Google Scholar] [CrossRef] [Green Version]

- Lin, Y.C.; Jiang, Y.Q.; Chen, X.M.; Wen, D.X.; Zhou, H.M. Effect of creep-aging on precipitates of 7075 aluminum alloy. Mater. Sci. Eng. A 2013, 588, 347–356. [Google Scholar] [CrossRef]

- Segal, V.M. New hot thermo-mechanical processing of heat treatable aluminum alloys. J. Mater. Process. Technol. 2016, 231, 50–57. [Google Scholar] [CrossRef]

- Zheng, J.H.; Dong, Y.; Zheng, K.; Dong, H.; Lin, J.; Jiang, J.; Dean, T.A. Experimental investigation of novel fast–ageing treatments for AA6082 in supersaturated solid solution state. J. Alloys Compd. 2019, 810, 151934. [Google Scholar] [CrossRef]

- Li, N.; Zheng, J.; Zhang, C.; Zheng, K.; Lin, J.; Dean, T.A. Investigation on fast and energy-efficient heat treatments of AA6082 in HFQ processes for automotive applications. MATEC Web Conf. 2015, 21, 05015. [Google Scholar] [CrossRef] [Green Version]

- Jung, S.H.; Lee, J.; Kawasaki, M. Effects of pre-strain on the aging behavior of Al 7075 alloy for hot-stamping capability. Metals 2018, 8, 137. [Google Scholar] [CrossRef] [Green Version]

- Vrolijk, M.; Koroschetz, C.; Holecek, M.; Snilsberg, K.E.; Jönsson, L.-O.; Anyasodor, G.; Lorenz, D. Investigation on Aluminium Hot and Warm Forming with the Help of Virtual Process Modeling. In Proceedings of the 6th International Seminar on Hot Sheet Metal Forming of High-Performance Steel CHS2, Atlanta, GA, USA, 4–7 June 2017; pp. 673–681. [Google Scholar]

- Scharifi, E.; Schade, T.; Ademaj, A.; Sajadifar, S.V.; Weidig, U.; Niendorf, T.; Steinhoff, K. Characterization of Mechanical Properties, Macroscopic Deformation Behavior, and Microstructure of Functionally Graded 22MnB5 Steel. Steel Res. Int. 2000, 633. [Google Scholar] [CrossRef]

- Mohamed, M.S.; Foster, A.D.; Lin, J.; Balint, D.S.; Dean, T.A. Investigation of deformation and failure features in hot stamping of AA6082: Experimentation and modelling. Int. J. Mach. Tools Manuf. 2012, 53, 27–38. [Google Scholar] [CrossRef]

- Scharifi, E.; Sajadifar, S.V.; Moeini, G.; Weidig, U.; Böhm, S.; Niendorf, T.; Steinhoff, K. Dynamic Tensile Deformation of High Strength Aluminum Alloys Processed Following Novel Thermomechanical Treatment Strategies. Adv. Eng. Mater. 2020, 22, 2000193. [Google Scholar] [CrossRef]

- Heider, B.; Scharifi, E.; Engler, T.; Oechsner, M.; Steinhoff, K. Influence of heated forming tools on corrosion behavior of high strength aluminum alloys. Mater. Werkst. 2021, 52, 145–151. [Google Scholar] [CrossRef]

- Sajadifar, S.V.; Scharifi, E.; Weidig, U.; Steinhoff, K.; Niendorf, T. Effect of Tool Temperature on Mechanical Properties and Microstructure of Thermo-Mechanically Processed AA6082 and AA7075 Aluminum Alloys. HTM J. Heat Treat. Mater. 2020, 75, 177–191. [Google Scholar] [CrossRef]

- Scharifi, E.; Savaci, U.; Kavaklioglu, Z.B.; Weidig, U.; Turan, S.; Steinhoff, K. Effect of thermo-mechanical processing on quench-induced precipitates morphology and mechanical properties in high strength AA7075 aluminum alloy. Mater. Charact. 2021, 174, 111026. [Google Scholar] [CrossRef]

- Zhao, H.; De Geuser, F.; Kwiatkowski da Silva, A.; Szczepaniak, A.; Gault, B.; Ponge, D.; Raabe, D. Segregation assisted grain boundary precipitation in a model Al-Zn-Mg-Cu alloy. Acta Mater. 2018, 156, 318–329. [Google Scholar] [CrossRef] [Green Version]

- Marlaud, T.; Deschamps, A.; Bley, F.; Lefebvre, W.; Baroux, B. Influence of alloy composition and heat treatment on precipitate composition in Al-Zn-Mg-Cu alloys. Acta Mater. 2010, 58, 248–260. [Google Scholar] [CrossRef]

- Buha, J.; Lumley, R.N.; Crosky, A.G. Secondary ageing in an aluminium alloy 7050. Mater. Sci. Eng. A 2008, 492, 1–10. [Google Scholar] [CrossRef]

- Gao, H.; Weng, T.; Liu, J.; Li, C.; Li, Z.; Wang, L. Hot stamping of an Al-Li alloy: A feasibility study. MATEC Web Conf. 2015, 21, 05007. [Google Scholar] [CrossRef] [Green Version]

- Maikranz-Valentin, M.; Weidig, U.; Schoof, U.; Becker, H.; Steinhoff, K. Components with Optimised Properties due to Advanced Thermo-mechanical Process Strategies in Hot Sheet Metal Forming. Steel Res. Int. 2008, 79, 92–97. [Google Scholar] [CrossRef]

- Humphreys, F.J. Nucleation in recrystallization. Mater. Sci. Forum 2004, 467–470, 107–116. [Google Scholar] [CrossRef]

- Fribourg, G.; Bréchet, Y.; Deschamps, A.; Simar, A. Microstructure-based modelling of isotropic and kinematic strain hardening in a precipitation-hardened aluminium alloy. Acta Mater. 2011, 59, 3621–3635. [Google Scholar] [CrossRef]

- Zhou, M.; Lin, Y.C.; Deng, J.; Jiang, Y.Q. Hot tensile deformation behaviors and constitutive model of an Al-Zn-Mg-Cu alloy. Mater. Des. 2014, 59, 141–150. [Google Scholar] [CrossRef]

- Edwards, G.A.; Stiller, K.; Dunlop, G.L.; Couper, M.J. The Precipitation Sequence in Al ± Mg ± Si Alloys. Acta Mater. 1998, 46, 3893–3904. [Google Scholar] [CrossRef]

- Kumar, M.; Sotirov, N.; Chimani, C.M. Investigations on warm forming of AW-7020-T6 alloy sheet. J. Mater. Process. Technol. 2014, 214, 1769–1776. [Google Scholar] [CrossRef]

- Lervik, A.; Marioara, C.D.; Kadanik, M.; Walmsley, J.C.; Milkereit, B.; Holmestad, R. Precipitation in an extruded AA7003 aluminium alloy: Observations of 6xxx-type hardening phases. Mater. Des. 2020, 186, 108204. [Google Scholar] [CrossRef]

- Picu, R.C.; Zhang, D. Atomistic study of pipe diffusion in Al-Mg alloys. Acta Mater. 2004, 52, 161–171. [Google Scholar] [CrossRef]

- Yang, B.; Milkereit, B.; Zhang, Y.; Rometsch, P.A.; Kessler, O.; Schick, C. Continuous cooling precipitation diagram of aluminium alloy AA7150 based on a new fast scanning calorimetry and interrupted quenching method. Mater. Charact. 2016, 120, 30–37. [Google Scholar] [CrossRef]

- Jiang, H.; Sandlöbes, S.; Gottstein, G.; Korte-Kerzel, S. On the effect of precipitates on the cyclic deformation behavior of an Al-Mg-Si alloy. J. Mater. Res. 2017, 32, 4398–4410. [Google Scholar] [CrossRef]

- McQueen, H.J.; Imbert, C.A.C. Dynamic recrystallization: Plasticity enhancing structural development. J. Alloys Compd. 2004, 378, 35–43. [Google Scholar] [CrossRef]

- McQueen, H.J.; Ryan, N.D. Constitutive analysis in hot working. Mater. Sci. Eng. A 2002, 322, 43–63. [Google Scholar] [CrossRef]

- Lv, J.; Zheng, J.-H.; Yardley, V.A.; Shi, Z.; Lin, J. A Review of Microstructural Evolution and Modelling of Aluminium Alloys under Hot Forming Conditions. Metals 2020, 10, 1516. [Google Scholar] [CrossRef]

| Chemical Elements (wt.%) | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others |

|---|---|---|---|---|---|---|---|---|---|

| AA7075—as received (AR) | 0.08 | 0.12 | 1.6 | 0.04 | 2.7 | 0.19 | 5.9 | 0.05 | 0.03 |

| Material | SHT Temperature (°C) | SHT Time (s) | Forming Temperature (°C) | Cooling | Aging |

|---|---|---|---|---|---|

| AA7075 (TM) | 480 | 300 | ~420 | Forming tool | - |

| AA7075 (ETM) | 480 | 300 | 420 | Cooling device | - |

| AA7075 (TM) | 480 | 300 | ~420 | Forming tool | 120 °C—(2, 20, 24) h |

| AA7075 (ETM) | 480 | 300 | 420 | Cooling device | 120 °C—(2, 6, 12, 16, 20, 24) h |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Scharifi, E.; Shoshmina, D.; Biegler, S.; Weidig, U.; Steinhoff, K. Influence of Hot Deformation on the Precipitation Hardening of High-Strength Aluminum AA7075 during Thermo-Mechanical Processing. Metals 2021, 11, 681. https://doi.org/10.3390/met11050681

Scharifi E, Shoshmina D, Biegler S, Weidig U, Steinhoff K. Influence of Hot Deformation on the Precipitation Hardening of High-Strength Aluminum AA7075 during Thermo-Mechanical Processing. Metals. 2021; 11(5):681. https://doi.org/10.3390/met11050681

Chicago/Turabian StyleScharifi, Emad, Daria Shoshmina, Stefan Biegler, Ursula Weidig, and Kurt Steinhoff. 2021. "Influence of Hot Deformation on the Precipitation Hardening of High-Strength Aluminum AA7075 during Thermo-Mechanical Processing" Metals 11, no. 5: 681. https://doi.org/10.3390/met11050681