High Manganese TWIP Steel with Increased Corrosion Resistance

Abstract

:1. Introduction

2. Experiment Description

3. Results and Discussion

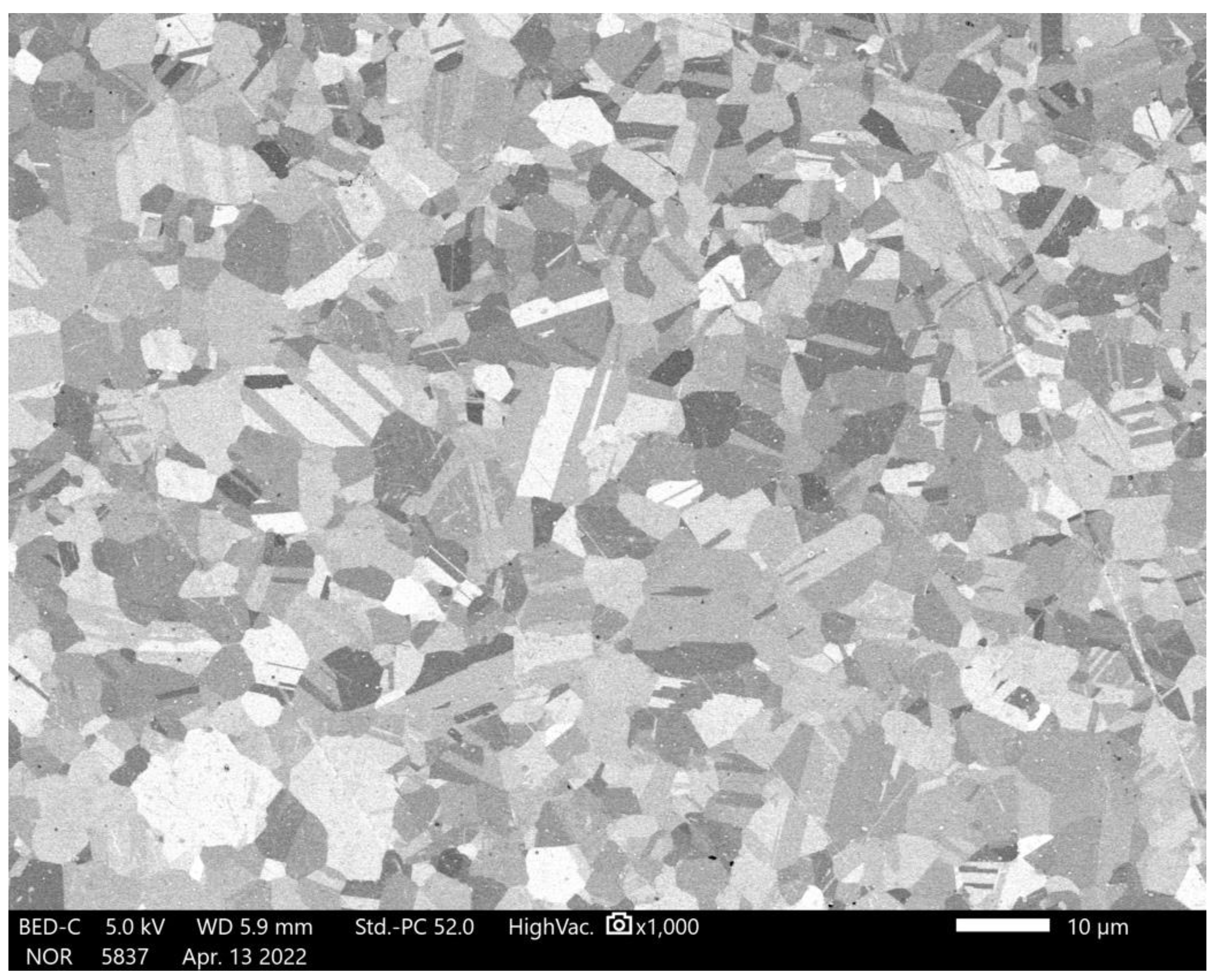

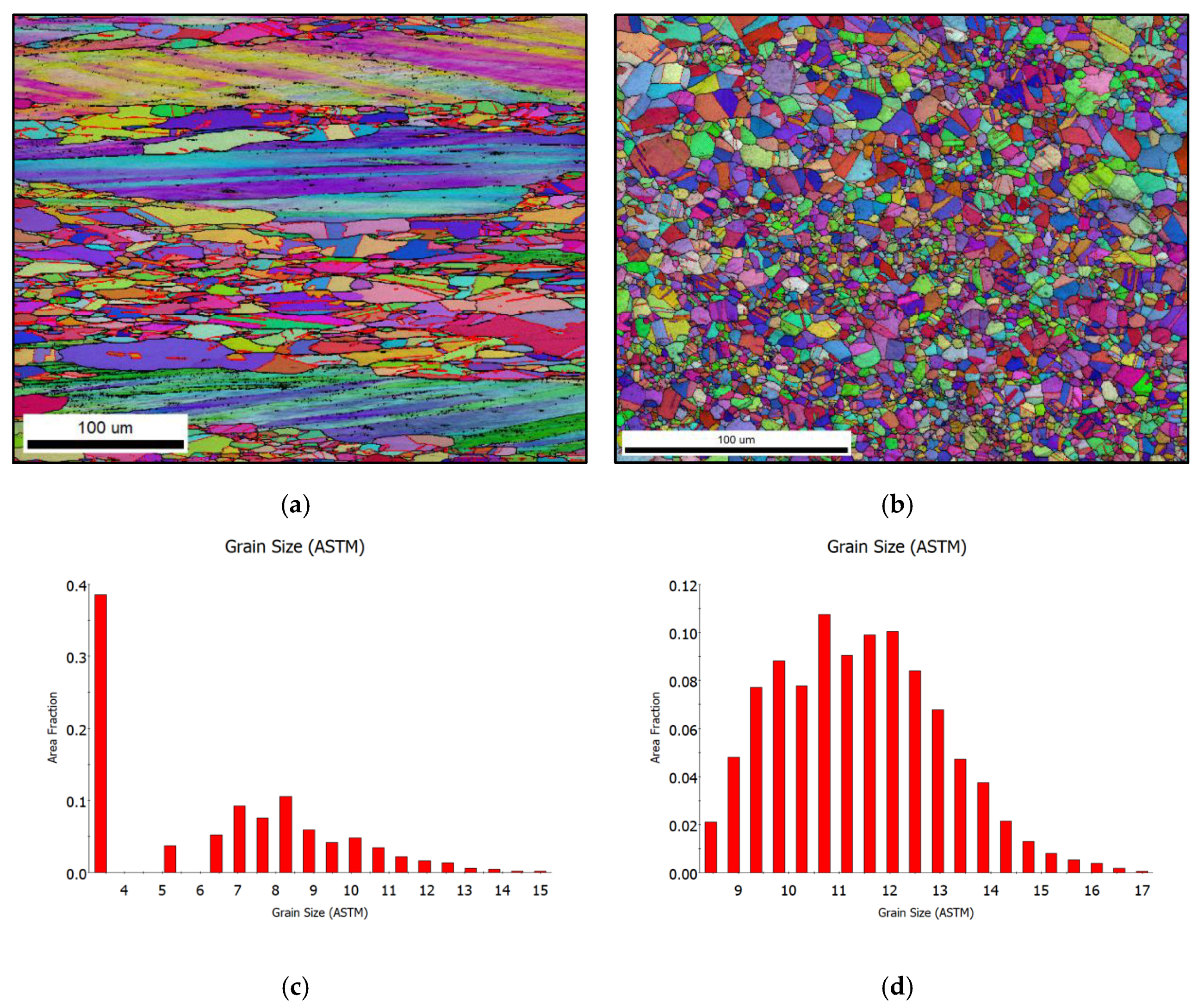

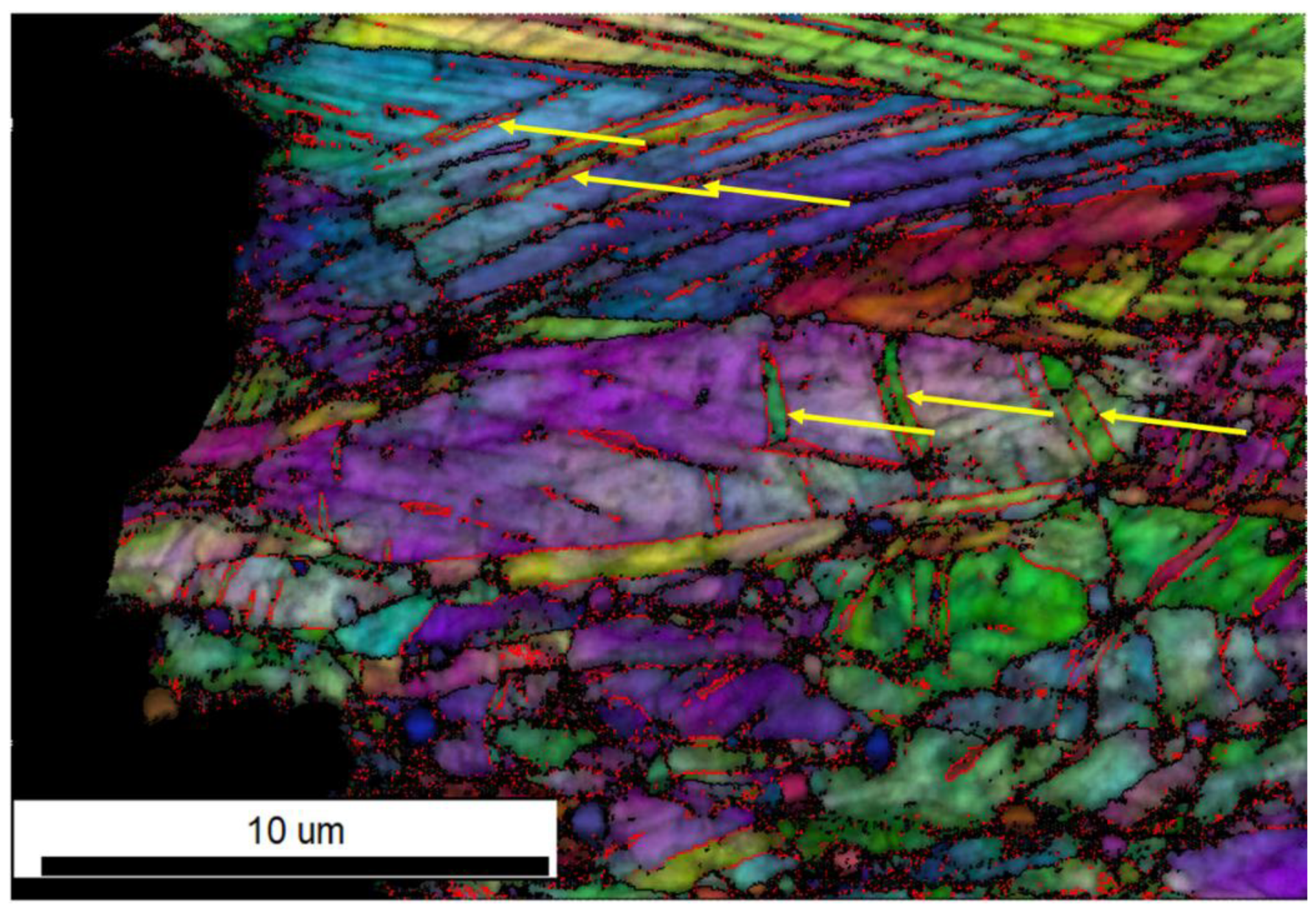

3.1. Microstructure

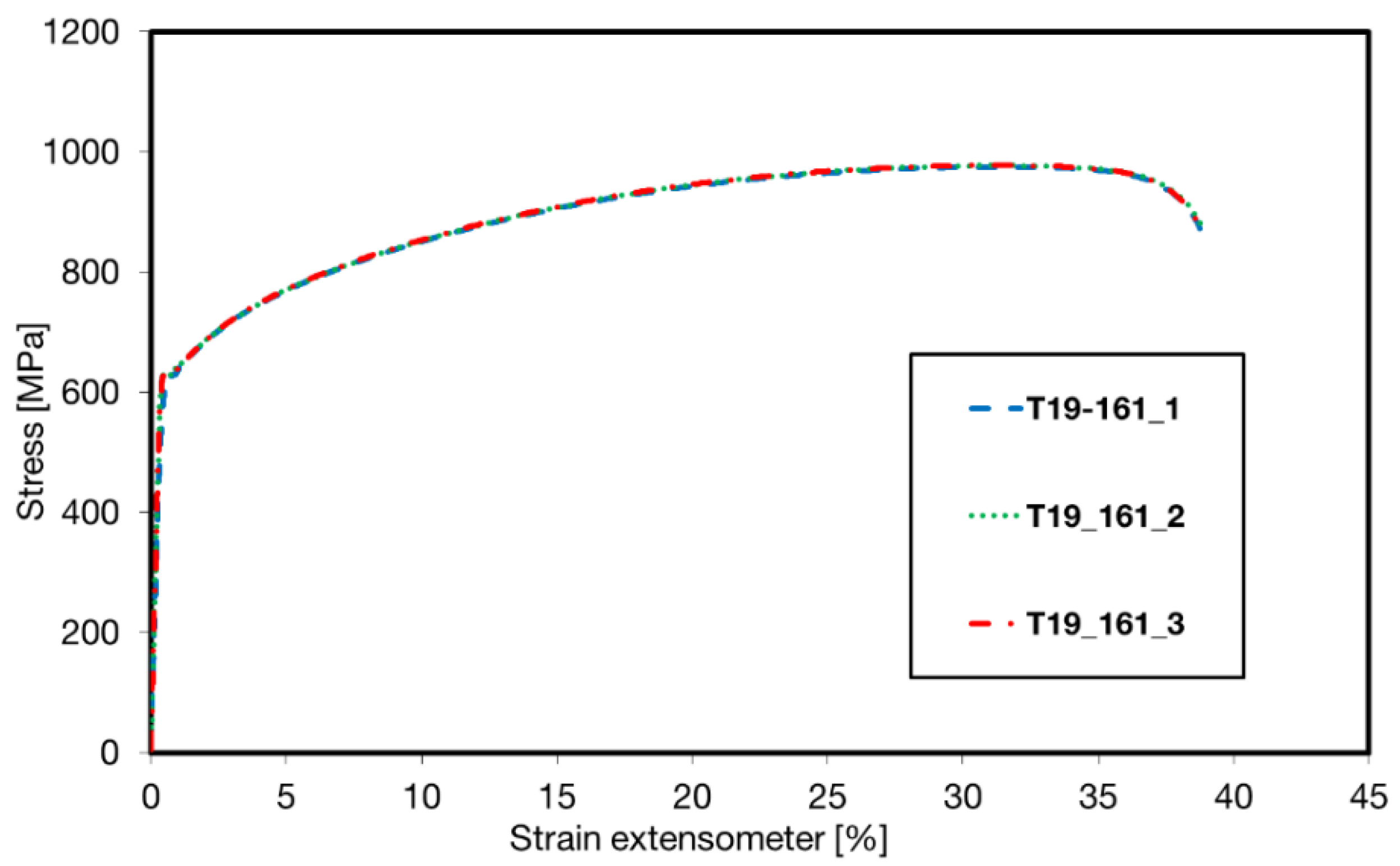

3.2. Mechanical Properties

3.3. Corrosion Behaviour

4. Conclusions

- The metal matrix of samples is single phase, fully austenitic with no presence of alpha or epsilon martensite in either the annealed or the cold rolled state.

- Microstructure after annealing is very fine-grained with an average grain size of G = 13.5 according to ASTM E112.

- The plastic deformation of this material consists of deformation twinning.

- Experimental steel reaches high strength of 976.7 ± 1.3 MPa combined with high elongation of 40.0 ± 0.5%.

- With the icorr parameter, the experimental steel’s corrosion resistance is similar to the martensitic stainless steel AISI 420.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Hofmann, H.; Mattissen, D.; Schaumann, T.W. Advanced Cold Rolled Steels for Automotive Applications. Steel Res. Int. 2009, 80, 22–28. [Google Scholar] [CrossRef]

- Cornette, D.; Cugy, P.; Hildenbrand, A.; Bouzekri, M.; Arcelor, G.L. Ultra High Strength FeMn TWIP Steels for automotive safety parts. Rev. Metall. Cah. D Inf. Tech. Rev. Met. Paris 2005, 102, 905–918. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Joost, W.J. Reducing Vehicle Weight and Improving U.S. Energy Efficiency Using Integrated Computational Materials Engineering. JOM 2012, 64, 1032–1038. [Google Scholar] [CrossRef] [Green Version]

- Kwon, O.; Lee, K.Y.; Kim, G.S.; Chin, K.G. New Trends in Advanced High Strength Steel Developments for Automotive Application. Mater. Sci. Forum 2010, 638–642, 136–141. [Google Scholar] [CrossRef]

- Forejtova, L.; Kolarik, L.; Suchanek, J.; Kolarikova, M.; Pilvousek, T. Svařitelnost ocelí pro automobilové karoserie. MM Spektrum 2017, 3, 90–92. [Google Scholar]

- Opiela, M.; Grajcar, A.; Krukiewicz, W. Corrosion behaviour of Fe-Mn-Si-Al austenitic steel in chloride solution. J. Achiev. Mater. Manuf. Eng. 2009, 33, 159–165. [Google Scholar]

- Grajcar, A.; Kołodziej, S.; Krukiewicz, W. Corrosion resistance of high-manganese austenitic steels. Arch. Mater. Sci. Eng. 2010, 41–42, 77–84. [Google Scholar]

- Hamada, A.S. Manufacturing, Mechanical Properties and Corrosion Behaviour of High-Mn TWIP Steels. Ph.D. Thesis, University of Oulu, Oulu, Finland, 2007. [Google Scholar]

- Khalissi, M.; Raman, R.S.; Khoddam, S. Stress Corrosion Cracking of Novel Steel for Automotive Applications. Procedia Eng. 2011, 10, 3381–3386. [Google Scholar] [CrossRef] [Green Version]

- Yuan, X.; Zhao, Y.; Li, X.; Chen, L. Effect of Cr on mechanical properties and corrosion behaviors of Fe-Mn-C-Al-Cr-N TWIP steels. J. Mater. Sci. Technol. 2017, 33, 1555–1560. [Google Scholar] [CrossRef]

- Kannan, M.B.; Raman, R.K.S.; Khoddam, S.; Liyanaarachchi, S. Corrosion behavior of twinning-induced plasticity (TWIP) steel. Mater. Corros. 2013, 64, 231–235. [Google Scholar] [CrossRef]

- Mujica, L.; Weber, S.; Theisen, W. Development of high-strength corrosion-resistant austenitic TWIP steel. La Metall. Ital. 2011, 6, 31–35. [Google Scholar]

- Sun, J.; Li, J.; Xie, J.; Yang, Y.; Wu, W.; Zhou, X.; Zhang, S.; Wang, Q. Properties of rapid arc discharge plasma nitriding of AISI 420 martensitic stainless: Effect of nitriding temperatures. J. Mater. Res. Technol. 2022, 19, 4804–4814. [Google Scholar] [CrossRef]

- Zhang, Z.; Yu, T.; Kovacevic, R. Erosion and corrosion resistance of laser cladded AISI 420 stainless steel reinforced with VC. Appl. Surf. Sci. 2017, 410, 225–240. [Google Scholar] [CrossRef]

| Heat No. | C | Mn | Cr | Si | N | Mo | Fe |

|---|---|---|---|---|---|---|---|

| T19-161 | 0.33 | 27.5 | 12.9 | 0.14 | 0.54 | 1.1 | Bal. |

| Heat No. | YS (0.2%) (MPa) | TS (MPa) | El (%) | RA (%) |

|---|---|---|---|---|

| T19-161 | 628.9 ± 5.3 | 976.7 ± 1.3 | 40.0 ± 0.5 | 48.4 ± 2.2 |

| Heat No. | Ecorr (mV/ACLE) | Rp (Ω·m2) | icorr (µA·cm−2) | ibarrier (µA·cm−2) | Ebarrier (mV/ACLE) |

|---|---|---|---|---|---|

| T19-161 | −463.4 ± 5.6 | 0.51 ± 0.02 | 0.34 ± 0.11 | 14.77 ± 6.21 | −354.9 ± 8.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Podany, P.; Gregor, T.; Studecky, T.; Donik, C. High Manganese TWIP Steel with Increased Corrosion Resistance. Metals 2022, 12, 1765. https://doi.org/10.3390/met12101765

Podany P, Gregor T, Studecky T, Donik C. High Manganese TWIP Steel with Increased Corrosion Resistance. Metals. 2022; 12(10):1765. https://doi.org/10.3390/met12101765

Chicago/Turabian StylePodany, Pavel, Tomas Gregor, Tomas Studecky, and Crtomir Donik. 2022. "High Manganese TWIP Steel with Increased Corrosion Resistance" Metals 12, no. 10: 1765. https://doi.org/10.3390/met12101765

APA StylePodany, P., Gregor, T., Studecky, T., & Donik, C. (2022). High Manganese TWIP Steel with Increased Corrosion Resistance. Metals, 12(10), 1765. https://doi.org/10.3390/met12101765