Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review

Abstract

:1. Introduction

2. Additive Manufacturing

- (i)

- Binder blasting;

- (ii)

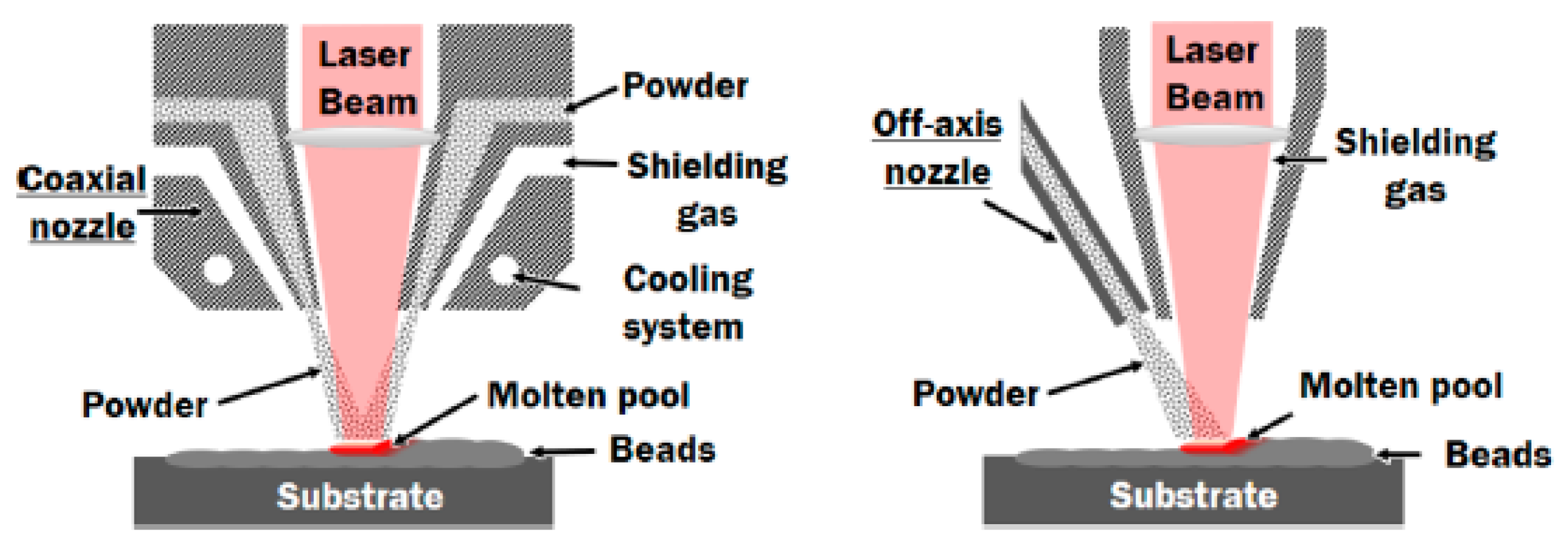

- Directed energy deposition—DED (comprised of processes such as direct deposition of metal), such as wire arc additive manufacturing (WAAM);

- (iii)

- Material extrusion (which includes fuse deposition modeling (FDM));

- (iv)

- Material jetting;

- (v)

- Powder bed fusion (which includes processes such as direct metal laser sintering (DMLS) and selective laser sintering (SLS));

- (vi)

- Sheet laminating (ultrasonic additive manufacturing (UAM) and laminated object manufacturing (LOM));

- (vii)

- Vat polymerization.

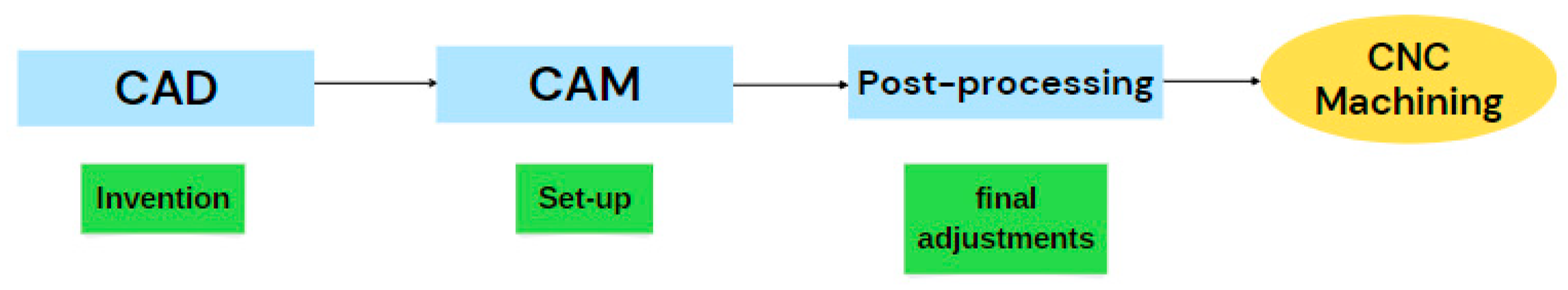

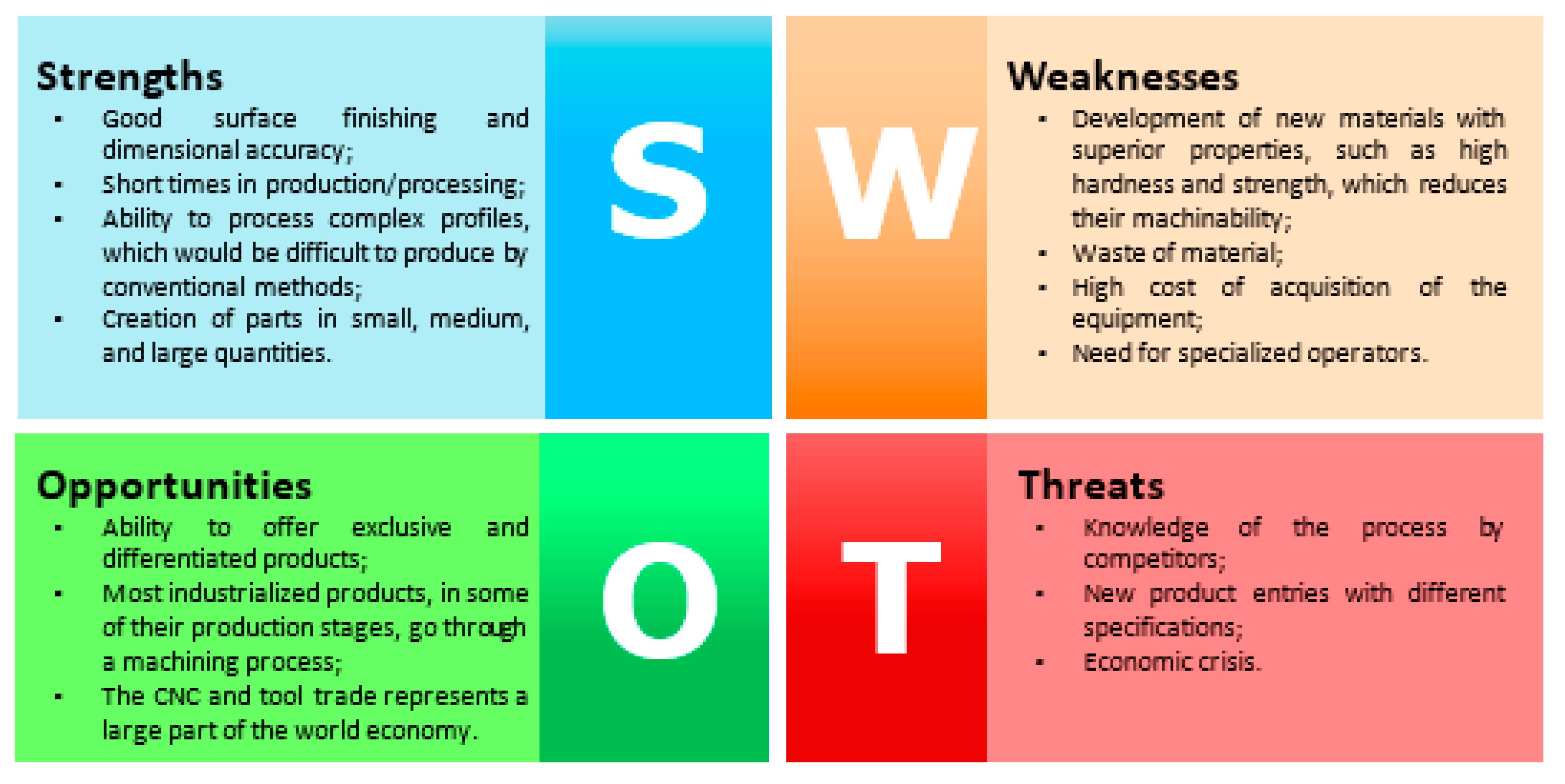

3. CNC Machining

Machining with 5 or More Axis

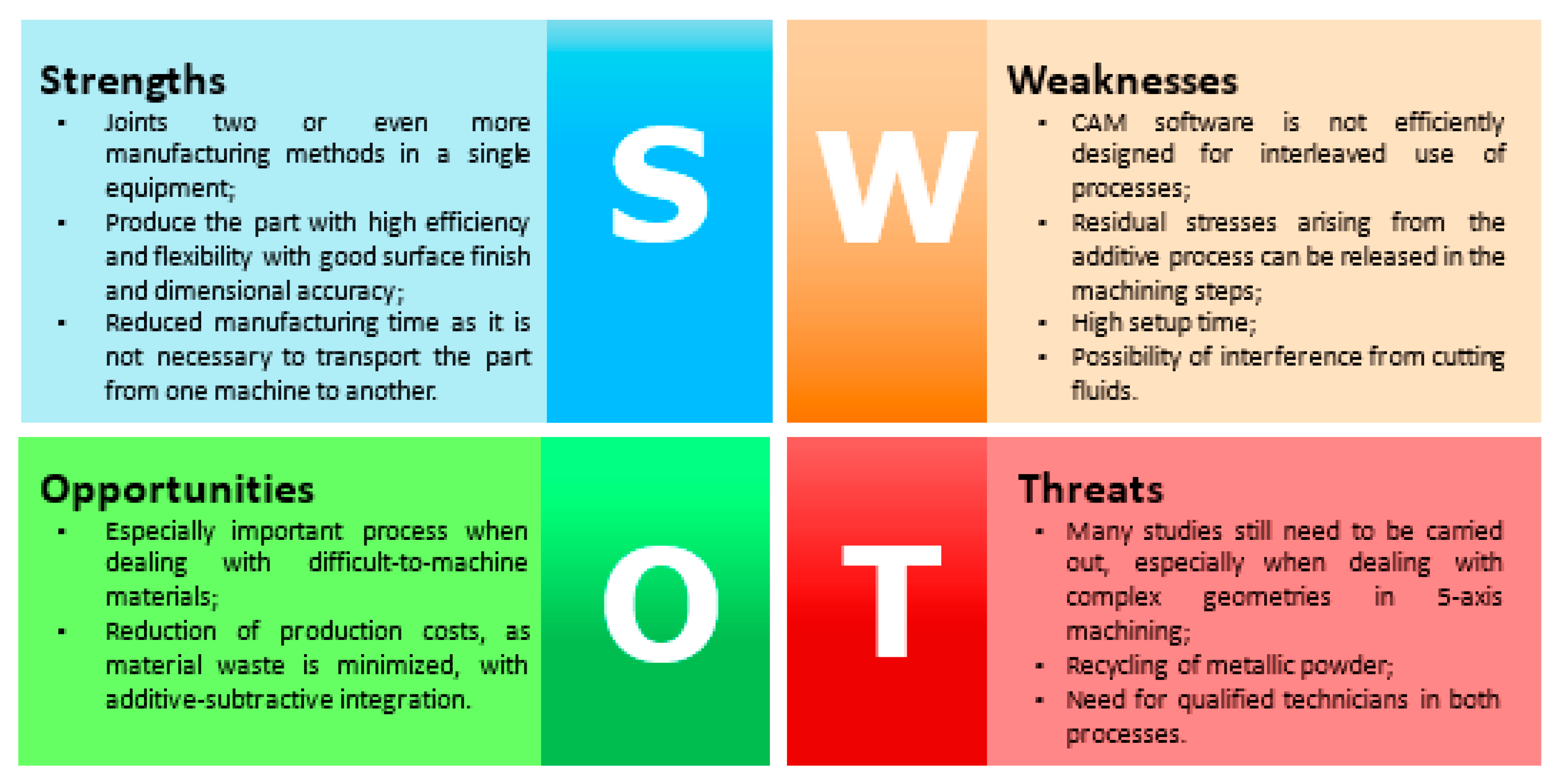

4. Hybrid Manufacturing Processes

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Bhattacharyya, B.; Doloi, B. Modern Machining Technology—Advanced, Hybrid, Micro Machining and Super Finishing Technology; Academic Press: San Diego, CA, USA, 2020; pp. 461–591. ISBN 9780128128947. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Luo, X.; Cai, Y.; Chavoshi, S.Z. Hybrid Machining-Theory, Methods, and Case Studies; Academic Press: London, UK, 2018; pp. 1–15. ISBN 9780128130599. [Google Scholar]

- Schuh, G.; Kreysa, J.; Orilski, S. Roadmap Hybride Produktion: Wie 1 + 1 = 3-Effekte in der Produktion maximiert werden können. Z. Wirtsch. Fabr. 2009, 104, 385–391. [Google Scholar] [CrossRef]

- Saxena, K.K.; Bellotti, M.; Qian, J.; Reynaerts, D.; Lauwers, B.; Luo, X. Chapter 2—Overview of Hybrid Machining Processes, Hybrid Machining; Academic Press: London, UK, 2018; pp. 21–41. ISBN 9780128130599. [Google Scholar]

- Karunakaran, K.P.; Suryakumar, S.; Pushpa, V.; Akula, S. Low cost integration of additive and subtractive processes for hybrid layered manufacturing. Robot. Comput.-Integr. Manuf. 2010, 26, 490–499. [Google Scholar] [CrossRef]

- Cortina, M.; Ruiz, J.E.; Villarón, I.; Arrizubieta, J.I.; Borgiattino, H.; Dünky, A.; Martinez, J.; Baine, S. Máquina Híbridas: A Integração de Processos. Available online: https://www.intermetal.pt/Artigos/265587-Maquinas-hibridas-integrando-processos.html (accessed on 13 January 2022).

- Matias, E.; Rao, B. 3D printing: On its historical evolution and the implications for business. In Proceedings of the PICMET’15: Management of the Technology Age, Hilton Portland, OR, USA, 2–6 August 2015; pp. 551–558. [Google Scholar] [CrossRef]

- Diegel, O. 10.02—Additive Manufacturing: An Overview. In Comprehensive Materials Processing; Hashmi, S., Batalha, G.F., Van Tyne, C.J., Yilbas, B., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 3–18. ISBN 9780080965338. [Google Scholar]

- Yamazaki, T. Development of A Hybrid Multi-Tasking Machine Tool: Integration of Additive Manufacturing Technology with CNC Machining. Procedia CIRP 2016, 42, 81–86. [Google Scholar] [CrossRef]

- Ashby, M.F.; Jones, D.R.H. Engineering Materials 2: An Introduction to Microstructures and Processing; Butterworth-Heinemann: Oxford, UK, 2013; pp. 280–296. ISBN 9780080966687. [Google Scholar]

- Mazak. 5-Axis. What Is 5-Axis Machining? Available online: https://www.mazakusa.com/machines/process/5-axis/ (accessed on 13 January 2022).

- Saxer, M.; Dimitrov, D.; de Beer, N. High-speed 5-axis machining for tooling applications. S. Afr. J. Ind. Eng. 2012, 23, 144–153. [Google Scholar] [CrossRef] [Green Version]

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Bogers, M.; Hadar, R.; Bilberg, A. Additive manufacturing for consumer-centric business models: Implications for supply chains in consumer goods manufacturing. Technol. Forecast. Soc. Chang. 2015, 102, 225–239. [Google Scholar] [CrossRef]

- Phaal, R.; O’Sullivan, E.; Routley, M.; Ford, S.; Probert, D. A framework for mapping industrial emergence. Technol. Forecast. Soc. Chang. 2011, 78, 217–230. [Google Scholar] [CrossRef]

- Afuah, A. Business Model Innovation: Concepts, Analysis and Cases; Routledge: New York, NY, USA, 2018; ISBN 9781138330528. [Google Scholar]

- Zott, C.; Amit, R.; Massa, L. The business model: Recent developments and future research. J. Manag. 2011, 37, 1019–1042. [Google Scholar] [CrossRef]

- Savolainen, J.; Collan, M. Additive manufacturing technology and business model change—A review of literature. Addit. Manuf. 2020, 32, 101070. [Google Scholar] [CrossRef]

- Tempelman, E.; Shercliff, H.; van Eyben, B.N. Manufacturing and Design—Understanding the Principles of How Things Are Made; Butterworth-Heinemann: Oxford, UK, 2014; pp. 187–200. ISBN 9780080999227. [Google Scholar]

- Alghamdi, S.S.; John, S.; Choudhury, N.R.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef] [PubMed]

- Loughborough University. The 7 Categories of Additive Manufacturing—Additive Manufacturing Research Group. Available online: https://www.lboro.ac.uk/research/amrg/about/the7categoriesofadditivemanufacturing/ (accessed on 13 January 2022).

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. Massachusetts Institute of Technology. U.S. Patent No. 5,204,055, 20 April 1993. [Google Scholar]

- Chen, Q.; Juste, E.; Lasgorceix, M.; Petit, F.; Leriche, A. Binder jetting process with ceramic powders: Influence of powder properties and printing parameters. Open Ceram. 2022, 9, 100218. [Google Scholar] [CrossRef]

- Lee, K.; Kim, H.; Ahn, D.; Lee, H. Thermo-mechanical characteristics of inconel 718 layer deposited on AISI 1045 steel substrate using a directed energy deposition process. J. Mater. Res. Technol. 2022, 17, 293–309. [Google Scholar] [CrossRef]

- Ahn, D.G. Direct metal additive manufacturing processes and their sustainable applications for green technology: A review. Int. J. Precis. Eng. Manuf. Green Technol. 2016, 3, 381–395. [Google Scholar] [CrossRef]

- Ahn, D.G. Directed Energy Deposition (DED) Process: State of the Art. Int. J. Precis. Eng. Manuf. Green Technol. 2021, 8, 703–742. [Google Scholar] [CrossRef]

- Chen, Z.; Guo, X.; Jing, S. Hardness Prediction and Verification Based on Key Temperature Features During the Directed Energy Deposition Process. Int. J. Precis. Eng. Manuf. Green Technol. 2020, 8, 453–469. [Google Scholar] [CrossRef]

- Tekumalla, S.; Tosi, R.; Tan, X.; Seita, M. Directed energy deposition and characterization of high-speed steels with high vanadium content. Addit. Manuf. Lett. 2022, 2, 100029. [Google Scholar] [CrossRef]

- Radhakrishnan, M.; Hassan, M.; Long, B.; Otazu, D.; Lienert, T.; Anderoglu, O. Microstructures and properties of Ti/TiC composites fabricated by laser-directed energy deposition. Addit. Manuf. 2021, 46, 102198. [Google Scholar] [CrossRef]

- Grossi, N.; Scippa, A.; Venturini, G.; Campatelli, G. Process Parameters Optimization of Thin-Wall Machining for Wire Arc Additive Manufactured Parts. Appl. Sci. 2020, 10, 7575. [Google Scholar] [CrossRef]

- Artaza, T.; Suárez, A.; Veiga, F.; Braceras, I.; Tabernero, I.; Larrañaga, O.; Lamikiz, A. Wire arc additive manufacturing Ti6Al4V aeronautical parts using plasma arc welding: Analysis of heat-treatment processes in different atmospheres. J. Mater. Res. Technol. 2020, 9, 15454–15466. [Google Scholar] [CrossRef]

- Veiga, F.; Gil Del Val, A.; Suárez, A.; Alonso, U. Analysis of the Machining Process of Titanium Ti6Al-4V Parts Manufactured by Wire Arc Additive Manufacturing (WAAM). Materials 2020, 13, 766. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Loughborough University. About Additive Manufacturing. Available online: https://www.lboro.ac.uk/research/amrg/about/the7categoriesofadditivemanufacturing/materialextrusion/ (accessed on 13 January 2022).

- Rosen, D. Design for Additive Manufacturing: Past, Present, and Future Directions. J. Mech. Des. 2014, 136, 090301. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused deposition modeling of thermoplastic elastomeric materials: Challenges and opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar] [CrossRef]

- Jin, Y.-A.; Li, H.; He, Y.; Fu, J.-Z. Quantitative analysis of surface profile in fused deposition modeling. Addit. Manuf. 2015, 8, 142–148. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- Tyagi, S.; Yadav, A.; Deshmukh, S. Review on mechanical characterization of 3D printed parts created using material jetting process. Mater. Today Proc. 2022, 51, 1012–1016. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Goodridge, R.; Ziegelmeier, S. Laser Additive Manufacturing—Materials, Design, Technologies, and Applications; Brandt, M., Ed.; Woodhead Publishing: Sawston, UK, 2017; pp. 181–204. ISBN 9780081004333. [Google Scholar]

- Zhang, Y.; Jarosinski, W.; Jung, Y.-G.; Zhang, J. Additive Manufacturing: Materials, Processes, Quantifications and Applications; Butterworth-Heinemann: Cambridge, MA, USA, 2018; pp. 39–51. ISBN 978-0-12-812155-9. [Google Scholar]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Chennai, India, 2019; pp. 7–31. ISBN 9780128140628. [Google Scholar]

- Gan, X.; Fei, G.; Wang, J.; Wang, Z.; Lavorgna, M.; Xia, H. Structure and Properties of Additive Manufactured Polymer Components; Friedrich, K., Walter, R., Soutis, C., Suresh, G.A., Habil, I., Fiedler, B., Eds.; Woodhead Publishing: Sawston, UK, 2020; pp. 149–185. ISBN 9780128195352. [Google Scholar]

- Nar, K.; Majewski, C.; Lewis, R. A comprehensive characterisation of Laser Sintered Polyamide-12 surfaces. Polym. Test. 2022, 106, 107450. [Google Scholar] [CrossRef]

- Friel, R.J. Power Ultrasonics—Applications of High-Intensity Ultrasound; Juan, A., Juárez, G., Karl, F.G., Eds.; Woodhead Publishing: Sawston, UK, 2015; pp. 313–335. ISBN 978-1-78242-028-6. [Google Scholar]

- Schwope, L.-A.; Friel, R.J.; Johnson, K.; Harris, R.A. Field repair and replacement part fabrication of military components using ultrasonic consolidation cold metal deposition. In Proceedings of the RTO-MP-AVT-163—Additive Technology for Repair of Military Hardware, Bonn, Germany, 19–22 October 2009; p. 22. [Google Scholar]

- Hehr, A.; Norfolk, M. A comprehensive review of ultrasonic additive manufacturing. Rapid Prototyp. J. 2019, 26, 445–458. [Google Scholar] [CrossRef]

- Chartrain, N.A.; Williams, C.B.; Whittington, A.R. A review on fabricating tissue scaffolds using vat photopolymerization. Acta Biomater. 2018, 74, 90–111. [Google Scholar] [CrossRef] [PubMed]

- Al Rashid, A.; Ahmed, W.; Khalid, M.Y.; Koç, M. Vat photopolymerization of polymers and polymer composites: Processes and applications. Addit. Manuf. 2021, 47, 102279. [Google Scholar] [CrossRef]

- Revilla-León, M.; Piedra-Cascón, W.; Aragoneses, R.; Sadeghpour, M.; Barmak, B.A.; Zandinejad, A.; Raigrodski, A.J. Influence of base design on the manufacturing accuracy of vat-polymerized diagnostic casts: An in vitro study. J. Prosthet. Dent. 2021. [Google Scholar] [CrossRef]

- Leary, M. Design for Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2020; pp. 283–293. ISBN 978-0-12-816721-2. [Google Scholar]

- Wong, K.V.; Hernandez, A. A Review of Additive Manufacturing. International Scholarly Research Network. ISRN Mech. Eng. 2012, 2012, 208760. [Google Scholar] [CrossRef] [Green Version]

- Khondoker, M.A.H.; Asad, A.; Sameoto, D. Printing with mechanically interlocked extrudates using a custom bi-extruder for fused deposition modelling. Rapid Prototyp. J. 2018, 24, 921–934. [Google Scholar] [CrossRef]

- Cresswell-Boyes, A.J.; Barber, A.H.; Mills, D.; Tatla, A.; Davis, G.R. Approaches to 3D printing teeth from X-ray microtomography. J. Microsc. 2018, 272, 207–212. [Google Scholar] [CrossRef]

- Park, S.H.; Su, R.; Jeong, J.; Guo, S.Z.; Qiu, K.; Joung, D.; Meng, F.; McAlpine, M.C. 3D printed polymer photodetectors. Adv. Mater. 2018, 30, e1803980. [Google Scholar] [CrossRef]

- Tofail, S.A.M.; Koumoulos, E.P.; Bandyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additive manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2017, 21, 22–37. [Google Scholar] [CrossRef]

- Pragana, J.P.M.; Sampaio, R.F.V.; Bragança, I.M.F.; Silva, C.M.A.; Martins, P.A.F. Hybrid metal additive manufacturing: A state–of–the-art review. Adv. Ind. Manuf. Eng. 2021, 2, 100032. [Google Scholar] [CrossRef]

- Zębala, W.; Plaza, M. Comparative study of 3- and 5-axis CNC centers for free-form machining of difficult-to-cut material. Int. J. Prod. Econ. 2014, 158, 345–358. [Google Scholar] [CrossRef]

- Baksi, S. CNC Machine: Types, Parts, Advantages, Disadvantages, Applications, and Specifications. Available online: https://learnmechanical.com/cnc-machine/#What_is_a_CNC_Machine (accessed on 20 January 2022).

- Hay, A. Ultimate Guide to CNC Machining. Available online: https://jiga.io/resource-center/cnc-machining/what-is-cnc-machining-guide/ (accessed on 22 January 2022).

- Varotsis, A.B. Introduction to CNC Machining. Available online: https://www.hubs.com/knowledge-base/cnc-machining-manufacturing-technology-explained/#pros-cons (accessed on 22 January 2022).

- Li, M. What Is CNC Milling, Advantages and Disadvantages. Available online: https://www.3qmachining.com/what-is-cnc-milling-advantages-and-disadvantages/ (accessed on 22 January 2022).

- Cloud, N.C. What’s the Difference between 3-Axis, 4-Axis & 5-Axis Milling? Available online: https://cloudnc.com/cnc-best-practices-3-whats-the-difference-between-3-axis-4-axis-5-axis-milling/ (accessed on 22 January 2022).

- Yu, Z.; Zhi-Tong, C.; Tao, N.; Ru-Feng, X. Tool orientation optimization for 3 + 2-axis CNC machining of sculptured surface. Comput. Aided Des. 2016, 77, 60–72. [Google Scholar] [CrossRef]

- Gray, P.; Bedi, S.; Ismail, F.; Rao, N.; Morphy, G. Comparison of 5-Axis and 3-Axis Finish Machining of Hydroforming Die Inserts. Int. J. Adv. Manuf. Technol. 2001, 17, 562–569. [Google Scholar] [CrossRef]

- Sheen, B.T.; You, C.F. Machining feature recognition and tool-path generation for 3-axis CNC milling. Comput. Aided Des. 2006, 38, 553–562. [Google Scholar] [CrossRef]

- Senatore, J.; Segonds, S.; Rubio, W.; Dessein, G. Correlation between machining direction, cutter geometry and step-over distance in 3-axis milling: Application to milling by zones. Comput. Aided Des. 2012, 44, 1151–1160. [Google Scholar] [CrossRef] [Green Version]

- D’Souza, R.M.; Sequin, C.; Wright, P.K. Automated tool sequence selection for 3-axis machining of free-form pockets. Comput. Aided Des. 2004, 36, 595–605. [Google Scholar] [CrossRef]

- Huang, L. What Is 4-Axis and 5-Axis CNC Machining? Available online: https://www.rapiddirect.com/blog/4-axis-and-5-axis-cnc-machining/ (accessed on 22 January 2022).

- Axinte, D.A.; Shukor, S.A.; Bozdana, A.T. An analysis of the functional capability of an in-house developed miniature 4-axis machine tool. Int. J. Mach. Tools Manuf. 2010, 50, 191–203. [Google Scholar] [CrossRef]

- Ding, S.; Jiang, R. Tool path generation for 4-axis contour EDM rough machining. Int. J. Mach. Tools Manuf. 2004, 44, 1493–1502. [Google Scholar] [CrossRef]

- Van Ligten, R.F.; Venkatesh, V.C. Diamond Grinding of Aspheric Surfaces on a CNC 4-Axis Machining Centre. CIRP Ann. 1985, 34, 295–298. [Google Scholar] [CrossRef]

- Tang, K.; Chen, L.; Chou, S.Y. Optimal workpiece setups for 4-axis numerical control machining based on machinability. Comput. Ind. 1998, 37, 27–41. [Google Scholar] [CrossRef]

- Magambo, S.; Ying, L. The NC Machining Post-Processing Technology Based on UG. Int. J. Sci. Res. 2013, 2, 131–134. [Google Scholar]

- Baghi, D.A.; Nafisi, S.; Hashemi, R.; Ebendorff-Heidepriem, H.; Ghomashchi, R. Effective post processing of SLM fabricated Ti-6Al-4 V alloy: Machining vs thermal treatment. J. Manuf. Process. 2021, 68, 1031–1046. [Google Scholar] [CrossRef]

- Chen, Z.C.; Wasif, M. A generic and theoretical approach to programming and post-processing for hypoid gear machining on multi-axis CNC face-milling machines. Int. J. Adv. Manuf. Technol. 2015, 81, 135–148. [Google Scholar] [CrossRef]

- Wang, Y.; Xu, J.; Sun, Y. Tool orientation adjustment for improving the kinematics performance of 5-axis ball-end machining via CPM method. Robot. Comput. Integr. Manuf. 2021, 68, 102070. [Google Scholar] [CrossRef]

- Xu, J.; Ji, Y.; Sun, Y.; Lee, Y. Spiral Tool Path Generation Method on Mesh Surfaces Guided by Radial Curves. J. Manuf. Sci. Eng. 2018, 140, 071016. [Google Scholar] [CrossRef]

- Xu, K.; Li, Y. Region based five-axis tool path generation for freeform surface machining via image representation. Robot. Comput. Integr. Manuf. 2019, 57, 230–240. [Google Scholar] [CrossRef]

- Bologa, O.; Breaz, R.E.; Racz, S.G.; Crenganiş, M. Decision-making Tool for Moving from 3-axes to 5-axes CNC Machine-tool. Procedia Comput. Sci. 2016, 91, 184–192. [Google Scholar] [CrossRef] [Green Version]

- My, C.A.; Bohez, E.L.J. A novel differential kinematics model to compare the kinematic performances of 5-axis CNC machines. Int. J. Mech. Sci. 2019, 163, 105117. [Google Scholar] [CrossRef]

- Xu, J.; Zhang, D.; Sun, Y. Kinematics performance oriented smoothing method to plan tool orientations for 5-axis ball-end CNC machining. Int. J. Mech. Sci. 2019, 157–158, 293–303. [Google Scholar] [CrossRef]

- Bizzarri, M.; Bartoň, M. Manufacturing of Screw Rotors Via 5-axis Double-Flank CNC Machining. Comput. Aided Des. 2020, 132, 102960. [Google Scholar] [CrossRef]

- Bo, P.; González, H.; Calleja, A.; de Lacalle, L.N.L.; Bartoň, M. 5-axis double-flank CNC machining of spiral bevel gears via custom-shaped milling tools—Part I: Modeling and simulation. Precis. Eng. 2020, 62, 204–212. [Google Scholar] [CrossRef] [Green Version]

- Prabha, K.A.; Prasad, B.S. Machining of Steam Turbine Blade on 5-Axis CNC Machine. Mater. Today Proc. 2019, 18, 3001–3007. [Google Scholar] [CrossRef]

- Huang, N.; Bi, Q.; Wang, Y. Identification of two different geometric error definitions for the rotary axis of the 5-axis machine tools. Int. J. Mach. Tools Manuf. 2015, 91, 109–114. [Google Scholar] [CrossRef]

- Wiessner, M.; Blaser, P.; Böhl, S.; Mayr, J.; Knapp, W.; Wegener, K. Thermal test piece for 5-axis machine tools. Precis. Eng. 2018, 52, S0141635917305767. [Google Scholar] [CrossRef]

- Chen, Q.; Li, W.; Jiang, C.; Zhou, Z.; Min, S. Separation and compensation of geometric errors of rotary axis in 5-axis ultra-precision machine tool by empirical mode decomposition method. J. Manuf. Process. 2021, 68, 1509–1523. [Google Scholar] [CrossRef]

- Ahmarn, M.; Stanislav, S.M. Optimization of rotations for six-axis machining. Int. J. Adv. Manuf. Technol. 2011, 53, 435–451. [Google Scholar] [CrossRef]

- Moriya, T.; Nakamoto, K.; Ishida, T.; Takeuchi, Y. Creation of V-shaped microgrooves with flat-ends by 6-axis control ultraprecision machining. CIRP Ann. Manuf. Technol. 2010, 59, 61–66. [Google Scholar] [CrossRef]

- Japitana, F.H.; Morishige, K.; Yasuda, S.; Takeuchi, Y. Manufacture of Overhanging Sharp Corner by Means of 6-Axis Control Machining with the Application of Ultrasonic Vibrations. JSME Int. J. Ser. C 2003, 46, 306–313. [Google Scholar] [CrossRef] [Green Version]

- Krimpenis, A.A.; Noeas, G.D. Application of Hybrid Manufacturing processes in microfabrication. J. Manuf. Process. 2022, 80, 328–346. [Google Scholar] [CrossRef]

- Qin, Y.; Xiao, J.; Wang, G. The Open Architecture CNC System Based on 6-axis Flame Pipe Cutting Machine. In Proceedings of the 2011 Third International Conference on Measuring Technology and Mechatronics Automation, Shanghai, China, 6–7 January 2011. [Google Scholar] [CrossRef]

- Carpiuc-Prisacari, A.; Poncelet, M.; Kazymyrenko, K.; Leclerc, H.; Hild, F. A complex mixed-mode crack propagation test performed with a 6-axis testing machine and full-field measurements. Eng. Fract. Mech. 2017, 176, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Huynh, H.N.; Riviere-Lorphevre, E.; Verlinden, O. Multibody modelling of a flexible 6-axis robot dedicated to robotic machining. In Proceedings of the 5th Joint International Conference on Multibody System Dynamics, Lisbon, Portugal, 24–28 June 2018. [Google Scholar]

- Duplak, J.; Hatala, M.; Duplakova, D.; Steranka, J. Comprehensive analysis and study of the machinability of a high strength aluminum alloy (EN AW-AlZn5.5MgCu) in the high-feed milling. Adv. Prod. Eng. Manag. 2018, 13, 455–465. [Google Scholar] [CrossRef]

- Zajac, J.; Duplak, J.; Duplakova, D.; Cizmar, P.; Olexa, I.; Bittner, A. Prediction of Cutting Material Durability by T = f(vc) Dependence for Turning Processes. Processes 2020, 8, 789. [Google Scholar] [CrossRef]

- Priyadarshi, S. Hybrid Machining Processes, Short Term Course on Advanced Machining Processes, 1–5 July 2013; Mechanical Engineering Department, MNNIT Allahabad: Uttar Pradesh, India, 2013. [Google Scholar]

- Cortina, M.; Arrizubieta, J.; Ruiz, J.; Ukar, E.; Lamikiz, A. Latest Developments in Industrial Hybrid Machine Tools that Combine Additive and Subtractive Operations. Materials 2018, 11, 2583. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Z.; Fu, J.; Shen, H.; Gan, W. A generic uniform scallop tool path generation method for five-axis machining of freeform surface. Comput. Aided Des. 2014, 56, 120–132. [Google Scholar] [CrossRef]

- Soshi, M.; Ring, J.; Young, C.; Oda, Y.; Mori, M. Innovative grid molding and cooling using an additive and subtractive hybrid CNC machine tool. CIRP Ann. Manuf. Technol. 2017, 66, 401–404. [Google Scholar] [CrossRef]

- Chen, L.; Xu, K.; Tang, K. Optimized sequence planning for multi-axis hybrid machining of complex geometries. Comput. Graph. 2017, 70, 176–187. [Google Scholar] [CrossRef]

- Flynn, J.M.; Shokrani, A.; Newman, S.T.; Dhokia, V. Hybrid Additive and Subtractive Machine Tools-Research and Industrial Developments. Int. J. Mach. Tools Manuf. 2016, 101, 79–101. [Google Scholar] [CrossRef] [Green Version]

- Li, L.; Haghighi, A.; Yang, Y. A novel 6-axis hybrid additive-subtractive manufacturing process: Design and case studies. J. Manuf. Process. 2018, 33, 150–160. [Google Scholar] [CrossRef]

- Chen, N.; Frank, M. Process planning for hybrid additive and subtractive manufacturing to integrate machining and directed energy deposition. Procedia Manuf. 2019, 34, 205–213. [Google Scholar] [CrossRef]

- Newman, S.T.; Zhu, Z.; Dhokia, V.; Shokrani, A. Process planning for additive and subtractive manufacturing technologies. CIRP Ann. Manuf. Technol. 2015, 64, 467–470. [Google Scholar] [CrossRef]

- Yang, Y.; Haghighi, A.; Li, L. Energy Consumption Study for 6-Axis Hybrid Additive-Subtractive Manufacturing Process. In Proceedings of the 2018 Industrial and Systems Engineering Conference, Orlando, FL, USA, 19–22 May 2018. [Google Scholar]

- Liou, F.W.; Choi, J.; Landers, R.G.; Janardhan, V.; Balakrishnan, S.N.; Agarwal, S. Research and development of a hybrid rapid manufacturing process. In Proceedings of the Twelfth Annual Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2001. [Google Scholar]

- Grzesik, W. Hybrid manufacturing of metallic parts integrated additive and subtractive processes. Mechanik 2018, 91, 468–475. [Google Scholar] [CrossRef]

- Ren, L.; Padathu, A.P.; Ruan, J.; Sparks, T.; Liou, F.W. Three dimensional die repair using a hybrid manufacturing system. In Proceedings of the 17th Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006; pp. 51–59. [Google Scholar]

- Cococcetta, N.; Jahan, M.P.; Schoop, J.; Ma, J.; Pearl, D.; Hassan, M. Post-processing of 3D printed thermoplastic CFRP composites using cryogenic machining. J. Manuf. Process. 2021, 68, 332–346. [Google Scholar] [CrossRef]

- Tapoglou, N.; Clulow, J. Investigation of hybrid manufacturing of stainless steel 316L components using direct energy deposition. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2020, 235, 1633–1643. [Google Scholar] [CrossRef]

- Hällgren, S.; Pejryd, L.; Ekengren, J. Additive Manufacturing and High Speed Machining—Cost Comparison of short Lead Time Manufacturing Methods. Procedia CIRP 2016, 50, 384–389. [Google Scholar] [CrossRef] [Green Version]

- Kaynak, Y.; Kitay, O. The effect of post-processing operations on surface characteristics of 316L stainless steel produced by selective laser melting. Addit. Manuf. 2018, 26, 84–93. [Google Scholar] [CrossRef]

- Bai, Q.; Wu, B.; Qiu, X.; Zhang, B.; Chean, J. Experimental study on additive/subtractive hybrid manufacturing of 6511 steel: Process optimization and machining characteristics. Int. J. Adv. Manuf. Technol. 2020, 108, 1–10. [Google Scholar] [CrossRef]

- Kaynak, Y.; Tascioglu, E. Finish machining-induced surface roughness, microhardness and XRD analysis of selective laser melted Inconel 718 alloy. Procedia CIRP 2018, 71, 500–504. [Google Scholar] [CrossRef]

- Salonitis, K.; D’Alvise, L.; Schoinochoritis, B.; Chantzis, D. Additive manufacturing and post-processing simulation: Laser cladding followed by high speed machining. Int. J. Adv. Manuf. Technol. 2015, 85, 2401–2411. [Google Scholar] [CrossRef]

- Pal, S.; Tiyyagura, H.R.; Drstvenšek, I.; Kumar, C.S. The effect of post-processing and machining process parameters on properties of Stainless Steel PH1 product produced by Direct Metal Laser Sintering. Procedia Eng. 2016, 149, 359–365. [Google Scholar] [CrossRef]

- Careri, F.; Imbrogno, S.; Umbrello, D.; Attallah, M.M.; Outeiro, J.; Batista, A.C. Machining and heat treatment as post-processing strategies for Ni-superalloys structures fabricated using direct energy deposition. J. Manuf. Process. 2021, 61, 236–244. [Google Scholar] [CrossRef]

- Heigel, J.C.; Phan, T.K.; Fox, J.C.; Gnaupel-Herold, T.H. Experimental Investigation of Residual Stress and its Impact on Machining in Hybrid Additive/Subtractive Manufacturing. Procedia Manuf. 2018, 26, 929–940. [Google Scholar] [CrossRef]

- Speidel, A.; Sélo, R.; Bisterov, I.; Mitchell-Smith, J.; Clare, A.T. Post processing of additively manufactured parts using electrochemical jet machining. Mater. Lett. 2021, 292, 129671. [Google Scholar] [CrossRef]

- Grzesik, W. Hybrid additive and subtractive manufacturing processes and systems: A review. J. Mach. Eng. 2018, 18, 5–24. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Yardley, V.A.; Shi, Z.; Lin, J. Challenges in additive manufacturing of high-strength aluminium alloys and current developments in hybrid additive manufacturing. Int. J. Lightweight Mater. Manuf. 2021, 4, 246–261. [Google Scholar] [CrossRef]

- Simpson, T.W. Combining Additive and Subtractive Processes for Hybrid Machining. Available online: https://www.mmsonline.com/articles/combining-additive-and-subtractive-processesfor-hybrid-machining (accessed on 16 January 2022).

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. Current trends and research opportunities in hybrid additive manufacturing. Int. J. Adv. Manuf. Technol. 2021, 113, 623–648. [Google Scholar] [CrossRef]

| Author/Year | Technique | Material | Description |

|---|---|---|---|

| Cococcetta et al. (2021) [112] | 3D printed + Dry, MQL and Cryogenic machining | CFRP | Analysis of printing and machining parameters and cooling/lubrication conditions in the production of printed CFRP thermoplastic compounds, from the comparison of three post-processing methods: dry, minimum quantity lubrication (MQL) and cryogenic machining. |

| Tapoglou et al. (2020) [113] | DED + Milling | 316L Steel | Production of 316L stainless steel parts using the DED technique with subsequent machining, from defining the best parameters for material deposition, to analyzing the machinability of the deposited material. |

| Hällgren et al. (2016) [114] | PBF + HSM | Aluminium | Analysis of the cost of serial production of parts if print speed increases, if machine cost or part mass is reduced, using GMP techniques such as additive manufacturing and high-speed machining (HSM). |

| Kaynak et al. (2018) [115] | SLM + FM/VSF/DF | 316L Steel | In order to improve the surface quality of the parts manufactured via selective laser melting (SLM), three post-processing techniques were performed: finishing machining (FM), vibrating machining surface finishing operations (VSF) and drag finishing (DF). The surface was analyzed to meet quality requirements, and it was verified that the DF method resulted in a less rough and more consistent surface finish. |

| Bai et al. (2020) [116] | SLM + Milling | 6511 Steel | Analysis of the production of 6511 martensitic stainless steel parts through selective laser melting (SLM) and end milling, optimizing the process parameters, and taking into account the residual stresses arising from the phase transformation of the martensitic steel. |

| Kaynak et al. (2018) [117] | SLM + Machining | Inconel 718 | Study of surface finish through machining, including surface roughness, microhardness and XRD analysis of Inconel 718 alloy, produced via SLM, verifying that the roughness had a decrease of 90% after post-processing with machining. |

| Salonitis et al. (2015) [118] | Laser Cladding + HSM | Steel | Quality verification of a steel tube manufactured via laser cladding after the high speed machining process, which reduced residual stresses and distortion from the additive manufacturing process. |

| Pal et al. (2016) [119] | DMLS + Machining | SS PH1 | Characterization of the mechanical properties of the PH1 stainless steel product produced via direct metal laser sintering (DMLS) in conjunction with machining process parameters and post-processing. |

| Careri et al. (2021) [120] | DED + Machining | Inconel 718 | Evaluation of surface finish, microstructure, microhardness and residual stresses from the manufacture of parts in Inconel 718 by DED, followed by two possible post-processing: machining + heat treatment or heat treatment + machining, verifying that the best production strategy was AD + M + DA. |

| Heigel et al. (2018) [121] | PBF + Machining | Stainless steel | Production of stainless steel cylinders through the laser powder bed fusion process, followed by machining, and analysis of residual stresses from the processes. |

| Speidel et al. (2021) [122] | PBF + EJM | Ti-6Al-4V | Due to the poor surface quality due to unmelted powder from the powder bed fusion process, this study analyzed the application of electrochemical jet machining in order to produce a good surface finish and increase the functionality of the part. |

| W. Grzesik [123] | General | General | This work provides a recent and brief overview of hybrid machining. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sebbe, N.P.V.; Fernandes, F.; Sousa, V.F.C.; Silva, F.J.G. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals 2022, 12, 1874. https://doi.org/10.3390/met12111874

Sebbe NPV, Fernandes F, Sousa VFC, Silva FJG. Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals. 2022; 12(11):1874. https://doi.org/10.3390/met12111874

Chicago/Turabian StyleSebbe, Naiara P. V., Filipe Fernandes, Vitor F. C. Sousa, and Francisco J. G. Silva. 2022. "Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review" Metals 12, no. 11: 1874. https://doi.org/10.3390/met12111874

APA StyleSebbe, N. P. V., Fernandes, F., Sousa, V. F. C., & Silva, F. J. G. (2022). Hybrid Manufacturing Processes Used in the Production of Complex Parts: A Comprehensive Review. Metals, 12(11), 1874. https://doi.org/10.3390/met12111874