Forming a Flanged Hole When Quenching Press-Hardened Steel for Mechanical Fastening

Abstract

1. Introduction

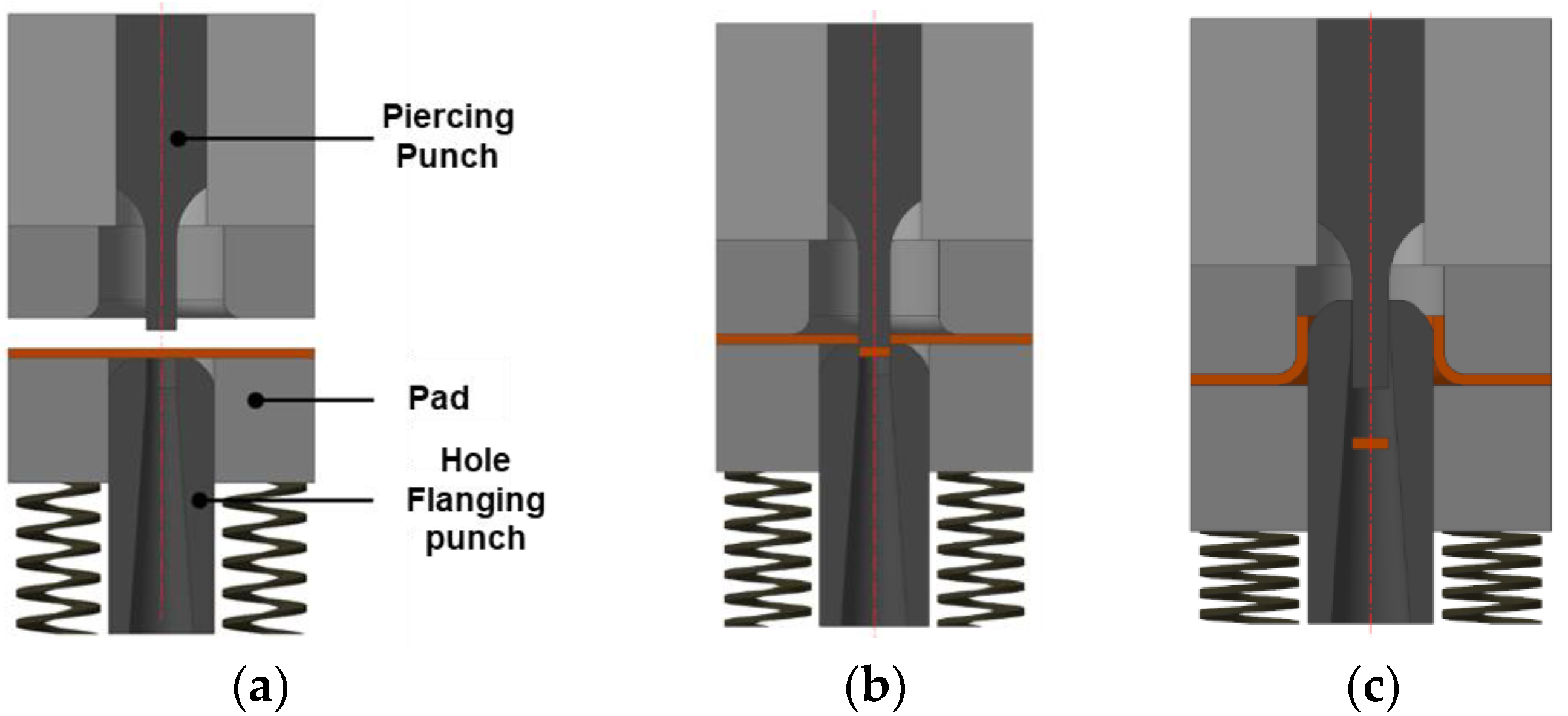

2. Experimental Setup

3. Simulations

3.1. Simulation of the Piercing Process for Forming the Pilot Hole

3.2. Simulation of the Hole Extrusion Process

4. Experiments

4.1. Experimental Conditions

4.2. Fracture Analysis of High-Temperature Hole-Flanging Specimen

4.3. Hardness Analysis for High-Temperature Hole-Flanging Specimen

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Martinsen, K.; Hu, S.; Carlson, B. Joining of dissimilar materials. CIRP Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Mori, K.; Kato, T.; Abe, Y.; Ravshanbek, Y. Plastic Joining of Ultra High Strength Steel and Aluminium Alloy Sheets by Self Piercing Rivet. CIRP Ann. 2006, 55, 283–286. [Google Scholar] [CrossRef]

- Sønstabø, J.K.; Holmstrøm, P.H.; Morin, D.; Langseth, M. Macroscopic strength and failure properties of flow-drill screw connections. J. Mater. Process. Technol. 2015, 222, 1–12. [Google Scholar] [CrossRef][Green Version]

- Gläsner, T.; Sunderkötter, C.; Hoffmann, H.; Volk, W.; Golle, R. Development of a 2-stage shear-cutting-process to reduce cut-edge-sensitivity of steels. J. Phys. Conf. Ser. 2017, 896, 12104. [Google Scholar] [CrossRef]

- Yoon, J.I.; Jung, J.; Kim, J.G.; Sohn, S.S.; Lee, S.; Kim, H.S. Key factors of stretch-flangeability of sheet materials. J. Mater. Sci. 2017, 52, 7808–7823. [Google Scholar] [CrossRef]

- Li, M.; VanTyne, C.J.; Moon, Y.H. The effect of mechanical properties on hole flangeability of stainless steel sheets. J. Mech. Sci. Technol. 2015, 29, 5233–5239. [Google Scholar] [CrossRef]

- Chen, X.; Jiang, H.; Cui, Z.; Lian, C.; Lu, C. Hole Expansion Characteristics of Ultra High Strength Steels. Procedia Eng. 2014, 81, 718–723. [Google Scholar] [CrossRef]

- Paul, S.K. Non-linear correlation between uniaxial tensile properties and shear-edge hole expansion Ratio. J. Mater. Eng. Perform. 2014, 23, 3610–3619. [Google Scholar] [CrossRef]

- Kim, J.H.; Seo, E.J.; Kwon, M.-H.; Kang, S.; De Cooman, B.C. Effect of quenching temperature on stretch flangeability of a medium Mn steel processed by quenching and partitioning. Mater. Sci. Eng. A 2018, 729, 276–284. [Google Scholar] [CrossRef]

- Kim, J.H.; Kwon, Y.J.; Lee, T.; Lee, K.-A.; Kim, H.S.; Lee, C.S. Prediction of hole expansion ratio for various steel sheets based on uniaxial tensile properties. Met. Mater. Int. 2018, 24, 187–194. [Google Scholar] [CrossRef]

- Balisetty, V.; Chakkingal, U.; Venugopal, S. Evaluation of stretch flangeability of dual-phase steels by hole expansion test. Int. J. Adv. Manuf. Technol. 2021, 114, 205–217. [Google Scholar] [CrossRef]

- Barnwal, V.K.; Lee, S.-Y.; Yoon, S.-Y.; Kim, J.-H.; Barlat, F. Fracture characteristics of advanced high strength steels during hole expansion test. Int. J. Fract. 2020, 224, 217–233. [Google Scholar] [CrossRef]

- Karelova, A. Hole expansion of dual-phase and complex-phase AHS steels—Effect of edge conditions. Steel Res. Int. 2009. [Google Scholar] [CrossRef]

- Mori, K.-I.; Abe, Y.; Suzui, Y. Improvement of stretch flangeability of ultra high strength steel sheet by smoothing of sheared edge. J. Mater. Process. Technol. 2010, 210, 653–659. [Google Scholar] [CrossRef]

- Madrid, M.; Van Tyne, C.J.; Sadagopan, S.; Pavlina, E.J.; Hu, J.; Clarke, K.D. Effects of Testing Method on Stretch-Flangeability of Dual-Phase 980/1180 Steel Grades. JOM 2018, 70, 918–923. [Google Scholar] [CrossRef]

- Pathak, N.; Butcher, C.; Worswick, M. Assessment of the Critical Parameters Influencing the Edge Stretchability of Advanced High-Strength Steel Sheet. J. Mater. Eng. Perform. 2016, 25, 4919–4932. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeon, Y.; Choi, H.; Kim, D. Forming a Flanged Hole When Quenching Press-Hardened Steel for Mechanical Fastening. Metals 2021, 11, 721. https://doi.org/10.3390/met11050721

Jeon Y, Choi H, Kim D. Forming a Flanged Hole When Quenching Press-Hardened Steel for Mechanical Fastening. Metals. 2021; 11(5):721. https://doi.org/10.3390/met11050721

Chicago/Turabian StyleJeon, Yongjun, Hyunseok Choi, and Dongearn Kim. 2021. "Forming a Flanged Hole When Quenching Press-Hardened Steel for Mechanical Fastening" Metals 11, no. 5: 721. https://doi.org/10.3390/met11050721

APA StyleJeon, Y., Choi, H., & Kim, D. (2021). Forming a Flanged Hole When Quenching Press-Hardened Steel for Mechanical Fastening. Metals, 11(5), 721. https://doi.org/10.3390/met11050721