Critical Assessment of Two-Dimensional Methods for the Microstructural Characterization of Cemented Carbides

Abstract

:1. Introduction

2. State of the Art: Description of Analysis Methods

2.1. Point Analysis (PA)

- When the point was situated inside the grain, the point was counted as a valid point and then assigned the value of 1;

- When the point was situated outside the grain, it was counted as an invalid point and assigned the value of 0;

- In case the point was exactly at the grain boundary, it was counted as a half valid point, and assigned the value of 0.5.

2.2. Line Analysis (LA)

- WC grain size dWC: It is the mean length of the linear intercepts within the WC phase. Its value was obtained by dividing the total intercept length ΣlWC by the WC grain number NWC, as shown in the following equation:

- Phase fraction of grains fg: It is the equivalent to the ratio between the total intercept length within the grains ΣlWC and the total intercept length within the binder ΣlCo, as shown in the following equation:

- Mean free path (MFP) λCo: It is the other two-phase parameter and defines the mean length of the linear intercepts within the (cobalt) binder. It was calculated by dividing the total intercept length ΣlCo by the number of binder interceptions NCo, as shown in the following equation:

2.3. Area Analysis (AA)

3. Experimental Aspects: Materials and Sample Preparation

3.1. Sample Preparation

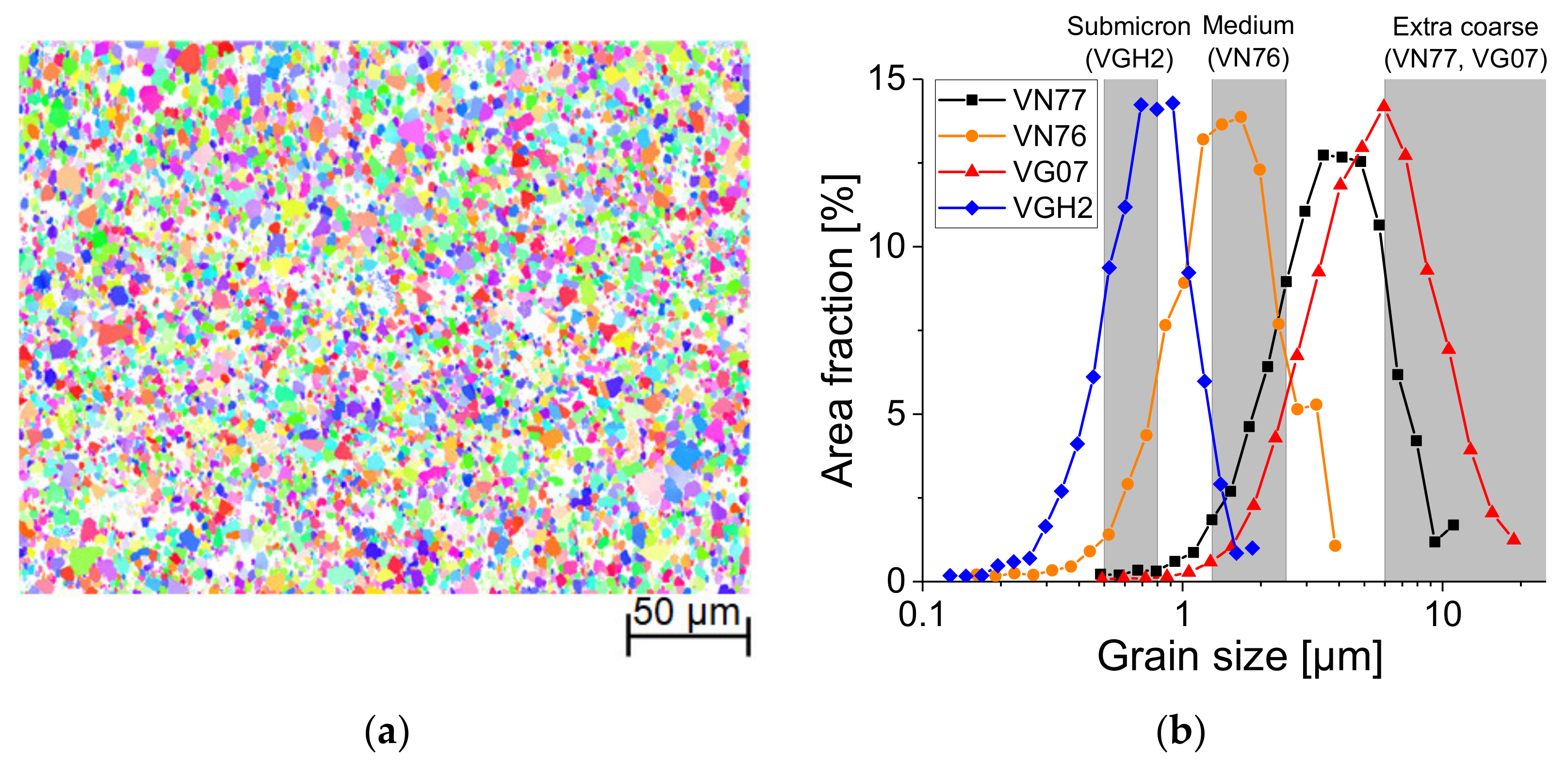

3.2. Studied Materials

3.2.1. Nominal Values of the One-Phase Properties of the Studied Hard Metal Grades

3.2.2. Nominal Values of the Two-Phase Properties of the Studied Hard Metal Grades

3.2.3. Reference Information of the Microstructural Parameters of the Studied Hard Metal Grades

3.3. Image Acquisition and Analysis Program

4. Results and Discussion

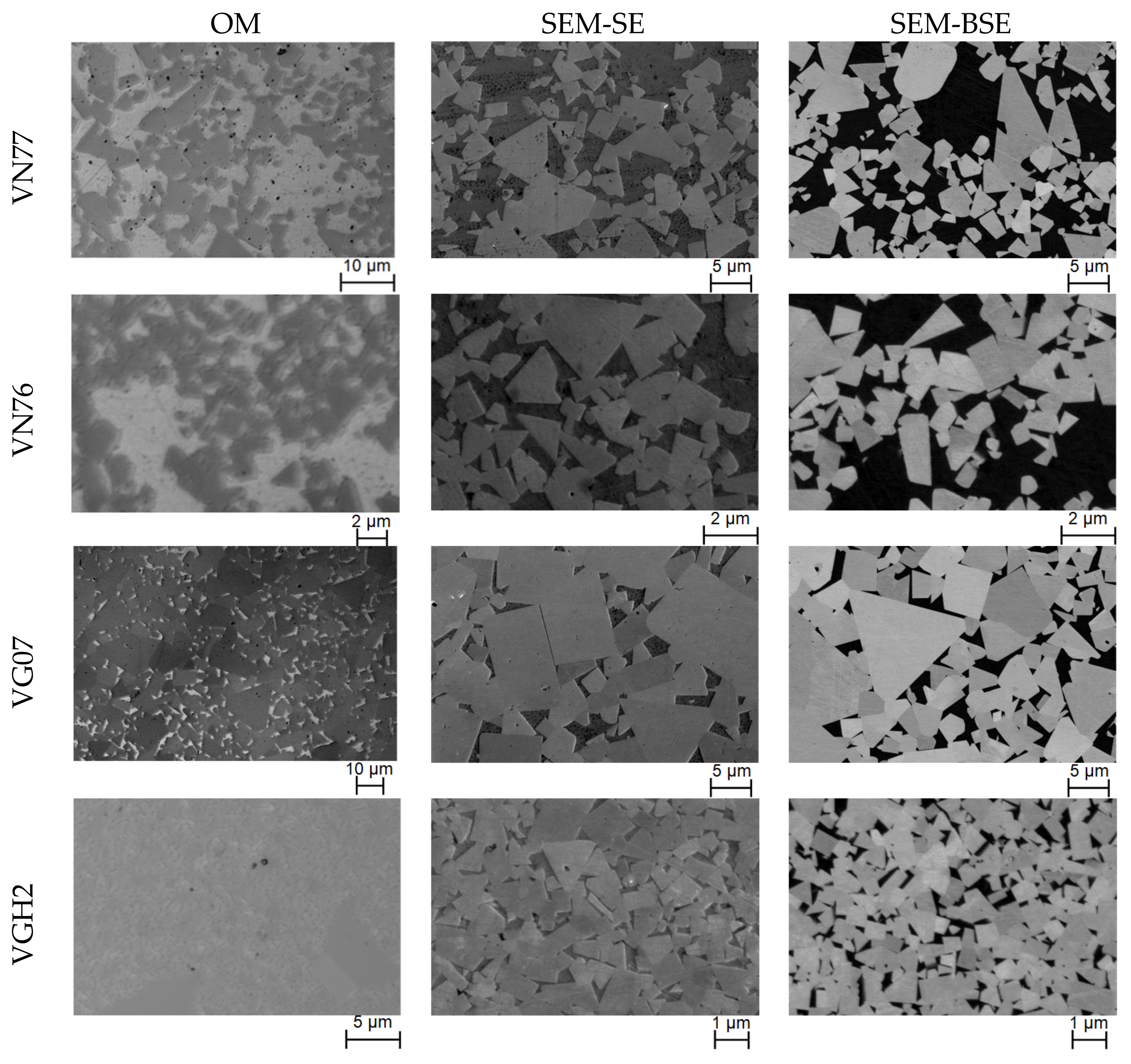

4.1. Image Acquisition

4.2. Microstructural Characterization

4.2.1. Point Analysis (PA)

4.2.2. Line Analysis (LA)

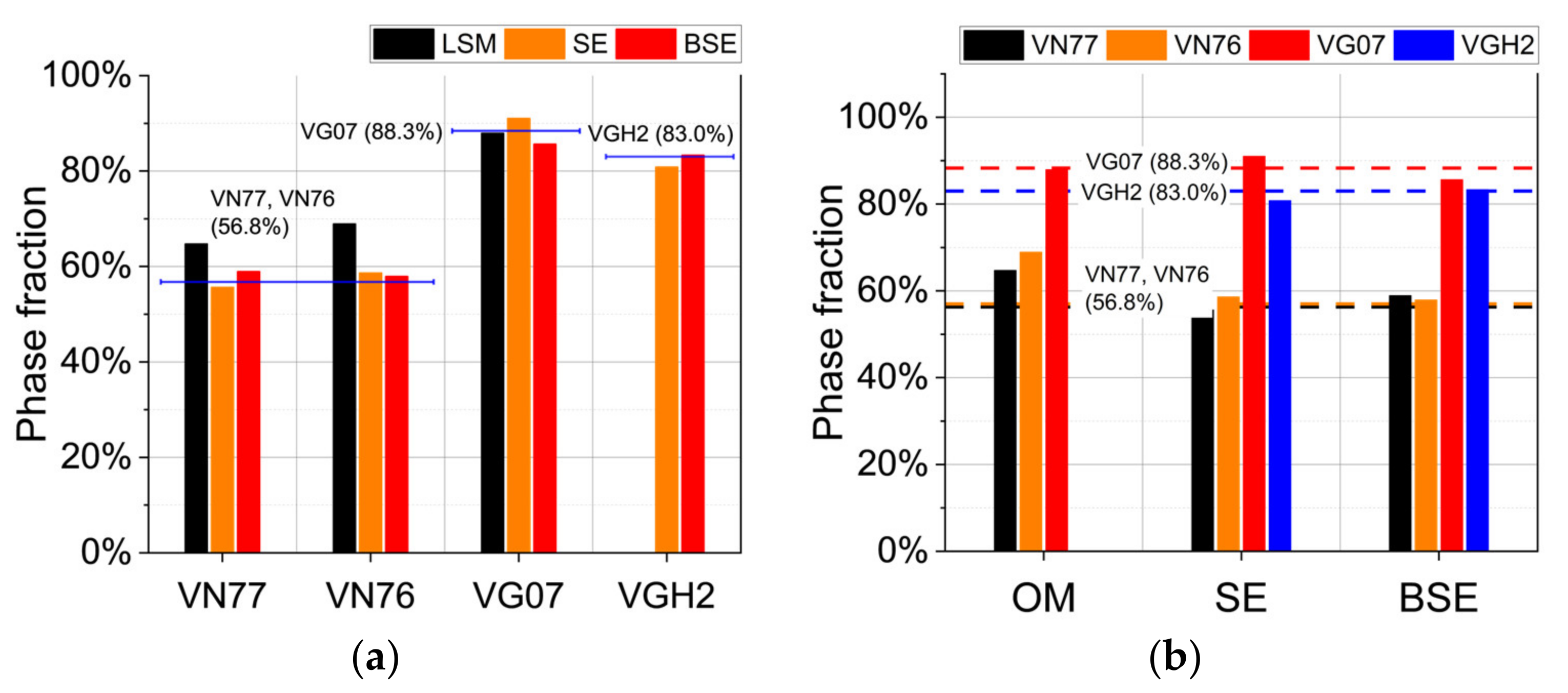

Phase Fraction

Grain Size

Contiguity and Mean Free Path (MFP)

4.2.3. Area Analysis (AA)

Phase Fraction

Carbide Grain Size

4.3. Result Comparison of the Microstructural Characterization

5. Concluding Remarks

- In the case of rough estimation, the combination of line analysis and optical microscope (LA+OM) is a good and fast choice for the estimation of the one-phase properties of cemented carbides, and the two-phase properties may then be obtained using empirical equations.

- In the case of a more precise estimation, the combination of line analysis and backscattered electrons (LA+BSE) can be applied to measure all four properties of cemented carbides and yield precise results.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schatt, W.; Wieters, K.-P.; Kieback, B. (Eds.) Pulvermetallurgie, 2nd ed.; Springer: Berlin, Heidelberg, Germany, 2007; pp. 504–540. [Google Scholar] [CrossRef]

- Tarragó, J.M.; Coureaux, D.; Torres, Y.; Wu, F.; Al-Dawery, I.; Llanes, L. Implementation of an effective time-saving two-stage methodology for microstructural characterization of cemented carbides. Int. J. Refract. Met. Hard Mater. 2016, 55, 80–86. [Google Scholar] [CrossRef] [Green Version]

- Lay, S.; Missiaen, J.M. Microstructure and Morphology of Hardmetals. In Comprehensive Hard Materials; Elsevier: Amsterdam, The Netherlands, 2014; Volume 1, pp. 91–120. ISBN 9780080965284. [Google Scholar]

- Jiménez-Piqué, E.; Turon-Vinas, M.; Chen, H.; Trifonov, T.; Fair, J.; Tarrés, E.; Llanes, L. Focused ion beam tomography of WC-Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2017, 67, 9–17. [Google Scholar] [CrossRef] [Green Version]

- Fang, S.; Llanes, L. Microstructural characterization of cemented carbides by 3D volume reconstruction. Mater. Charact. 2020, 159, 110061. [Google Scholar] [CrossRef]

- García, J.; Ciprés, V.C.; Blomqvist, A.; Kaplan, B. Cemented carbide microstructures: A review. Int. J. Refract. Met. Hard Mater. 2019, 80, 40–68. [Google Scholar] [CrossRef]

- Davidovits, P.; Egger, M.D. Scanning laser microscope. Nature 1969, 223, 831. [Google Scholar] [CrossRef]

- Bauer, W.; Weber, M.; Chanbai, S. White Light Interferometry. In Encyclopedia of Tribology; Springer: Boston, MA, USA, 2013; pp. 4115–4127. [Google Scholar] [CrossRef]

- Engqvist, H.; Uhrenius, B. Determination of the average grain size of cemented carbides. Int. J. Refract. Met. Hard Mater. 2003, 21, 31–35. [Google Scholar] [CrossRef]

- Okamoto, S.; Nakazono, Y.; Otsuka, K.; Shimoitani, Y.; Takada, J. Mechanical properties of WC/Co cemented carbide with larger WC grain size. Mater. Charact. 2005, 55, 281–287. [Google Scholar] [CrossRef]

- Seiler, H. Secondary electron emission in the scanning electron microscope. J. Appl. Phys. 1983, 54, R1–R18. [Google Scholar] [CrossRef]

- Joy, D.C. Introduction to the scanning electron microscope. Microsc. Microanal. 2003, 9, 1556–1557. [Google Scholar] [CrossRef] [Green Version]

- Pérez-Arantegui, J. Electron microscopy. In Reference Module in Chemistry, Molecular Sciences and Chemical; Elsevier: Amsterdam, The Netherlands, 2017. [Google Scholar] [CrossRef]

- Borgh, I.; Hedström, P.; Odqvist, J.; Borgenstam, A.; Ågren, J.; Gholinia, A.; Winiarski, B.; Withers, P.J.; Thompson, G.E.; Mingard, K.; et al. On the three-dimensional structure of WC grains in cemented carbides. Acta Mater. 2013, 61, 4726–4733. [Google Scholar] [CrossRef]

- Mingard, K.P.; Roebuck, B.; Jones, H.G.; Stewart, M.; Cox, D.; Gee, M.G. Visualisation and measurement of hardmetal microstructures in 3D. Int. J. Refract. Met. Hard Mater. 2018, 71, 285–291. [Google Scholar] [CrossRef]

- Johansson, S.A.; Öhman, M.; Ekh, M.; Wahnström, G. CCBuilder: A software that produces synthetic microstructures of WC-Co cemented carbides. Int. J. Refract. Met. Hard Mater. 2019, 78, 210–218. [Google Scholar] [CrossRef]

- Rueden, C.T.; Schindelin, J.; Hiner, M.C.; DeZonia, B.E.; Walter, A.E.; Arena, E.T.; Eliceiri, K.W. ImageJ2: ImageJ for the next generation of scientific image data. BMC Bioinform. 2017, 18, 529. [Google Scholar] [CrossRef] [Green Version]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Cardona, A. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Roebuck, B.; Bennett, E.G. Phase size distribution in WC/Co hardmetal. Metallography 1986, 19, 27–47. [Google Scholar] [CrossRef]

- Luyckx, S.; Love, A.D. Empirical quantitative relationships among grain size, mean free path, contiguity and cobalt content in WC-Co hardmetal. Trans. R. Soc. S. Afr. 2003, 58, 145–148. [Google Scholar] [CrossRef]

- Brieseck, M.; Lengauer, W.; Gneiß, B.; Wagner, K.; Wagner, S. A straightforward method for analysing the grain-size distribution in tungsten carbide—Cobalt hardmetals. Microchim. Acta. 2010, 168, 309–316. [Google Scholar] [CrossRef]

- ISO 4499-2; Hardmetals—Metallographic Determination of Microstructure—Part 2: Measurement of WC Grain Size. International Organization for Standardization: Geneva, Switzerland, 2018; p. 17.

- Roebuck, B.; Bennett, E.G. The Metallographic Measurement of Hardmetal Grain Size. Measurement Good Practice Guide No. 22; National Physical Laboratory: Teddington, TW, USA, 2000; Available online: https://eprintspublications.npl.co.uk/1915/ (accessed on 1 July 2022).

- Morrell, R.; Roebuck, B.; Bennett, E.G.; Lay, L.A. Microstructural Measurement on Ceramics and Hardmetals. Measurement Good Practice Guide No. 21; National Physical Laboratory: Teddington, TW, USA, 2007; Available online: https://www.npl.co.uk/gpgs/microstructural-measurements-on-ceramics-and-hardmetals (accessed on 1 July 2022).

- Gurland, J. The measurement of grain contiguity in two-phase alloys. Trans. Met. Soc. AIME 1958, 212, 452–460. [Google Scholar]

- Roebuck, B.; Mingard, K.P.; Jones, H.; Bennett, E.G. Aspects of the metrology of contiguity measurements in WC based hard materials. Int. J. Refract. Met. Hard Mater. 2017, 62, 161–169. [Google Scholar] [CrossRef]

- Lee, H.C.; Gurland, J. Hardness and deformation of cemented tungsten carbide. Mater. Sci. Eng. 1978, 33, 125–133. [Google Scholar] [CrossRef]

- Pang, M.; Du, Y.; Zhang, W.; Peng, Y.; Zhou, P. A simplified hardness model for WC–Co–Cubic cemented carbides. J. Min. Met. Sect. B Met. 2021, 57, 253–259. [Google Scholar] [CrossRef]

- Roebuck, B.; Phatak, C.; Birks-Agnew, I. A Comparison of the Linear Intercept and Equivalent Circle Methods for Grain Size Measurement in WC/Co Hardmetals; National Physical Laboratory: Teddington, TW, USA, 2004; Available online: https://eprintspublications.npl.co.uk/2947/ (accessed on 1 July 2022).

- Mingard, K.; Roebuck, B. Interlaboratory Measurements of contiguity in WC-Co hardmetals. Metals 2019, 9, 328. [Google Scholar] [CrossRef] [Green Version]

- Mingard, K.P.; Roebuck, B.; Bennett, E.G.; Gee, M.G.; Nordenstrom, H.; Sweetman, G.; Chan, P. Comparison of EBSD and conventional methods of grain size measurement of hardmetals. Int. J. Refract. Met. Hard Mater. 2009, 27, 213–223. [Google Scholar] [CrossRef]

- Wright, S.I. A parametric study of electron backscatter diffraction based grain size measurements. Pract. Metallogr. 2010, 47, 16–33. [Google Scholar] [CrossRef]

- Golovchan, V.T.; Litoshenko, N.V. On the contiguity of carbide phase in WC-Co hardmetals. Int. J. Refract. Met. Hard Mater. 2003, 21, 241–244. [Google Scholar] [CrossRef]

| Polishing Sequence | Cameo Disk | MD-Allegro | MD-Dac | MD-Nap |

|---|---|---|---|---|

| Lubricant | Water | DS 6 µm | DS 3 µm | DS 1 µm |

| Force (N) | 20 | 20 | 20 | 20 |

| Speed (rpm) | 150 | 150 | 150 | 150 |

| Time (min) | 5 | 5 | 5 | 5 |

| HM Grade * | VN77 | VN76 | VG07 | VGH2 |

|---|---|---|---|---|

| WC (wt.%) | 70% | 70% | 93% | 89.7% |

| WC (vol.%) ** | 56.8% | 56.8% | 88.3% | 83.0% |

| Ni (wt.%) | 14.25% | 14.25% | 0% | 0% |

| Co (wt.%) | 14.25% | 14.25% | 7% | 9.5% |

| Grain size (µm) | Extra coarse (>6.0) | Medium (1.3–2.5) | Extra coarse (>6.0) | Submicron (0.5–0.8) |

| Grain size (µm) *** | 2.14 | 0.81 | 3.04 | 0.51 |

| Density (g/cm³) | 12.7 | 12.7 | 14.8 | 14.5 |

| Hardness (HV30) | 600 | 730 | 1180 | 1600 |

| HM Grade | VN77 | VN76 | VG07 | VGH2 | ||||

|---|---|---|---|---|---|---|---|---|

| Grain size/Deviation (µm) | ||||||||

| Headings | 2.14 | 1.44 | 0.81 | 0.58 | 3.04 | 2.11 | 0.51 | 0.26 |

| HM Grade | VN77 | VN76 | VG07 | VGH2 |

|---|---|---|---|---|

| Phase fraction/WC (vol.%) | 56.8% | 56.8% | 88.3% | 83.0% |

| Grain size (µm) | 2.14 | 0.81 | 3.04 | 0.51 |

| 0.24 | 0.23 | 0.67 | 0.61 | |

| (µm) | 2.15 | 0.80 | 1.22 | 0.27 |

| Analysis Method | Image Acquisition ** | Phase Fraction | Grain Size | Contiguity | MFP |

|---|---|---|---|---|---|

| PA | OM | ✓ | N.A. | N.A. | N.A. |

| SE | ✓ | N.A. | N.A. | N.A. | |

| BSE | ✓ | N.A. | N.A. | N.A. | |

| LA | OM | ✓ | ✓ | ✓ | ✓ |

| SE | ✓ | ✓ | ✓ | ✓ | |

| BSE | ✓ | ✓ | ✓ | ✓ | |

| AA | OM | ✓ | ✓ | N.A. | N.A. |

| SE | ✓ | ✓ | N.A. | N.A. | |

| BSE | ✓ | ✓ | N.A. | N.A. |

| Image | Magnification | Objective Lens | Image | Magnification | Objective Lens |

| VN77 (OM) | 2000 | 500 × 4 | VG07 (OM) | 4000 | 500 × 8 |

| VN76 (OM) | 4000 | 500 × 8 | VGH2 (OM) | 4000 | 500 × 8 |

| Image | Detector * | Acceleration Voltage | Horizontal Field Width (µm) | ||

| VN77 (SEM-SE) | ETD | 5.00 KV | 59.2 | ||

| VN76 (SEM-SE) | ETD | 5.00 KV | 25.9 | ||

| VG07 (SEM-SE) | ETD | 5.00 KV | 59.2 | ||

| VGH2 (SEM-SE) | ETD | 5.00 KV | 13.8 | ||

| VN77 (SEM-BSE) | CBS | 5.00 KV | 59.2 | ||

| VN76 (SEM-BSE) | CBS | 5.00 KV | 25.9 | ||

| VG07 (SEM-BSE) | CBS | 5.00 KV | 59.2 | ||

| VGH2 (SEM-BSE) | CBS | 5.00 KV | 13.8 | ||

| Phase Fraction (vol%) | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| PA+OM | 55.1% | −1.7% | 64.3% | 7.5% | 90.8% | 2.5% | - | - | 3.9% |

| PA+SE | 52.7% | −4.1% | 59.8% | 3.0% | 93.8% | 5.5% | 85.7% | 2.7% | 3.8% |

| PA+BSE | 53.7% | −3.1% | 59.3% | 2.5% | 88.0% | −0.3% | 85.2% | 2.2% | 2.0% |

| PA (mean) | 53.8% | −3.0% | 61.1% | 4.3% | 90.8% | 2.5% | 85.5% | 2.5% | 3.1% |

| N (nom. vol.%) | 56.8% | 56.8% | 88.3% | 83.0% | - | ||||

| Phase Fraction (vol%) | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| LA+OM | 64.7% | 7.9% | 68.9% | 12.1% | 87.9% | −0.4% | - | - | 6.8% |

| LA+SE | 55.6% | −1.2% | 58.6% | 1.8% | 91.0% | 2.7% | 80.8% | −2.2% | 2.0% |

| LA+BSE | 58.9% | 2.1% | 57.9% | 1.1% | 85.6% | −2.7% | 83.3% | 0.3% | 1.6% |

| LA (mean) | 59.7% | 2.9% | 61.8% | 5.0% | 88.2% | −0.1% | 82.1% | −0.9% | 2.3% |

| N (nom. vol.%) | 56.8% | 56.8% | 88.3% | 83.0% | - | ||||

| Grain Size (µm) | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| LA+OM | 2.54 | 18.7% | 1.45 | 79.0% | 4.51 | 48.4% | - | - | 48.7% |

| LA+SE | 1.63 | −23.8% | 0.84 | 3.7% | 3.56 | 17.1% | 0.41 | −19.6% | 16.1% |

| LA+BSE | 1.95 | -8.9% | 0.84 | 3.7% | 2.65 | −12.8% | 0.48 | −5.9% | 7.8% |

| LA (mean) | 2.04 | −4.7% | 1.04 | 28.4% | 3.57 | 17.4% | 0.45 | −11.8% | 15.6% |

| N (nom. EBSD) | 2.14 | 0.81 | 3.04 | 0.51 | - | ||||

| Contiguity | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| LA+OM | 0.50 | 0.26 | 0.72 | 0.49 | 0.66 | −0.01 | - | - | 0.25 |

| LA+SE | 0.58 | 0.34 | 0.41 | 0.18 | 0.74 | 0.07 | 0.66 | 0.05 | 0.16 |

| LA+BSE | 0.37 | 0.13 | 0.50 | 0.27 | 0.72 | 0.05 | 0.74 | 0.13 | 0.15 |

| LA (mean) | 0.48 | 0.24 | 0.54 | 0.31 | 0.71 | 0.04 | 0.70 | 0.09 | 0.17 |

| N (nom. EBSD) | 0.24 | 0.23 | 0.67 | 0.61 | |||||

| MFP (µm) | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| LA+OM | 2.17 | 0.02 | 1.58 | 0.78 | 0.97 | −0.25 | - | - | 0.35 |

| LA+SE | 2.39 | 0.24 | 0.80 | 0.00 | 0.76 | −0.46 | 0.18 | −0.09 | 0.20 |

| LA+BSE | 1.95 | −0.2 | 0.99 | 0.19 | 1.08 | −0.14 | 0.24 | −0.03 | 0.14 |

| LA (mean) | 2.17 | 0.02 | 1.12 | 0.32 | 0.94 | −0.28 | 0.21 | −0.06 | 0.17 |

| N (nom. EBSD) | 2.15 | 0.80 | 1.22 | 0.27 | |||||

| Phase Fraction | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| AA+OM | 44.1% | −12.7% | 60.7% | 3.9% | 92.1% | 3.8% | - | - | 6.8% |

| AA+SE | 56.0% | −0.8% | 59.2% | 2.4% | 91.5% | 3.2% | 86.0% | 3.0% | 2.4% |

| AA+BSE | 59.0% | 2.2% | 61.5% | 4.7% | 86.8% | −1.5% | 84.4% | 1.4% | 2.5% |

| AA (mean) | 53.0% | −3.8% | 60.5% | 3.7% | 90.1% | 1.8% | 85.2% | 2.2% | 2.9% |

| N (nom. vol.%) | 56.8% | 56.8% | 88.3% | 83.0% | - | ||||

| Grain Size (µm) | VN77 | VN76 | VG07 | VGH2 | Avg. Dev. | ||||

|---|---|---|---|---|---|---|---|---|---|

| M | Δ | M | Δ | M | Δ | M | Δ | ||

| AA+OM | 3.06 | 43.0% | 1.87 | 130.9% | 5.54 | 82.2% | - | - | 85.4% |

| Circle | 2.68 | 25.2% | 1.64 | 102.5% | 4.86 | 59.9% | - | - | 62.5% |

| Square | 3.36 | 57.0% | 2.06 | 154.3% | 6.09 | 100.3% | - | - | 103.9% |

| Triangle | 3.13 | 46.3% | 1.91 | 135.8% | 5.66 | 86.2% | - | - | 89.4% |

| AA+SE | 2.25 | 5.1% | 1.23 | 51.9% | 4.09 | 34.5% | 0.6 | 17.6% | 27.3% |

| Circle | 2.06 | −3.7% | 1.08 | 33.3% | 3.59 | 18.1% | 0.52 | 2.0% | 14.3% |

| Square | 2.28 | 6.5% | 1.35 | 66.7% | 4.49 | 47.7% | 0.66 | 29.4% | 37.6% |

| Triangle | 2.4 | 12.1% | 1.26 | 55.6% | 4.18 | 37.5% | 0.61 | 19.6% | 31.2% |

| AA+BSE | 2.41 | 12.6% | 1.08 | 33.3% | 3.98 | 30.9% | 0.63 | 23.5% | 25.1% |

| Circle | 2.12 | −0.9% | 0.95 | 17.3% | 3.49 | 14.8% | 0.55 | 7.8% | 10.2% |

| Square | 2.65 | 23.8% | 1.19 | 46.9% | 4.37 | 43.8% | 0.69 | 35.3% | 37.4% |

| Triangle | 2.47 | 15.4% | 1.11 | 37.0% | 4.07 | 33.9% | 0.64 | 25.5% | 28.0% |

| AA (mean) | 2.57 | 20.1% | 1.39 | 71.6% | 4.53 | 49.0% | 0.61 | 19.6% | 40.1% |

| N (nom. EBSD) | 2.14 | 0.81 | 3.04 | 0.51 | - | ||||

| Analysis Method | Image Acquisition * | Accessibility | Operability | Accuracy | |

|---|---|---|---|---|---|

| Phase Fraction | Grain Size | ||||

| PA | OM | + | + | + | N.A. |

| SE | 0 | 0 | + | N.A. | |

| BSE | 0 | 0 | + | N.A. | |

| LA | OM | + | 0 | 0 | − |

| SE | 0 | − | + | 0 | |

| BSE | 0 | − | + | + | |

| AA | OM | + | + | 0 | − |

| SE | 0 | 0 | + | 0 | |

| BSE | 0 | 0 | + | 0 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fang, S.; Salán, N.; Pauly, C.; Llanes, L.; Mücklich, F. Critical Assessment of Two-Dimensional Methods for the Microstructural Characterization of Cemented Carbides. Metals 2022, 12, 1882. https://doi.org/10.3390/met12111882

Fang S, Salán N, Pauly C, Llanes L, Mücklich F. Critical Assessment of Two-Dimensional Methods for the Microstructural Characterization of Cemented Carbides. Metals. 2022; 12(11):1882. https://doi.org/10.3390/met12111882

Chicago/Turabian StyleFang, Shiqi, Núria Salán, Christoph Pauly, Luis Llanes, and Frank Mücklich. 2022. "Critical Assessment of Two-Dimensional Methods for the Microstructural Characterization of Cemented Carbides" Metals 12, no. 11: 1882. https://doi.org/10.3390/met12111882

APA StyleFang, S., Salán, N., Pauly, C., Llanes, L., & Mücklich, F. (2022). Critical Assessment of Two-Dimensional Methods for the Microstructural Characterization of Cemented Carbides. Metals, 12(11), 1882. https://doi.org/10.3390/met12111882