Superplastic Behavior of Overaged 2024 Aluminum Alloy after Friction Stir Processing

Abstract

:1. Introduction

2. Materials and Experimental Procedure

3. Results and Discussion

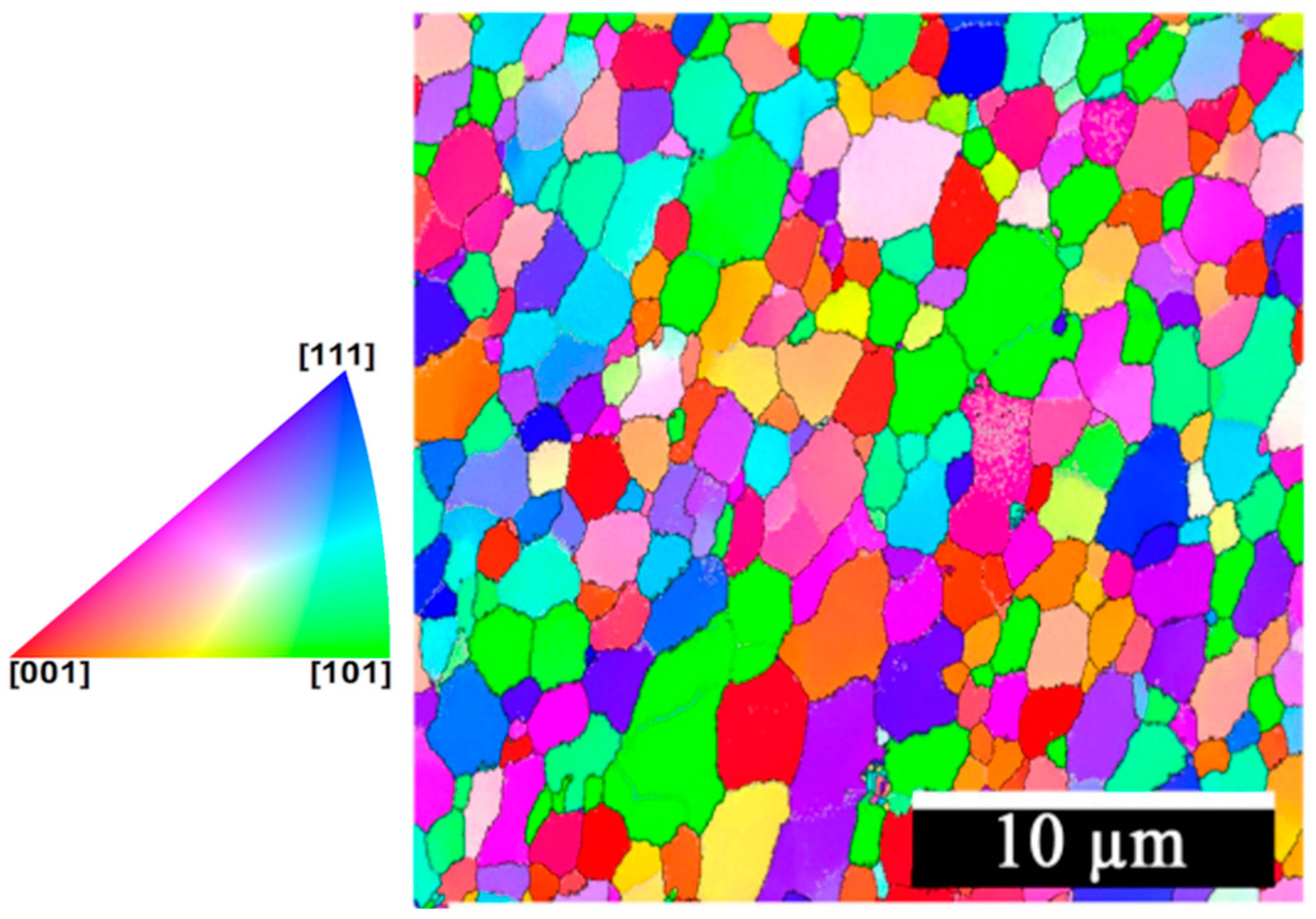

3.1. Microstructures

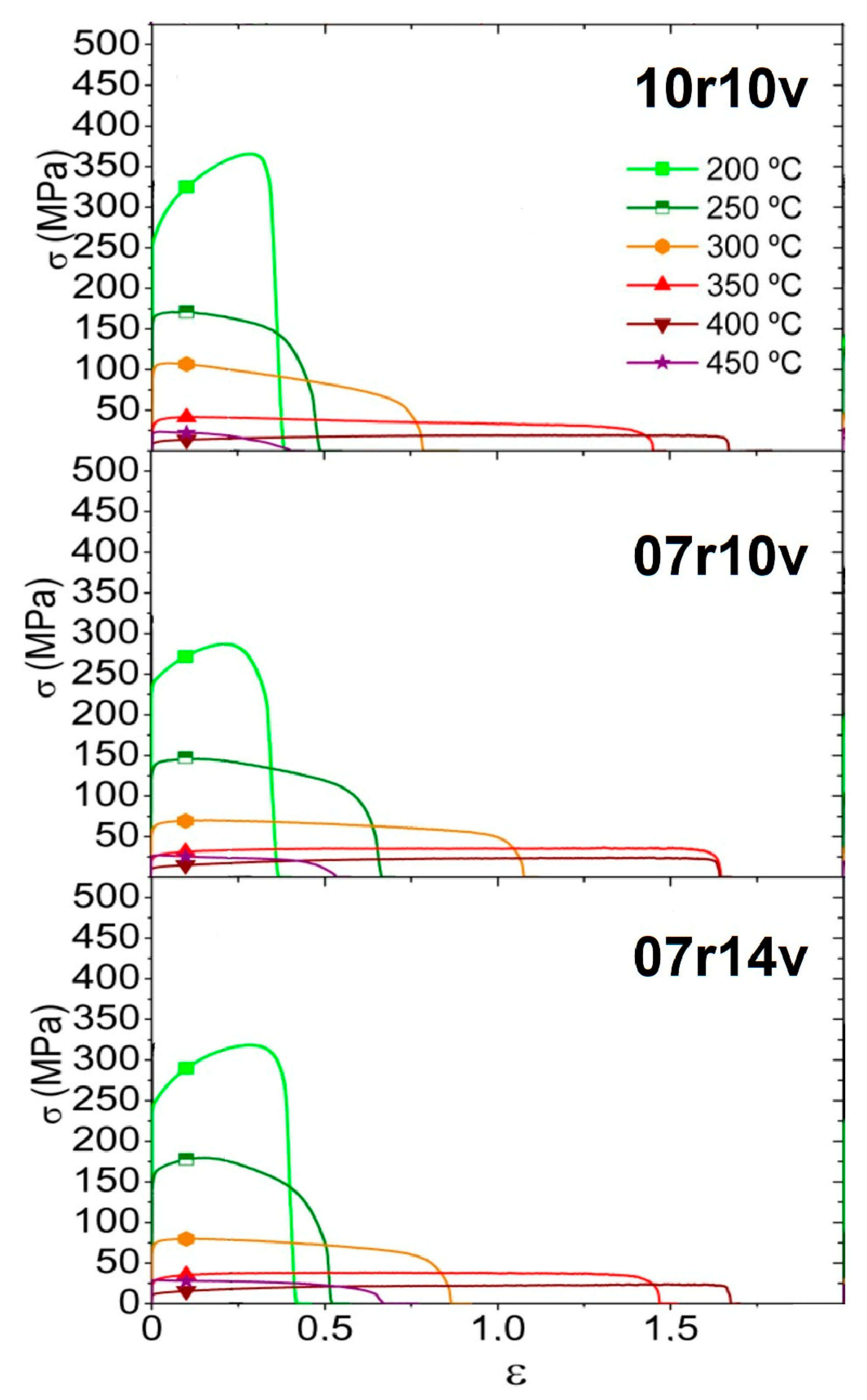

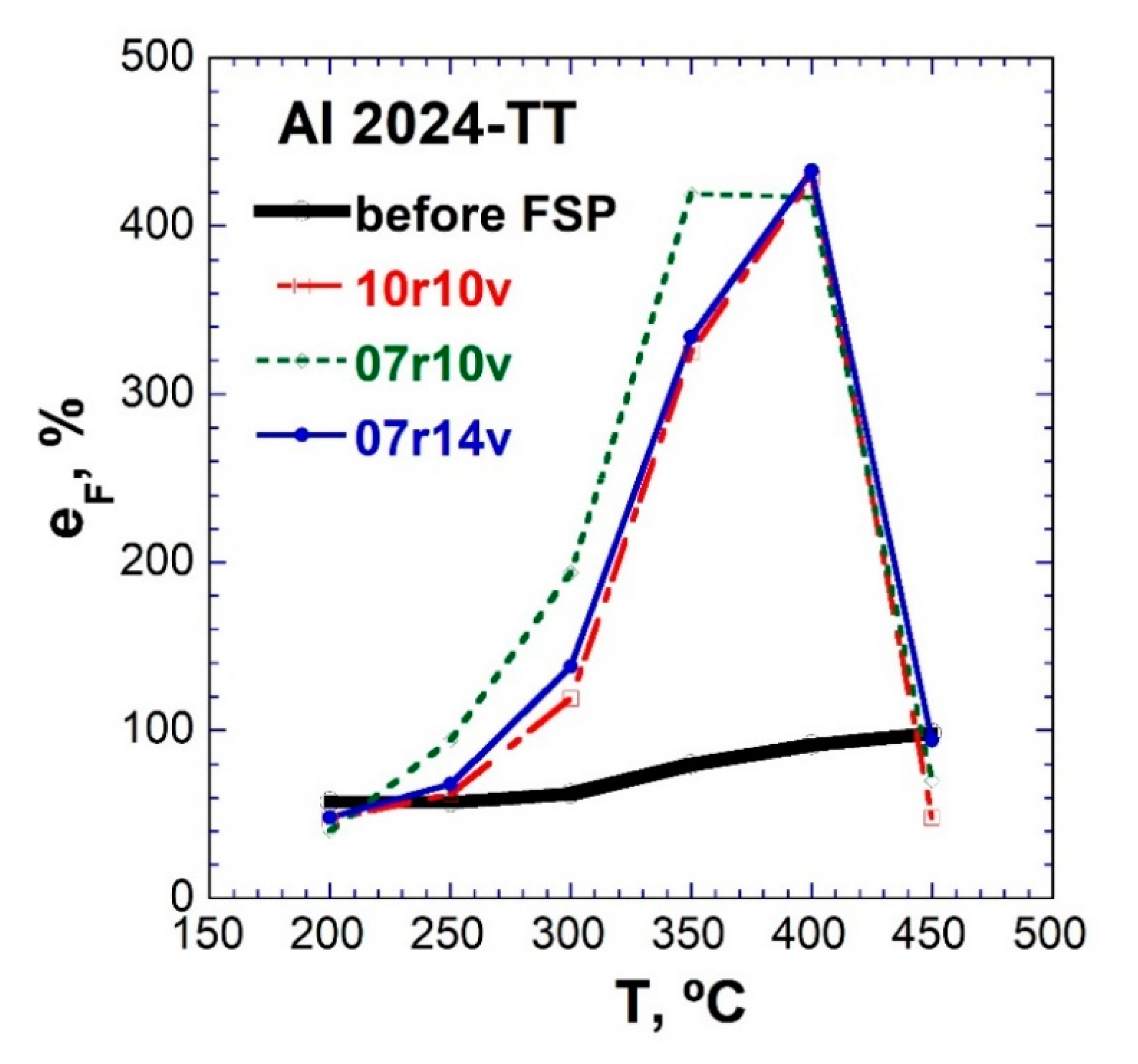

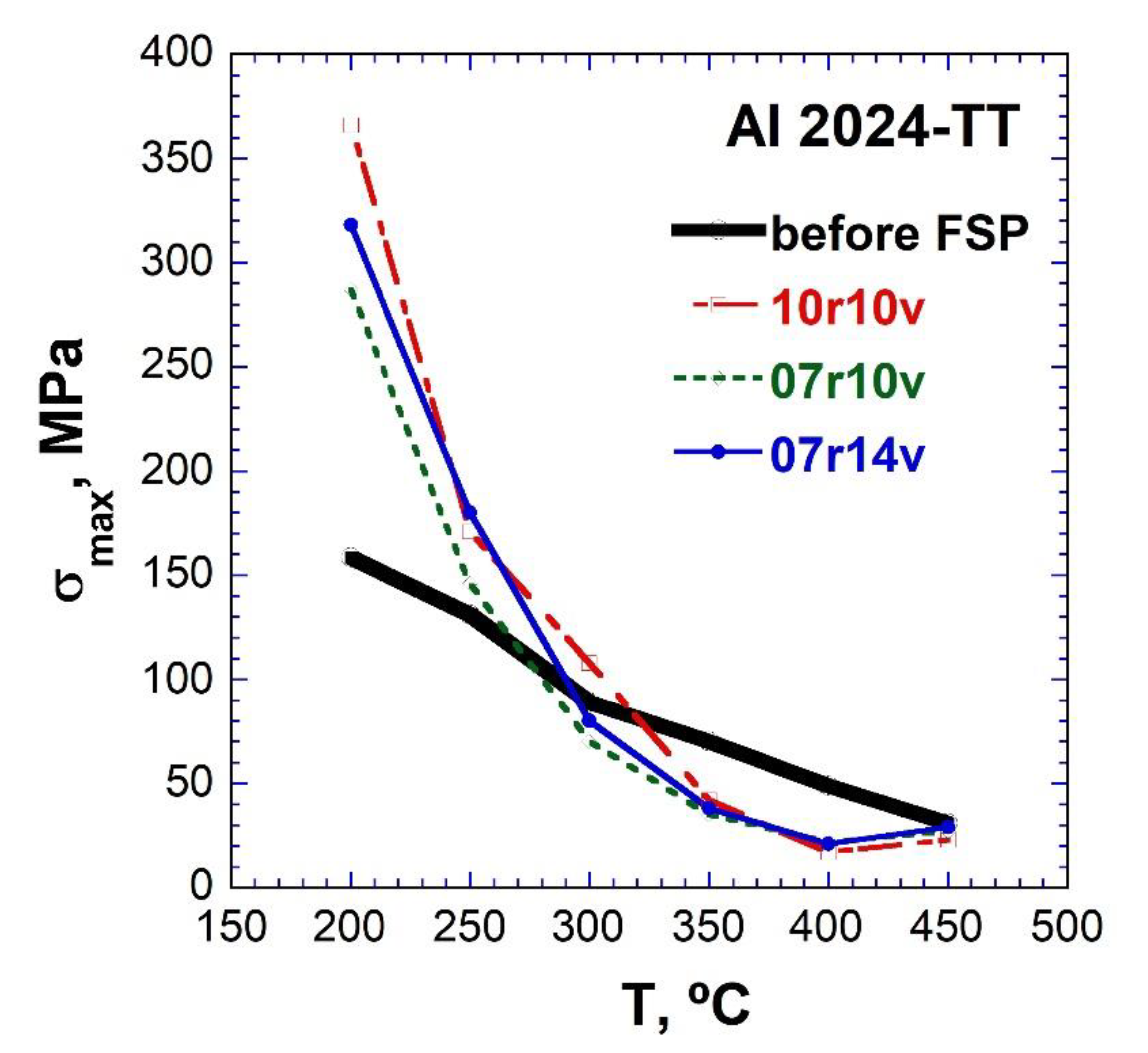

3.2. Tensile Tests at Medium and High Temperatures

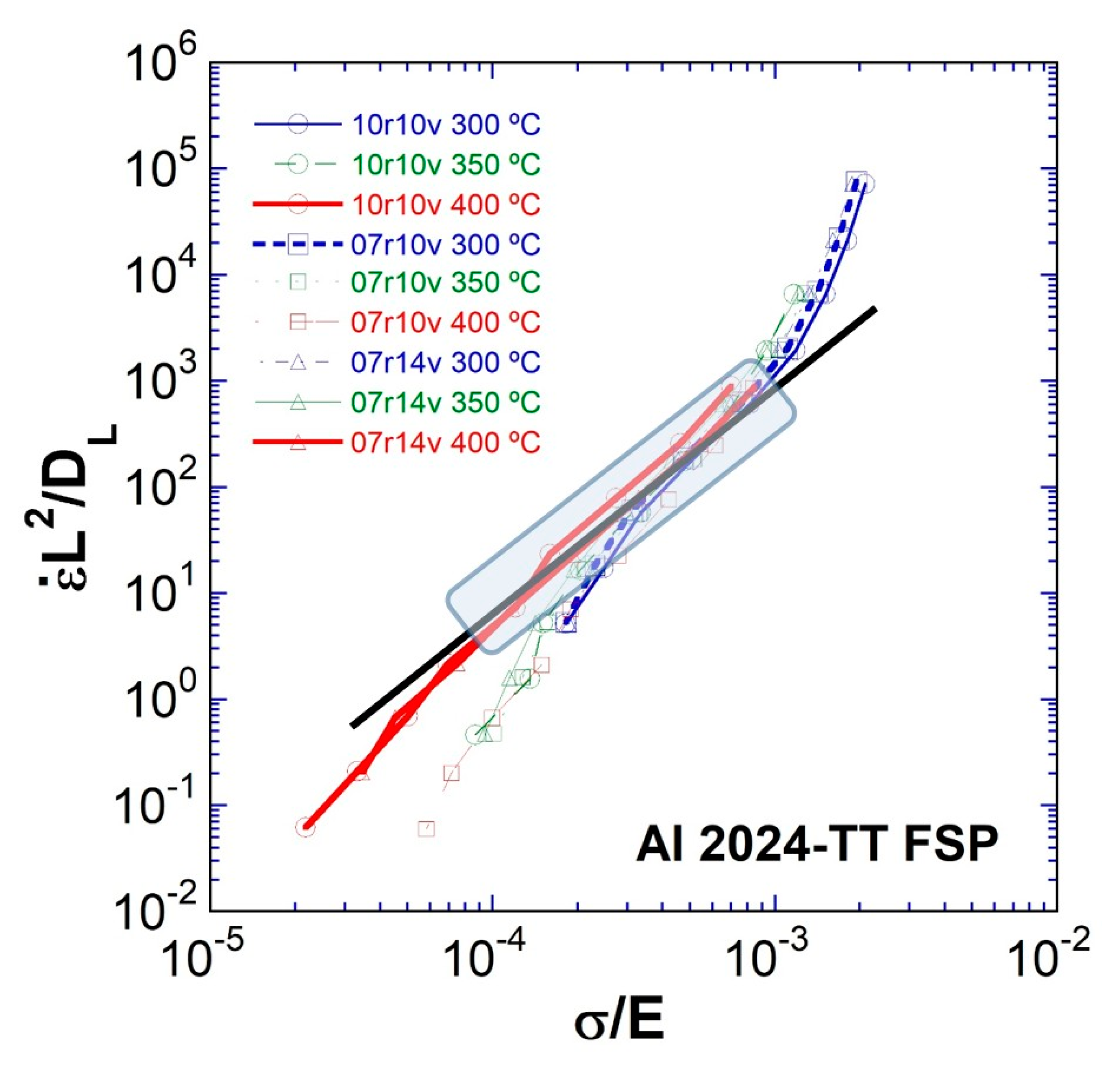

3.3. Strain-Rate Change Tensile Tests

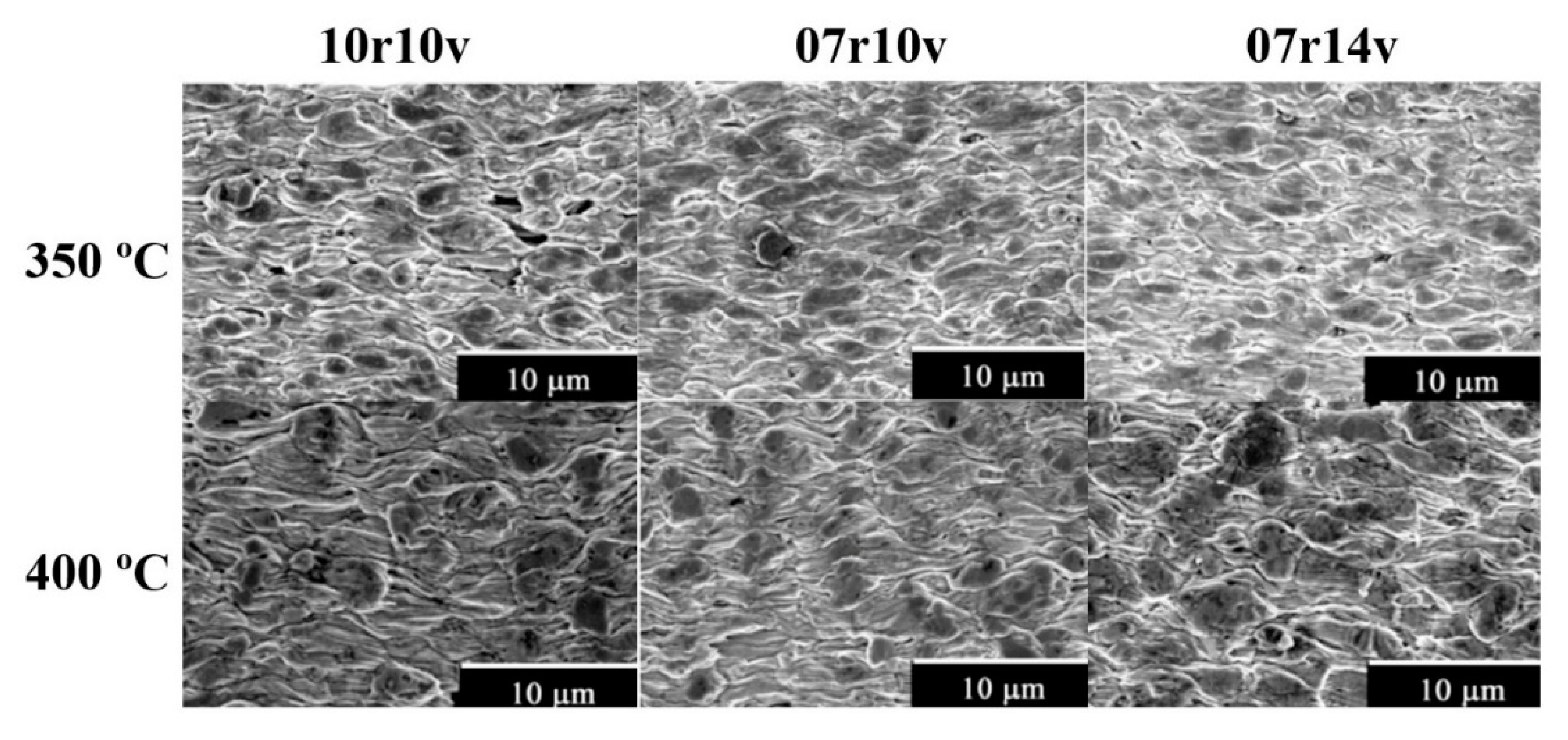

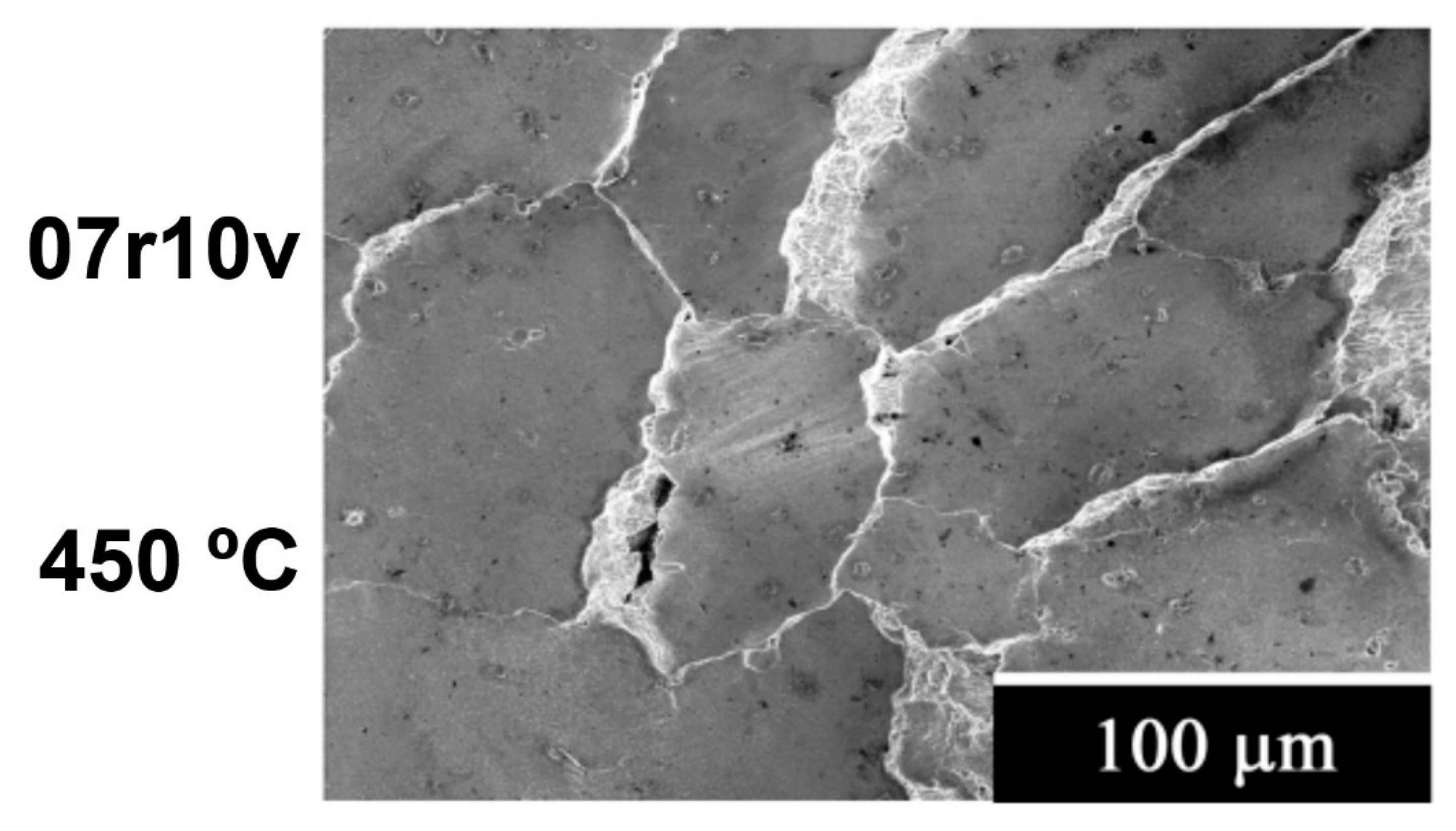

3.4. Microstructures after Testing

3.5. Deformation Mechanisms

4. Conclusions

- (1)

- After the TT temper, the microstructure was formed by coarse, barely elongated grains. Grain size was considerably reduced by severe FSP processing, reaching values about 1 µm.

- (2)

- A rapid decrease in the stress with temperature from 200 °C to 350 °C for all FSP processed materials was observed. On the other hand, the non-processed Al 2024-TT material showed a slower decrease, with the same stress at 450 °C as for the FSP materials.

- (3)

- The ductility increases substantially with temperature up 400 °C. At this temperature, the ductility is higher than 400% for all FSP processed materials. However, a strong decrease in ductility is obtained at 450 °C, due to extensive grain coarsening, and thus, grain boundary sliding is no longer the controlling deformation mechanism. On the other hand, the coarse-grained non-processed Al 2024-TT alloy presents a moderate increase in ductility up to 450 °C with values lower than 100%.

- (4)

- Similar strain rates at a given stress are observed in the superplastic regime, which are attributed to similar grain sizes in the three FSP materials during deformation.

- (5)

- The controlling mechanism in the low-stress regime is grain boundary sliding, as expected from fine, equiaxed and highly misoriented grains after friction stir processing.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kaçar, H.; Atik, E.; Meriç, C. The effect of precipitation-hardening conditions on wear behaviours at 2024 aluminium wrought alloy. J. Mater. Process. Technol. 2003, 142, 762–766. [Google Scholar] [CrossRef]

- Mao, J.; Kang, S.B.; Park, J.O. Grain refinement, thermal stability and tensile properties of 2024 aluminum alloy after equal-channel angular pressing. J. Mater. Process. Technol. 2005, 159, 314–320. [Google Scholar] [CrossRef]

- Mishra, R.; Mahoney, M.; McFadden, S.; Mara, N.; Mukherjee, A. High strain rate superplasticity in a friction stir processed 7075 Al alloy. Scr. Mater. 2000, 42, 163–168. [Google Scholar] [CrossRef]

- Mishra, R.S.; Mahoney, M.W. Friction Stir Processing: A New Grain Refinement Technique to Achieve High Strain Rate Superplasticity in Commercial Alloys. Mater. Sci. Forum 2001, 357–359, 507–514. [Google Scholar] [CrossRef]

- Hebesberger, T.; Stüwe, H.P.; Vorhauer, A.; Wetscher, F.; Pippan, R. Structure of Cu deformed by high pressure torsion. Acta Mater. 2005, 53, 393–402. [Google Scholar] [CrossRef]

- Khatibi, G.; Horky, J.; Weiss, B.; Zehetbauer, M.J. High cycle fatigue behaviour of copper deformed by high pressure torsion. Int. J. Fatigue 2010, 32, 269–278. [Google Scholar] [CrossRef]

- Rezaei, M.R.; Toroghinejad, M.R.; Ashrafizadeh, F. Production of nano-grained structure in 6061 aluminum alloy strip by accumulative roll bonding. Mater. Sci. Eng. A 2011, 529, 442–446. [Google Scholar] [CrossRef]

- Hidalgo-Manrique, P.; Cepeda-Jimenez, C.M.; Ruano, O.A.; Carreño, F. Effect of warm accumulative roll bonding on the evolution of microstructure, texture and creep properties in the 7075 aluminium. Mater. Sci. Eng. A 2012, 556, 287–294. [Google Scholar] [CrossRef] [Green Version]

- Zhilyaev, A.P.; Oh-Ishi, K.; Raab, G.I.; McNelley, T.R. Influence of ECAP processing parameters on texture and microstructure of commercially pure aluminum. Mater. Sci. Eng. A 2006, 441, 245–252. [Google Scholar] [CrossRef]

- El-Danaf, E.A.; Soliman, M.S.; Almajid, A.A.; El-Rayes, M.M. Enhancement of mechanical properties and grain size refinement of commercial purity aluminum 1050 processed by ECAP. Mater. Sci. Eng. A 2007, 458, 226–234. [Google Scholar] [CrossRef]

- Thompson, B.; Doherty, K.; Su, J.; Mishra, R. Nano-Sized Grain Refinement Using Friction Stir Processing. In Proceedings of the TMS 142nd Annual Meeting and Exhibition, San Antonio, TX, USA, 3–7 March 2013; pp. 9–19. [Google Scholar] [CrossRef]

- Patel, V.V.; Badheka, V.; Kumar, A. Effect of polygonal pin profiles on friction stir processed superplasticity of AA7075 alloy. J. Mater. Process. Technol. 2017, 240, 68–76. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. High strain rate superplasticity in a commercial 2024 Al alloy via friction stir processing. Mater. Sci. Eng. A 2003, 359, 290–296. [Google Scholar] [CrossRef]

- Pradeep, S.; Pancholi, V. Effect of microstructural inhomogeneity on superplastic behaviour of multipass friction stir processed aluminium alloy. Mater. Sci. Eng. A 2013, 561, 78–87. [Google Scholar] [CrossRef]

- Smolej, A.; Klobčar, D.; Skaza, B.; Nagode, A.; Slaček, E.; Dragojević, V.; Smolej, S. Superplasticity of the rolled and friction stir processed Al–4.5 Mg–0.35Sc–0.15Zr alloy. Mater. Sci. Eng. A 2014, 590, 239–245. [Google Scholar] [CrossRef]

- Lee, S.; Furukawa, M.; Horita, Z.; Langdon, T.G. Developing a superplastic forming capability in a commercial aluminum alloy without scandium or zirconium additions. Mater. Sci. Eng. A 2003, 342, 294–301. [Google Scholar] [CrossRef]

- Kulas, M.-A.; Green, W.P.; Taleff, E.M.; Krajewski, P.E.; McNelley, T.R. Deformation mechanisms in superplastic AA5083 materials. Met. Mater. Trans. A 2005, 36, 1249–1261. [Google Scholar] [CrossRef]

- Chezan, A.R.; De Hosson, J.T.M. Superplastic behavior of coarse-grained aluminum alloys. Mater. Sci. Eng. A 2005, 410–411, 120–123. [Google Scholar] [CrossRef] [Green Version]

- Kulas, M.-A.; Krajewski, P.E.; Bradley, J.R.; Taleff, E.M. Forming-Limit Diagrams for Hot-Forming of AA5083 Aluminum Sheet: Continuously Cast Material. J. Mater. Eng. Perform. 2007, 16, 308–313. [Google Scholar] [CrossRef]

- Mizuguchi, T.; Ito, T.; Kimura, K.; Tanaka, Y. Contributions of Grain Boundary Sliding and Solute Drag Creep to High-Temperature Ductility in Fine-Grained Polycrystalline 5083 Alloys. Adv. Mater. Res. 2014, 922, 360–365. [Google Scholar] [CrossRef]

- Ito, T.; Mizuguchi, T. Superplastic Elongation through Deformation Mechanism Transition during High-Temperature Deformation in Thermally Unstable Fine-Grained Aluminum Solid Solution Alloy. Key Eng. Mater. 2016, 723, 21–26. [Google Scholar] [CrossRef]

- Ito, T.; Mizuguchi, T. Superplastic-Like Elongation by Transition of Deformation Mechanism from Grain Boundary Sliding to Solute Drag Creep in Fine-Grained Al-Mg Solid Solution Alloy. Mater. Sci. Forum 2018, 941, 1216–1221. [Google Scholar] [CrossRef]

- Bhatta, L.; Pesin, A.; Zhilyaev, A.P.; Tandon, P.; Kong, C.; Yu, H. Recent Development of Superplasticity in Aluminum Alloys: A Review. Metals 2020, 10, 77. [Google Scholar] [CrossRef] [Green Version]

- Ruano, O.A.; Álvarez-Leal, M.; Orozco-Caballero, A.; Carreño, F. Superplasticity of a friction stir processed overaged WE54 magnesium alloy. J. Magnes. Alloy. 2022. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Álvarez-Leal, M.; Ruano, O.A.; Carreño, F. Improving the mechanical properties of a WE54 magnesium alloy through severe friction stir processing and rapid cooling. Mater. Sci. Eng. A 2022, 856, 143963. [Google Scholar] [CrossRef]

- Lundy, T.S.; Murdock, J.F. Diffusion of Al26 and Mn54 in Aluminum. J. Appl. Phys. 1962, 33, 1671–1673. [Google Scholar] [CrossRef]

- Weertman, J. Theory of Steady-State Creep Based on Dislocation Climb. J. Appl. Phys. 1955, 26, 1213–1217. [Google Scholar] [CrossRef]

- Ruano, O.A.; Sherby, O.D. On constitutive equations for various diffusion-controlled creep mechanisms. J. Phys. Appl. 1988, 23, 625–637. [Google Scholar] [CrossRef]

- Sherby, O.D.; Burke, P.M. Mechanical behavior of crystalline solids at elevated temperature. Prog. Mater. Sci. 1968, 13, 323–390. [Google Scholar] [CrossRef]

- Charit, I.; Mishra, R.S. Low temperature superplasticity in a friction-stir-processed ultrafine grained Al–Zn–Mg–Sc alloy. Acta Mater. 2005, 53, 4211–4223. [Google Scholar] [CrossRef]

- Li, X.P.; Covelli, L.; Tagliaferri, V.; Liu, Y.W. Superplasticity of commercial 2014 aluminium alloy processed by a simple thermomechanical method. J. Mater. Sci. Lett. 1991, 10, 585–587. [Google Scholar] [CrossRef]

- Zheng, W.; Baoliang, Z. Superplasticity in the 2024AI alloy. J. Mater. Sci. Lett. 1994, 13, 1806–1808. [Google Scholar] [CrossRef]

- Matsuki, K.; Sugahara, H.; Aida, T.; Takatsuji, N.; Kusui, J.; Yokoe, K. Effect of Microstructure Refinement on High Strain Rate Superplasticity in a PM 2024Al–Fe–Ni Alloy. Mater. Trans. JIM 1999, 40, 737–743. [Google Scholar] [CrossRef] [Green Version]

- Matsuki, K.; Aida, T.; Kusui, J. Effect of Deformation Temperature on High Strain Rate Superplastic Properties in PM 2024Al-Fe-Ni Alloys. Mater. Sci. Forum 1999, 304–306, 255–260. [Google Scholar] [CrossRef]

- Kaibyshev, R.; Kazakulov, I.; Gromov, D.; Musin, F.; Lesuer, D.R.; Nieh, T.G. Superplasticity in a 2219 aluminum alloy. Scr. Mater. 2001, 44, 2411–2417. [Google Scholar] [CrossRef]

- Horita, Z.; Lee, S.; Ota, S.; Neishi, K.; Langdon, T.G. Equal-Channel Angular Pressing as a Production Tool for Superplastic Materials. Mater. Sci. Forum 2001, 357–359, 471–476. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Cepeda-Jiménez, C.M.; Hidalgo-Manrique, P.; Rey, P.; Gesto, D.; Verdera, D.; Ruano, O.A.; Carreño, F. Lowering the temperature for high strain rate superplasticity in an Al–Mg–Zn–Cu alloy via cooled friction stir processing. Mater. Chem. Phys. 2013, 142, 182–185. [Google Scholar] [CrossRef]

- Adabbo, H.E.; González-Doncel, G.; Ruano, O.A.; Belzunce, J.M.; Sherby, O.D. Strain hardening during superplastic deformation of A1-7475 alloy. J. Mater. Res. 1989, 4, 587–594. [Google Scholar] [CrossRef]

- Perez-Prado, M.T.; González-Doncel, G.; Ruano, O.A.; McNelley, T.R. Texture analysis of the transition from slip to grain boundary sliding in a discontinuously recrystallized superplastic aluminum alloy. Acta Mater. 2001, 49, 2259–2268. [Google Scholar] [CrossRef] [Green Version]

- Musin, F.; Kaibyshev, R.; Motohashi, Y.; Itoh, G. High strain rate superplasticity in a commercial Al–Mg–Sc alloy. Scr. Mater. 2004, 50, 511–516. [Google Scholar] [CrossRef]

- Orozco-Caballero, A.; Ruano, O.A.; Rauch, E.F.; Carreño, F. Severe friction stir processing of an Al-Zn-Mg-Cu alloy: Misorientation and its influence on superplasticity. Mater. Des. 2018, 137, 128–139. [Google Scholar] [CrossRef]

| Element | Cu | Mg | Mn | Si | Fe | Zn | Ti | Cr | Al |

|---|---|---|---|---|---|---|---|---|---|

| wt. % | 4.3 | 1.5 | 0.6 | <0.5 | <0.5 | 0.15 | 0.03 | 0.007 | Balance |

| r (rpm) | v (mm/min) | HI (rpm2/(mm/min)) | Designation |

|---|---|---|---|

| 1000 | 1000 | 1000 | 10r10v |

| 700 | 1000 | 490 | 07r10v |

| 700 | 1400 | 350 | 07r14v |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Orozco-Caballero, A.; Álvarez-Leal, M.; Carreño, F.; Ruano, O.A. Superplastic Behavior of Overaged 2024 Aluminum Alloy after Friction Stir Processing. Metals 2022, 12, 1880. https://doi.org/10.3390/met12111880

Orozco-Caballero A, Álvarez-Leal M, Carreño F, Ruano OA. Superplastic Behavior of Overaged 2024 Aluminum Alloy after Friction Stir Processing. Metals. 2022; 12(11):1880. https://doi.org/10.3390/met12111880

Chicago/Turabian StyleOrozco-Caballero, Alberto, Marta Álvarez-Leal, Fernando Carreño, and Oscar A. Ruano. 2022. "Superplastic Behavior of Overaged 2024 Aluminum Alloy after Friction Stir Processing" Metals 12, no. 11: 1880. https://doi.org/10.3390/met12111880