Abstract

Ferrite number (FN) is a crucial parameter for austenite steel-welding products, since it has a specific relationship with crack sensitivity and other important properties. In this paper, artificial neural network (ANN) models were built to predict FN, based on the GTAW tests of 304L plates produced by two different steelworks, Dongfang Special Steel hot-rolled sheet (DFSS) and Anshan Iron and Steel cold-rolled sheet (ASIS). The results show that a high performance, of more than 98% accuracy, can be achieved when the models of DFSS and ASIS are modeled separately, and that accuracy is also above 96% when an integrated model is built. The influences of nitrogen content and multiwelding parameters, such as travel speed, wire-feed rate, welding current and arc length, on FN are also analyzed through the FN-prediction model for DFSS. The results show that FN increases monotonously with the increase of nitrogen content, but the influences of either of the other two parameters on FN are nonlinear.

1. Introduction

Liquefied natural gas (LNG) which is the most promising clean energy, has received a lot of attention, as the world grows more concerned with environmental pollution. Austenitic stainless steel, especially SS304/304L, characteristized by excellent strength, ductility and good corrosion resistance, is widely used in the LNG corridor [1]. The outstanding mechanical properties of austenitic stainless steel obtain from a certain amount of retained ferrite in its microstructure. The content and morphology of ferrite directly affect the properties of austenitic stainless steel. Many scholars have studied its internal relationship [2,3]. Hauser and Van Echo [4] found that the strength of austenitic stainless increases with the increase of the ferrite number (FN) from 2 to 16 in the cladding metal, at room temperature. However, excessive retained ferrite, which is its body-centered cubic brittle phase, results in the decrease of ductility. As Lippold et al. [5] showed, there was a 50% reduction in fracture toughness when the FN increased from zero to ten. John C. et al. [1] discovered the welded metals with an FN of 3–7 were both resistant to solidification cracking and had good fracture toughness, at extremely low temperature, in the industry. The morphology of ferrite will also affect its corrosion resistance and mechanical properties [6,7,8]. Hence, FN has a serious influence of the mechanical properties of austenitic stainless steel. However, ER308L filler material, which is generally used for 304L plates, can only guarantee an FN ranging from 3–13, mostly 8–10, while the LNG welding-procedure qualification (WPQ) requires an FN to be under 7.

In order to obtain the excellent mechanical properties of austenitic stainless steel, many researchers have tried to predict and control the FN by studying the relationship between FN and welding parameters such as voltage, current and welding speed, which determines the FN directly by changing the heat input and cooling rate. For example, R. Prabhu and T. Alwarsamy [9] found that FN decreased constantly with increase in welding speed, however, and that FN increased with the increase in welding current by pulsed MIG welding. Rati Salujaa’s experiment [10] show that welding current and arc voltage have inverse effects on retained ferrite, as increase in heat input decreased the amount of retained ferrite content in Grade 304L welds in Pulse GMAW. The effect of individual welding parameters on FN has been studied clearly [11,12,13], and their influence on the subsequent mechanical properties in the metal contained them is also discussed [14,15], but the relationship of multiple welding parameters and FN that are non-linear and time-varying and -coupling is still difficult to establish. Thus, many scholars further discussed the matter by establishing mathematical models [16,17,18]; Jay Vora’s study [19] has reported the optimization of machining variables of the A-TIG welding technique by integrating response surface methodology (RSM) with an innovative heat-transfer-search (HTS) optimization algorithm, an artificial neural net (ANN), which is based on non-linear models and has been used to predict FN [20,21,22].

Vitek et al. [23] established FNN-1999 by using neural-network analysis and WRC-1992, which expanded the input range of composition and considered the influence of alloy element-concentration changes and interactions on FN. Based on this, Vitek et al. [24] further established a new prediction method, the Oak Ridge Ferrite Number (ORFN), which not only expanded the composition range and data sources but also considered the effect of cooling rates on FN, compared with FNN-1999. Vasudevan et al. [25] solved the over-fitting of test data in neural-network analysis by establishing a Bayesian neural network (BNN), which considers the influence of interactions between elements on FN and can automatically identify input variables and provide meaningful error lines. In Italo do Valle Tomaz’s study [26], a five-factor, five-level central-composite-design (CCD) matrix was used to conduct GTAW experiments. An artificial neural network (ANN) was used to simulate the GTAW process and then combined with a genetic algorithm (GA) to determine welding parameters that can provide an optimal weld.

However, the nitrogen content in GTAW shielding gas, which has attracted wide attention in recent years because nitrogen strongly promotes the formation of austenite and sharply reduces FN. Shankar et al. [27] showed that the FN of welds can be effectively controlled by changing the nitrogen content in GTAW shielding gas. Tseng et al. [28] found that the retained ferrite content in 316L stainless-steel TIG welds decreased rapidly as the content of nitrogen gas added to the argon shielding gas was increased. Kuanghung et al. [29] also obtained the same conclusion in the welds of 304 stainless steel. Hence, adding nitrogen content in shielding gas has become an important solution for controlling FN. Yet, the relationship between the nitrogen content, as well as the welding parameters with the FN is still not clear.

In this paper, the ANN between FN and welding parameters, which includes all the controllable characteristics, is finally established based on the orthogonal experimental method. In Section 2, the materials performance and the welding process is introduced. In Section 3, the ANN models of the two different steelworks, DFSS and ASIS, modeled separately, and the accuracies of the models are discussed. In Section 4, a holistic model of two steelworks is built and its precision is tested. In Section 5, the coupling relationships between two/three parameters are also discussed. The conclusion is shown in Section 6.

2. Materials and Methods

The abbreviation of physical symbols used in this paper is shown in Table 1.

Table 1.

The nomenclature of physical quantities.

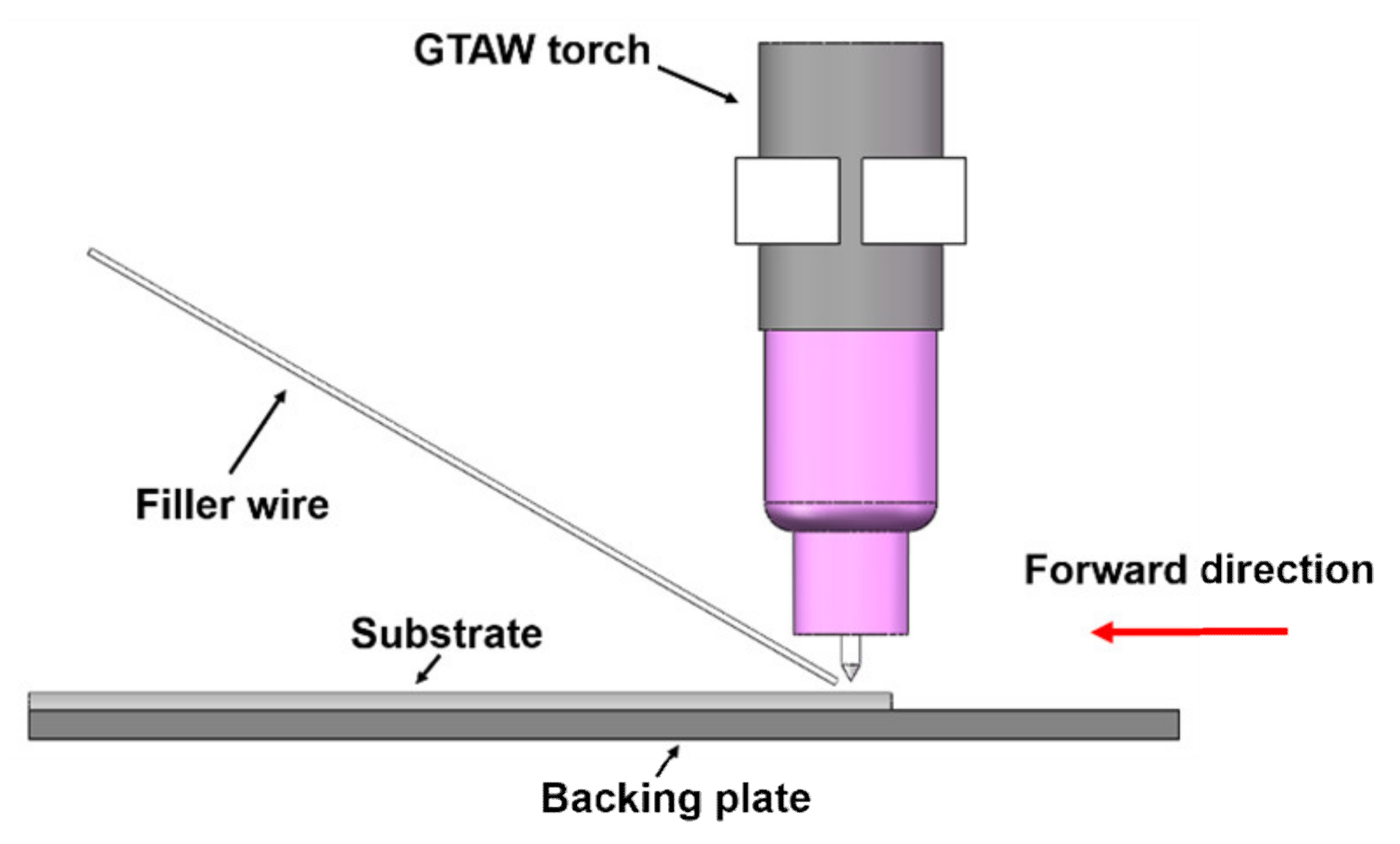

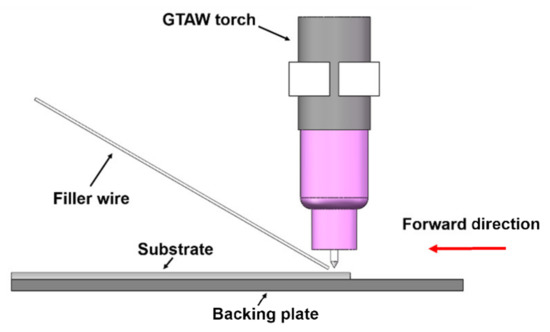

The set-up of GTAW process was shown in Figure 1. Stainless steel 304L plates with thickness of 3 mm were used in the GTAW orthogonal test. There are two kinds of plates produced by Dong fang steelworks and An gang steelworks, respectively. In order to remove contamination like dusts, oils and oxides, the surfaces of the plates were polished before welding. T-308L welding wire, with diameter of 1.2 mm, was used as filler material. The composition of 304L is presented in Table 2.

Figure 1.

Experimental set up for GTAW.

Table 2.

Composition of 304L (mass fraction, %).

To explore the relationship between the welding parameters with the FN, the orthogonal tests contained five factors and five levels of welding parameters were conducted, the detailed parameters of which are shown in Table 3, where A, B, C, D and E represent a travel speed, wire-feed rate, welding current, arc length and nitrogen content, respectively. The flow rate of Ar-N2 mixed shielding gas was constant at 20 L/min. Thus, the L25 (55) orthogonal array was used to perform the five factors and five levels of orthogonal experiment in the study of FN. The welding machine is Dynasty 700 (Miller Electrical Equipment Manufacturing Co.Ltd, Appleton, WI, USA)

Table 3.

Factors and levels.

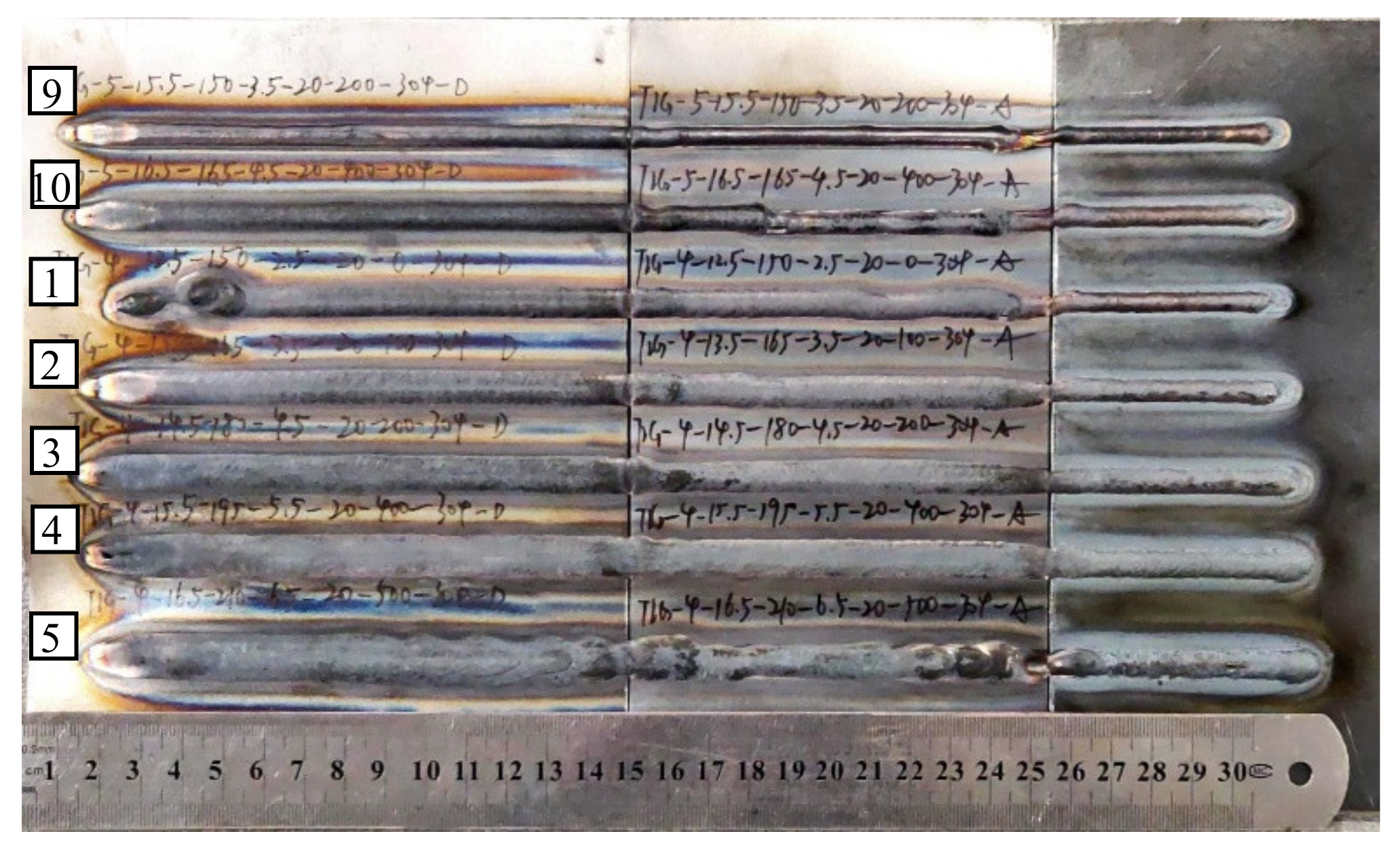

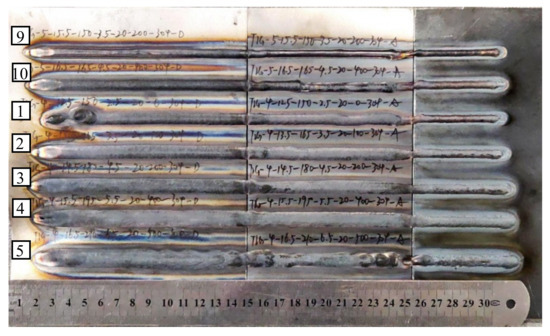

In order to ensure the welding parameters of the two kinds of plates were the same, Dongfang Special Steel hot-rolled sheet (DFSS) and Anshan Iron and Steel cold-rolled sheet (ASIS) were assembled for the tests, and carbon steel plates were used as run-on plates. The weld surface appearances are shown in Figure 2.

Figure 2.

Weld surface appearance.

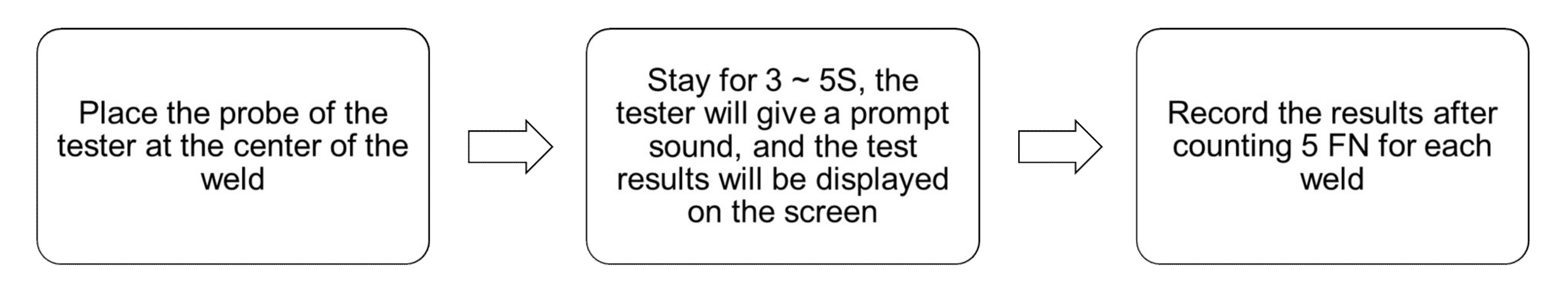

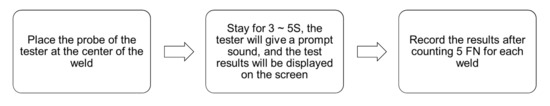

FN was measured at five different points along the welding direction by using Feritscope FMP30. Before the FN-measurement test, the carbon-steel sheet had been removed by mechanical means such that the FN measurement results are not affected, the test process is shown in Figure 3 and the results are shown in Table 4. The average FN of these five points is regarded as the FN of this weld. The FN of this 304L stainless steel plate is about 0.2, which is measured by the same ferrite number detector.

Figure 3.

The test process of FN.

Table 4.

FN of different welds.

3. Results and Discussion

3.1. Modeling of the FN-Prediction Models

In this section, the FN-prediction neural-network models for DFSS and ASIS are separately developed, based on the orthogonal test data, by using the ANN model from the MatLab software. The inputs of the two models both include five factors: welding speed, wire-feed rate, welding current, arc length and nitrogen content. The outputs of both models are univariate FN. Since 25 groups of tests with different welding parameters were conducted and 5 FN values were recorded in each group of tests, a total of 125 samples were obtained for DFSS or ASIS, collectively. The 125 samples are randomly divided into training set, validation set and test set, accounting for 70%, 15% and 15% respectively. The two models were trained by the Levenberg–Marquardt algorithm, which combines the advantages of the Gauss–Newton algorithm and the gradient descent method and can provide numerical solutions of nonlinear minimization. The numbers of hidden layers of the two models were both set to one in advance, and their training results, with different numbers of hidden nodes, are shown in Table 5 and Table 6, respectively. The computer used was a desktop machine with an Intel i9, 3.60 GHz processor and 16.0 GB RAM.

Table 5.

Training results of the FN-prediction model for DFSS with different numbers of hidden nodes.

Table 6.

Training results of the FN-prediction model for ASIS with different numbers of hidden nodes.

3.2. The Accuracies of the FN-Prediction Models

Regardless of the model, it can be observed that the correlation coefficients of the training set (R_Training), validation set (R_Validation), test set (R_Test) and total samples (R_All) are all small when there are fewer nodes in the hidden layer, which indicates that the phenomenon of ‘underfitting’ is occurring. In this case, the model not only learns poorly during training, but also shows poor performance in predicting new data. However, when the number of hidden nodes is large, the coeffiients of R_Validation and R_Test are markedly smaller than for R_Training, which means the phenomenon of ‘overfitting’ is occurring. In such case, the model becomes very biased in predicting new data. Therefore, the number of hidden nodes in the hidden layer should neither be too small nor too large, but at a moderate level. By setting the number of hidden nodes to six and eight respectively, the FN-prediction models for DFSS and ASIS can reach best performance, in which the mean square error (MSE) is small, and the R_Training, R_Validation and R_Test are close to one and approximate in value.

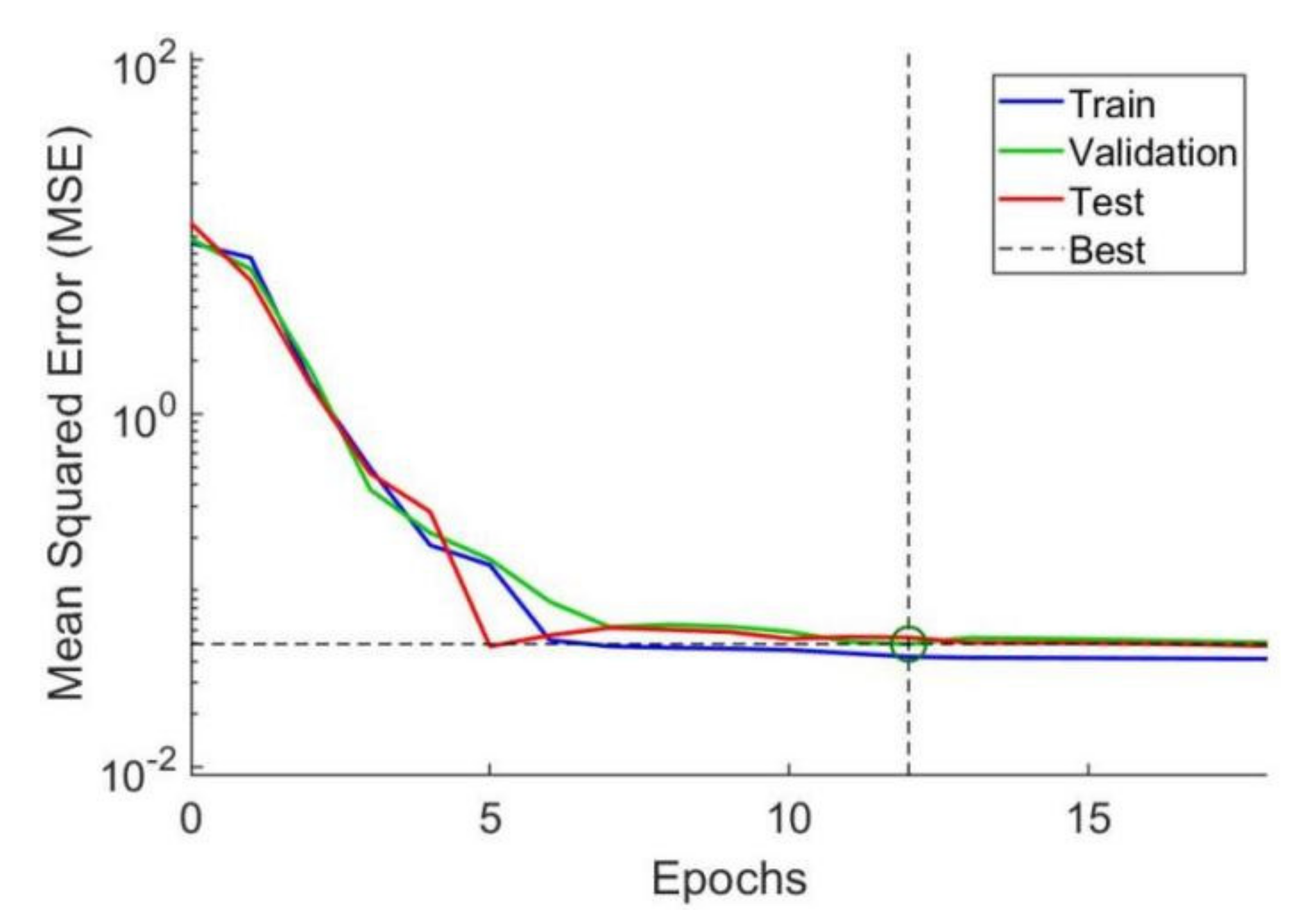

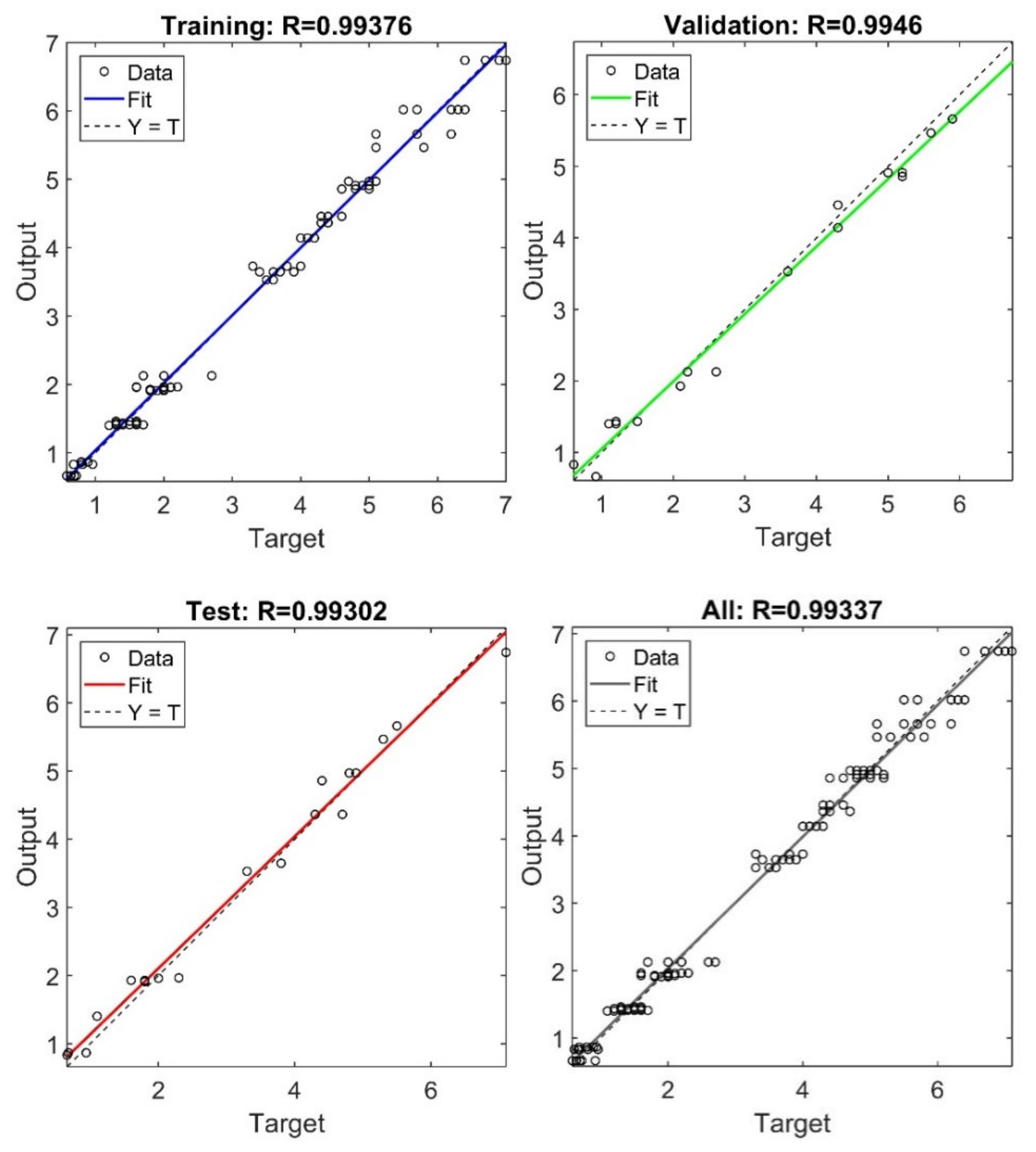

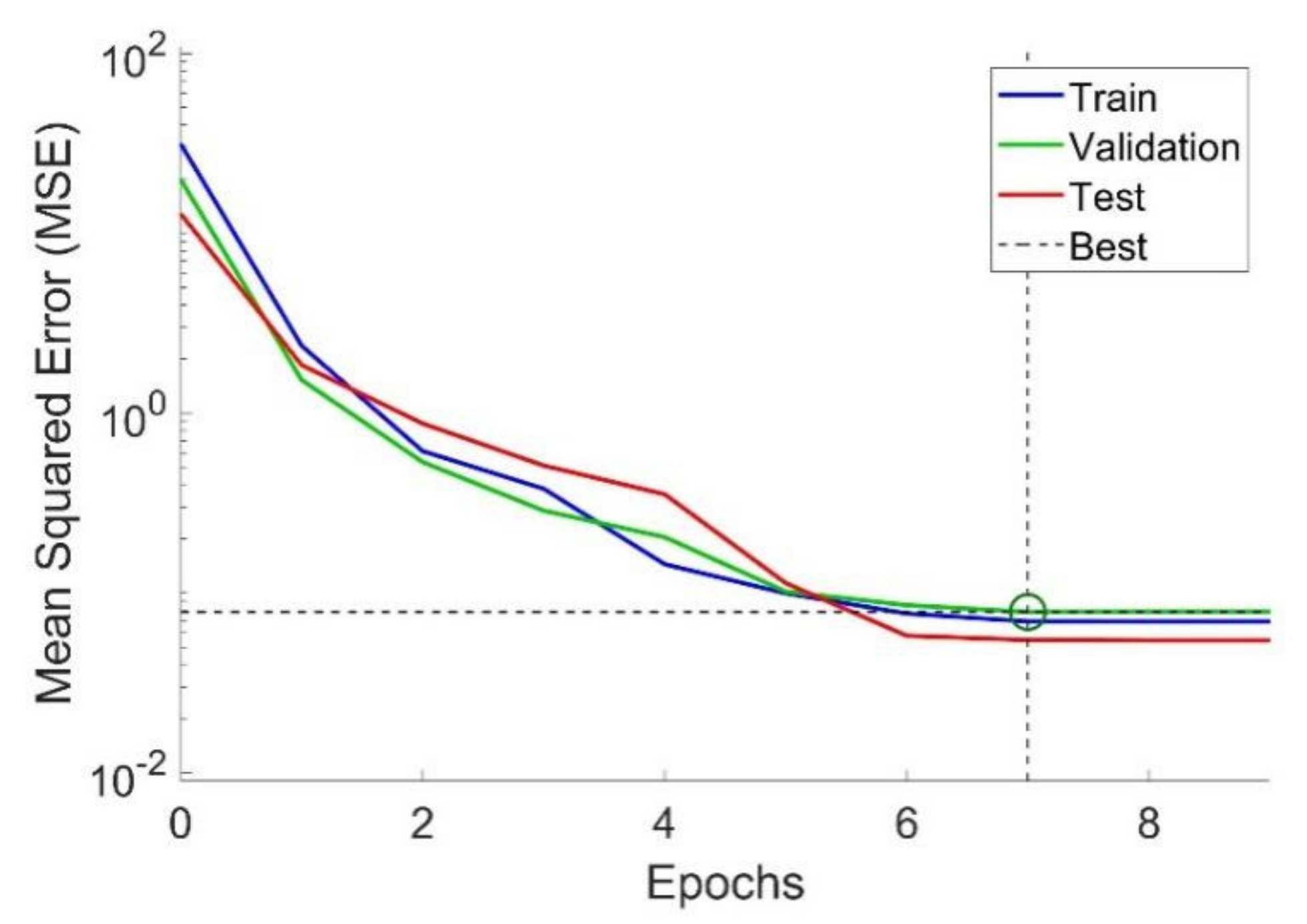

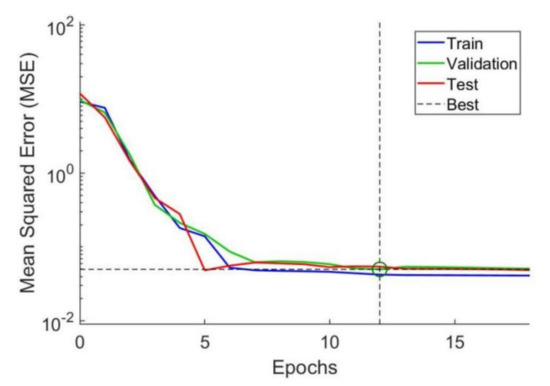

The training curve of the FN-prediction model for DFSS with six hidden nodes is shown in Figure 4. A total of 12 epochs were trained, and the best validation performance (MSE) reached 0.0498 at epoch 12. The correlation results of the model are shown in Figure 5. It is observed that R_All reached 0.99337 and the target–output points are closely distributed near the 45-degree straight line, which indicates that the model had good performance.

Figure 4.

Training curve of the FN prediction model for DFSS with six hidden nodes.

Figure 5.

Correlation results of the FN prediction model for DFSS with six hidden nodes.

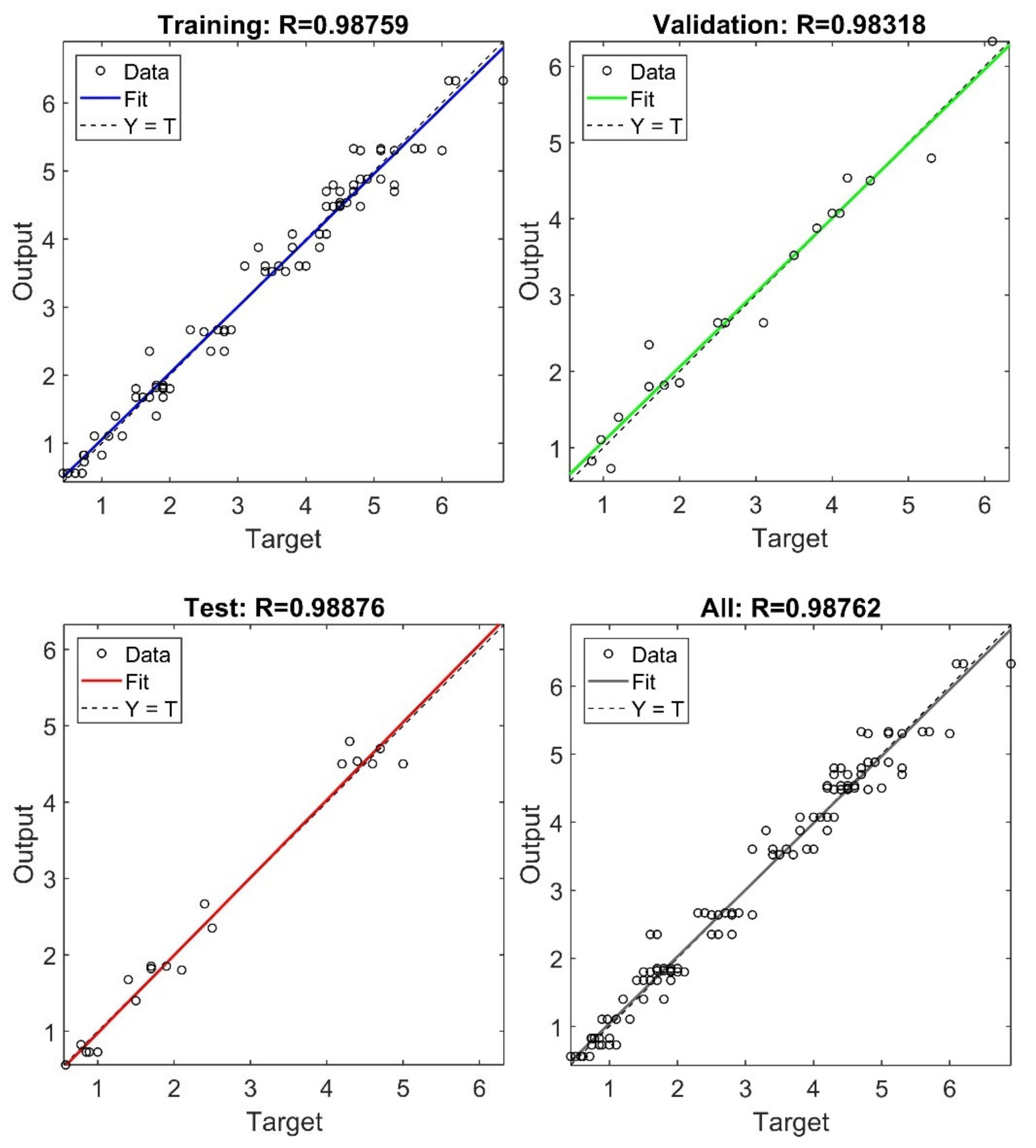

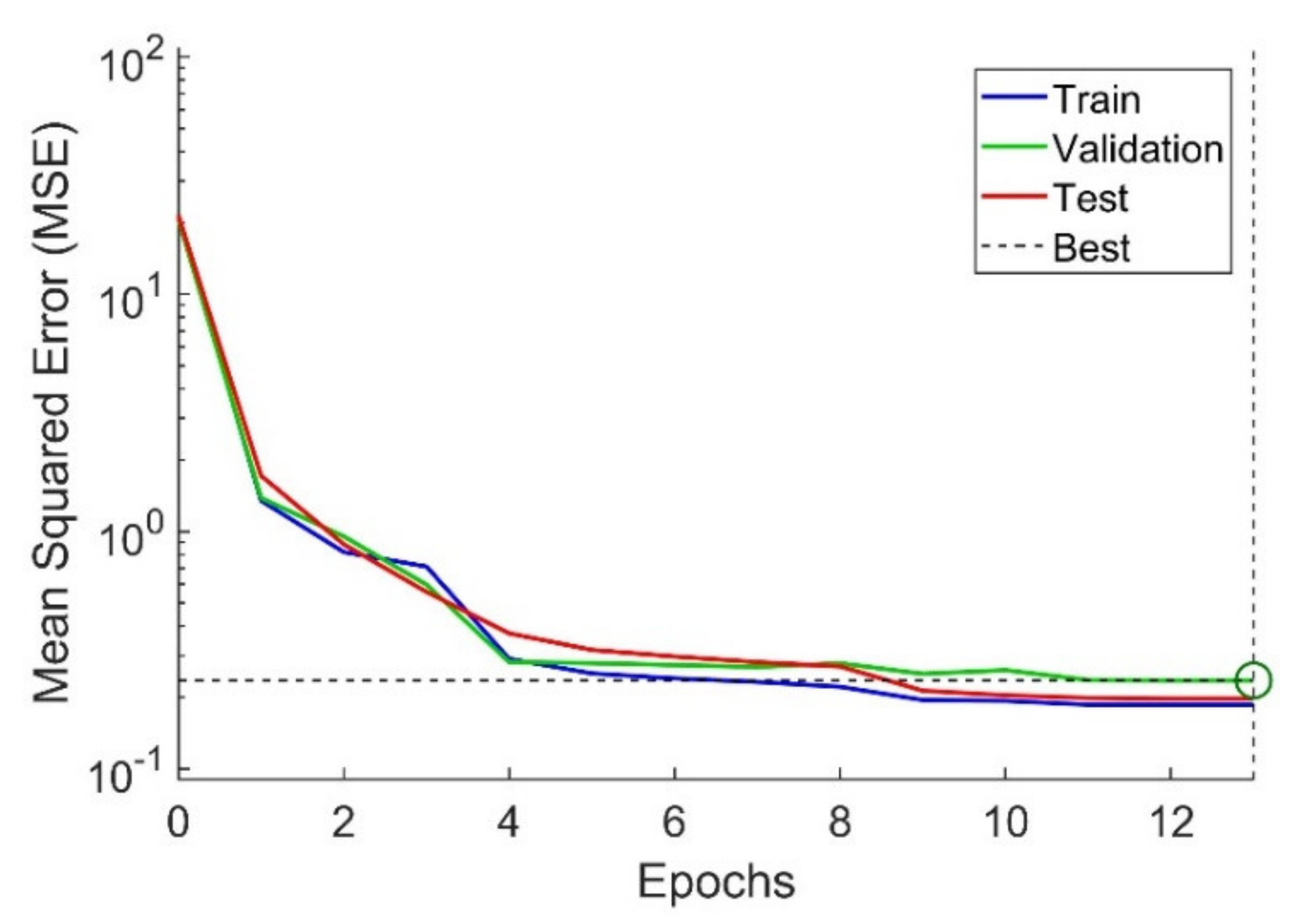

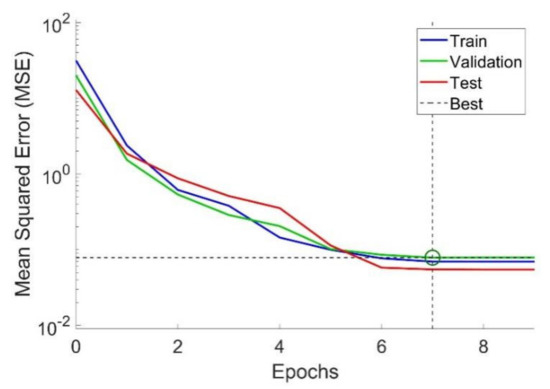

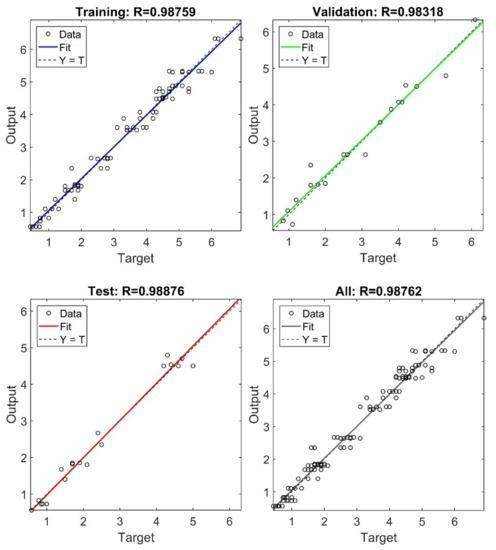

The training curve of the FN-prediction model for ASIS with eight hidden nodes is shown in Figure 6. A total of seven epochs are trained, and the best validation performance (MSE) reached 0.0784 at epoch seven. The correlation results of the model are shown in Figure 7. R_All reached 0.98762 and the target–output points were also distributed intensively near the 45-degree straight line.

Figure 6.

Training curve of the FN-prediction model for ASIS with eight hidden nodes.

Figure 7.

Correlation results of the FN-prediction model for ASIS with eight hidden nodes.

The parameters of the neural-network model should not be too many, because more parameters will increase the risk of ‘overfitting’. As the two FN-prediction models with one hidden layer and six or eight hidden nodes achieved good training results, there was no need to add more hidden layers.

4. FN-Prediction Model under Holistic Modeling

In this section, an FN-prediction neural-network model under holistic modeling is developed based on the orthogonal test data of DFSS and ASIS together. The 125 samples for each material are combined and randomly divided into the training set, validation set and test set, accounting for 70%, 15% and 15% respectively. The same training algorithm, Levenberg–Marquardt, is selected. The number of hidden layers is still set to one. The training results of the holistic FN-prediction model with different numbers of hidden nodes are shown in Table 7.

Table 7.

Training results of the holistic FN-prediction model with different numbers of hidden nodes.

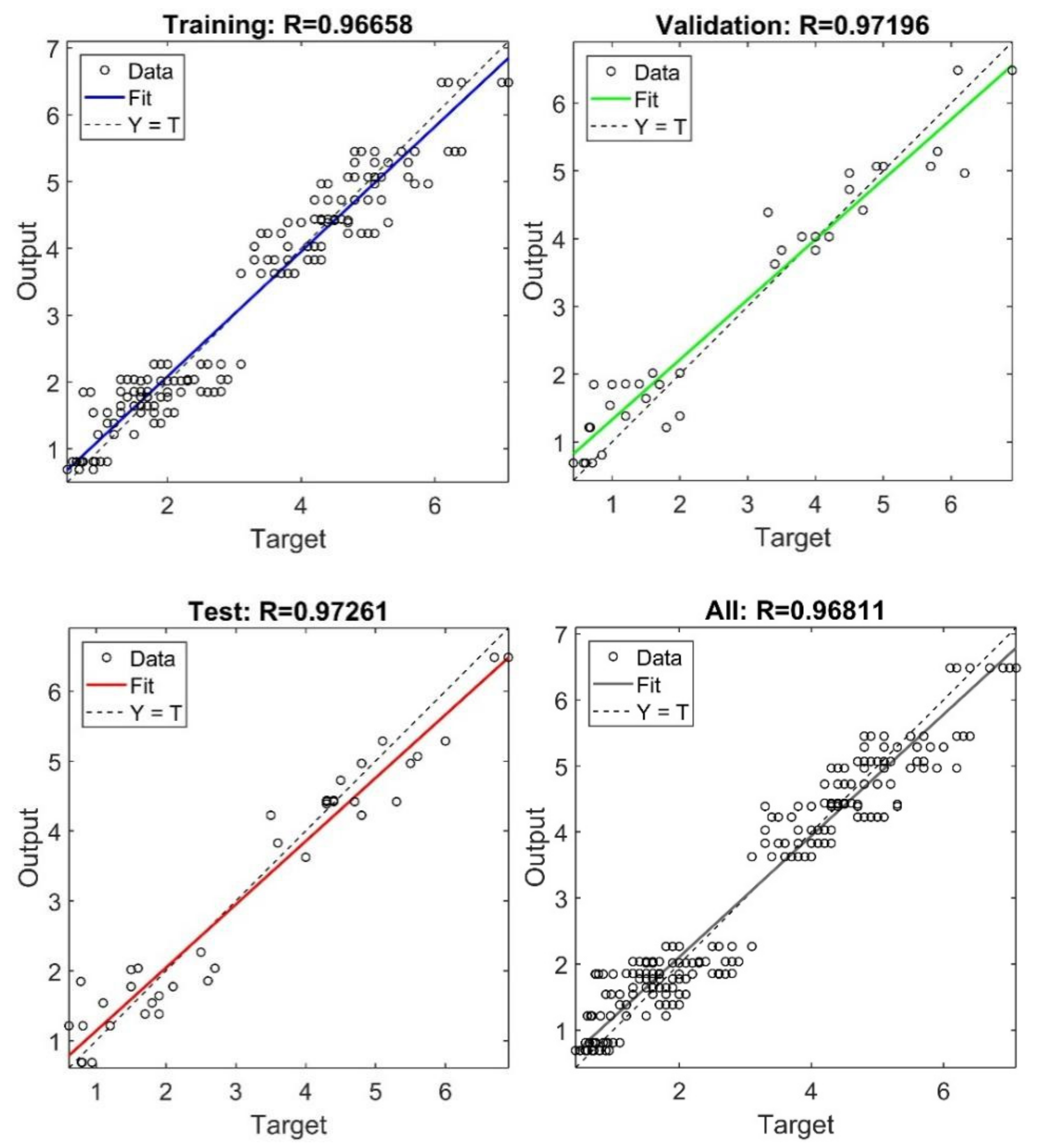

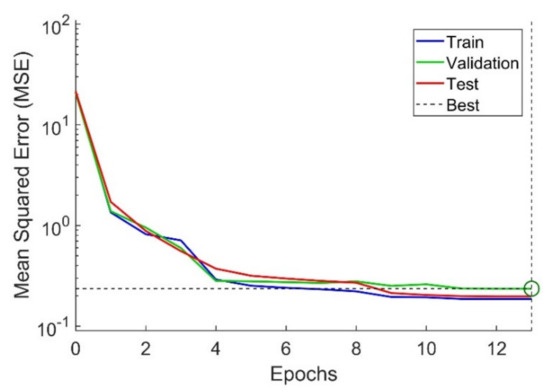

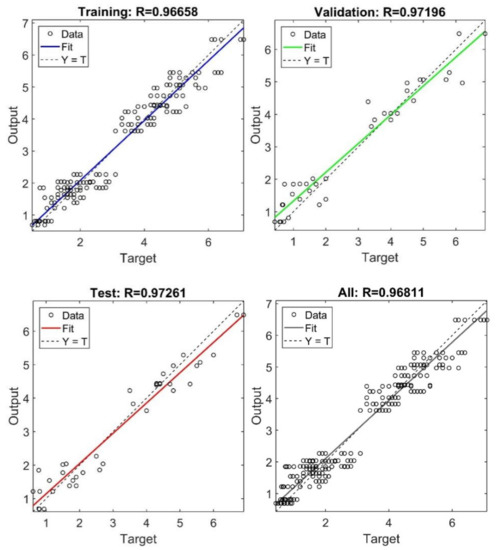

Among all the training results, the holistic FN-prediction model with six hidden nodes was ideal. The training curve of the model is shown in Figure 8. A total of 13 epochs were trained, and the best validation performance (MSE) reached 0.2356 at epoch 13. The correlation results of the model are satisfactory, as shown in Figure 9. R_All reached 0.96811, which is still very close to one, only a little lower than that of the FN-prediction model for DFSS or ASIS. The target–output points basically fall near the straight line of 45 degrees, indicating that the output values are highly consistent with the target values. In view of this, it can be concluded that the ANN-based FN-prediction model is relatively stable and is insensitive to different materials with different manufacturers and heat-treatment conditions. In production, the test data of different steels can be trained together to obtain a general model, which can be used to predict FN conveniently with only a slight loss of accuracy.

Figure 8.

Training curve of the holistic FN-prediction model with six hidden nodes.

Figure 9.

Correlation results of the holistic FN-prediction model with six hidden nodes.

5. Influence Analysis of Various Factors

In this section, the influence of various factors on FN is analyzed based on the FN-prediction model for DFSS. It is known that FN will decrease with the increase of nitrogen content in the shielding gas, while the other four factors (welding speed, wire-feed rate, welding current and arc length) affect FN irregularly from heat input and dilution rate. For example, the increase of heat input or the decrease of dilution rate will both reduce FN.

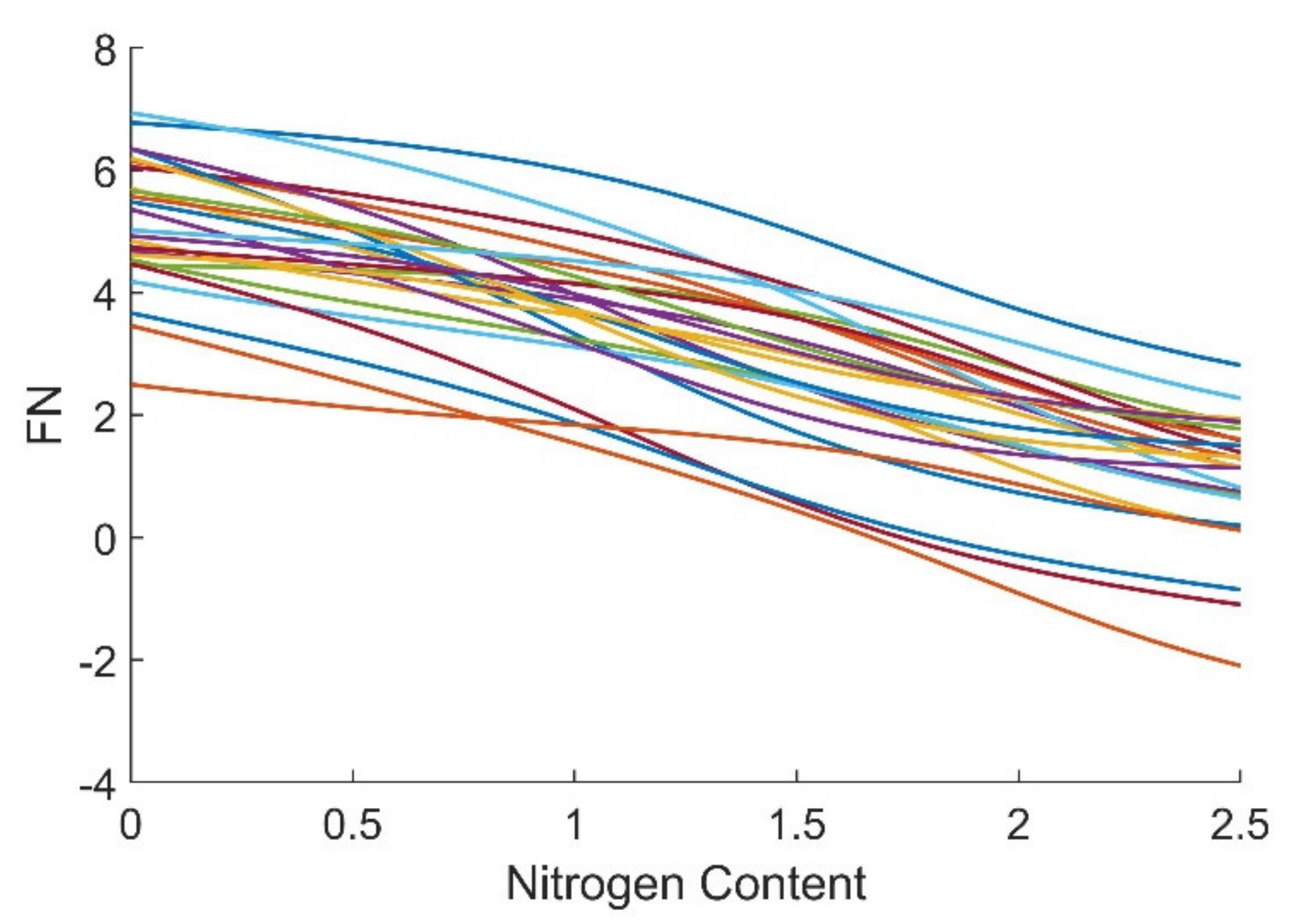

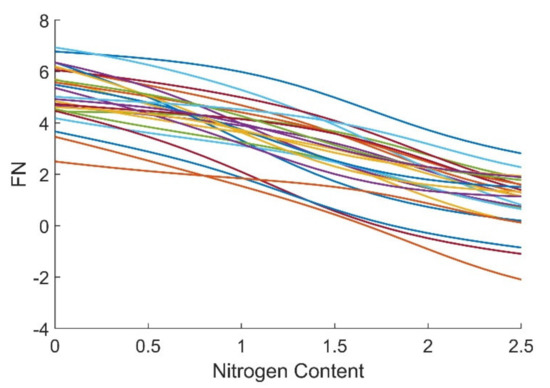

The correlation curves of nitrogen content (from 0 to 2.5) and FN were drawn, as shown in Figure 10. Since the FN-prediction model needed five inputs, the other four factors were set to those in the orthogonal test, such that a total of 25 curves were drawn. It is observed that FN decreases monotonously with the increase of nitrogen content in each curve, as predicted. In production, as long as the other four welding parameters and a variation range of nitrogen content are given, the FN–nitrogen-content curve can be easily obtained from the FN-prediction model. In this way, the engineers can expediently know how much nitrogen should be added to the shielding gas from the curve, as well as the FN value expected, so as to achieve the accurate control of FN.

Figure 10.

Influence of nitrogen content on FN.

Welding speed, wire-feed rate, welding current and arc length all affect FN from two aspects: heat input and dilution rate, which correspond to the high temperature residence time and Creq/Nieq ratio respectively. The specific analyses are shown in Table 8 and Table 9.

Table 8.

Influence analysis of welding speed, wire-feed rate, welding current and arc length on FN from the perspective of heat input.

Table 9.

Influence analysis of welding speed, wire-feed rate, welding current and arc length on FN from the perspective of dilution rate.

- (1)

- Welding speed. With the increase of welding speed, heat input decreases, causing the high temperature residence time to decrease. Due to the insufficient transformation from ferrite to austenite, FN will increase. On the other hand, the increase of welding speed decreases the dilution rate of the base metal, causing the Creq/Nieq ratio to reduce, thus the FN in the weld will decrease.

- (2)

- Wire-feed rate. As wire-feed rate increases, more heat is used to melt welding consumables, resulting in a decrease in heat input and an increase in FN. On the other hand, the increase of wire-feed rate will decrease the dilution rate of the base metal, causing FN to decrease.

- (3)

- Welding current and arc length. With the increase of welding current and arc length, the heat input and dilution rate will both increase, causing FN to decrease or increase respectively.

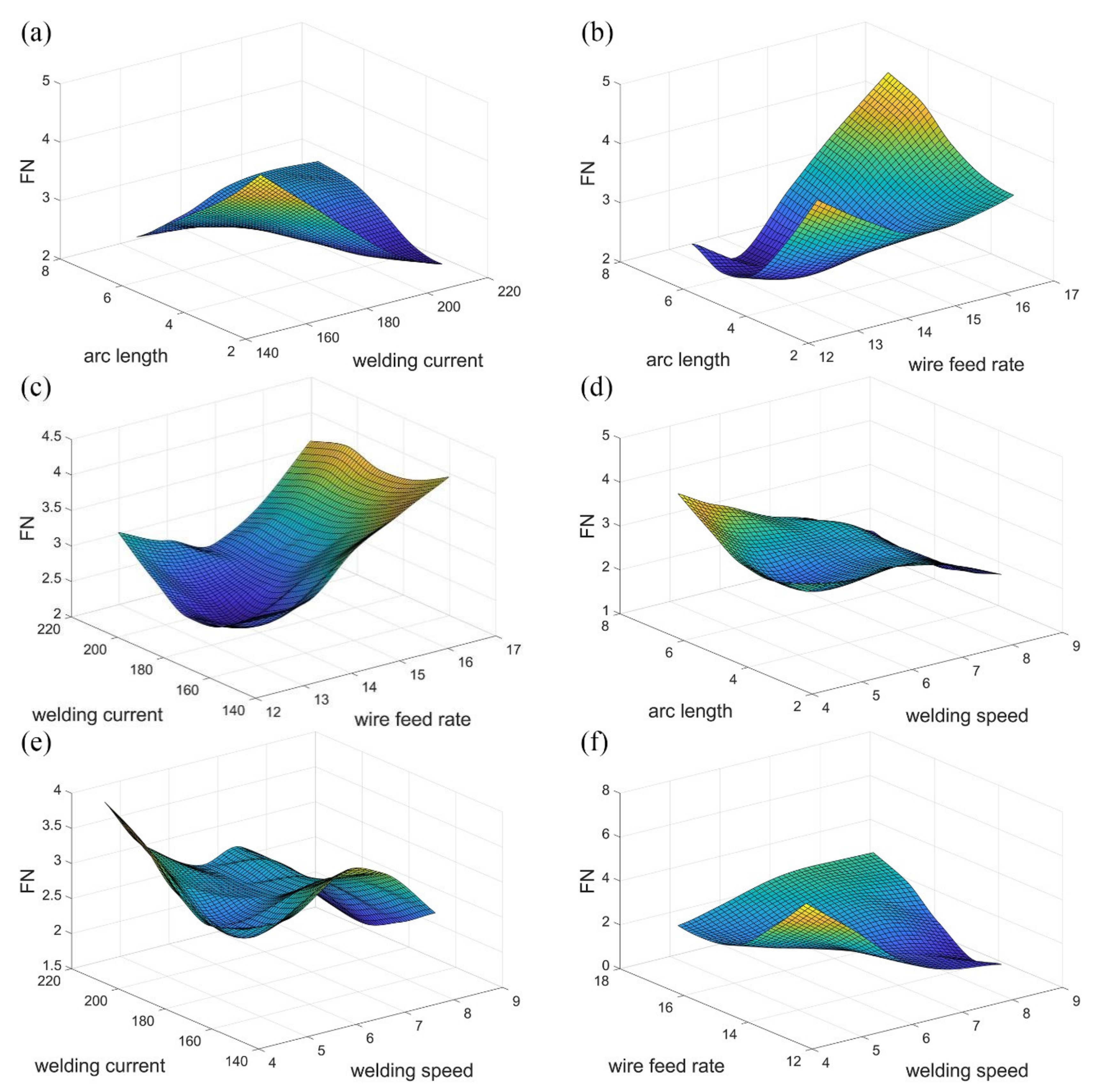

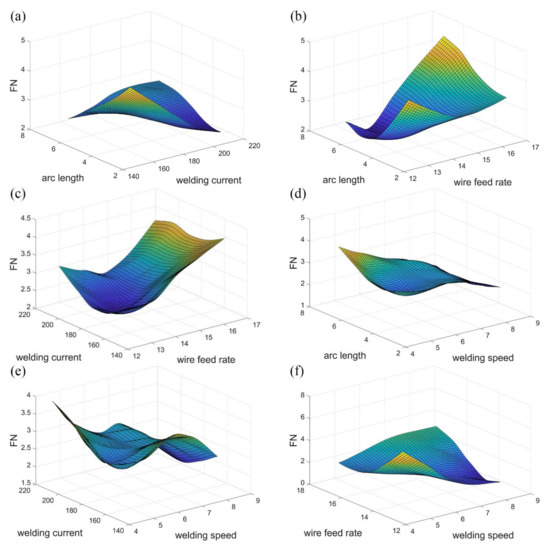

In order to illustrate, in detail, the above rules, the resultant surfaces with each input pair and output FN values of the FN-prediction model for DFSS are demonstrated in Figure 9. Since a total of five inputs were required, a group of inputs was selected (welding speed = 6.15 mm/s, wire-feed rate = 14.5 mm/s, welding current = 180 A, arc length = 4.5 mm, and nitrogen content = 1.25%). Nitrogen content is always fixed at 1.25%. When analyzing the influence of every other two variables on FN, the values of the remaining two variables are fixed.

It can be observed that the nonlinearity is substantial in modeling FN to the four welding parameters. In Figure 11a, FN decreases, initially, with the increase in arc length and welding current when the two parameters are both small, which indicates that FN depends more on heat input and high-temperature residence time at this time. As the arc length and welding current increase beyond a certain equilibrium position, FN starts to increase. At this time, FN depends more on dilution rate and Creq/Nieq ratio. The same condition, shown in Figure 11f, holds similar rules for wire-feed rate and welding speed to FN. The small wire-feed rate and welding speed represent large heat input and dilution rate. As the two variables increase, the heat input and dilution rate gradually decrease. FN decreases firstly and then increases, indicating that the decisive factor of FN has changed from Creq/Nieq ratio to high-temperature residence time. The surface changes in other figures can be similarly explained, and provide us with detailed knowledge about the correlation between FN and welding parameters.

Figure 11.

DFSS model surfaces with different input parameters. (a) arc length and welding current (welding speed = 6.15 mm/s, wire-feed rate = 14.5 mm/s), (b) arc length and wire-feed rate (welding speed = 6.15 mm/s, welding current = 180 A), (c) welding current and wire-feed rate (welding speed = 6.15 mm/s, arc length = 4.5 mm), (d) arc length and welding speed (wire-feed rate = 14.5 mm/s, welding current = 180 A), (e) welding current and welding speed (wire-feed rate = 14.5 mm/s, arc length = 4.5 mm), and (f) wire-feed rate and welding speed (welding current = 180 A, arc length = 4.5 mm).

6. Conclusions

The ANN models between FN and welding parameters, which include nitrogen content, were developed based on the orthogonal test data of 304L steel by using the GTAW process. The influences of each parameter were detailed analyzed and the coupling relationships between two/three parameters were also discussed. The main conclusions are as follows:

- The ANN-based FN-prediction models trained by the orthogonal test data were stable and insensitive to different materials with different manufacturers and heat-treatment conditions. High performance can be achieved by modeling different materials separately. In the FN-prediction models for DFSS and ASIS, the correlation coefficients of total samples (R_All) reached 0.99337 and 0.98762 respectively. The effect of holistic modeling of different materials was also satisfactory, and could meet the requirements of engineering practice. In the holistic FN-prediction model, R_All reached 0.96811.

- FN decreased monotonously with the increase in nitrogen content. In production, through the FN-prediction models proposed in this paper, FN can be accurately and easily controlled by adjusting the nitrogen content in the shielding gas when other welding parameters are fixed.

- The influences of welding speed, wire-feed rate, arc length and welding current on FN were analyzed based on the FN-prediction model for DFSS. The results show that the influences of either parameters on FN were nonlinear. The FN-prediction models proposed in this paper can provide useful information to researchers about this nonlinearity.

Author Contributions

S.C. Conceptualization; Data curation; Writing—original draft; Writing—review & editing, F.C.: Funding acquisition; Project administration; Supervision, S.W.: Funding acquisition; Project administration; Supervision, L.L.: Data curation, Supervision, F.L.: Supervision, Z.S.: Funding acquisition; Project administration; Supervision, Y.Z.: Investigation. All authors have read and agreed to the published version of the manuscript.

Funding

This program is supported by the National Natural Science Foundation of China (Grant No. 51775372).

Institutional Review Board Statement

The study did not involve humans or animals.

Informed Consent Statement

The study did not involve humans.

Data Availability Statement

The study did not report any data.

Acknowledgments

All individuals included in this section have consented to the acknowledgement.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Lippold, J.C.; Kotecki, D.J. Welding Metallurgy and Weldability of Stainless Steels; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005; p. 376. [Google Scholar]

- Brooks, J.A.; Thompson, A.W. Microstructural development and solidification cracking susceptibility of austenitic stainless steel welds. Int. Mater. Rev. 1991, 36, 16–44. [Google Scholar] [CrossRef]

- Nissley, N.E.; Lippold, J.C. Development of the strain-to-fracture test for evaluating ductility-dip cracking in austenitic alloys. Weld. J. 2003, 82, 355s–364s. [Google Scholar]

- Hauser, D.; Van Echo, J.A. Effects of ferrite content in austenitic stainless steel welds. Weld. J. 1982, 61, 37s–44s. [Google Scholar]

- Lippold, J.C.; Juhas, M.C.; Dalder, E.N.C. The relationship between microstructure and fracture behavior of fully austenitic Type 316L weld filler materials at 4.2K. Metall. Trans. 1985, 16A, 1835–1848. [Google Scholar] [CrossRef]

- Kumar, S.; Shahi, A.S.; Sharma, V.; Malhotra, D. Effect of Welding Heat Input and Post-weld Thermal Aging on the Sensitization and Pitting Corrosion Behavior of AISI 304L Stainless Steel Butt Welds. JMEPEG 2021, 30, 1619–1640. [Google Scholar] [CrossRef]

- Janiczak, R.; Pańcikiewicz, K. Laser welding of austenitic ferrofluid container for the KRAKsat satellite. Weld. World 2021, 65, 1347–1357. [Google Scholar] [CrossRef]

- Rogalski, G.; Świerczyńskanska, A.S.; Landowski, M. Mechanical and Microstructural Characterization of TIG Welded Dissimilar Joints between 304L Austenitic Stainless Steel and Incoloy 800HT Nickel Alloy. Metals 2020, 10, 559. [Google Scholar] [CrossRef]

- Prabhu, R.; Alwarsamy, T. Effect of process parameters on ferrite number in cladding of 317L stainless steel by pulsed MIG welding. J. Mech. Sci. Technol. 2017, 31, 1341–1347. [Google Scholar] [CrossRef]

- Salujaa, R.; Moeed, K.M. Experimental Investigation of Solidification-Mode And Response Surface Modeling Of Ferrite-Content In Grade 304L Pulse GMA Welded Plates. Mater. Today Proc. 2019, 18, 3876–3890. [Google Scholar] [CrossRef]

- Ganesan, V.M.D.; Mathew, K.B.; Rao, S. Influence of nitrogen on tensile properties of 316LN SS. Mater. Sci. Technol. 2013, 25, 615–618. [Google Scholar] [CrossRef]

- Nage, D.D.; Raja, V.S. Effect of nitrogen addition on the stress corrosion cracking behavior of 904 L stainless steel welds in 288 °C deaerated water. Corros. Sci. 2006, 48, 2317–2331. [Google Scholar] [CrossRef]

- Singn, S.; Hurtig, K.; Andersson, J. Investigation on effect of welding parameters on solidification cracking of austenitic stainless steel 314. Procedia Manuf. 2018, 25, 351–357. [Google Scholar] [CrossRef]

- Moslemi, N.; Redzuan, N.; Ahmad, N. Effect of Current on Characteristic for 316 Stainless Steel Welded Joint Including Microstructure and Mechanical Properties. Procedia CIRP 2015, 26, 560–564. [Google Scholar] [CrossRef] [Green Version]

- Wang, Z.; Todd, A.P.; Allison, M.B. Effect of processing parameters on microstructure and tensile properties of austenitic stainless steel 304L made by directed energy deposition additive manufacturing. Acta Mater. 2016, 110, 226–235. [Google Scholar] [CrossRef] [Green Version]

- Schaeffler, A.L. Canstitution diagram for stainless steel weld metal. Met. Prog. 1949, 56, 680–690. [Google Scholar]

- Kotecki, D.J.; Siewert, T.A. Constitution diagram for stainless steel weld metals: A modification of the WRC-1988 diagram. Weld. J. 1992, 71, 171–s–178–s. [Google Scholar]

- Chan, B.; Pacey, J.; Bibby, M. Modelling gas metal arc weld geometry using artificial neural network technology. Can. Metall. Q. 1999, 1, 43–51. [Google Scholar] [CrossRef]

- Vora, J.; Patel, V.; Srinivasan, S.; Chaudhari, R.; Pimenov, D.; Giasin, K.; Sharma, S. Optimization of Activated Tungsten Inert Gas Welding Process Parameters Using Heat Transfer Search Algorithm: With Experimental Validation Using Case Studies. Metals 2021, 11, 981. [Google Scholar] [CrossRef]

- Vasudevan, M.; Murugananth, M.; Bhaduri, A.K. Application of Bayesian neural network for modeling and prediction of FN in austenitic stainless steel welds. In Mathematical Modeling of Weld Phenomena-VI; Institute of Material: Cambridge, UK, 2002; pp. 1079–1099. [Google Scholar]

- Bermejo, M.A. Predictive and measurement methods for delta ferrita determination in stainless steel. Weld. J. 2012, 91, 113–s–121–s. [Google Scholar]

- Pantel, T.; Sheth, S.; Modi, B.S.; Pantel, P. Experimental investigation and comparison of regression model and artificial neural network to predict weld height in MIG welding for dual plate check valve. In Proceedings of the International Conference on Advances in Materials and Product Design AMPD, Surat, India, 10–11 January 2015. [Google Scholar]

- Vitek, J.M.; Iskander, Y.S.; Oblow, E.M. Improved ferrite number prediction in stainless steel arc welds using artificial neural networks (Part 1): Neural network development. Weld. J. 2000, 79, 33–40. [Google Scholar]

- Vitek, J.M.; David, S.A.; Hinman, C.R. Improved ferrite number prediction model that accounts for cooling rate effects (Part 1): Model Development. Weld. J. 2003, 82, 10–17. [Google Scholar]

- Vasudevan, M.; Bhaduri, A.K.; Raj, B. Delta ferrite prediction in stainless steel welds using neural network analysis and comparison with other prediction methods. J. Mater. Process. Technol. 2003, 142, 20–28. [Google Scholar] [CrossRef]

- Tomaz, I.d.V.; Colaço, F.H.G.; Sarfraz, S.; Pomenov, D.; Gupta, M. Pintaude G. Investigations on quality characteristics in gas tungsten arc welding process using artificial neural network integrated with genetic algorithm. The Int. J. Adv. Manuf. Technol. 2021, 113, 3569–3583. [Google Scholar] [CrossRef]

- Shankar, V.; Mannan, S.L.; Gill, T.P.S. Effect of nitrogen addition on microstructure and fusion zone cracking in type 316L stainless steel weld metals. Mater. Sci. Eng. A 2003, 343, 170–181. [Google Scholar] [CrossRef]

- Tseng, K.H.; Hsien, K.C. Effect of Ar-N2 mixed gas on morphology and microstructure of type 316L stainless steel TIG weld metal. Adv. Mater. Res. 2011, 295, 1919–1924. [Google Scholar] [CrossRef]

- Tseng, K.; Chou, C. Effect of nitrogen addition to shielding gas on residual stress of stainless steel weldments. Sci. Technol. Weld. Join. 2002, 7, 57–62. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).