Optimization of Process Control Parameters for WEDM of Al-LM25/Fly Ash/B4C Hybrid Composites Using Evolutionary Algorithms: A Comparative Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fabrication of Al (LM25)/Fly Ash/B4C Hybrid Composites

2.2. Machining of Hybrid Composites Using WEDM

2.3. Measurement and Calculation of Output Responses

3. Experimental Observations and Analysis

4. Algorithmic Approach

- (a)

- Grasshoppers can effectively identify the assured areas of the available search space.

- (b)

- The global search by the grasshoppers is carried out by the large-scale and unexpected changes in the preliminary steps of optimization.

- (c)

- The exploitation of search space is permitted due to the local movement of grasshoppers in the final steps of optimization.

- (d)

- The gradual balance of exploration and exploitation is used to find the precise approximation of the global optimum.

- (e)

- The improvement of the average fitness of grasshoppers is used to enhance the initial random population.

- (f)

- The approximation of the global optimum is very accurate relative to the number of iterations.

4.1. Influence of WEDM Parameters on VRR

4.2. Influence of WEDM Parameters on Surface Roughness

4.3. Microstructure Analysis of Machined Surface

5. Conclusions

- From the ANOVA results, the GV, TN, and PR were the most significant parameters in deciding the SR value. The GV, TN, and TF were the most significant parameters in deciding the VRR value.

- The presence of hard reinforcement particles in composites restricts the effective volume removal during machining and condenses the surface quality even at higher cutting speed and pulse-on time. Therefore, the selection of an appropriate wt% of reinforcement is necessary for improved machining performances.

- SEM micrographs revealed the augmented micro-cracks, reinforcement debris, and craters at kerf surfaces due to the presence of hard reinforcement particles. The hard phases of reinforcements will restrict the removal of material from the substrate even at a higher gap voltage, leading to variation in contraction stresses during the WEDM process.

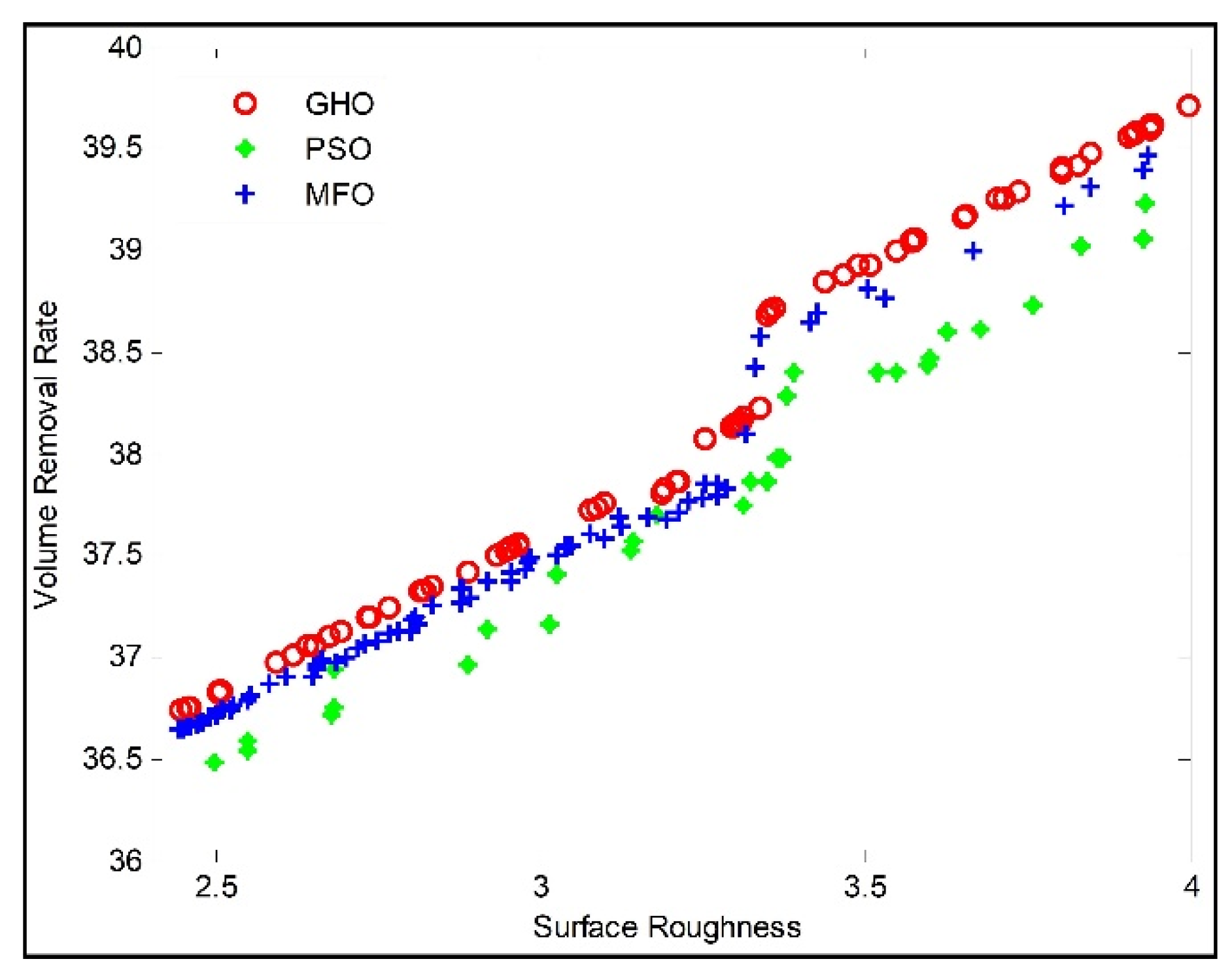

- The minimum values of the mean and standard deviation of the performance metrics, namely SP and IGD, were used to confirm the effectiveness of the proposed GHO algorithm.

- The predicted values of VRR and SR for the optimum combination of process control parameters obtained from the GHO algorithm were 36.7243 mm3/min and 2.43104 microns.

- The optimum values of VRR and SR obtained from the confirmation experiment were 35.9321 mm3/min and 2.47007 microns, respectively, and the corresponding deviations were 2.16% and −1.61%, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- McDanels, D.L. Analysis of stress-strain, fracture, and ductility behavior of aluminum matrix composites containing discon-tinuous silicon carbide reinforcement. Metall. Trans. A 1985, 16, 1105–1115. [Google Scholar] [CrossRef]

- Ralph, B.; Yuen, H.C.; Lee, W.B. The processing of metal matrix composites—an overview. J. Mater. Process. Technol. 1997, 63, 339–353. [Google Scholar] [CrossRef]

- Ramnath, B.V.; Elanchezhian, C.; Annamalai, R.M.; Aravind, S.; Atreya, T.S.; Vignesh, V.; Subramanian, C. Aluminium metal matrix composites–a review. Rev. Adv. Mater. Sci. 2014, 38, 55–60. [Google Scholar]

- Prakash, J.; Moorthy, T.; Peter, J.M. Experimental Investigations on Machinability of Aluminium Alloy (A413)/Flyash/B4C Hybrid Composites Using Wire EDM. Procedia Eng. 2013, 64, 1344–1353. [Google Scholar] [CrossRef] [Green Version]

- Kuş, A.; Motorcu, A.R.; Ekici, E. Wire Electrical Discharge Machining of a Hybrid Composite: Evaluation of Kerf Width and Surface Roughness. Univ. J. Fac. Eng. 2016, 21, 245. [Google Scholar] [CrossRef]

- Vetrivel, K.P.; Subramanian, R.; Vinoth, K.S. An Analysis on Process Control of Machining in Electrical Discharge Machine by Hybrid Composites using DoE. Int. J. Control Theory Appl. 2016, 9, 2611–2619. [Google Scholar]

- Chou, Y.K.; Liu, J. CVD diamond tool performance in metal matrix composite machining. Surf. Coat. Technol. 2005, 200, 1872–1878. [Google Scholar] [CrossRef]

- Iwai, Y.; Honda, T.; Miyajima, T.; Iwasaki, Y.; Surappa, M.; Xu, J. Dry sliding wear behavior of Al2O3 fiber reinforced aluminum composites. Compos. Sci. Technol. 2000, 60, 1781–1789. [Google Scholar] [CrossRef]

- Hu, H.; Lavernia, E.; Harrigan, W.; Kajuch, J.; Nutt, S. Microstructural investigation on B4C/Al-7093 composite. Mater. Sci. Eng. A 2001, 297, 94–104. [Google Scholar] [CrossRef]

- Ciftci, I.; Turker, M.; Seker, U. Evaluation of tool wear when machining SiCp-reinforced Al-2014 alloy matrix composites. Mater. Design 2004, 25, 251–255. [Google Scholar] [CrossRef]

- Puhan, D.; Mahapatra, S.S.; Sahu, J.; Das, L. A hybrid approach for multi-response optimization of non-conventional ma-chining on AlSiCp MMC. Measurement 2013, 46, 3581–3592. [Google Scholar] [CrossRef]

- Lau, W.; Yue, T.M.; Lee, T.; Lee, W.B. Un-conventional machining of composite materials. J. Mater. Process. Technol. 1995, 48, 199–205. [Google Scholar] [CrossRef]

- Garg, R.K.; Singh, K.K.; Sachdeva, A.; Sharma, V.S.; Ojha, K.; Singh, S. Review of research work in sinking EDM and WEDM on metal matrix composite materials. Int. J. Adv. Manuf. Technol. 2010, 50, 611–624. [Google Scholar] [CrossRef]

- Singh, H.; Garg, R. Effects of process parameters on material removal rate in WEDM. J. Achiev. Mater. Manuf. Eng. 2009, 32, 70–74. [Google Scholar]

- Lahane, S.D.; Rodge, M.K.; Sharma, S.B. Multi-response optimization of Wire-EDM process using principal component anal-ysis. J. Eng. 2012, 2, 38–47. [Google Scholar]

- Chandrashekarappa, M.P.G.; Kumar, S.; Jagadish, J.; Pimenov, D.; Giasin, K. Experimental Analysis and Optimization of EDM Parameters on HcHcr Steel in Context with Different Electrodes and Dielectric Fluids Using Hybrid Taguchi-Based PCA-Utility and CRITIC-Utility Approaches. Metals 2021, 11, 419. [Google Scholar] [CrossRef]

- Prakash, C.; Singh, S.; Pruncu, C.I.; Mishra, V.; Królczyk, G.; Pimenov, D.Y.; Pramanik, A. Surface Modification of Ti-6Al-4V Alloy by Electrical Discharge Coating Process Using Partially Sintered Ti-Nb Electrode. Materials 2019, 12, 1006. [Google Scholar] [CrossRef] [Green Version]

- Aggarwal, V.; Pruncu, C.I.; Singh, J.; Sharma, S.; Pimenov, D.Y. Empirical Investigations during WEDM of Ni-27Cu-3.15Al-2Fe-1.5Mn Based Superalloy for High Temperature Corrosion Resistance Applications. Materials 2020, 13, 3470. [Google Scholar] [CrossRef]

- Sen, B.; Hussain, S.A.I.; Das Gupta, A.; Gupta, M.K.; Pimenov, D.Y.; Mikołajczyk, T. Application of Type-2 Fuzzy AHP-ARAS for Selecting Optimal WEDM Parameters. Metals 2020, 11, 42. [Google Scholar] [CrossRef]

- Mirjalili, S.Z.; Mirjalili, S.; Saremi, S.; Faris, H.; Aljarah, I. Grasshopper optimization algorithm for multi-objective optimization problems. Appl. Intell. 2018, 48, 805–820. [Google Scholar] [CrossRef]

- Saremi, S.; Mirjalili, S.; Lewis, A. Grasshopper Optimisation Algorithm: Theory and application. Adv. Eng. Softw. 2017, 105, 30–47. [Google Scholar] [CrossRef] [Green Version]

- Lmalghan, R.; Rao, K.M.C.; Arunkumar, S.; Shrikantha, S.R.; Herbert, M.A. Machining Parameters Optimization of AA6061 Using Response Surface Methodology and Particle Swarm Optimization. Int. J. Precis. Eng. Manuf. 2018, 19, 695–704. [Google Scholar] [CrossRef]

- Mirjalili, S. Moth-flame optimization algorithm: A novel nature-inspired heuristic paradigm. Knowl. Based Syst. 2015, 89, 228–249. [Google Scholar] [CrossRef]

- Khalilpourazari, S.; Naderi, B.; Khalilpourazary, S. Multi-objective stochastic fractal search: A powerful algorithm for solving complex multi-objective optimization problems. Soft Comput. 2020, 24, 3037–3066. [Google Scholar] [CrossRef]

- Alduroobi, A.A.A.; Ubaid, A.M.; Tawfiq, M.A.; Elias, R.R. Wire EDM process optimization for machining AISI 1045 steel by use of Taguchi method, artificial neural network and analysis of variances. Int. J. Syst. Assur. Eng. Manag. 2020, 11, 1314–1338. [Google Scholar] [CrossRef]

- Gopalakannan, S.; Senthilvelan, T. Application of response surface method on machining of Al–SiC nanocomposites. Meas-urement 2013, 46, 2705–2715. [Google Scholar] [CrossRef]

- Modi, M.; Agarwal, G. Effect of aluminium and chromium powder mixed dielectric fluid on electrical discharge machining effectiveness. Adv. Prod. Eng. Manag. 2019, 14, 323–332. [Google Scholar] [CrossRef] [Green Version]

- Gaikwad, M.U.; Jatti, V.S. Investigation and Optimization of Process Parameters in Electrical Discharge Machining (EDM) Process for NiTi 60. Mater. Res. Express 2019, 6, 065707. [Google Scholar] [CrossRef]

- Świercz, R.; Oniszczuk-Świercz, D.; Chmielewski, T. Multi-Response Optimization of Electrical Discharge Machining Using the Desirability Function. Micromachines 2019, 10, 72. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- VinothKumar, S.; Pradeep Kumar, M. Machining process parameter and surface integrity in conventional EDM and cryogenic EDM of Al-SiCp MMC. J. Manuf. Process. 2015, 20, 70–78. [Google Scholar] [CrossRef]

- VinothKumar, S.; Pradeep Kumar, M. Experimental investigation of the process parameter on AISI D2 tool steel under cryogenic cooling electrode in EDM process. J. Mech. Sci. Technol. 2015, 29, 3865–3871. [Google Scholar]

- VinothKumar, S.; Pradeep Kumar, M. Optimization of cryogenic cooled EDM machining process parameters using grey rela-tional analysis. J. Mech. Sci. Technol. 2014, 28, 3777–3784. [Google Scholar]

| Contents | Si | Fe | Mg | Mn | Ti | Cu | Ni | Zn | Pb | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Composition in (%) | 7.5 | 0.5 | 0.6 | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | 0.1 | Balance |

| Contents | Oxides | Si | Al | Fe | Ti | K | Ca | Loss in Ignition |

|---|---|---|---|---|---|---|---|---|

| Composition in (%) | 38.88 | 26.43 | 16.73 | 3.8 | 1.4 | 0.99 | 0.5 | Balance |

| Weight Percentage of Reinforcements | Composition |

|---|---|

| 3% | LM25 alloy + 1.5% Fly ash + 1.5% B4C |

| 6% | LM25 alloy + 3% Fly ash + 3% B4C |

| 9% | LM25 alloy + 4.5% Fly ash + 4.5% B4C |

| Machine Tool Parameters | Specification |

|---|---|

| Cutting tool | Brass wire (Diameter 250 Microns) |

| Workpiece size | 100 mm × 100 mm × 10 mm |

| Max. workpiece weight | 200 kg (workpiece height 150 mm) |

| Dielectric fluid | Deionized water |

| Conductivity of dielectric | 15–20 mho |

| Number of axes controlled | 5 Axis AC Servo Motor |

| Wire feed | Servo feed |

| Parameter | Symbol | Unit | Levels | ||

|---|---|---|---|---|---|

| 1 | 2 | 3 | |||

| Gap voltage (GV) | A | Volts | 30 | 50 | 70 |

| Pulse-on time (TN) | B | Micro seconds | 2 | 6 | 10 |

| Pulse-off time (TF) | C | Micro seconds | 2 | 6 | 10 |

| Wire feed (WF) | D | m/min | 4 | 6 | 8 |

| Percentage of reinforcement (PR) | E | % | 3 | 6 | 9 |

| Exp. No. | V | TN | TF | WF | PR | SR | VRR |

|---|---|---|---|---|---|---|---|

| A | B | C | D | E | |||

| 1 | 30 | 2 | 2 | 4 | 3 | 3.9422 | 27.812 |

| 2 | 30 | 2 | 6 | 6 | 6 | 4.4423 | 21.099 |

| 3 | 30 | 2 | 10 | 8 | 9 | 4.0059 | 18.860 |

| 4 | 30 | 6 | 2 | 6 | 9 | 3.6863 | 35.556 |

| 5 | 30 | 6 | 6 | 8 | 3 | 3.4239 | 29.230 |

| 6 | 30 | 6 | 10 | 4 | 6 | 3.2950 | 24.249 |

| 7 | 30 | 10 | 2 | 8 | 6 | 3.4722 | 38.400 |

| 8 | 30 | 10 | 6 | 4 | 9 | 3.2518 | 32.960 |

| 9 | 30 | 10 | 10 | 6 | 3 | 3.5210 | 28.370 |

| 10 | 50 | 2 | 2 | 4 | 3 | 4.2472 | 21.712 |

| 11 | 50 | 2 | 6 | 6 | 6 | 4.7826 | 16.388 |

| 12 | 50 | 2 | 10 | 8 | 9 | 4.4781 | 15.075 |

| 13 | 50 | 6 | 2 | 6 | 9 | 4.8644 | 27.211 |

| 14 | 50 | 6 | 6 | 8 | 3 | 3.9459 | 22.196 |

| 15 | 50 | 6 | 10 | 4 | 6 | 3.9965 | 18.443 |

| 16 | 50 | 10 | 2 | 8 | 6 | 4.8497 | 30.236 |

| 17 | 50 | 10 | 6 | 4 | 9 | 4.1811 | 24.615 |

| 18 | 50 | 10 | 10 | 6 | 3 | 3.4539 | 23.274 |

| 19 | 70 | 2 | 2 | 4 | 3 | 4.3104 | 12.942 |

| 20 | 70 | 2 | 6 | 6 | 6 | 4.1547 | 10.235 |

| 21 | 70 | 2 | 10 | 8 | 9 | 4.4036 | 09.553 |

| 22 | 70 | 6 | 2 | 6 | 9 | 4.8786 | 17.305 |

| 23 | 70 | 6 | 6 | 8 | 3 | 3.4595 | 13.551 |

| 24 | 70 | 6 | 10 | 4 | 6 | 3.7516 | 11.914 |

| 25 | 70 | 10 | 2 | 8 | 6 | 4.6963 | 18.743 |

| 26 | 70 | 10 | 6 | 4 | 9 | 3.7186 | 15.419 |

| 27 | 70 | 10 | 10 | 6 | 3 | 3.9576 | 13.635 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 11 | 5.74041 | 0.52186 | 7.23 | 0.000 |

| Linear | 5 | 3.67652 | 0.73530 | 10.18 | 0.000 |

| GV | 1 | 1.02259 | 1.02259 | 14.16 | 0.002 |

| TN | 1 | 0.74615 | 0.74615 | 10.33 | 0.006 |

| TF | 1 | 0.02062 | 0.02062 | 0.29 | 0.601 |

| WF | 1 | 0.23136 | 0.23136 | 3.20 | 0.094 |

| PR | 1 | 0.88973 | 0.88973 | 12.32 | 0.003 |

| Square | 3 | 1.46905 | 0.48968 | 6.78 | 0.004 |

| GV × GV | 1 | 0.96729 | 0.96729 | 13.40 | 0.002 |

| TN × TN | 1 | 0.19751 | 0.19751 | 2.74 | 0.119 |

| WF × WF | 1 | 0.30425 | 0.30425 | 4.21 | 0.058 |

| 2-Way Interaction | 3 | 0.77329 | 0.25776 | 3.57 | 0.040 |

| GV × TN | 1 | 0.22666 | 0.22666 | 3.14 | 0.097 |

| GV × TF | 1 | 0.18593 | 0.18593 | 2.58 | 0.129 |

| TN × WF | 1 | 0.36071 | 0.36071 | 5.00 | 0.041 |

| Error | 15 | 1.08302 | 0.07220 | - | - |

| Total | 26 | 6.82343 | - | - | - |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 10 | 1583.99 | 158.399 | 195.35 | 0.000 |

| Linear | 5 | 1431.33 | 286.265 | 353.05 | 0.000 |

| GV | 1 | 986.26 | 986.257 | 1216.34 | 0.000 |

| TN | 1 | 287.81 | 287.808 | 354.95 | 0.000 |

| TF | 1 | 81.40 | 81.401 | 100.39 | 0.000 |

| WF | 1 | 1.85 | 1.855 | 2.29 | 0.150 |

| PR | 1 | 2.16 | 2.157 | 2.66 | 0.122 |

| Square | 2 | 13.71 | 6.855 | 8.45 | 0.003 |

| GV × GV | 1 | 6.32 | 6.315 | 7.79 | 0.013 |

| TN × TN | 1 | 7.39 | 7.394 | 9.12 | 0.008 |

| 2-Way Interaction | 3 | 47.54 | 15.846 | 19.54 | 0.000 |

| GV × TN | 1 | 23.78 | 23.778 | 29.33 | 0.000 |

| GV × TF | 1 | 22.42 | 22.416 | 27.65 | 0.000 |

| TN × WF | 1 | 1.34 | 1.343 | 1.66 | 0.216 |

| Error | 16 | 12.97 | 0.811 | - | - |

| Total | 26 | 1596.96 | - | - | - |

| GHO Algorithm | PSO Algorithm | MFO Algorithm | |||

|---|---|---|---|---|---|

| Parameter | Value | Parameter | Value | Parameter | Value |

| Intensity of attraction (f) | 0.5 | Learning factors (C1 & C2) | 2 & 2 | Position of moth close to the flame (t) | −1 to −2 |

| Attractive length scale (l) | 1.5 | Inertia weight (ω) | 0.6 | Update mechanism | Logarithmic spiral |

| No. of Grasshopper (N) | 30 | Particle size (N) | 30 | No. of moths (N) | 30 |

| Maximum & minimum decreasing coefficient (cmin) | 1.0 & 0.00001 | ||||

| No. of iterations (nitr) | 100 | No. of iterations (nitr) | 100 | No. of iterations (nitr) | 100 |

| Algorithm | GV | TN | TF | WF | PR | SR | VRR |

|---|---|---|---|---|---|---|---|

| GHO | 29.89 | 9.7900 | 1.97 | 3.98 | 3.03 | 36.6650 | 2.4356 |

| PSO | 30.40 | 9.8500 | 2.08 | 4.07 | 2.96 | 36.3990 | 2.4971 |

| MFO | 31.04 | 9.9171 | 1.86 | 3.82 | 3.25 | 36.3686 | 2.4484 |

| Statistics | GHO | PSO | MFO | |||

|---|---|---|---|---|---|---|

| IGD | SP | IGD | SP | IGD | SP | |

| Min | 0.1609 | 3.0701 | 0.1164 | 2.4904 | 0.1129 | 2.6311 |

| Max | 0.2530 | 3.5689 | 0.3475 | 4.8051 | 0.2715 | 3.8328 |

| Mean | 0.1932 | 3.2897 | 0.1999 | 3.4751 | 0.2008 | 3.4047 |

| Median | 0.1896 | 3.2943 | 0.1859 | 3.3203 | 0.1922 | 3.4725 |

| Standard Deviation | 0.0230 | 0.1293 | 0.0546 | 0.6476 | 0.0437 | 0.2945 |

| Parameter | VRR (mm3/min) | SR (microns) | |||||

|---|---|---|---|---|---|---|---|

| Level | Value | GHO Algorithm | Experimental Value | % of Deviation | GHO Algorithm | Experimental Value | % of Deviation |

| GV | 29.89 | 36.6650 | 35.873 | 2.4356 | 2.4748 | ||

| TN | 9.79 | ||||||

| TF | 1.97 | 2.16 | −1.61 | ||||

| WF | 3.98 | ||||||

| PR | 3.03 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lenin, N.; Sivakumar, M.; Selvakumar, G.; Rajamani, D.; Sivalingam, V.; Gupta, M.K.; Mikolajczyk, T.; Pimenov, D.Y. Optimization of Process Control Parameters for WEDM of Al-LM25/Fly Ash/B4C Hybrid Composites Using Evolutionary Algorithms: A Comparative Study. Metals 2021, 11, 1105. https://doi.org/10.3390/met11071105

Lenin N, Sivakumar M, Selvakumar G, Rajamani D, Sivalingam V, Gupta MK, Mikolajczyk T, Pimenov DY. Optimization of Process Control Parameters for WEDM of Al-LM25/Fly Ash/B4C Hybrid Composites Using Evolutionary Algorithms: A Comparative Study. Metals. 2021; 11(7):1105. https://doi.org/10.3390/met11071105

Chicago/Turabian StyleLenin, Nagarajan, Mahalingam Sivakumar, Gurusamy Selvakumar, Devaraj Rajamani, Vinothkumar Sivalingam, Munish Kumar Gupta, Tadeusz Mikolajczyk, and Danil Yurievich Pimenov. 2021. "Optimization of Process Control Parameters for WEDM of Al-LM25/Fly Ash/B4C Hybrid Composites Using Evolutionary Algorithms: A Comparative Study" Metals 11, no. 7: 1105. https://doi.org/10.3390/met11071105

APA StyleLenin, N., Sivakumar, M., Selvakumar, G., Rajamani, D., Sivalingam, V., Gupta, M. K., Mikolajczyk, T., & Pimenov, D. Y. (2021). Optimization of Process Control Parameters for WEDM of Al-LM25/Fly Ash/B4C Hybrid Composites Using Evolutionary Algorithms: A Comparative Study. Metals, 11(7), 1105. https://doi.org/10.3390/met11071105