Local Strengthening Design and Compressive Behavior Study of the Triangular Honeycomb Structure

Abstract

:1. Introduction

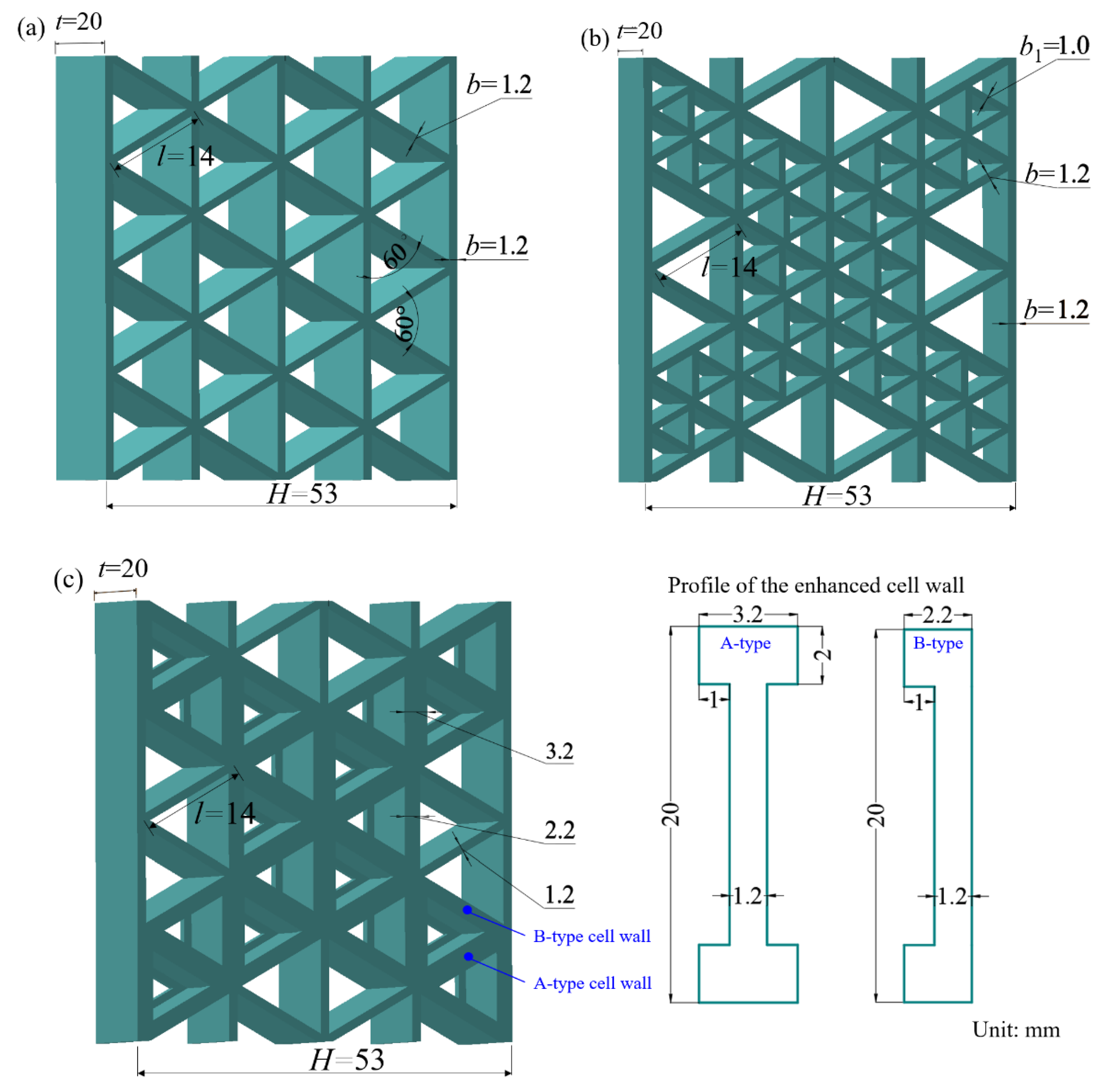

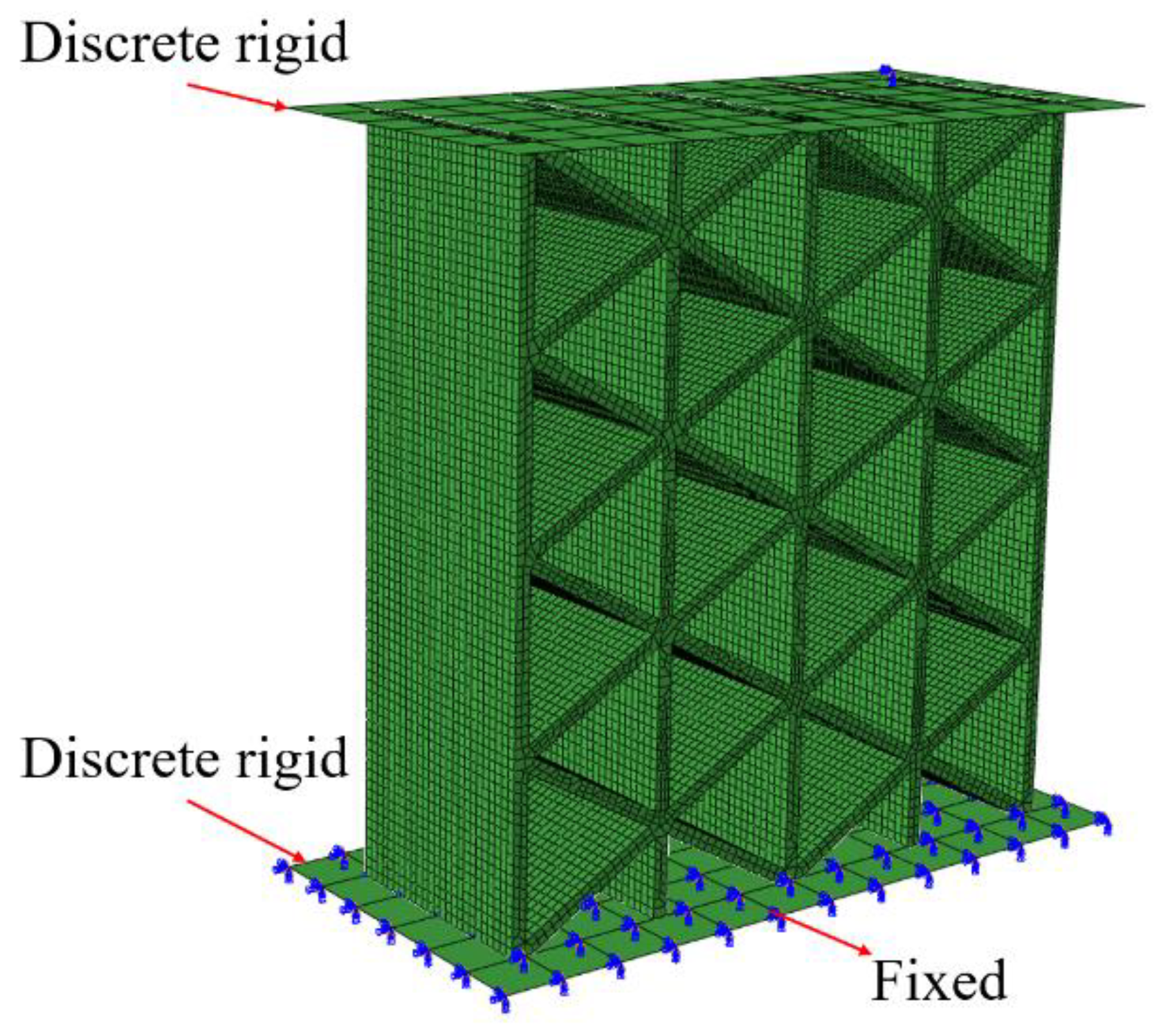

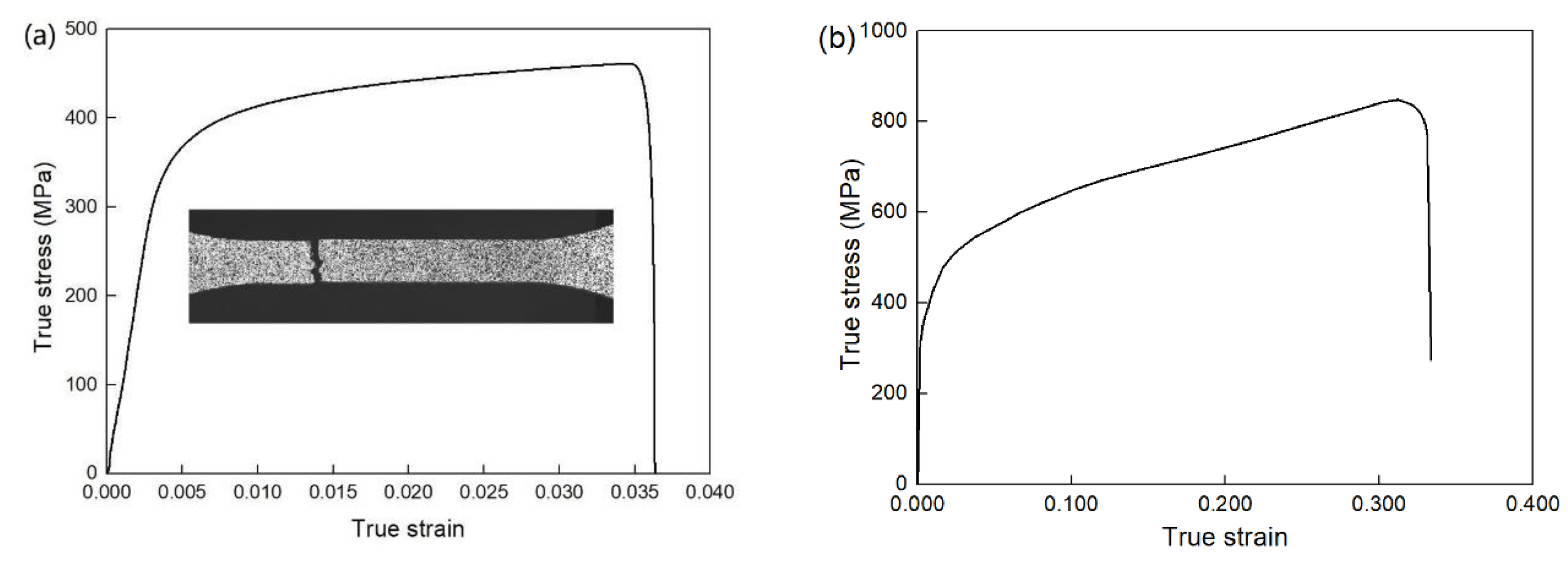

2. Experiment

3. Finite Element Analysis

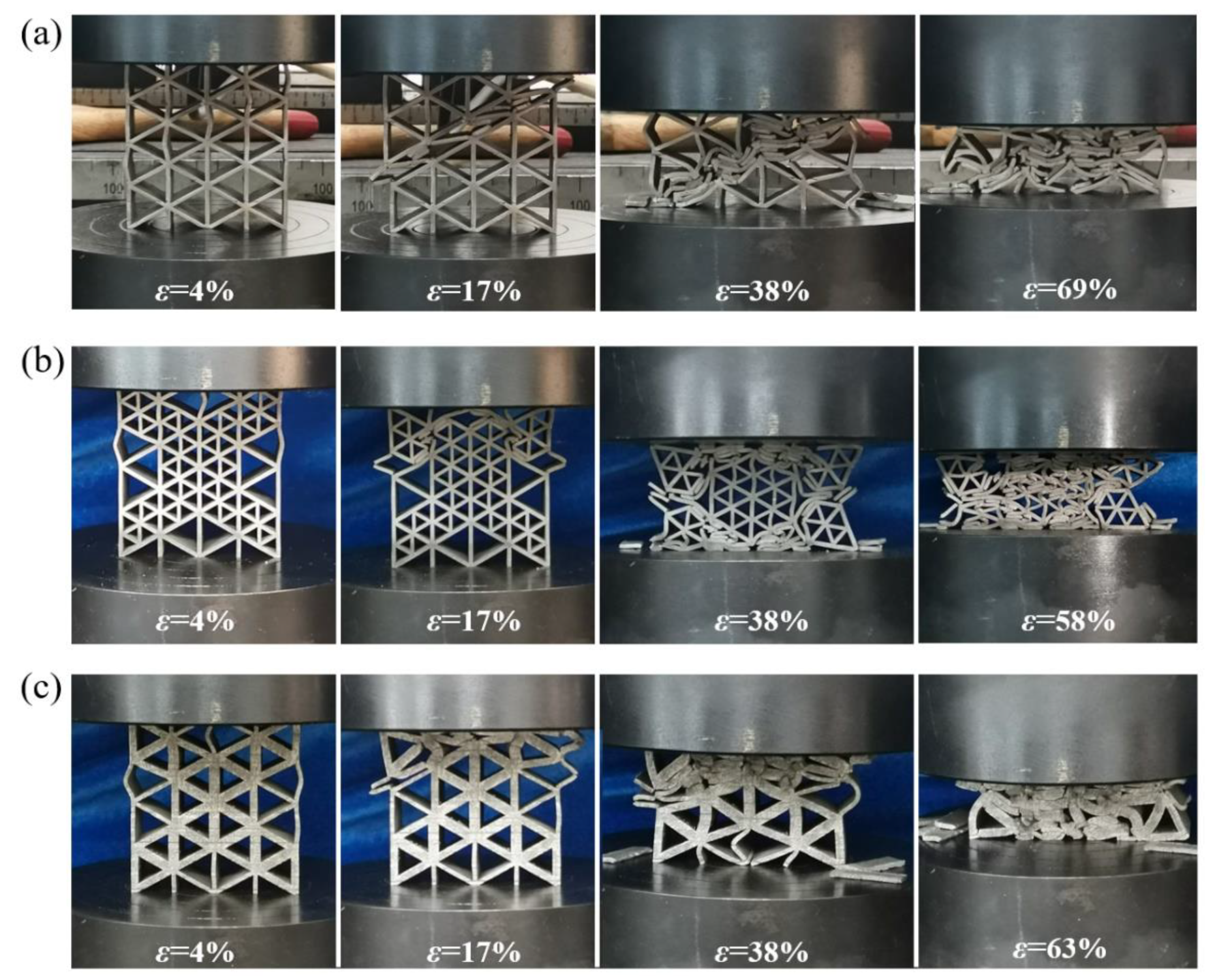

4. Results and Discussion

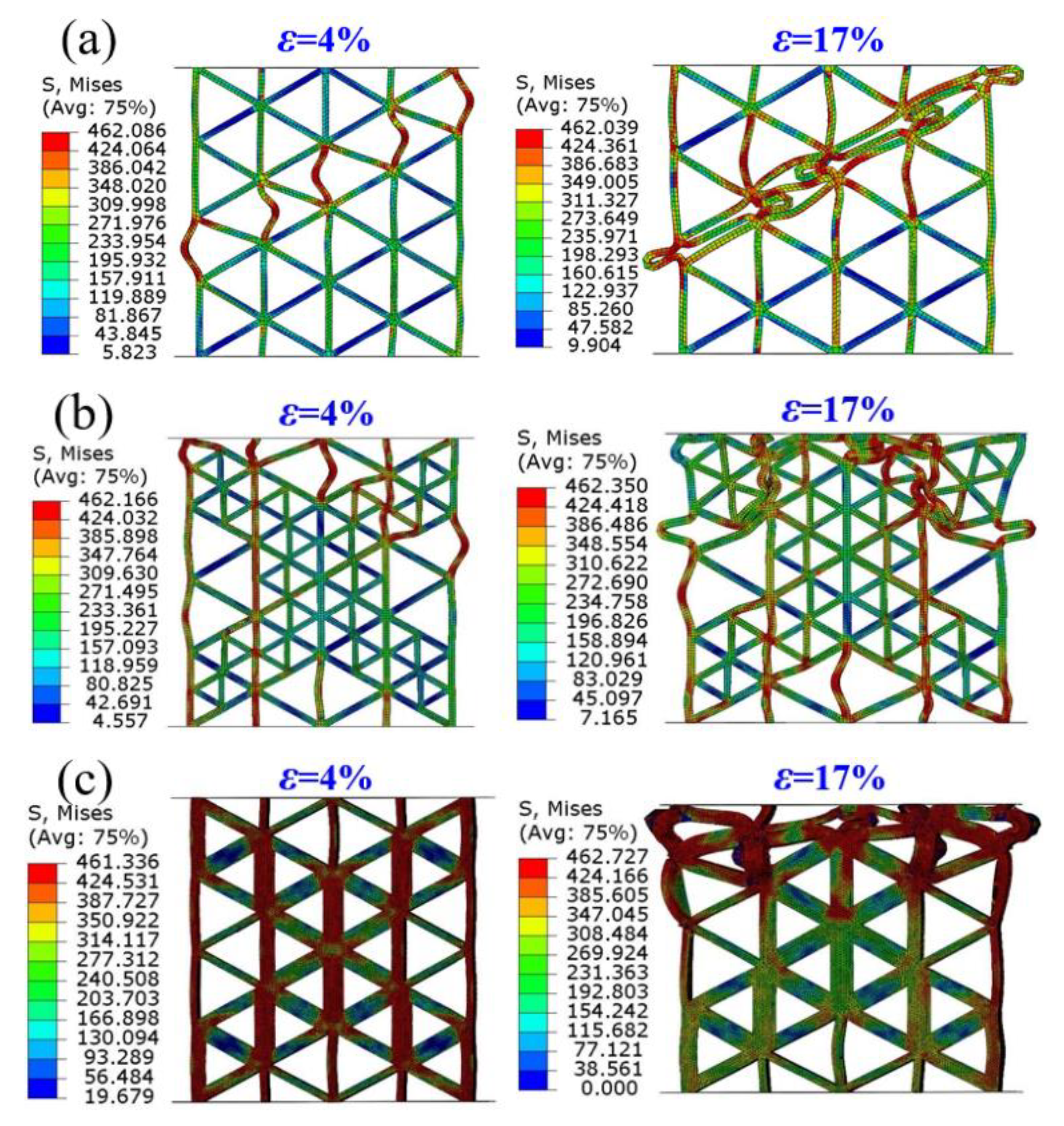

4.1. Failure Morphology

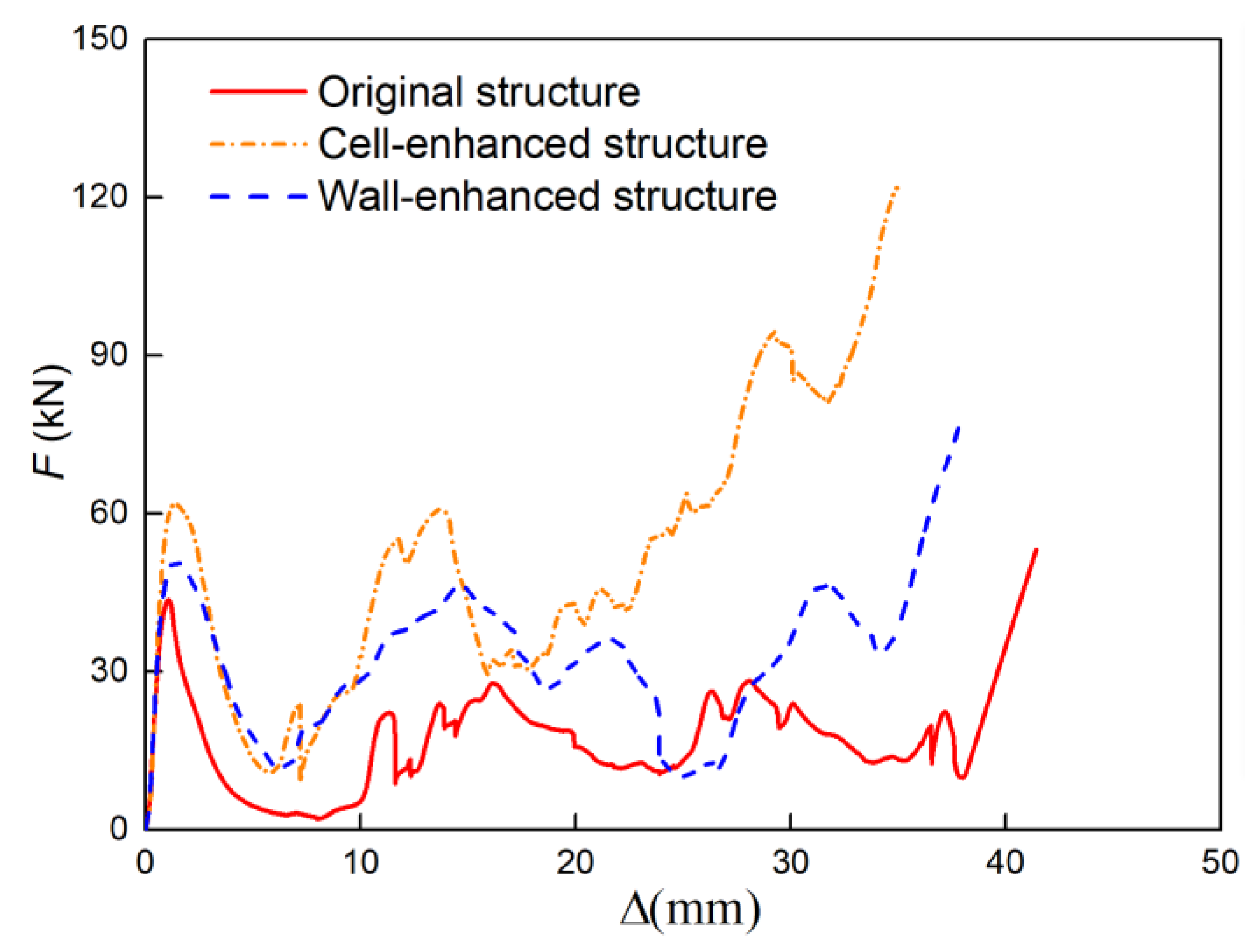

4.2. Stiffness and Strength

4.3. Microstructure Analysis

4.4. Discussion

5. Conclusions

- (1)

- The cell-enhanced and wall-enhanced honeycomb structures possess higher stiffness and peak load than the original honeycomb structure, in which the peak load of the cell-enhanced structure is the largest. The peak load of the triangular honeycomb structure is related to the stress concentration. Uniform stress distribution is beneficial to improve the mechanical properties of the structure.

- (2)

- The locally enhanced method can effectively optimize the diagonal fracture band failure of triangular honeycomb materials. The fracture band of the cell-enhanced triangular honeycomb structure under compressive load becomes more localized, while the wall-enhanced structure fails layer by layer.

- (3)

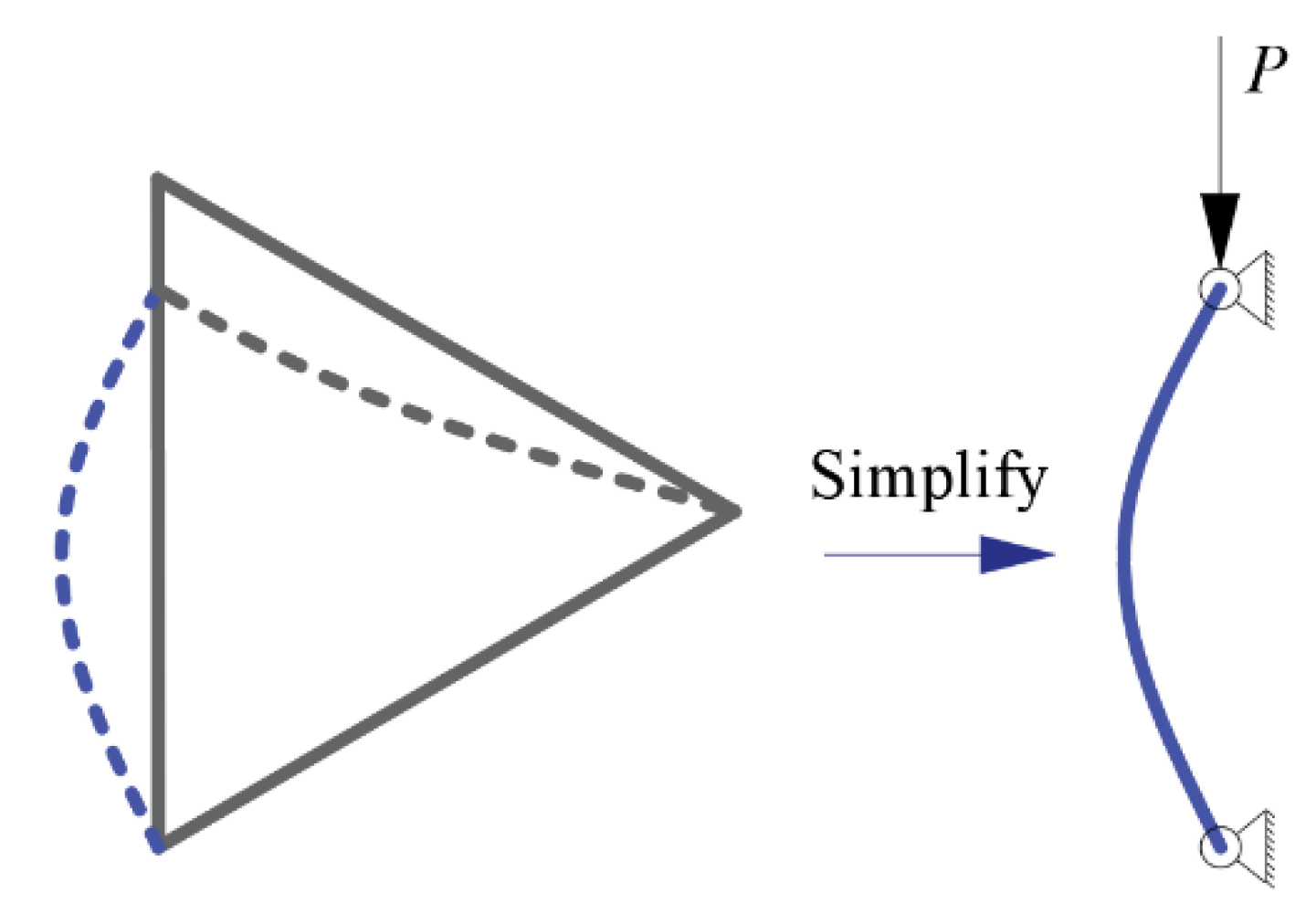

- For the triangular honeycomb structure under in-plane compression, the appearance of the fracture band is caused by the buckling of the walls, which is related to the topological structure.

- (4)

- The grain of SLM 316L steel is very fine, and the grain morphology in different scales is different. The unmelted particles and voids reduce the plasticity and strength of the SLM 316L steel greatly.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DebRoy, T.; Mukherjee, T.; Milewski, J.O.; Elmer, J.W.; Ribic, B.; Blecher, J.J.; Zhang, W. Scientific, technological and economic issues in metal printing and their solutions. Nat. Mater. 2019, 18, 1026–1032. [Google Scholar] [CrossRef] [PubMed]

- Sabban, R.; Bahl, S.; Chatterjee, K.; Suwas, S. Globularization using heat treatment in additively manufactured Ti-6Al-4V for high strength and toughness. Acta Mater. 2019, 162, 239–254. [Google Scholar] [CrossRef]

- Ge, J.; Lin, J.; Lei, Y.; Fu, H. Location-related thermal history, microstructure, and mechanical properties of arc additively manufactured 2Cr13 steel using cold metal transfer welding. Mater. Sci. Eng. A 2018, 715, 144–153. [Google Scholar] [CrossRef]

- Liu, S.Y.; Shin, Y.C. Additive manufacturing of Ti6Al4V alloy: A review. Mater. Des. 2019, 164, 107552. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Nazir, A.; Abate, K.M.; Kumar, A.; Jeng, J.Y. A state-of-the-art review on types, design, optimization, and additive manufacturing of cellular structures. Int. J. Adv. Manuf. Technol. 2019, 104, 3489–3510. [Google Scholar] [CrossRef]

- Wang, P.; Zheng, Z.; Liao, S.; Yu, J. Strain-rate effect on initial crush stress of irregular honeycomb under dynamic loading and its deformation mechanism. Acta Mech. Sinica-Prc. 2017, 34, 117–129. [Google Scholar] [CrossRef]

- Ashab, A.S.M.; Ruan, D.; Lu, G.; Wong, Y.C. Quasi-static and dynamic experiments of aluminum honeycombs under combined compression-shear loading. Mater. Des. 2016, 97, 183–194. [Google Scholar] [CrossRef]

- Zhao, Y.; Ge, M.; Ma, W. The effective in-plane elastic properties of hexagonal honeycombs with consideration for geometric nonlinearity. Compos. Struct. 2020, 234, 111749. [Google Scholar]

- Liang, S.; Chen, H.L. Investigation on the square cell honeycomb structures under axial loading. Compos. Struct. 2006, 72, 446–454. [Google Scholar] [CrossRef]

- Langrand, B.; Casadei, F.; Marcadon, V.; Portemont, G.; Kruch, S. Experimental and finite element analysis of cellular materials under large compaction levels. Int. J. Solids Struct. 2017, 128, 99–116. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, H. Theoretical and numerical investigation on the crush resistance of rhombic and kagome honeycombs. Compos. Struct. 2013, 96, 143–152. [Google Scholar] [CrossRef]

- Hohe, J.; Becker, W. Effective elastic properties of triangular grid structures. Compos. Struct. 1999, 45, 131–145. [Google Scholar] [CrossRef]

- Liu, W.; Li, H.; Zhang, J.; Bai, Y. In-plane mechanics of a novel cellular structure for multiple morphing applications. Compos. Struct. 2019, 207, 598–611. [Google Scholar] [CrossRef]

- Zhang, D.; Fei, Q.; Zhang, P. In–plane dynamic crushing behavior and energy absorption of honeycombs with a novel type of multi-cells. Thin-Walled Struct. 2017, 117, 199–210. [Google Scholar] [CrossRef]

- Yang, X.; Xi, X.; Pan, Q.; Liu, H. In-plane dynamic crushing of a novel circular-celled honeycomb nested with petal-shaped mesostructure. Compos. Struct. 2019, 226, 111219. [Google Scholar] [CrossRef]

- Peng, X.L.; Bargmann, S. A novel hybrid-honeycomb structure: Enhanced stiffness, tunable auxeticity and negative thermal expansion. Int. J. Mech. Sci. 2021, 190, 106021. [Google Scholar] [CrossRef]

- Deshpande, A.S.; Burgert, I.; Paris, O. Hierarchically structured ceramics by highprecision nanoparticle casting of wood. Small 2006, 2, 994–998. [Google Scholar] [CrossRef]

- Weaver, J.C.; Aizenberg, J.; Fantner, G.E.; Kisailus, D.; Woesz, A.; Allen, P.; Fields, K.; Porter, M.J.; Zok, F.W.; Hansma, P.K.; et al. Hierarchical assembly of the siliceous skeletal lattice of the hexactinellid sponge Euplectella aspergillum. J. Stuct. Biol. 2007, 158, 93–106. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Stress concentration factors in tubular T/Y-joints strengthened with FRP subjected to compressive load in offshore structures. Int. J. Fatigue 2020, 140, 105719. [Google Scholar] [CrossRef]

- Nassiraei, H.; Rezadoost, P. Static capacity of tubular X-joints reinforced with fiber reinforced polymer subjected to compressive load. Eng. Struct. 2021, 236, 112041. [Google Scholar] [CrossRef]

- Fang, J.; Sun, G.; Qiu, N.; Pang, T.; Li, S.; Li, Q. On hierarchical honeycombs under out-of-plane crushing. Int. J. Solids Struct. 2018, 135, 1–13. [Google Scholar] [CrossRef]

- Chen, Y.; Li, T.; Jia, Z.; Scarpa, F.; Yao, C.W.; Wang, L. 3D printed hierarchical honeycombs with shape integrity under large compressive deformations. Mater. Des. 2018, 137, 226–234. [Google Scholar] [CrossRef] [Green Version]

- Nassiraei, H. Static strength of tubular T/Y-joints reinforced with collar plates at fire induced elevated temperature. Mar. Struct. 2019, 67, 102635. [Google Scholar] [CrossRef]

- Nassiraei, H.; Zhu, L.; Lotfollahi-Yaghin, M.A.; Ahmadi, H. Static capacity of tubular X-joints reinforced with collar plate subjected to brace compression. Thin Wall Struct. 2017, 119, 256–265. [Google Scholar] [CrossRef]

- Li, M.; Lai, C.L.; Zheng, Q.; Han, B.; Wu, H.; Fan, H.L. Design and mechanical properties of hierarchical isogrid structures validated by 3D printing technique. Mater. Des. 2019, 168, 107664. [Google Scholar] [CrossRef]

- Fan, H.; Luo, Y.; Yang, F.; Li, W. Approaching perfect energy absorption throughstructural hierarchy. Int. J. Eng. Sci. 2018, 130, 12–32. [Google Scholar] [CrossRef]

- Oftadeh, R.; Haghpanah, B.; Papadopoulos, J.; Hamouda, A.M.S.; Nayeb-Hashemi, H.; Vaziri, A. Mechanics of anisotropic hierarchical honeycombs. Int. J. Mech. Sci. 2014, 81, 126–136. [Google Scholar] [CrossRef]

- He, Q.; Feng, J.; Zhou, H. A numerical study on the in-plane dynamic crushing of selfsimilar hierarchical honeycombs. Mech. Mater. 2019, 138, 103151. [Google Scholar] [CrossRef]

- Zhang, D.; Fei, Q.; Jiang, D.; Li, Y. Numerical and analytical investigation on crushing of fractal-like honeycombs with self-similar hierarchy. Compos. Struct. 2018, 192, 289–299. [Google Scholar] [CrossRef]

- Liu, L.; Kamm, P.; García-Moreno, F.; Banhart, J.; Pasini, D. Elastic and failure response of imperfect three-dimensional metallic lattices: The role of geometric defects induced by selective laser melting. J. Mech. Phys. Solids 2017, 107, 160–184. [Google Scholar] [CrossRef]

- Du Plessis, A.; Razavi, S.M.J.; Berto, F. The effects of microporosity in struts of gyroid lattice structures produced by laser powder bed fusion. Mater. Des. 2020, 194, 108899. [Google Scholar] [CrossRef]

- Roach, A.M.; White, B.C.; Garland, A.; Jared, B.H.; Carroll, J.D.; Boyce, B.L. Size-dependent stochastic tensile properties in additively manufactured 316L stainless steel. Addit. Manuf. 2020, 32, 101090. [Google Scholar] [CrossRef]

- Gu, H.Y.; Pavier, M.; Shterenlikht, A. Experimental study of modulus, strength and toughness of 2D triangular lattices. Int. J Solids Struct. 2018, 152–153, 207–216. [Google Scholar] [CrossRef]

- Ge, J.G.; Yan, X.C.; Lei, Y.P.; Ahmed, M.; O’Reilly, P.; Zhang, C.; Lupoi, R.; Yin, S. A detailed analysis on the microstructure and compressive properties of selective laser melted Ti6Al4V lattice structures. Mater. Des. 2021, 198, 109292. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.F.; Wikman, S.; Cui, D.Q.; Shen, Z.J. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F. Cellular Solids: Structure and Properties; Cambridge University Press: Cambridge, UK, 1999; pp. 655–656. [Google Scholar]

- Liu, Y.J.; Ren, D.C.; Li, S.J.; Wang, H.; Zhang, L.C.; Sercombe, T.B. Enhanced fatigue characteristics of a topology-optimized porous titanium structure produced by selective laser melting. Addit. Manuf. 2020, 32, 101060. [Google Scholar] [CrossRef]

- Tolosa, I.; Garciandia, F.; Zubiri, F.; Zapirain, F.; Esnaola, A. Study of mechanical properties of AISI 316stainless steel processed by “selective laser melting”, following different manufacturing strategies. Int. J. Adv. Manuf. Tech. 2010, 51, 639–647. [Google Scholar] [CrossRef]

| Stiffness (kN/mm) | Peak Load (kN) | |

|---|---|---|

| Original structure | 55.367 | 43.67 |

| Cell-enhanced structure | 65.77 | 60.78 |

| Wall-enhanced structure | 57.56 | 50.96 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Wu, W.; Liu, J. Local Strengthening Design and Compressive Behavior Study of the Triangular Honeycomb Structure. Metals 2022, 12, 1779. https://doi.org/10.3390/met12111779

Zhang Q, Wu W, Liu J. Local Strengthening Design and Compressive Behavior Study of the Triangular Honeycomb Structure. Metals. 2022; 12(11):1779. https://doi.org/10.3390/met12111779

Chicago/Turabian StyleZhang, Qian, Wenwang Wu, and Jianlin Liu. 2022. "Local Strengthening Design and Compressive Behavior Study of the Triangular Honeycomb Structure" Metals 12, no. 11: 1779. https://doi.org/10.3390/met12111779

APA StyleZhang, Q., Wu, W., & Liu, J. (2022). Local Strengthening Design and Compressive Behavior Study of the Triangular Honeycomb Structure. Metals, 12(11), 1779. https://doi.org/10.3390/met12111779