Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder

Abstract

:1. Introduction

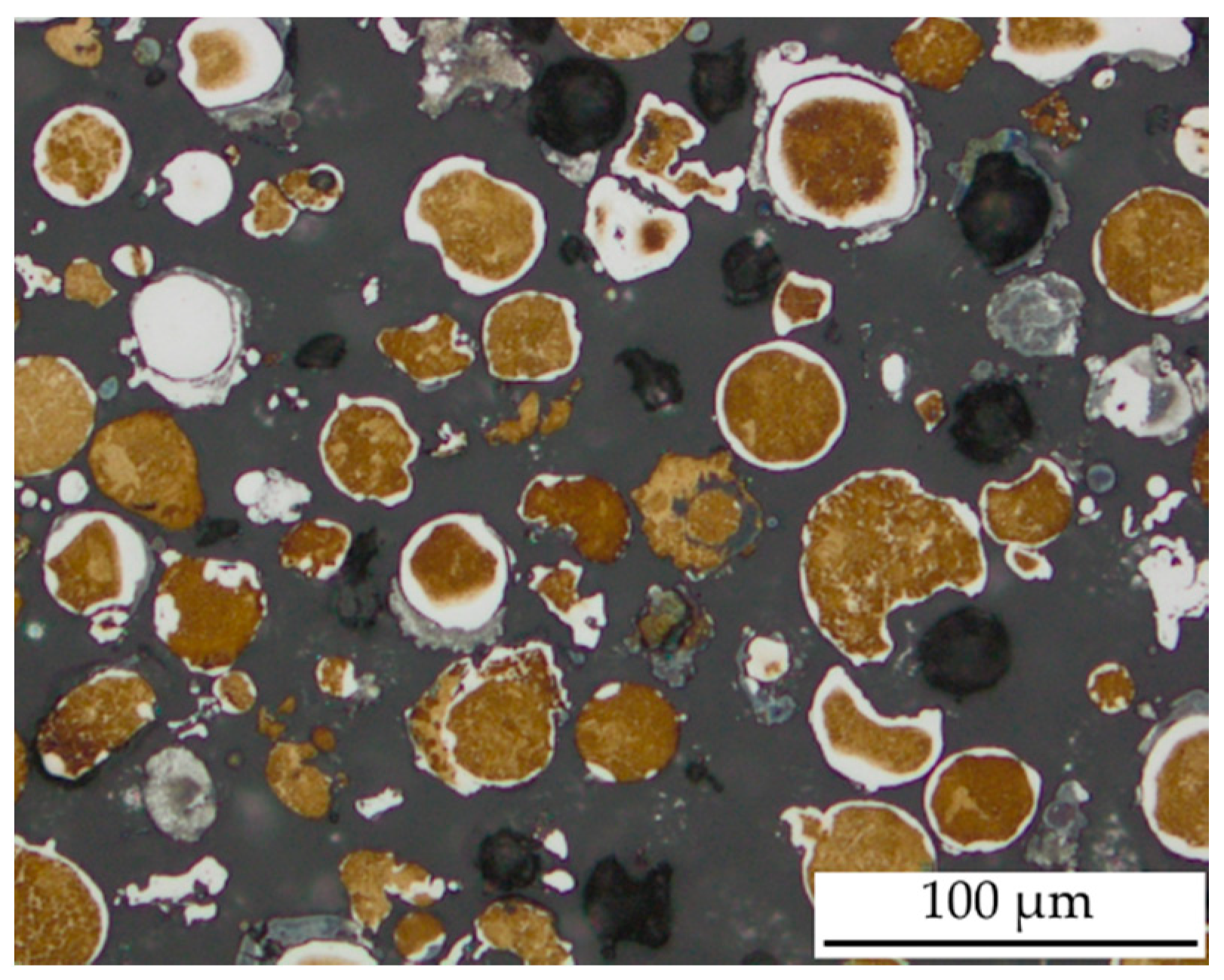

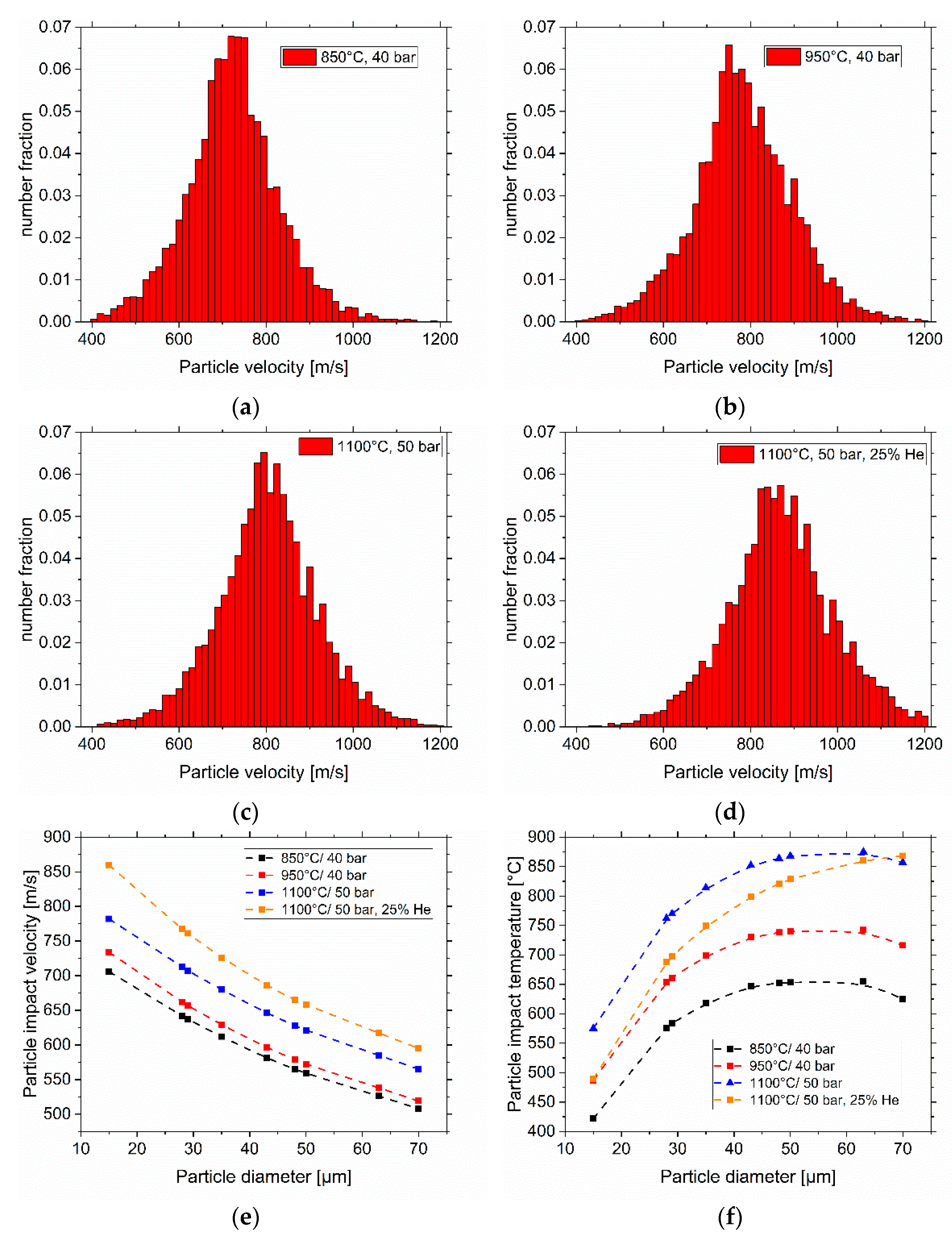

2. Materials and Methods

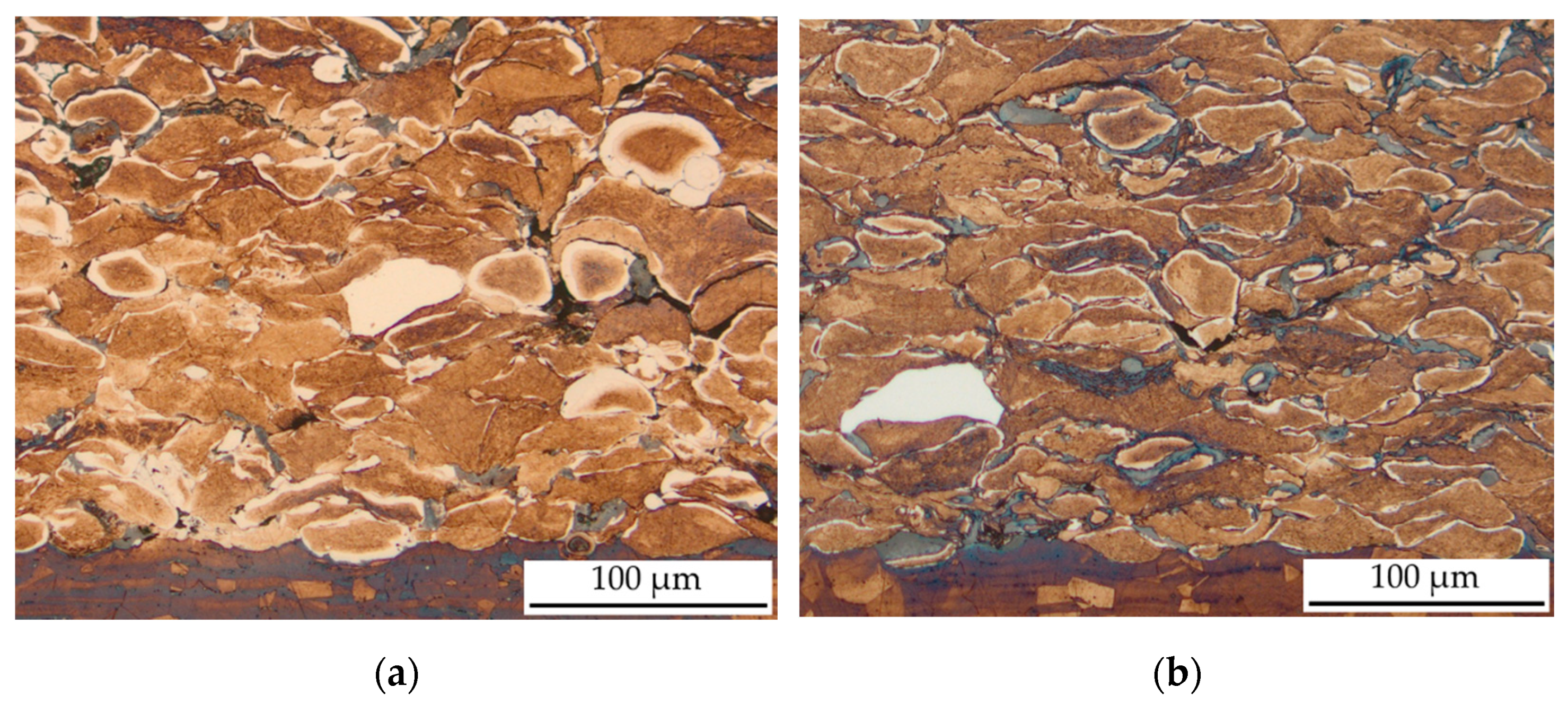

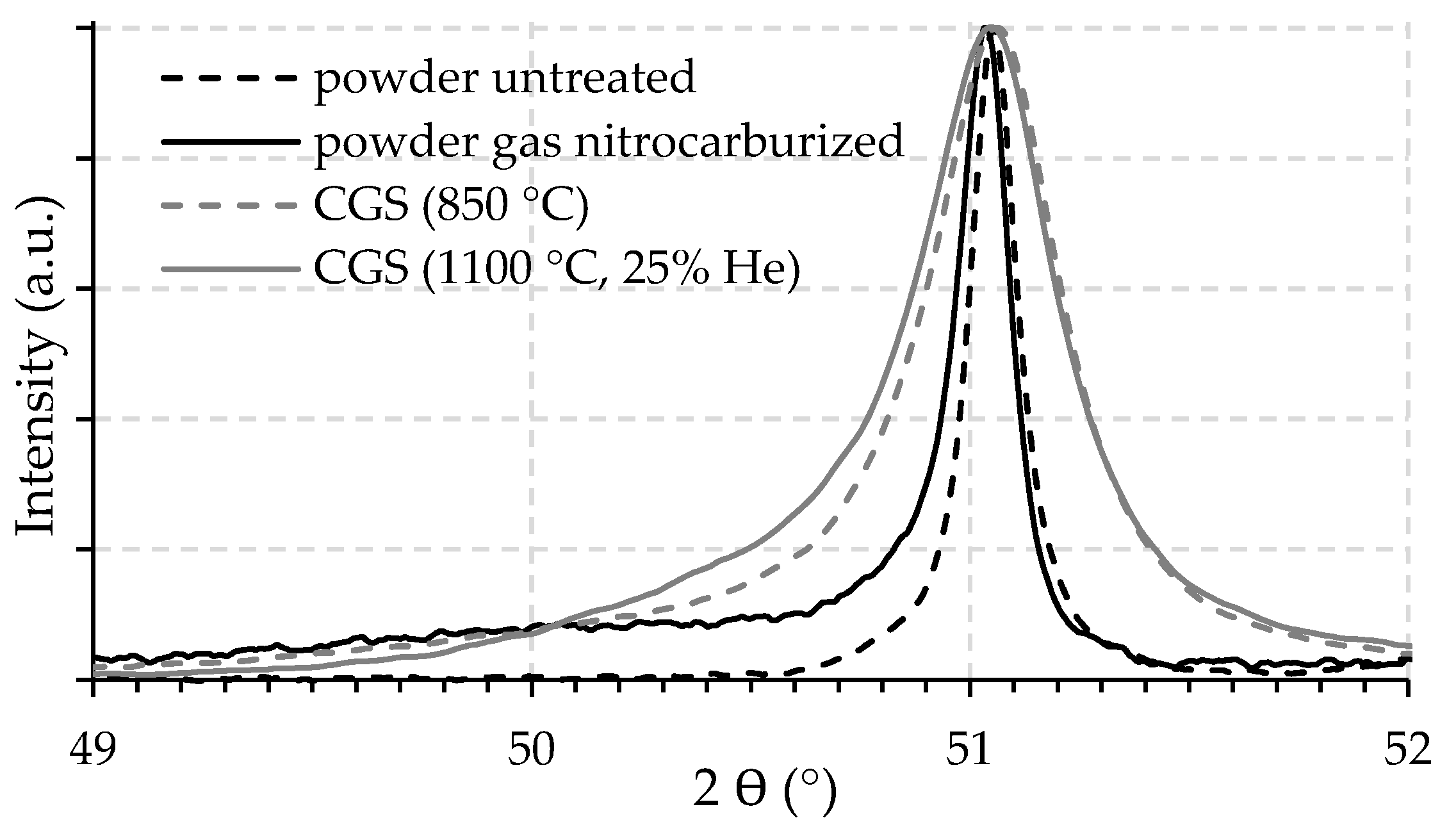

3. Results

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, C.; Li, C.X.; Dong, H.; Bell, T. Low temperature plasma nitrocarburising of AISI 316 austenitic stainless steel. Surf. Coat. Technol. 2005, 191, 195–200. [Google Scholar] [CrossRef]

- Bell, T. Current status of supersaturated surface engineered S-phase materials. In Key Engineering Materials; Trans Tech Publications: Zurich, Switzerland, 2008; pp. 289–295. [Google Scholar] [CrossRef]

- Borgioli, F. From Austenitic Stainless Steel to Expanded Austenite-S Phase: Formation, Characteristics and Properties of an Elusive Metastable Phase. Metals 2020, 10, 187. [Google Scholar] [CrossRef] [Green Version]

- Nestler, M.C.; Spies, H.; Hermann, K. Production of duplex coatings by thermal spraying and nitriding. Surf. Eng. 1996, 12, 299–302. [Google Scholar] [CrossRef]

- Wielage, B.; Rupprecht, C.; Lindner, T.; Hunger, R. Surface modification of austenitic thermal spray coatings by low-temperature carburization. In Proceedings of the International Thermal Spray Conference & Exposition 2011, Hamburg, Germany, 27–29 September 2011; p. 276. Available online: www.researchgate.net/publication/320323004 (accessed on 1 November 2021).

- Adachi, S.; Ueda, N. Formation of S-phase layer on plasma sprayed AISI 316L stainless steel coating by plasma nitriding at low temperature. Thin Solid Film 2012, 523, 11–14. [Google Scholar] [CrossRef]

- Park, G.; Bae, G.; Moon, K.; Lee, C. Effect of plasma nitriding and nitrocarburinzing on HVOF-sprayed stainless steel coatings. J. Therm. Spray Technol. 2013, 22, 1366–1373. [Google Scholar] [CrossRef]

- Adachi, S.; Ueda, N. Effect of Cold-Spray Conditions Using a Nitrogen Propellant Gas on AISI 316L Stainless Steel-Coating Microstructures. Coatings 2017, 7, 87. [Google Scholar] [CrossRef] [Green Version]

- Adachi, S.; Ueda, N. Wear and Corrosion Properties of Cold-Sprayed AISI 316L Coatings Treated by Combined Plasma Carburizing and Nitriding at Low Temperature. Coatings 2018, 8, 456. [Google Scholar] [CrossRef] [Green Version]

- Lindner, T.; Mehner, T.; Lampke, T. Surface modification of austenitic thermal-spray coatings by low-temperature nitrocarburizing. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2016; Volume 118. [Google Scholar] [CrossRef]

- Lindner, T.; Kutschmann, P.; Löbel, M.; Lampke, T. Hardening of HVOF-Sprayed Austenitic Stainless-Steel Coatings by Gas Nitriding. Coatings 2018, 8, 348. [Google Scholar] [CrossRef] [Green Version]

- Kutschmann, P.; Lindner, T.; Börner, K.; Reese, U.; Lampke, T. Effect of Adjusted Gas Nitriding Parameters on Microstructure and Wear Resistance of HVOF-Sprayed AISI 316L Coatings. Materials 2019, 12, 1760. [Google Scholar] [CrossRef] [Green Version]

- Duan, C.; Shen, Y.; Feng, X.; Chen, C.; Zhang, J. Nitriding of Fe–18Cr–11Mn powders using mechanical alloying method through aerating nitrogen circularly. Mater. Sci. Technol. 2016, 32, 1231–1239. [Google Scholar] [CrossRef]

- Gnedovets, A.G.; Ankudinov, A.B.; Zelenskii, V.A.; Kovalev, E.P.; Wisniewska-Weinert, H.; Alymov, M.I. Synthesis of Micron Particles with Fe–Fe4N Core–Shell Structure at Low-Temperature Gaseous Nitriding of Iron Powder in a Stream of Ammonia. Inorgan. Mater. Appl. Res. 2016, 7, 303–309. [Google Scholar] [CrossRef]

- Lindner, T.; Löbel, M.; Lampke, T. Phase Stability and Microstructure Evolution of Solution-Hardened 316L Powder Feedstock for Thermal Spraying. Metals 2018, 8, 1063. [Google Scholar] [CrossRef] [Green Version]

- Grujicic, M.; Zhao, C.L.; Tong, C.; DeRosset, W.S.; Helfricht, D. Analysis of the impact velocity of powder particles in the cold-gas dynamic-spray process. Mater. Sci. Eng. A 2004, 368, 222–230. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef] [Green Version]

- Rokni, M.R.; Nutt, S.R.; Widener, C.A.; Champagne, V.K.; Hrabde, R.H. Review of Relationship Between Particle Deformation, Coating Microstructure, and Properties in High-Pressure Cold Spray. J. Therm. Spray Technol. 2017, 26, 1308–1355. [Google Scholar] [CrossRef]

- Assadi, H.; Gärtner, F.; Stoltenhoff, T.; Kreye, H. Bonding mechanism in cold gas spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; DeRosset, W.S.; Helfricht, D. Adiabatic shear instability based mechanism for particles/substrate bonding in the cold-gas dynamic-spray process. Mater. Des. 2004, 25, 681–688. [Google Scholar] [CrossRef]

- Schmidt, T.; Gärtner, F.; Assadi, H.; Kreye, H. Development of a generalized parameter window for cold spray deposition. Acta Mater. 2006, 54, 729–742. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gärtner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From Particle Acceleration to Impact and Bonding in Cold Spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef] [Green Version]

- Assadi, H.; Schmidt, T.; Richter, H.; Kliemann, J.O.; Binder, K.; Gartner, F.; Klassen, T.; Kreye, H. On Parameter Selection in Cold Spraying. J. Therm. Spray Technol. 2011, 20, 1161–1176. [Google Scholar] [CrossRef]

- Al-Mangour, B.; Vo, P.; Mongrain, R.; Irissou, E.; Yue, S. Effect of Heat Treatment on the Microstructure and Mechanical Properties of Stainless Steel 316L Coatings Produced by Cold Spray for Biomedical Applications. J. Therm. Spray Technol. 2013, 23, 641–652. [Google Scholar] [CrossRef] [Green Version]

- Xie, Y.; Planche, M.-P.; Raoelison, R.; Liao, H.; Suo, X.; Hervé, P. Effect of Substrate Preheating on Adhesive Strength of SS 316L Cold Spray Coatings. J. Therm. Spray Technol. 2016, 26, 123–130. [Google Scholar] [CrossRef]

- Huang, R.Z.; Sun, B.; Ohno, N.; Fukanuma, H. Study on the Influences of DPV-2000 Software Parameters on the Measured Results in Cold Spray, in Thermal Spray 2006: Science, Innovation, and Application (ASM International). 2006. Available online: https://www.researchgate.net/publication/268346796 (accessed on 1 November 2021).

- Fukanuma, H.; Ohno, N.; Sun, B.; Huang, R. In-flight particle velocity measurements with DPV-2000 in cold spray. Surf. Coat. Technol. 2006, 201, 1935–1941. [Google Scholar] [CrossRef]

- Mauer, G.; Singh, R.; Rauwald, K.-H.; Schrüfer, S.; Wilson, S.; Vaßen, R. Diagnostics of Cold-Sprayed Particle Velocities Approaching Critical Deposition Conditions. J. Therm. Spray Technol. 2017, 26, 1423–1433. [Google Scholar] [CrossRef]

- Pattison, J.; Celetto, S.; Khan, A.; O’Neill, W. Standoff distance and bow shock phenomena in the Cold Spray process. Surf. Coat. Technol. 2008, 202, 1443–1454. [Google Scholar] [CrossRef]

- Champagne, V.K.; Helfritch, D.J.; Dinavahi, S.P.G.; Leyman, P.F. Theoretical and Experimental Particle Velocity in Cold Spray. J. Therm. Spray Technol. 2011, 20, 425–431. [Google Scholar] [CrossRef]

- Huang, R.; Fukanuma, H. Study of the Influence of Particle Velocity on Adhesive Strength of Cold Spray Deposits. J. Therm. Spray Technol. 2012, 21, 541–549. [Google Scholar] [CrossRef]

- List, A.; Gärtner, F.; Schmidt, T.; Klassen, T. Impact Conditions for Cold Spraying of Hard Metallic Glasses. J. Therm. Spray Technol. 2012, 21, 531–540. [Google Scholar] [CrossRef]

- Suo, X.; Yin, S.; Planche, M.-P.; Liu, T.; Liao, H. Strong effect of carrier gas species on particle velocity during cold spray processes. Surf. Coat. Technol. 2015, 268, 90–93. [Google Scholar] [CrossRef]

- Özdemir, O.Ç.; Conahan, J.M.; Müftü, S. Particle Velocimetry, CFD, and the Role of Particle Sphericity in Cold Spray. Coatings 2020, 10, 1254. [Google Scholar] [CrossRef]

- Schiller, L.; Naumann, A. Über die grundlegenden Berechnungen bei der Schwerkraftaufbereitung. Vdi Zeits 1933, 77, 318–320. [Google Scholar]

- Haider, A.; Levenspiel, O. Drag Coefficient and Terminal Velocity of Spherical and Nonspherical Particles. Powder Technol. 1989, 58, 63–70. [Google Scholar] [CrossRef]

- Wadell, H. The Coefficient of Resistance as a Function of Renoylds Number for Solids of Various Shapes. J. Frankl. Inst. 1934. [Google Scholar] [CrossRef]

| Temperature (°C) | Pressure (Bar) | N2/He Ratio (%/%) |

|---|---|---|

| 850 | 40 | 100/0 |

| 950 | 40 | 100/0 |

| 1100 | 50 | 100/0 |

| 1100 | 50 | 75/25 |

| Mode | Force | Speed | Length | Tip | Radius |

|---|---|---|---|---|---|

| progressive | 1–200 N | 2.5 mm/min | 5 mm | truncated diamond cone | 200 µm |

| Parameter Setting | Impact Speed (m/s) | CSM | Impact Temperature (°C) | ||

|---|---|---|---|---|---|

| 15 µm | 35 µm | 15 µm | 35 µm | ||

| 850 °C | 706 | 612 | 717 ± 106 | 422 | 618 |

| 950 °C | 734 | 629 | 775 ± 114 | 487 | 699 |

| 1100 °C | 782 | 680 | 796 ± 114 | 575 | 814 |

| 1100 °C, 25% He | 860 | 726 | 863 ± 121 | 489 | 749 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lindner, T.; Löbel, M.; Grimm, M.; Fiebig, J. Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder. Metals 2022, 12, 30. https://doi.org/10.3390/met12010030

Lindner T, Löbel M, Grimm M, Fiebig J. Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder. Metals. 2022; 12(1):30. https://doi.org/10.3390/met12010030

Chicago/Turabian StyleLindner, Thomas, Martin Löbel, Maximilian Grimm, and Jochen Fiebig. 2022. "Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder" Metals 12, no. 1: 30. https://doi.org/10.3390/met12010030

APA StyleLindner, T., Löbel, M., Grimm, M., & Fiebig, J. (2022). Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder. Metals, 12(1), 30. https://doi.org/10.3390/met12010030