Real-Time Weld Gap Monitoring and Quality Control Algorithm during Weaving Flux-Cored Arc Welding Using Deep Learning

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

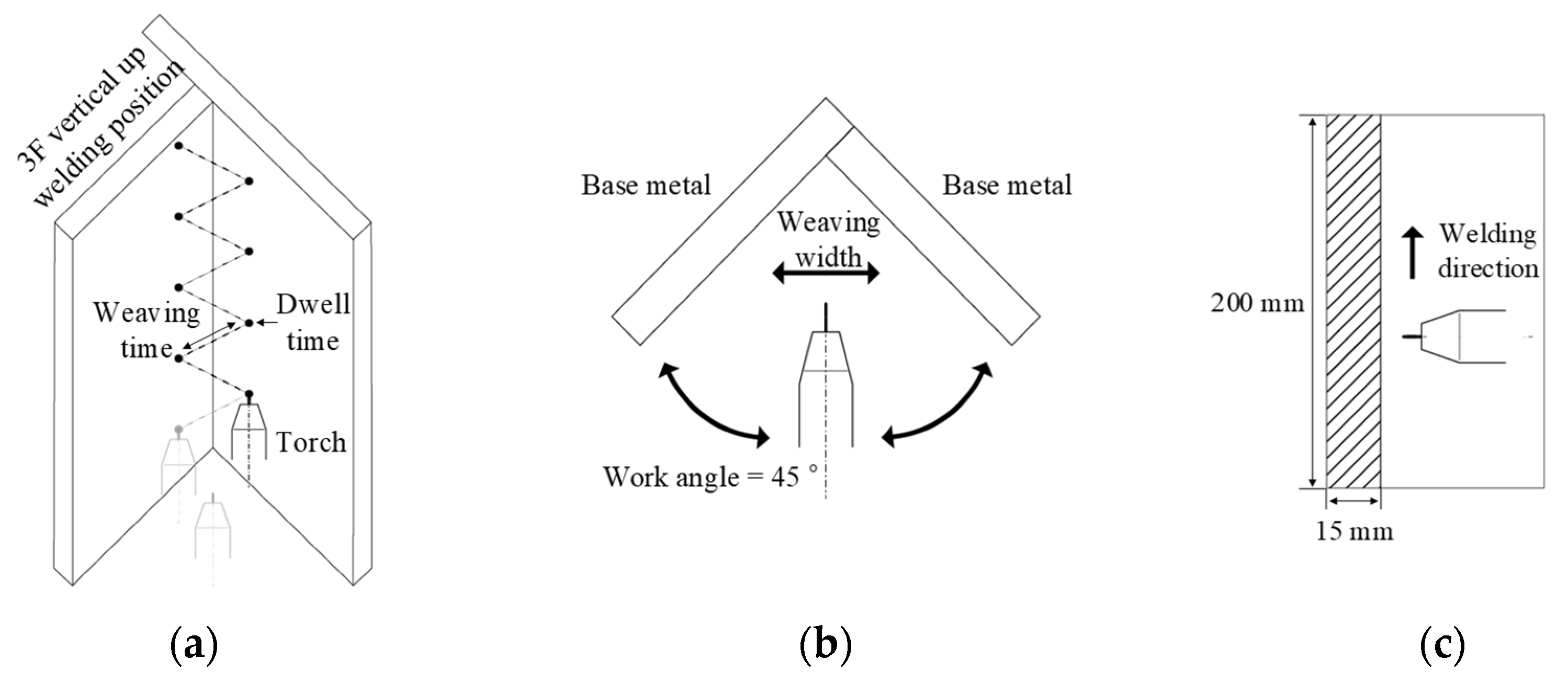

2.2. Experimental Equipment and Procedure

3. Results and Discussion

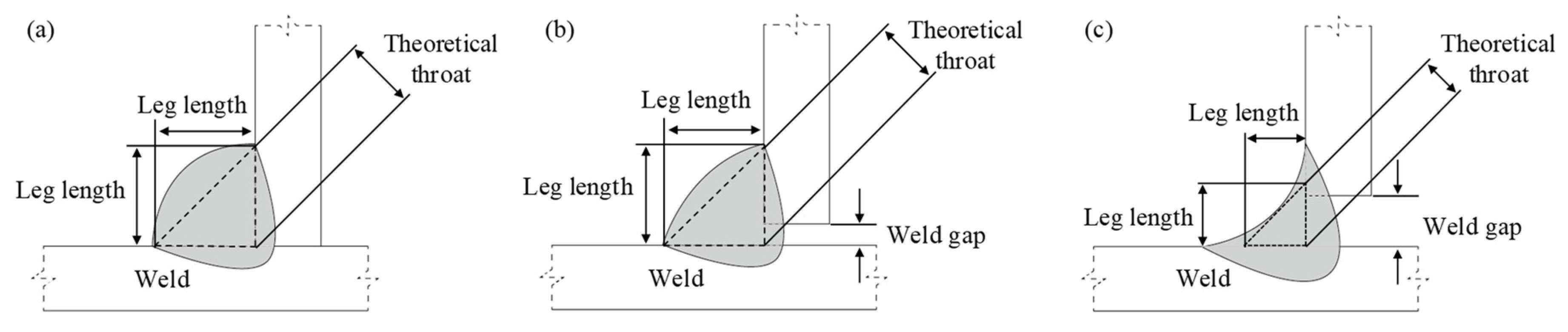

3.1. Effect of Gap and Welding Speed on Weld Bead Shape Parameters

3.2. Feature Parameter Extraction from Welding Current and Voltage Signals

3.3. Training and Validation of the Proposed DNN-Based Weld Gap Monitoring and Weld Deposition Rate Control Model

3.4. Bead Shape Control for Gap Compensation Using DNN

3.4.1. Weld Gap Monitoring Performance Evaluation (Offline)

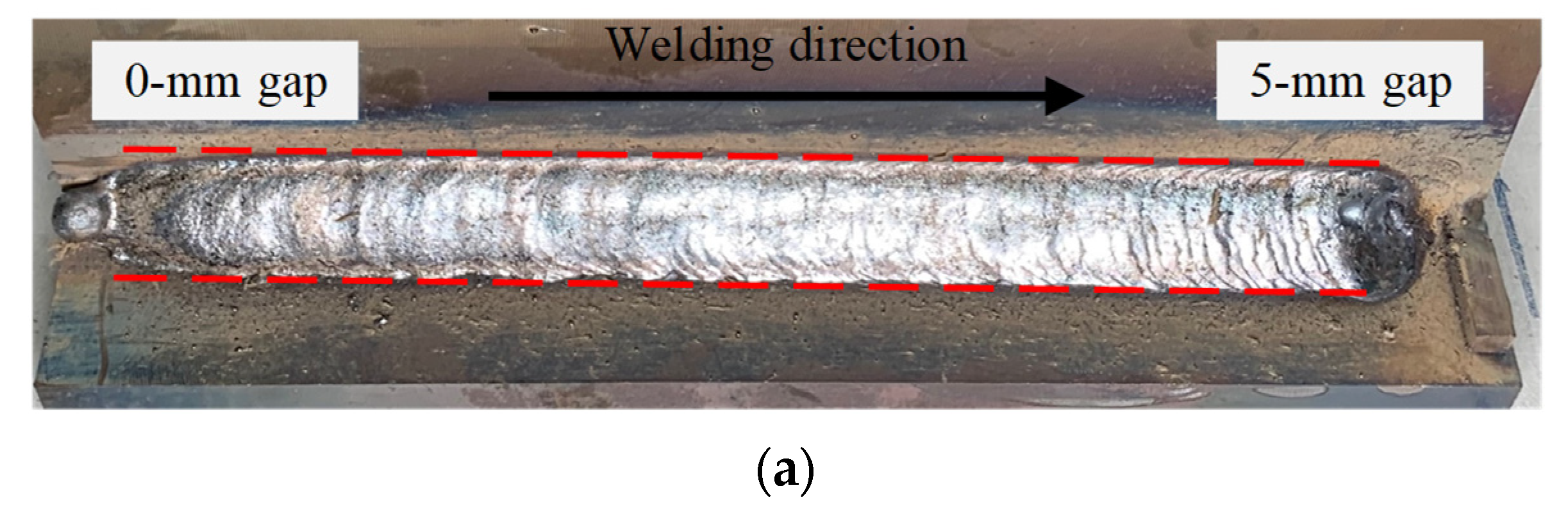

3.4.2. Real-Time Welding Quality Control

4. Conclusions

- The proposed DNN-based gap detection model was trained based on the feature variables extracted from the welding current and voltage signals, leading to a training accuracy of approximately 94.3%.

- For both offline and online cases, the verification process was performed with data that were not included in the training data (obtained through additional experiments). In this process, average accuracies of 93.7% and 87.7% were obtained for offline and online cases, respectively. In the online test, the weld gap detection performance decreased slightly at the beginning of the section where the weld gap changed.

- The trained DNN model for weld gap detection and weld deposition rate control was verified using test plates with linear changing gaps (0–5 mm). The results indicate that uniform external welding beads were achieved by controlling the welding robot based on real-time weld gap detection results.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Urbański, T.; Graczyk, T.; Taraska, M.; Iwańkowicz, R. Assessment of technological usefulness of panel production line in shipbuilding process. Pol. Marit. Res. 2018, 25, 134–144. [Google Scholar] [CrossRef] [Green Version]

- Ogbonna, O.; Akinlabi, S.; Madushele, N.; Mashinini, M.; Abioye, A.A. Application of MIG and TIG welding in automobile industry. J. Phys. Conf. Ser. 2019, 1378, 042065. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, F.; Liang, Z.; Ying, Y.; Lin, Q.; Wei, H. Correlation analysis of penetration based on keyhole and plasma plume in laser welding. J. Mater. Process. Technol. 2018, 256, 1–12. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Yazdian, N.; Ma, J.; Kovacevic, R. High power laser welding of thick steel plates in a horizontal butt joint configuration. Opt. Laser Technol. 2016, 83, 1–12. [Google Scholar] [CrossRef]

- Turichin, G.; Kuznetsov, M.; Tsibulskiy, I.; Firsova, A. Hybrid laser-arc welding of the high-strength shipbuilding steels: Equipment and technology. Phys. Procedia 2017, 89, 156–163. [Google Scholar] [CrossRef]

- Lopes, T.C.; Sikora, C.; Molina, R.G.; Schibelbain, D.; Rodrigues, L.; Magatão, L. Balancing a robotic spot welding manufacturing line: An industrial case study. Eur. J. Oper. Res. 2017, 263, 1033–1048. [Google Scholar] [CrossRef]

- Dean, D.; Hidekazu, M.; Wei, L. Numerical simulation of welding distortion in large structures. Comput. Methods Appl. Mech. Eng. 2007, 196, 4613–4627. [Google Scholar]

- Vuherer, T.; Maruschak, P.O.; Samardžić, I. Behaviour of coarse grain heat affected zone (HAZ) during cycle loading. Metalurgija 2012, 51, 301–304. [Google Scholar]

- Zhao-Hui, W.; Ji-Wang, D.; Ming-Hua, Z.; Xiu-Min, F. Survey on flexible shipbuilding technologies for curved ship-blocks. Procedia Eng. 2017, 174, 800–807. [Google Scholar] [CrossRef]

- Zhang, Y.; You, D.; Gao, X.; Zhang, N.; Gao, P.P. Welding defects detection based on deep learning with multiple optical sensors during disk laser welding of thick plates. J. Manuf. Syst. 2019, 51, 87–94. [Google Scholar] [CrossRef]

- Yu, J.; Lee, H.; Kim, D.-Y.; Kang, M.; Hwang, I. Quality assessment method based on a spectrometer in laser beam welding process. Metals 2020, 10, 839. [Google Scholar] [CrossRef]

- Shin, S.; Jin, C.; Yu, J.; Rhee, S. Real-time detection of weld defects for automated welding process base on deep neural network. Metals 2020, 10, 389. [Google Scholar] [CrossRef] [Green Version]

- Nagesh, D.; Datta, G. Prediction of weld bead geometry and penetration in shielded metal-arc welding using artificial neural networks. J. Mater. Process. Technol. 2002, 123, 303–312. [Google Scholar] [CrossRef]

- Pinto-Lopera, J.E.; ST Motta, J.M.; Absi Alfaro, S.C. Real-time measurement of width and height of weld beads in GMAW processes. Sensors 2016, 16, 1500. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Yu, H.; Zhong, J.; Lin, T.; Chen, S. Real-time seam tracking control technology during welding robot GTAW process based on passive vision sensor. J. Mater. Process. Technol. 2012, 212, 1654–1662. [Google Scholar] [CrossRef]

- Zou, Y.; Wang, Y.; Zhou, W.; Chen, X. Real-time seam tracking control system based on line laser visions. Opt. Laser Technol. 2018, 103, 182–192. [Google Scholar] [CrossRef]

- Lei, T.; Huang, Y.; Shao, W.; Liu, W.; Rong, Y. A tactual weld seam tracking method in super narrow gap of thick plates. Robot. Comput. Manuf. 2020, 62, 101864. [Google Scholar] [CrossRef]

- Na, S.J.; Moon, H.S. Signal processing algorithm for analysis of welding phenomena. J. Weld Join 1996, 14, 24–32. [Google Scholar]

- Kang, M.J.; Rhee, S. The statistical models for estimating the amount of spatter in the short circuit transfer mode of GMAW. Weld J. 2001, 80, 1–8. [Google Scholar]

- Kang, M.J.; Rhee, S. A study on the development of the arc stability index using multiple regression analysis in the short-circuit transfer region of gas metal arc welding. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2001, 215, 195–205. [Google Scholar] [CrossRef]

- Wu, C.S.; Gao, J.Q.; Hu, J.K. Real-time sensing and monitoring in robotic gas metal arc welding. Meas. Sci. Technol. 2006, 18, 303–310. [Google Scholar] [CrossRef]

- Zhang, Z.; Chen, X.; Chen, H.; Zhong, J.; Chen, S. Online welding quality monitoring based on feature extraction of arc voltage signal. Int. J. Adv. Manuf. Technol. 2014, 70, 1661–1671. [Google Scholar] [CrossRef]

- Jin, C.; Shin, S.; Yu, J.; Rhee, S. Prediction model for back-bead monitoring during gas metal arc welding using supervised deep learning. IEEE Access 2020, 8, 224044–224058. [Google Scholar] [CrossRef]

- Zhou, F.; Tao, M.; Bai, X.; Liu, J. Narrow-band interference suppression for SAR based on independent component analysis. IEEE Trans. Geosci. Remote Sens. 2013, 51, 4952–4960. [Google Scholar] [CrossRef]

- Meyer, F.J.; Nicoll, J.B.; Doulgeris, A.P. Characterization and extent of randomly-changing radio frequency interference in ALOS PALSAR data. In Proceedings of the 2011 IEEE International Geoscience and Remote Sensing Symposium, Vancouver, BC, Canada, 24–29 July 2011; pp. 2448–2451. [Google Scholar] [CrossRef]

- Natsuaki, R.; Motohka, T.; Watanabe, M.; Shimada, M.; Suzuki, S. An autocorrelation-based radio frequency interference detection and removal method in azimuth-frequency domain for SAR image. IEEE J. Sel. Top. Appl. Earth Obs. Remote Sens. 2017, 10, 5736–5751. [Google Scholar] [CrossRef]

- Chu, Y.X.; Hu, S.; Hou, W.; Wang, P.; Marin, S. Signature analysis for quality monitoring in short-circuit GMAW. Weld J. 2004, 83, 336–343. [Google Scholar]

- Ioffe, S.; Szegedy, C. Batch normalization: Accelerating deep network training by reducing internal covariate shift. In Proceedings of the 32nd International Conference on Machine Learning, Lille, France, 6–11 July 2015; Volume 37, pp. 448–456. [Google Scholar]

- Srivastava, N.; Hinton, G.; Krizhevsky, A.; Sutskever, I.; Salakhutdinov, R. Dropout: A simple way to prevent neural networks from overfitting. J. Mach. Learn. Res. 2014, 15, 1929–1958. [Google Scholar]

- Shang, W.; Sohn, K.; Almeida, D.; Lee, H. Understanding and improving convolutional neural networks via concatenated rectified linear units. In Proceedings of the International Conference on Machine Learning, New York, NY, USA, 19–24 June 2016; pp. 2217–2225. [Google Scholar]

- Kingma, D.P.; Ba, J. Adam: A method for stochastic optimization. arXiv 2014, arXiv:1412.6980. [Google Scholar]

| Chemical Composition (wt%) | Mechanical Properties | |||||||

|---|---|---|---|---|---|---|---|---|

| SS 400 | C | Si | Mn | P | S | YP (MPa) | TS (MPa) | EI (%) |

| 0.1744 | 0.252 | 0.773 | 0.0127 | 0.0037 | 281 | 457 | 26 | |

| Welding Parameter | Parameter Value |

|---|---|

| Welding type | FCAW |

| Welding speed (cm/min) | 10.8, 13.2, 16.0 |

| CTWD (mm) | 18 |

| Wire feed rate (m/min) | 6.8 |

| Welding voltage (V) | 29 |

| Welding joint | T-fillet joint |

| Shield gas | CO2-100% (25 L/min) |

| Weld gap (mm) | 0, 2, 4 |

| Weaving speed (Hz) | 0.9 |

| Weaving width (mm) | 9 |

| Torch work angle (°) | 45 |

| Robot Motion | Weld Gap (mm) | ||

|---|---|---|---|

| 0 | 2 | 4 | |

| Motion 1 |  |  |  |

| Motion 2 |  |  |  |

| Motion 3 |  |  |  |

| Feature Variable Number | Description | Symbol |

|---|---|---|

| X1 | Average welding current value in one weaving section | |

| X2 | Average of bottom peak value (current) | |

| X3 | Standard deviation of bottom peak value (current) | |

| X4 | Average of top peak value (current) | |

| X5 | Average value of top to bottom peak with respect to median filter | |

| X6 | Average value of bottom to top peak with respect to median filter | |

| X7 | Average voltage value in one weaving section | |

| X8 | Average of bottom peak value (voltage) | |

| X9 | Standard deviation of bottom peak value (voltage) | |

| X10 | Average of top peak value (voltage) | |

| X11 | Average value of top to bottom peak with respect to median filter | |

| X12 | Average value of bottom to top peak with respect to median filter | |

| X13 | Maximum value of current frequency | |

| X14 | Average value of current frequency | |

| X15 | Standard deviation value of current frequency | |

| X16 | Maximum amplitude (current frequency) | |

| X17 | Average value of amplitude | |

| X18 | Standard deviation value of amplitude | |

| X19 | Maximum value of voltage frequency | |

| X20 | Average value of voltage frequency | |

| X21 | Standard deviation value of voltage frequency | |

| X22 | Maximum amplitude (voltage frequency) | |

| X23 | Average value of amplitude | |

| X24 | Standard deviation value of amplitude |

| DNN Structure | Input Node | Hidden Layer | Number of Nodes | Training Accuracy (%) | Training Loss | Validation Accuracy (%) | Validation Loss |

|---|---|---|---|---|---|---|---|

| Structure 1 | 24 | 5 | 64-64-64-64-64 | 88.6 | 0.42 | 83.6 | 0.51 |

| Structure 2 | 5 | 128-128-128-128-128 | 90.2 | 0.25 | 88 | 0.29 | |

| Structure 3 | 5 | 256-128-128-64-64 | 94.3 | 0.15 | 92 | 0.22 | |

| Structure 4 | 4 | 256-128-128-64 | 89.5 | 0.36 | 85 | 0.44 | |

| Structure 5 | 4 | 128-128-64-64 | 88.4 | 0.39 | 81 | 0.48 |

| Layer Number | Type | Output Shape | Number of Parameters | Arguments |

|---|---|---|---|---|

| - | Input | 24 | Range = [0,1,2] | |

| 1 | Dense_1 | 256 | 6400 | |

| 2 | Batch Normalization_1 | 256 | 1024 | |

| 3 | Activation_1 | 256 | Function = ReLU | |

| 4 | Dropout_1 | 256 | Probability = 0.5 | |

| 5 | Dense_2 | 128 | 32896 | |

| 6 | Batch Normalization_2 | 128 | 512 | |

| 7 | Activation_2 | 128 | Function = ReLU | |

| 8 | Dropout_2 | 128 | Probability = 0.5 | |

| 9 | Dense_3 | 128 | 16512 | |

| 10 | Batch Normalization_3 | 128 | 512 | |

| 11 | Activation_3 | 128 | Function = ReLU | |

| 12 | Dropout_3 | 128 | Probability = 0.5 | |

| 13 | Dense_4 | 64 | 8256 | |

| 14 | Batch Normalization_4 | 64 | 256 | |

| 15 | Activation_4 | 64 | Function = ReLU | |

| 16 | Dropout_4 | 64 | Probability = 0.5 | |

| 17 | Dense_5 | 64 | 4160 | |

| 18 | Batch Normalization_5 | 64 | 256 | |

| 19 | Activation_5 | 64 | Function = ReLU | |

| 20 | Dropout_5 | 64 | Probability = 0.5 | |

| 21 | Dense_6 | 3 | 195 | Function = Softmax |

| 22 | Batch Normalization_6 | 3 | 12 | |

| 23 | Activation_6 | 3 | Function = ReLU |

| Welding Speed (cm/min) | Output | Support | Correctly Estimated | Error | Accuracy % | Average Accuracy % |

|---|---|---|---|---|---|---|

| 16 (motion 1) | Class 0 | 38 | 34 | 4 | 89.5 | 92.8 |

| Class 1 | 45 | 40 | 5 | 88.9 | ||

| Class 2 | 36 | 36 | 0 | 100 | ||

| 13.2 (motion 2) | Class 0 | 47 | 43 | 4 | 91.5 | 94.1 |

| Class 1 | 48 | 46 | 2 | 95.8 | ||

| Class 2 | 39 | 37 | 2 | 94.9 | ||

| 10.8 (motion 3) | Class 0 | 54 | 50 | 4 | 92.6 | 94.07 |

| Class 1 | 59 | 58 | 1 | 98.3 | ||

| Class 2 | 46 | 42 | 4 | 91.3 |

| Variable | Support | Correctly Estimated | Error | Accuracy % | Average Accuracy % |

|---|---|---|---|---|---|

| Class 0 (0 mm gap) | 30 | 27 | 3 | 90 | 86 |

| Class 1 (2 mm gap) | 53 | 37 | 16 | 69.8 | |

| Class 2 (4 mm gap) | 47 | 46 | 1 | 97.9 |

| Variable | Support | Correctly Estimated | Error | Accuracy % | Average Accuracy % |

|---|---|---|---|---|---|

| Class 0 (0 mm gap) | 43 | 40 | 3 | 93 | 89.4 |

| Class 1 (2 mm gap) | 43 | 40 | 3 | 93 | |

| Class 2 (4 mm gap) | 45 | 37 | 8 | 82.2 |

| Thickneass of Theoretical Throat (mm) | Weld Gap (mm) | ||

|---|---|---|---|

| 0 | 2 | 4 | |

| Without control | 7.353 | 6.928 | 6.363 |

| With control | 7.623 | 7.494 | 7.706 |

| Thickneass of Theoretical Throat (mm) | Weld Gap (mm) | ||

|---|---|---|---|

| 4 | 2 | 0 | |

| Without control | 7.353 | 6.928 | 6.363 |

| With control | 7.623 | 7.494 | 7.706 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, C.; Rhee, S. Real-Time Weld Gap Monitoring and Quality Control Algorithm during Weaving Flux-Cored Arc Welding Using Deep Learning. Metals 2021, 11, 1135. https://doi.org/10.3390/met11071135

Jin C, Rhee S. Real-Time Weld Gap Monitoring and Quality Control Algorithm during Weaving Flux-Cored Arc Welding Using Deep Learning. Metals. 2021; 11(7):1135. https://doi.org/10.3390/met11071135

Chicago/Turabian StyleJin, Chengnan, and Sehun Rhee. 2021. "Real-Time Weld Gap Monitoring and Quality Control Algorithm during Weaving Flux-Cored Arc Welding Using Deep Learning" Metals 11, no. 7: 1135. https://doi.org/10.3390/met11071135

APA StyleJin, C., & Rhee, S. (2021). Real-Time Weld Gap Monitoring and Quality Control Algorithm during Weaving Flux-Cored Arc Welding Using Deep Learning. Metals, 11(7), 1135. https://doi.org/10.3390/met11071135