The Effect of Thermomechanical Processing Sequence on the Dispersoid Distribution and Final Mechanical Properties of Spray-Formed Al-Cu-Li Alloy

Abstract

:1. Introduction

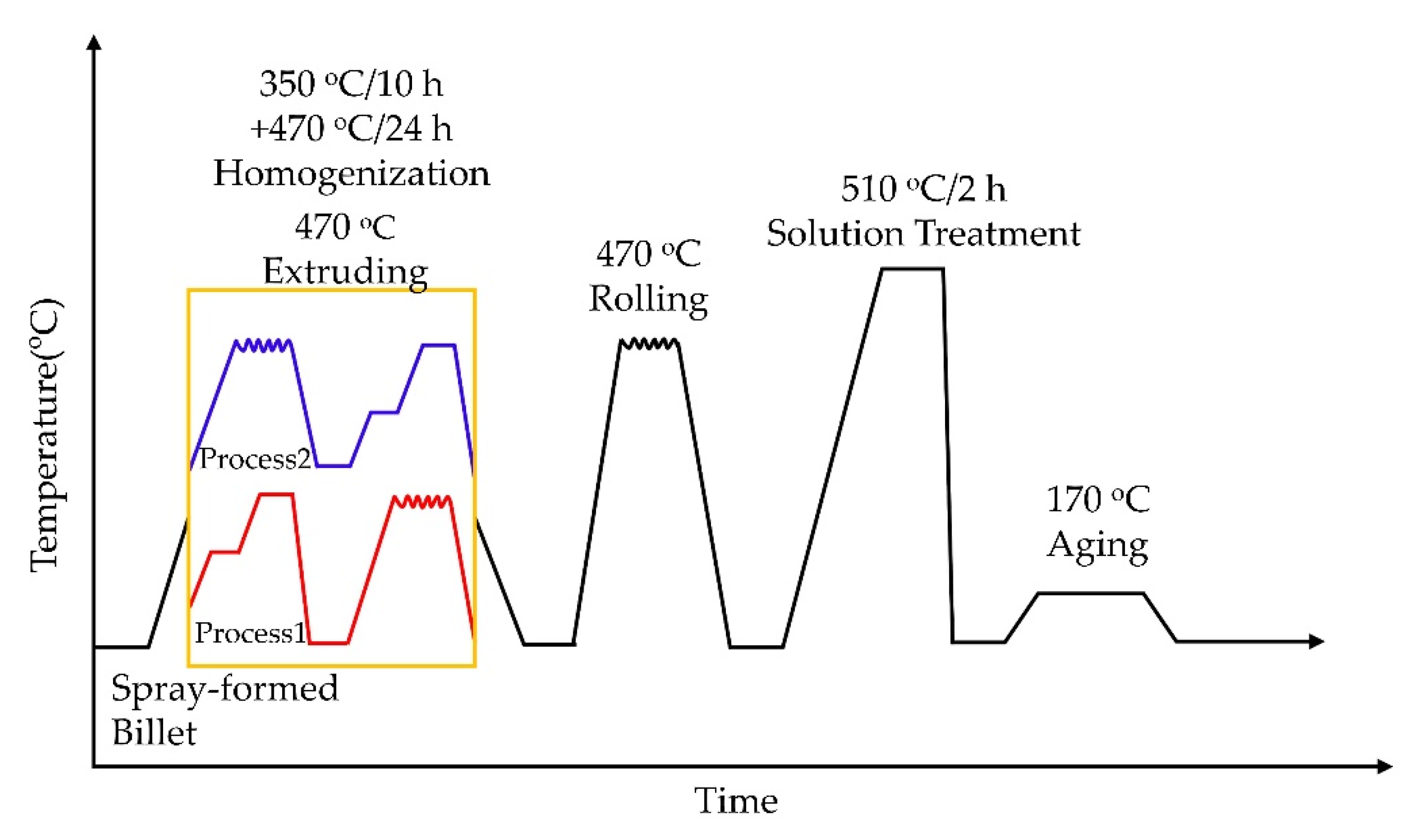

2. Materials and Methods

3. Results

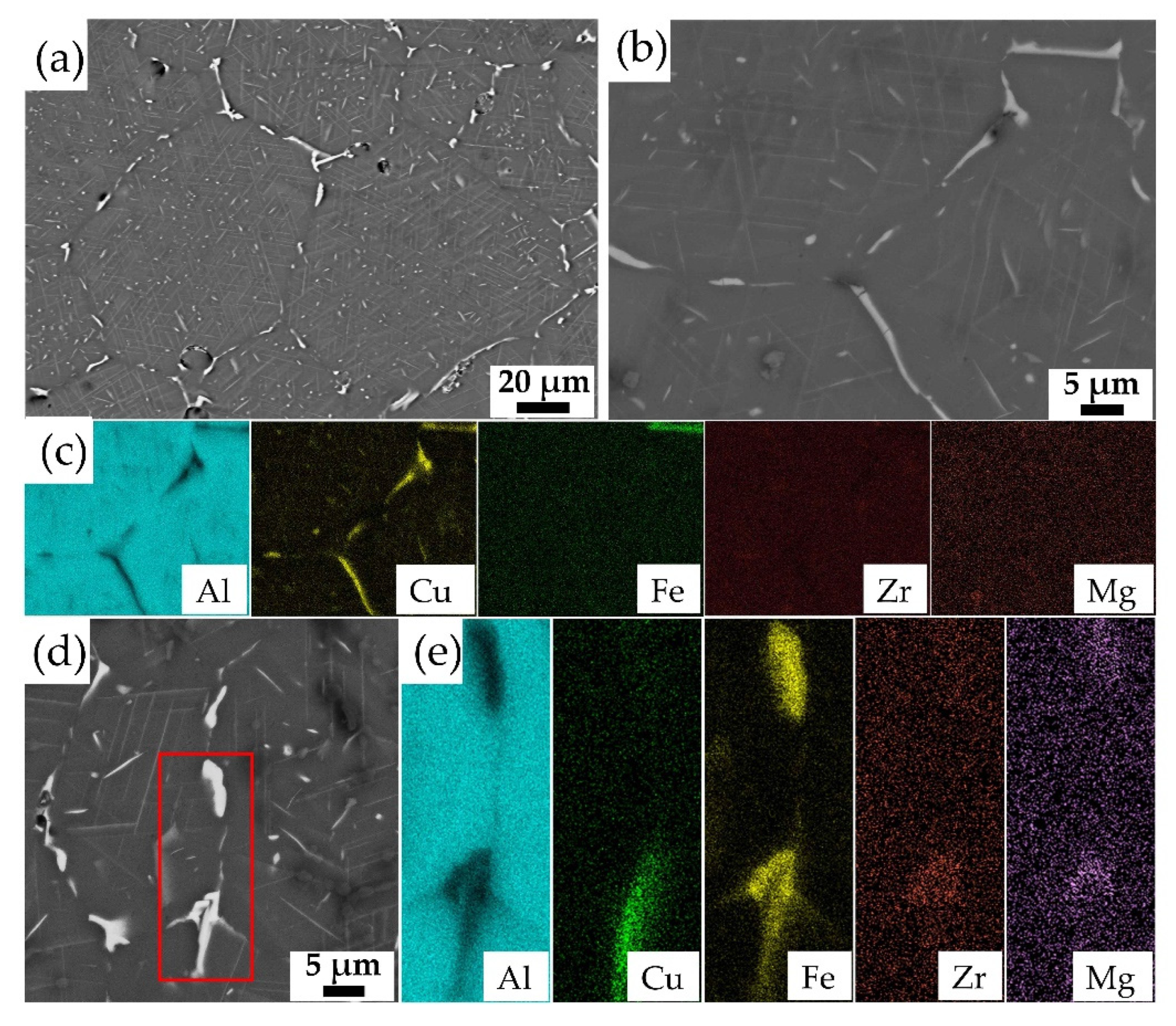

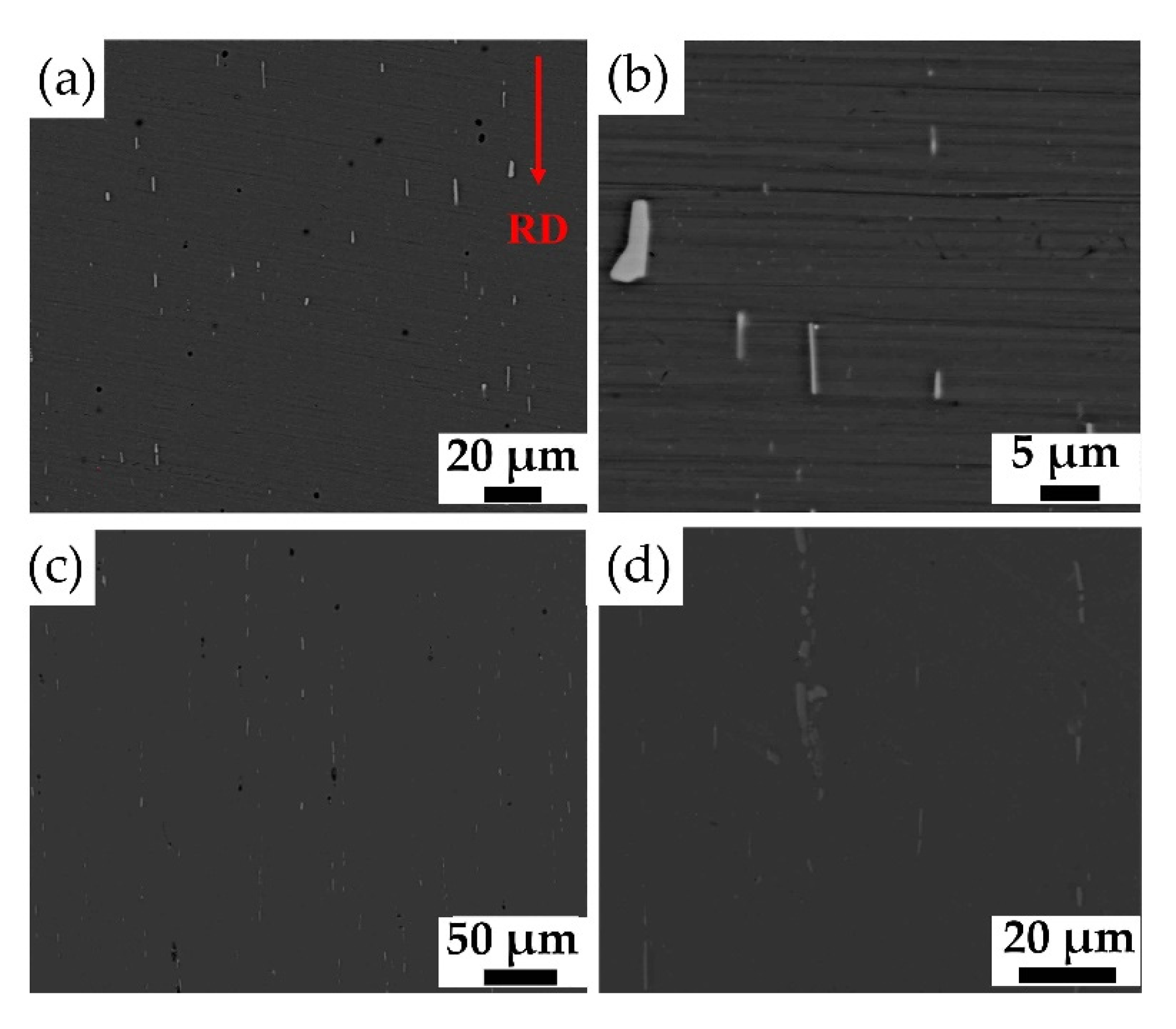

3.1. Microstructure of Sprayed Condition

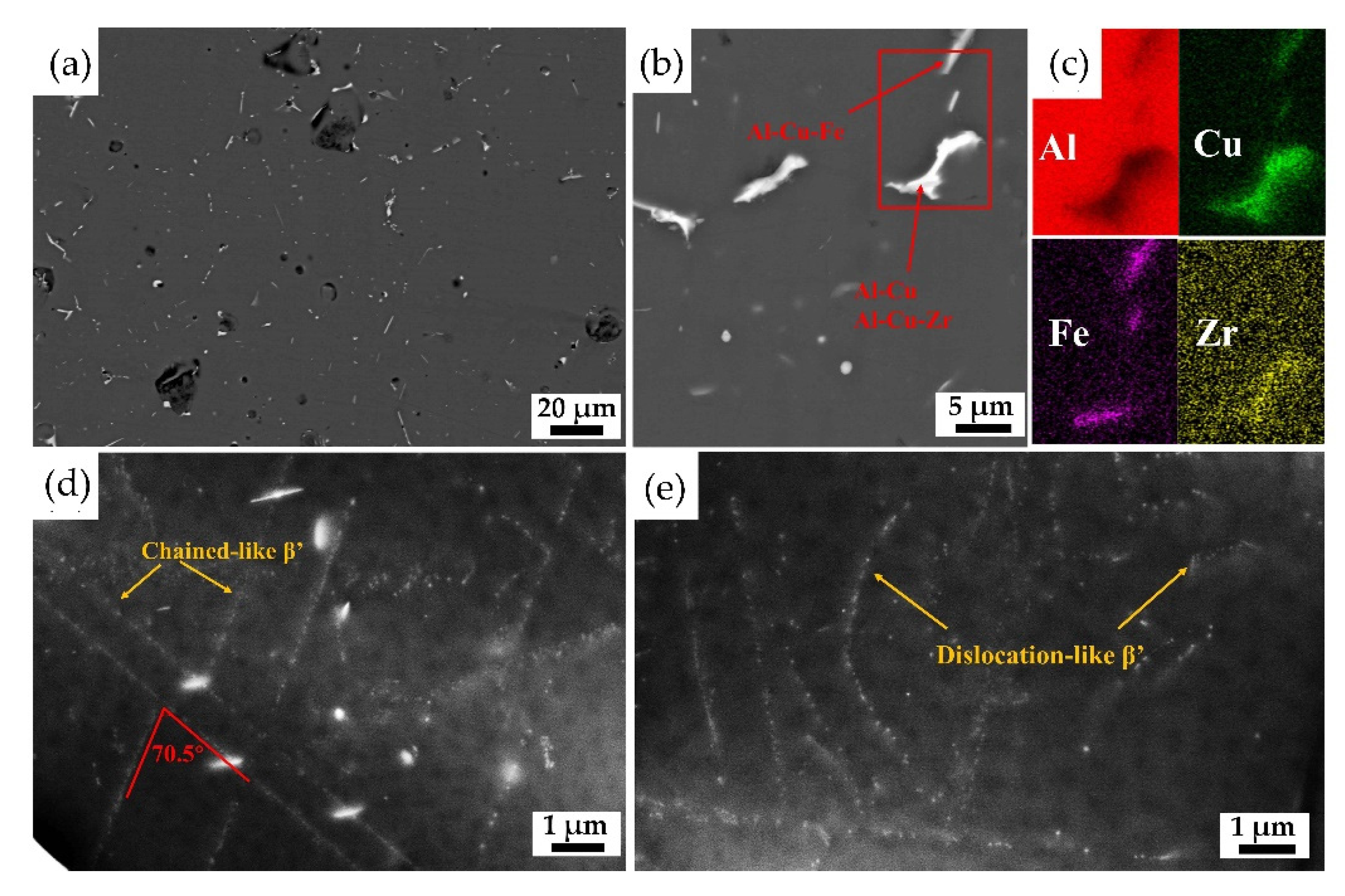

3.2. Microstructure of As-Homogenized Conditions

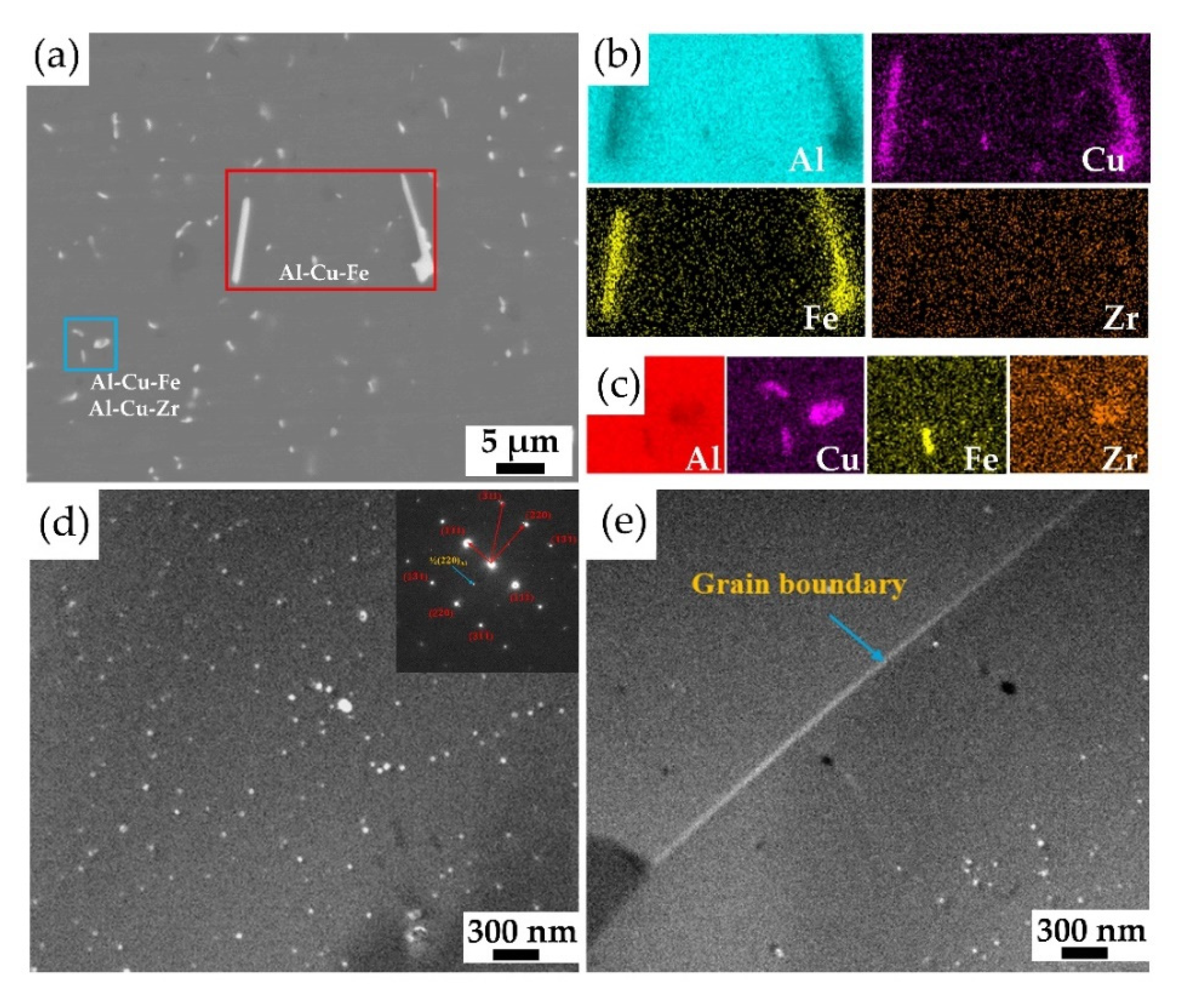

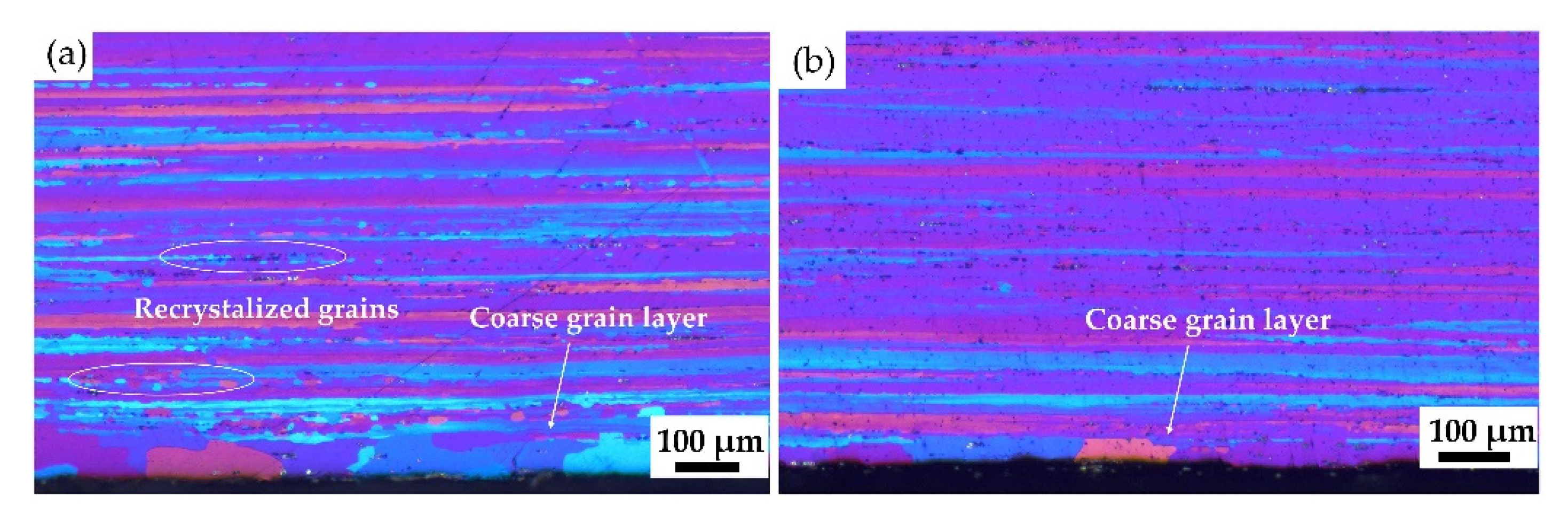

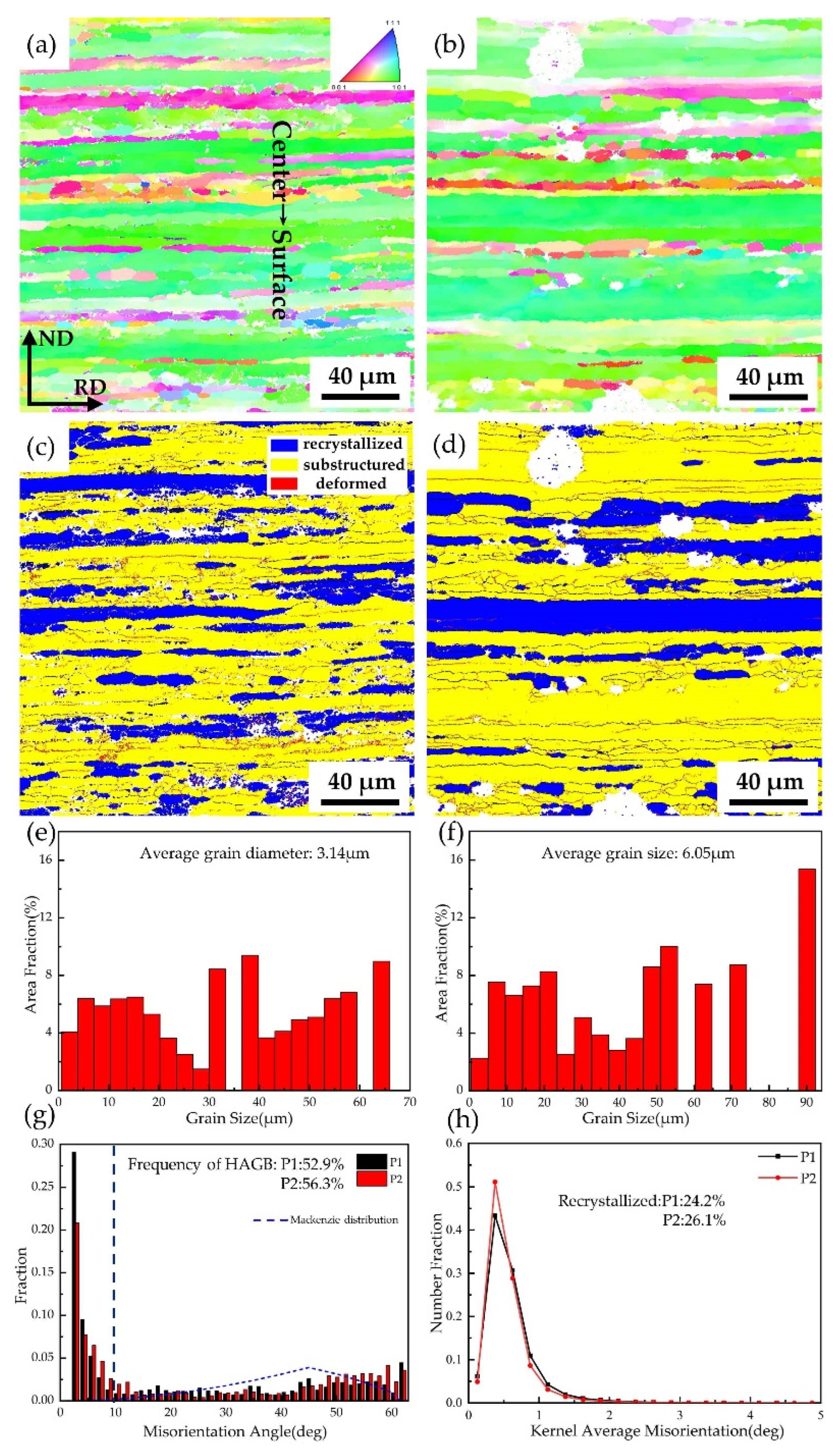

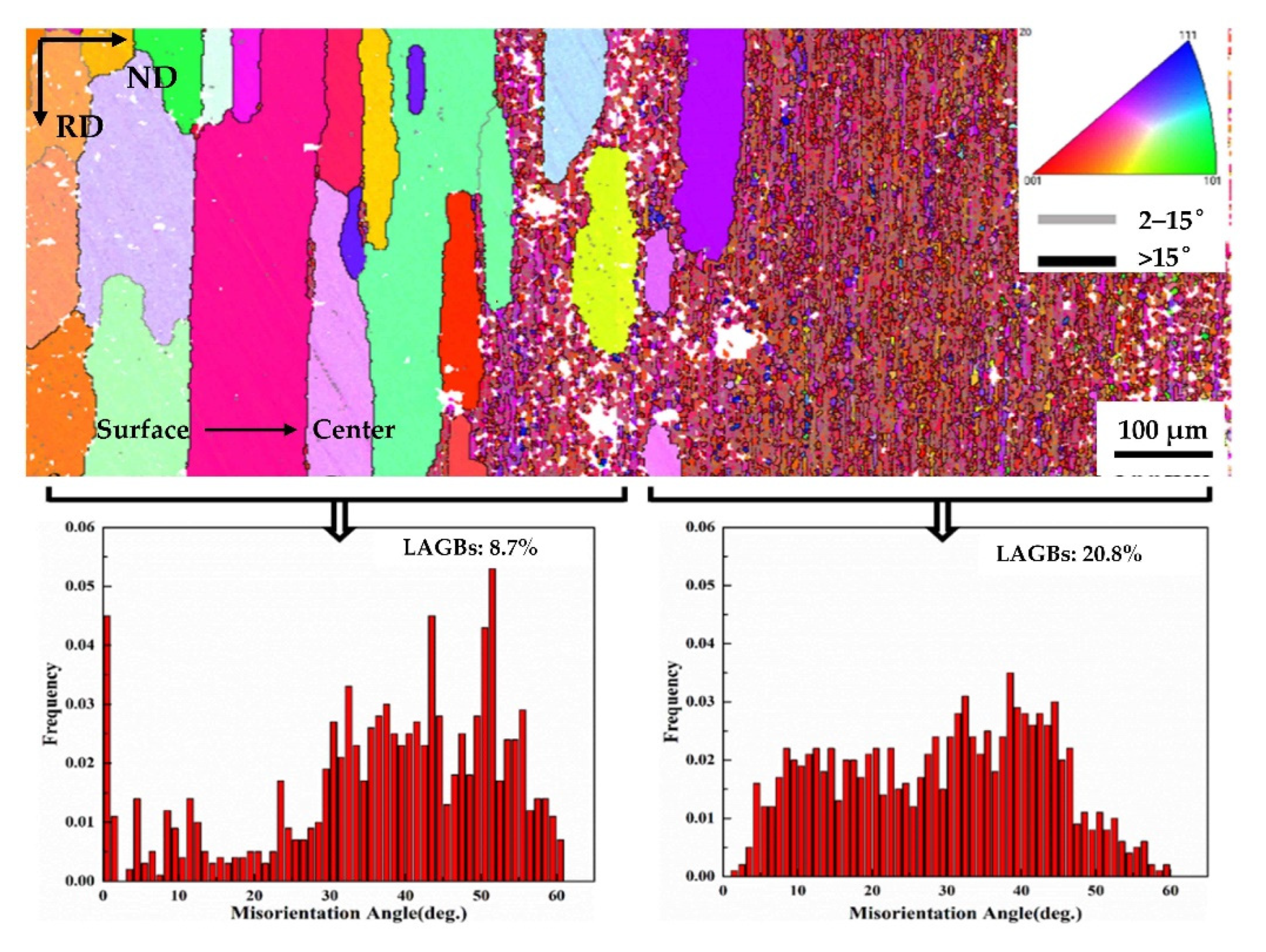

3.3. Microstructures Evolution after Solution Treatment

3.4. Mechanical Properties of Solution Treatment Sheet

4. Discussions

5. Conclusions

- Switching the order of homogenization and extrusion will affect the microstructure and mechanical properties of the spray formed 2195 alloy. Direct two-step homogenization on the as-deposited alloy results in an inhomogeneous distribution of the β′ phase due to the preferential nucleation of β′ phase on the T1 plates. The introduction of extrusion on the as-deposited alloy can obviously break the continuous coarse primary phases and dissolve the T1 phase, and during the following two-step homogenization, most of the β′ particles are uniformly distributed due to the absence of the T1 phase.

- The refined and uniform distribution of the β′ phase in the “extrusion-homogenization” process produces a smaller coarse grain layer in the sheet surface compared with the “homogenization-extrusion” processed sample with inhomogeneous distribution of the β′ phase.

- Compared with a direct homogenized sample, the “extrusion-homogenization” process produces larger grain sizes and low density of dislocations due to the low thickness reduction during the deformation. Therefore, switching the sequence of extrusion and homogenization produces lower strength but higher elongation for the spray formed 2195 alloy after peak aging.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, P.; Zhan, L.; Liu, C.; Wang, Q.; Li, H.; Liu, D.; Hu, Z. Pre-strain-dependent natural ageing and its effect on subsequent artificial ageing of an Al-Cu-Li alloy. J. Alloys Compd. 2019, 790, 8–19. [Google Scholar] [CrossRef]

- Rioja, R.J.; Liu, J. The evolution of Al-Li base products for aerospace and space applications. Metall. Mater. Trans. A 2012, 43, 3325–3337. [Google Scholar] [CrossRef]

- Jeyakumar, M.; Kumar, S.; Gupta, G.S. Microstructure and properties of the spray-formed and extruded 7075 Al alloy. Mater. Manuf. Process. 2010, 25, 777–785. [Google Scholar] [CrossRef]

- Moore, K.L.; Sykes, J.M.; Hogg, S.C.; Grant, P.S. Pitting corrosion of spray formed Al–Li–Mg alloys. Corros. Sci. 2008, 50, 3221–3226. [Google Scholar] [CrossRef]

- Liu, B.; Lei, Q.; Xie, L.; Wang, M.; Li, Z. Microstructure and mechanical properties of high product of strength and elongation Al-Zn-Mg-Cu-Zr alloys fabricated by spray deposition. Mater. Des. 2016, 96, 217–223. [Google Scholar] [CrossRef]

- Liu, Q.; Fan, G.; Tan, Z.; Li, Z.; Zhang, D.; Wang, J.; Zhang, H. Precipitation of Al3Zr by two-step homogenization and its effect on the recrystallization and mechanical property in 2195 Al-Cu-Li alloys. Mater. Sci. Eng. A 2021, 821, 141637. [Google Scholar] [CrossRef]

- Pu, Q.; Jia, Z.; Kong, Y.; Yang, Q.; Zhang, Z.; Fan, X.; Zhang, H.; Lin, L.; Liu, Q. Microstructure and mechanical properties of 2195 alloys prepared by traditional casting and spray forming. Mater. Sci. Eng. A 2020, 784, 139337. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, G.; Chen, X.; Xu, X.; Chen, L.; Zhang, C. Effect of inter-annealing between two stages of extrusion on the microstructure and mechanical property for spray deposited Al-Cu-Li alloy 2195. J. Mater. Res. Technol. 2019, 8, 3891–3907. [Google Scholar] [CrossRef]

- Wang, Y.; Zhao, G.; Xu, X.; Chen, X.; Zhang, W. Microstructures and mechanical properties of spray deposited 2195 Al-Cu-Li alloy through thermo-mechanical processing. Mater. Sci. Eng. A 2018, 727, 78–89. [Google Scholar] [CrossRef]

- Suresh, M.; Sharma, A.; More, A.M.; Nayan, N.; Suwas, S. Effect of Scandium addition on evolution of microstructure, texture and mechanical properties of thermo-mechanically processed Al-Li alloy AA2195. J. Alloys Compd. 2018, 740, 364–374. [Google Scholar] [CrossRef]

- Deng, Y.; Xu, J.; Chen, J.; Guo, X. Effect of double-step homogenization treatments on the microstructure and mechanical properties of Al-Cu-Li–Zr alloy. Mater. Sci. Eng. A 2020, 795, 139975. [Google Scholar] [CrossRef]

- Guo, Z.; Zhao, G.; Chen, X.G. Effects of two-step homogenization on precipitation behavior of Al3Zr dispersoids and recrystallization resistance in 7150 aluminum alloy. Mater. Charact. 2015, 102, 122–130. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Robson, J.D. Heterogeneous Zr solute segregation and Al3Zr dispersoid distributions in Al-Cu-Li alloys. Acta Mater. 2015, 93, 73–86. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Robson, J.D.; Sigli, C.; Prangnell, P.B. Interactions between zirconium and manganese dispersoid-forming elements on their combined addition in Al-Cu-Li alloys. Acta Mater. 2012, 60, 5245–5259. [Google Scholar] [CrossRef]

- Guo, Y.; Li, J.; Lu, D.; Deng, S.; Zeng, G.; Ma, Y.; You, W.; Chen, Y.; Zhang, X.; Zhang, R. Characterization of Al3Zr precipitation via double-step homogenization and recrystallization behavior after subsequent deformation in 2195 Al-Li alloy. Mater. Charact. 2021, 182, 111549. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, X.; Zhao, G.; Xu, X.; Chen, X.; Zhang, C. Microstructure evolution of spray deposited and as-cast 2195 Al-Li alloys during homogenization. J. Mater. Sci. Technol. 2021, 82, 161–178. [Google Scholar] [CrossRef]

- Xu, A.; Han, J.; Wang, H.; Zheng, W.; Niu, K. Progress in dispersoids distribution precipitating during homogenising Zr-containing Al-Cu-Li and Al–Zn–Mg alloys. Mater. Sci. Technol. 2020, 36, 1903–1921. [Google Scholar] [CrossRef]

- Tsivoulas, D.; Prangnell, P.B. The effect of Mn and Zr dispersoid-forming additions on recrystallization resistance in Al-Cu-Li AA2198 sheet. Acta Mater. 2014, 77, 1–16. [Google Scholar] [CrossRef]

- Yang, S.; Shen, J.; Yan, X.; Li, X.; Zhang, F.; Sun, B. Homogenization Treatment Parameter Optimization and Microstructural Evolution of Al-Cu-Li Alloy. Rare Met. Mater. Eng. 2017, 46, 28–34. [Google Scholar]

- Zhang, J.; Zeng, H.; Wang, C.; Tang, Z. Effect of Al3Zr dispersoid on microstructure and mechanical properties of Al-Cu-Li alloy during composite spinning-extrusion forming. Front. Mater. 2022, 9, 822589. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Li, B.L.; Wu, X.L.; Gao, K.Y.; Wang, W.; Nie, Z.R. Effects of homogenization on precipitation of Al3(Er,Zr) particles and recrystallization behavior in a new type Al-Zn-Mg-Er-Zr alloy. Mater. Sci. Eng. A 2017, 689, 313–322. [Google Scholar] [CrossRef]

- Mackenzie, J.K. Second paper on statistics associated with the random disorientation of cubes. Biometrika 1958, 45, 229–240. [Google Scholar] [CrossRef]

- Suresh, K.S.; Gurao, N.P.; Singh, D.S.; Suwas, S.; Chattopadhyay, K.; Zherebtsov, S.V.; Salishchev, G.A. Effect of equal channel angular pressing on grain refinement and texture evolution in a biomedical alloy Ti13Nb13Zr. Mater. Charact. 2013, 82, 73–85. [Google Scholar] [CrossRef]

- Deng, Y.; Zhang, Y.; Wan, L.; Zhu, A.; Zhang, X. Three-stage homogenization of Al-Zn-Mg-Cu alloys containing trace Zr. Metall. Mater. Trans. A 2013, 44, 2470–2477. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Recrystallization and Related Annealing Phenomena; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar]

- Zhang, C.; Liu, M.; Meng, Z.; Zhang, Q.; Zhao, G.; Chen, L.; Zhang, H.; Wang, J. Microstructure evolution and precipitation characteristics of spray-formed and subsequently extruded 2195 Al-Li alloy plate during solution and aging process. J. Mater. Process. Technol. 2020, 283, 116718. [Google Scholar] [CrossRef]

- Hausler, I.; Schwarze, C.; Bilal, M.U.; Ramirez, D.V.; Hetaba, W.; Kamachali, R.D.; Skrotzki, B. Precipitation of T1 and θ’ phase in Al-4Cu-1Li-0.25Mn during age hardening: Microstructural investigation and phase-field simulation. Materials 2017, 10, 117. [Google Scholar] [CrossRef] [Green Version]

- Ta, N.; Bilal, M.U.; Hausler, I.; Saxena, A.; Lin, Y.Y.; Schleifer, F.; Fleck, M.; Glatzel, U.; Skrotzki, B.; Darvishi Kamachali, R. Simulation of the θ’ precipitation process with interfacial anisotropy effects in Al-Cu alloys. Materials 2021, 14, 1280. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, Y.; Zhang, X.; Huang, Y.; Ding, L.; Lei, X.; Weng, Y.; Cao, L.; Zhang, K.; Jia, Z. The Effect of Thermomechanical Processing Sequence on the Dispersoid Distribution and Final Mechanical Properties of Spray-Formed Al-Cu-Li Alloy. Metals 2022, 12, 1893. https://doi.org/10.3390/met12111893

Ning Y, Zhang X, Huang Y, Ding L, Lei X, Weng Y, Cao L, Zhang K, Jia Z. The Effect of Thermomechanical Processing Sequence on the Dispersoid Distribution and Final Mechanical Properties of Spray-Formed Al-Cu-Li Alloy. Metals. 2022; 12(11):1893. https://doi.org/10.3390/met12111893

Chicago/Turabian StyleNing, Yaru, Xingchen Zhang, Yunjia Huang, Lipeng Ding, Xiuchuan Lei, Yaoyao Weng, Lingfei Cao, Ke Zhang, and Zhihong Jia. 2022. "The Effect of Thermomechanical Processing Sequence on the Dispersoid Distribution and Final Mechanical Properties of Spray-Formed Al-Cu-Li Alloy" Metals 12, no. 11: 1893. https://doi.org/10.3390/met12111893