Failure Mechanism and Strength Prediction Model of T-Joint of Composite Sandwich Structure

Abstract

:1. Introduction

2. Materials and Methods

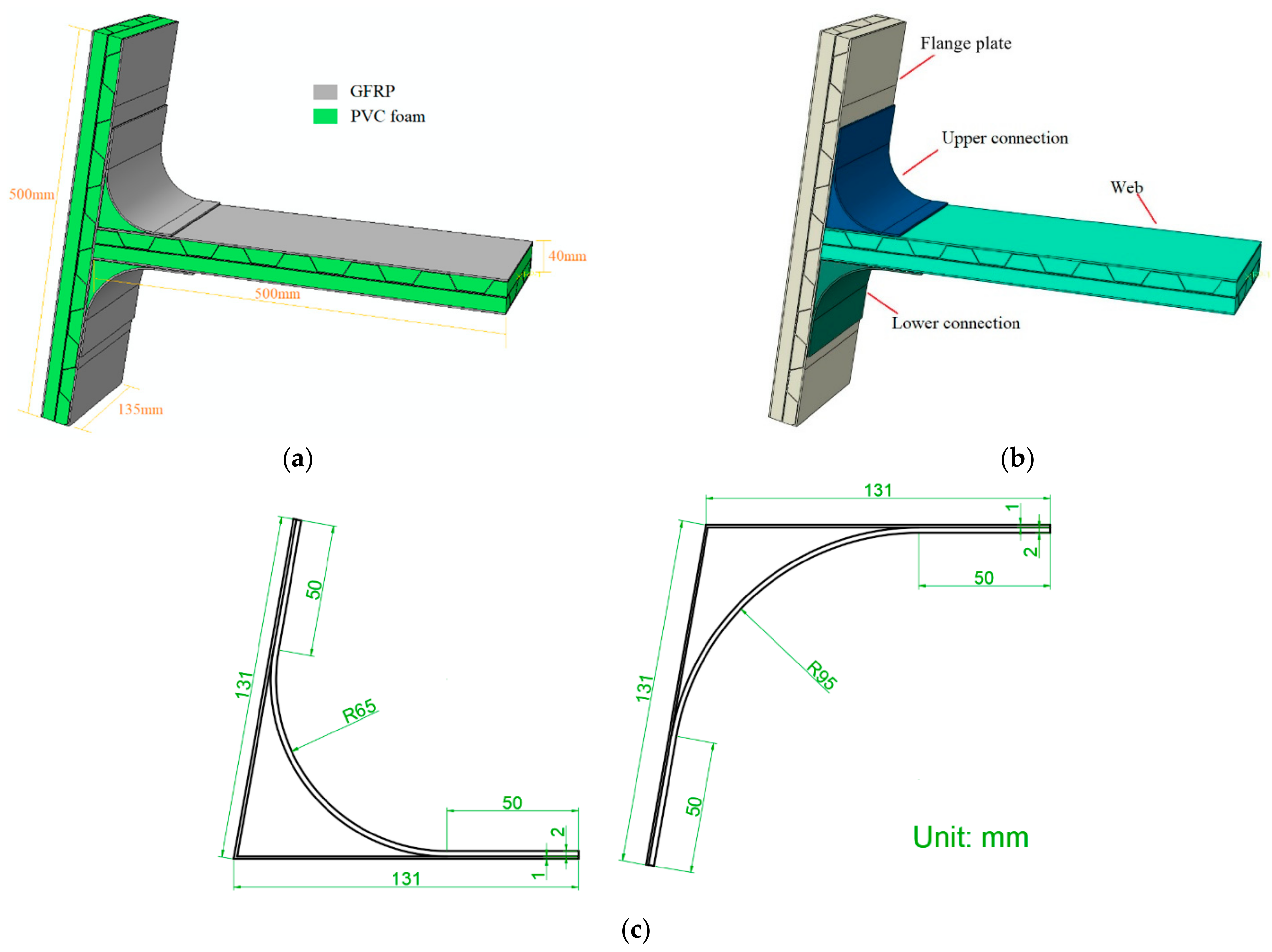

2.1. Experiment

2.2. Finite Element Analysis Method for T-Joint

2.3. Ultimate Bearing Capacity Prediction Model of the T-Joint

2.3.1. Simplified Mechanical Model of T-Joint

2.3.2. The Calculation Model of Bending Ultimate Bearing Capacity of Composite Laminates Based on Neural Network

3. Results

3.1. Results of the Experiment

3.2. Simulation Results

3.2.1. Bending Simulation Result

3.2.2. Ultimate Bearing Capacity of T-Joint

3.3. Verification of Ultimate Bearing Capacity Prediction Model

4. Conclusions

- A type of adhesive T-joint was manufactured by VARI method and subjected to the bending and shearing load according to the actual service condition. The main failure modes of T-joint are local failure of the web panel and arc failure of the lower connector.

- A finite element analysis method was established based on the 3D-Hashin damage initiation criterion and Chang-Chang damage evolution criterion. The web’s failure mode was the compressive matrix failure and the damage on the lower connector was the fiber compressive failure when the joint reached its maximum load-bearing capacity.

- The adhesive T-joint was simplified into bars, and a strength prediction model of the simplified lower connector is established based on the artificial neural network algorithm. The predicted ultimate bearing capacity of the T-joint showed a good agreement with the simulation, and the maximum relative error was less than 3%.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ramnath, B.V.; Alagarraja, K.; Elanchezhian, C. Review on Sandwich Composite and their Applications. Mater. Today Proc. 2019, 16, 859–864. [Google Scholar] [CrossRef]

- Hou, Y.; Neville, R.; Scarpa, F.; Remillat, C.; Gu, B.; Ruzzene, M. Graded conventional-auxetic Kirigami sandwich structures: Flatwise compression and edgewise loading. Compos. Part B Eng. 2014, 59, 33–42. [Google Scholar] [CrossRef]

- Bedon, C.; Amadio, C. Buckling analysis of simply supported flat glass panels subjected to combined in-plane uniaxial compressive and edgewise shear loads. Eng. Struct. 2014, 59, 127–140. [Google Scholar] [CrossRef]

- Zhao, C.-Q.; Li, D.-S.; Ge, T.-Q.; Jiang, L.; Jiang, N. Experimental study on the compression properties and failure mechanism of 3D integrated woven spacer composites. Mater. Des. 2014, 56, 50–59. [Google Scholar] [CrossRef]

- Fan, H.; Yang, L.; Sun, F.; Fang, D. Compression and bending performances of carbon fiber reinforced lattice-core sandwich composites. Compos. Part A Appl. Sci. Manuf. 2013, 52, 118–125. [Google Scholar] [CrossRef]

- Wang, L.; Liu, W.; Wan, L.; Fang, H.; Hui, D. Mechanical performance of foam-filled lattice composite panels in four-point bending: Experimental investigation and analytical modeling. Compos. Part B Eng. 2014, 67, 270–279. [Google Scholar] [CrossRef]

- Li, J.; Hunt, J.F.; Gong, S.; Cai, Z. Simplified analytical model and balanced design approach for light-weight wood-based structural panel in bending. Compos. Struct. 2016, 136, 16–24. [Google Scholar] [CrossRef] [Green Version]

- Moreno, M.S.; Gutiérrez, A.R.; Vicente, J.L.M. Different response under tension and compression of unidirectional carbon fibre laminates in a three-point bending test. Compos. Struct. 2016, 136, 706–711. [Google Scholar] [CrossRef]

- Liu, J.; He, Z.; Liu, J.; Huang, W. Bending response and failure mechanism of composite sandwich panel with Y-frame core. Thin-Walled Struct. 2019, 145, 106387. [Google Scholar] [CrossRef]

- Sun, Y.; Guo, L.-C.; Wang, T.-S.; Yao, L.-J.; Sun, X.-Y. Bending strength and failure of single-layer and double-layer sandwich structure with graded truss core. Compos. Struct. 2019, 226, 111204. [Google Scholar] [CrossRef]

- Mouritz, A. Review of z-pinned laminates and sandwich composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Sun, C.; Jia, P.; Chen, C.; Moradi, A.; Zhou, J.; Al Teneiji, M.; Cantwell, W.; Guan, Z. The effect of carbon fibre stitching on the tensile behaviour of secondary bonded single- and double-lap composite joints. Compos. Struct. 2021, 265, 113774. [Google Scholar] [CrossRef]

- Aimmanee, S.; Hongpimolmas, P. Stress analysis of adhesive-bonded tubular-coupler joints with optimum variable-stiffness composite adherend under torsion. Compos. Struct. 2017, 164, 76–89. [Google Scholar] [CrossRef]

- Aydin, M.D.; Akpinar, S. The strength of the adhesively bonded T-joints with embedded supports. Int. J. Adhes. Adhes. 2014, 50, 142–150. [Google Scholar] [CrossRef]

- Hühne, C.; Zerbst, A.-K.; Kuhlmann, G.; Steenbock, C.; Rolfes, R. Progressive damage analysis of composite bolted joints with liquid shim layers using constant and continuous degradation models. Compos. Struct. 2010, 92, 189–200. [Google Scholar] [CrossRef]

- Koricho, E.G.; Belingardi, G. An experimental and finite element study of the transverse bending behaviour of CFRP composite T-joints in vehicle structures. Compos. Part B Eng. 2015, 79, 430–443. [Google Scholar] [CrossRef]

- Bigaud, J.; Aboura, Z.; Martins, A.; Verger, S. Analysis of the mechanical behavior of composite T-joints reinforced by one side stitching. Compos. Struct. 2018, 184, 249–255. [Google Scholar] [CrossRef]

- Thummalapalli, V.K.; Donaldson, S.L. Biomimetic composite structural T-joints. J. Bionic Eng. 2012, 9, 377–384. [Google Scholar] [CrossRef]

- Romanoff, J.; Remes, H.; Socha, G.; Jutila, M.; Varsta, P. The stiffness of laser stake welded T-joints in web-core sandwich structures. Thin-Walled Struct. 2007, 45, 453–462. [Google Scholar] [CrossRef]

- Omidali, M.; Khedmati, M.R. Numerical investigation on novel geometrical configuration for adhesively bonded T-joint between aluminum and sandwich panel. Thin-Walled Struct. 2018, 131, 122–134. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Weinberg, K. Characterization of sandwich composite T-joints under different ageing conditions. Compos. Struct. 2018, 197, 80–88. [Google Scholar] [CrossRef]

- Wu, H.; Xiao, J.; Xing, S.; Wen, S.; Yang, F.; Yang, J. Numerical and experimental investigation into failure of T700/bismaleimide composite T-joints under tensile loading. Compos. Struct. 2015, 130, 63–74. [Google Scholar] [CrossRef]

- Burns, L.; Mouritz, A.; Pook, D.; Feih, S. Strength improvement to composite T-joints under bending through bio-inspired design. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1971–1980. [Google Scholar] [CrossRef]

- Hisada, S.; Minakuchi, S.; Takeda, N. Cure-induced strain and failure in deltoid of composite T-joints. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106210. [Google Scholar] [CrossRef]

- Abbasi, S.; Ladani, R.; Wang, C.; Mouritz, A. Improving the structural properties of composite T-joints by z-weaving of continuous metallic filaments. Compos. Struct. 2021, 260, 113509. [Google Scholar] [CrossRef]

- Barzegar, M.; Moallem, M.D.; Mokhtari, M. Progressive damage analysis of an adhesively bonded composite T-joint under bending, considering micro-scale effects of fiber volume fraction of adherends. Compos. Struct. 2021, 258, 113374. [Google Scholar] [CrossRef]

- Ravindran, A.R.; Ladani, R.B.; Wang, C.H.; Mouritz, A.P. Strengthening of composite T-joints using 1D and 2D carbon nanoparticles. Compos. Struct. 2021, 255, 112982. [Google Scholar] [CrossRef]

- Guo, S.; Li, W. Numerical analysis and experiment of sandwich T-joint structure reinforced by composite fasteners. Compos. Part B Eng. 2020, 199, 108288. [Google Scholar] [CrossRef]

- Bai, J.-B.; Dong, C.; Xiong, J.-J.; Luo, C.-Y.; Chen, D. Progressive damage behaviour of RTM-made composite T-joint under tensile loading. Compos. Part B Eng. 2019, 160, 488–497. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Anders, D.; Weinberg, K. Influence of strain rate on fracture behavior of sandwich composite T-joints. Eur. J. Mech. A/Solids 2019, 78. [Google Scholar] [CrossRef]

- Hou, W.; Xu, X.; Han, X.; Wang, H.; Tong, L. Multi-objective and multi-constraint design optimization for hat-shaped composite T-joints in automobiles. Thin-Walled Struct. 2019, 143, 106232. [Google Scholar] [CrossRef]

- Hashin, Z. Fataigue failure criteria for unidirectional fiber composites. J. Appl. Mech. 1981, 48, 846–852. [Google Scholar] [CrossRef]

- Chang, F.-K.; Chang, K.-Y. A Progressive Damage Model for Laminated Composites Containing Stress Concentrations. J. Compos. Mater. 1987, 21, 834–855. [Google Scholar] [CrossRef]

| No. | Part Name | Layer | Fiber | Resin |

|---|---|---|---|---|

| 1 | Outside of upper connector | 10 | 200 g/m2 plain woven cloth | Merican 30-200P |

| 2 | Inside of upper connector | 5 | ||

| 3 | Outside of lower connector | 10 | ||

| 4 | Inside of lower connector | 5 | ||

| 5 | Face panel of the sandwich | 10 | ||

| 6 | Corrugation of the sandwich | 4 | ||

| 7 | Middle layer of the sandwich | 4 |

| Elastic Modulus (GPa) | Poisson’s Ratio | Shear Modulus (GPa) | |||

|---|---|---|---|---|---|

| E11 = E22 | E33 | μ12 | μ13 = μ23 | G12 | G13 = G23 |

| 22 | 9 | 0.3 | 0.45 | 4 | 8 |

| Tensile Strength (MPa) | Compressive Strength (MPa) | ShearStrength (MPa) | |||

| XT = YT | ZT | XC = YC | ZC | S12 | S13 = S23 |

| 354 | 20 | 128 | 90 | 38 | 20 |

| Elastic Modulus (MPa) | Poisson’s Ratio | Shear Modulus (MPa) | Density (kg/m3) | ||

|---|---|---|---|---|---|

| Ec | μc | Gc | ρc | ||

| 80 | 0.2 | 25 | 80 | ||

| Compressive Strength (MPa) | Tensile Strength (MPa) | Shear Strength (MPa) | |||

| 1.35 | 1.9 | 1.35 | |||

| Knn MPa | Kss MPa | Ktt MPa | σn MPa | σs MPa | σt MPa | Gnn N/mm | Gss N/mm | Gtt N/mm |

|---|---|---|---|---|---|---|---|---|

| 1586 | 1586 | 1586 | 15 | 15 | 15 | 0.3 | 1.2 | 1.2 |

| No. | L (mm) | w (mm) | t (mm) | XC (MPa) | S23 (MPa) | Ultimate Load (N) |

|---|---|---|---|---|---|---|

| 1 | 50 | 20 | 2.6 | 120 | 25 | 4357 |

| 2 | 80 | 20 | 2.6 | 120 | 25 | 3461 |

| 3 | 100 | 20 | 2.6 | 120 | 25 | 3440 |

| 4 | 120 | 20 | 2.6 | 120 | 25 | 3453 |

| 5 | 150 | 20 | 2.6 | 120 | 25 | 3197 |

| 6 | 180 | 20 | 2.6 | 120 | 25 | 3213 |

| 7 | 100 | 10 | 3 | 140 | 30 | 2102 |

| 8 | 100 | 15 | 3 | 140 | 30 | 3155 |

| 9 | 100 | 20 | 3 | 140 | 30 | 4202 |

| 10 | 100 | 30 | 3 | 140 | 30 | 6313 |

| 11 | 100 | 40 | 3 | 140 | 30 | 8391 |

| 12 | 100 | 50 | 3 | 140 | 30 | 10,511 |

| 13 | 150 | 40 | 1.6 | 100 | 20 | 5168 |

| 14 | 150 | 40 | 2 | 100 | 20 | 6559 |

| 15 | 150 | 40 | 2.6 | 100 | 20 | 9782 |

| 16 | 150 | 40 | 3 | 100 | 20 | 11,288 |

| 17 | 150 | 40 | 4 | 100 | 20 | 15,052 |

| 18 | 150 | 40 | 5 | 100 | 20 | 18,813 |

| 19 | 50 | 10 | 1.6 | 80 | 15 | 1125 |

| 20 | 120 | 30 | 2 | 80 | 35 | 4431 |

| 21 | 120 | 30 | 2 | 100 | 35 | 4431 |

| 22 | 120 | 30 | 2 | 120 | 35 | 4476 |

| 23 | 120 | 30 | 2 | 140 | 35 | 4476 |

| 24 | 120 | 30 | 2 | 160 | 35 | 4431 |

| 25 | 120 | 30 | 2 | 180 | 35 | 4431 |

| 26 | 80 | 15 | 4 | 160 | 15 | 7973 |

| 27 | 80 | 15 | 4 | 160 | 20 | 7973 |

| 28 | 80 | 15 | 4 | 160 | 25 | 7973 |

| 29 | 80 | 15 | 4 | 160 | 30 | 7973 |

| 30 | 80 | 15 | 4 | 160 | 35 | 7973 |

| 31 | 80 | 15 | 4 | 160 | 40 | 7973 |

| Neurons | MAE/MPa | RMSE/MPa | R2 |

|---|---|---|---|

| 7 | 0.0182 | 0.0263 | 0.99845 |

| 9 | 0.0189 | 0.0277 | 0.99826 |

| 10 | 0.0120 | 0.0165 | 0.99948 |

| 11 | 0.0197 | 0.0273 | 0.99795 |

| 12 | 0.0070 | 0.0075 | 0.99987 |

| 13 | 0.0114 | 0.0135 | 0.99949 |

| No. | l mm | w mm | t mm | XC MPa | τyz MPa | F1/kN | Error/% | |

|---|---|---|---|---|---|---|---|---|

| FEM | ANN | |||||||

| 1 | 218.55 | 150 | 3.4 | 128 | 20 | 31.622 | 31.499 | 0.39 |

| 2 | 218.55 | 150 | 2.8 | 128 | 20 | 15.970 | 15.912 | 0.36 |

| 3 | 167.12 | 150 | 2.8 | 128 | 20 | 39.303 | 38.177 | 2.88 |

| 4 | 192.84 | 150 | 2.2 | 128 | 20 | 84.866 | 83.983 | 1.04 |

| 5 | 167.12 | 150 | 2.2 | 128 | 20 | 125.628 | 124.862 | 0.61 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; Li, M.; Lu, X.; Zhu, X. Failure Mechanism and Strength Prediction Model of T-Joint of Composite Sandwich Structure. Metals 2021, 11, 1197. https://doi.org/10.3390/met11081197

Liu Y, Li M, Lu X, Zhu X. Failure Mechanism and Strength Prediction Model of T-Joint of Composite Sandwich Structure. Metals. 2021; 11(8):1197. https://doi.org/10.3390/met11081197

Chicago/Turabian StyleLiu, Yang, Mingxuan Li, Xiaofeng Lu, and Xiaolei Zhu. 2021. "Failure Mechanism and Strength Prediction Model of T-Joint of Composite Sandwich Structure" Metals 11, no. 8: 1197. https://doi.org/10.3390/met11081197

APA StyleLiu, Y., Li, M., Lu, X., & Zhu, X. (2021). Failure Mechanism and Strength Prediction Model of T-Joint of Composite Sandwich Structure. Metals, 11(8), 1197. https://doi.org/10.3390/met11081197