Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation

Abstract

1. Introduction

2. Materials and Methods

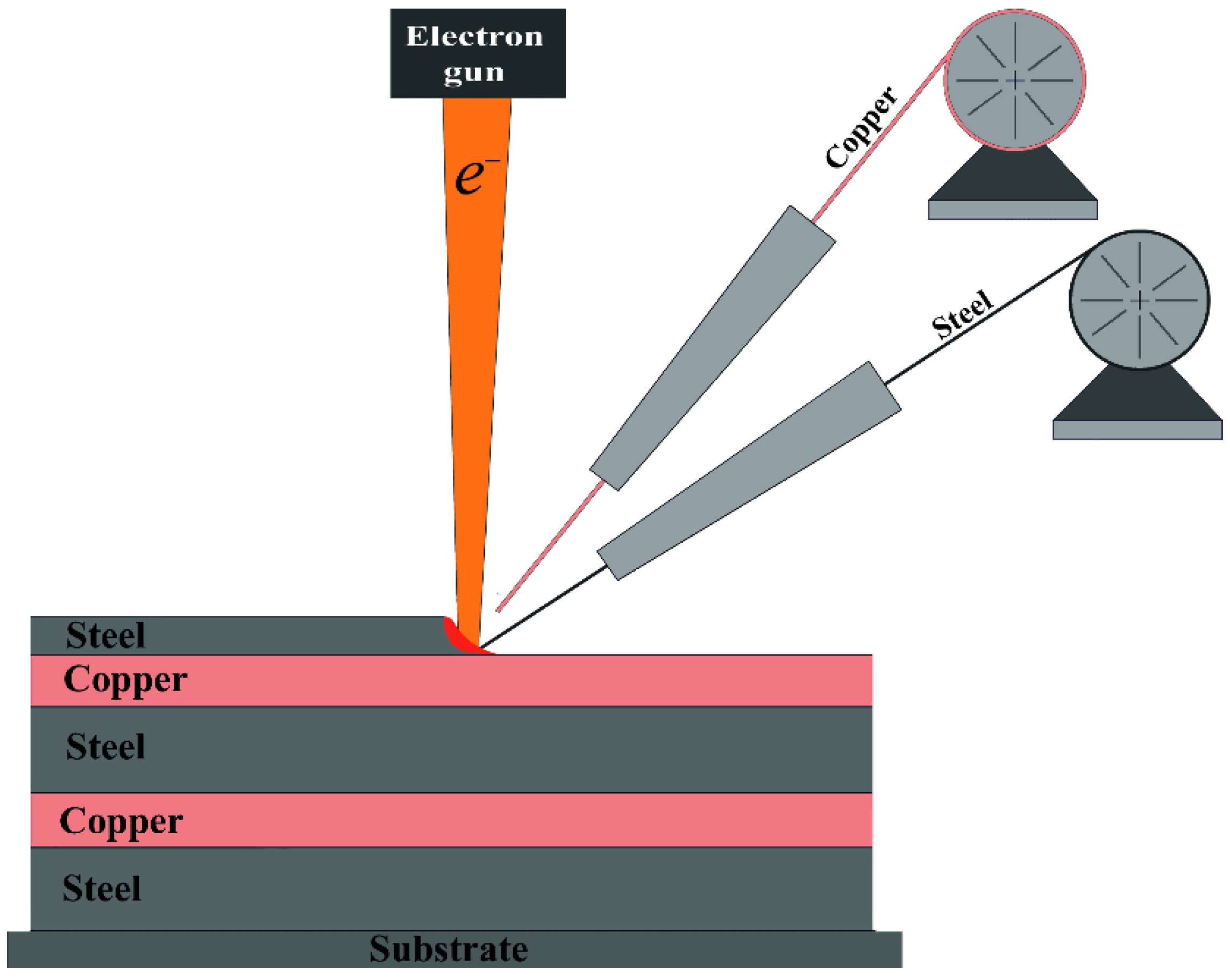

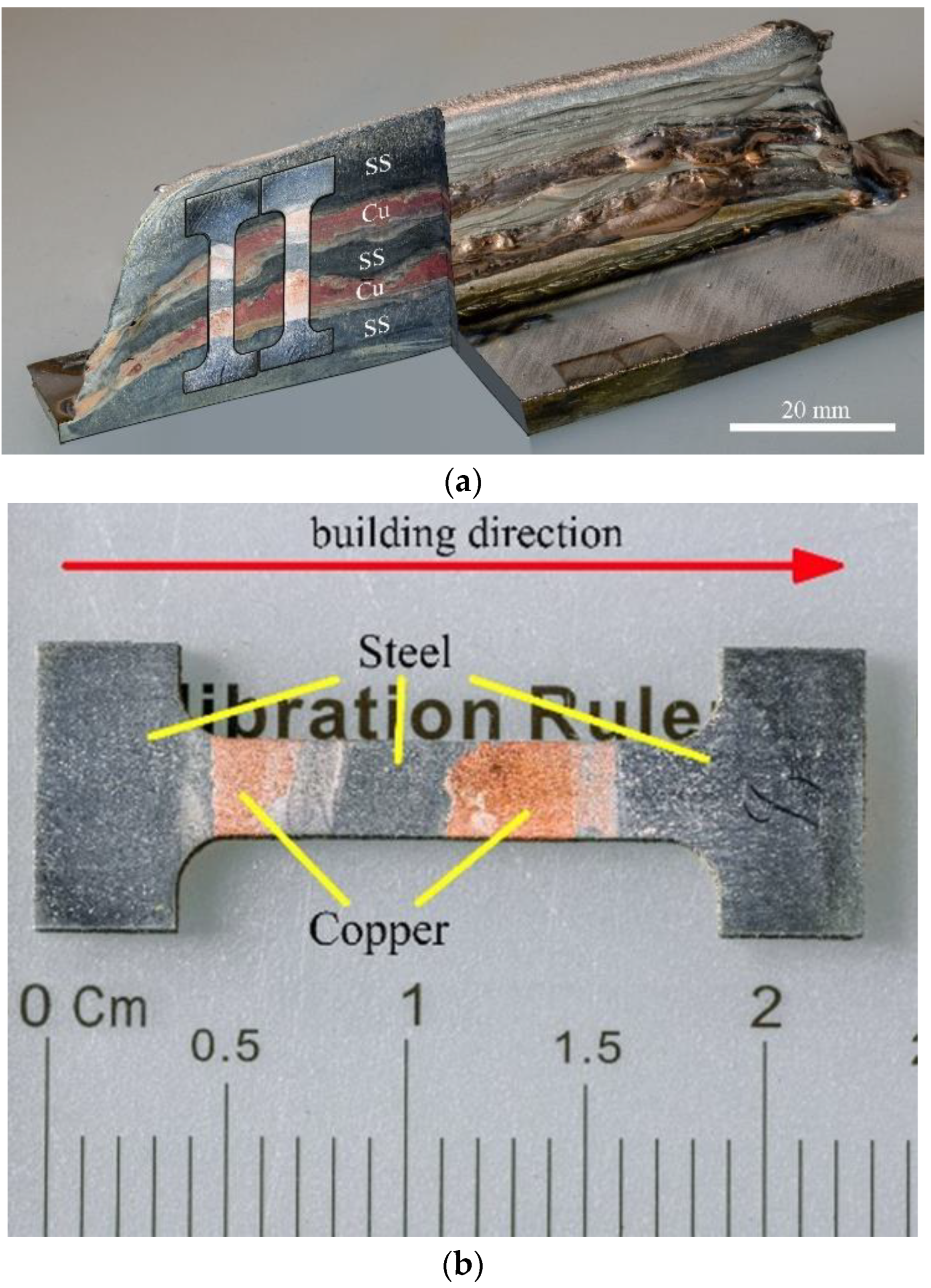

2.1. Additive Sample Growth

2.2. Mechanical Tests

2.3. DIC

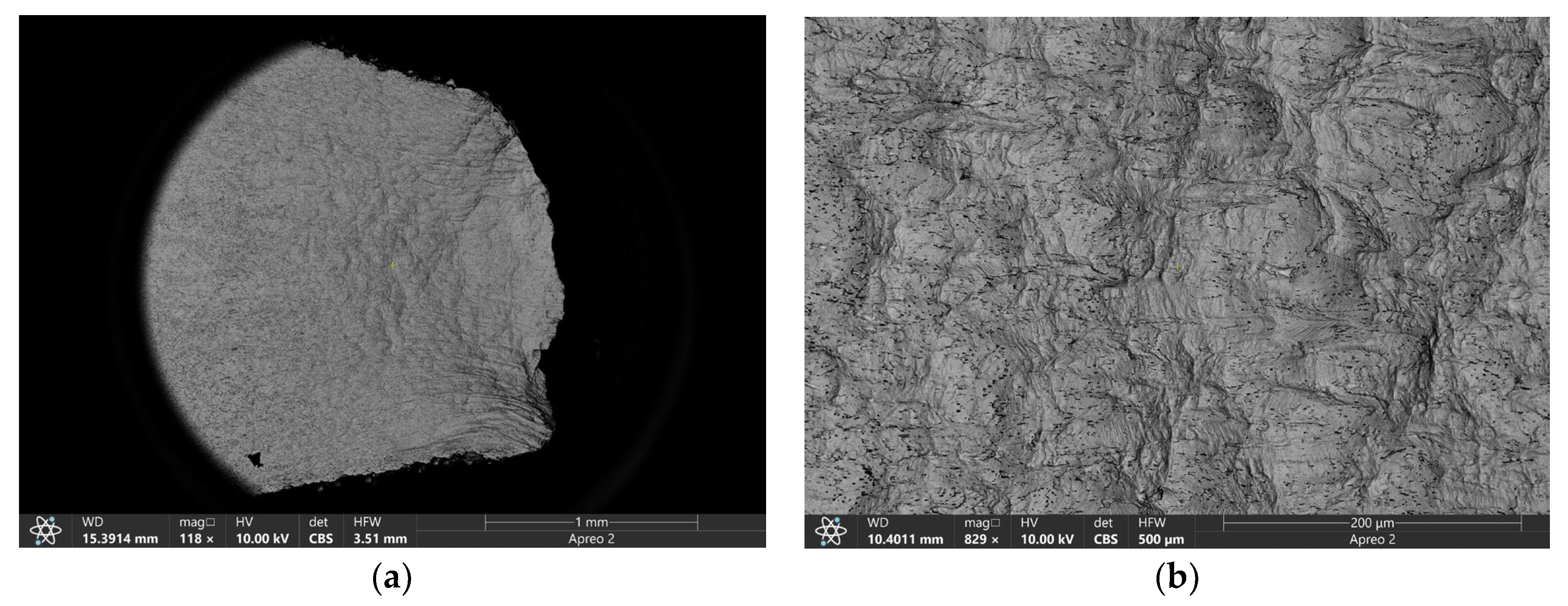

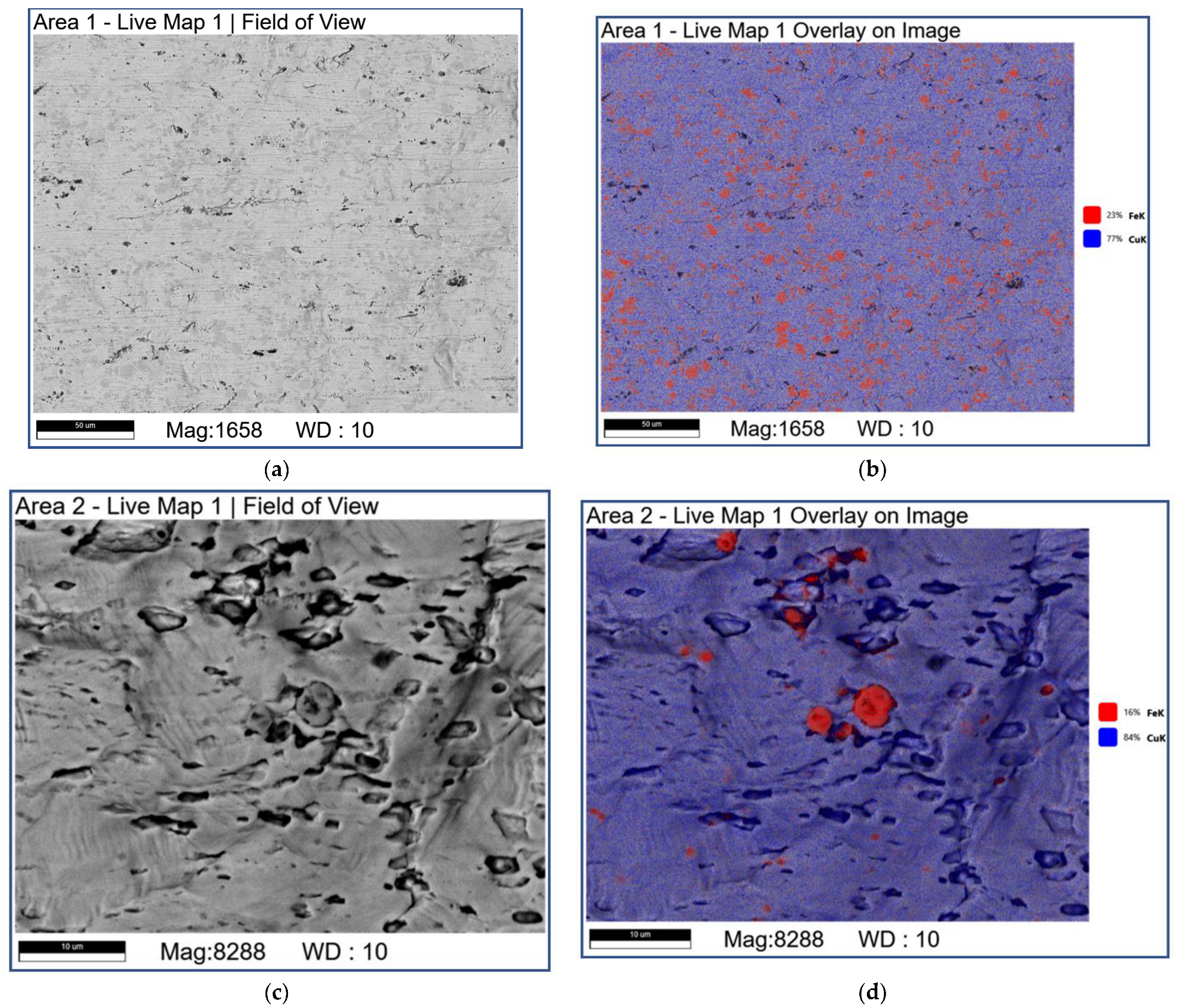

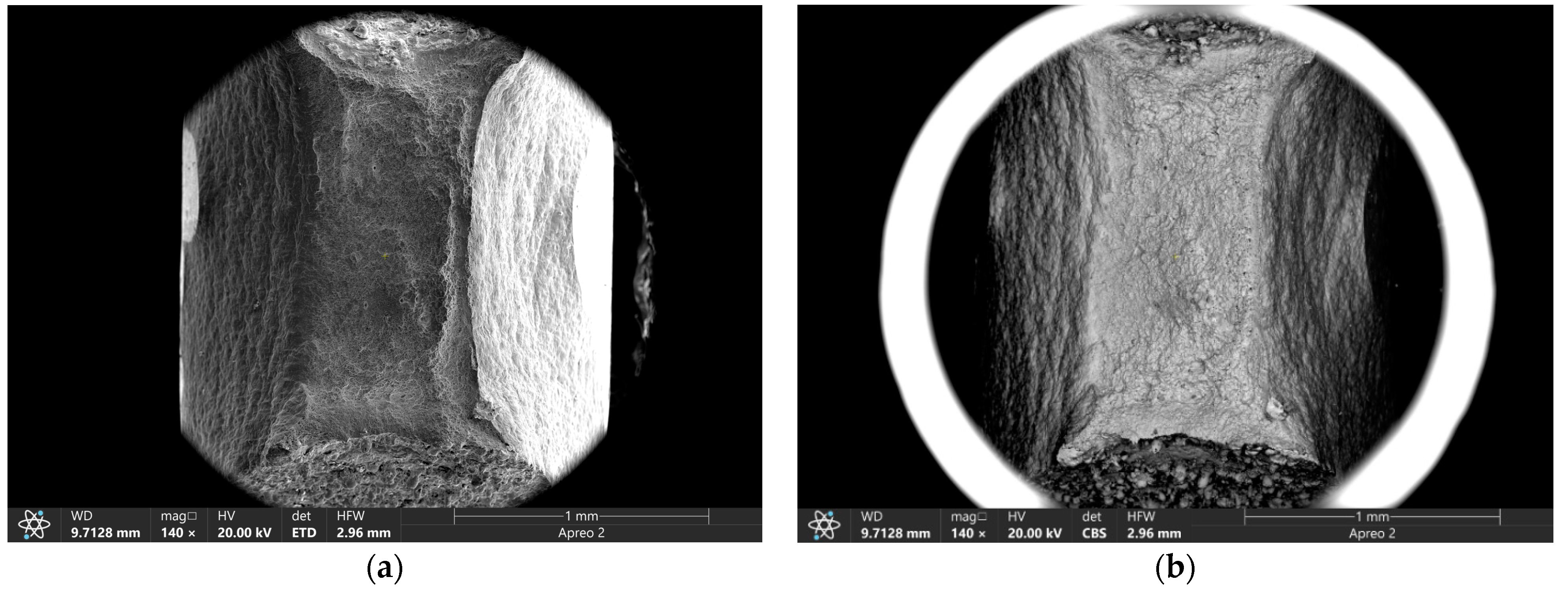

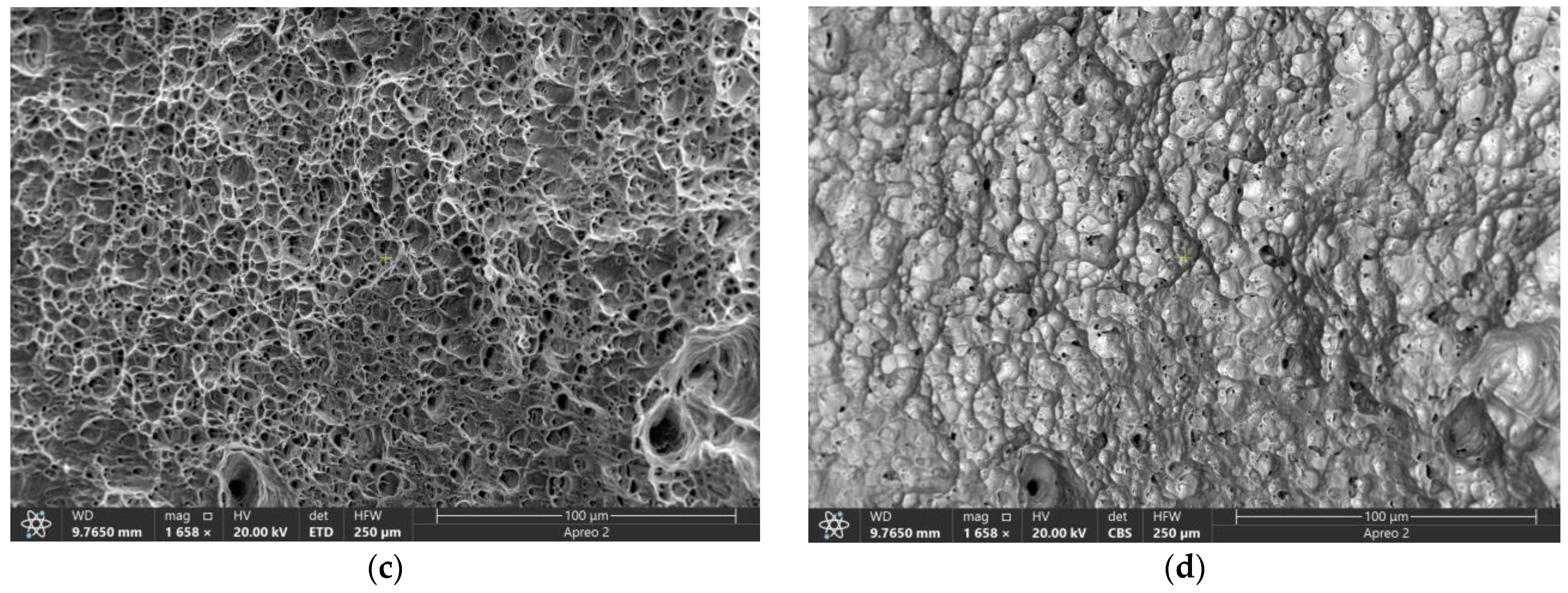

2.4. Structural Studies before and after Tensile Tests

3. Results

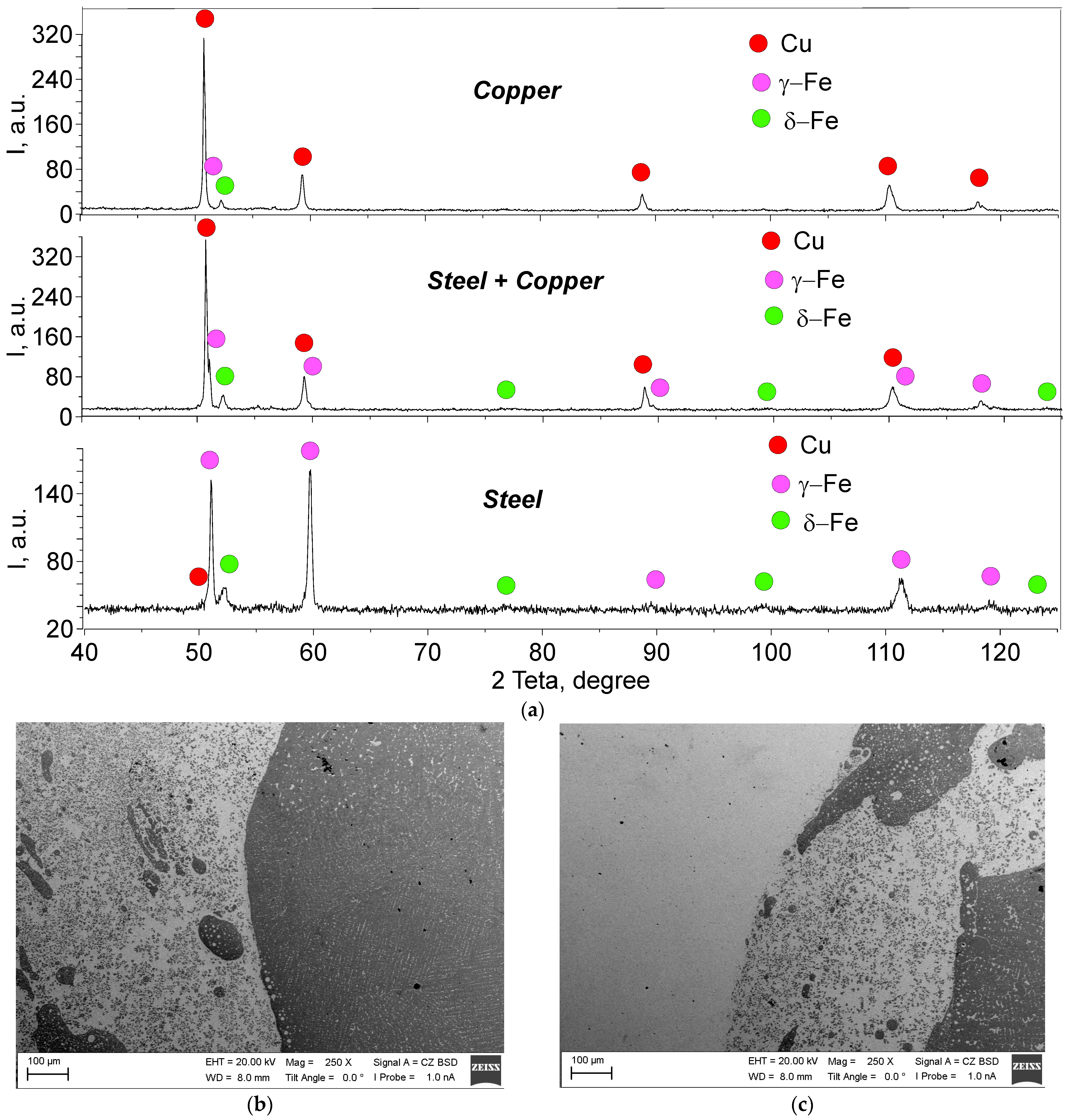

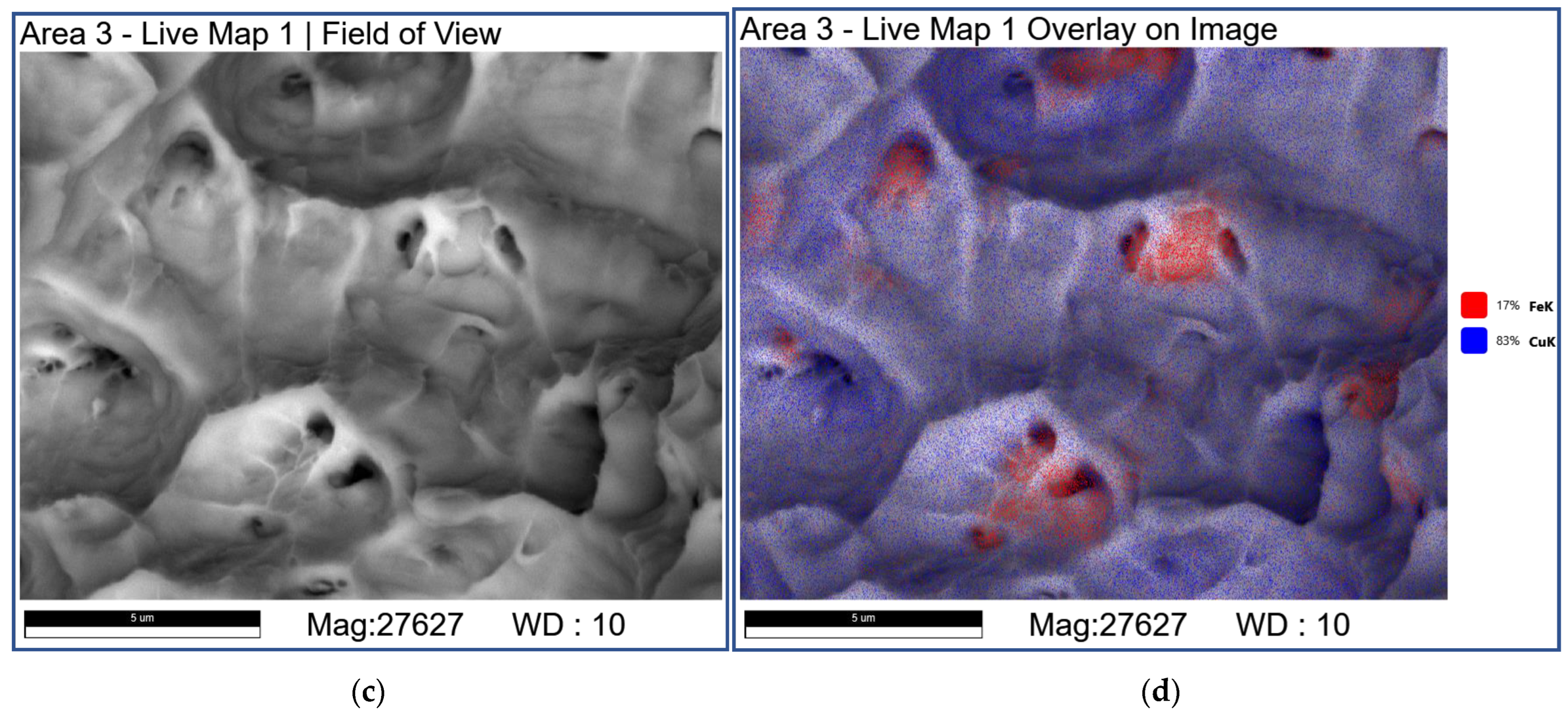

3.1. Initial “Steel-Copper”Structure

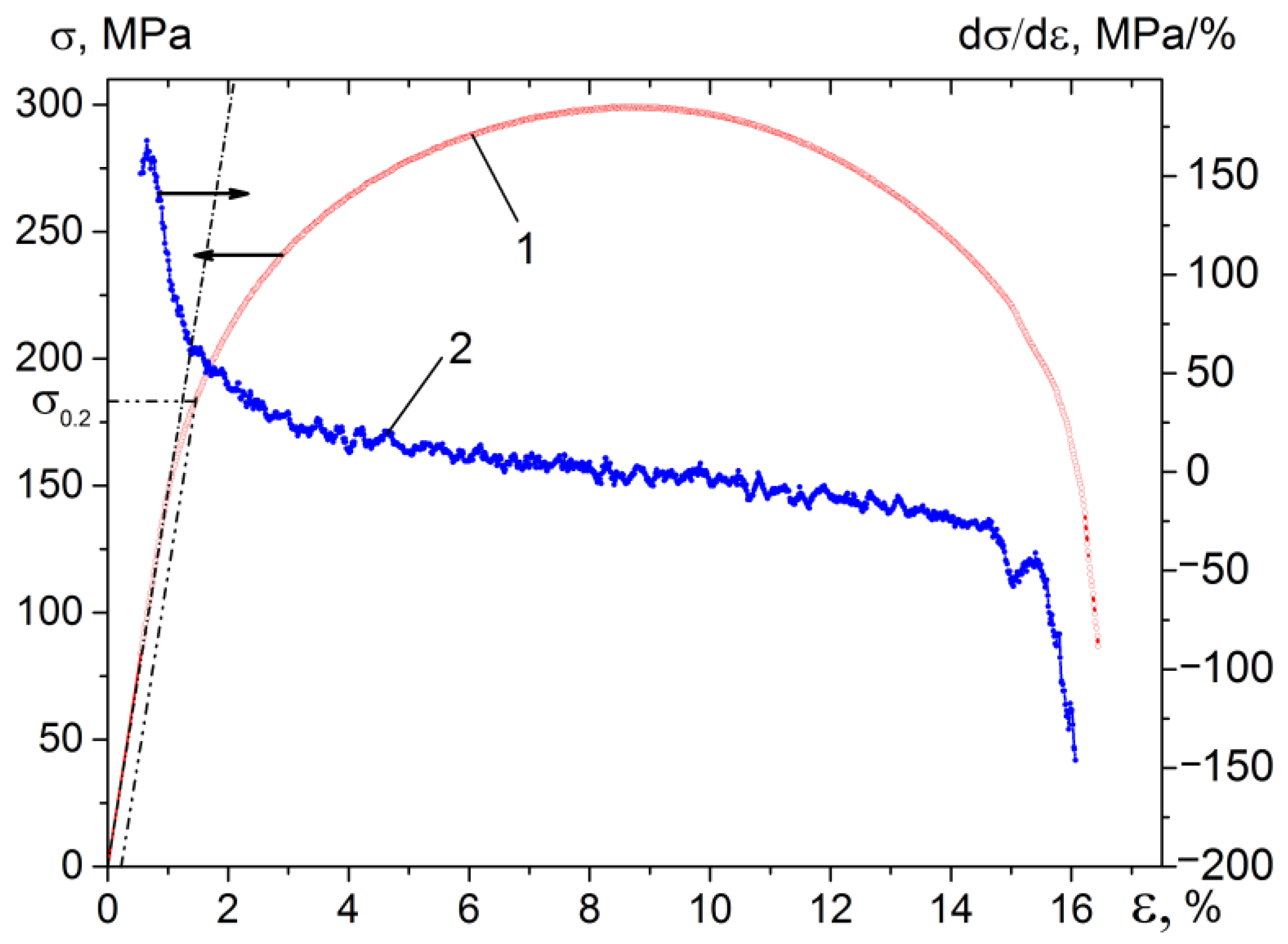

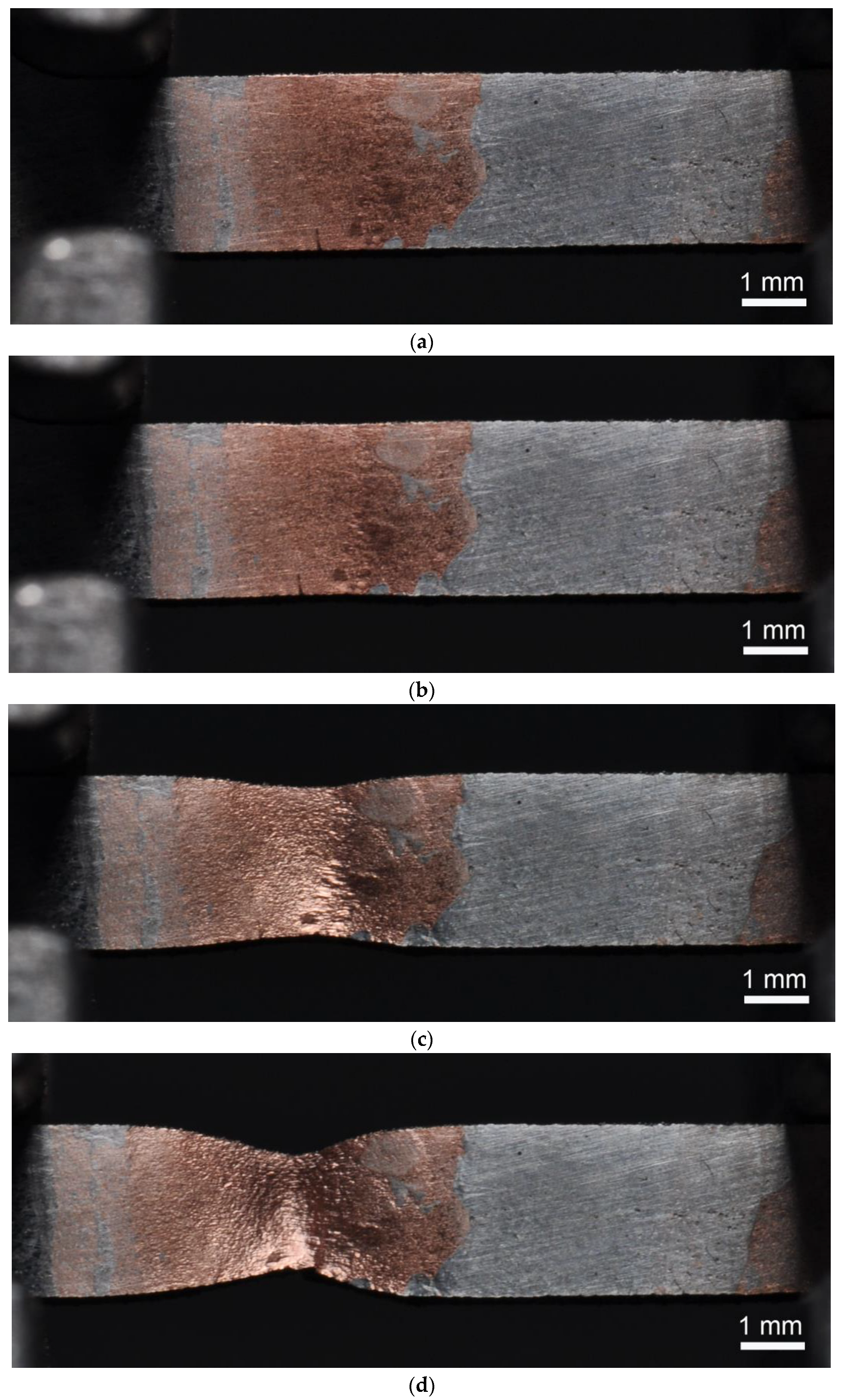

3.2. Tensile Tests

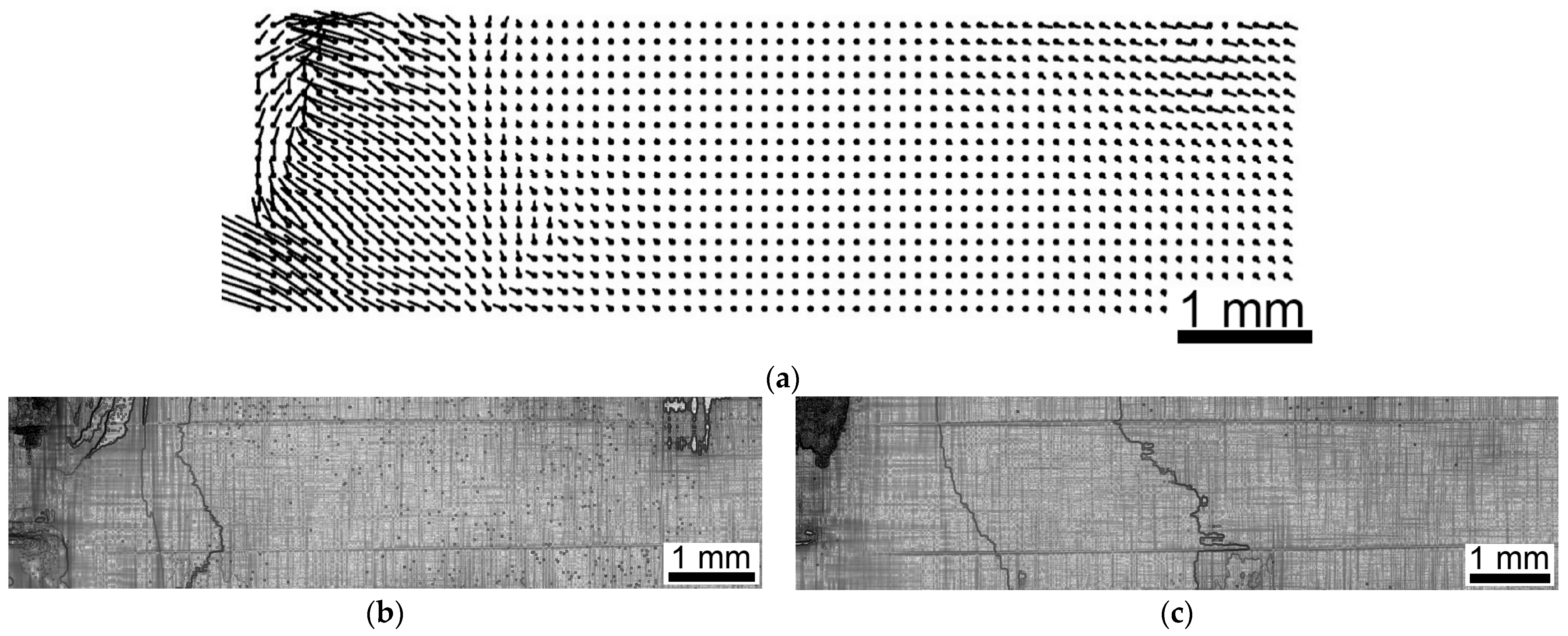

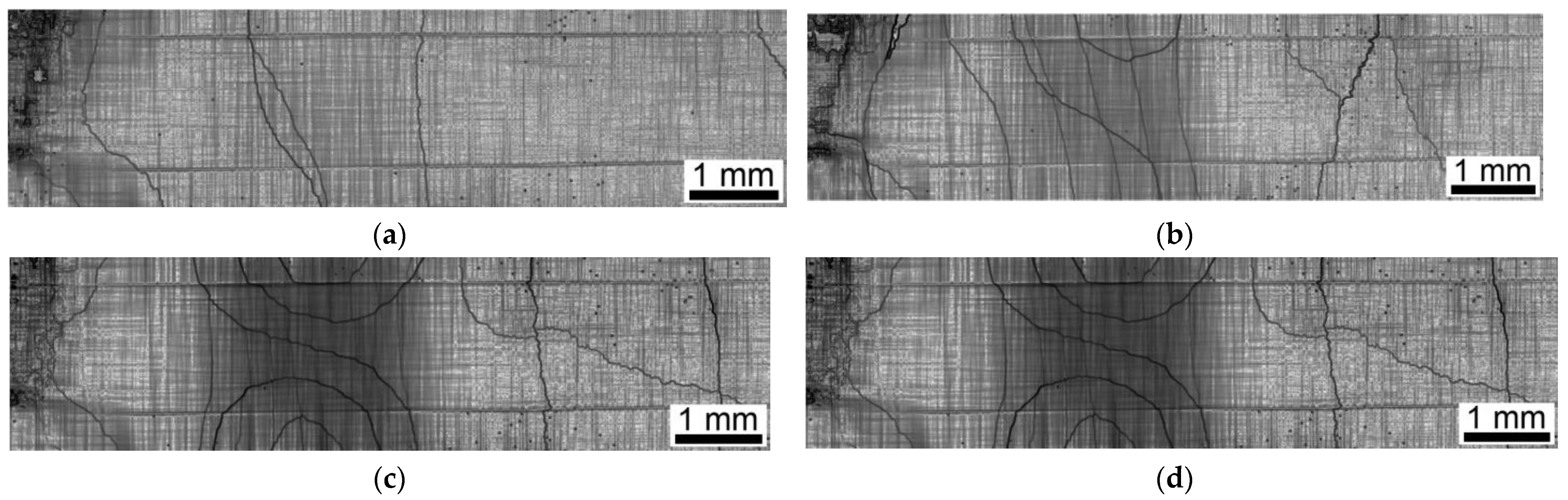

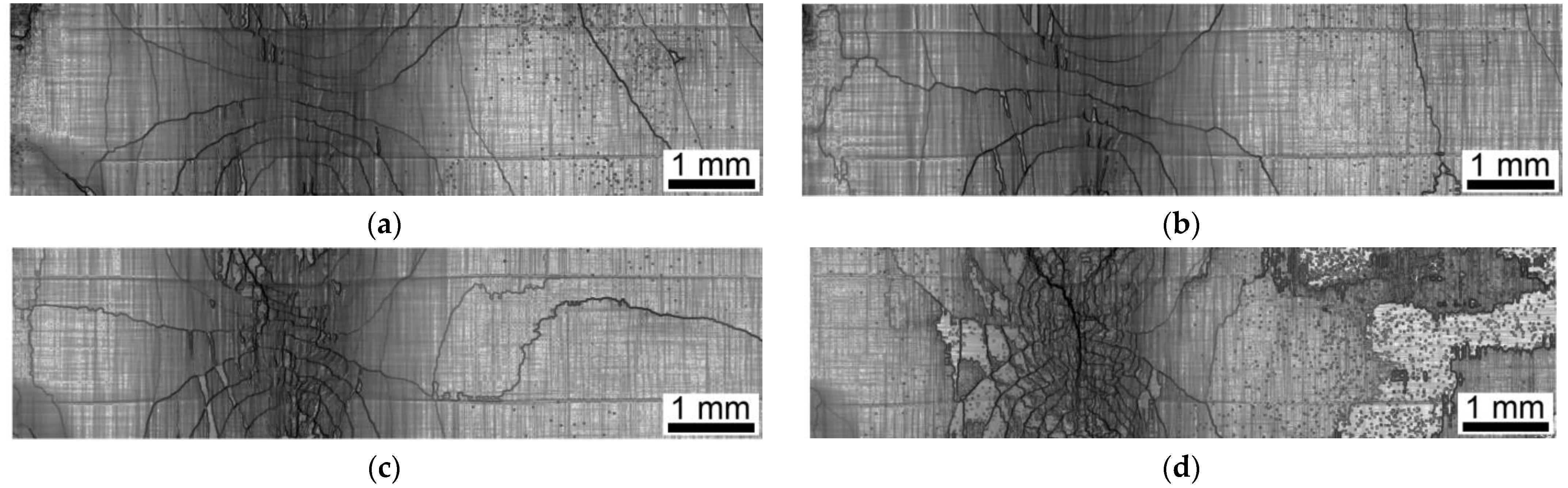

3.3. Digital Image Correlation

3.3.1. Run-in Stage () (Zero Stage)

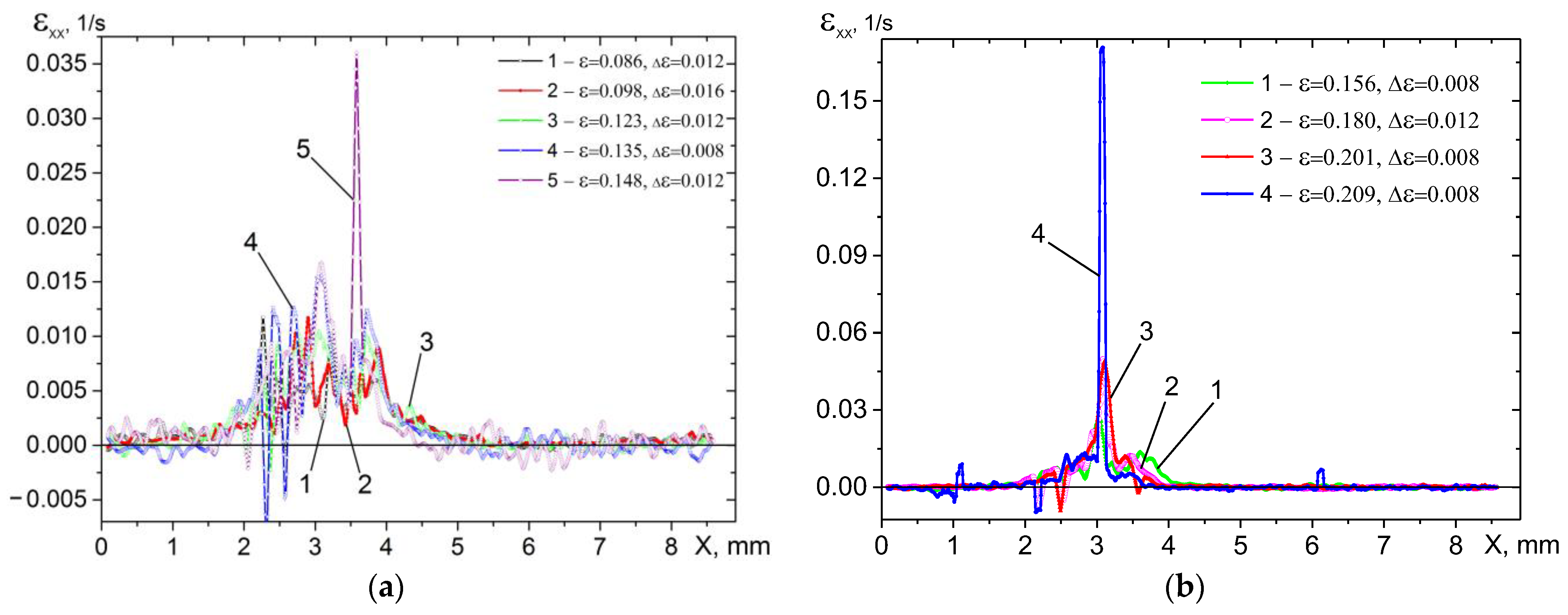

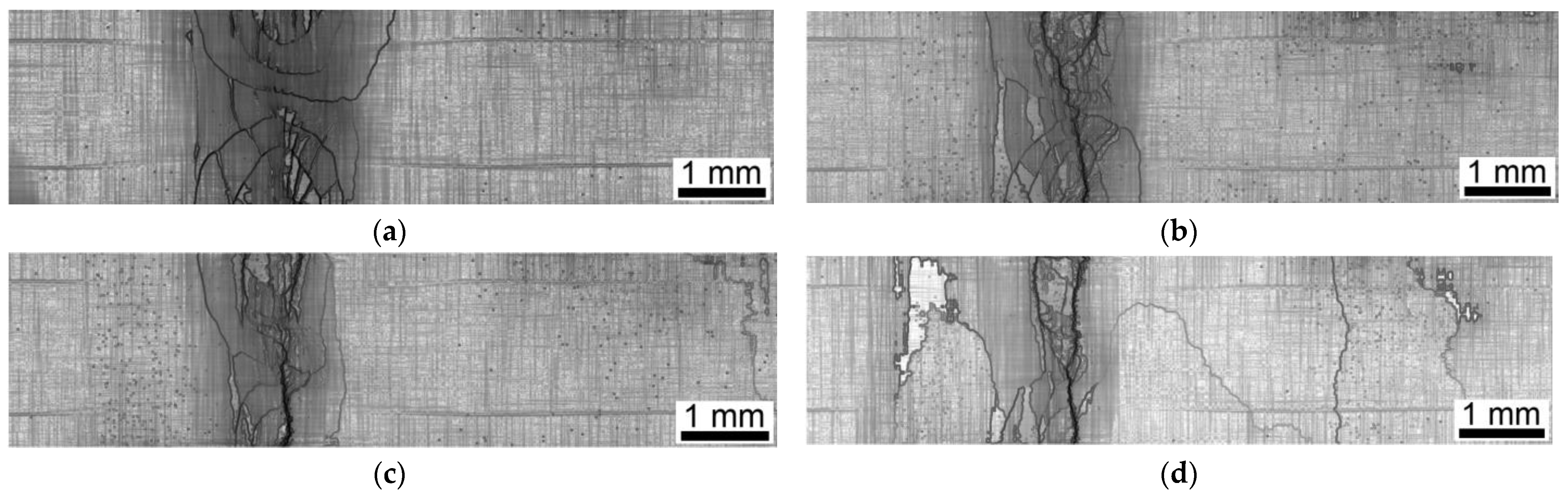

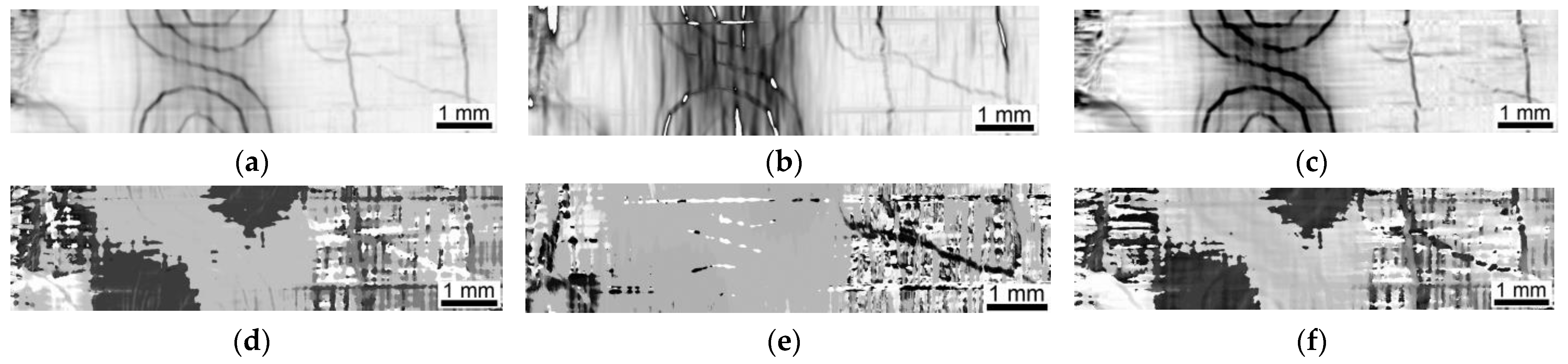

3.3.2. Stage of Formation and Development of a Stable Neck (First Stage)

3.3.3. Stage of Unstable Neck Development (Second Stage)

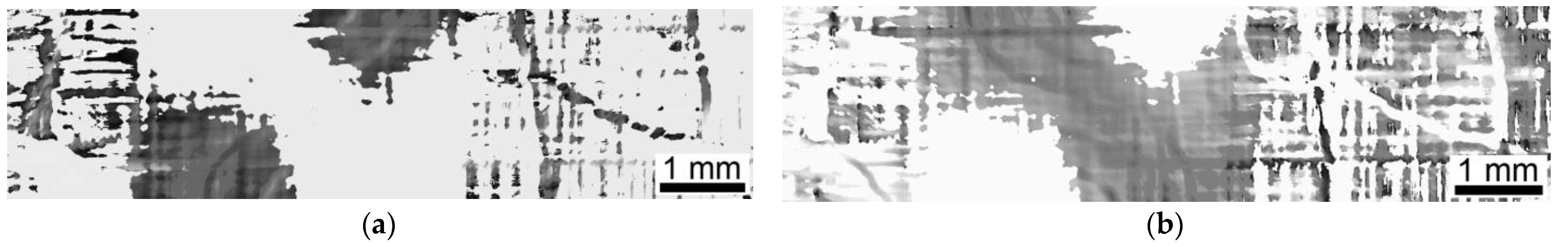

3.3.4. Crack Stage (Third Stage)

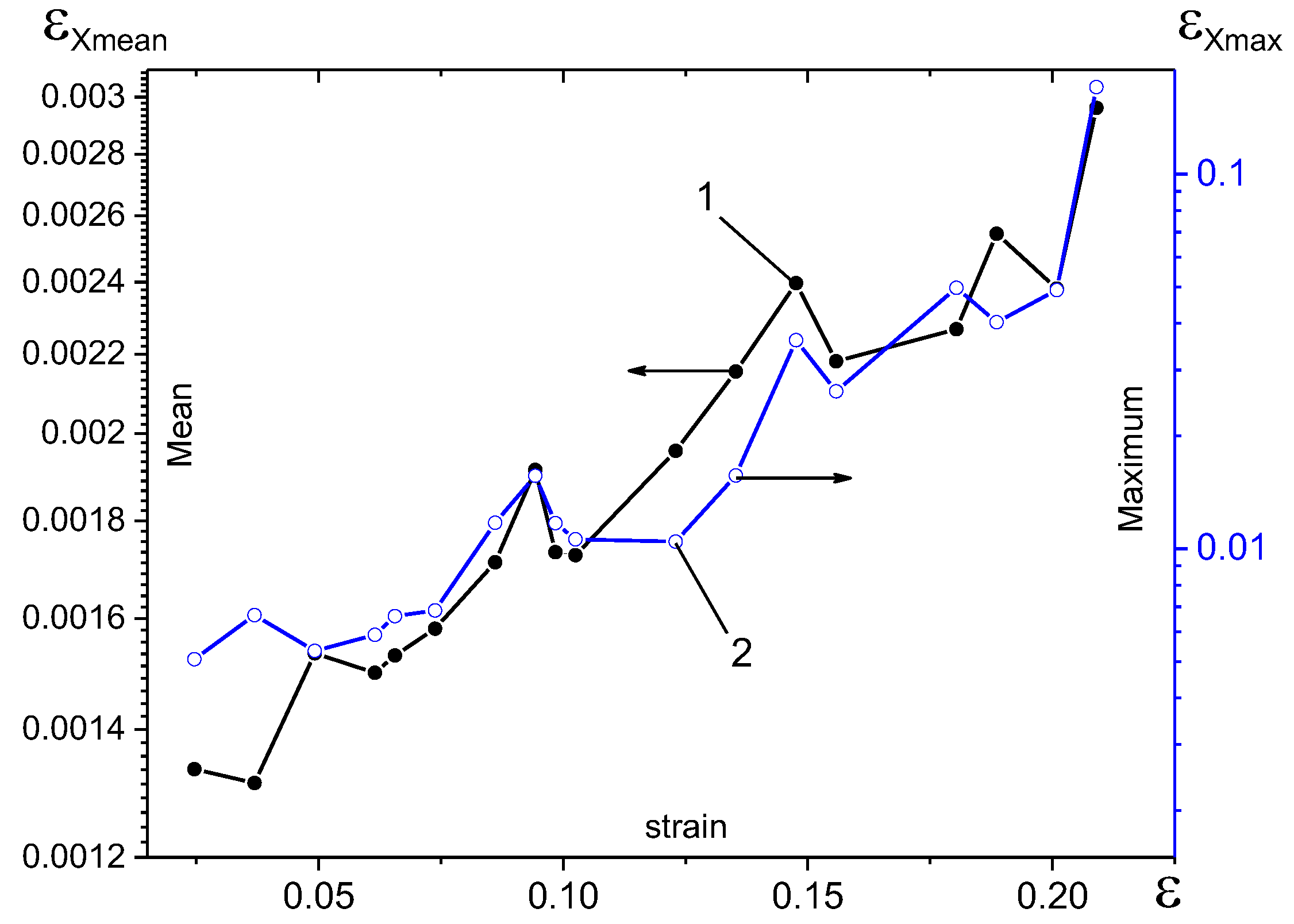

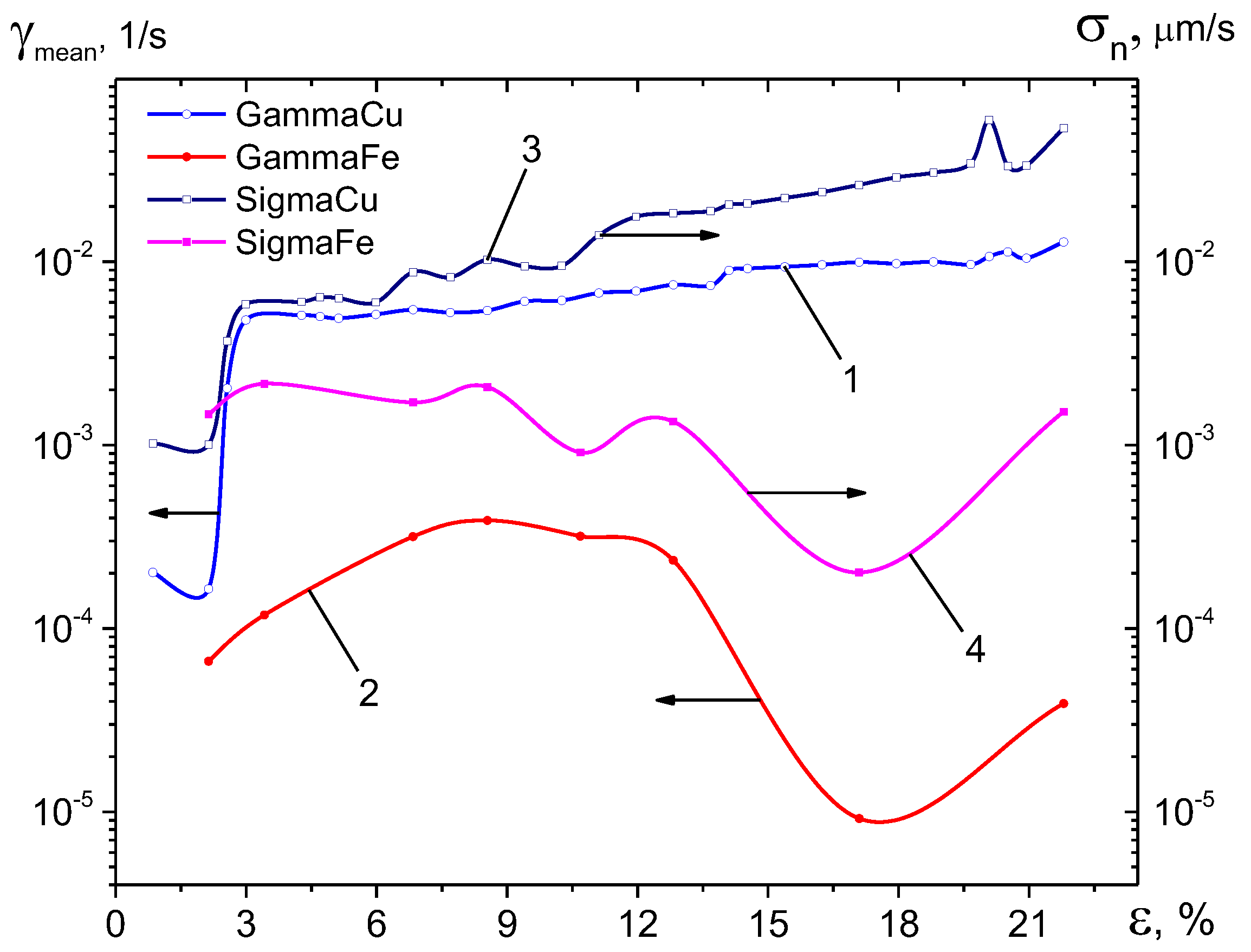

3.3.5. Evolution Curves Based on Deformation

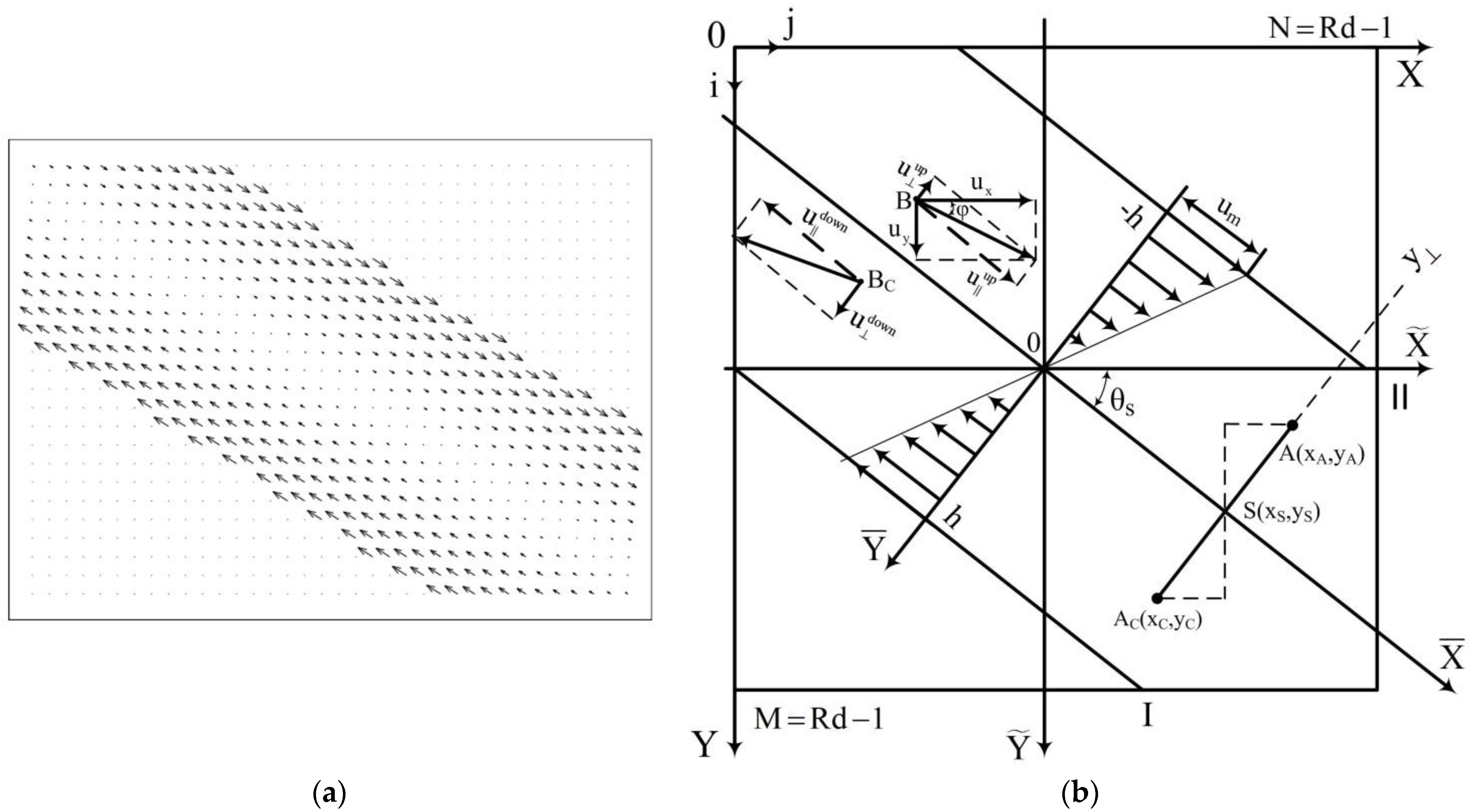

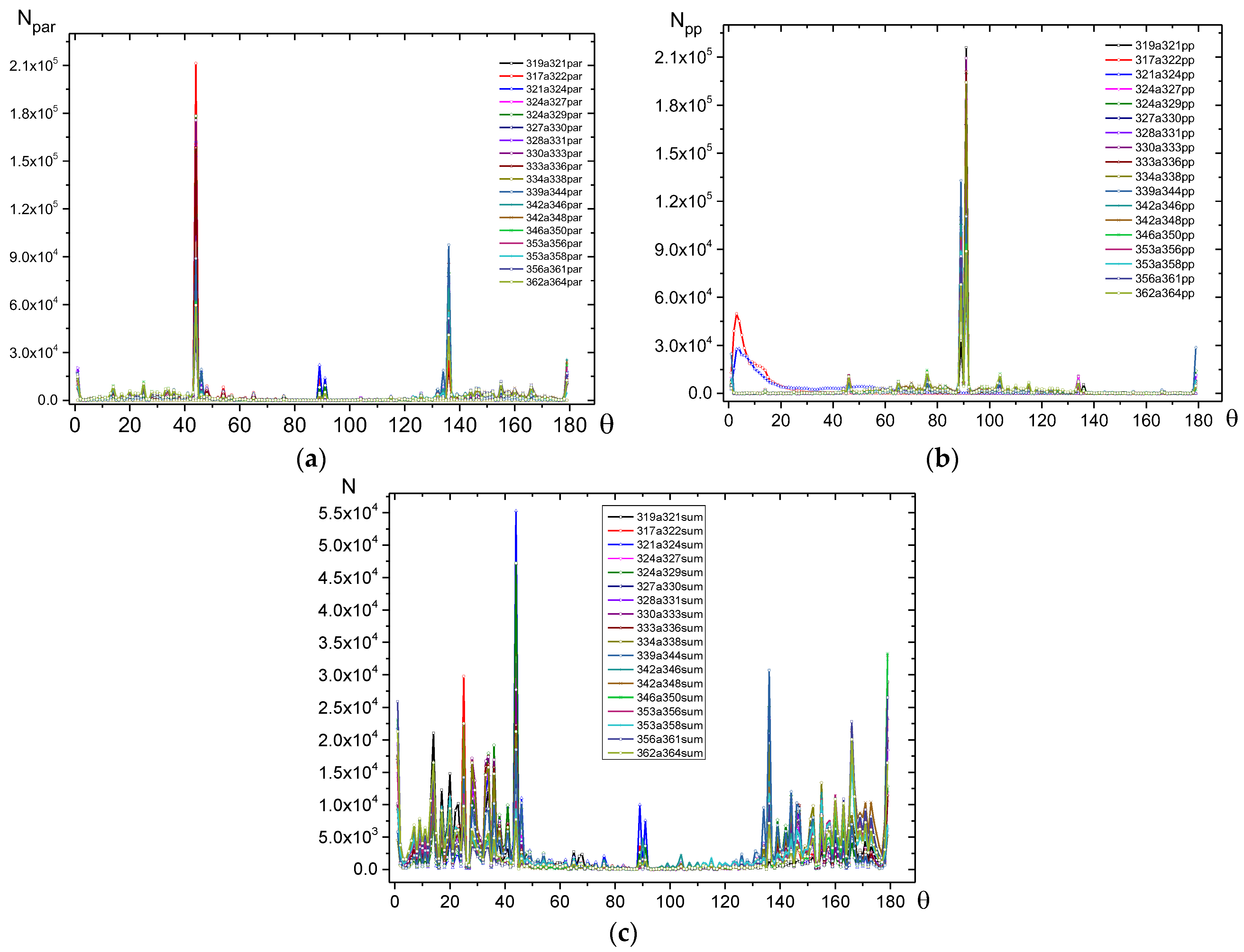

3.3.6. Analysis of Shear Characteristics

3.3.7. Evolution Curves Based on Average Strain in the Areas of Interest

3.4. Study of the Structure and Elemental Composition of Samples after Tensile Tests by SEM and EDS

4. Discussion

5. Conclusions

- Tensile tests were carried out on “copper-steel” joints which showed the next mechanical characteristics: UTS = 299 MPa, elastic limit σE = 150 MPa, yield strength , the relative elongation is 15.4%.

- In the strain range (), V-shaped shear lines are referred to neck formation and they firstly form in copper and then spread to steel. In the range of strain () the formation of longitudinal shear lines becomes a competing deformation mechanism, which leads to the formation of the block structure. At the last, third stage, in the range of strain (), the plasticity resource expires, cracks are formed in central part of the two necks, and main crack is a cause of the joint fracture.

- The study of the evolutionary curves of average strain revealed that the strain rate of copper is 2–3 orders of magnitude higher than that of steel, since copper has a significantly higher ductility. At , steel still competes with copper, where the strain also increases exponentially. In the range , the strain rate in steel remains approximately constant, while at, it decreases by an order of magnitude, which correlates with the appearance of the first macrocracks.

- Thus, in the present work, it is shown that, when stretched, double wire—feed electron beam additive manufactured samples from dissimilar materials (copper and steel) demonstrate high reliability under loading due to the interface zone between materials (copper and steel) to high degrees of deformation remains almost free of defects. The resulting materials can find their application in areas where high thermal conductivity, corrosion resistance and mechanical strength are required.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Kolubaev, E.A.; Rubtsov, V.E.; Chumaevsky, A.V.; Astafurova, E.G. Scientific Approaches to Micro-, Meso- and Macrostructural Design of Bulk Metallic and Polymetallic Materials by Wire-Feed Electron-Beam Additive Manufacturing. Phys. Mesomech. 2022, in press. [Google Scholar] [CrossRef]

- Osipovich, K.; Vorontsov, A.; Chumaevskii, A.; Gurianov, D.; Shamarin, N.; Savchenko, N.; Kolubaev, E. Characterization of a Bimetallic Multilayered Composite “Stainless Steel/Copper” Fabricated with Wire-Feed Electron Beam Additive Manufacturing. Metals 2021, 11, 1151. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Astafurova, E.G.; Chumaevskii, A.V.; Kalashnikov, K.N.; Astafurov, S.V.; Maier, G.G.; Melnikov, E.V.; Moskvina, V.A.; Panchenko, M.Y.; Tarasov, S.Y.; et al. Gradient transition zone structure in “steel–copper” sample produced by double wire-feed electron beam additive manufacturing. J. Mater. Sci. 2020, 55, 9258–9272. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Werley Cipriano Farias, F.; Zhang, K.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Schell, N.; Capek, J.; Polatidis, E.; Santos, T.G.; et al. Wire and arc additive manufacturing of 316L stainless steel/Inconel 625 functionally graded material: Development and characterization. J. Mater. Res. Technol. 2022, 21, 237–251. [Google Scholar] [CrossRef]

- Rodrigues, T.A.; Bairrão, N.; Werley Cipriano Farias, F.; Shamsolhodaei, A.; Shen, J.; Zhou, N.; Maawad, E.; Schell, N.; Santos, T.G.; Oliveira, J.P. Steel-copper functionally graded material produced by twin-wire and arc additive manufacturing. Mater. Des. 2022, 213, 110270. [Google Scholar] [CrossRef]

- Liu, M. Effect of uniform corrosion on mechanical behavior of E690 high-strength steel lattice corrugated panel in marine environment: A finite element analysis. Mater. Res. Express 2021, 8, 066510. [Google Scholar] [CrossRef]

- Liu, M. Finite element analysis of pitting corrosion on mechanical behavior of E690 steel panel. Anti-Corros. Methods Mater. 2022, 28, 7527–7536. [Google Scholar] [CrossRef]

- Shukhardin, S.V. Dual and Multi-Component Systems Based on Copper, 1st ed.; Science: Moscow, Russia, 1979. [Google Scholar]

- Mai, T.A.; Spowage, A.C. Characterisation of dissimilar joints in laser welding of steel–kovar, copper–steel and copper– aluminium. Mater. Sci. Eng. A 2004, 374, 224–233. [Google Scholar] [CrossRef]

- Tan, C.; Chew, Y.; Bi, G.; Wang, D.; Ma, W.; Yang, Y.; Zhou, K. Additive manufacturing of steel–copper functionally graded material with ultrahigh bonding strength. J. Mater. Sci. Technol. 2021, 72, 217–222. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, C.; Pan, T.; Flood, A.; Zhang, Y.; Li, L.; Lio, F. Additive manufacturing of copper-H13 tool steel bi-metallic structures via Ni-based multi-interlayer. Addit. Manuf. 2020, 36, 101474. [Google Scholar] [CrossRef]

- Shu, X.; Chen, G.; Liu, J.; Zhang, B.; Feng, J. Microstructure evolution of copper/steel gradient deposition prepared using electron beam freeform fabrication. Mater. Lett. 2018, 213, 374–377. [Google Scholar] [CrossRef]

- Efstathiou, C.; Sehitoglu, H.; Lambros, J. Multiscale Strain Measurements of Plastically Deforming Polycrystalline Titanium: Role of Deformation Heterogeneities. Int. J. Plast. 2010, 26, 93–106. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components-Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Forsstrom, A.; Bossuyt, S.; Yagodzinskyy, Y.; Tsuzaki, K.; Hanninen, H. Strain localization in copper canister FSW welds for spent nuclear fuel disposal. J. Nucl. Mater. 2019, 523, 347–359. [Google Scholar] [CrossRef]

- Forsström, A.; Luumi, L.; Bossuyt, S.; Hänninen, H. Localisation of plastic deformation in friction stir and electron beam copper welds. Mater. Sci. Technol. 2016, 33, 1119–1129. [Google Scholar] [CrossRef]

- Bao, J.; Benaarbia, A.; Bao, S.; Guo, X.; Wang, Y.; Sun, W. High temperature strain heterogeneities tracking within hole-specimens of FV566 turbine steel via digital image correlation. Mater. Sci. Eng. A 2020, 777, 139068. [Google Scholar] [CrossRef]

- Taniguchi, A.; Maeyama, T.; Uchida, M.; Kaneko, Y. Macroscopic and Microscopic Non-Uniform Deformations of Polycrystalline Pure Copper During Uniaxial Tensile Test with High Stress Gradient. Key Eng. Mater. 2019, 794, 246–252. [Google Scholar] [CrossRef]

- Guo, Y.Z.; Li, F.D.; Suo, T.; Tang, Z.B.; Li, Y.L. A close observation on the deformation behavior of bicrystal copper under tensile loading. Mech. Mater. 2013, 62, 80–89. [Google Scholar] [CrossRef]

- Balit, Y.; Charkaluk, E.; Constantinescu, A. Digital image correlation for microstructural analysis of deformation pattern in additively manufactured 316L thin walls. Addit. Manuf. 2020, 31, 100862. [Google Scholar] [CrossRef]

- Balit, Y.; Guévenoux, C.; Tanguy, A.; Upadhyay, M.V.; Charkaluk, E.; Constantinescu, A. High resolution digital image correlation for microstructural strain analysis of a stainless steel repaired by Directed Energy Deposition. Mater. Lett. 2020, 270, 127632. [Google Scholar] [CrossRef]

- Saranarayanan, R.; Lakshminarayanan, A.K.; Venkatraman, B. A combined full-field imaging and metallography approach to assess the local properties of gas tungsten arc welded copper–stainless steel joints. Arch. Civ. Mech. Eng. 2019, 19, 251–267. [Google Scholar] [CrossRef]

- Kibitkin, V.V.; Solodushkin, A.I.; Pleshanov, V.S. Measuring the Quantitative Characteristics of Local Vortices on a Plane of a Deformed Material. Optoelectron. Instrum. Data Process. 2018, 54, 600–607. [Google Scholar] [CrossRef]

- Kibitkin, V.V.; Solodushkin, A.I.; Pleshanov, V.S. Evolution of the deformation structure for welded joints of low-carbon steel at low-cyclic fatigue. AIP Conf. Proc. 2016, 1783, 020089. [Google Scholar] [CrossRef]

- Kibitkin, V.V.; Solodushkin, A.I.; Pleshanov, V.S. Identification of the shear-type displacement vector field and evaluation of its characteristics. Optoelectron. Instrum. Data Process. 2016, 52, 347–353. [Google Scholar] [CrossRef]

- Liu, S.C.; Jie, J.C.; Zhang, J.J.; Wang, P.F.; Wang, T.M.; Li, T.J.; Yin, G.M. A surface energy driven dissolution model for immiscible Cu-Fe alloy. J. Mol. Liq. 2018, 261, 232–238. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Osipovich, K.S.; Chumaevskii, A.V.; Gusarova, A.V.; Kalashnikov, K.N.; Kolubaev, E.A. Mechanical properties of “Copper-Steel” polymetal, produced by electron-beam wire-feed additive manufacturing. High Temp. Mater. Process. 2020, 24, 91–98. [Google Scholar] [CrossRef]

- Long, Y.; Liao, K.; Huang, X. Microstructure evolution and shear band formation in an ultrafine-grained Ti–6Al–4V alloy during cold compression. Mater. Sci. Eng. A 2022, 856, 144026. [Google Scholar] [CrossRef]

- Kibitkin, V.; Solodushkin, A.; Pleshanov, V.; Napryushkin, A. On a choice of input parameters for calculation the vector field and deformation with DIC. Measurement 2017, 95, 266–272. [Google Scholar] [CrossRef]

- Guo, S.; Zhou, Q.; Kong, J.; Peng, Y.; Xiang, Y.; Luo, T.-Y.; Wang, K.-H.; Zhu, J. Effect of beam offset on the characteristics of copper/304stainless steel electron beam welding. Vacuum 2016, 128, 205–212. [Google Scholar] [CrossRef]

- Liu, Z.H.; Zhang, D.Q.; Sing, S.L.; Chua, C.K.; Loh, L.E. Interfacial characterization of SLM parts in multi-material processing Metallurgical diffusion between 316L stainless steel and C18400 copper alloy. Mater. Charact. 2014, 94, 116–125. [Google Scholar] [CrossRef]

- Imran, M.K.; Masood, S.H.; Brandt, M.; Bhattacharya, S.; Mazumder, J. Direct metal deposition (DMD) of H13 tool steel on copper alloy substrate Evaluation of mechanical properties. Mater. Sci. Eng. A 2011, 528, 3342–3349. [Google Scholar] [CrossRef]

- Tan, C.; Zhou, K.; Ma, W.; Min, L. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture. Mater. Des. 2018, 155, 77–85. [Google Scholar] [CrossRef]

- Karnati, S.; Zhang, Y.; Liou, F.F.; Newkirk, J.W. On the Feasibility of Tailoring Copper–Nickel Functionally Graded Materials Fabricated through Laser Metal Deposition. Metals 2019, 9, 287. [Google Scholar] [CrossRef]

- Hunt, J.D. Cellular and Primary Dendrite Spacings. In Solidification and Casting of Metals: Proceedings of an International Conference on Solidification, Organized Jointly by the Sheffield Mettallurgical and Engineering Association with the Metals Society; Casting of Metals: Sheffield, UK, 1979; pp. 3–9. [Google Scholar]

- Foehring, D.; Chew, H.B.; Lambros, J. Characterizing the tensile behavior of additively manufactured Ti-6Al-4V using multiscale digital image correlation. Mater. Sci. Eng. A 2018, 724, 536–546. [Google Scholar] [CrossRef]

- Zhang, K.; Wang, S.; Liu, W.; Shang, X. Characterization of stainless steel parts by laser metal deposition shaping. Mater. Des. 2014, 55, 104–119. [Google Scholar] [CrossRef]

| Material | Fe | Cu | Ni | Cr | Mn | Ti | Si | C |

|---|---|---|---|---|---|---|---|---|

| AISI 321 | Bal. | to 0.3 | 9–11 | 17–19 | to 2 | – | to 0.8 | to 0.08 |

| C11000 | to 0.005 | Bal. | to 0.002 | – | – | – | – | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kibitkin, V.; Vorontsov, A.; Osipovich, K.; Shamarin, N.; Chumaevskii, A.; Rubtsov, V.; Moskvichev, E.; Savchenko, N.; Kolubaev, E. Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation. Metals 2022, 12, 1797. https://doi.org/10.3390/met12111797

Kibitkin V, Vorontsov A, Osipovich K, Shamarin N, Chumaevskii A, Rubtsov V, Moskvichev E, Savchenko N, Kolubaev E. Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation. Metals. 2022; 12(11):1797. https://doi.org/10.3390/met12111797

Chicago/Turabian StyleKibitkin, Vladimir, Andrey Vorontsov, Kseniya Osipovich, Nikolay Shamarin, Andrey Chumaevskii, Valery Rubtsov, Evgeny Moskvichev, Nickolai Savchenko, and Evgeny Kolubaev. 2022. "Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation" Metals 12, no. 11: 1797. https://doi.org/10.3390/met12111797

APA StyleKibitkin, V., Vorontsov, A., Osipovich, K., Shamarin, N., Chumaevskii, A., Rubtsov, V., Moskvichev, E., Savchenko, N., & Kolubaev, E. (2022). Characterizing the Tensile Behavior of Double Wire-Feed Electron Beam Additive Manufactured “Copper–Steel” Using Digital Image Correlation. Metals, 12(11), 1797. https://doi.org/10.3390/met12111797