Roll Bonding Processes: State-of-the-Art and Future Perspectives

Abstract

:1. Introduction

2. Process Description

2.1. Introduction

2.2. Process Variants

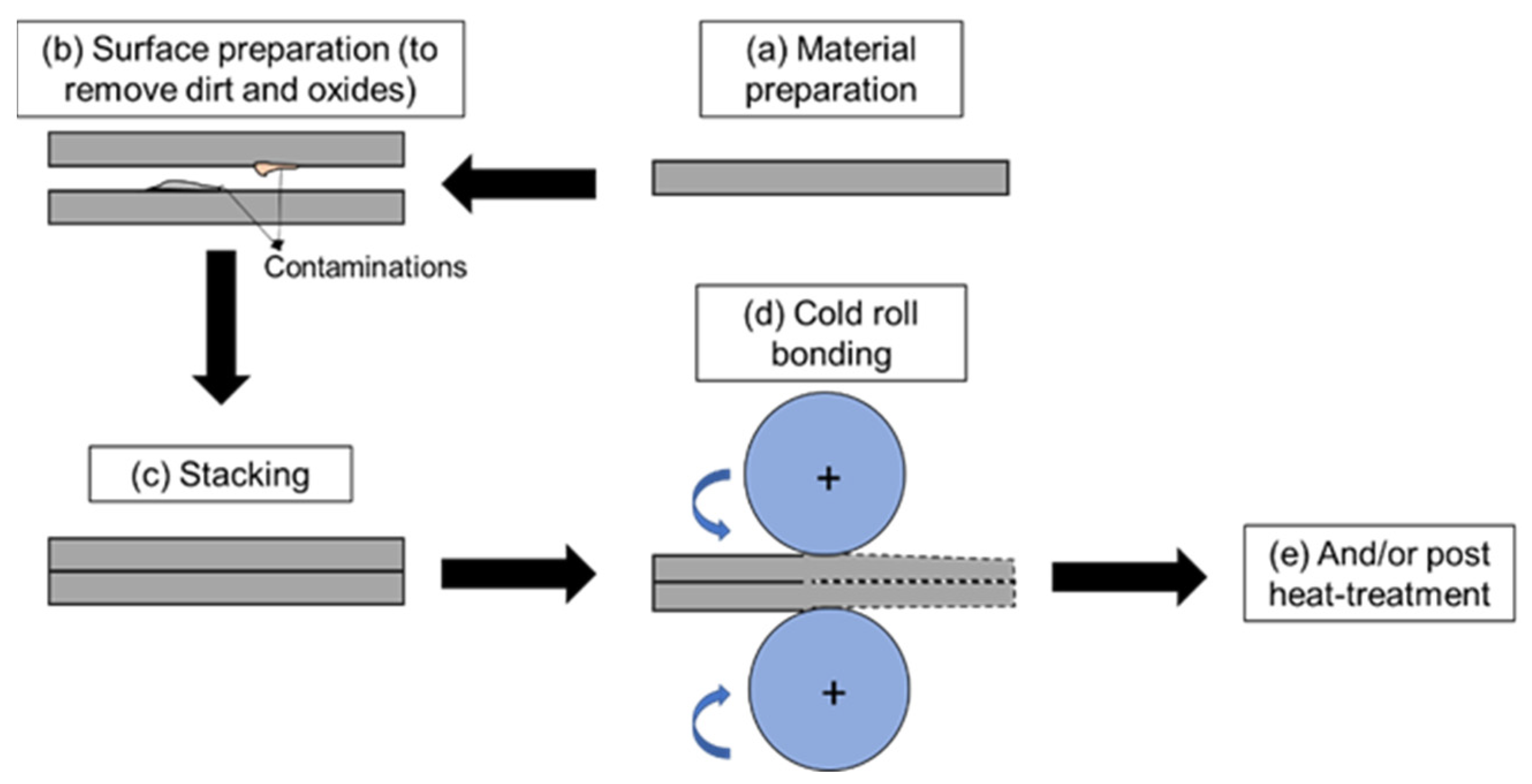

2.2.1. Cold Roll Bonding (CRB) Process

2.2.2. Hot Roll Bonding (HRB) Process

2.2.3. Accumulative Roll Bonding (ARB) Process

2.3. Bond Formation Mechanisms

2.4. Research Needs

3. Characterization and Evaluation

3.1. Key Process Parameters

3.1.1. Percent Reduction Factor

3.1.2. Rolling Speed

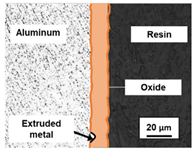

3.1.3. Surface Preparation

3.1.4. Heat Treatment

3.2. Research Needs

3.3. Joint Evaluation

3.3.1. Microstructural Characterization

3.3.2. Research Needs

3.3.3. Mechanical Evaluation

3.3.4. Research Needs

3.3.5. Defects in RB Joints

3.3.6. Failure Modes Relationship with Ductility and Formability

3.3.7. Research Needs

3.3.8. Electrical Evaluation

3.3.9. Corrosion Evaluation

3.3.10. Research Needs

4. Modeling and Simulation

Research Needs

5. Process Merits and Applications

5.1. Advantages and Limitations

5.2. Applications

6. Critical Analysis

6.1. Engineering Guidelines

6.2. Process–Structure–Property (PSP) Relationship

7. Future Perspectives and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Conflicts of Interest

References

- Cai, W.; Daehn, G.; Vivek, A.; Li, J.; Khan, H.; Mishra, R.S.; Komarasamy, M. A state-of-the-art review on solid-state metal joining. ASME J. Manuf. Sci. Eng. 2019, 141, 031012. [Google Scholar] [CrossRef]

- Wang, K.; Khan, H.A.; Li, Z.; Lyu, S.; Li, J. Micro friction stir welding of multilayer aluminum alloy sheets. J. Mater. Process. Technol. 2018, 260, 137–145. [Google Scholar] [CrossRef]

- Khan, H.; Li, J.; Shao, C. Analyses of friction stir riveting processes: A review. ASME J. Manuf. Sci. Eng. 2017, 139, 090801. [Google Scholar] [CrossRef] [Green Version]

- Wang, K.; Li, Y.; Banu, M.; Li, J.; Guo, W.; Khan, H. Effect of interfacial preheating on welded joints during ultrasonic composite welding. J. Mater. Process. Technol. 2017, 246, 116–122. [Google Scholar] [CrossRef]

- Göken, M.; Höppel, H.W. Tailoring Nanostructured, Graded, and Particle-Reinforced Al Laminates by Accumulative Roll Bonding. Adv. Mater. 2011, 23, 2663–2668. [Google Scholar] [CrossRef]

- Khan, H.A.; Wang, K.; Li, J. Interfacial bonding mechanism and mechanical properties of micro friction stir blind riveting for multiple Cu/Al ultra-thin layers. Mater. Charact. 2018, 141, 32–40. [Google Scholar] [CrossRef]

- Mansouri, H.; Eghbali, B.; Afrand, M. Producing multi-layer composite of stainless steel/aluminum/copper by accumulative roll bonding (ARB) process. J. Manuf. Process. 2019, 46, 298–303. [Google Scholar] [CrossRef]

- Horik, L.R.V.; Pfaffenberger, R.T. Roll Welded Structure and Process. U.S. Patent No. 3453717 A, 8 July 1969. [Google Scholar]

- Yang, W. An Investigation of Bonding Mechanism in Metal Cladding by Warm Rolling. Ph.D. Thesis, Texas A&M University, College Station, TX, USA, 2011. [Google Scholar]

- Bay, N.; Clemensen, C.; Juelstorp, O.; Wanheim, T. Bond Strength in Cold Roll Bonding. CIRP Ann. Manuf. Technol. 1985, 34, 221–224. [Google Scholar] [CrossRef]

- Li, L.; Nagai, K.; Yin, F. Progress in Cold Roll Bonding of Metals. Sci. Technol. Adv. Mater. 2008, 9, 023001. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, D.; Zhao, D.W. Analysis of Asymmetrical Rolling of Unbounded Clad Sheet by Slab Method Considering Vertical Shear Stress. ISIJ Int. 2015, 55, 1058–1066. [Google Scholar] [CrossRef] [Green Version]

- Pan, D.; Gao, K.; Yu, J. Cold Roll Bonding of Bimetallic Sheets and Strips. Mater. Sci. Technol. 1989, 5, 934–939. [Google Scholar] [CrossRef]

- Schmidt, H.C.; Homberg, W.; Orive, A.G.; Grundmeier, G.; Hordych, I.; Maier, H.J. Cold pressure welding of aluminum-steel blanks: Manufacturing process and electrochemical surface preparation. AIP Conf. Proc. 2018, 1960, 050007. [Google Scholar]

- Wei, Y.; Li, H.; Sun, F.; Zou, J. The interfacial characterization and performance of Cu/Al-conductive head processed by explosion welding, cold pressure welding, and solid-liquid casting. Metals 2019, 9, 237. [Google Scholar] [CrossRef] [Green Version]

- Mao, Z.; Xie, J.; Wang, A.; Wang, W.; Ma, D.; Liu, P. Effects of annealing temperature on the interfacial microstructure and bonding strength of Cu/Al clad sheets produced by twin-roll casting and rolling. J. Mater. Process. Technol. J. Mater. Process. Technol. 2020, 285, 116804. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Cold roll bonding bond strengths: A review. Mater. Sci. Technol. 2011, 27, 1101–1108. [Google Scholar] [CrossRef]

- Tang, C.; Liu, Z.; Zhou, D.; Wu, S. Surface Treatment with the Cold Roll Bonding Process for an Aluminum Alloy and Mild Steel. Strength Mater. 2015, 47, 150–155. [Google Scholar] [CrossRef]

- Groche, P.; Wohletz, S.; Mann, A.; Krech, M.; Monnerjahn, V. Conjoint Forming–Technologies for Simultaneous Forming and Joining. In Materials Science and Engineering; IOP Conference Series; IOP Publishing: Bristol, UK, 2016; Volume 119, p. 012025. [Google Scholar]

- Qi, Z.; Yu, C.; Xiao, H. Microstructure and bonding properties of magnesium alloy AZ31/CP-Ti clad plates fabricated by rolling bonding. J. Manuf. Process. 2018, 32, 175–186. [Google Scholar] [CrossRef]

- Frolov, Y.; Haranich, Y.; Bobukh, O.; Remez, O.; Voswinkel, D.; Grydin, O. Deformation of expanded steel mesh inlay inside aluminum matrix during the roll bonding. J. Manuf. Process. 2020, 58, 857–867. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Utsunomiya, H.; Tanigawa, S. Ultra-Fine-Grained Bulk Steel Produced by Accumulative Roll-Bonding (ARB) Process. Scr. Mater. 1999, 40, 795–800. [Google Scholar] [CrossRef] [Green Version]

- Jamaati, R.; Toroghinejad, M.R. Manufacturing of High-Strength Aluminum/Alumina Composite by Accumulative Roll Bonding. Mater. Sci. Eng. A 2010, 527, 4146–4151. [Google Scholar] [CrossRef]

- Vaidyanath, L.R.; Nicholas, M.G.; Milner, D.R. Significance of Surface Preparation in Cold Pressure Welding. Br. Weld. J. 1959, 7, 1–6. [Google Scholar]

- Quadir, M.Z.; Wolz, A.; Hoffman, M.; Ferry, M. Influence of Processing Parameters on the Bond Toughness of Roll Bonded Aluminum Strip. Scr. Mater. 2008, 58, 959–962. [Google Scholar] [CrossRef]

- Jamaati, R.; Toroghinejad, M.R. Investigation of the Parameters of the Cold Roll Bonding (CRB) Process. Mater. Sci. Eng. A 2010, 527, 2320–2326. [Google Scholar] [CrossRef]

- Naseri, M.; Reihanian, M.; Borhani, E. Bonding behavior during cold roll-cladding of tri-layered Al/brass/Al composite. J. Manuf. Process. 2016, 24, 125–137. [Google Scholar] [CrossRef]

- Cave, J.A.; Williams, J.D. The Mechanisms of Cold Pressure Welding. J. Inst. Met. 1973, 101, 203. [Google Scholar]

- Movahedi, M.; Kokabi, A.H.; Seyed Reihani, S.M. Investigation on the Bond Strength of Al-1100/St-12 Roll Bonded Sheets, Optimization, and Characterization. Mater. Des. 2011, 32, 3143–3149. [Google Scholar] [CrossRef]

- McEwan, K.J.B.; Milner, D.R. Pressure Welding of Dissimilar Metals. Br. Weld. J. 1962, 9, 406–420. [Google Scholar]

- Hosseini, H.R.M.; Kokabi, A.H. Cold Roll Bonding of 5754-Aluminium Strips. Mater. Sci. Eng. A 2002, 335, 186–190. [Google Scholar] [CrossRef]

- Manesh, H.D.; Shahabi, H.S. Effective Parameters on Bonding Strength of Roll Bonded Al/St/Al Multilayer Strips. J. Alloys Compd. 2010, 476, 292–299. [Google Scholar] [CrossRef]

- Tsuji, N.; Toyoda, T.; Minamino, Y.; Koizumi, Y.; Yamane, T.; Komatsu, M.; Kiritani, M. Microstructural Change of Ultrafine-Grained Aluminum during High-Speed Plastic Deformation. Mater. Sci. Eng. A 2003, 350, 108–116. [Google Scholar] [CrossRef]

- Wu, G.Q.; Li, Z.F.; Luo, G.X.; Huang, Z. The Effects of Various Finished Surfaces on Diffusion Bonding. Modeling Simul. Mater. Sci. Eng. 2008, 16, 085006. [Google Scholar] [CrossRef]

- Sahin, M. Effect of Surface Roughness on Weldability in Aluminum Sheets Joined by Cold Pressure Welding. Ind. Lubr. Tribol. 2008, 60, 249–254. [Google Scholar] [CrossRef]

- Cantalejos, N.A.; Cusminsky, G. Morphology of the Interface of Roll Bonded Aluminum. J. Inst. Met. 1972, 100, 20–23. [Google Scholar]

- Mori, K. Simulation of Materials Processing: Theory, Applications, and Models; A.A. Balkema Publishers: Tokyo, Japan, 2001. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. The Role of Surface Preparation Parameters on Cold Roll Bonding of Aluminum Strips. J. Mater. Eng. Perform. 2011, 20, 191–197. [Google Scholar] [CrossRef]

- Mahabunphachai, S.; Koç, M.; Ni, J. Pressure Welding of Thin Sheet Metals: Experimental Investigations and Analytical Modeling. ASME J. Manuf. Sci. Eng. 2009, 131, 041003. [Google Scholar] [CrossRef]

- Mohamed, H.A.; Washbush, J. Mechanism of Solid-State Pressure Welding. Weld. Res. Suppl. 1975, 9, 302. [Google Scholar]

- Agers, B.M.; Singer, A.R. The Mechanism of Small Tool Pressure Welding. Br. Weld. J. 1964, 11, 313. [Google Scholar]

- Jamaati, R.; Toroghinejad, M.R. Effect of Friction, Annealing Conditions and Hardness on the Bond Strength of Al/Al Strips Produced by Cold Roll Bonding Process. Mater. Des. 2010, 31, 4508–4513. [Google Scholar] [CrossRef]

- Buchner, M.; Buchner, B.; Buchmayr, B.; Kilian, H.; Riemelmoser, F. Investigation of Different Parameters on Roll-Bonding Quality of Aluminum and Steel Sheets. Int. J. Mater. Form. 2008, 1, 1279–1282. [Google Scholar] [CrossRef]

- Abbasi, M.; Toroghinejad, M.R. Effects of Processing Parameters on the Bond Strength of Cu/Cu Roll-Bonded Strips. J. Mater. Process. Technol. 2010, 210, 560–563. [Google Scholar] [CrossRef]

- Lukaschkin, N.D.; Borissow, A.P.; Erlikh, A.I. The System Analysis of Metal Forming Technique in Welding Processes. J. Mater. Proc. Technol. 1997, 66, 264–269. [Google Scholar] [CrossRef]

- Yan, H.; Lenard, J.G. A Study of Warm and Cold Roll-Bonding of Aluminum Alloy. Mater. Sci. Eng. A 2004, 385, 419–428. [Google Scholar] [CrossRef]

- Krzyzanowski, M.; Beynon, J.H. Oxide Behavior in Hot Rolling: Metal Forming Science and Practice; Lenard, J.G., Ed.; Elsevier: Oxford, UK, 2002. [Google Scholar]

- Butlin, J.; Mackay, C.A. Experiment on the Roll-Bonding of Tin Coatings to Non-Ferrous Substrate. Sheet Met. Ind. 1979, 11, 1063–1072. [Google Scholar]

- Luo, J.G.; Acoff, V.L. Using Cold Roll Bonding and Annealing to Process Ti/Al Multi-Layered Composites from Elemental Foils. Mater. Sci. Eng. A 2004, 379, 164–172. [Google Scholar] [CrossRef]

- Taheri, A.K.; Majlessi, S.A. An investigation into the production of bi-and tri-layered strips by drawing through wedge-shaped dies. J. Mater. Eng. Perf. 1992, 1, 285–291. [Google Scholar] [CrossRef]

- Marouf, B.T.; Bagheri, R.; Mahmudi, R. Effects of Number of Layers and Adhesive Ductility on Impact Behavior of Laminates. Mater. Lett. 2004, 58, 2721–2724. [Google Scholar] [CrossRef]

- Khan, H.A.; Pei, S.; Chen, N.; Miller, S.; Li, J. Evaluation of μFSBR joint performance by process-physics based quality criteria and online monitoring algorithm. J. Mater. Proc. Technol. 2020, 278, 116508. [Google Scholar] [CrossRef]

- Scharnweber, J.; Chekhonin, P.; Oertel, C.G.; Romberg, J.; Freudenberger, J.; Jaschinski, J.; Skrotzki, W. Microstructure, Texture, and Mechanical Properties of Laminar Metal Composites Produced by Accumulative Roll Bonding. Adv. Eng. Mater. 2019, 21, 1800210. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.X.; An, Q.; Yin, F.X.; Wang, S.; Chen, C.X. Interface formation and bonding mechanisms of hot-rolled stainless steel-clad plate. J. Mater. Sci. 2019, 54, 11357–11377. [Google Scholar] [CrossRef]

- Yu, C.; Qi, Z.-C.; Yu, H.; Xu, C.; Xiao, H. Microstructural and Mechanical Properties of Hot Roll Bonded Titanium Alloy/Low Carbon Steel Plate. J. Mater. Eng. Perform. 2018, 27, 1664–1672. [Google Scholar] [CrossRef]

- Wu, K.; Chang, H.; Maawad, E.; Gan, W.M.; Brokmeier, H.G.; Zheng, M.Y. Microstructure and Mechanical Properties of the Mg/Al Laminated Composite Fabricated by Accumulative Roll Bonding (ARB). Mater. Sci. Eng. A 2010, 527, 3073–3078. [Google Scholar] [CrossRef]

- Hebert, R.J.; Perepezko, J.H. Deformation-Induced Synthesis and Structural Transformations of Metallic Multilayers. Scr. Mater. 2004, 50, 807–812. [Google Scholar] [CrossRef]

- Huang, X.; Tsuji, N.; Hansen, N.; Minamino, Y. Microstructural Evolution during Accumulative Roll-Bonding of Commercial Purity Aluminum. Mater. Sci. Eng. A 2003, 340, 265–271. [Google Scholar] [CrossRef]

- Abbasi, M.; Taheri, A.K.; Salehi, M.T. Growth Rate of Intermetallic Compounds in Al/Cu Bimetal Produced by Cold Roll Welding Process. J. Alloys Compd. 2001, 319, 233–241. [Google Scholar] [CrossRef]

- Chaudhari, P.G.; Acoff, V.L. Titanium Aluminide Sheets Made Using Roll Bonding and Reaction Annealing. Intermetallics 2010, 18, 472–478. [Google Scholar] [CrossRef]

- Yi, S.; Schestakow, I.; Zaefferer, S. Twinning-Related Microstructural Evolution during Hot Rolling and Subsequent Annealing of Pure Magnesium. Mater. Sci. Eng. A 2009, 516, 58–64. [Google Scholar] [CrossRef]

- Zhang, R.G.; Acoff, V.L. Processing Sheet Materials by Accumulative Roll Bonding and Reaction Annealing from Ti/Al/Nb Elemental Foils. Mater. Sci. Eng. A 2007, 463, 67–73. [Google Scholar] [CrossRef]

- Li, X.B.; Zu, G.Y.; Wang, P. Microstructural Development and its Effects on Mechanical Properties of Al/Cu Laminated Composite. Trans. Nonferrous Met. Soc. China 2015, 25, 36–45. [Google Scholar] [CrossRef]

- Mungole, T.; Mansoor, B.; Ayoub, G.; Field, D.P. Bifurcation in deformation behavior of Cu and Ta by accumulative roll-bonding at high temperature. Scr. Mater. 2017, 136, 87–91. [Google Scholar] [CrossRef]

- Chekhonin, P.; Scharnweber, J.; Scharnweber, M.; Oertel, C.G.; Hausöl, T.; Öppel, H.W.H.; Jaschinski, J.; Marr, T.; Skrotzki, W. Mechanical Properties of Aluminum Laminates Produced by Accumulative Roll Bonding. Cryst. Res. Technol. 2013, 48, 532–537. [Google Scholar] [CrossRef]

- Borts, B.V.; Korotkova, I.M.; Lopata, O.O.; Sytin, V.I.; Tkachenko, V.I.; Vorobyov, I.O. Production of Dissimilar Metals Materials by the Method of Solid-State Joining. Open J. Met. 2014, 4, 40–47. [Google Scholar] [CrossRef] [Green Version]

- Luo, Z.; Wang, G.; Xie, G. Interfacial Microstructure and Properties of a Vacuum Hot Roll-Bonded Titanium-Stainless Steel-Clad Plate with a Niobium Interlayer. Acta Metall. Sin. 2013, 26, 754–760. [Google Scholar] [CrossRef] [Green Version]

- Saboktakin, M.; Razavi, G.R.; Monajati, H. The Effect of Copper Interlayer on Metallurgical Properties of Roll Bonding Titanium Clad Steel. In International Conference on Advanced Materials Engineering; IACSIT Press: Singapore, 2011. [Google Scholar]

- Lauvdal, S. Experimental Studies of Cold Roll Bonded Aluminum Alloys. Master’s Thesis, Institutt for Materialteknologi, Trondheim, Norway, 11 August 2011. [Google Scholar]

- Wang, C.; Jiang, Y.; Xie, J.; Zhou, D.; Zhang, X. Interface formation and bonding mechanism of embedded aluminum-steel composite sheet during cold roll bonding. Mater. Sci. Eng. A. 2017, 708, 50–59. [Google Scholar] [CrossRef]

- Le, H.R.; Sutcliffe, M.P.; Wang, P.Z.; Burstein, G.T. Surface oxide fracture in cold aluminum rolling. Acta Mater. 2004, 52, 911–920. [Google Scholar] [CrossRef]

- Azimi, M.; Toroghinejad, M.R.; Shamanian, M.; Kestens, L.A. The effect of strain on the formation of an intermetallic layer in an Al-Ni laminated composite. Metals 2017, 7, 445. [Google Scholar] [CrossRef] [Green Version]

- Mozaffari, A.; Hosseini, M.; Manesh, H.D. Al/Ni metal intermetallic composite produced by accumulative roll bonding and reaction annealing. J. Alloys Compd. 2011, 509, 9938–9945. [Google Scholar] [CrossRef]

- Hong, S.T.; Weil, K.S. Niobium-clad 304L stainless steel PEMFC bipolar plate material: Tensile and bend properties. J. Power Sources 2007, 168, 408–417. [Google Scholar] [CrossRef]

- Asim, K.; Hosford, W.F.; Pan, J.; Hong, S.T.; Weil, K.S. Mechanical Behavior and Failure Mechanism of Nb-Clad Stainless-Steel Sheets. SAE Int. J. Mater. Manuf. 2009, 2, 547–554. [Google Scholar] [CrossRef]

- Choi, S.H.; Kim, K.H.; Oh, K.H.; Lee, D.N. Tensile deformation behavior of stainless-steel clad aluminum bilayer sheet. Mater. Sci. Eng. A. 1997, 222, 158–165. [Google Scholar] [CrossRef]

- Matsumoto, H.; Watanabe, S.; Handa, S. Fabrication of pure Al/Mg-Li alloy clad plate and its mechanical properties. J. Mater. Process. Technol. 2005, 169, 9–15. [Google Scholar] [CrossRef]

- Kang, G.T.; Song, J.S.; Hong, S.I. Effect of Roll Bonding Temperature on the Strength and Electrical Conductivity of an α-Brass-Clad Cu–1Cr Alloy Composite. Phys. Met. Metallogr. 2017, 118, 190–197. [Google Scholar] [CrossRef]

- Yao, G.C.; Mei, Q.S.; Li, J.Y.; Li, C.L.; Ma, Y.; Chen, F.; Liu, M. Cu/C composites with a good combination of hardness and electrical conductivity fabricated from Cu and graphite by accumulative roll-bonding. Mater. Des. 2016, 110, 124–129. [Google Scholar] [CrossRef]

- Naeini, M.F.; Shariat, M.H.; Eizadjou, M. On the chloride-induced pitting of ultra-fine grains 5052 aluminum alloy produced by the accumulative roll bonding process. J. Alloys Compd. 2011, 509, 4696–4700. [Google Scholar] [CrossRef]

- Mahdi, K.; Mohsen, B.; Habib, D.M.; Mahmood, P.; Babak, H. Evaluation of corrosion properties of Al/nanosilica nanocomposite sheets produced by accumulative roll bonding (ARB) process. J. Alloys Compd. 2013, 576, 66–71. [Google Scholar]

- Khara, S.; Choudhary, S.; Sangal, S.; Mondal, K. Corrosion-resistant Cr-coating on mild steel by powder roll bonding. Surf. Coat. Technol. 2016, 296, 203–210. [Google Scholar] [CrossRef]

- Alil, A.; Popović, M.; Bajat, J.; Romhanji, E. Mechanical and corrosion properties of AA5083 alloy sheets produced by accumulative roll bonding (ARB) and conventional cold rolling (CR). Mater. Corros. 2018, 69, 858–869. [Google Scholar] [CrossRef]

- Wright, P.K.; Snow, D.A.; Tay, C.K. Interfacial conditions and bond strength in cold pressure welding by rolling. Met. Technol. 1978, 5, 24–31. [Google Scholar] [CrossRef]

- Das, M.P.; Nafari, N. Adhesive Forces at Bimetallic Interfaces. Solid State Commun. 1986, 63, 367–370. [Google Scholar] [CrossRef]

- Yu, H.; Lu, C.; Tieu, A.K.; Godbole, A.; Su, L.; Sun, Y.; Liu, M.; Tang, D.; Kong, C. Fabrication of Ultra-Thin Nanostructured Bimetallic Foils by Accumulative Roll Bonding and Asymmetric Rolling. Sci. Rep. UK 2013, 3, 2373. [Google Scholar] [CrossRef] [PubMed]

- Fratini, L.; Merklein, M.; Boehm, W.; Campanella, D. Modeling Aspects in Accumulative Roll Bonding Process by Explicit Finite Element Analysis. Key Eng. Mater. 2013, 549, 452–459. [Google Scholar] [CrossRef]

- Yong, J.; Dashu, P.; Dong, L.; Luoxing, L. Analysis of Clad Sheet Bonding by Cold Rolling. J. Mater. Proc. Technol. 2000, 105, 32–37. [Google Scholar] [CrossRef]

- Pan, S.C.; Huang, M.N.; Tzou, G.Y.; Syu, S.W. Analysis of Asymmetrical Cold and Hot Bond Rolling of Unbounded Clad Sheet under Constant Shear Friction. J. Mater. Process. Technol. 2006, 177, 114–120. [Google Scholar] [CrossRef]

- Hwang, Y.M.; Tzou, G.Y. An Analytical Approach to Asymmetrical Cold and Hot Rolling of Clad Sheet using the Slab Method. J. Mater. Process. Technol. 1996, 62, 249–259. [Google Scholar] [CrossRef]

- Chaudhari, G.P.; Acoff, V. Cold Roll Bonding of Multi-Layered Bi-Metal Laminate Composites. Compos. Sci. Technol. 2009, 69, 1667–1675. [Google Scholar] [CrossRef]

- Herrmann, J.; Suttner, S.; Merklein, M. Experimental investigation and numerical modeling of the bond shear strength of multi-layered 6000 series aluminum alloys. Procedia Eng. 2017, 183, 283–290. [Google Scholar] [CrossRef]

- Lee, S.; Lee, D.N. Slab Analysis of Roll Bonding of Silver Clad Phosphor Bronze Sheets. Mater. Sci. Technol. 1990, 7, 1042–1050. [Google Scholar] [CrossRef]

- Tzou, G.Y. Theoretical Study on the Cold Sandwich Sheet Rolling Considering Coulomb Friction. J. Mater. Proc. Technol. 2001, 114, 41–50. [Google Scholar] [CrossRef]

- Tzou, G.Y.; Tieu, A.K.; Huang, M.N.; Lin, C.Y.; Wu, E.Y. Analytical Approach to the Cold and Hot Bond Rolling of Sandwich Sheet with outer Hard and Inner Soft Layers. J. Mater. Proc. Technol. 2002, 125, 664–669. [Google Scholar] [CrossRef]

- Rezaii, A.; Shafiei, E.; Ostovan, F.; Daneshmanesh, H. Experimental & theoretical investigation of roll bonding process of multilayer strips by finite element method. J. Manuf. Process 2020, 54, 54–69. [Google Scholar]

- Karakozov, E.S.; Vasil’ev, V.N.; Paraev, S.A. Cold Welding Aluminum and Copper Foil. Part 1. Plastic Deformation Process. Weld. Int. 1991, 5, 300–303. [Google Scholar] [CrossRef]

- Barlow, C.Y.; Nielsen, P.; Hansen, N. Multilayer Roll Bonded Aluminum Foil: Processing, Microstructure, and Flow Stress. Acta Mater. 2004, 52, 3967–3972. [Google Scholar] [CrossRef]

- Movahedi, M.; Madaah-Hosseini, H.R.; Kokabi, A.H. The Influence of Roll Bonding Parameters on the Bond Strength of Al-3003/Zn Soldering Sheets. Mater. Sci. Eng. A 2000, 487, 417–423. [Google Scholar] [CrossRef]

- Peng, X.K.; Wuhrer, R.; Heness, G. Rolling Strain Effects on the Interlaminar Properties of Roll Bonded Copper/Aluminum Metal Laminates. J. Mater. Sci. 2000, 35, 4357–4363. [Google Scholar] [CrossRef]

- Peng, X.K.; Wuhrer, R.; Heness, G. On the Interface Development and Fracture Behavior of Roll Bonded Copper/Aluminum Metal Laminates. J. Mater. Sci. 1999, 34, 2029–2038. [Google Scholar] [CrossRef]

- Saito, Y.; Utsunomiya, H.; Tsuji, N.; Sakai, T. Novel Ultra-High Straining Process for Bulk Materials—Development of the Accumulative Roll-Bonding (ARB) Process. Acta Mater. 1999, 47, 579–583. [Google Scholar] [CrossRef]

- Saito, Y.; Tsuji, N.; Utsunomiya, H.; Sakai, T.; Hong, R.G. Ultra-Fine-Grained Bulk Aluminum Produced by Accumulative Roll-Bonding (ARB) Process. Scr. Mater. 1998, 39, 1221–1227. [Google Scholar] [CrossRef]

- Ohsaki, S.; Kato, S.; Tsuji, N.; Ohkubo, T.; Hono, K. Bulk Mechanical Alloying of Cu–Ag and Cu/Zr Two-Phase Microstructures by Accumulative Roll-Bonding Process. Acta Mater. 2007, 55, 2885–2895. [Google Scholar] [CrossRef]

- You, C.; Xie, W.; Miao, S.; Liang, T.; Zeng, L.; Zhang, X.; Wang, H. High strength, high electrical conductivity, and thermally stable bulk Cu/Ag nanolayered composites prepared by cross accumulative roll bonding. Mater. Des. 2021, 200, 109455. [Google Scholar] [CrossRef]

- Eivani, A.; Shojaei, A.; Salehi, M.; Jafarian, H.; Park, N. On the evolution of microstructure and fracture behavior of multilayered copper sheet fabricated by accumulative roll bonding. J. Mater. Res. Technol. 2020, 10, 291–305. [Google Scholar] [CrossRef]

- Shayan, M.; Eghbali, B.; Niroumand, B. The role of accumulative roll bonding after stir casting process to fabricate high-strength and nanostructured AA2024-(SiO2 + TiO2) hybrid nanocomposite. J. Alloys Compd. 2020, 845, 156281. [Google Scholar] [CrossRef]

- Zheng, H.; Wu, R.; Hou, L.; Zhang, J.; Zhang, M. Mathematical analysis and its experimental comparisons for the accumulative roll bonding (ARB) process with different superimposed layers. J. Magnes. Alloys 2020. [Google Scholar] [CrossRef]

- Jafarian, H.R.; Mahdavian, M.M.; Shams, S.A.; Eivani, A.R. Microstructure analysis and observation of peculiar mechanical properties of Al/Cu/Zn/Ni multi-layered composite produced by Accumulative-Roll-Bonding (ARB). Mater. Sci. Eng. A. 2020, 805, 140556. [Google Scholar] [CrossRef]

- Zhu, Y.; Li, Z.; Xiao, Z.; Qiu, W.; Fang, M.; Chen, Z. Effect of accumulative roll-bonding process on phase transformation and magnetic properties of polycrystalline cobalt. Mater. Charact. 2020, 163, 110290. [Google Scholar] [CrossRef]

- Rodríguez-Espinoza, B.L.; García-Pastor, F.A.; Martínez-Poveda, B.; Quesada, A.R.; Lopez-Crespo, P. High-strength low-modulus biocompatible Nb-1Zr alloy processed by accumulative roll bonding. Mater. Sci. Eng. A. 2020, 797, 140226. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, S.R. Fabrication and Mechanical Properties of a Nanostructured Complex Aluminum Alloy by Three-Layer Stack Accumulative Roll-Bonding. Arch. Metall. Mater. 2015, 60, 1195–1198. [Google Scholar] [CrossRef]

- Ma, M.; Huo, P.; Liu, W.C.; Wang, G.J.; Wang, D.M. Microstructure and mechanical properties of Al/Ti/Al laminated composites prepared by roll bonding. Mater. Sci. Eng. A. 2015, 636, 301–310. [Google Scholar] [CrossRef]

- Liu, H.S.; Zhang, B.; Zhang, G.P. Microstructures and mechanical properties of Al/Mg alloy multilayered composites produced by accumulative roll bonding. J. Mater. Sci Technol. 2011, 27, 15–21. [Google Scholar] [CrossRef]

- Schmidt, C.W.; Knieke, C.; Maier, V.; Höppel, H.W.; Peukert, W.; Göken, M. Accelerated grain refinement during accumulative roll bonding by nanoparticle reinforcement. Scr. Mater. 2011, 64, 245–248. [Google Scholar] [CrossRef]

- Alizadeh, M.; Paydar, M.H. Fabrication of nanostructured Al/SiCP composite by accumulative roll-bonding (ARB) process. J. Alloys Compd. 2010, 492, 231–235. [Google Scholar] [CrossRef]

- Hausöl, T.; Maier, V.; Schmidt, C.W.; Winkler, M.; Höppel, H.W.; Göken, M. Tailoring materials properties by accumulative roll bonding. Adv. Eng. Mater. 2010, 12, 740–746. [Google Scholar] [CrossRef]

- Tsuji, N.; Saito, Y.; Lee, S.H.; Minamino, Y. ARB (Accumulative Roll-Bonding) and other new techniques to produce bulk ultrafine-grained materials. Adv. Eng. Mater. 2003, 5, 338–344. [Google Scholar] [CrossRef]

- Tsuji, N.; Ito, Y.; Saito, Y.; Minamino, Y. Strength and ductility of ultrafine-grained aluminum and iron produced by ARB and annealing. Scr. Mater. 2002, 47, 893–899. [Google Scholar] [CrossRef]

- Hebesberger, T.; Stüwe, H.P.; Vorhauer, A.; Wetscher, F.; Pippan, R. Structure of Cu deformed by high pressure torsion. Acta Mater. 2005, 53, 393–402. [Google Scholar] [CrossRef]

| RB Process | Operating Conditions | Key Process Variants | Process Features |

|---|---|---|---|

| Cold roll bonding | Tp < Recrystallization temperature | Cold pressure welding by rolling | Severe plastic deformation is achieved without heating generally at high pressures. |

| Clad sheet by rolling | |||

| Hot roll bonding | Tp > Recrystallization temperature | - Sheets can be heated pre-, post-, and inter-rolling cyclesto obtain tailored microstructure. - Hot rollers are used during the rolling cycles for obtaining the ductility and tailored microstructure. | |

| Warm roll bonding | Tp = beginning of Recrystallization temperature | Sheets are pre-heated close to half of melting temperature to soften the material. |

| Nature of Defect | Key Process Parameters | Defect Morphology | Reported by |

|---|---|---|---|

| Interfacial gaps | Rolling speed Sheet thickness |  | Wang et al. [69] |

| Presence of oxide layer | Surface treatment |  | * Le et al. [70] |

| Brittle Intermetallics | High rolling temperatures and/or high post or inter-rolling cycles HT temperatures |  | ** Azimi et al. [71] |

| Porosity and cracks | Prolonged heat treatment cycles |  | Mozafferi et al. [72] |

| Material Combination | Applications |

|---|---|

| Cu/Al | Heat exchangers, electrical components |

| Cu/Al/steel | Cookware |

| Ti/stainless steel/Ni | The bipolar electrode in the fuel cell |

| Nb/Stainless steel | Fuel cell bipolar plate |

| Cu/Ag | Electrical components and appliances |

| Al/steel/Al | Automotive exhaust systems |

| Materials * | Temperature (°C) | No of Cycles | Single Pass Reduction (%) | Grain Information | Tensile Strength (MPa) | Reference |

|---|---|---|---|---|---|---|

| Cu/Ag (nano-cross layered composite) | ^ RT | 15 | ~50 | (layer thickness) 20 nm | 938 (420% increase) | (You et al., 2021) [105] |

| Cu | ^ RT | 6 | 60 | Dia 1000–2000 nm (sub grain dia 148 nm) | 467 (127% increase) | (Eivani et al., 2020) [106] |

| Cast and rolled sheet of AA2024- [0.5 vol% SiO2 p + 1 vol% TiO2 p] composite | ^ RT | 5 | 50 | 70 nm | 552 (112% increase) | (Shayan et al., 2020) [107] |

| Mg-14Li-3Al-2Gd | 200 | 6 | 50 | 14.5 μm | 229 (78% increase) | (Zheng et al., 2020) [108] |

| # Al/Cu/Zn/Ni foil (multi-layered composite) | ^ RT | 5 | 50 | UFG (no size information) | 314 (pure Al had a value 74 MPa) | (Jafarian et al., 2020) [109] |

| Co (cross layered) | 500 | 5 | 50 | 1010 nm | No info about strength [Coercivity 50.2 Oe (60% reduction)] | (Zhu et al., 2020) [110] |

| Nb-1wt% Zr | 700 | 5 | 50 | 800 nm | 680 (191% increase) | (Rodríguez-Espinoza et al., 2020) [111] |

| AA1050/AA5052 | RT | 7 | 67 | UFG, Dia 350 nm | 285 (100% increase) | (Lee et al., 2015) [112] |

| Al-6061/Ti-6Al-4V | 500 | 1 | 38 | Dia 1200 nm | 200 | (Ma et al., 2015) [113] |

| Al/Cu | RT | 1 | 72 | UFG, Al 200 nm, Cu 100 nm | 290 | (Li et al., 2015) [61] |

| Al/AZ31 | 280 | 3 | 54 | Al 1000 nm, 500 nm | 475 (Ultimate Bend Strength) | (Liu et al., 2011) [114] |

| Al/Al2O3 p (0.1 vol%) | 125 | 10 | 50 | 400 nm | 160 | (Schmidt et al., 2011) [115] |

| Al/SiC p (1 vol%) | RT | 8 | 50 | UFG, Dia 180 nm | 244 | (Alizadeh and Paydar, 2010) [116] |

| Al/Ti foil | RT | 4 | 50 | (Hausöl et al., 2010) [117] | ||

| Al/Al2O3 p | RT | 8 | 50 | - | - | |

| AA6014/AA5754 | 230 | 3 | 50 | |||

| Al | RT | 8 | 50 | UFG, Pancake type, Dia 210 nm | 310 | (Tsuji et al., 2003) [118] |

| Al7075 | 250 | 5 | - | UFG, Pancake type, Dia 300 nm | 376 | |

| IF Steel | 500 | 7 | 50 | UFG, Pancake type, Dia 210 nm | 870 | |

| SS400 | RT | 5 | - | UFG, Pancake type, Dia 110 nm | 1030 | |

| Al 1100 | 200 | 6 | 50 | UFG, Dia 270 nm | 275 | (Tsuji et al., 2002) [119] |

| IF Steel | 500 | 5 | 50 | UFG, Dia 210 nm | 820 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Khan, H.A.; Asim, K.; Akram, F.; Hameed, A.; Khan, A.; Mansoor, B. Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals 2021, 11, 1344. https://doi.org/10.3390/met11091344

Khan HA, Asim K, Akram F, Hameed A, Khan A, Mansoor B. Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals. 2021; 11(9):1344. https://doi.org/10.3390/met11091344

Chicago/Turabian StyleKhan, Haris Ali, Kamran Asim, Farooq Akram, Asad Hameed, Abdullah Khan, and Bilal Mansoor. 2021. "Roll Bonding Processes: State-of-the-Art and Future Perspectives" Metals 11, no. 9: 1344. https://doi.org/10.3390/met11091344

APA StyleKhan, H. A., Asim, K., Akram, F., Hameed, A., Khan, A., & Mansoor, B. (2021). Roll Bonding Processes: State-of-the-Art and Future Perspectives. Metals, 11(9), 1344. https://doi.org/10.3390/met11091344