A Finite Element Analysis of the Effects of Preheating Substrate Temperature and Power Input on Selective Laser Melting

Abstract

1. Introduction

2. Thermal Modelling

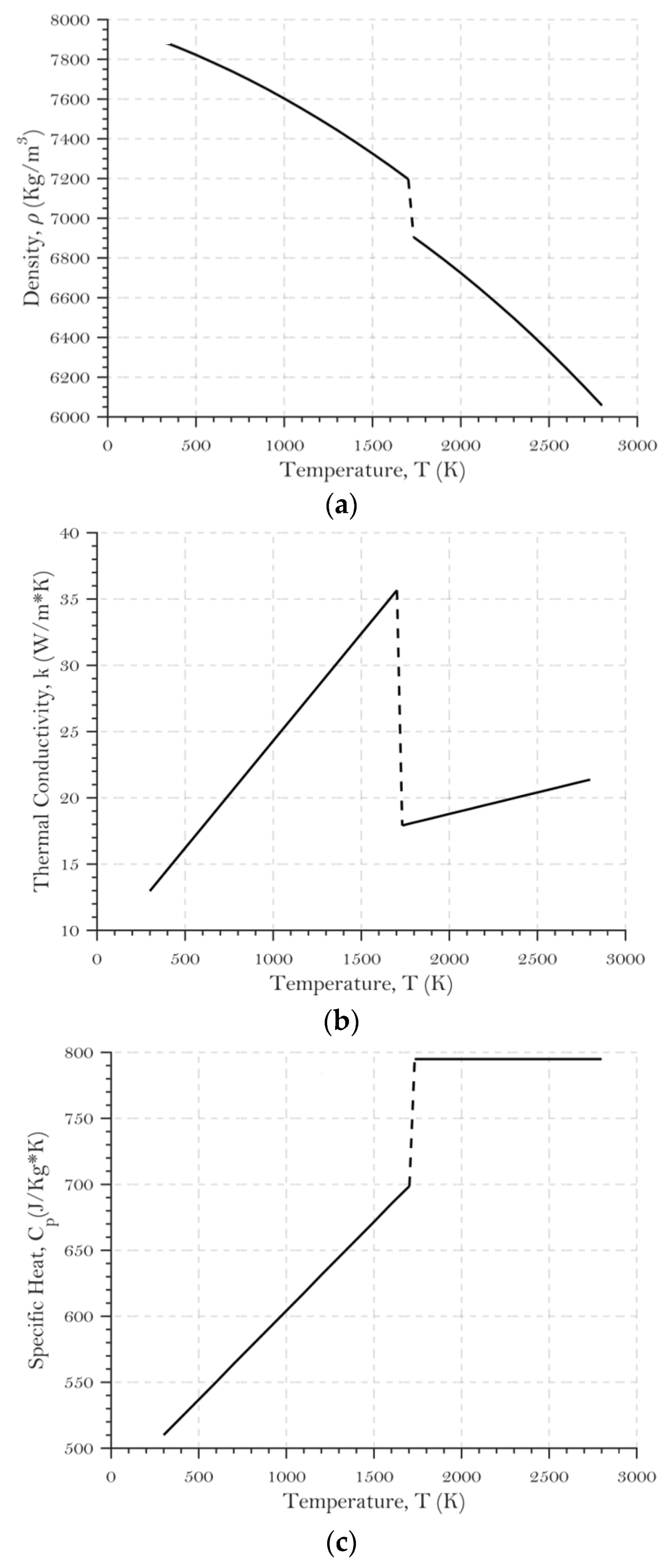

2.1. Powder Properties

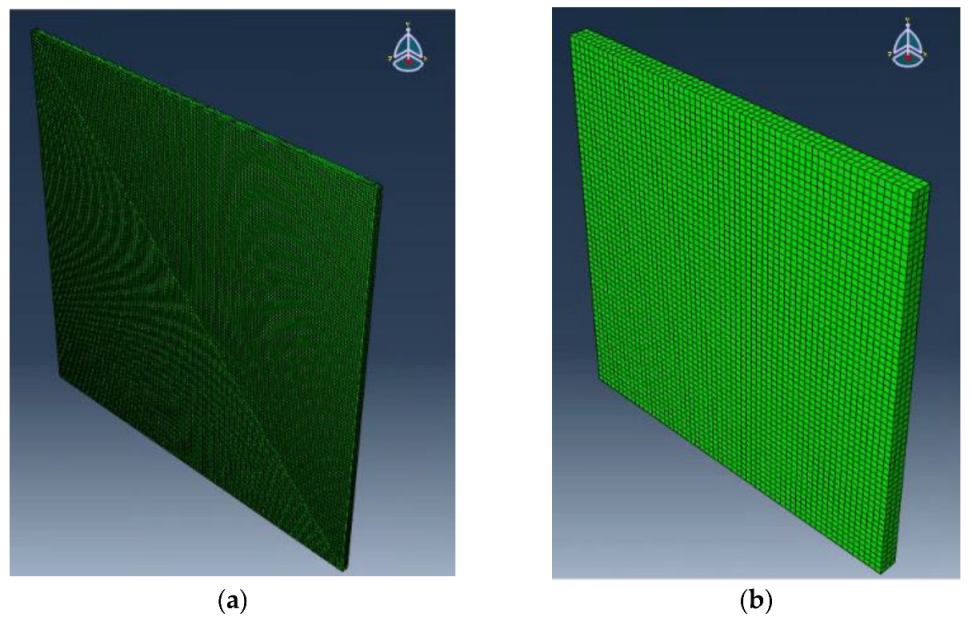

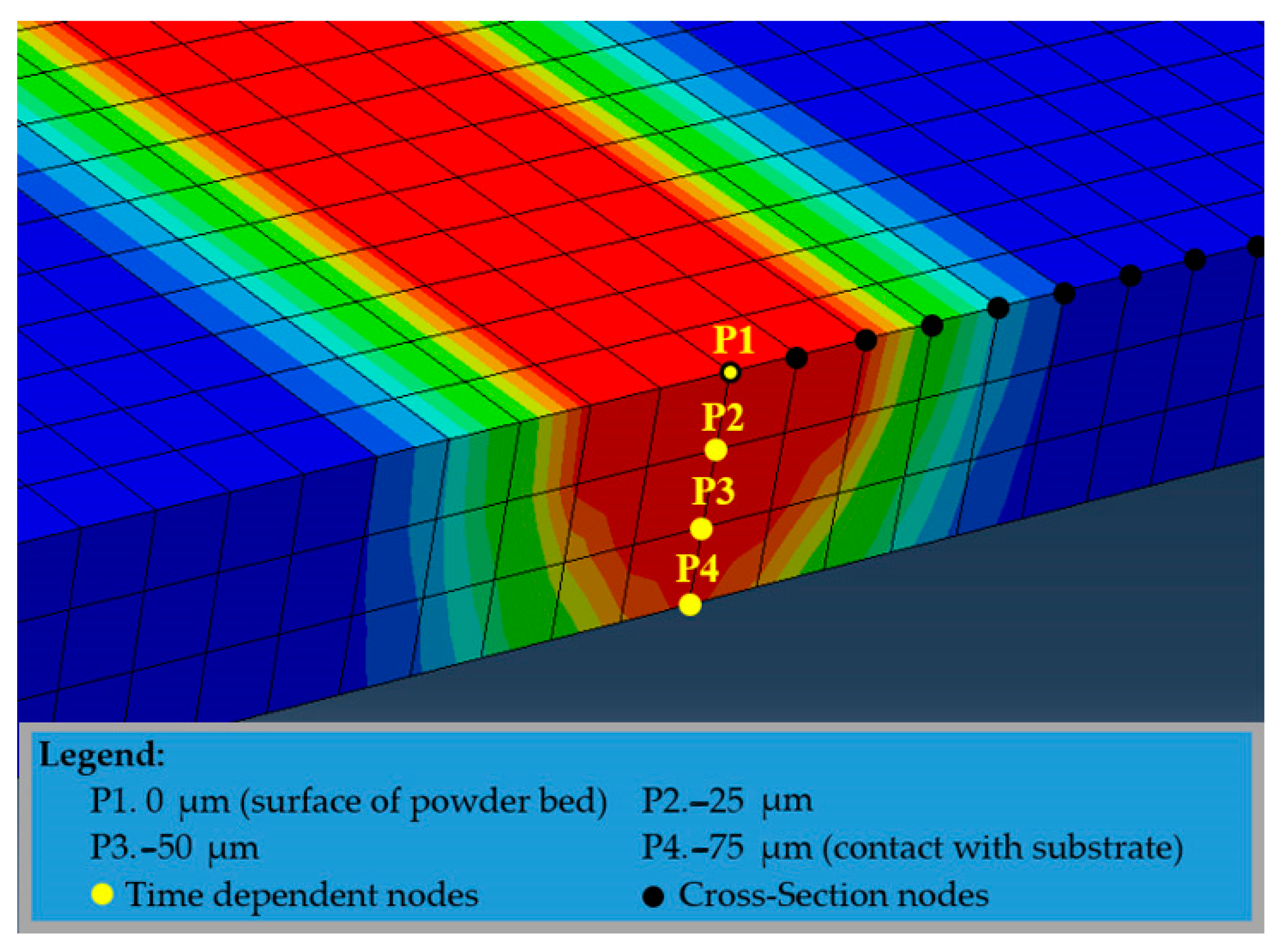

2.2. FEM Thermal Modelling

- -

- Thermo-fluid effects are not included, thus the Marangoni effect and fluid flow in the melt pool are not considered in this study.

- -

- Vaporization of the material is not implemented, but the phenomenon only occurs when utilizing a considerably high laser power input (P = 400 W).

- -

- A single track of laser is simulated, and the influence of the hatch distance is neglected in order to only focus on the effect of the packing structure and particle diameter in the temperature distributions.

- -

- Only the average diameter of powder particles is considered when calculating the effective thermal conductivity of the powder state.

- -

- The contact between powder and substrate was omitted. Instead, the preheat temperature of the substrate is accounted for as a boundary condition in order to isolate the variable and study the effect of the temperature alone within the analysis.

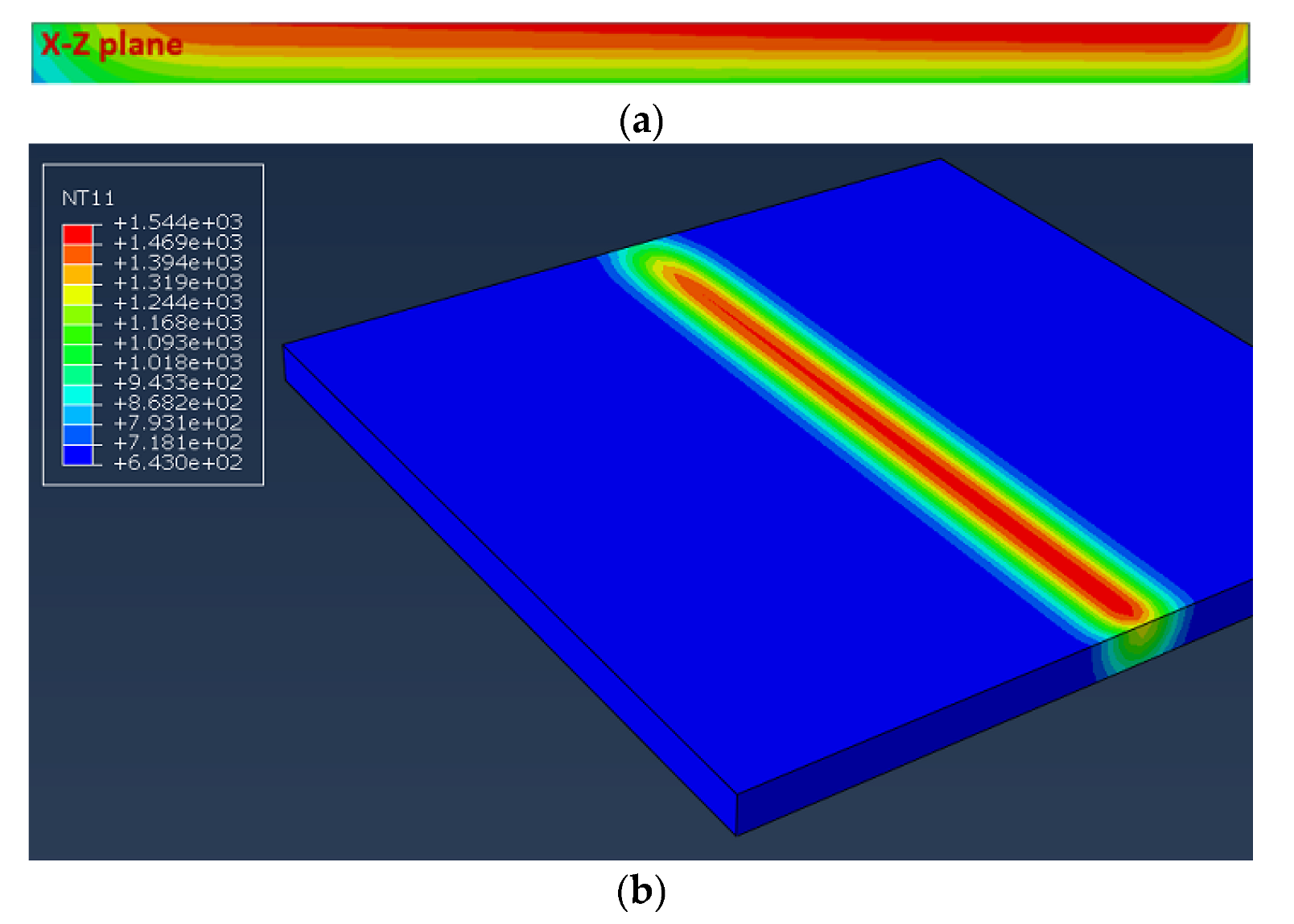

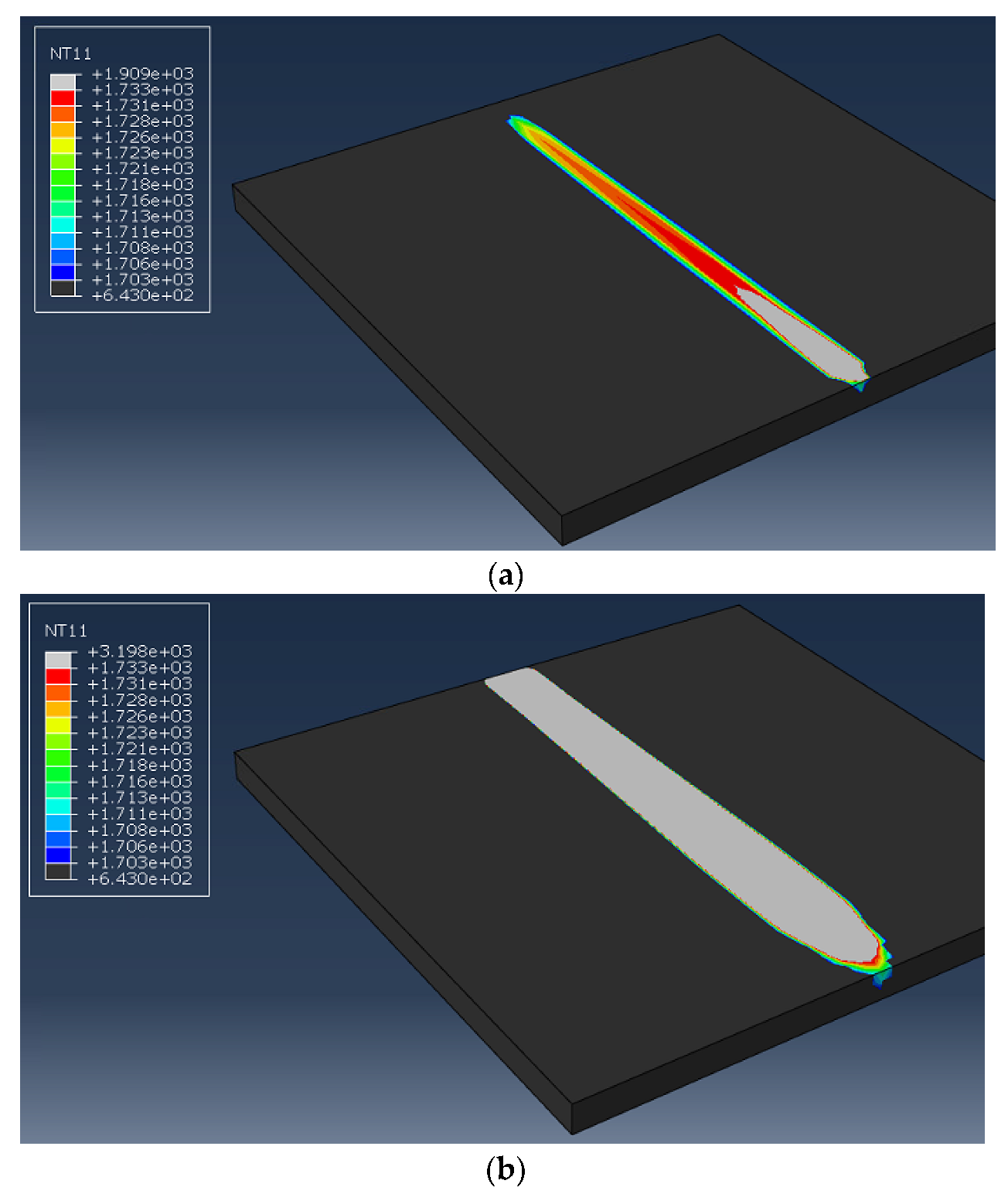

2.3. Model Verification

3. Sensitivity Analysis of Substrate Temperature and Power Input

| Parameters | Values |

|---|---|

| Latent heat of fusion, Lf [J/Kg] | 273,790.0 [9] |

| Solidus temperature, Ts [K] | 1703 [9] |

| Liquidus temperature, TL [K] | 1733 [9] |

| Porosity of the bed, φ [%] | 0.467 [13] |

| Solid emissivity, ε | 0.44 [27] |

| Powder emissivity, εp [ ] | 0.6 [13] |

| Preheat Temperature, T0 [K] | 298, 373, and 648 [3] |

| Absorption coefficient, ηabs [ ] | 0.40 [26] |

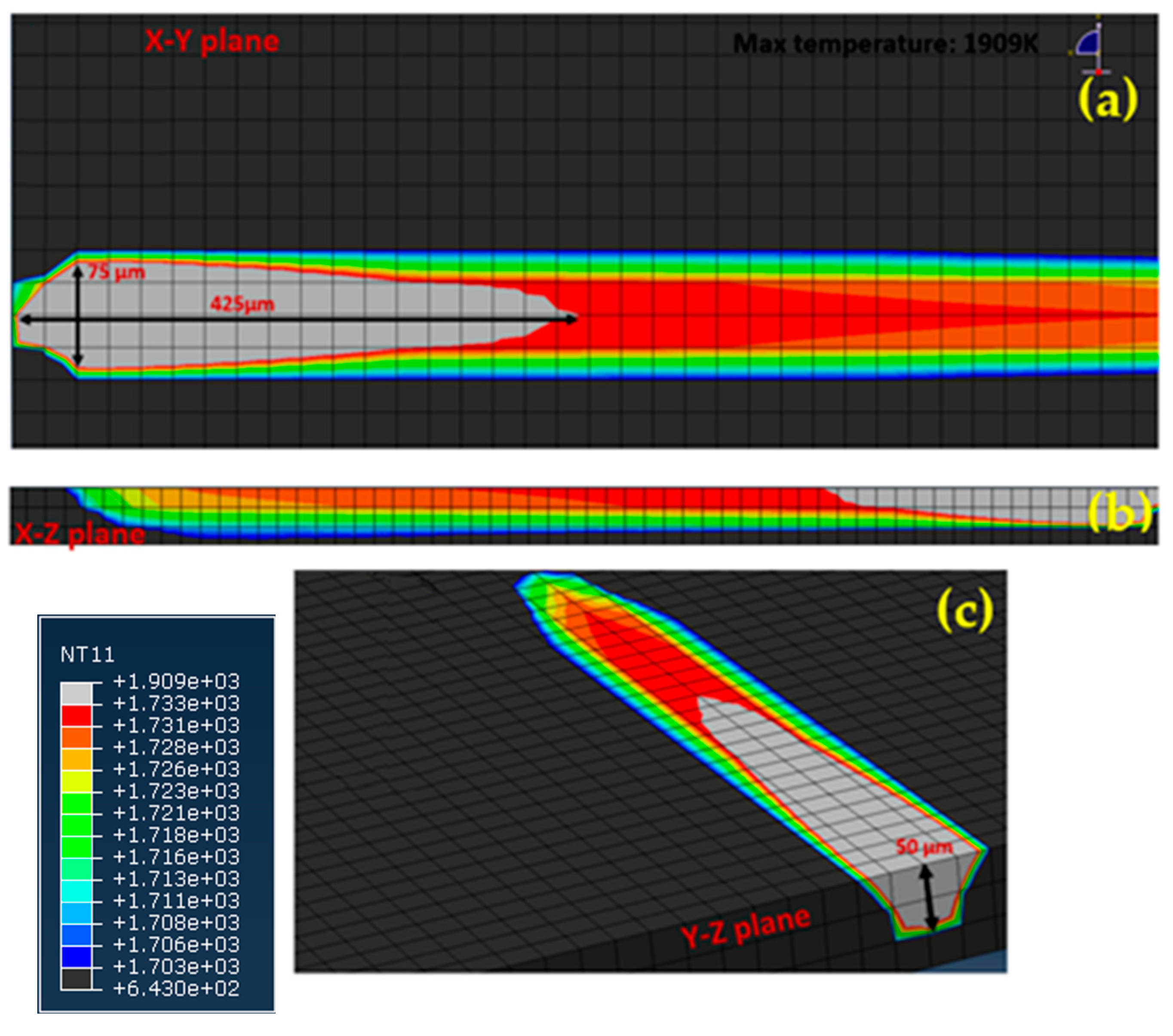

| Laser spot diameter, [µm] | 50 [3] |

| Layer thickness, [µm] | 75 [3] |

| Laser Power input, P [W] | 100, 200, 400 [3] |

| Scanning speed, v [m/s] | 1.0 [3] |

| Average powder diameter, xR [µm] | 20 [28] |

| Convection coefficient, h [W/(m^2K)] | 10 [29] |

| Gas thermal conduct, kg [W/mK] | 0.016 [30] |

| Time step, t [ms] | 1.5 [13] |

4. Melt Pool Analysis

5. Discussion

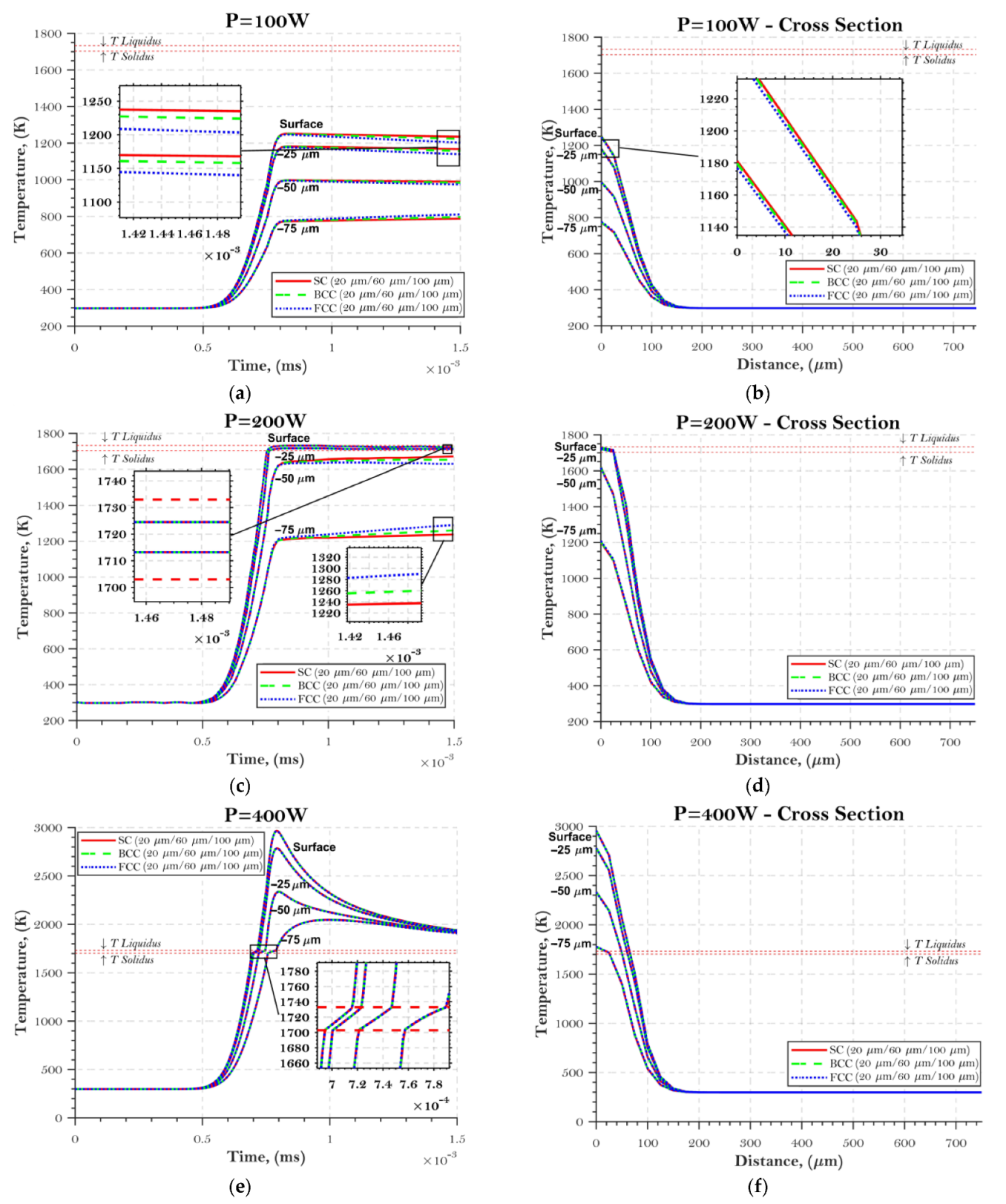

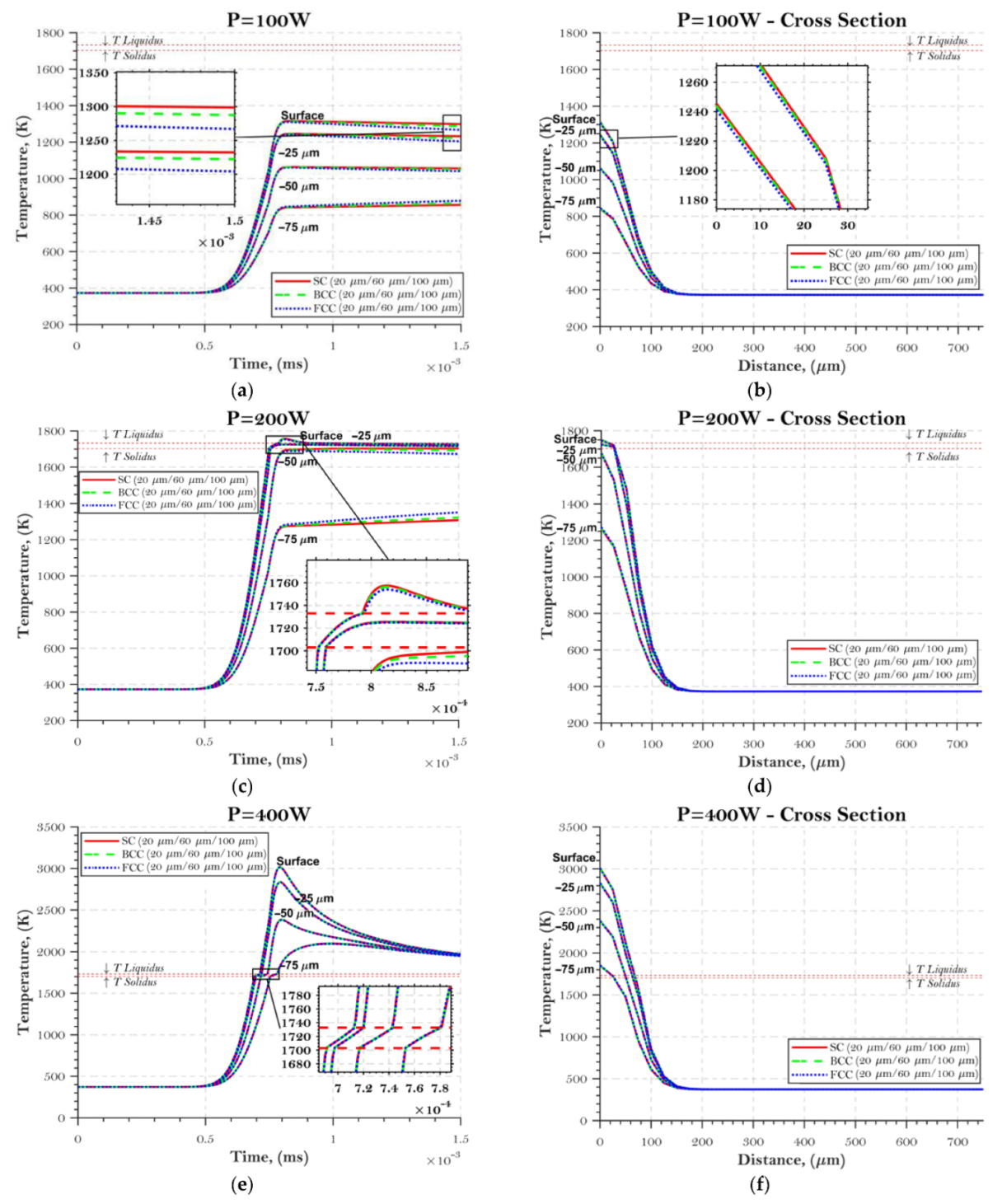

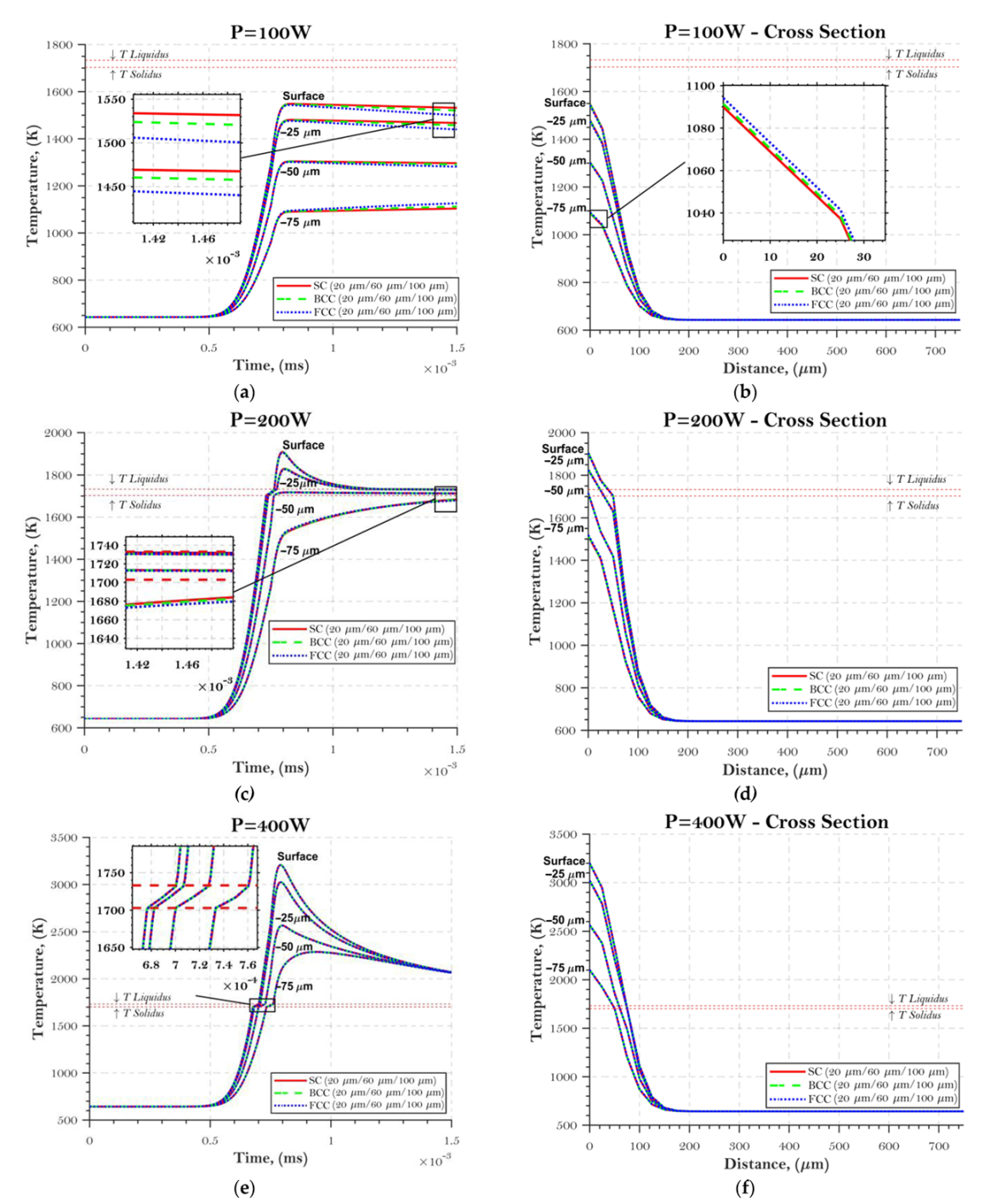

- was the lowest power input at which temperatures did not reach the melting point. According to Gibson, the powder can sinter at half the melting point temperatures, and in the current investigation, the achieved was around for . The of the material was , more than enough for necking to occur among the particles. However, we cannot draw further conclusions on the degree to which the material would effectively consolidate since the temperature mentioned is only at the surface of the powder bed. On the bottom surface, the temperature was , sufficient to start the sintering between the particles at a smaller scale. is strongly recommended to be used with , given the aforementioned statements. When using and , the achieved was around and , respectively, and the was around and , on the threshold of the sintering condition mentioned by Gibson and thus not enough to fully consolidate the material.

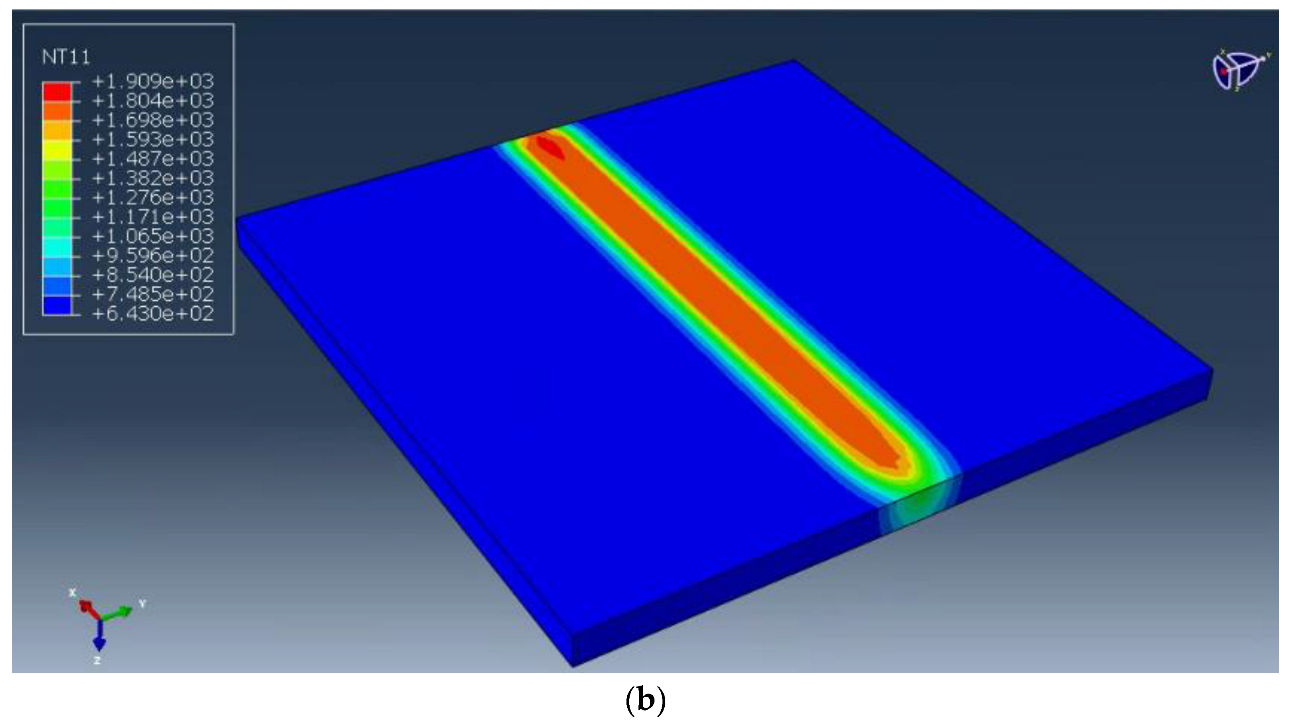

- is the ideal situation among all the power inputs analyzed, given the melt pool behavior and the temperature gradients. For , we achieved the optimal temperature gradient of , the lowest of all the conditions simulated, and thus this temperature is strongly recommended with this power input. The main reason is that the temperature distribution was just enough to reach the for , , and , with a . In this case, when the temperatures are between the and , the latent heat of fusion plays an important role, consuming most of the heat to change the phase from the solid state to liquid and vice versa. For this reason, the temperature gradient is relatively small compared to other power inputs, even for the other substrate temperatures.

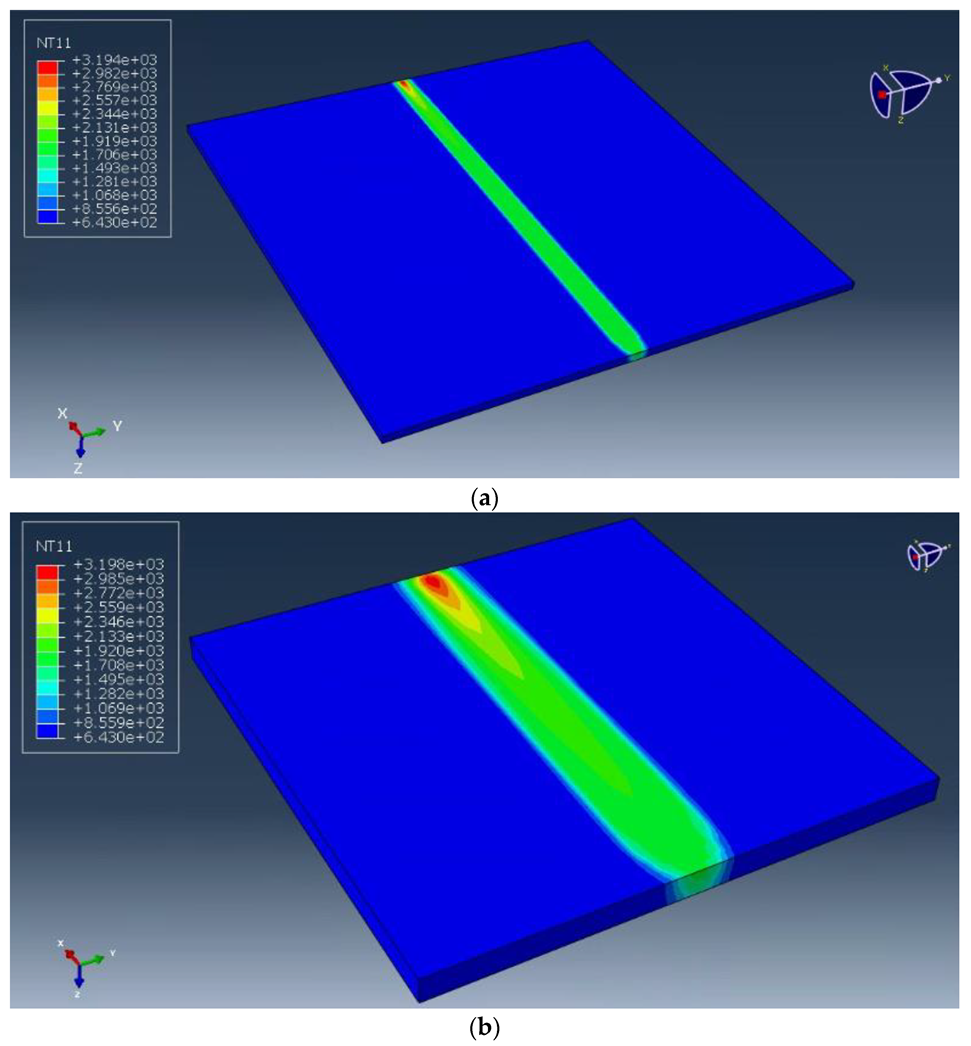

- is not recommended as a power input to be used for SS-304L, the reason being that temperatures reached when using , with a temperature gradient of between the top and bottom of the powder bed. Another observation is the high cooling rate in Figure 7e from at the top surface to , where all layers’ temperatures are equalized. This can be explained by the fact that the model accounted for convection and radiation, which is an exponential function of the temperature as seen in Equation (3). Therefore, when in a liquid state, the cooling rate is much higher, especially in Figure 7e, but also for Figure 5e and Figure 6e. In addition, the entire thickness of the powder bed exceeded the melting point, as the melt pool analysis showed; consequently, the HAZ is very large, indicating that re-melting from previously layers or substrate could occur.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Power | Enlarged FEM Model | Original FEM Model | Error (%) |

|---|---|---|---|

| P = 100 W | 1551 | 1544 | 4% |

| P = 200 W | 1912 | 1909 | 1.5% |

| P = 400 W | 3194 | 3198 | 1.2% |

| Node | Enlarged FEM Model | Original FEM Model | Error (%) |

|---|---|---|---|

| N1 | 1542.41 | 1545.11 | 0.175% |

| N2 | 1486.40 | 1488.25 | 0.124% |

| N3 | 1317.58 | 1318.75 | 0.089% |

| N4 | 1171.86 | 1172.67 | 0.069% |

| N5 | 1041.70 | 1042.19 | 0.047% |

| N6 | 926.70 | 926.96 | 0.029% |

| N7 | 832.80 | 832.93 | 0.015% |

| N8 | 762.04 | 762.09 | 0.007% |

| N9 | 712.84 | 712.85 | 0.002% |

References

- Fayazfar, H.; Salarian, M.; Rogalsky, A.; Sarker, D.; Russo, P.; Paserin, V.; Toyserkani, E. A Critical Review of Powder-Based Additive Manufacturing of Ferrous Alloys: Process Parameters, Microstructure and Mechanical Properties. Mater. Des. 2018, 144, 98–128. [Google Scholar] [CrossRef]

- Renishaw. Available online: https://www.renishaw.com (accessed on 19 July 2022).

- SLM Solutions Group AG. Available online: https://www.slm-solutions.com/ (accessed on 19 July 2022).

- Mercelis, P.; Kruth, J.P. Residual Stresses in Selective Laser Sintering and Selective Laser Melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- Ahmadi, A.; Moghaddam, N.S.; Elahinia, M.; Karaca, H.E.; Mirzaeifar, R. Finite Element Modeling of Selective Laser Melting 316L Stainless Steel Parts for Evaluating the Mechanical Properties. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, MSEC 2016; American Society of Mechanical Engineers Digital Collection, Blacksburg, VA, USA, 27 September 2016; Volume 2. [Google Scholar]

- Abd-Elghany, K.; Bourell, D.L. Property Evaluation of 304L Stainless Steel Fabricated by Selective Laser Melting. Rapid Prototyp. J. 2012, 18, 420–428. [Google Scholar] [CrossRef]

- Yakout, M.; Cadamuro, A.; Elbestawi, M.A.; Veldhuis, S.C. The Selection of Process Parameters in Additive Manufacturing for Aerospace Alloys. Int. J. Adv. Manuf. Technol. 2017, 92, 2081–2098. [Google Scholar] [CrossRef]

- Kim, C.S. Thermophysical Properties of Stainless Steels; Argonne National Laboratory (ANL): Lemont, IL, USA, 1975. [Google Scholar]

- Wakao, N.; Kagei, S. Heat and Mass Transfer in Packed Beds; Taylor & Francis: Abingdon, UK, 1982. [Google Scholar]

- Sumin Sih, S.; Barlow, J.W. The Prediction of the Emissivity and Thermal Conductivity of Powder Beds. Part. Sci. Technol. 2004, 22, 291–304. [Google Scholar] [CrossRef]

- Kovalev, O.B.; Gusarov, A.V. Modeling of Granular Packed Beds, Their Statistical Analyses and Evaluation of Effective Thermal Conductivity. Int. J. Therm. Sci. 2017, 114, 327–341. [Google Scholar] [CrossRef]

- de Moraes, D.; Czekanski, A. Parametric Thermal FE Analysis on the Laser Power Input and Powder Effective Thermal Conductivity during Selective Laser Melting of SS304L. J. Manuf. Mater. Processing 2018, 2, 47. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Kovalev, E.P. Model of Thermal Conductivity in Powder Beds. Phys. Rev. B Condens. Matter Mater. Phys. 2009, 80, 024202. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; ISBN 9781139171731. [Google Scholar]

- Abyzov, A.M.; Goryunov, A.V.; Shakhov, F.M. Effective Thermal Conductivity of Disperse Materials. I. Compliance of Common Models with Experimental Data. Int. J. Heat Mass Transf. 2013, 67, 752–767. [Google Scholar] [CrossRef]

- Dul’nev, G.N.; Yu, P.; Zarichnyak, R. Teploprovodnost’ Smesei i Kompozitzionnykh Materialov [Thermal Conductivity of Mixtures and Composites] . 1974. Available online: https://www.studmed.ru/dulnev-gn-zarichnyak-yup-teploprovodnost-smesey-i-kompozicionnyh-materialov_b81fea63440.html (accessed on 2 October 2022).

- Vinokurov, V.A. Welding Stresses and Distortion: Determination and Elimination; British Library Lending Division: London, UK, 1977; ISBN 0853501661. [Google Scholar]

- de Moraes, D.A.; Czekanski, A. Thermal Modeling of 304L Stainless Steel for Selective Laser Melting: Laser Power Input Evaluation. In Proceedings of the 2017 ASME International Mechanical Engineering Congress and Exposition, Proceedings (IMECE), Tampa, FL, USA, 3–9 November 2017; Volume 2. [Google Scholar]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A Three-Dimensional Finite Element Analysis of the Temperature Field during Laser Melting of Metal Powders in Additive Layer Manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- DS Simulia. Abaqus v6.14 Documentation; DS Simulia: Vélizy-Villacoublay, France; Waltham, MA, USA; Shanghai, China, 2014. [Google Scholar]

- Nikolaos, V. Linking Abaqus 6.13/6.12 with Intel Fortran Compiler and Microsoft Visual Studio (64-Bit Architecture Systems Only). Bachelor’s Thesis, University of Thessaly, Volos, Greece, 2014; pp. 1–8. [Google Scholar]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the Effect of Laser Scan Strategy on Residual Stress in Selective Laser Melting through Thermo-Mechanical Simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Cho, D.-H. Determining the Temperature Field of Selective Laser Melting Process for Different Heat Source Paths. Master’s Thesis, Northeastern University, Boston, MA, USA, 2016. [Google Scholar]

- Li, X.P.; Roberts, M.; Liu, Y.J.; Kang, C.W.; Huang, H.; Sercombe, T.B. Effect of Substrate Temperature on the Interface Bond between Support and Substrate during Selective Laser Melting of Al–Ni–Y–Co–La Metallic Glass. Mater. Des. 2015, 65, 1–6. [Google Scholar] [CrossRef]

- Fan, Z. Numerical Modeling of Heat Transfer and Fluid Flow in Laser Metal Deposition by Powder Injection. Ph.D. Thesis, Missouri University of Science and Technology, Rolla, MI, USA, 2013. [Google Scholar]

- Gubareff, G.G.; Janssen, J.E.; Torborg, R.H. Thermal Radiation Properties Survey: A Review of the Literature; Honeywell Research Center: Minneapolis, MN, USA, 1960. [Google Scholar]

- Brown, B. Characterization of 304L Stainless Steel by Means of Minimum Input Energy on the Selective Laser Melting Platform. Master’s Thesis, Missouri University of Science and Technology, Rolla, MI, USA, 2015. [Google Scholar]

- Denlinger, E.R.; Jagdale, V.; Srinivasan, G.V.; El-Wardany, T.; Michaleris, P. Thermal Modeling of Inconel 718 Processed with Powder Bed Fusion and Experimental Validation Using in Situ Measurements. Addit. Manuf. 2016, 11, 7–15. [Google Scholar] [CrossRef]

- Goldak, J.; Chakravarti, A.; Bibby, M. A New Finite Element Model for Welding Heat Sources. Metall. Trans. B 1984, 15, 299–305. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Moraes, D.A.; Abdelhamid, M.; Czekanski, A. A Finite Element Analysis of the Effects of Preheating Substrate Temperature and Power Input on Selective Laser Melting. Metals 2022, 12, 1707. https://doi.org/10.3390/met12101707

de Moraes DA, Abdelhamid M, Czekanski A. A Finite Element Analysis of the Effects of Preheating Substrate Temperature and Power Input on Selective Laser Melting. Metals. 2022; 12(10):1707. https://doi.org/10.3390/met12101707

Chicago/Turabian Stylede Moraes, Diego A., Mohamed Abdelhamid, and Aleksander Czekanski. 2022. "A Finite Element Analysis of the Effects of Preheating Substrate Temperature and Power Input on Selective Laser Melting" Metals 12, no. 10: 1707. https://doi.org/10.3390/met12101707

APA Stylede Moraes, D. A., Abdelhamid, M., & Czekanski, A. (2022). A Finite Element Analysis of the Effects of Preheating Substrate Temperature and Power Input on Selective Laser Melting. Metals, 12(10), 1707. https://doi.org/10.3390/met12101707