Abstract

Lightweight materials are in constant progress due to the new requirements of mobility. At the same time, it is mandatory to meet the internal standards of the original equipment manufacturers to guarantee product quality, and market regulations are necessary to reduce or eliminate pollution emissions. In order to reach these technical requirements, the design is optimized, and new materials and alloys are evaluated. The search for these new types of materials is long and expensive. For this search, new technologies have emerged, such as integrated computational materials engineering, which is a valuable tool to forecast through simulation alloy characteristics that meet specific requirements without fabrication. This research develops an artificial neural network to establish the chemical composition of a new aluminum alloy based on the desired manufacturing characteristics as well as fatigue strength. For this, the proposed artificial neural network was trained with the chemical composition of preexisting aluminum-based alloys and the resulting desired mechanical properties. The significant contribution of the proposed research consists not only of the neural network high-performance forecasting but also the fact that for to train and validate it, not only simulations of its responses to the different possibilities of alloys were tried but also validated through an experimental laboratory test performed by uniaxial machine. The proposed artificial neural network results show an average correlation of 99.33% between its forecasting and laboratory testing.

1. Introduction

New materials and alloys for products with specific applications have become a growing need within the modern industry. Where development times are shortened, resources are managed with new methods that guarantee the reduction in manufacturing times. Consequently, tools such as integrated computational materials engineering are based on principles where computation contributes to generating new materials, reducing the cost and time of the design phases [1]. was employed to develop different alloy materials, such as iron, titanium, and aluminum, among others. Aluminum alloys are of interest due to their profitable properties, cost and applications.

The aluminum casting industry plays an essential part in the metal-mechanic industry since it occupy the second place in the construction of different parts after iron. The feature and mechanical properties of the aluminum alloys could be improved with regard to the type of additive elements. An aluminum material is selected based on its importance; after iron, it is the second material used in construction [2]. It is used in different transportation methods, such as in aircraft, where it is employed due to its strength against corrosion, mechanical loads and UV protection [3,4]. In automotive vehicles, aluminum is used in body, wheels, powertrain and chassis components; some geometries are built with castings due to a high volume production. Casting is the solidification of a melt in a mold. It can be performed via different processes such as shaw, investment and permanent molds such as gravity, low-pressure die casting, squeeze casting, semi centrifugal and centrifugal die casting [5,6].

Aluminum alloys can be customized through additive elements. The structure generated by the alloys and the process develop the material structure and its homogenization, which are important for the component process and its mechanical properties. The alloys depend on the required factor, and mechanical properties treatments (forging, rolling, etc.), heat treatments (quenching, annealing, etc.) and elements treatments . and improve in mechanical strength while maintaining deformability. Using , , and does not alter its flowability, and by adding and , its machinability is improved [7].

The relationships in materials for chemical composition and its result in mechanical properties are nonlinear; this depends on microstructure and alloying elements in the processing variables. Aluminum alloy fatigue strength depends on its chemical composition; with a high content of Si, Fe, and Mn, the reduction in fatigue life is significant [8]; increasing the Si content also decreases its capability to manage the impact, increasing the number of a cracks in a matrix resulting in a reduction in the resistance of crack initiation [9]. Another source of detrimental microstructural effects is porosity and nonmetallic inclusion [10,11]. These inhomogeneities can be introduced to strengthen the metal matrix or by its process [12], while porosity results from entrapment gases and their rejection during solidification, and voids are the result of volume contraction during cooling.

A typical casting process includes gravity die casting and lost foam casting [13]. The fabrication process of gravity sand-cast generates residual stresses, affecting the fatigue strength due to the casting process [14].

In order to analyze the expected strength of the aluminum alloy, the chemical composition, mechanical response and manufacturing process are evaluated using numerical tools. Genel [15] demonstrated that could be used to predict the strain-life fatigue properties using monotonic properties. Dini et al. [16] applied to define the mechanical behavior of materials inducing plasticity in steel for transformation-induced plasticity steel and twinning-induced plasticity . Sabhani [17] analyzed its mechanical properties by analyzing parameters such as the temperature gradient in the cooling rate with to predict the monotonic response. Figueria Pujol and Andrade Pinto [18] introduced a novel approach to fatigue life prediction under step-stress conditions using a feedforward neural network. Fu et al. [19] proposed a back-propagation neural network to predict the mechanical properties of magnesium alloys using microhardness. can be used to predict mechanical properties, but also the microstructure of alloys, which are dependent on parameters such as temperature and time, means and rate of cooling [20]. have also been employed to predict the Vickers hardness of alloys, as proposed by Abd El-Rehim et al. [21]. Alam et al. [22] developed an to estimate the lattice parameters of the composite materials, which are complex systems involving combinations of materials, but their behavior is also influenced by the direction of how the material is placed on the component. The change of properties as a function of the measurement direction in a component generates anisotropic materials. Xie et al. [23] proposed a to obtain the properties through non-destructive methods using indentation tests to predict anisotropy. Another material with complex structures is shape memory alloys; their behavior is affected by thermodynamic parameters obtaining deformation and energy deformation capacities [24,25]. By predicting the mechanical behavior of an alloy, it paves the way for proposing the constitutive equation of the material, Cheng et al. [26] proposed the use of neural networks for the development of constitutive equations for alloys.

Vassilopoulos [27] proved the feasibility of using for modeling the fatigue life of composite materials. Jun li et al. [28] proposed a feedforward neural network model with backpropagation based on the Levenberg–Marquardt algorithm for very-high-cycle fatigue analysis. Camara et al. [29] developed an ANN capable of estimating the fatigue behavior of aluminum overhead conductors. The work of Oliveira et al. [30] introduced a new ANN approach to forecast the effects of mean stress, stress gradient and size on fretting life using non-local parameters. Zhan et. al. [31] presented the prediction of fatigue life through a combination of the continuum damage mechanics-based fatigue models and a multi-layer perceptron . Pierce [32] analyzed fatigue life in glass fiber composite sandwich materials using a neural network. Janezic [33] proposed an approach to describe the scatter of a cyclic stress–strain curve using a hybrid neural network. Durodola [34] proposed an to predict fatigue damage, including the effect of mean stress in the frequency domain. Li et al. [35] proposed a fuzzy-filtered neural network to predict material fatigue using a new training method called conjugated Levenberg–Marquardt (CLM), representing an improvement in terms of efficiency and convergence. Lofti and Beiss [36] predicted the process parameters on powder metallurgy and its effect on the endurance limit using a neural network; this develops an optimized tool to define the optimum material composition and process condition based on target fatigue strength.

In this work, was developed to design an aluminum alloy based on the chemical composition. The components were melted in with four different compositions also used as the input; different studies were developed to implement neural networks in the prediction of the different mechanical properties under quasi-static load requirements; this work developed, implemented and validated the synthetic information parameters to perform the prediction of fatigue life under dynamic considerations. The proposal was validated with experimental results using the uniaxial test. The average error of the prediction was 0.67%, and the input information was obtained through different experimental tests, including 52 fatigue tests to describe the chemical composition; analyses for each batch of material proposed, each of which represented different combinations of binders; and 16 chemical analyses and 360 hardness measurements.

2. Fatigue Life Prediction Using ANN

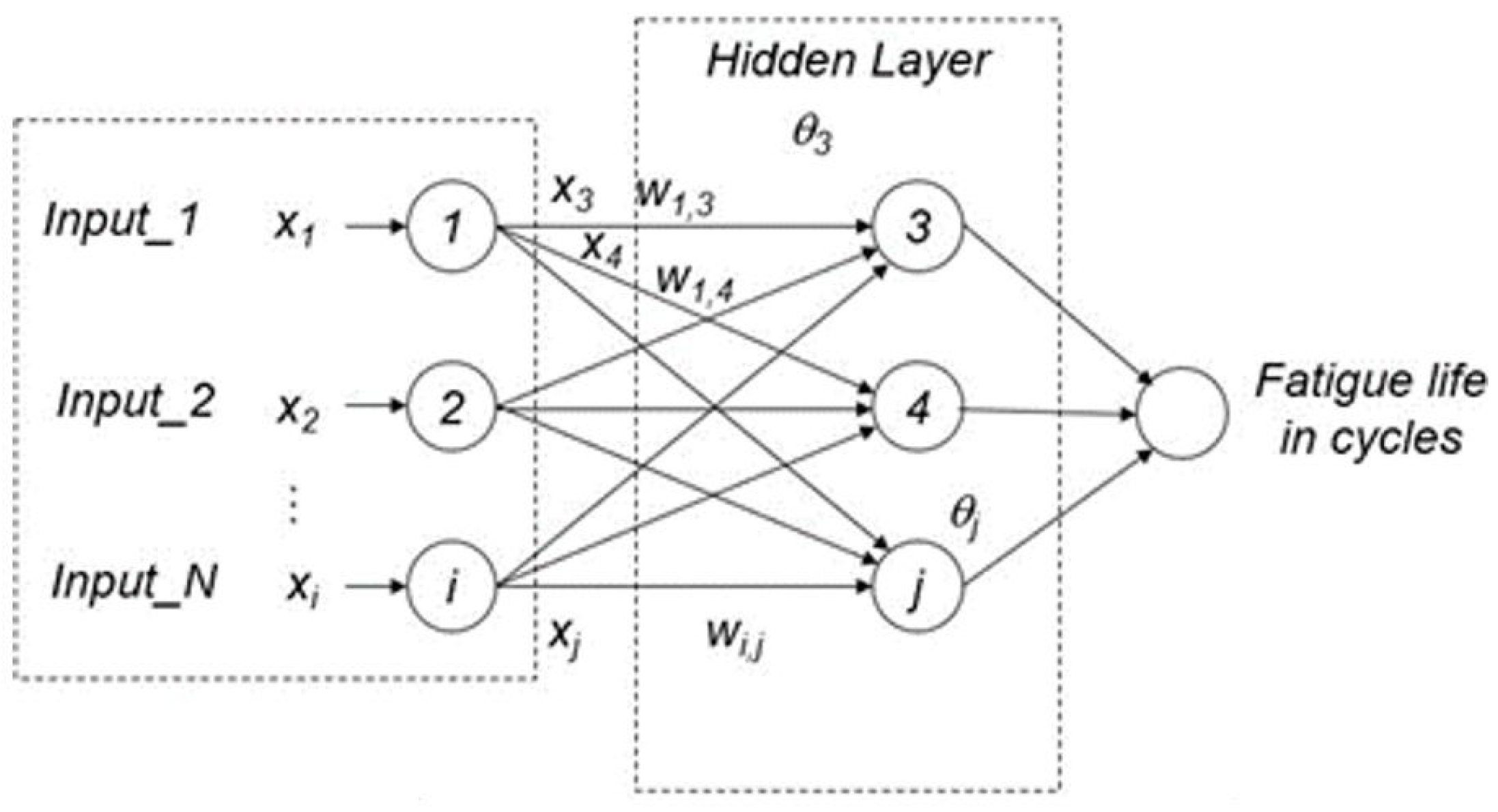

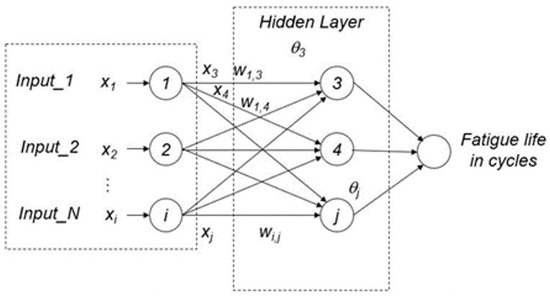

is a tool for the designer to develop new concepts and analyze its mechanical response in and ; Orbanic and Fajdiga [37] proposed to free fatigue and in different materials as nanocomposites. Aluminum alloys have low weldability using the traditional fusion process, so Shojaeefard et al. [38] proposed a friction process using to join the cast and wrought aluminum alloys. An was implemented to analyze the nonlinear phenomenon; it considers all connections between inputs and responses to evaluate the effect of interconnections (synapses). Synaptic weights are internal parameters modified based on the process responses by themselves. By extracting the relationships of inputs and expected behaviors among the input, hidden, and output layers, Figure 1 shows a feed-forward network.

Figure 1.

ANN topology.

The activation function influences the training process. It models the non-linearities in the data; as such, in this work, a sigmoid function was selected, even though there are others. Most authors recommend the sigmoid one due the fact that, in most cases, it describes non-linearities sufficiently well. It is expressed by:

where x is the weighted sum of the input.

The prediction is evaluated by comparing the output against the expected responses using statistical parameters such as the mean squared error and mean absolute percentage error to monitor the process as a supervised learning process.

The topology of the network can change according to the hidden units , the relationships on the input vector , the parametric vector and the elements around it; it is important to remark that these relationships influence the learning process. The radial neural networks are expressed as follows:

The Gaussian activation function is shown in Equation (5)

The unknown parameters are evaluated to minimize the error between the desired output and the network output . To update the weight and reduce the error, the backpropagation learning algorithm is expressed by

Starting from the output layer m of the network and setting , the application of the chain rule gives rises to

Thus,

For the layer

Then

and

is the activation of neuron i.

By defining the error signal for the neuron of the layer as:

(7) is rewritten as

where is the bias input to neuron I in layer . (14)–(16) indicate how the error signals propagate backwards from the output layer of the network through the hidden layer of the input layer, hence the name “backpropagation”.

The steepest descent minimization of the error function defined by (7) produces the following increments for updating .

where in the output layer

Furthermore, in other layers

The constants and represent the learning rates for the weights and biases, respectively. Although a large value of learning reduces the learning times process, it results in oscillations and divergence. To avoid it, a moment term is included, so (20) and (21) become

where and are momentum constants which determine the effect of the past changes of and on the current updating direction in the weight and the bias space, respectively. This effectively filters out high-frequency variations in the error surface. To summarize, the backpropagation algorithm updates the weights and thresholds of the networks according to

and

The proposed for this work topology has 40 hidden neurons; 70% of the samples are for training and 15% are for validation and testing, respectively. The parameters used to train the are the chemical composition of each batch, hardness, Young modulus, yield stress, and ultimate tensile strength; in addition, a vectorization of the chemical composition was used as synthetic data, and all the chemical elements were normalized using the aluminum as a reference, expressed by:

where chemical element is the composition for every element.

In addition to this, a normalized cycle was used as training data, as shown in Equation (27).

where n is the number the cycles of the specimen under test, are the simples at the load level and N is the number of samples.

3. Mechanical and Chemical Tests

In order to obtain excellent castability while maintaining the mechanical strength, four alloys were proposed—hereafter referred to as batch 1, batch 2, batch 3 and batch 4. The characteristics of each batch are shown in Table 1, which shows the result of the chemical composition using the norm ASTM E1251-17a. Four measurements were made per batch; additionally, statistical values such as the maximum (Max), minimum (Min) and average (Ave) were added in order to make a comparison between batches.

Table 1.

Chemical composition of alloy proposals.

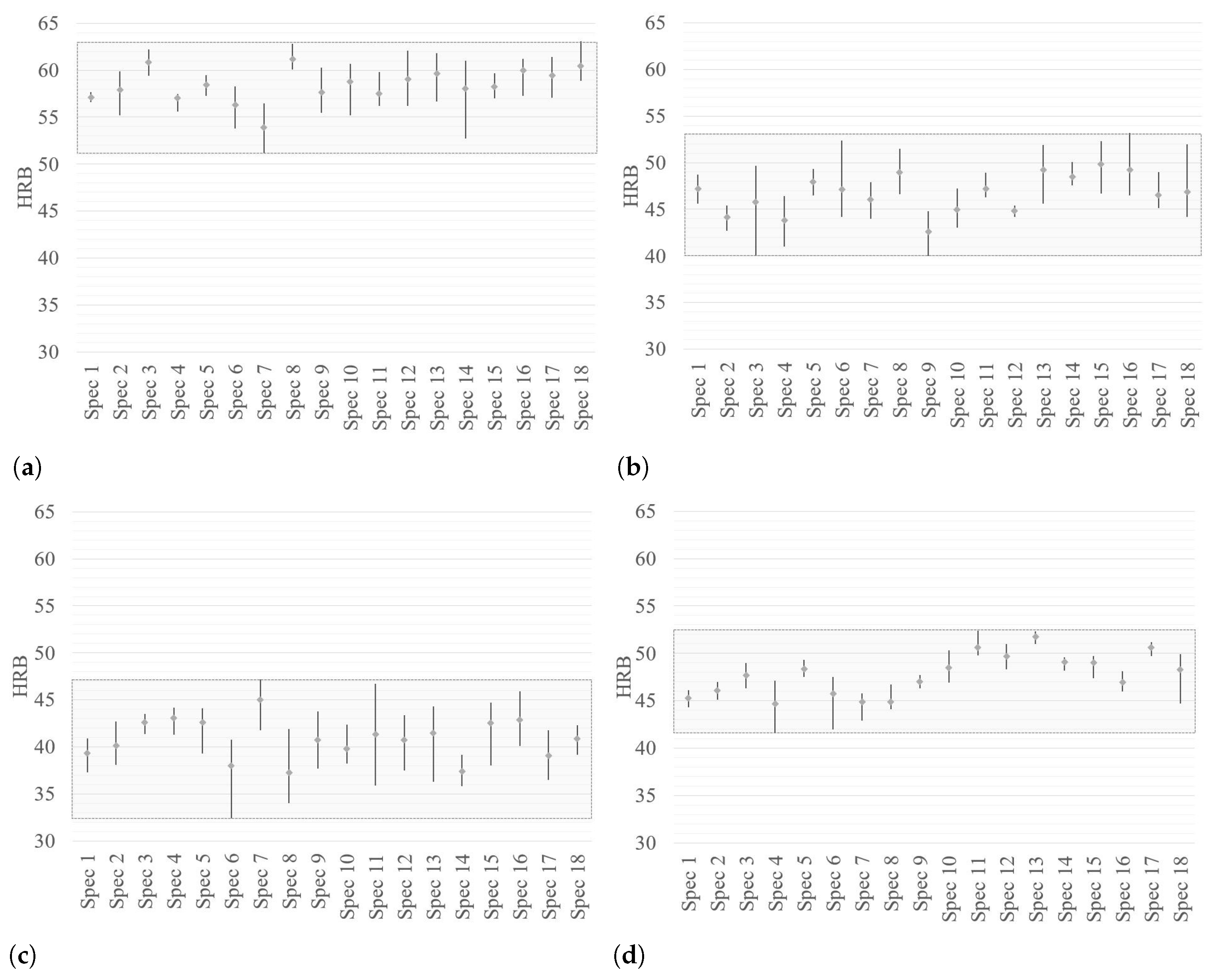

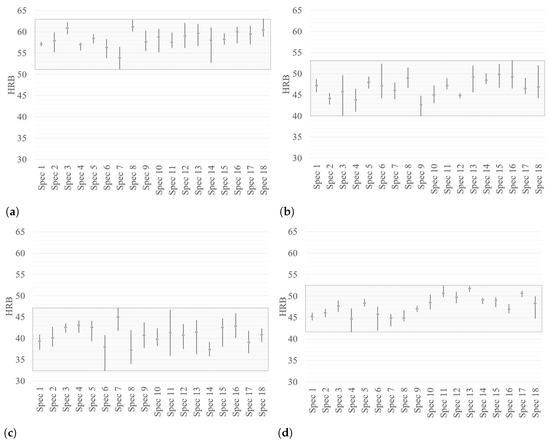

Hardness can be related to the component’s mechanical strength; it can also be used as a parameter to train the . The Rockwell Hardness B scale (HRB) used for the training is based on the average, the maximum and the minimum value of the measurement based on the standard ASTM B648-10. Figure 2 shows the behavior of the different measurements; for each specimen, five measurements were made to guarantee reliability. Hence, the maximum (Max), minimum (min), and mean (Ave) values are reported in Table 2.

Figure 2.

Hardness results: (a) batch 1; (b) batch 2; (c) batch 3; and (d) batch 4.

Table 2.

Hardness measurements summary (HRB).

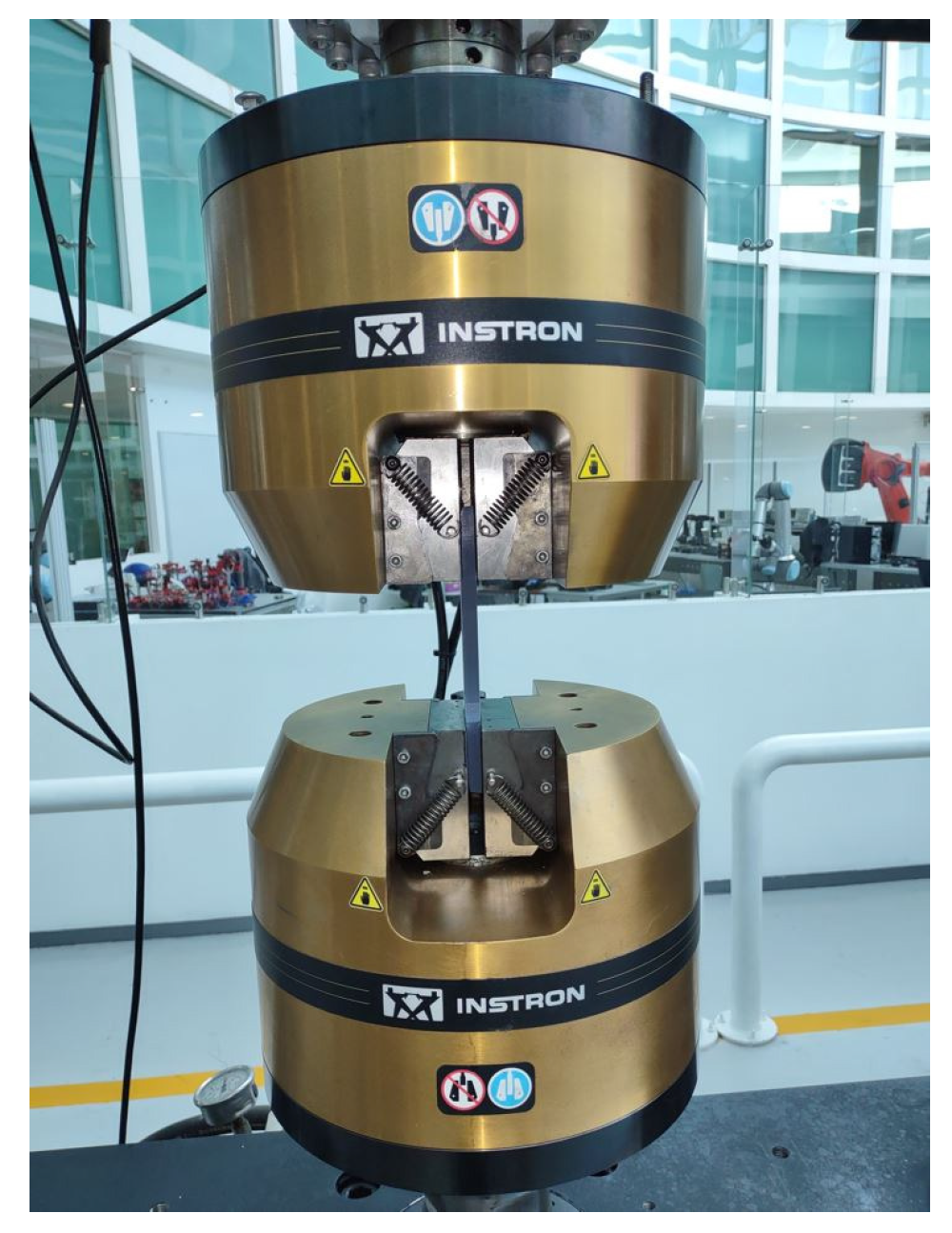

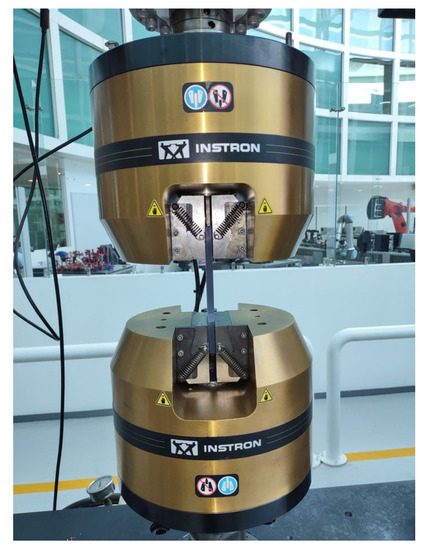

In order to evaluate the mechanical behavior under repeated loads, the experimental fatigue tests were performed on a uniaxial Instron machine, as shown in Figure 3. In this test equipment, the test pieces were mounted to be evaluated under cyclic loads, a force check was carried out, and when there is an increase in displacement of 0.5 mm, the test is automatically stopped to verify the status of the test.

Figure 3.

Uniaxial fatigue test.

4. Results and Discussion

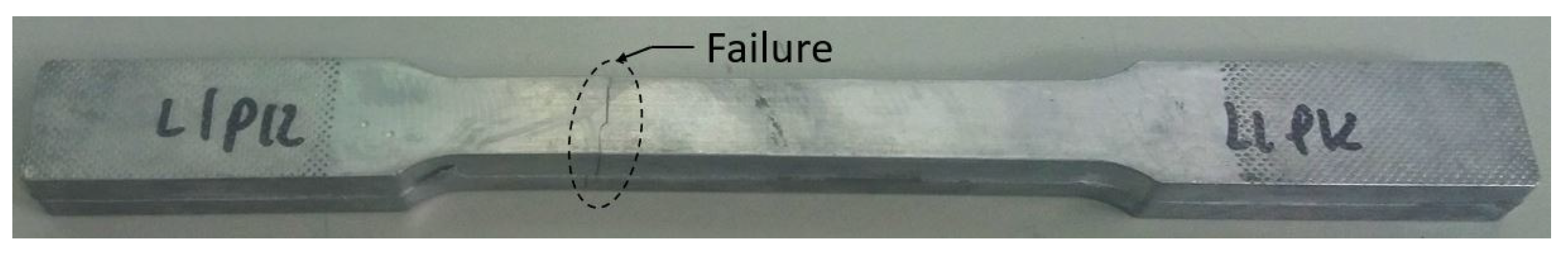

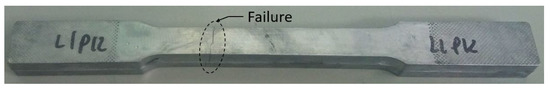

To analyze the test result, when the fatigue test stops and presents some kind of failure, it is disassembled for a physical inspection. All the components have the same kind of failure, as shown in Figure 4. This failure is located in the central area of the geometry.

Figure 4.

Crack in the specimen under test.

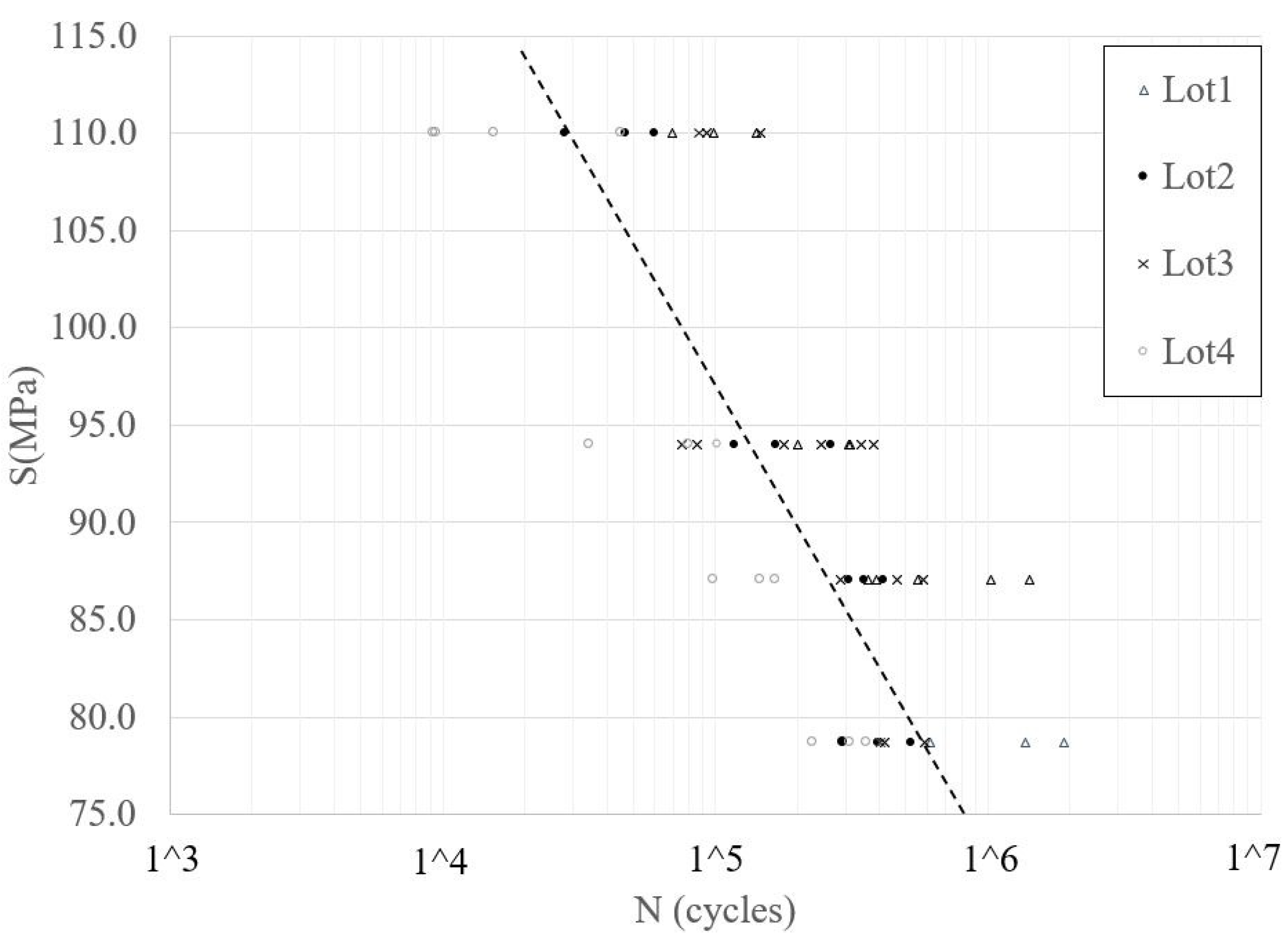

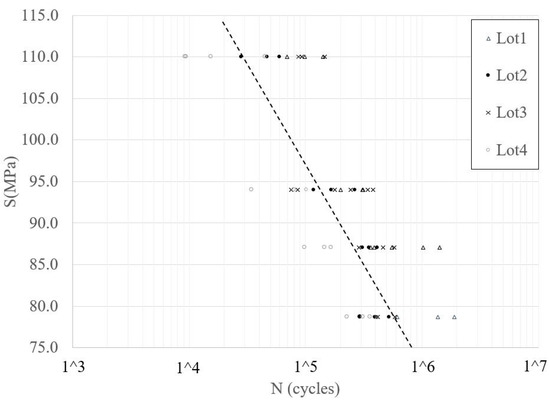

Figure 5 shows the fatigue experimental test results for the four batches at different load levels; this amplitude-cycles (S-N) tendency shows the trend at different load amplitudes. It is possible to observe the global behavior of the four batches, where it is known that batch 1 has greater durability than batch 4 and batch 3 has less dispersion of results at high loads, however, it tends to show a failure before batch 2 at the lowest load.

Figure 5.

Uniaxial fatigue test results.

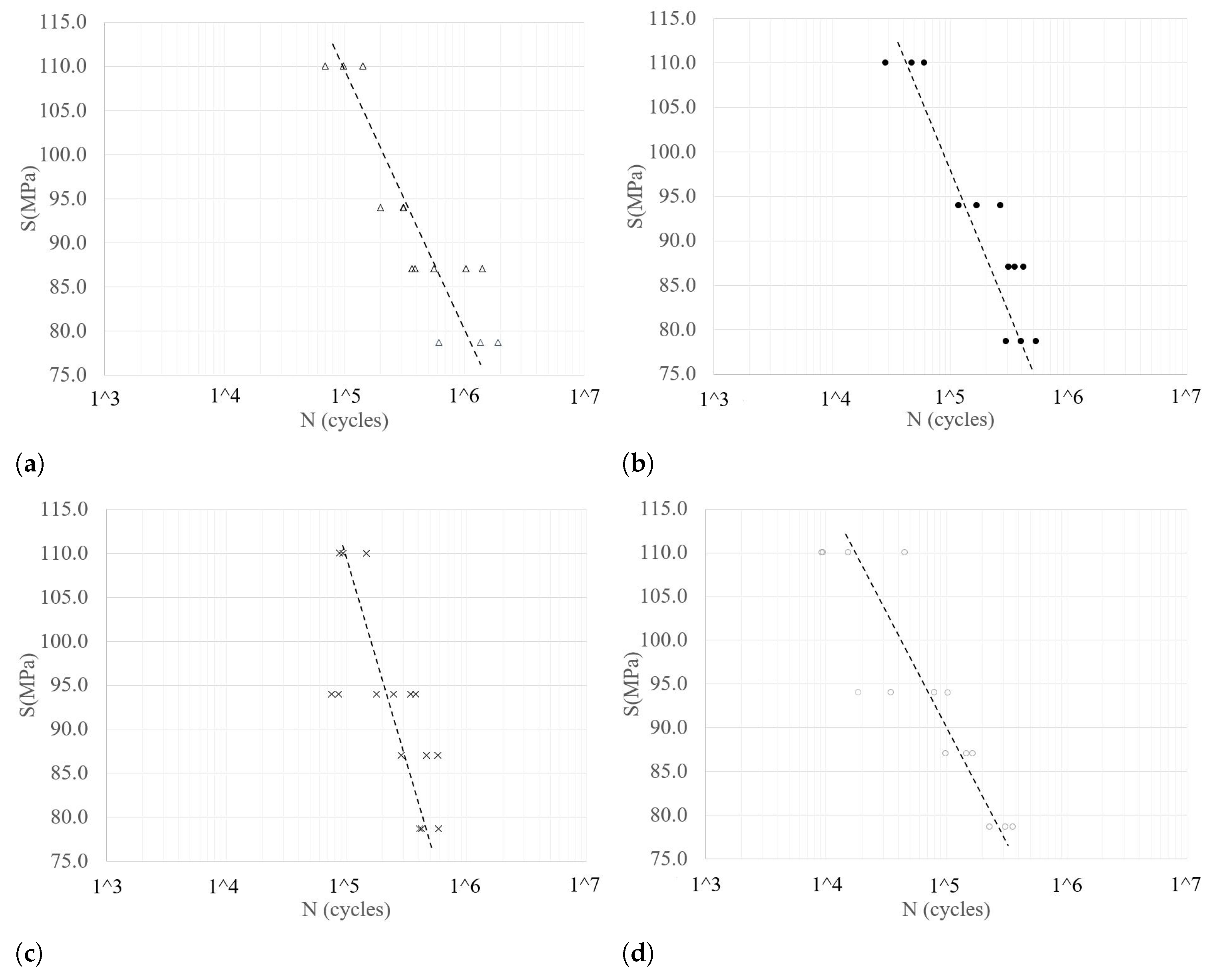

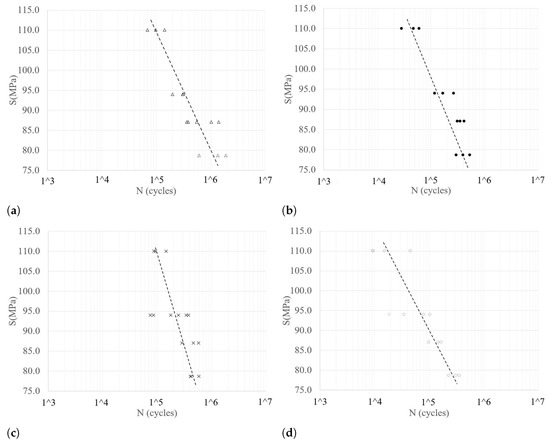

Statistical analysis was performed to evaluate the scatter for each load level per batch; it meets the requirement to have a dispersion below 0.3. The results per batch are shown in Figure 6.

Figure 6.

Experimental fatigue results: (a) batch 1; (b) batch 2; (c) batch 3; and (d) batch 4.

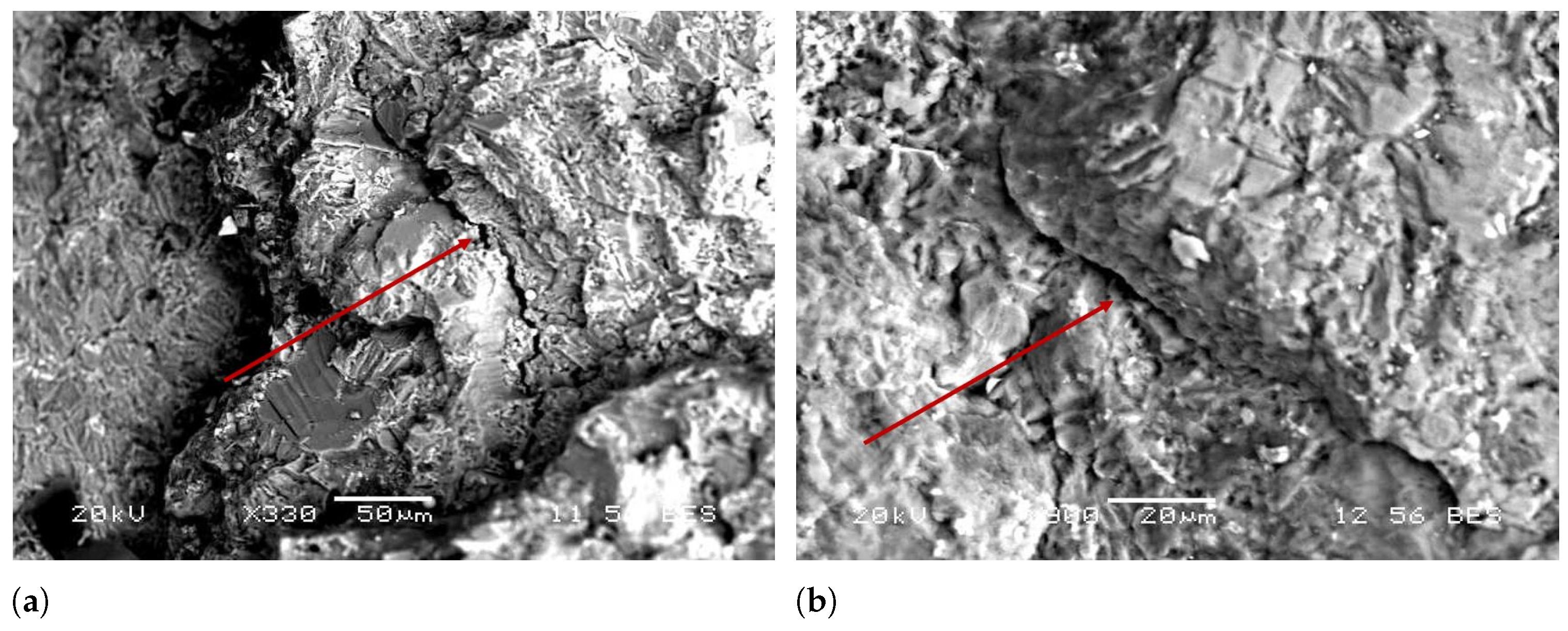

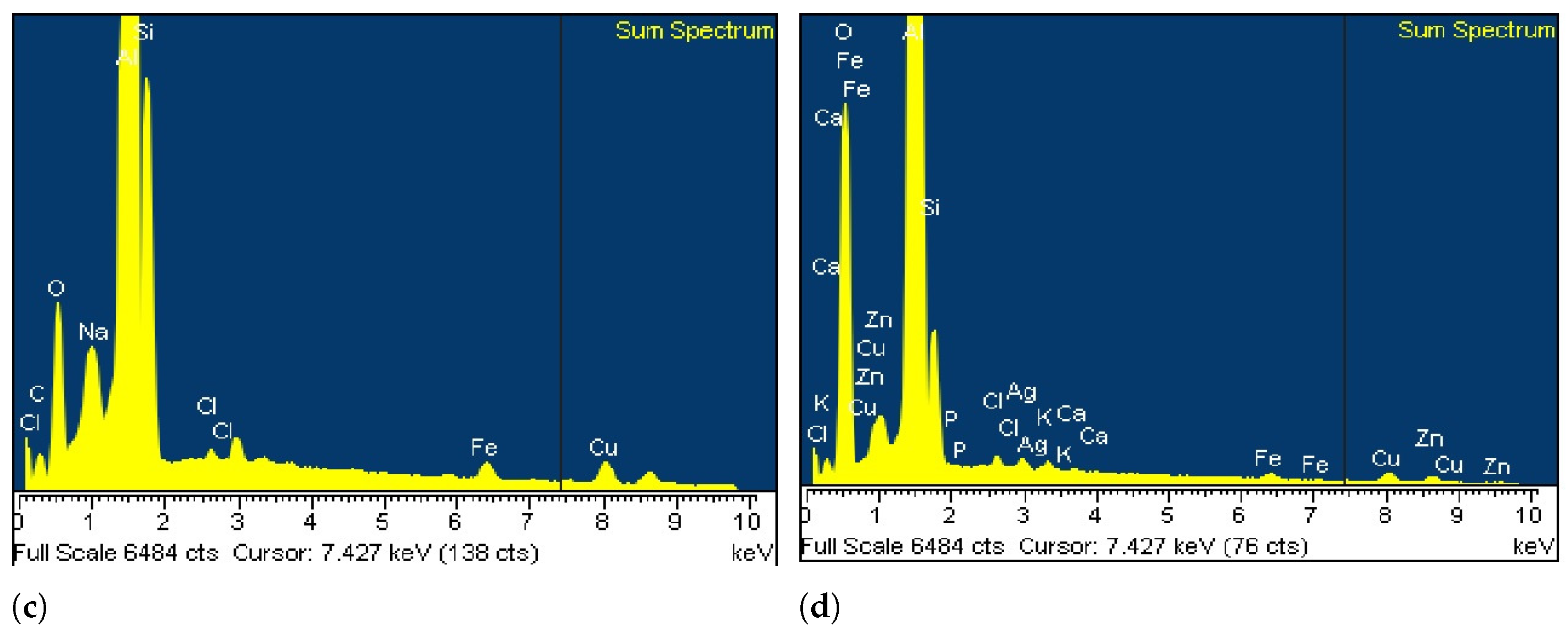

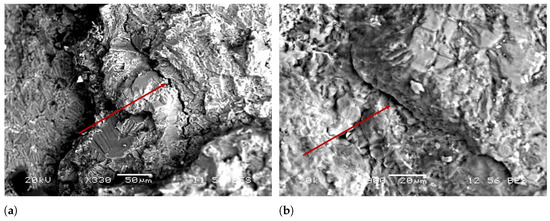

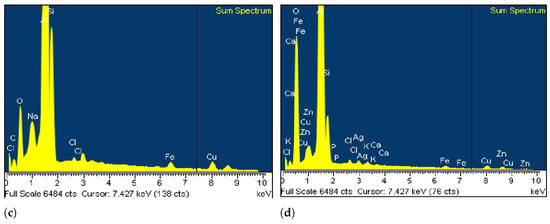

Crack positions were analyzed to identify any pattern, as shown in Figure 7. The alloy components have an effect not only on developing resistance to static loads but also in the manufacturing process of the present casting study, which requires that the material flow uniformly avoids the generation of voids in the component, and that an adequate filling undergoes uniform cooling to develop the homogeneous structure. In components with inclusion, the alumina () is located in failure.

Figure 7.

SEM analysis: (a) batch 3 Part 3; and (b) batch 4 Part 4; (c) composition of failure area; and (d) composition in inclusion.

Although there are four different compositions, the failure is mainly in alumina; the other alloying process does not generate a specific area to generate a crack. However, for the overall behavior, the alloys have different mechanical strengths for hardness and fatigue; there is no presence of slag inclusions. The batch with lower scatter is the second one, as shown in Figure 6. Whereas in the different compositions proposed, the fault is nucleated in the Alumina, it is possible to consider that, for the evaluated alloys, in terms of durability, the alloys do not affect generating failures under dynamic loads at the microstructural level. However, if they change the hardness properties, as seen in Figure 2. The alloys of batches 2 and 4 show similar behavior in terms of Brinell hardness; the highest hardness is obtained with batch 1, and the lowest with batch 2.

5. Conclusions

In the present work, an was proposed through integrated computational materials engineering . The presented algorithm can provide a consistent evaluation of the specific properties according to the chemical composition of the alloy, resulting in a powerful tool for applications such as product design, material selection, and the simulation of mechanical applications.

Through the , new parameters were proposed to generate synthetic fatigue using the chemical composition of the alloy and a normalized parameter based on the experimental failure. The results achieved by the estimation compared with the experimental results found an average prediction error of 0.67%. Based on this result, the material chemical composition can be used in training parameters, including the parameter proposed in Equation (25), the normalized parameter for the cycles improves the forecasting based on the fact that this parameter (Equation (26)) generates a relationship between the result and the average results for each load level; this parameter includes the experimental results scattered in the prediction computation. Thus, it can be shown that the prediction capacity of the is sufficiently high and reliable for use in the industry.

Four different aluminum alloys have been used to train and validate the fatigue strength based on their chemical composition and hardness. It is impossible to extrapolate this prediction to load levels beyond the experimental load case. Numerical tools such as can be used in the mechanical design area to predict its behavior under dynamic tests.

As a result of the performed experiments, the capacity of the to generate alloys with specific applications for the metal-mechanical industry was proven. The experimentation demonstrates that the found alloys have a better capacity for resistance to fatigue than conventional alloys. In this case, the samples from batch 1 that present conventional specification have a lower fatigue resistance than those from batch 2 and batch 3. Therefore, the resulting materials can be used in mechanical devices where the fatigue resistance of either the device or the assembly of the component is important.

The hardness does not have a relationship with the global result of the durability; experimentally, it was also observed that the batch with the highest hardness is batch 1, which also has the highest fatigue resistance, as observed in Figure 6a. On the other hand, batch 3 had the lowest hardness, showing the lowest resistance to fatigue in batch 4 (Figure 6c), which has a hardness similar to batch 3.

The component fatigue prediction has different factors that contribute to increasing the dispersion of results, including material, manufacturing processes, and loads [39]. This work combines two of them by including the chemical composition of the material and the casting process. Some models predict quasi-static behavior based on hardness, but based on the results presented for the case of dynamic loads, it is impossible to obtain a linear relationship. Hence, it is important to use learning processes, such as neural networks, to complement the training process. As such, synthetic parameters for the chemical composition and the fatigue cycles are proposed.

Finally, two points can be established concerning the alloy’s structure and how it is cast in conventional casting processes. First, the alloying elements are uniformly incorporated within the material mixture; this is seen in the evaluation of the cracks present in the specimens, where it can be seen that the predominant element is alumina without the impurities or inclusions within these areas that could cause failures. Second, the materials used to form these alloys are commonly used in the industry, such as automotive scrap, aircraft fuselage, computer parts, and household appliances, making them easily fabricable at large scales.

Author Contributions

Investigation, M.J.-M.; Methodology, M.A.-P.; Resources, C.M.-I. All authors have read and agreed to the published version of the manuscript.

Funding

The APC was funded by Tecnologico de Monterrey.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- An Introduction to Integrated Computational Materials Engineering (ICME). In Integrated Computational Materials Engineering (ICME) for Metals; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2012; Chapter 1; pp. 1–44.

- Tijani, Y.; Heinrietz, A.; Bruder, T.; Hanselka, H. Quantitative evaluation of fatigue life of cast aluminum alloys by non-destructive testing and parameter model. Int. J. Fatigue 2013, 57, 73–78. [Google Scholar] [CrossRef]

- Zavodska, D.; Tillova, E.; Guagliano, M.; Kucharikova, L.; Chalupova, M. Fatigue Resistance of Self-hardening Aluminium Cast Alloy. Mater. Today Proc. 2017, 4, 6001–6006. [Google Scholar] [CrossRef]

- Sonsino, C.; Franz, R. Multiaxial fatigue assessment for automotive safety components of cast aluminium EN AC-42000 T6 (G-AlSi7Mg0.3 T6) under constant and variable amplitude loading. Int. J. Fatigue 2017, 100, 489–501. [Google Scholar] [CrossRef]

- El Khoukhi, D.; Morel, F.; Saintier, N.; Bellett, D.; Osmond, P.; Le, V.D.; Adrien, J. Experimental investigation of the size effect in high cycle fatigue: Role of the defect population in cast aluminium alloys. Int. J. Fatigue 2019, 129, 105222. [Google Scholar] [CrossRef]

- Serrano-Munoz, I.; Buffiere, J.Y.; Verdu, C. Casting defects in structural components: Are they all dangerous? A 3D study. Int. J. Fatigue 2018, 117, 471–484. [Google Scholar] [CrossRef]

- Belayadi, A.; Bourahla, B. Neural network model for 7000 (Al-Z) alloys: Classification and prediction of mechanical properties. Phys. B Condens. Matter 2019, 554, 114–120. [Google Scholar] [CrossRef]

- Ovono Ovono, D.; Guillot, I.; Massinon, D. Study on low-cycle fatigue behaviours of the aluminium cast alloys. J. Alloys Compd. 2008, 452, 425–431. [Google Scholar] [CrossRef]

- Abuhasel, K.; Ibrahim, M.; Elgallad, E.; Samuel, F. On the impact toughness of Al–Si cast alloys. Mater. Des. 2016, 91, 388–397. [Google Scholar] [CrossRef]

- Le, V.D.; Morel, F.; Bellett, D.; Saintier, N.; Osmond, P. Multiaxial high cycle fatigue damage mechanisms associated with the different microstructural heterogeneities of cast aluminium alloys. Mater. Sci. Eng. A 2016, 649, 426–440. [Google Scholar] [CrossRef]

- Zerbst, U.; Klinger, C. Material defects as cause for the fatigue failure of metallic components. Int. J. Fatigue 2019, 127, 312–323. [Google Scholar] [CrossRef]

- Murakami, Y. Material defects as the basis of fatigue design. Int. J. Fatigue 2012, 41, 2–10. [Google Scholar] [CrossRef]

- Dezecot, S.; Maurel, V.; Buffiere, J.Y.; Szmytka, F.; Koster, A. 3D characterization and modeling of low cycle fatigue damage mechanisms at high temperature in a cast aluminum alloy. Acta Mater. 2017, 123, 24–34. [Google Scholar] [CrossRef]

- Koutiri, I.; Bellett, D.; Morel, F.; Augustins, L.; Adrien, J. High cycle fatigue damage mechanisms in cast aluminium subject to complex loads. Int. J. Fatigue 2013, 47, 44–57. [Google Scholar] [CrossRef]

- Genel, K. Application of artificial neural network for predicting strain-life fatigue properties of steels on the basis of tensile tests. Int. J. Fatigue 2004, 26, 1027–1035. [Google Scholar] [CrossRef]

- Dini, G.; Najafizadeh, A.; Monir-Vaghefi, S.; Ebnonnasir, A. Predicting of mechanical properties of Fe–Mn–(Al, Si) TRIP/TWIP steels using neural network modeling. Comput. Mater. Sci. 2009, 45, 959–965. [Google Scholar] [CrossRef]

- SHABANI, M.O.; ALIZADEH, M.; MAZAHERY, A. Modelling of mechanical properties of cast A356 alloy. Fatigue Fract. Eng. Mater. Struct. 2011, 34, 1035–1040. [Google Scholar] [CrossRef]

- Figueira Pujol, J.C.; Andrade Pinto, J.M. A neural network approach to fatigue life prediction. Int. J. Fatigue 2011, 33, 313–322. [Google Scholar] [CrossRef]

- Fu, Y.; Shao, Z.; Liu, C.; Wang, Y.; Xu, Y.; Zhu, X. Modeling the Mechanical Properties of Heat-Treated Mg-Zn-RE-Zr-Ca-Sr Alloys with the Artificial Neural Network and the Regression Model. Crystals 2022, 12, 754. [Google Scholar] [CrossRef]

- Fu, Y.; Liu, C.; Song, Y.; Hao, H.; Xu, Y.; Shao, Z.; Wang, J.; Zhu, X. Modeling of Microstructure and Mechanical Properties of Heat Treated ZE41-Ca-Sr Alloys for Integrated Computing Platform. Crystals 2022, 12, 1237. [Google Scholar] [CrossRef]

- Abd El-Rehim, A.F.; Zahran, H.Y.; Habashy, D.M.; Al-Masoud, H.M. Simulation and Prediction of the Vickers Hardness of AZ91 Magnesium Alloy Using Artificial Neural Network Model. Crystals 2020, 10, 290. [Google Scholar] [CrossRef]

- Alam, M.A.; Ya, H.H.; Azeem, M.; Yusuf, M.; Soomro, I.A.; Masood, F.; Shozib, I.A.; Sapuan, S.M.; Akhter, J. Artificial Neural Network Modeling to Predict the Effect of Milling Time and TiC Content on the Crystallite Size and Lattice Strain of Al7075-TiC Composites Fabricated by Powder Metallurgy. Crystals 2022, 12, 372. [Google Scholar] [CrossRef]

- Xia, J.; Won, C.; Kim, H.; Lee, W.; Yoon, J. Artificial Neural Networks for Predicting Plastic Anisotropy of Sheet Metals Based on Indentation Test. Materials 2022, 15, 1714. [Google Scholar] [CrossRef] [PubMed]

- Lenzen, N.; Altay, O. Machine Learning Enhanced Dynamic Response Modelling of Superelastic Shape Memory Alloy Wires. Materials 2022, 15, 304. [Google Scholar] [CrossRef] [PubMed]

- Hmede, R.; Chapelle, F.; Lapusta, Y. Review of Neural Network Modeling of Shape Memory Alloys. Sensors 2022, 22, 5610. [Google Scholar] [CrossRef] [PubMed]

- Cheng, P.; Wang, D.; Zhou, J.; Zuo, S.; Zhang, P. Comparison of the Warm Deformation Constitutive Model of GH4169 Alloy Based on Neural Network and the Arrhenius Model. Metals 2022, 12, 1429. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P.; Georgopoulos, E.F.; Dionysopoulos, V. Artificial neural networks in spectrum fatigue life prediction of composite materials. Int. J. Fatigue 2007, 29, 20–29. [Google Scholar] [CrossRef]

- Li, J.; Yang, Z.; Qian, G.; Berto, F. Machine learning based very-high-cycle fatigue life prediction of Ti-6Al-4V alloy fabricated by selective laser melting. Int. J. Fatigue 2022, 158, 106764. [Google Scholar] [CrossRef]

- Câmara, E.C.B.; Kalombo, R.; Ferreira, J.; Araújo, J.A.; Júnior, R.C.S.F. Estimating the fatigue behavior of a family of aluminum conductor cables using ANNs applying the Poffenberger-Swart formula. Int. J. Fatigue 2022, 159, 106766. [Google Scholar] [CrossRef]

- Oliveira, G.A.B.; Júnior, R.C.S.F.; Veloso, L.A.C.M.; Araújo, J.A. A hybrid ANN-multiaxial fatigue nonlocal model to estimate fretting fatigue life for aeronautical Al alloys. Int. J. Fatigue 2022, 162, 107011. [Google Scholar] [CrossRef]

- Zhan, Z.; Ao, N.; Hu, Y.; Liu, C. Defect-induced fatigue scattering and assessment of additively manufactured 300M-AerMet100 steel: An investigation based on experiments and machine learning. Eng. Fract. Mech. 2022, 264, 108352. [Google Scholar] [CrossRef]

- Pierce, S.G.; Worden, K.; Bezazi, A. Uncertainty analysis of a neural network used for fatigue lifetime prediction. Mech. Syst. Signal Process. 2008, 22, 1395–1411. [Google Scholar] [CrossRef]

- Janežič, M.; Klemenc, J.; Fajdiga, M. A neural-network approach to describe the scatter of cyclic stress–strain curves. Mater. Des. 2010, 31, 438–448. [Google Scholar] [CrossRef]

- Artificial neural network for random fatigue loading analysis including the effect of mean stress. Int. J. Fatigue 2018, 111, 321–332. [CrossRef]

- Li, D.; Wang, W.; Ismail, F. Enhanced fuzzy-filtered neural networks for material fatigue prognosis. Appl. Soft Comput. 2013, 13, 283–291. [Google Scholar] [CrossRef]

- Lotfi, B.; Beiss, P. Application of neural networking for fatigue limit prediction of powder metallurgy steel parts. Mater. Des. 2013, 50, 440–445. [Google Scholar] [CrossRef]

- Orbanić, P.; Fajdiga, M. A neural network approach to describing the fretting fatigue in aluminium-steel couplings. Int. J. Fatigue 2003, 25, 201–207. [Google Scholar] [CrossRef]

- Shojaeefard, M.H.; Khalkhali, A.; Akbari, M.; Asadi, P. Investigation of friction stir welding tool parameters using FEM and neural network. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2015, 229, 209–217. [Google Scholar] [CrossRef]

- Jimenez-Martinez, M.; Alfaro-Ponce, M. Effects of synthetic data applied to artificial neural networks for fatigue life prediction in nodular cast iron. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 10. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).