The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy

Abstract

:1. Introduction

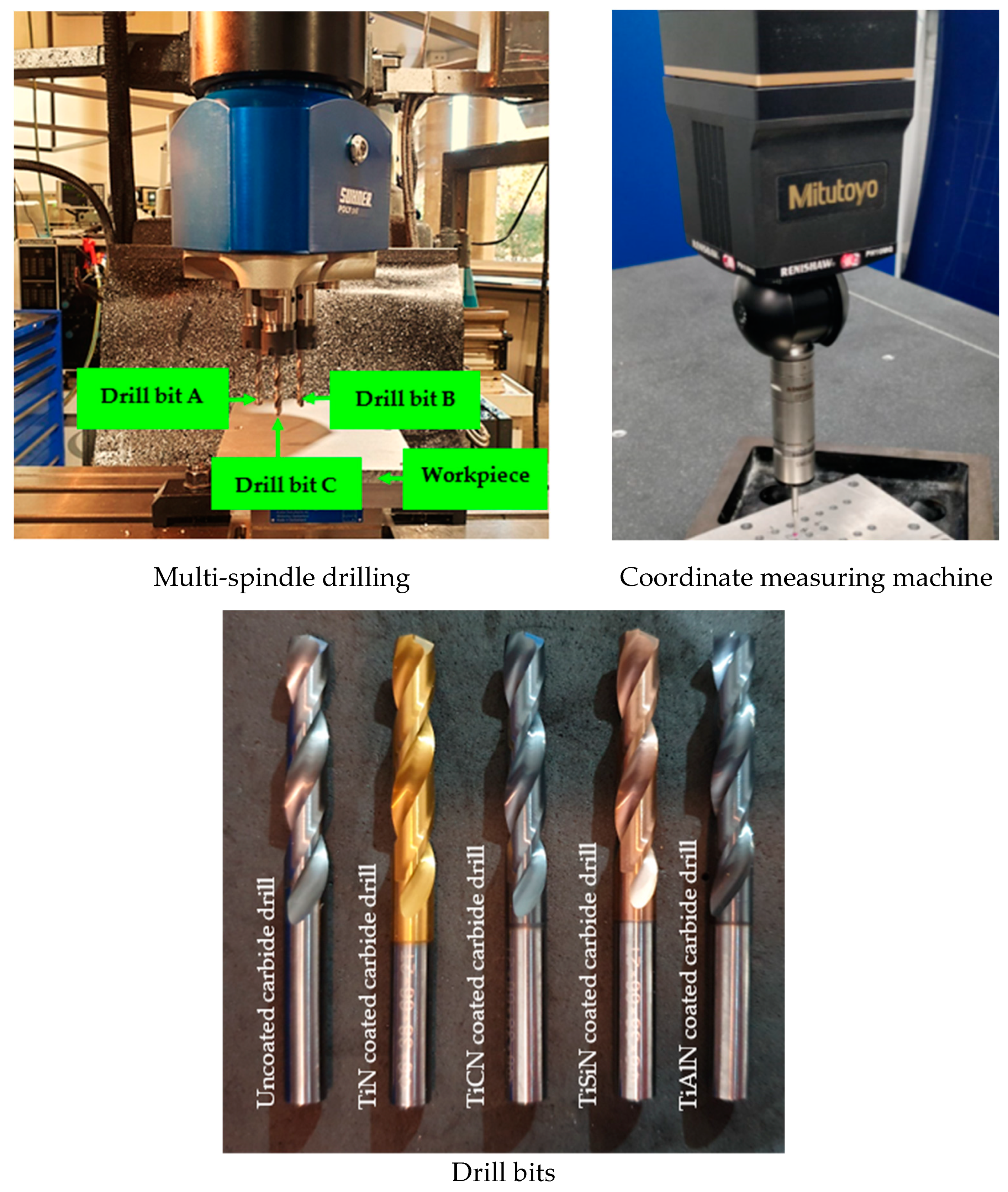

2. Materials and Methods

3. Results

3.1. Hole Size, Circularity, Cylindricity and Perpendicularity

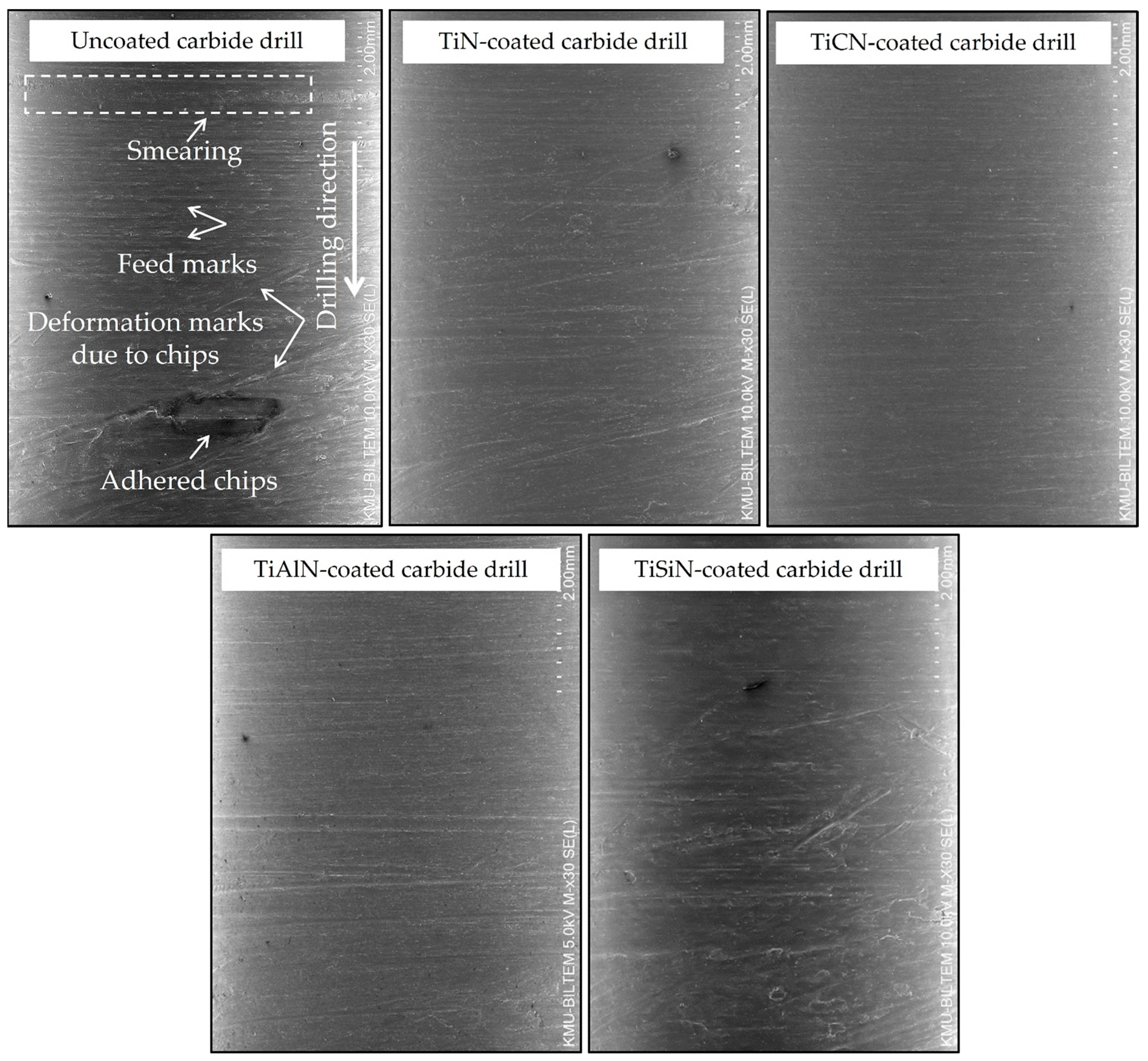

3.2. Surface Damage Analysis

4. Discussion

5. Conclusions

- The surface damage found on the inner hole surface was metal debris adhesion, smeared material, and feed marks.

- Uncoated-carbide drills performed better at low cutting parameters, yielded high-quality holes, and fewer defects on the inner hole surface.

- TiCN-coated carbide drills gave better hole accuracy and less damage in the inner hole wall surface at the highest spindle speed, followed by the TiN.

- The worst surface finish with irregular patterns around the top and bottom of the hole edges and most oversized holes were obtained by TiSiN-coated carbide drills following the TiAlN.

- Overall, the uncoated carbide drills outperformed better at low cutting parameters, while the TiN coated drills were recommended for high-quality holes at high cutting parameters selected in this study.

- Regarding cutting parameters, the hole size, circularity, and cylindricity increased with the increase in the spindle speed with a varying percentage contribution from the ANOVA results. The feed had a varying effect on the hole quality; however, in some cases, it was seen that there was less error in hole size, circularity, and cylindricity error at the high feed. However, further investigation at high cutting parameters is required to better understand the performance of tool coatings at a wider range of cutting parameters using a multi-spindle simultaneous drilling process, which will be the scope of a future study.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Habib, N.; Sharif, A.; Hussain, A.; Aamir, M.; Giasin, K.; Pimenov, D.Y.; Ali, U. Analysis of Hole Quality and Chips Formation in the Dry Drilling Process of Al7075-T6. Metals 2021, 11, 891. [Google Scholar] [CrossRef]

- Efstathiou, C.; Vakondios, D.; Lyronis, A.; Sofiakis, K.; Antoniadis, A. Finite Element Modeling and Experimental Study of Burr Formation in Drilling Processes. In Proceedings of the ASME 2016 International Mechanical Engineering Congress and Exposition, Phoenix, AZ, USA, 13–17 November 2016; p. 9. [Google Scholar]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Vafadar, A. A review: Drilling performance and hole quality of aluminium alloys for aerospace applications. J. Mater. Res. Technol. 2020, 9, 12484–12500. [Google Scholar] [CrossRef]

- Aamir, M.; Tu, S.; Giasin, K.; Tolouei-Rad, M. Multi-hole simultaneous drilling of aluminium alloy: A preliminary study and evaluation against one-shot drilling process. J. Mater. Res. Technol. 2020, 9, 3994–4006. [Google Scholar] [CrossRef]

- Rivero, A.; Aramendi, G.; Herranz, S.; de Lacalle, L.L. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Iqbal, A.; Zhao, G.; Zaini, J.; Gupta, M.K.; Jamil, M.; He, N.; Nauman, M.M.; Mikolajczyk, T.; Pimenov, D.Y. Between-the-Holes Cryogenic Cooling of the Tool in Hole-Making of Ti-6Al-4V and CFRP. Materials 2021, 14, 795. [Google Scholar] [CrossRef] [PubMed]

- Haan, D.; Batzer, S.; Olson, W.; Sutherland, J. An experimental study of cutting fluid effects in drilling. J. Mater. Process. Technol. 1997, 71, 305–313. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Feasibility of tool configuration and the effect of tool material, and tool geometry in multi-hole simultaneous drilling of Al2024. Int. J. Adv. Manuf. Technol. 2020, 111, 861–879. [Google Scholar] [CrossRef]

- Vafadar, A.; Hayward, K.; Tolouei-Rad, M. Drilling reconfigurable machine tool selection and process parameters optimization as a function of product demand. J. Manuf. Syst. 2017, 45, 58–69. [Google Scholar] [CrossRef] [Green Version]

- Hanif, M.I.; Aamir, M.; Ahmed, N.; Maqsood, S.; Muhammad, R.; Akhtar, R.; Hussain, I. Optimization of facing process by indigenously developed force dynamometer. Int. J. Adv. Manuf. Technol. 2019, 100, 1893–1905. [Google Scholar] [CrossRef]

- Tönshoff, H.; Spintig, W.; König, W.; Neises, A. Machining of holes developments in drilling technology. CIRP Ann. 1994, 43, 551–561. [Google Scholar] [CrossRef]

- Sinmazçelik, T.; Avcu, E.; Bora, M.Ö.; Çoban, O. A review: Fibre metal laminates, background, bonding types and applied test methods. Mater. Des. 2011, 32, 3671–3685. [Google Scholar] [CrossRef]

- Sahu, S. Performance Evaluation of Uncoated and Multi Layer Tin Coated Carbide Tool in Hard Turning. Master’s Thesis, National Institute of Technology, Rourkela, India, 2012. [Google Scholar]

- Armarego, E.; Verezub, S.; Samaranayake, P. The effect of coatings on the cutting process, friction, forces and predictive cutting models in machining operations. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 347–356. [Google Scholar] [CrossRef]

- Haron, C.C.; Ginting, A.; Goh, J. Wear of coated and uncoated carbides in turning tool steel. J. Mater. Process. Technol. 2001, 116, 49–54. [Google Scholar] [CrossRef]

- Tolouei-Rad, M.; Aamir, M. Analysis of the Performance of Drilling Operations for Improving Productivity. In Drilling; Tolouei-Rad, M., Ed.; IntechOpen: London, UK, 2021; Available online: https://www.intechopen.com/online-first/analysis-of-the-performance-of-drilling-operations-for-improving-productivity (accessed on 18 August 2020).

- Aamir, M.; Tu, S.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Optimization and modeling of process parameters in multi-hole simultaneous drilling using taguchi method and fuzzy logic approach. Materials 2020, 13, 680. [Google Scholar] [CrossRef] [Green Version]

- Vafadar, A.; Tolouei-Rad, M.; Hayward, K. An integrated model to use drilling modular machine tools. Int. J. Adv. Manuf. Technol. 2019, 102, 2387–2397. [Google Scholar] [CrossRef]

- Tolouei-Rad, M. Intelligent analysis of utilization of special purpose machines for drilling operations. In Intelligent Systems; Koleshko, V.M., Ed.; InTech: Croatia, 2012; pp. 297–320. ISBN 978-953-51-0054-6. Available online: http://www.intechopen.com/books/intelligent-systems/intelligent-analysis-of-utilization-of-special-purposemachines-for-drilling-operations (accessed on 18 August 2020).

- Tolouei-Rad, M. An efficient algorithm for automatic machining sequence planning in milling operations. Int. J. Prod. Res. 2003, 41, 4115–4131. [Google Scholar] [CrossRef]

- Sun, D.; Lemoine, P.; Keys, D.; Doyle, P.; Malinov, S.; Zhao, Q.; Qin, X.; Jin, Y. Hole-making processes and their impacts on the microstructure and fatigue response of aircraft alloys. Int. J. Adv. Manuf. Technol. 2018, 94, 1719–1726. [Google Scholar] [CrossRef] [Green Version]

- Aamir, M.; Giasin, K.; Tolouei-Rad, M.; Ud Din, I.; Hanif, M.I.; Kuklu, U.; Pimenov, D.Y.; Ikhlaq, M. Effect of Cutting Parameters and Tool Geometry on the Performance Analysis of One-Shot Drilling Process of AA2024-T3. Metals 2021, 11, 854. [Google Scholar] [CrossRef]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. (1980–2015) 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A. Machinability of Al2024, Al6061, and Al5083 alloys using multi-hole simultaneous drilling approach. J. Mater. Res. Technol. 2020, 9, 10991–11002. [Google Scholar] [CrossRef]

- Giasin, K.; Hodzic, A.; Phadnis, V.; Ayvar-Soberanis, S. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: Experimental and finite element study. Int. J. Adv. Manuf. Technol. 2016, 87, 2041–2061. [Google Scholar] [CrossRef]

- Statoncoating. Coatings for Cutting Tools. Available online: https://www.statoncoating.com/en/coatings/coatings-cutting-tools (accessed on 18 August 2020).

- Al-Tameemi, H.A.; Al-Dulaimi, T.; Awe, M.O.; Sharma, S.; Pimenov, D.Y.; Koklu, U.; Giasin, K. Evaluation of Cutting-Tool Coating on the Surface Roughness and Hole Dimensional Tolerances during Drilling of Al6061-T651 Alloy. Materials 2021, 14, 1783. [Google Scholar] [CrossRef] [PubMed]

- Engdahl, N.C. CVD Diamond Coated Rotating Tools for Composite Machining. In Proceedings of the Aerospace Manufacturing and Automated Fastening Conference and Exhibition, Toulouse, France, 12 September 2006; p. 9. [Google Scholar]

- Sheikh-Ahmad, J.Y. Machining of Polymer Composites; Springer: Boston, MA, USA, 2009; p. 315. [Google Scholar]

- Nouari, M.; List, G.; Girot, F.; Coupard, D. Experimental analysis and optimisation of tool wear in dry machining of aluminium alloys. Wear 2003, 255, 1359–1368. [Google Scholar] [CrossRef]

- Nouari, M.; List, G.; Girot, F.; Gehin, D. Effect of machining parameters and coating on wear mechanisms in dry drilling of aluminium alloys. Int. J. Mach. Tools Manuf. 2005, 45, 1436–1442. [Google Scholar] [CrossRef]

- Koklu, U.; Morkavuk, S.; Featherston, C.; Haddad, M.; Sanders, D.; Aamir, M.; Pimenov, D.Y.; Giasin, K. The effect of cryogenic machining of S2 glass fibre composite on the hole form and dimensional tolerances. Int. J. Adv. Manuf. Technol. 2021, 115, 125–140. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Vafadar, A.; Koklu, U.; Keeble, W. Evaluation of the Surface Defects and Dimensional Tolerances in Multi-Hole Drilling of AA5083, AA6061, and AA2024. Appl. Sci. 2021, 11, 4285. [Google Scholar] [CrossRef]

- Kurt, M.; Kaynak, Y.; Bagci, E. Evaluation of drilled hole quality in Al 2024 alloy. Int. J. Adv. Manuf. Technol. 2008, 37, 1051–1060. [Google Scholar] [CrossRef]

- Giasin, K.; Hawxwell, J.; Sinke, J.; Dhakal, H.; Köklü, U.; Brousseau, E. The effect of cutting tool coating on the form and dimensional errors of machined holes in GLARE® fibre metal laminates. Int. J. Adv. Manuf. Technol. 2020, 107, 2817–2832. [Google Scholar] [CrossRef] [Green Version]

- Giasin, K.; Ayvar-Soberanis, S.; French, T.; Phadnis, V. 3D Finite Element Modelling of Cutting Forces in Drilling Fibre Metal Laminates and Experimental Hole Quality Analysis. Appl. Compos. Mater. 2017, 24, 113–137. [Google Scholar] [CrossRef] [Green Version]

- Souza, C.C.; Arencibia, R.V.; Costa, H.L.; Piratelli Filho, A. A contribution to the measurement of circularity and cylindricity deviations. In Proceedings of the ABCM Symposium Series in Mechatronics, Natal, RN, Brazil, 24–28 October 2011; p. 791. [Google Scholar]

- Selvarajan, L.; Narayanan, C.S.; Jeyapaul, R.; Manohar, M. Optimization of EDM process parameters in machining Si3N4–TiN conductive ceramic composites to improve form and orientation tolerances. Measurement 2016, 92, 114–129. [Google Scholar] [CrossRef]

- Giasin, K. The effect of drilling parameters, cooling technology, and fiber orientation on hole perpendicularity error in fiber metal laminates. Int. J. Adv. Manuf. Technol. 2018, 97, 4081–4099. [Google Scholar] [CrossRef] [Green Version]

- Liang, X.; Liu, Z.; Wang, B. State-of-the-art of surface integrity induced by tool wear effects in machining process of titanium and nickel alloys: A review. Measurement 2019, 132, 150–181. [Google Scholar] [CrossRef]

- Buehler. Solutions for Materials Preparation, Testing & Analysis: Don’t Smear It! Avoiding Surface Deformation in Polishing. Available online: https://metallography-matters.buehler.com/2018/09/17/dont-smear-it-avoiding-surface-deformation-in-polishing/#:~:text=To%20prevent%20smearing%2C%20it’s%20best,polishing%20surface%20can%20also%20help (accessed on 6 March 2021).

- Davoudinejad, A.; Ashrafi, S.A.; Hamzah, R.I.R.; Niazi, A. Experimental analysis of wear mechanism and tool life in dry drilling of Al2024. Adv. Mater. Res. 2012, 566, 217–221. [Google Scholar] [CrossRef]

- Sun, F.; Qu, S.; Su, F.; Deng, Z.; Li, X. Effect of micro-void on surface integrity after machining of Ti-6Al-4V workpieces prepared by HIP and forging. Int. J. Adv. Manuf. Technol. 2018, 98, 3167–3177. [Google Scholar] [CrossRef]

- Oberg, E. Machinery’s Handbook 29th Edition-Full Book; Industrial Press: New York, NY, USA, 2012. [Google Scholar]

- Aamir, M.; Tolouei-Rad, M.; Vafadar, A.; Raja, M.N.A.; Giasin, K. Performance Analysis of Multi-Spindle Drilling of Al2024 with TiN and TiCN Coated Drills Using Experimental and Artificial Neural Networks Technique. Appl. Sci. 2020, 10, 8633. [Google Scholar] [CrossRef]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K. Multi-spindle drilling of Al2024 alloy and the effect of TiAlN and TiSiN-coated carbide drills for productivity improvement. Int. J. Adv. Manuf. Technol. 2021, 114, 3047–3056. [Google Scholar] [CrossRef]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S.; Krolczyk, G.M.; Prakash, C. Evaluating hole quality in drilling of Al 6061 alloys. Materials 2018, 11, 2443. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hosokawa, A.; Shimamura, K.; Ueda, T. Cutting characteristics of PVD-coated tools deposited by unbalanced magnetron sputtering method. CIRP Ann. 2012, 61, 95–98. [Google Scholar] [CrossRef]

- Jindal, P.; Santhanam, A.; Schleinkofer, U.; Shuster, A. Performance of PVD TiN, TiCN, and TiAlN coated cemented carbide tools in turning. Int. J. Refract. Met. Hard Mater. 1999, 17, 163–170. [Google Scholar] [CrossRef]

- Thorne, E.J. Cutting Tool Engineering-Aluminum Can Be Hard to Drill, Despite Its Easy Rep. Available online: https://www.ctemag.com/news/articles/aluminum-can-be-hard-drill-despite-its-easy-rep# (accessed on 17 August 2020).

- Bouzakis, K.-D.; Skordaris, G.; Gerardis, S.; Katirtzoglou, G.; Makrimallakis, S.; Pappa, M.; LilI, E.; M’Saoubi, R. Ambient and elevated temperature properties of TiN, TiAlN and TiSiN PVD films and their impact on the cutting performance of coated carbide tools. Surf. Coat. Technol. 2009, 204, 1061–1065. [Google Scholar] [CrossRef]

- Prengel, H.; Pfouts, W.; Santhanam, A. State of the art in hard coatings for carbide cutting tools. Surf. Coat. Technol. 1998, 102, 183–190. [Google Scholar] [CrossRef]

- Ko, S.-L.; Lee, J.-K. Analysis of burr formation in drilling with a new-concept drill. J. Mater. Process. Technol. 2001, 113, 392–398. [Google Scholar] [CrossRef]

- Shanmughasundaram, P.; Subramanian, R. Study of parametric optimization of burr formation in step drilling of eutectic Al–Si alloy–Gr composites. J. Mater. Res. Technol. 2014, 3, 150–157. [Google Scholar] [CrossRef] [Green Version]

- Mann, J.Y.; Milligan, I.S. Aircraft Fatigue: Design, Operational and Economic Aspects; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

| Coatings | Oxidation Temperature (°C) | Hardness (GPa) | Friction Coefficient (µ) |

|---|---|---|---|

| Uncoated | 500 | 26 | 0.4–0.6 |

| TiN | 600 | 23 | 0.4–0.5 |

| TiCN | 400 | 27 | 0.2 |

| TiAlN | 700–800 | 32 | 0.5–0.7 |

| TiSiN | 1000 | 35 | 0.6 |

| Specifications | |

|---|---|

| Type | Twist drill |

| Material | Carbide |

| Coatings | TiN, TiCN, TiAlN, and TiSiN |

| Number of flutes | 2 |

| Drill diameter | 6 mm |

| Point angle | 140 |

| Helix angle | 30° |

| Overall length | 66 mm |

| Hole Deviation (µm) | ||||||

|---|---|---|---|---|---|---|

| Spindle Speed (rpm) | Feed (mm/rev) | Uncoated Carbide | TiN | TiCN | TiAlN | TiSiN |

| 1007 | 0.04 | 4 | 25 | 11 | 44 | 73 |

| 1007 | 0.08 | 6 | 25 | 13 | 27 | 67 |

| 1007 | 0.14 | 3 | 21 | 13 | 11 | 52 |

| 2015 | 0.04 | 14 | 87 | 22 | 36 | 86 |

| 2015 | 0.08 | 6 | 49 | 31 | 70 | 52 |

| 2015 | 0.14 | 10 | 76 | 66 | 73 | 29 |

| 3025 | 0.04 | 52 | 48 | 4 | 76 | 119 |

| 3025 | 0.08 | 86 | 35 | 27 | 51 | 106 |

| 3025 | 0.14 | 24 | 21 | 23 | 27 | 36 |

| Source | Hole Size | Circularity | Cylindricity | Perpendicularity | ||||

|---|---|---|---|---|---|---|---|---|

| p Value | Contribution | p Value | Contribution | p Value | Contribution | p Value | Contribution | |

| Spindle speed | 0.001 | 12.72% | 0.2 | 2.84% | 0.2 | 12.09% | 0.452 | 1.95% |

| Feed | 0.049 | 4.12% | 0.003 | 13.77% | 0.003 | 24.22% | 0.34 | 2.71% |

| Coating type | 0 | 33.97% | 0 | 46.37% | 0 | 30.32% | 0 | 61.29% |

| 2-Way Interactions | 0.006 | 40.15% | 0.198 | 24.28% | 0.198 | 24.49% | 0.818 | 15.30% |

| Spindle speed × Feed | 0.045 | 7.01% | 0.018 | 13.09% | 0.018 | 9.65% | 0.693 | 2.64% |

| Spindle speed × Coating type | 0.005 | 20.23% | 0.926 | 2.31% | 0.926 | 6.41% | 0.713 | 6.25% |

| Feed × Coating type | 0.035 | 12.91% | 0.271 | 8.88% | 0.271 | 8.43% | 0.7 | 6.41% |

| Error | - | 9.04% | - | 12.74% | - | 8.88% | - | 18.74% |

| Total | - | 100.00% | - | 100.00% | - | 100.00% | - | 100.00% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aamir, M.; Davis, A.; Keeble, W.; Koklu, U.; Giasin, K.; Vafadar, A.; Tolouei-Rad, M. The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy. Metals 2021, 11, 1103. https://doi.org/10.3390/met11071103

Aamir M, Davis A, Keeble W, Koklu U, Giasin K, Vafadar A, Tolouei-Rad M. The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy. Metals. 2021; 11(7):1103. https://doi.org/10.3390/met11071103

Chicago/Turabian StyleAamir, Muhammad, Adrian Davis, William Keeble, Ugur Koklu, Khaled Giasin, Ana Vafadar, and Majid Tolouei-Rad. 2021. "The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy" Metals 11, no. 7: 1103. https://doi.org/10.3390/met11071103

APA StyleAamir, M., Davis, A., Keeble, W., Koklu, U., Giasin, K., Vafadar, A., & Tolouei-Rad, M. (2021). The Effect of TiN-, TiCN-, TiAlN-, and TiSiN Coated Tools on the Surface Defects and Geometric Tolerances of Holes in Multi-Spindle Drilling of Al2024 Alloy. Metals, 11(7), 1103. https://doi.org/10.3390/met11071103