Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix

Abstract

:1. Introduction

2. Experimental

2.1. Experiment Materials

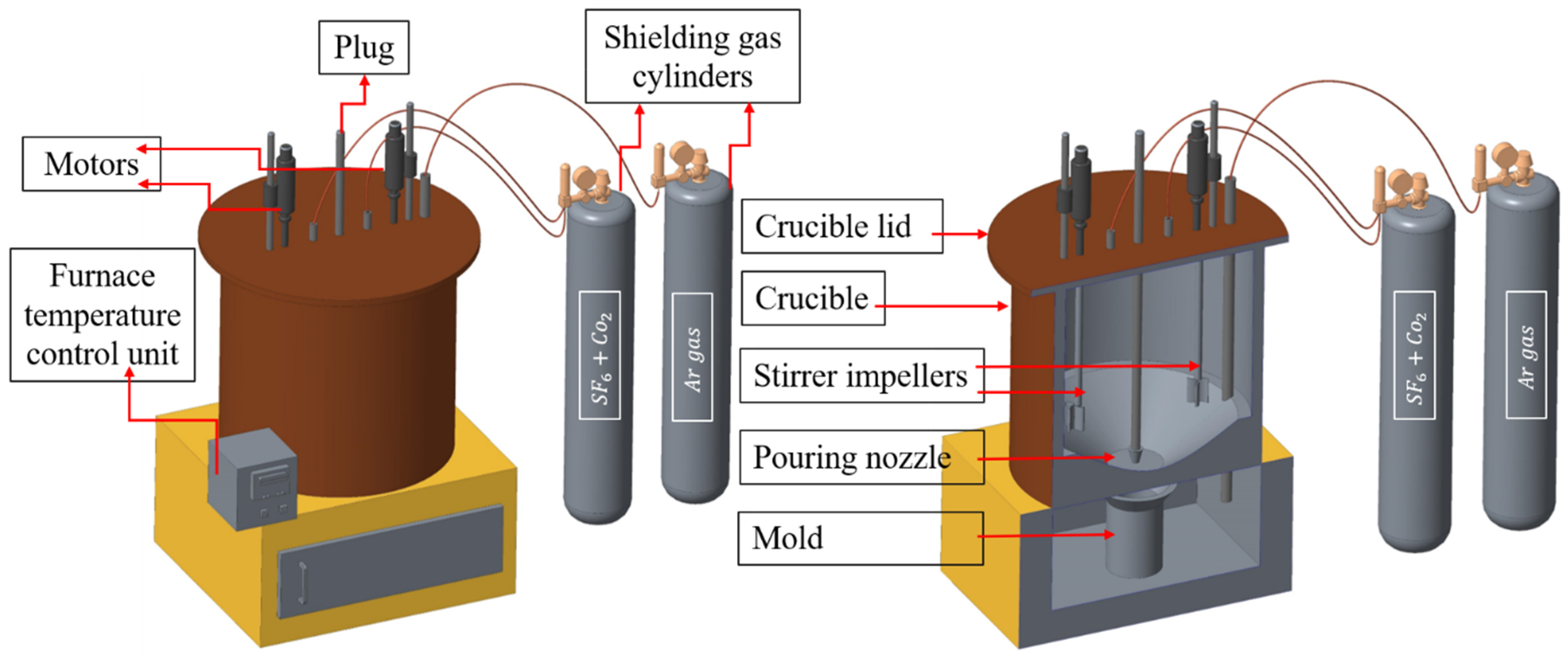

2.2. Composite Preparation

2.3. Microstructure

2.4. Mechanical Test at Room Temperature

2.4.1. Harness Test

2.4.2. Tensile Test

2.4.3. Compression Test

2.4.4. Impact Test

3. Results

3.1. Microhardness

3.2. Mechanical Properties

3.2.1. Tensile Properties

3.2.2. Compression Properties

3.2.3. Impact Properties

3.3. X-Ray Diffraction (XRD) Texture Analysis

3.4. Microstructural Analysis

4. Discussion

4.1. The Strengthening Mechanism of Microhardness

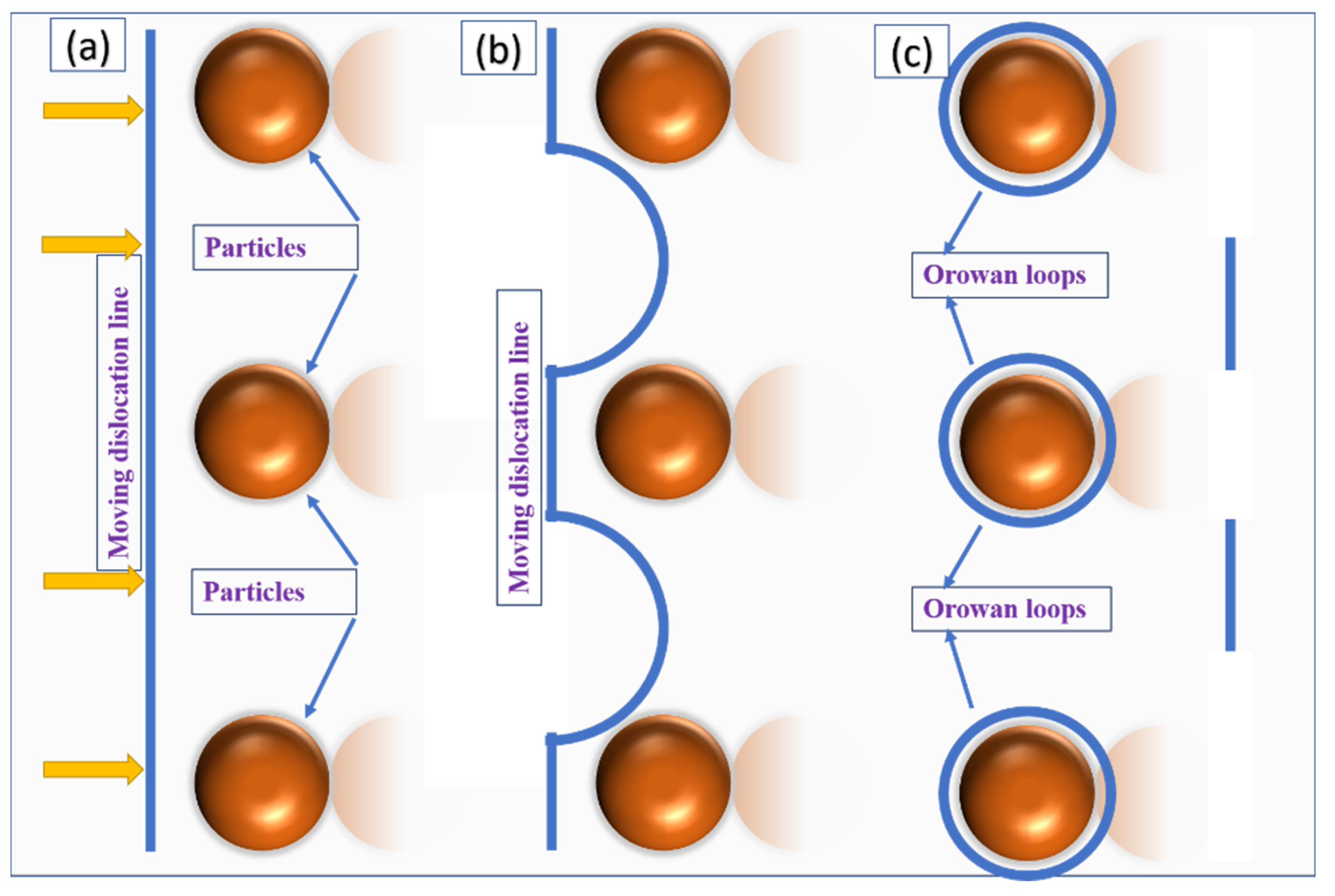

4.2. Strengthening Mechanism of the Mechanical Properties

4.3. Quantitative Phases Influences on Mechanical Properties

4.4. Fracture Surface Analysis

5. Conclusions

- The addition of β-SiCp (0.5 and 1 wt.%) nanoparticles resulted in grain refinement, particle strengthening and creation of quantitative phases Mg2Si (cubic) and SiC (rhombo.h.axes), which improved the microhardness of the AZ91 matrix by 18.6% and 14.66%, respectively. Similarly, a 17.49% increment in microhardness was generated by adding 0.5% SiCp + 1% Bi + 0.4% Sb to the AZ91 matrix. However, the microhardness of alloy codes 3 and 4 slightly decreased because of the reduction in Mg0.97Zn0.03 (hexagonal) brittle phases.

- The small number of 0.5 wt.% β-SiC nanoparticles remarkably improved the tensile and yield values by 40.10% and 5.47% (169.33 and 72.82 MPa, respectively). The best yield strength of 82.75 MPa (increased by 19.85%) was obtained from the AZ91 matrix (alloy code 4) with 0.5 wt.% SiCp, 1 wt.% Bi and 0.4 wt.% Sb as reinforcements. Strength was related to the mismatch of the CTE and the existence of quantitative phases of Mg2Si, Mg3Bi2, Mg3Sb2 and Mg0.97Zn0.03 in the AZ91 matrix.

- Compression properties increased by 2.68%, 6.23% and 8.38% for alloy codes 2 to 4, respectively. CTE augmentation; the shear transfer effect of the load; the Orowan strengthening effect and the dispersion of quantitative phases Mg2Si, Mg3Bi and Mg3Sb2 in the composites presented delays in crack propagation and occurrence at the particle–matrix interface.

- The addition of β-SiC remarkably reduced brittle Al–Mn-based phases; thus, the absorbed Charpy impact energy improved by 236% (2.89 J) and 192% (2.35 J) for alloy codes 2 and 4, respectively.

- Alloy code 4 (0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb) gained impact energy negatively, 0.98 J (−80%), because of the increment in reinforcement quantity and the creation of C60, SiCp and Mg2Si phases. Al–Mn-based brittle phases, such as Al6Mn, were observed in the XRD pattern. A large number of dimples and microcracks were created in alloy code 4′s impact test fracture morphology because of the sinking and floating comportments of SiCp, Sb and Bi.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, Z.R.; Wang, S.Q.; Gao, M.J.; Zhao, Y.T.; Chen, K.M.; Cui, X.H. A new-developed magnesium matrix composite by reactive sintering. Compos. Part A Appl. Sci. Manuf. 2008, 39, 1427–1432. [Google Scholar] [CrossRef]

- Meng, F.; Lv, S.; Yang, Q.; Qin, P.; Zhang, J.; Guan, K.; Huang, Y.; Hort, N.; Li, B.; Liu, X.; et al. Developing a die casting magnesium alloy with excellent mechanical performance by controlling intermetallic phase. J. Alloys Compd. 2019, 795, 436–445. [Google Scholar] [CrossRef]

- Joost, W.J.; Krajewski, P.E. Towards magnesium alloys for high-volume automotive applications. Scr. Mater. 2017, 128, 107–112. [Google Scholar] [CrossRef]

- Jin, T.; Zhou, Z.; Qiu, J.; Wang, Z.; Zhao, D.; Shu, X.; Yan, S. Investigation on the yield behavior of AZ91 magnesium alloy. J. Alloys Compd. 2018, 738, 79–88. [Google Scholar] [CrossRef]

- Lin, X.Z.; Chen, D.L. Strain controlled cyclic deformation behavior of an extruded magnesium alloy. Mater. Sci. Eng. A 2008, 496, 106–113. [Google Scholar] [CrossRef]

- Lee, S.W.; Park, S.H. Static recrystallization mechanism in cold-rolled magnesium alloy with off-basal texture based on quasi in situ EBSD observations. J. Alloys Compd. 2020, 844, 156185. [Google Scholar] [CrossRef]

- Martynenko, N.; Lukyanova, E.; Serebryany, V.; Prosvirnin, D.; Terentiev, V.; Raab, G.; Dobatkin, S.; Estrin, Y. Effect of equal channel angular pressing on structure, texture, mechanical and in-service properties of a biodegradable magnesium alloy. Mater. Lett. 2019, 238, 218–221. [Google Scholar] [CrossRef]

- Mironov, S.; Onuma, T.; Sato, Y.S.; Kokawa, H. Microstructure evolution during friction-stir welding of AZ31 magnesium alloy. Acta Mater. 2015, 100, 301–312. [Google Scholar] [CrossRef]

- Bian, M.; Huang, X.; Chino, Y. Improving flame resistance and mechanical properties of magnesium–silver–calcium sheet alloys by optimization of calcium content. J. Alloys Compd. 2020, 837, 155551. [Google Scholar] [CrossRef]

- Wang, H.Y.; Rong, J.; Yu, Z.Y.; Zha, M.; Wang, C.; Yang, Z.Z.; Bu, R.Y.; Jiang, Q.C. Tensile properties, texture evolutions and deformation anisotropy of as-extruded Mg-6Zn-1Zr magnesium alloy at room and elevated temperatures. Mater. Sci. Eng. A 2017, 697, 149–157. [Google Scholar] [CrossRef]

- Yang, C.; Zhang, B.; Zhao, D.; Wang, X.; Sun, Y.; Xu, X.; Liu, F. Microstructure evolution of as-cast AlN/AZ91 composites and room temperature compressive properties. J. Alloys Compd. 2019, 774, 573–580. [Google Scholar] [CrossRef]

- Huang, S.J.; Ali, A.N. Effects of heat treatment on the microstructure and microplastic deformation behavior of SiC particles reinforced AZ61 magnesium metal matrix composite. Mater. Sci. Eng. A 2018, 711, 670–682. [Google Scholar] [CrossRef]

- Nie, K.; Guo, Y.; Deng, K.; Kang, X. High strength TiCp/Mg-Zn-Ca magnesium matrix nanocomposites with improved formability at low temperature. J. Alloys Compd. 2019, 792, 267–278. [Google Scholar] [CrossRef]

- Sun, X.F.; Wang, C.J.; Deng, K.K.; Nie, K.B.; Zhang, X.C.; Xiao, X.Y. High strength SiCp/AZ91 composite assisted by dynamic precipitated Mg17Al12 phase. J. Alloys Compd. 2018, 732, 328–335. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Yang, X.; Xu, F.; Yang, C.; Li, B.; Li, Y.; Liu, Z.; Zheng, Q. Processing, microstructure and ageing behavior of in-situ submicron TiB2 particles reinforced AZ91 Mg matrix composites. J. Alloys Compd. 2018, 764, 96–106. [Google Scholar] [CrossRef]

- Wang, X.J.; Hu, X.S.; Liu, W.Q.; Du, J.F.; Wu, K.; Huang, Y.D.; Zheng, M.Y. Ageing behavior of as-cast SiCp/AZ91 Mg matrix composites. Mater. Sci. Eng. A 2017, 682, 491–500. [Google Scholar] [CrossRef]

- Huang, S.J.; Abbas, A. Effects of tungsten disulfide on microstructure and mechanical properties of AZ91 magnesium alloy manufactured by stir casting. J. Alloys Compd. 2020, 817, 153321. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Xu, F.; Yang, C.; Li, Y.; Liu, Z.; Zheng, Q. Tribological behavior of in-situ nanosized TiB2 particles reinforced AZ91 matrix composite. Tribol. Int. 2018, 128, 130–139. [Google Scholar] [CrossRef]

- Ganguly, S.; Mondal, A.K. Influence of SiC nanoparticles addition on microstructure and creep behavior of squeeze-cast AZ91-Ca-Sb magnesium alloy. Mater. Sci. Eng. A 2018, 718, 377–389. [Google Scholar] [CrossRef]

- Zhu, Y.P.; Jin, P.P.; Fei, W.D.; Xu, S.C.; Wang, J.H. Effects of Mg2B2O5 whiskers on microstructure and mechanical properties of AZ31B magnesium matrix composites. Mater. Sci. Eng. A 2017, 684, 205–212. [Google Scholar] [CrossRef]

- Sun, X.F.; Wang, C.J.; Deng, K.K.; Kang, J.W.; Bai, Y.; Nie, K.B.; Shang, S.J. Aging behavior of AZ91 matrix influenced by 5 μm SiCp: Investigation on the microstructure and mechanical properties. J. Alloys Compd. 2017, 727, 1263–1272. [Google Scholar] [CrossRef]

- Elen, L.; Zengin, H.; Turen, Y.; Turan, M.E.; Sun, Y.; Ahlatci, H. Effects of bismuth (bi) additions on microstructure and mechanical properties of AZ91 alloy. In Proceedings of the Metal 2015—24th International Conference on Metallurgy and Materials, Conference Proceedings, Brno, Czech Republic, 3–5 June 2015; pp. 1124–1128. [Google Scholar]

- Guangyin, Y.; Yangshan, S.; Wenjiang, D. Effect of bismuth and antimony additions on the microstructure and mechanical properties of AZ91 magnesium alloy. Mater. Sci. Eng. A 2001, 308, 38–44. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.J. Investigation of severe plastic deformation effects on microstructure and mechanical properties of WS2/AZ91 magnesium metal matrix composites. Mater. Sci. Eng. A 2020, 780, 139211. [Google Scholar] [CrossRef]

- ASTM International. E3 Preparation of Metallographic Specimens. Annu. B ASTM Stand. 2017, 11, 1–17. [Google Scholar]

- ASTM E8 ASTM E8/E8M standard test methods for tension testing of metallic materials 1. Annu. B. ASTM Stand. 4 2010, 1–27. [CrossRef]

- E9-19 Standard Test Methods of Compression Testing of Metallic Materials at Room Temperature. ASTM B. Stand. 2019, 1–10. [CrossRef]

- Yi, Y.S.; Li, R.F.; Xie, Z.Y.; Meng, Y.; Sugiyama, S. Effects of reheating temperature and isothermal holding time on the morphology and thixo-formability of SiC particles reinforced AZ91 magnesium matrix composite. Vacuum 2018, 154, 177–185. [Google Scholar] [CrossRef]

- ASTM International. ASTM E23—18, Standard Test Methods for Notched Bar Impact Testing of Metallic Materials. ASTM Int. 2018, 1–26. [Google Scholar] [CrossRef]

- Qiao, X.G.; Ying, T.; Zheng, M.Y.; Wei, E.D.; Wu, K.; Hu, X.S.; Gan, W.M.; Brokmeier, H.G.; Golovin, I.S. Microstructure evolution and mechanical properties of nano-SiCp/AZ91 composite processed by extrusion and equal channel angular pressing (ECAP). Mater. Charact. 2016, 121, 222–230. [Google Scholar] [CrossRef]

- Viswanath, A.; Dieringa, H.; Ajith Kumar, K.K.; Pillai, U.T.S.; Pai, B.C. Investigation on mechanical properties and creep behavior of stir cast AZ91-SiCp composites. J. Magnesuim Alloy. 2015, 3, 16–22. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, A.; Swaminathan, J.; Pillai, U.T.S.; Guguloth, K.; Pai, B.C. Effect of combined addition of Si and Sb on the microstructure and creep properties of AZ91 magnesium alloy. Mater. Sci. Eng. A 2008, 485, 86–91. [Google Scholar] [CrossRef]

- Zhou, X.; Su, D.; Wu, C.; Liu, L. Tensile mechanical properties and strengthening mechanism of hybrid carbon nanotube and silicon carbide nanoparticle-reinforced magnesium alloy composites. J. Nanomater. 2012, 2012, 851862. [Google Scholar] [CrossRef]

- Zhao, W.; Huang, S.J.; Wu, Y.J.; Kang, C.W. Particle size and particle percentage effect of AZ61/SiCp magnesium matrix micro- and nano-composites on their mechanical properties due to extrusion and subsequent annealing. Metals 2017, 7, 293. [Google Scholar] [CrossRef] [Green Version]

- Srinivasan, A.; Pillai, U.T.S.; Pai, B.C. Effects of elemental additions (Si and Sb) on the ageing behavior of AZ91 magnesium alloy. Mater. Sci. Eng. A 2010, 527, 6543–6550. [Google Scholar] [CrossRef]

- Guangyin, Y.; Yangshan, S.; Weiming, Z. Improvements of tensile strength and creep resistance of Mg-9Al based alloy with antimony addition. J. Mater. Sci. Lett. 1999, 18, 2055–2057. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, W.; Ding, W.; Zhu, Y.; Mabuchi, M. Effect of Sb on the Microstructure and Mechanical Properties of AZ91 Magnesium Alloy. Metall. Mater. Trans. A 2001, 32, 787–794. [Google Scholar] [CrossRef]

- Bag, A.; Zhou, W. Tensile and fatigue behavior of AZ91D magnesium alloy. J. Mater. Sci. Lett. 2001, 20, 457–459. [Google Scholar] [CrossRef]

- Srinivasan, A.; Swaminathan, J.; Gunjan, M.K.; Pillai, U.T.S.; Pai, B.C. Effect of intermetallic phases on the creep behavior of AZ91 magnesium alloy. Mater. Sci. Eng. A 2010, 527, 1395–1403. [Google Scholar] [CrossRef]

- Srinivasan, A.; Pillai, U.T.S.; Pai, B.C. Microstructure and mechanical properties of Si and Sb added AZ91 magnesium alloy. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2005, 36, 2235–2243. [Google Scholar] [CrossRef]

- Nguyen, Q.B.; Gupta, M. Increasing significantly the failure strain and work of fracture of solidification processed AZ31B using nano-Al2O3 particulates. J. Alloys Compd. 2008, 459, 244–250. [Google Scholar] [CrossRef]

- Inegbenebor, A.O.; Bolu, C.A.; Babalola, P.O.; Inegbenebor, A.I.; Fayomi, O.S.I. Aluminum Silicon Carbide Particulate Metal Matrix Composite Development Via Stir Casting Processing. Silicon 2018, 10, 343–347. [Google Scholar] [CrossRef]

- Xiao, P.; Gao, Y.; Xu, F.; Yang, S.; Li, B.; Li, Y.; Huang, Z.; Zheng, Q. An investigation on grain refinement mechanism of TiB2 particulate reinforced AZ91 composites and its effect on mechanical properties. J. Alloys Compd. 2019, 780, 237–244. [Google Scholar] [CrossRef]

- Aydin, F.; Sun, Y.; Emre Turan, M. The Effect of TiB2 Content on Wear and Mechanical Behavior of AZ91 Magnesium Matrix Composites Produced by Powder Metallurgy. Powder Metall. Met. Ceram. 2019, 57, 564–572. [Google Scholar] [CrossRef]

- Deng, K.; Shi, J.; Wang, C.; Wang, X.; Wu, Y.; Nie, K.; Wu, K. Microstructure and strengthening mechanism of bimodal size particle reinforced magnesium matrix composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1280–1284. [Google Scholar] [CrossRef]

- Habibnejad-Korayem, M.; Mahmudi, R.; Poole, W.J. Enhanced properties of Mg-based nano-composites reinforced with Al2O3 nano-particles. Mater. Sci. Eng. A 2009, 519, 198–203. [Google Scholar] [CrossRef]

- Huang, S.J.; Lin, P.C. Grain refinement of AM60/Al2O3p magnesium metal-matrix composites processed by ECAE. Kov. Mater. 2013, 51, 357–366. [Google Scholar]

- Karbalaei Akbari, M.; Baharvandi, H.R.; Shirvanimoghaddam, K. Tensile and fracture behavior of nano/micro TiB2 particle reinforced casting A356 aluminum alloy composites. Mater. Des. 2015, 66, 150–161. [Google Scholar] [CrossRef]

- Huang, S.J.; Ho, C.H.; Feldman, Y.; Tenne, R. Advanced AZ31 Mg alloy composites reinforced by WS2 nanotubes. J. Alloys Compd. 2016, 654, 15–22. [Google Scholar] [CrossRef]

- Saba, F.; Zhang, F.; Liu, S.; Liu, T. Reinforcement size dependence of mechanical properties and strengthening mechanisms in diamond reinforced titanium metal matrix composites. Compos. Part B Eng. 2019, 167, 7–19. [Google Scholar] [CrossRef]

- Tokarski, T. Effect of rapid solidification on the structure and mechanical properties of AZ91 magnesium alloy. Solid State Phenom. 2012, 186, 120–123. [Google Scholar] [CrossRef]

- Abbas, A.; Huang, S.J. ECAP effects on microstructure and mechanical behavior of annealed WS2/AZ91 metal matrix composite. J. Alloys Compd. 2020, 835, 155466. [Google Scholar] [CrossRef]

| Elements | Al | Zn | Mn | Fe | Si | Cu | Ni | Mg |

|---|---|---|---|---|---|---|---|---|

| Wt.% Concentration | 8.95 | 0.84 | 0.26 | 0.005 | 0.009 | 0.0008 | 0.0007 | Balance |

| Composite Code | Wt.% of Reinforcements | |||

|---|---|---|---|---|

| AZ91 | β-SiCp (50 nm) | Bismuth (Bi) (50 µm) | Antimony (Sb) (150 µm) | |

| Code 1 | 100 | 0 | 0 | 0 |

| Code 2 | 99.5 | 0.5 | 0 | 0 |

| Code 3 | 99 | 1 | 0 | 0 |

| Code 4 | 98.1 | 0.5 | 1 | 0.4 |

| Alloy Code | Composition | Microhardness (HV) | Increment in Microhardness (%) |

|---|---|---|---|

| Code 1 | Pure AZ91 | 68.21 | - |

| Code 2 | AZ91 + 0.5 wt.% SiCp | 80.90 | 18.60 |

| Code 3 | AZ91 + 1 wt.% SiCp | 78.21 | 14.66 |

| Code 4 | AZ91 + 0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb | 80.14 | 17.49 |

| Alloy Code | Types of Castings | 0.2% Yield Strength (MPa) | UTS (MPa) | Elongation (%) |

|---|---|---|---|---|

| Code 1 | Pure AZ91 | 69.05 ± 2 | 120.87 ± 4 | 6.0 ± 0.1 |

| Code 2 | AZ91 + 0.5 wt.% SiCp | 72.82 ± 3 | 169.33 ± 2 | 21.6 ± 0.3 |

| Code 3 | AZ91 + 1 wt.% SiCp | 59.38 ± 3 | 118.07 ± 3 | 10.6 ± 0.2 |

| Code 4 | AZ91 + 0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb | 82.75 ± 1 | 159.60 ± 4 | 11.2 ± 0.2 |

| Other study [17] | AZ91(as-cast) + 1 wt.% WS2 | 67.93 ± 3 | 140.81 ± 6 | 9.01 ± 0.5 |

| Other study [30] | AZ91(as-cast) +1 wt.% SiCp | 116 | 139 | 0.78 |

| Alloy Code | Types of Castings | Maximum Compressive Strength (MPa) | Compression Ratio (%) |

|---|---|---|---|

| Code 1 | Pure AZ91 | 345.14 ± 13 | 16.17 ± 0.3 |

| Code 2 | AZ91 + 0.5 wt.% SiCp | 354.38 ± 10 | 15.73 ± 0.1 |

| Code 3 | AZ91 + 1 wt.% SiCp | 366.63 ± 13 | 15.90 ± 0.3 |

| Code 4 | AZ91 + 0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb | 374.07 ± 13 | 15.54 ± 0.3 |

| Alloy Code | Types of Casting | Absorbed Energy (J) | Increment in Absorbed Energy (%) |

|---|---|---|---|

| Code 1 | Pure AZ91 | 1.23 | - |

| Code 2 | AZ91 + 0.5 wt.% SiCp | 2.89 | 236 |

| Code 3 | AZ91 + 1 wt.% SiCp | 2.35 | 192 |

| Code 4 | AZ91 + 0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb | 0.98 | −80 |

| Alloy Code | Composition | Major Phases | Quantitative Values (%) | Structure |

|---|---|---|---|---|

| Code 1 | Pure AZ91 | Mg17Al12 | 6.81 | Cubic |

| Mg0.97Zn0.03 | 91.30 | Hexagonal | ||

| Al6Mn | 1.89 | Orthorhombic | ||

| Code 2 | AZ91 + 0.5 wt.% SiCp | Mg17Al12 | 5.18 | Cubic |

| Mg0.97Zn0.03 | 90.38 | Hexagonal | ||

| SiC | 2.52 | Rhombo.h.axes | ||

| Mg2Si | 1.92 | Cubic | ||

| Code 3 | AZ91 + 1 wt.% SiCp | Mg17Al12 | 4.64 | Cubic |

| Mg0.97Zn0.03 | 86.99 | Hexagonal | ||

| SiC | 2.69 | Rhombo.h.axes | ||

| Mg2Si | 2.11 | Cubic | ||

| C60 | 1 | Monoclinic | ||

| Al6Mn | 2.57 | Orthorhombic | ||

| Code 4 | AZ91 + 0.5 wt.% SiCp + 1 wt.% Bi + 0.4 wt.% Sb | Mg17Al12 | 15.53 | Cubic |

| Mg0.97Zn0.03 | 41.37 | Hexagonal | ||

| SiC | 14.15 | Rhombo.h.axes | ||

| Mg2Si | 2.03 | Cubic | ||

| C60 | 1.31 | Monoclinic | ||

| Mg3Bi2 | 15.83 | Hexagonal | ||

| Mg3Sb2 | 4.13 | Hexagonal | ||

| Al6Mn | 5.64 | Orthorhombic |

| Strengthening Mechanism | Values (MPa) | Strengthening Contribution (%) |

|---|---|---|

| 0.17 | 1.712 | |

| 7.67 | 77.24 | |

| 2.09 | 21.05 | |

| 9.93 | - | |

| 13.70 | 72.48 |

| Al–Mn Phases | Alloy Code 1 | Alloy Code 2 | Alloy Code 3 | Alloy Code 4 |

|---|---|---|---|---|

| Al78Mn22 | ✓ | × | × | ✓ |

| Al0.43Mn0.47 | ✓ | × | ✓ | ✓ |

| Al6Mn [51] | ✓ | × | × | ✓ |

| Al80Mn20 | × | × | × | ✓ |

| Al10Mn3 | × | × | × | ✓ |

| Al86Mn14 | × | × | ✓ | × |

| Al81Mn19 | × | ✓ | ✓ | ✓ |

| Al77Mn23 | ✓ | ✓ | × | × |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, S.-J.; Diwan Midyeen, S.; Subramani, M.; Chiang, C.-C. Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix. Metals 2021, 11, 898. https://doi.org/10.3390/met11060898

Huang S-J, Diwan Midyeen S, Subramani M, Chiang C-C. Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix. Metals. 2021; 11(6):898. https://doi.org/10.3390/met11060898

Chicago/Turabian StyleHuang, Song-Jeng, Sikkanthar Diwan Midyeen, Murugan Subramani, and Chao-Ching Chiang. 2021. "Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix" Metals 11, no. 6: 898. https://doi.org/10.3390/met11060898

APA StyleHuang, S. -J., Diwan Midyeen, S., Subramani, M., & Chiang, C. -C. (2021). Microstructure Evaluation, Quantitative Phase Analysis, Strengthening Mechanism and Influence of Hybrid Reinforcements (β-SiCp, Bi and Sb) on the Collective Mechanical Properties of the AZ91 Magnesium Matrix. Metals, 11(6), 898. https://doi.org/10.3390/met11060898