In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching & Partitioning Processing for Development of Third-Generation Advanced High Strength Steels

Abstract

1. Introduction

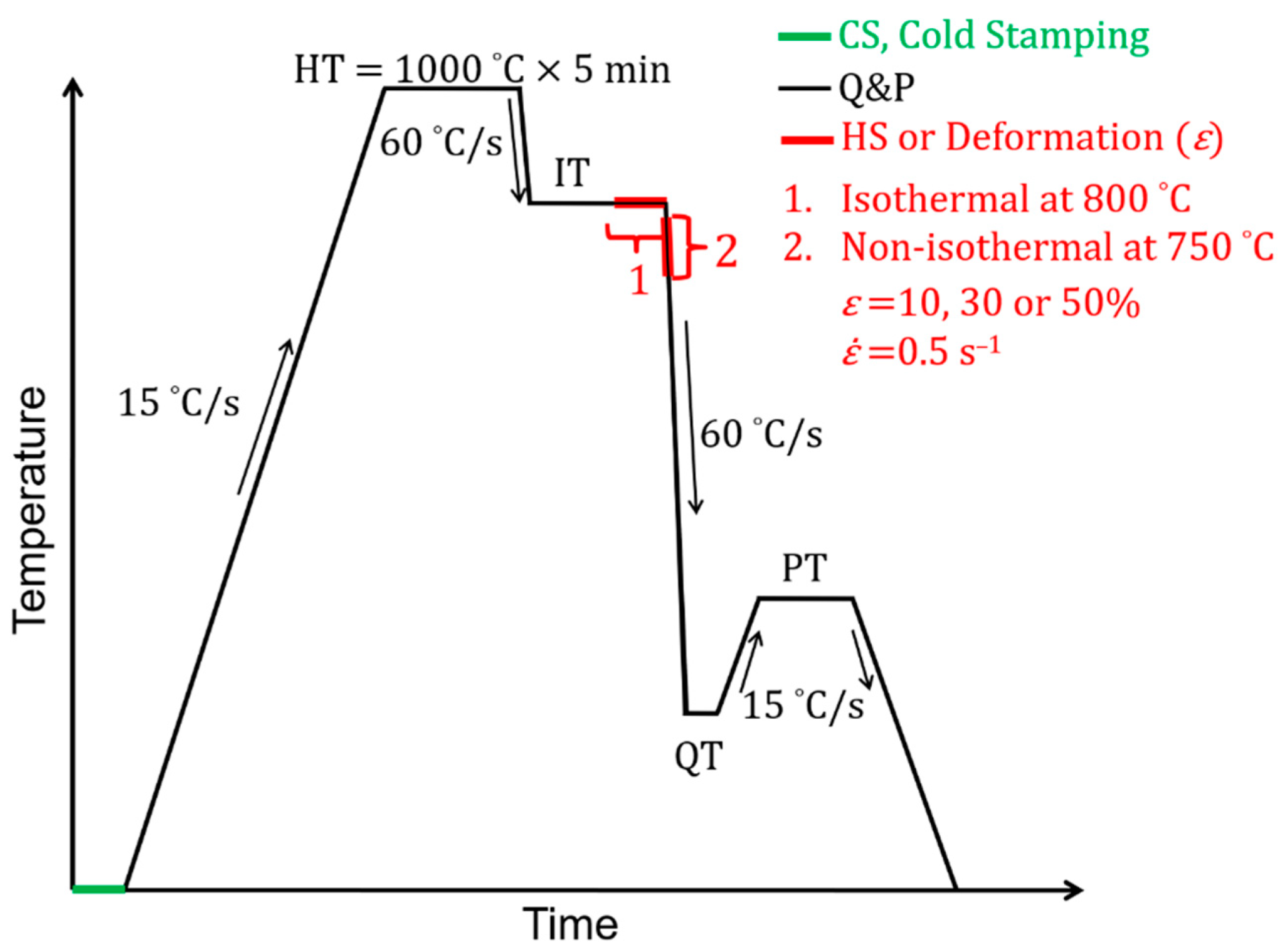

2. Materials and Methods

3. Results and Discussion

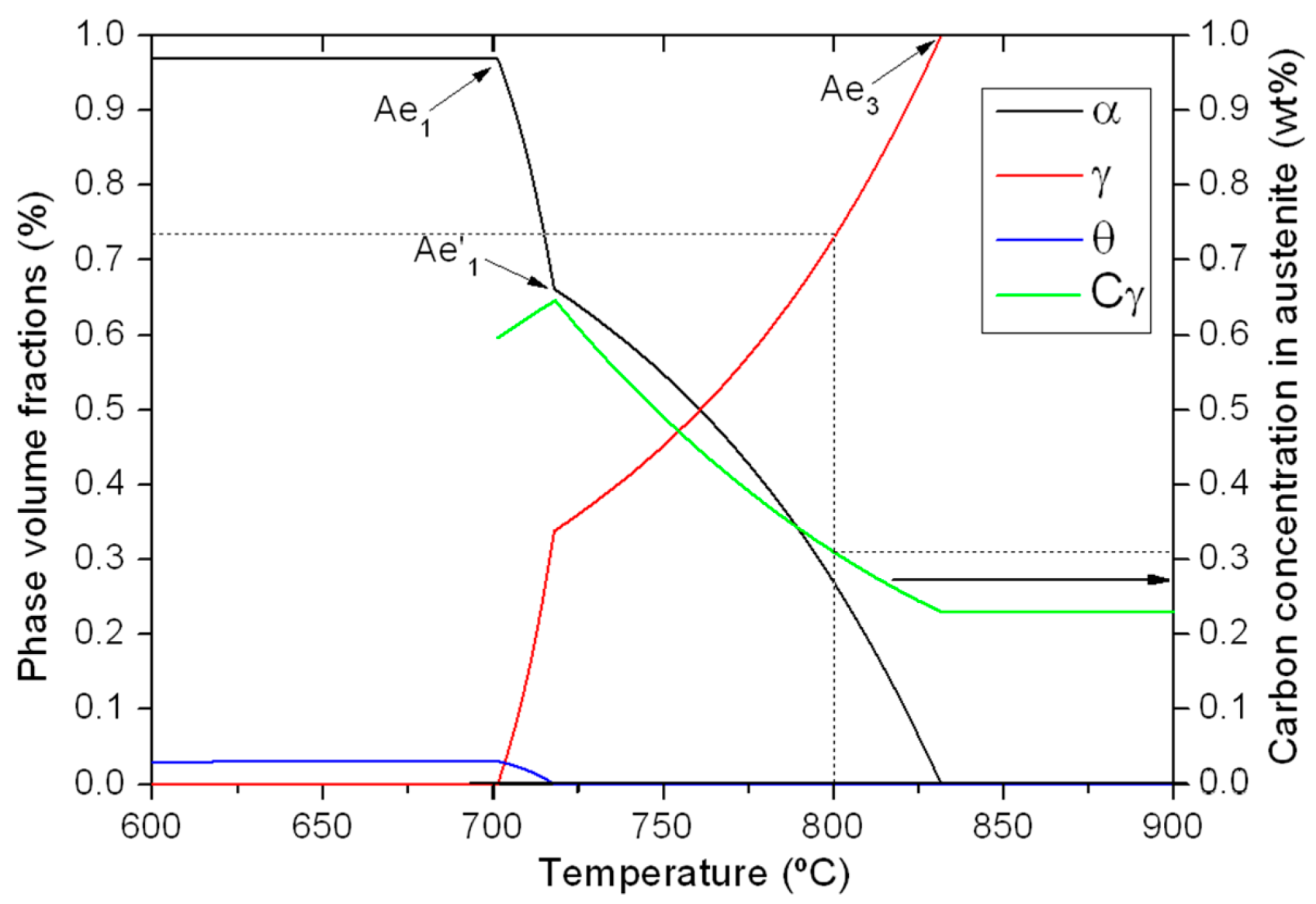

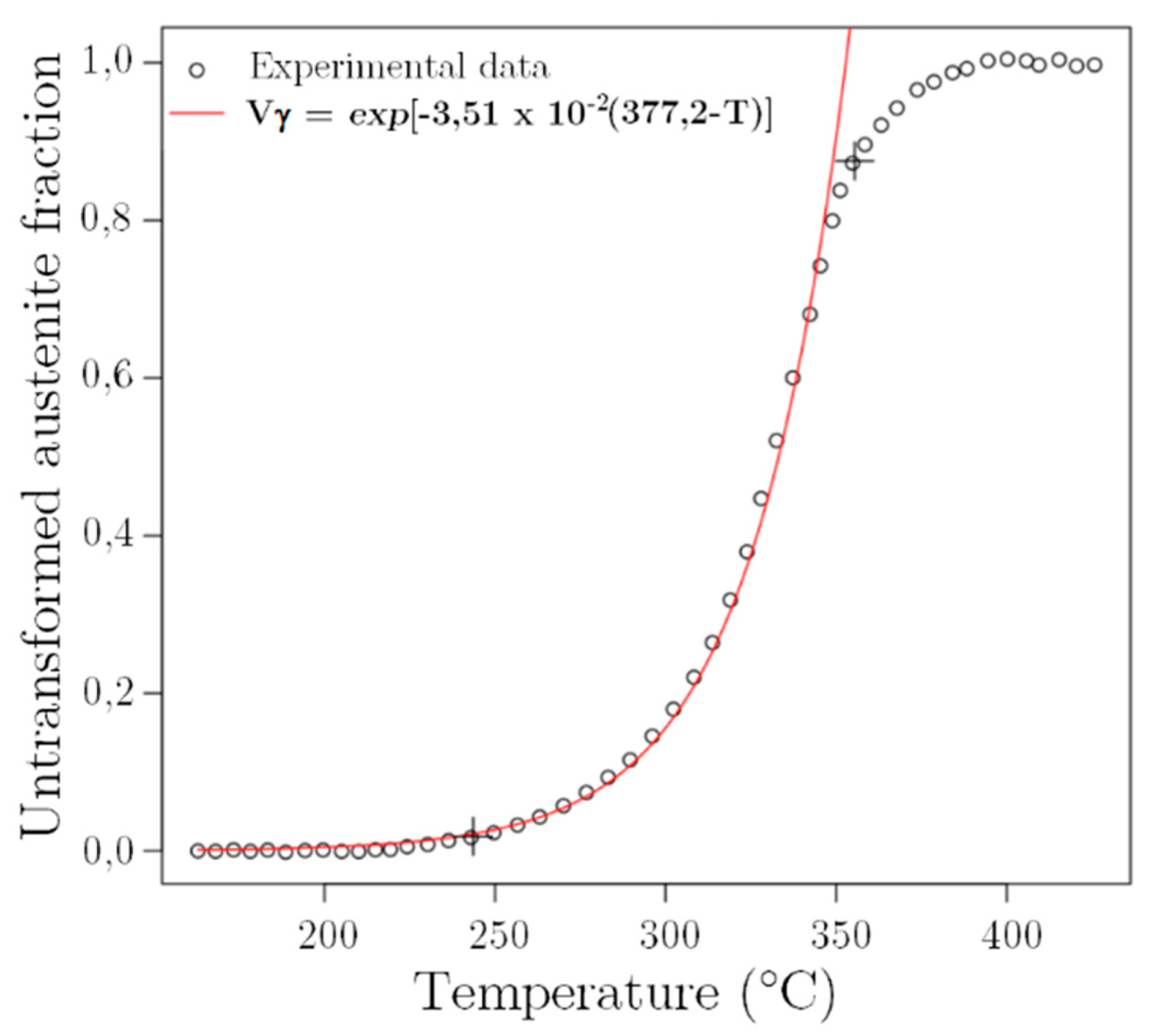

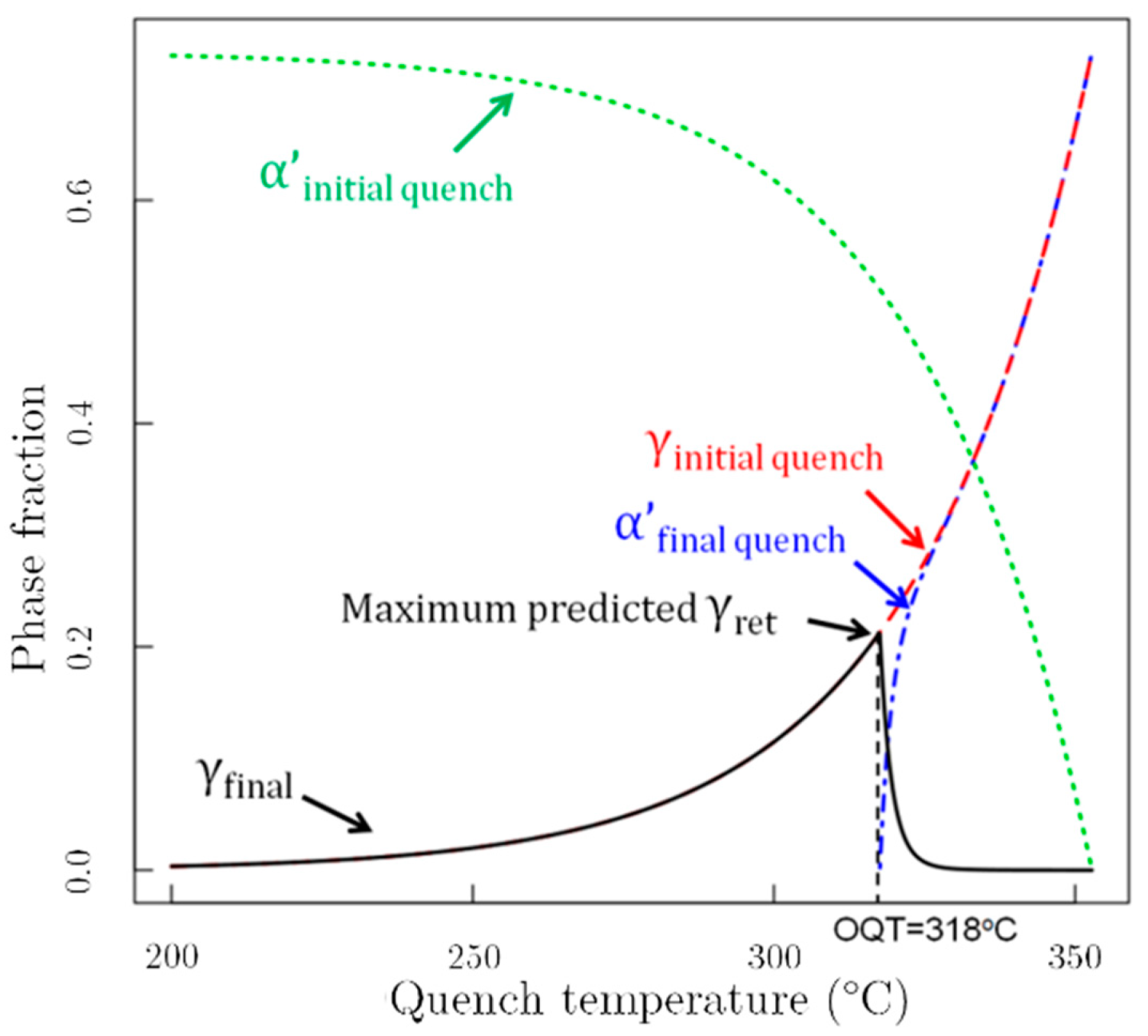

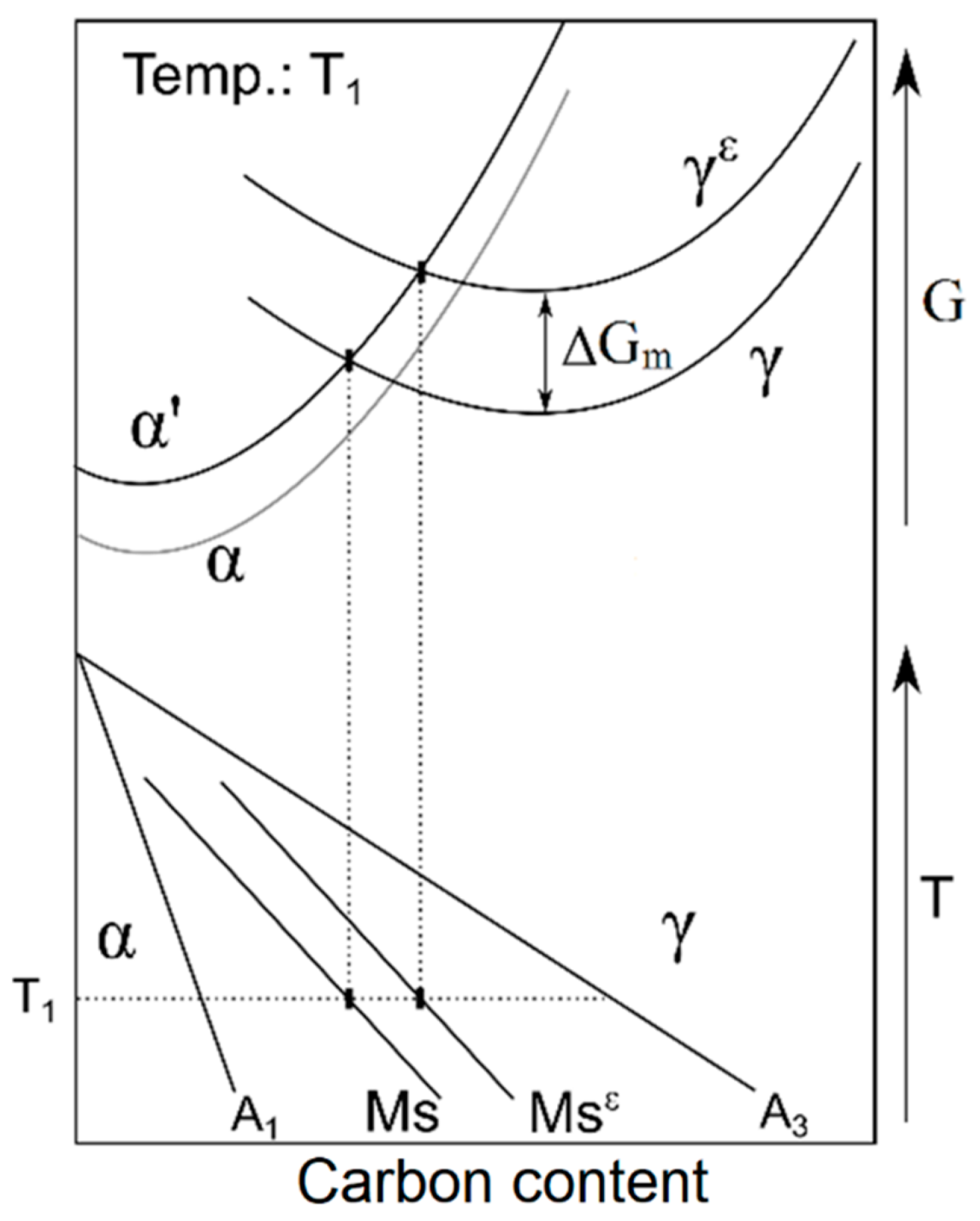

3.1. Optimal Quenching Temperature

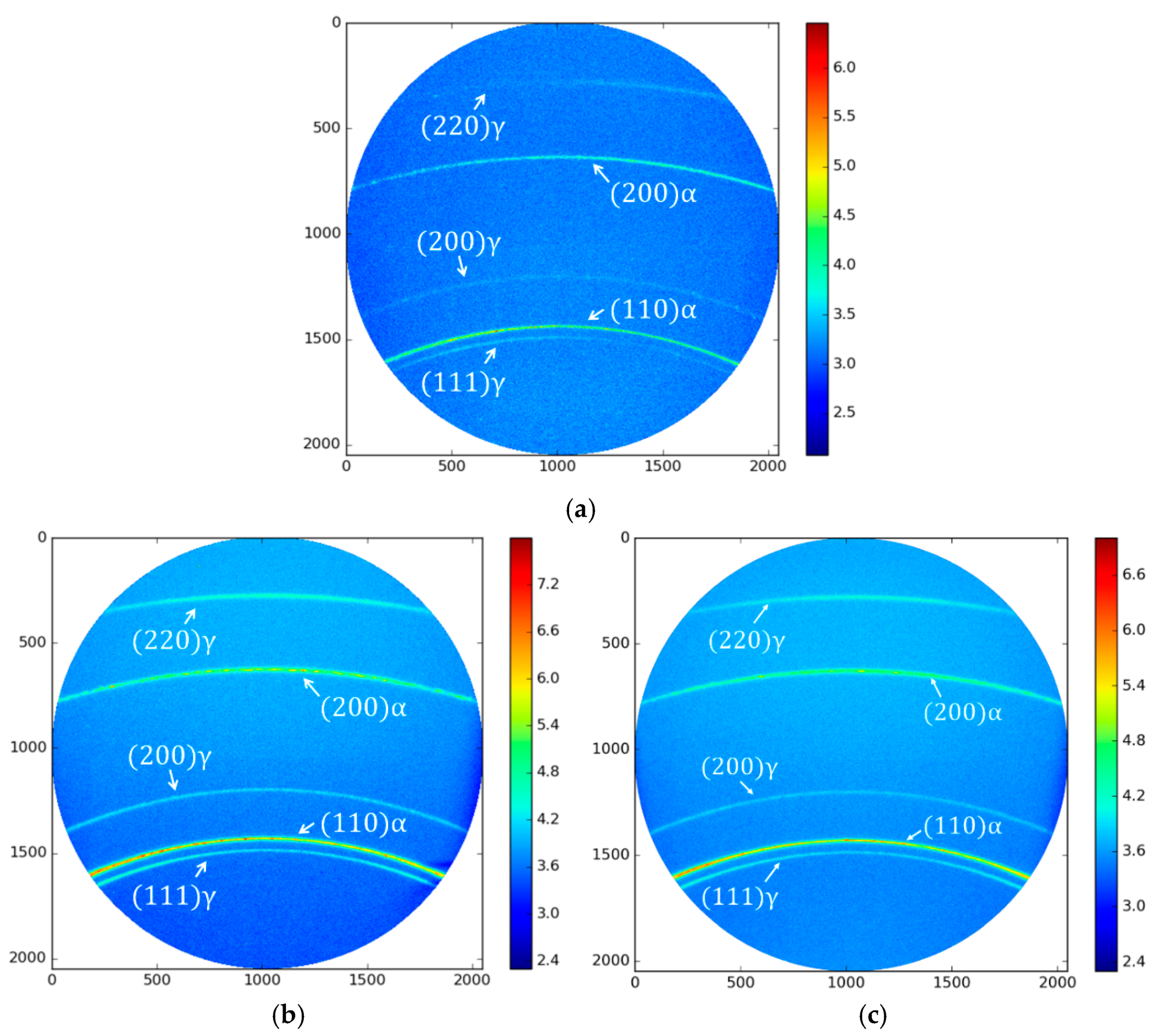

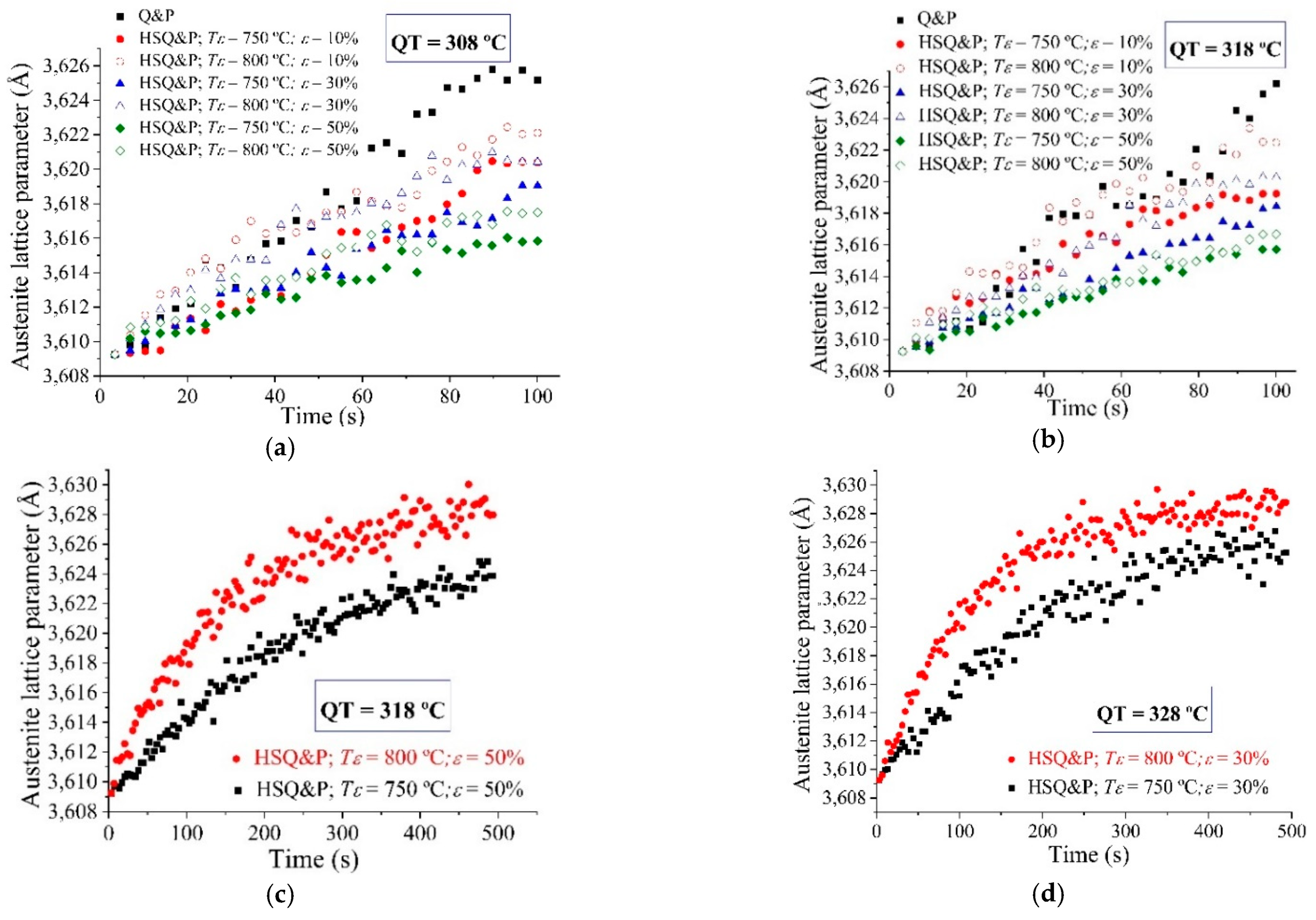

3.2. In Situ X-ray Diffraction

3.3. Microstructural Characterization

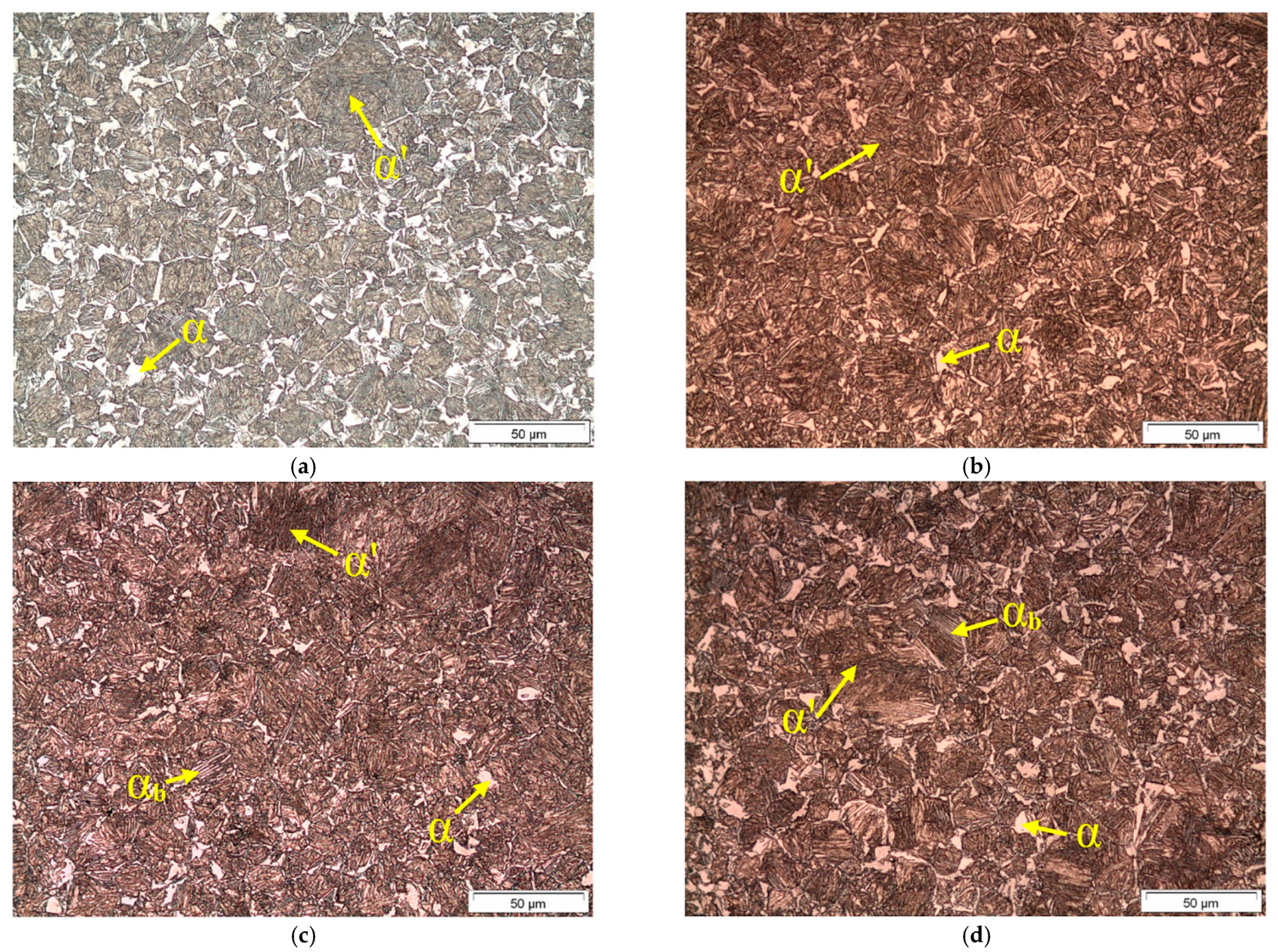

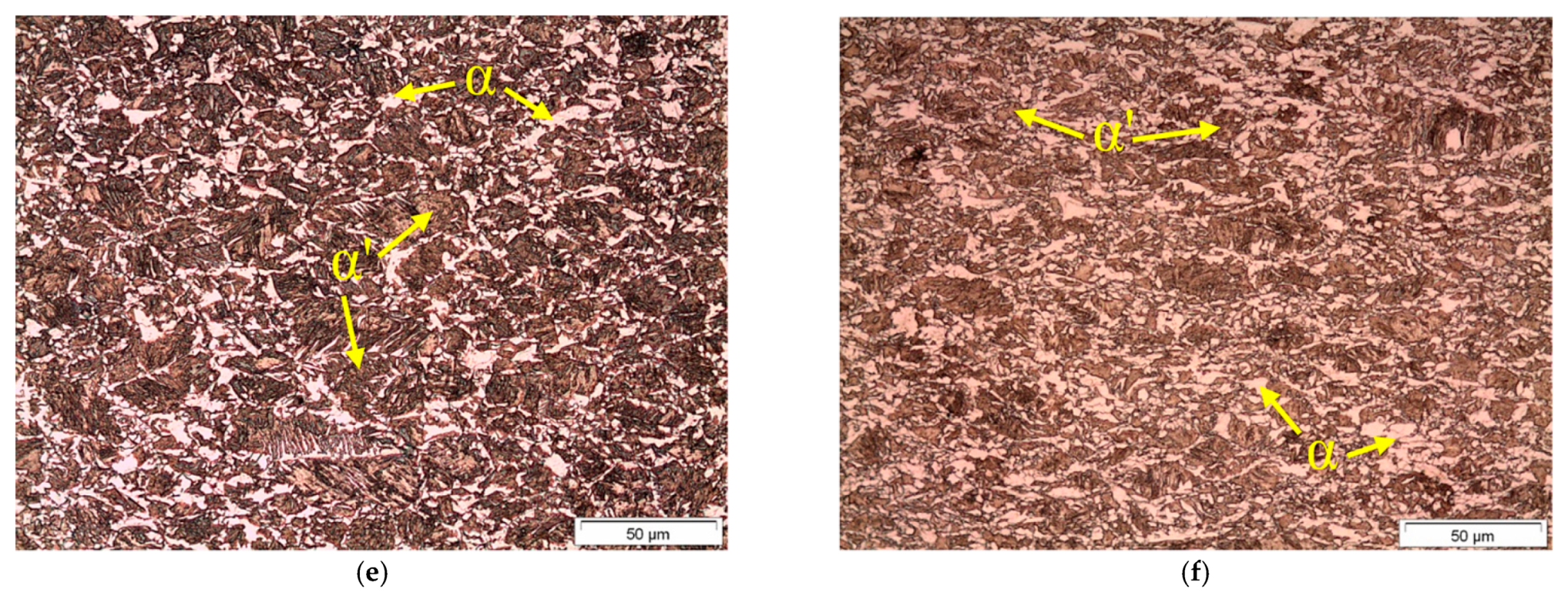

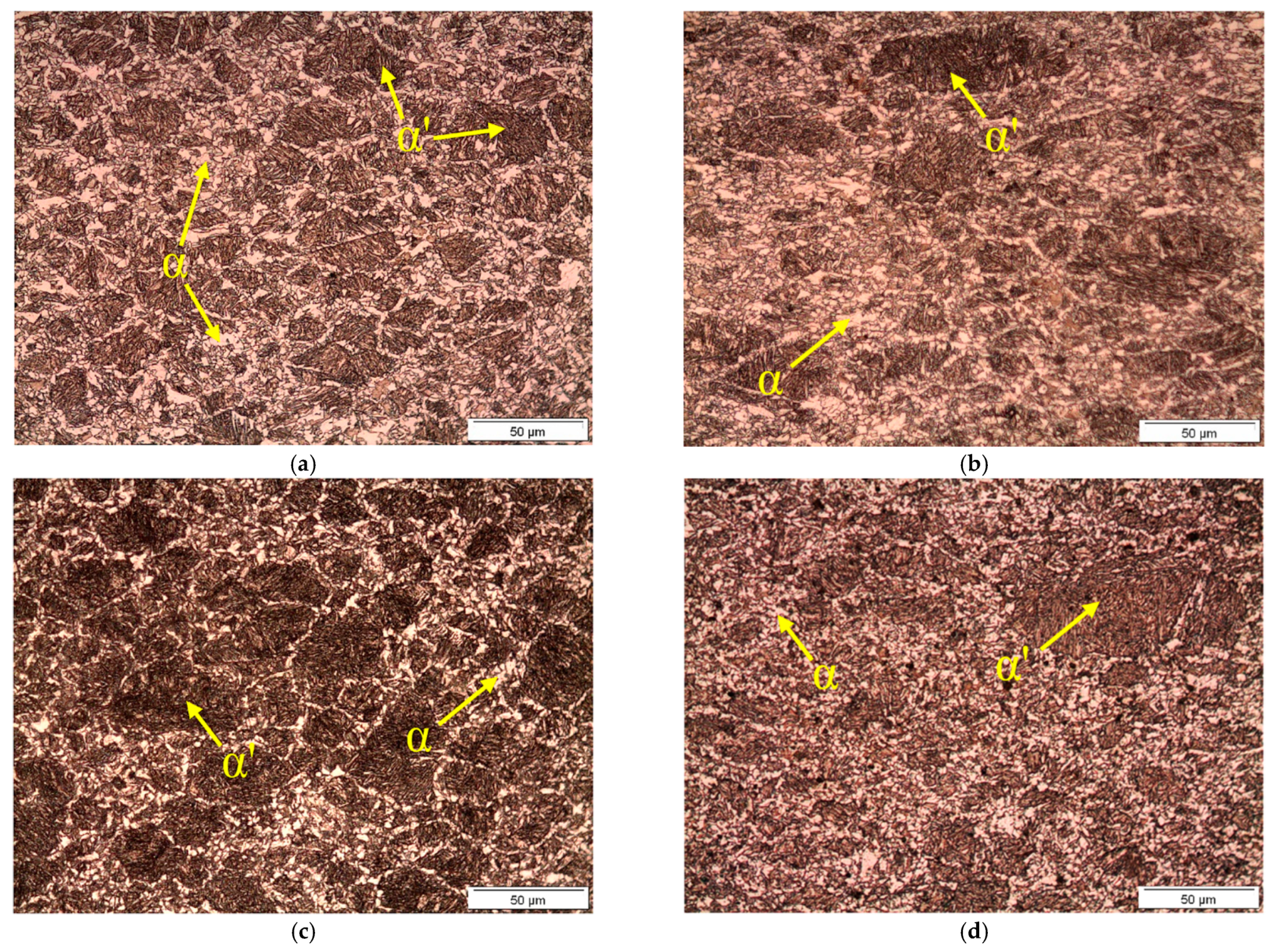

3.3.1. Light Microscopy

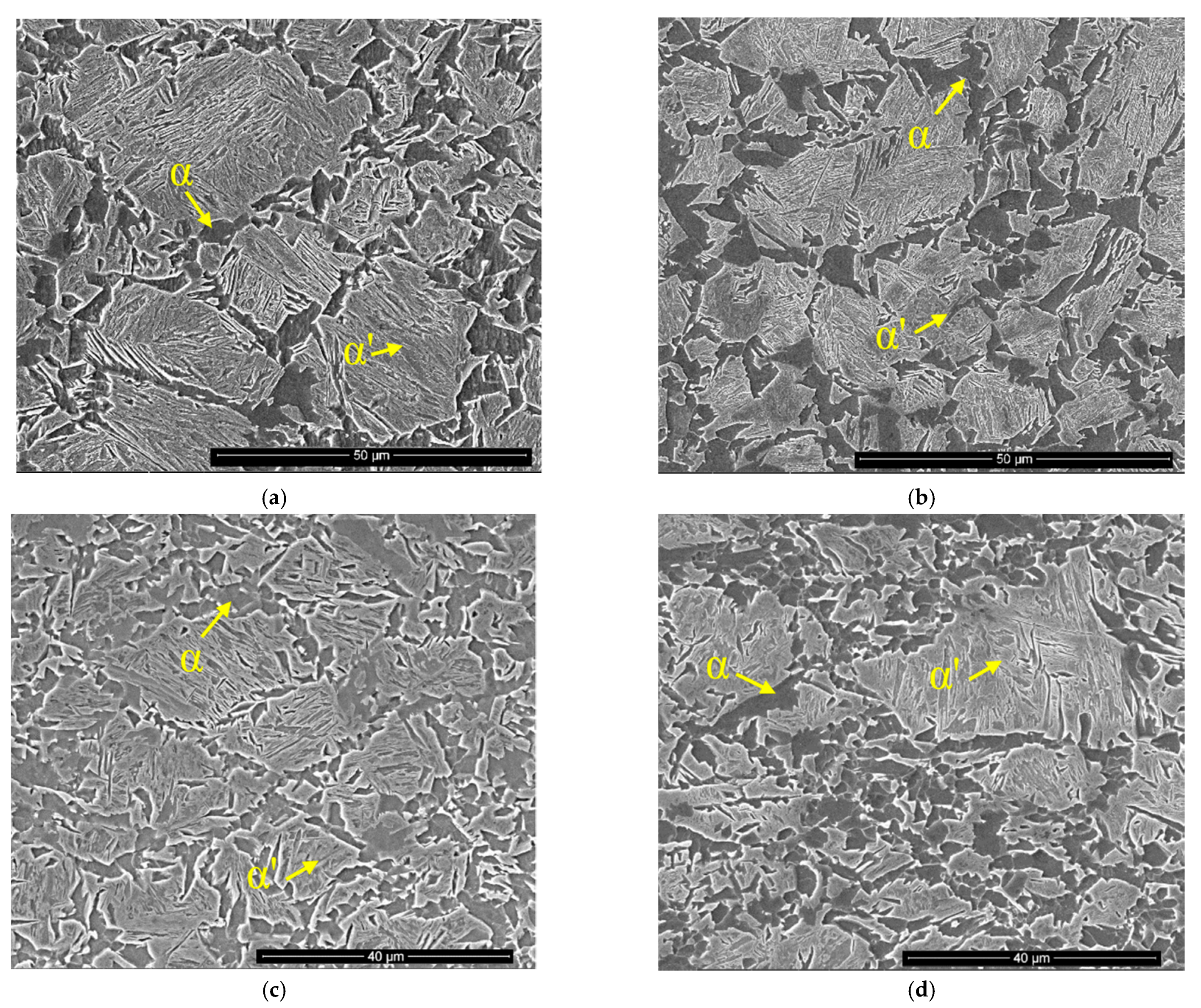

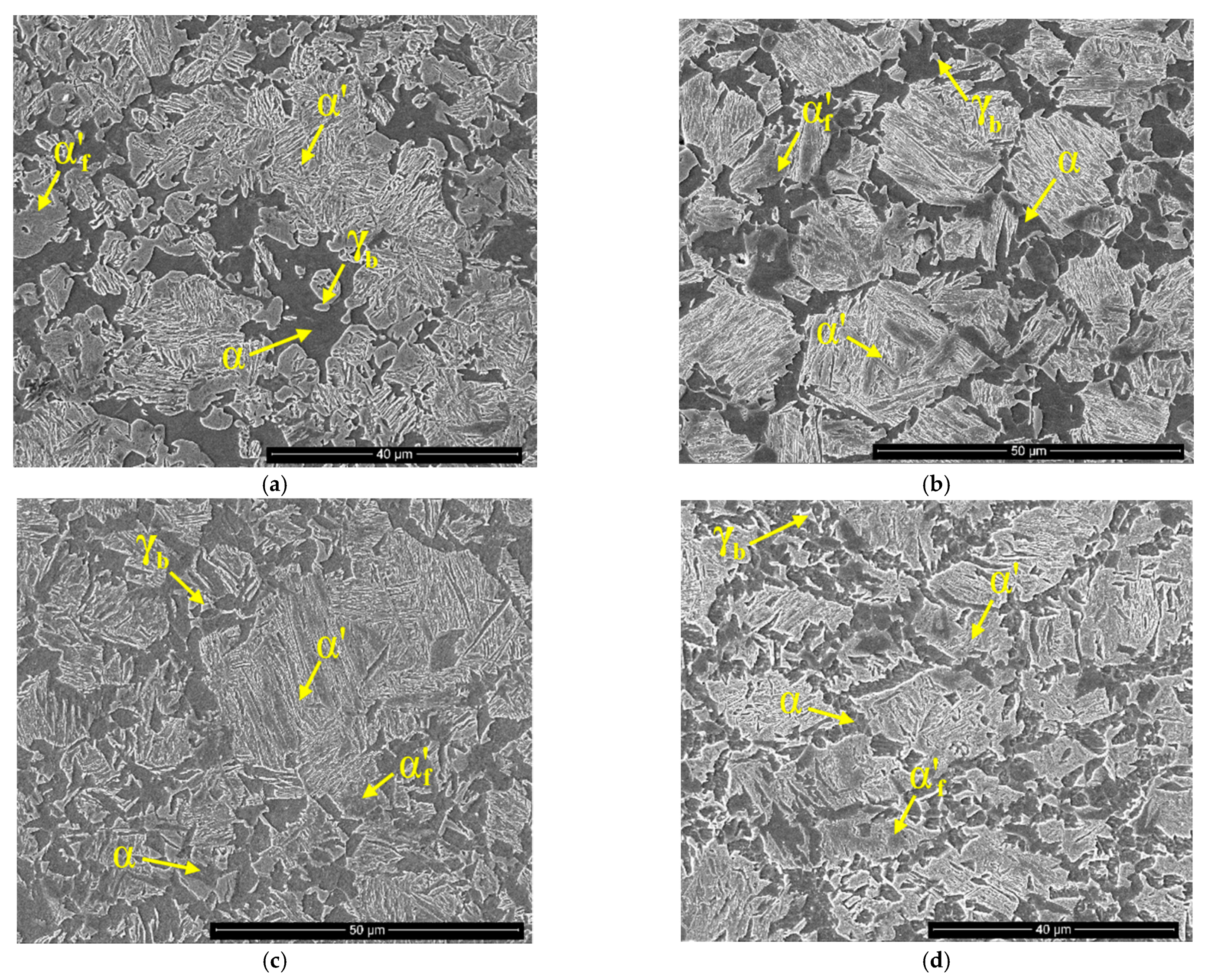

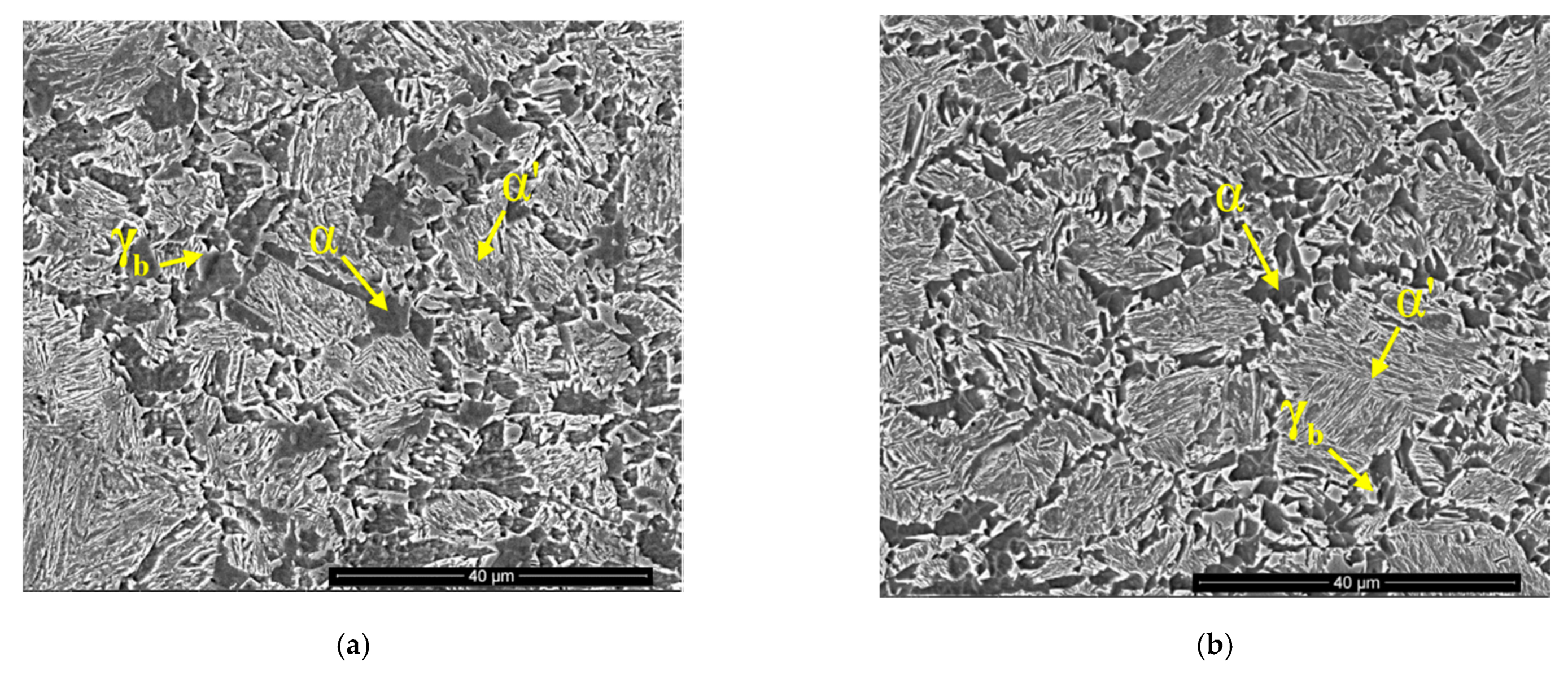

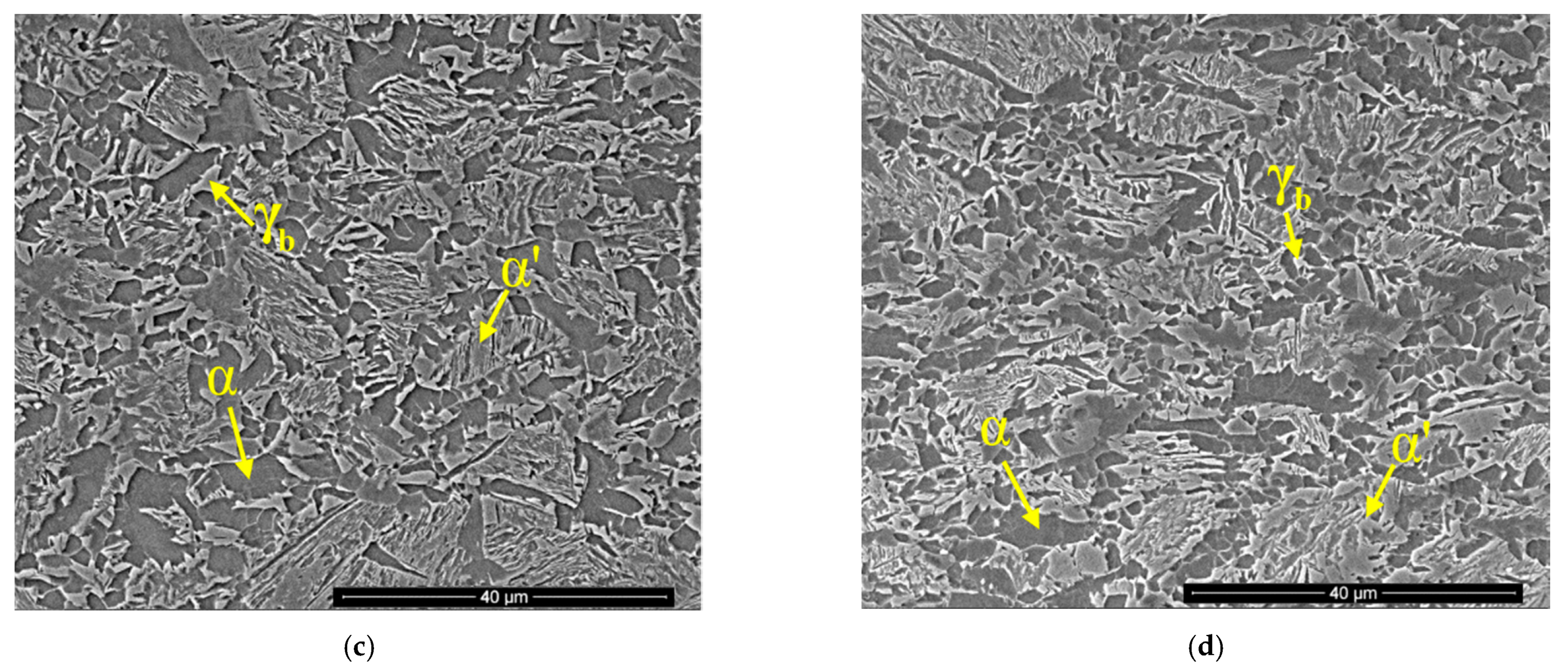

3.3.2. Scanning Electron Microscopy

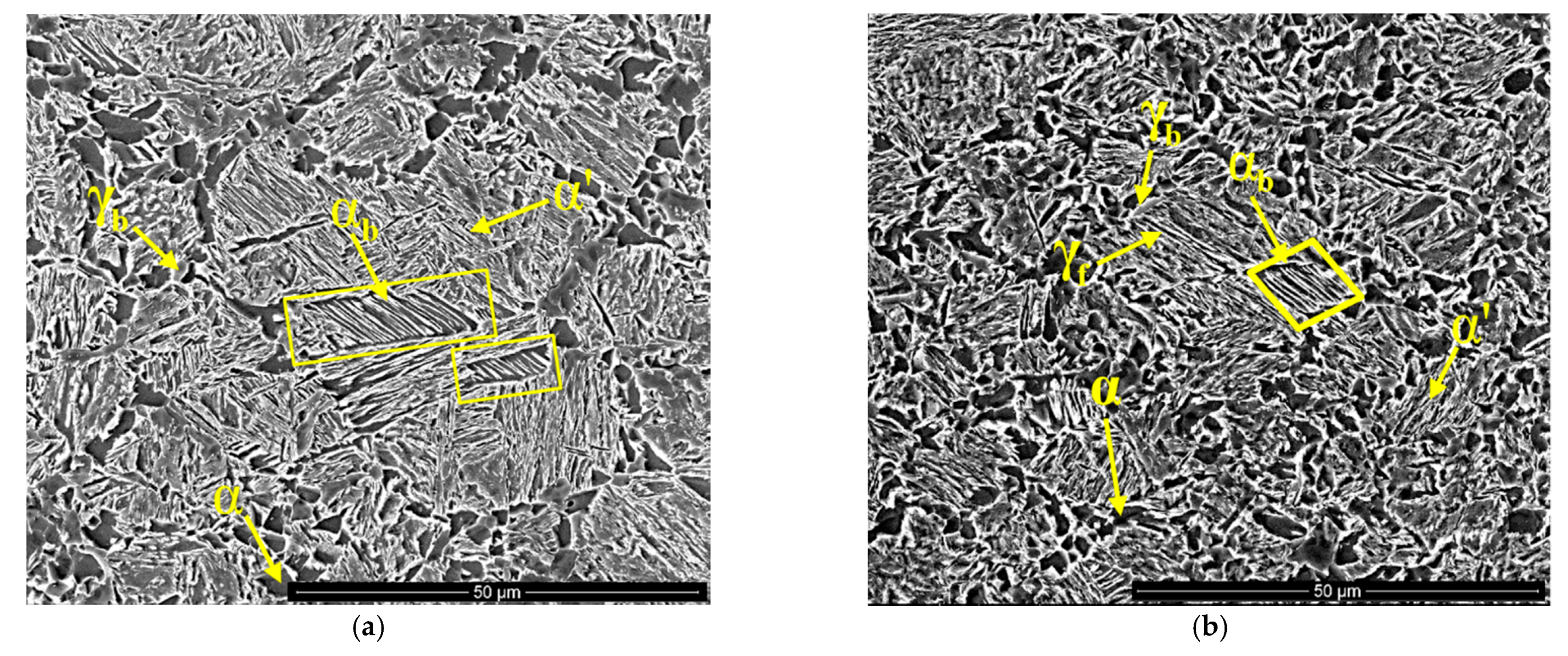

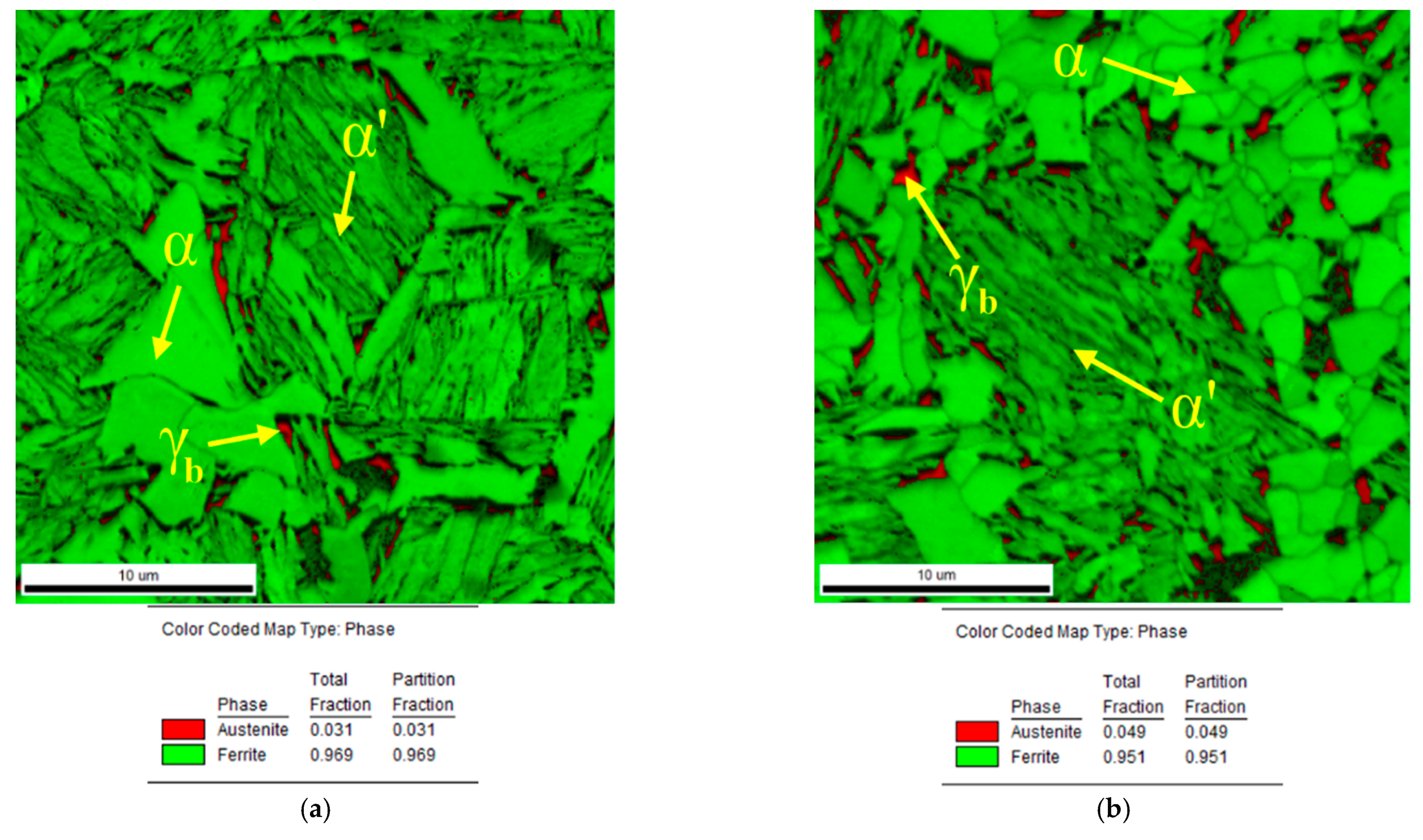

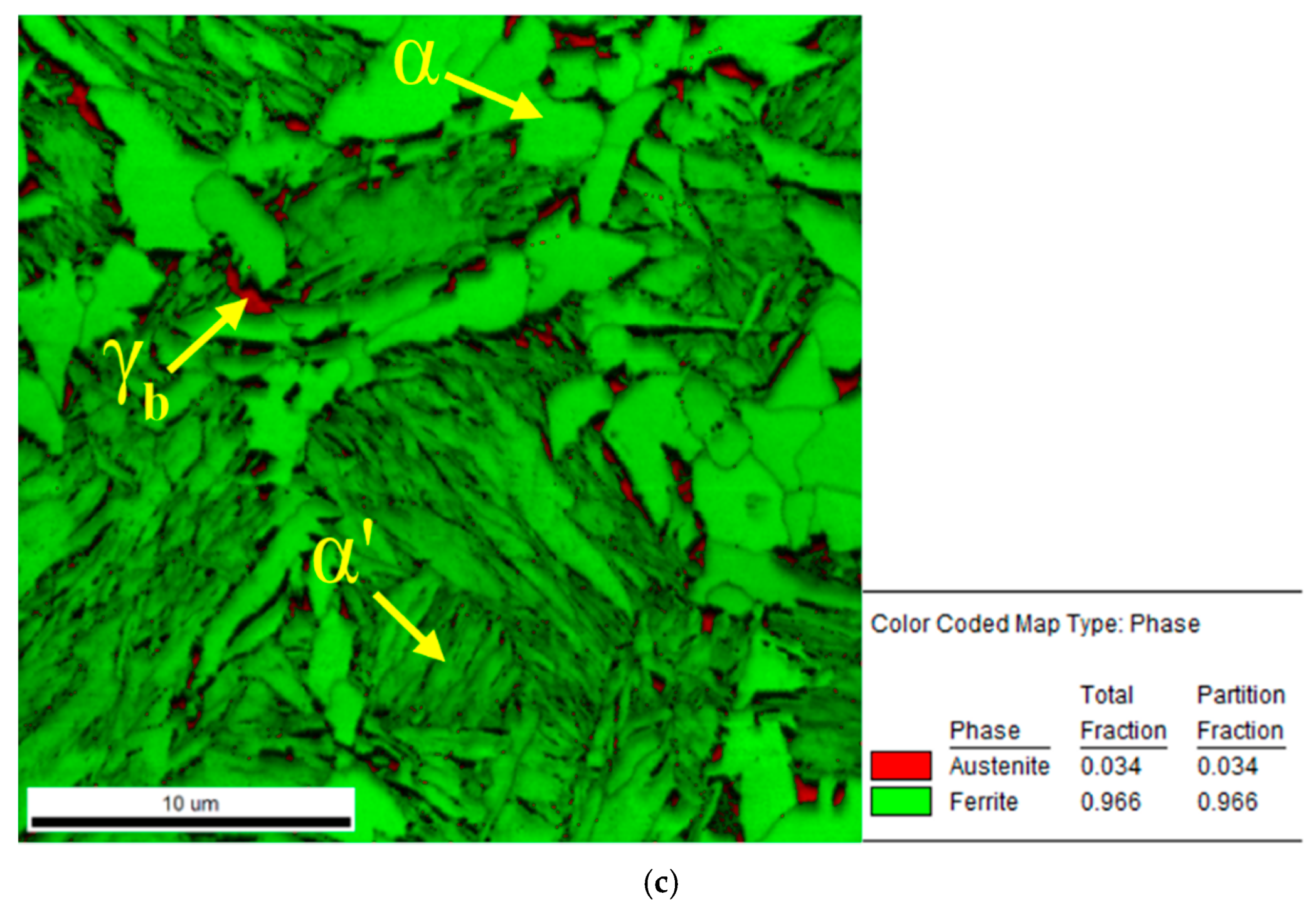

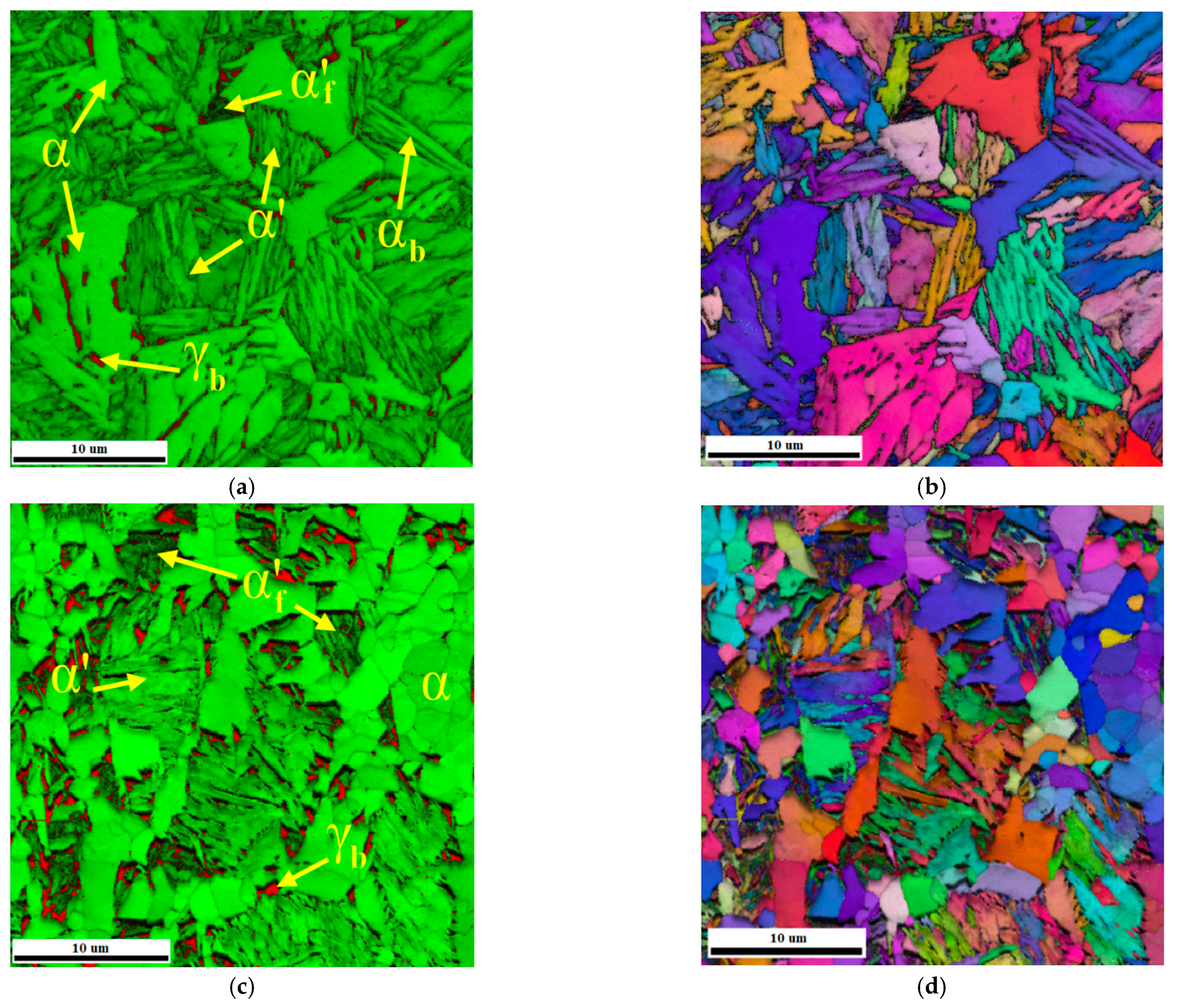

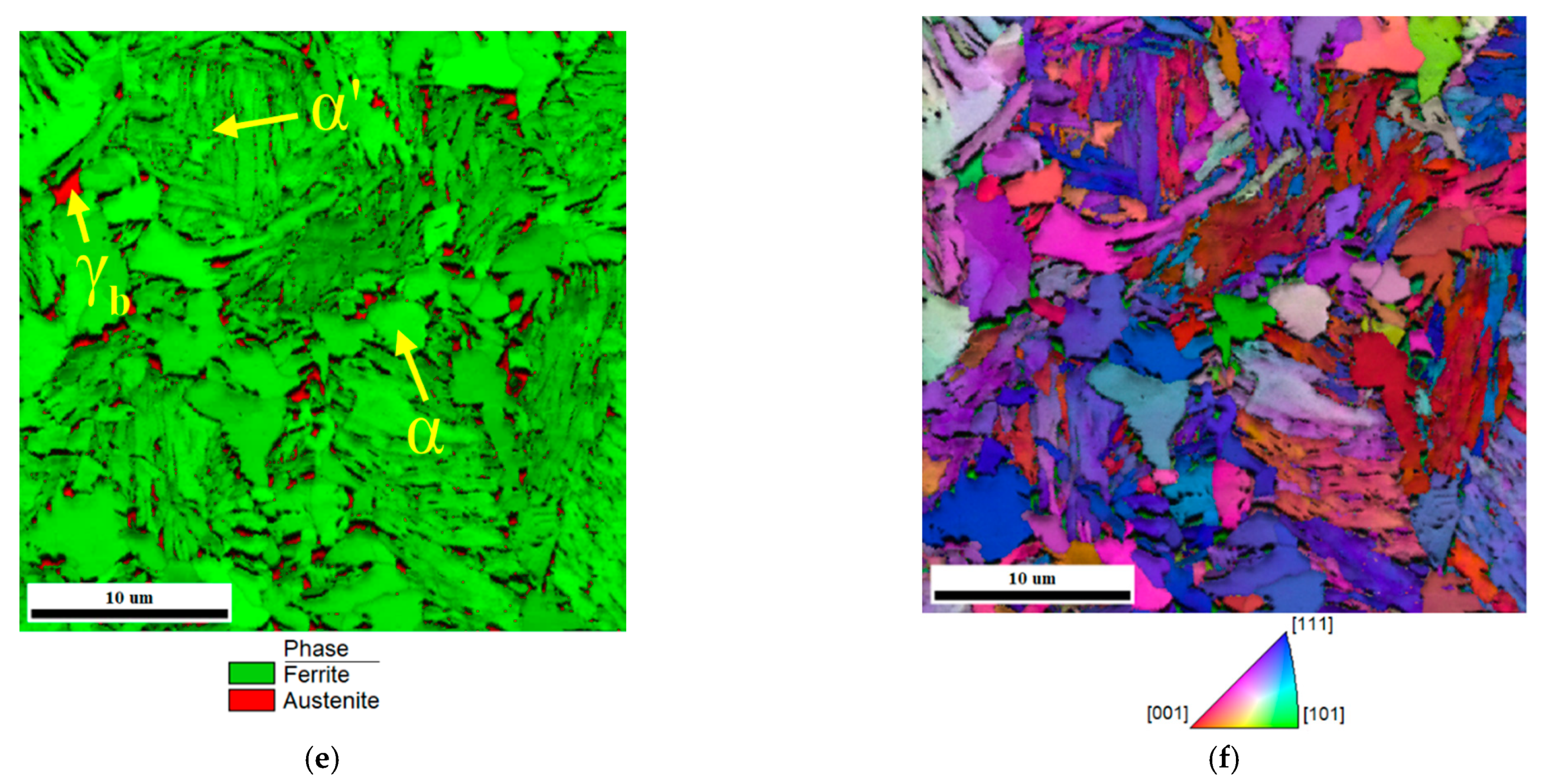

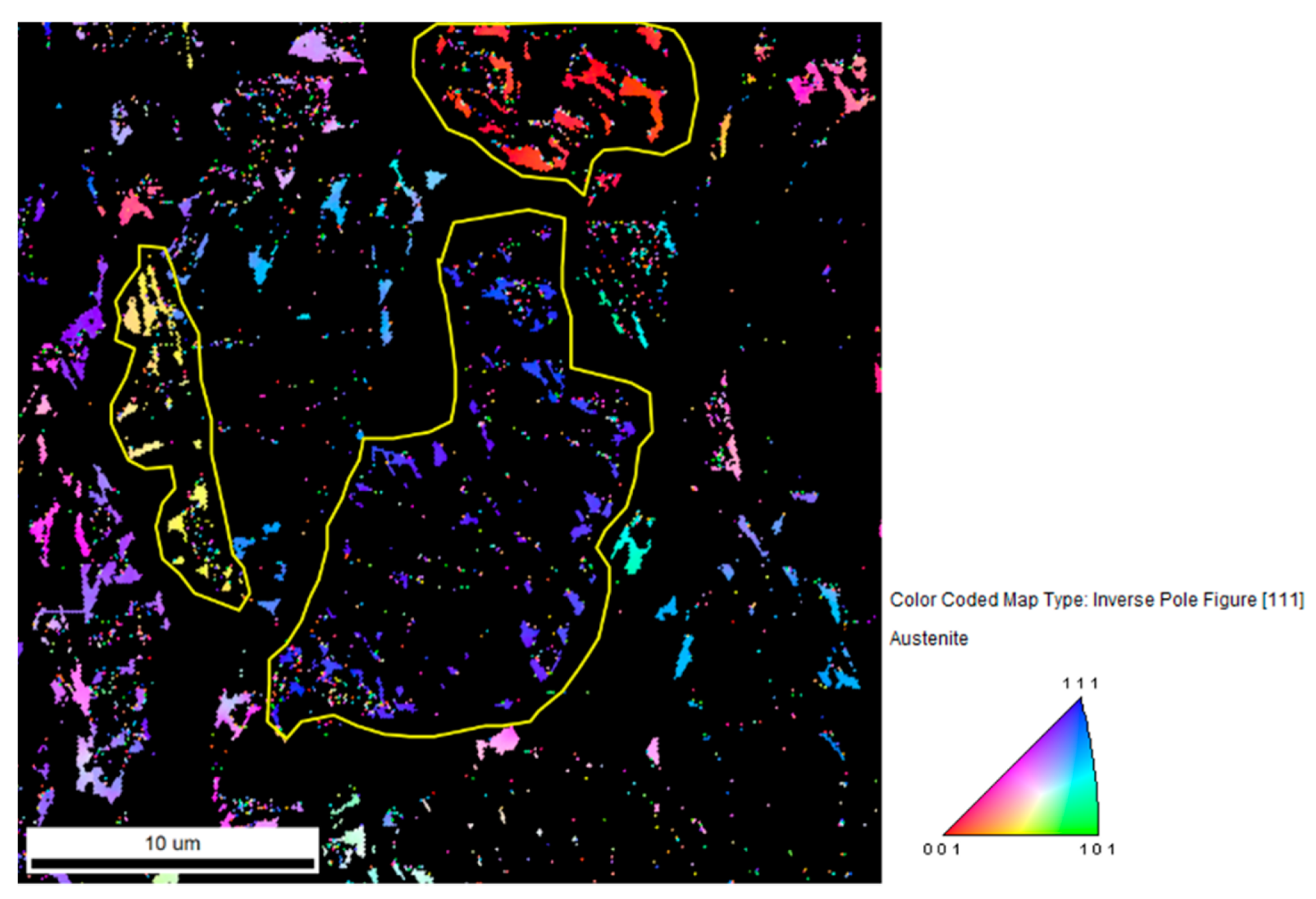

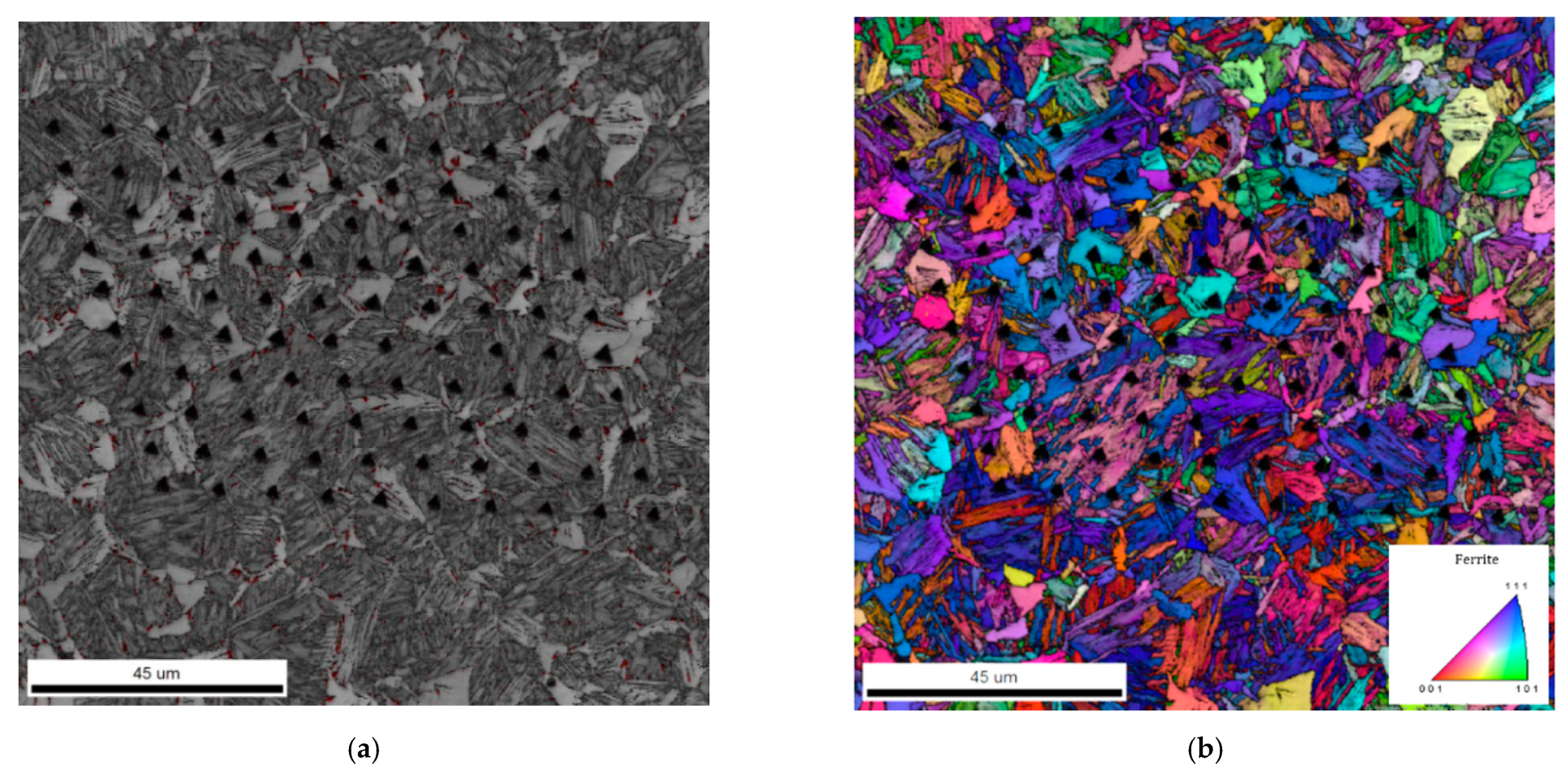

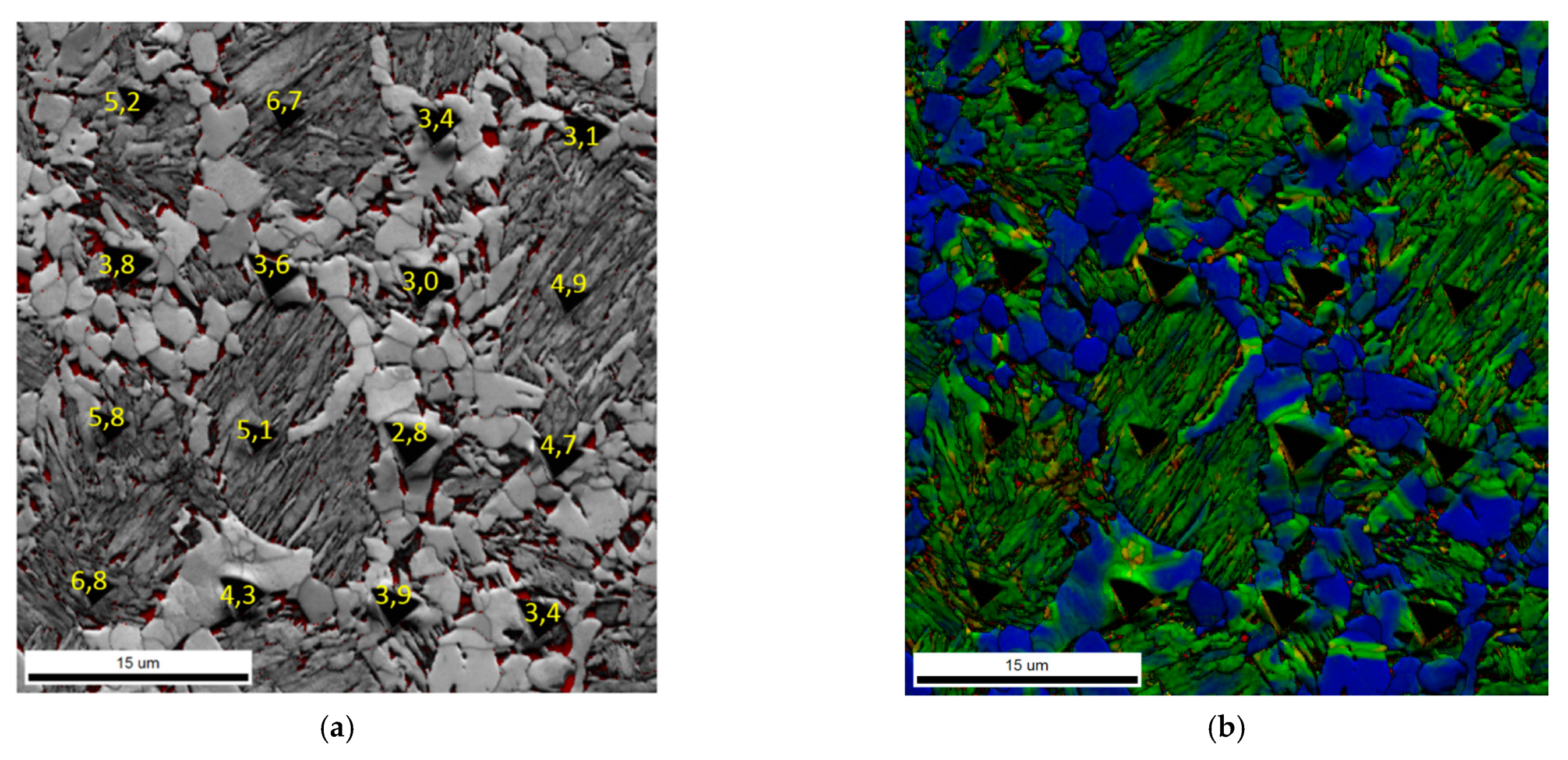

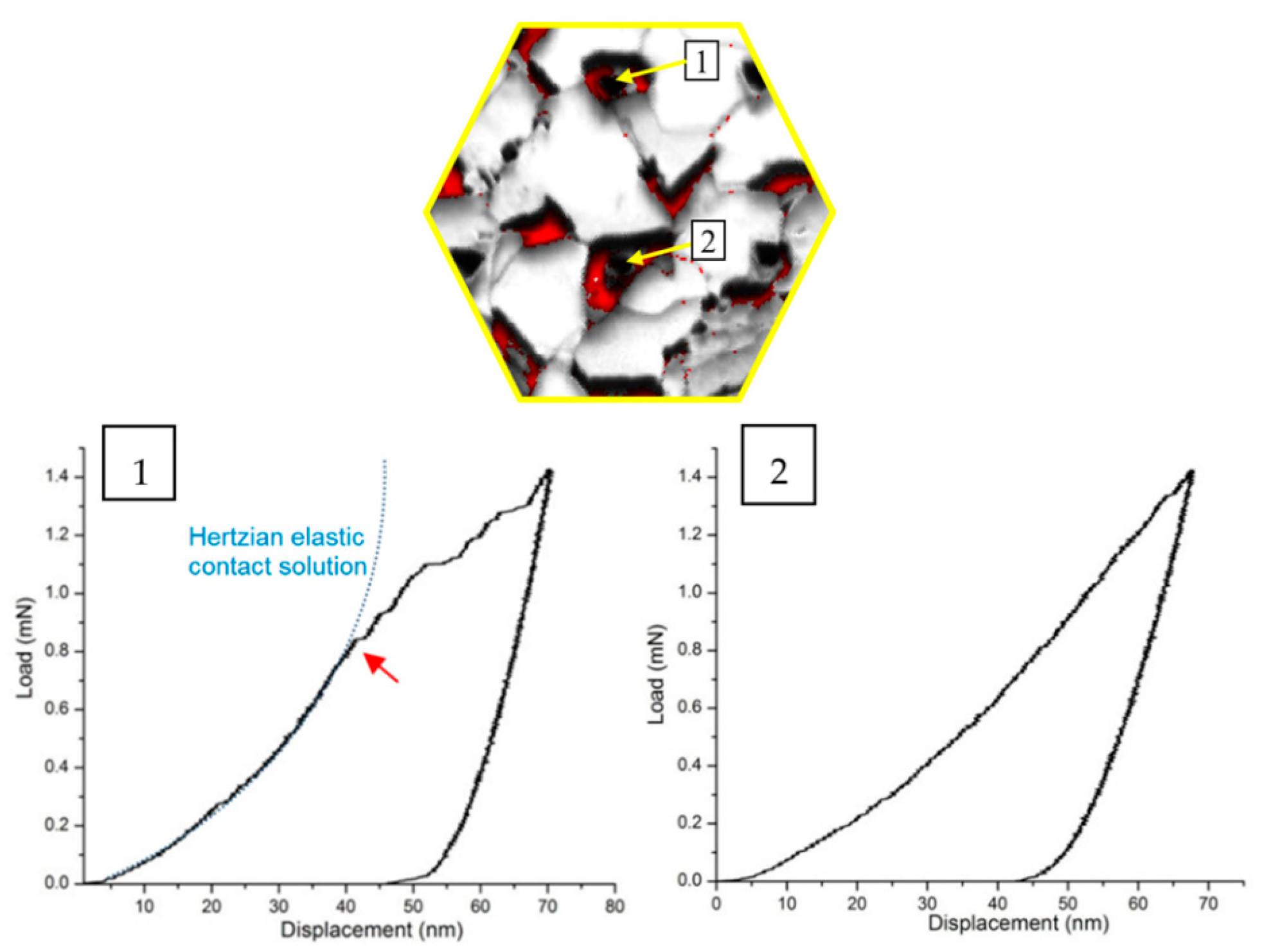

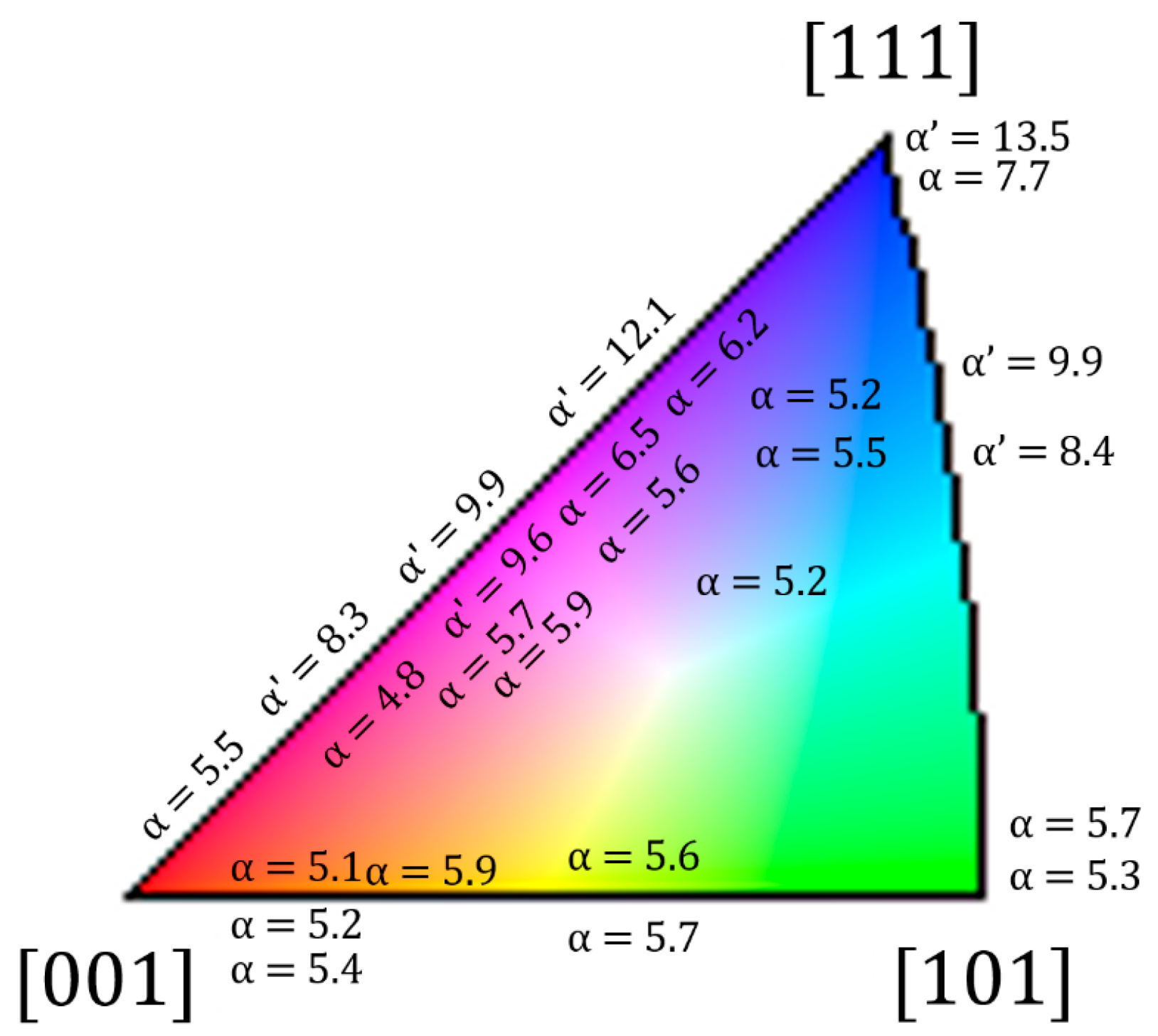

3.3.3. Backscattered Electron Diffraction (EBSD)

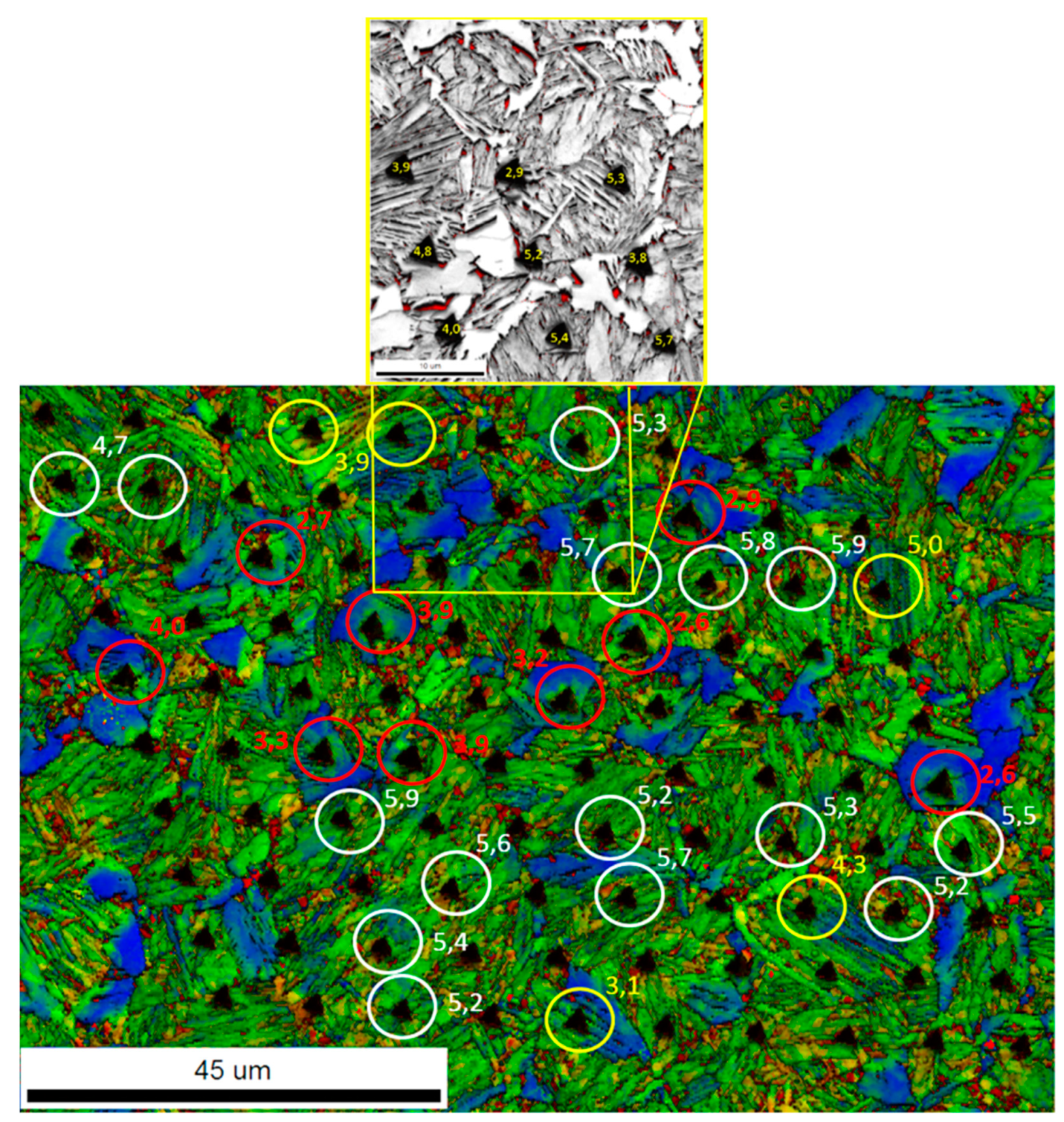

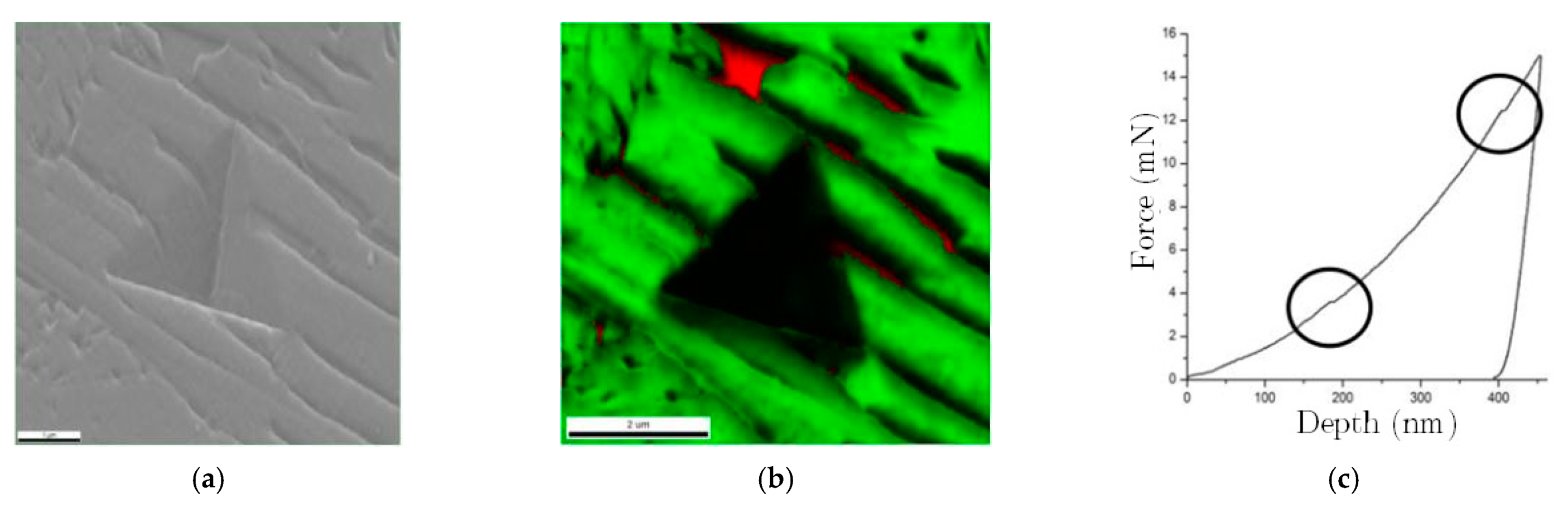

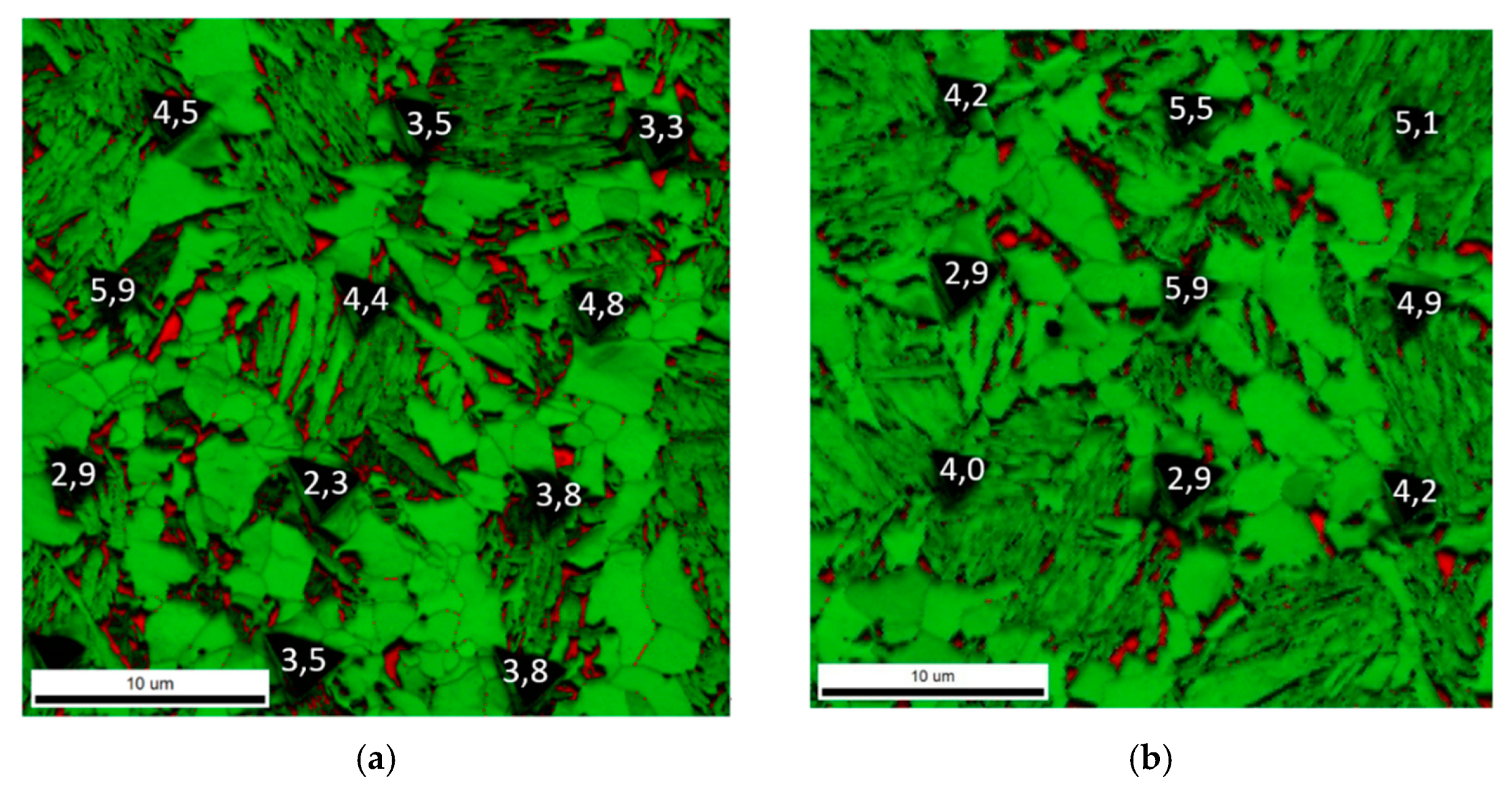

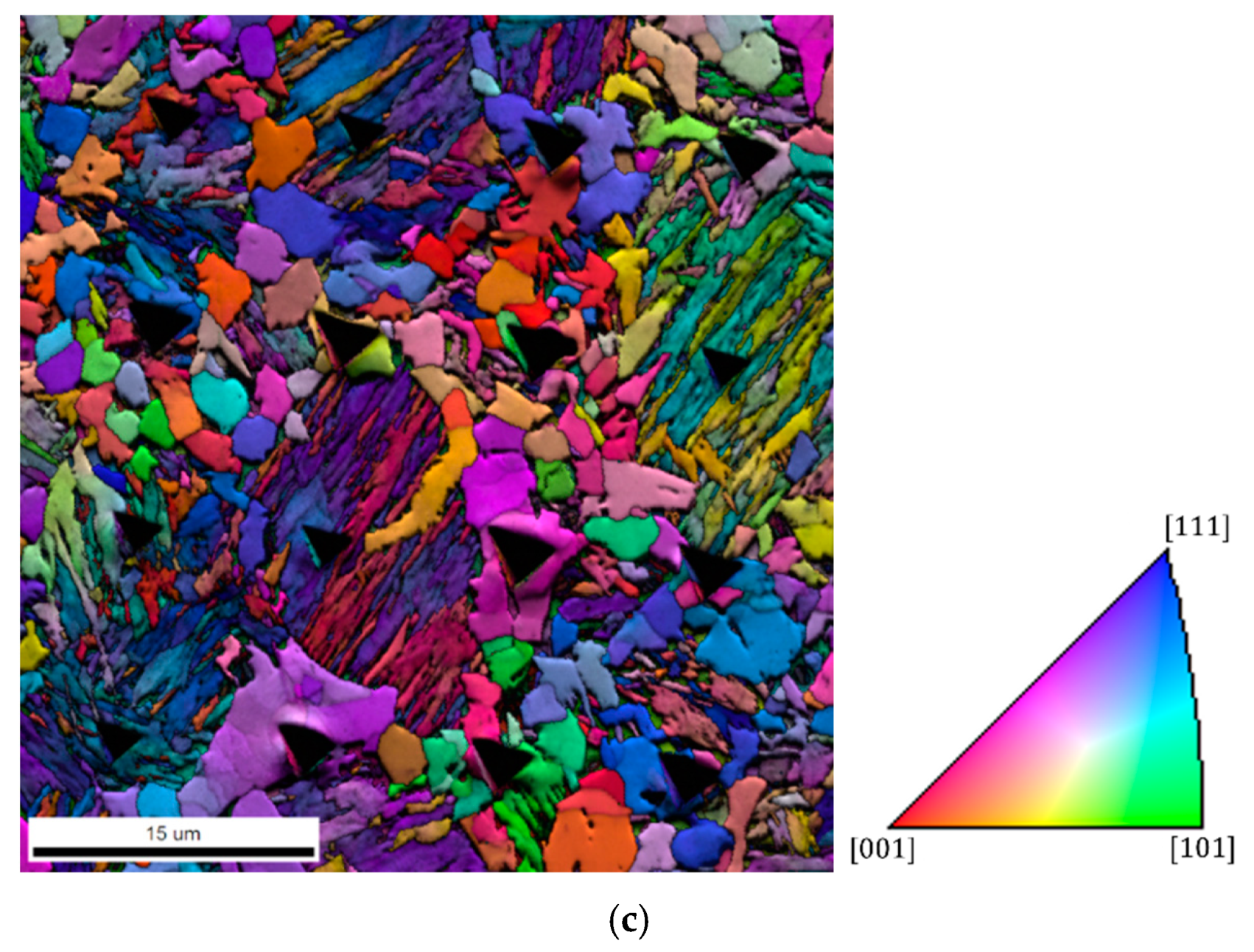

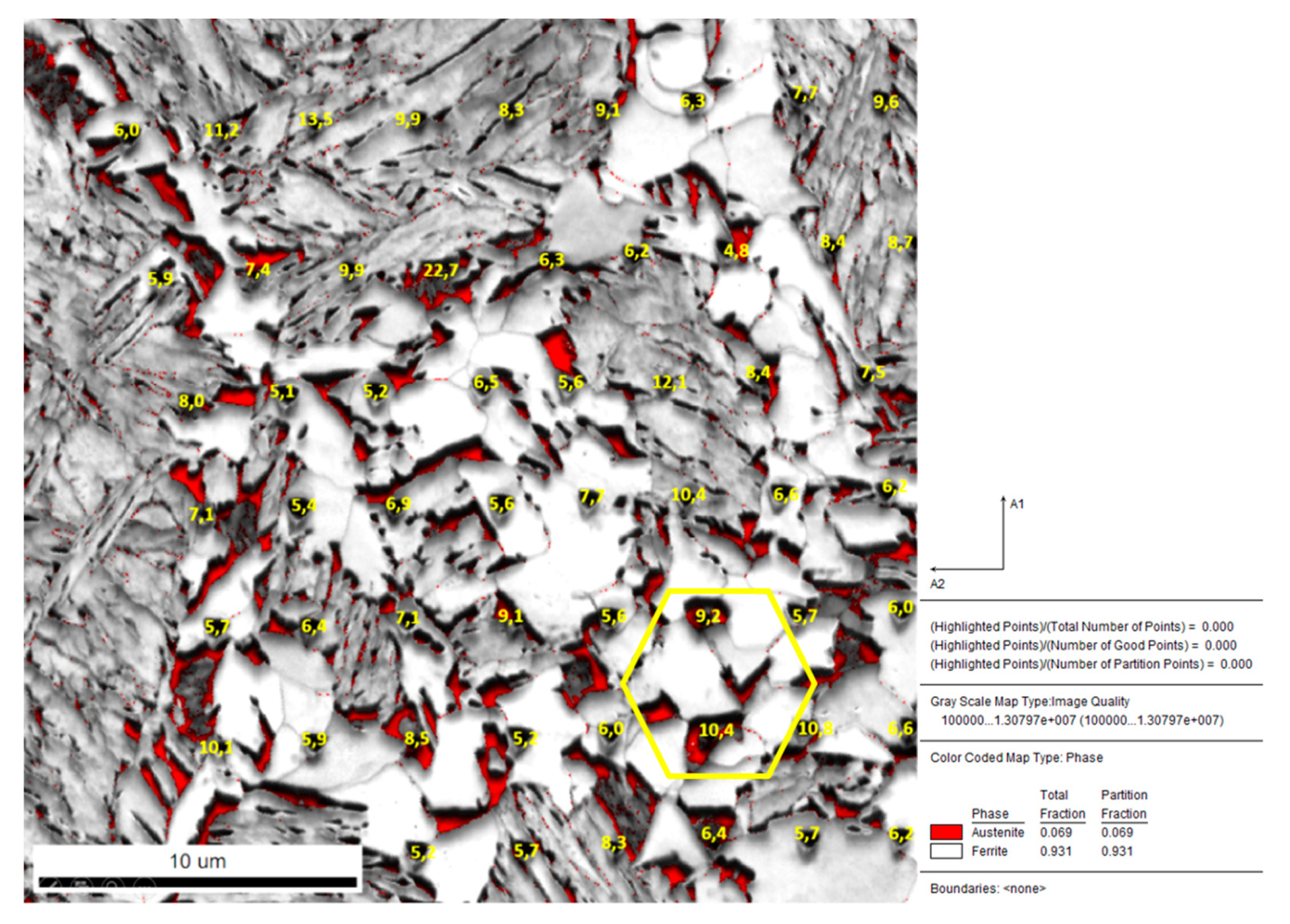

3.3.4. EBSD and Nanoindentation

3.4. Stereology and Hardness

4. Summary and Conclusions

- The described methodology to calculate the optimal quenching temperature, including intercritical austenitization, allows estimating the appropriate quenching temperature for the Q&P and HSQ&P processes to obtain a substantial amount of retained austenite at room temperature. This prediction proved helpful in obtaining the highest amounts of retained austenite, even considering the restrictions imposed by the constrained carbon equilibrium model.

- In situ synchrotron X-ray diffraction showed the evident effect of the carbon enrichment of austenite during the partitioning stage. Furthermore, increasing the amount of deformation promotes less carbon enrichment of austenite. Isothermal deformation at 800 °C favors a higher carbon enrichment when compared to the samples non-isothermally deformed at 750 °C. Therefore, carbon enrichment during the partitioning stage does not depend solely on the Q&P heat treatment parameters, but also on the conditions created in the microstructure at high temperatures by isothermal or non-isothermal deformations.

- The results of synchrotron radiation using a 2D detector allowed us to observe that textures are present in the material since before the heat treatment and at the beginning and end of the partitioning stage, confirming that crystallographic texture does not appear as a consequence of the Q&P treatment parameters.

- Austenite deformation promotes diffusional phase transformation (DIFT ferrite), which results in carbon redistribution between supersaturated ferrite and austenite prior to martensitic transformation, leading to enrichment of untransformed austenite and, consequently, to a decrease in the Ms temperature. This phenomenon appears to be predominant for deformation percentages up to 30%. However, for larger strains, the increase in total free energy by creating a mechanical driving force caused by the strain is the predominant phenomenon.

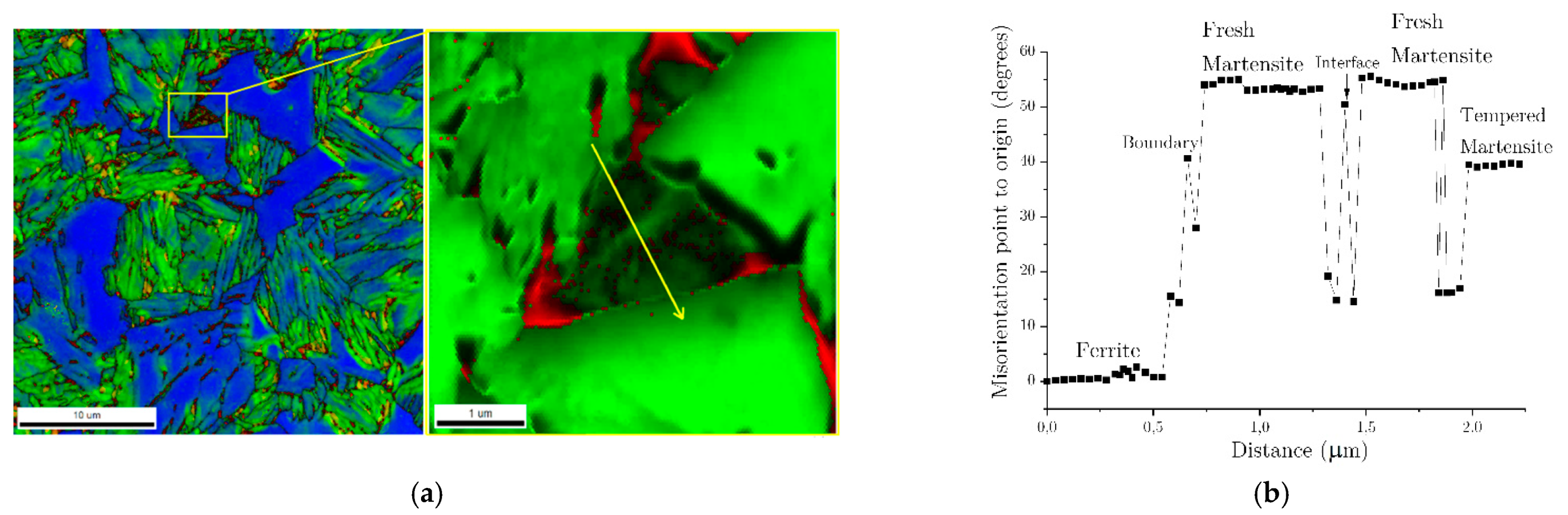

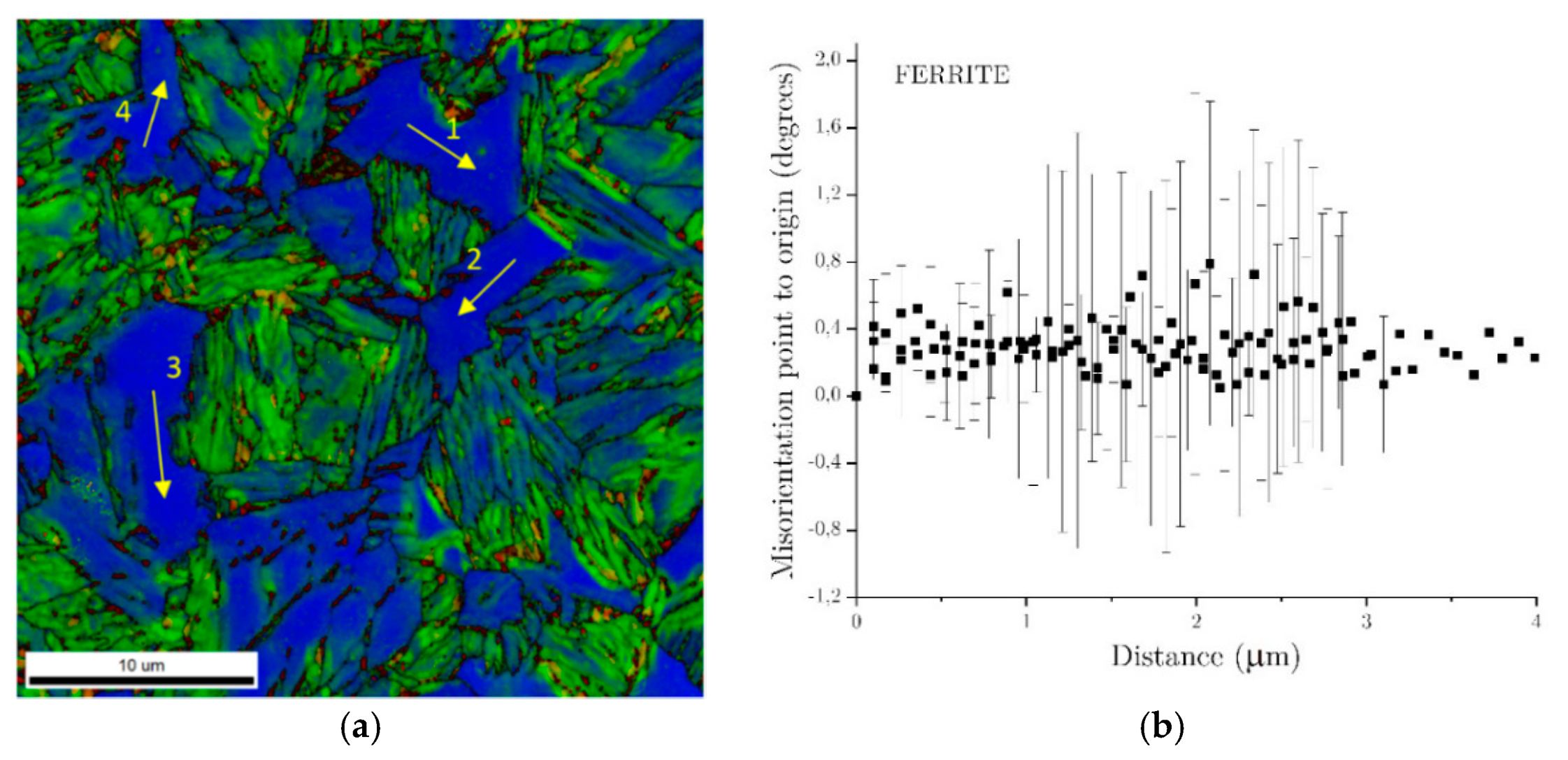

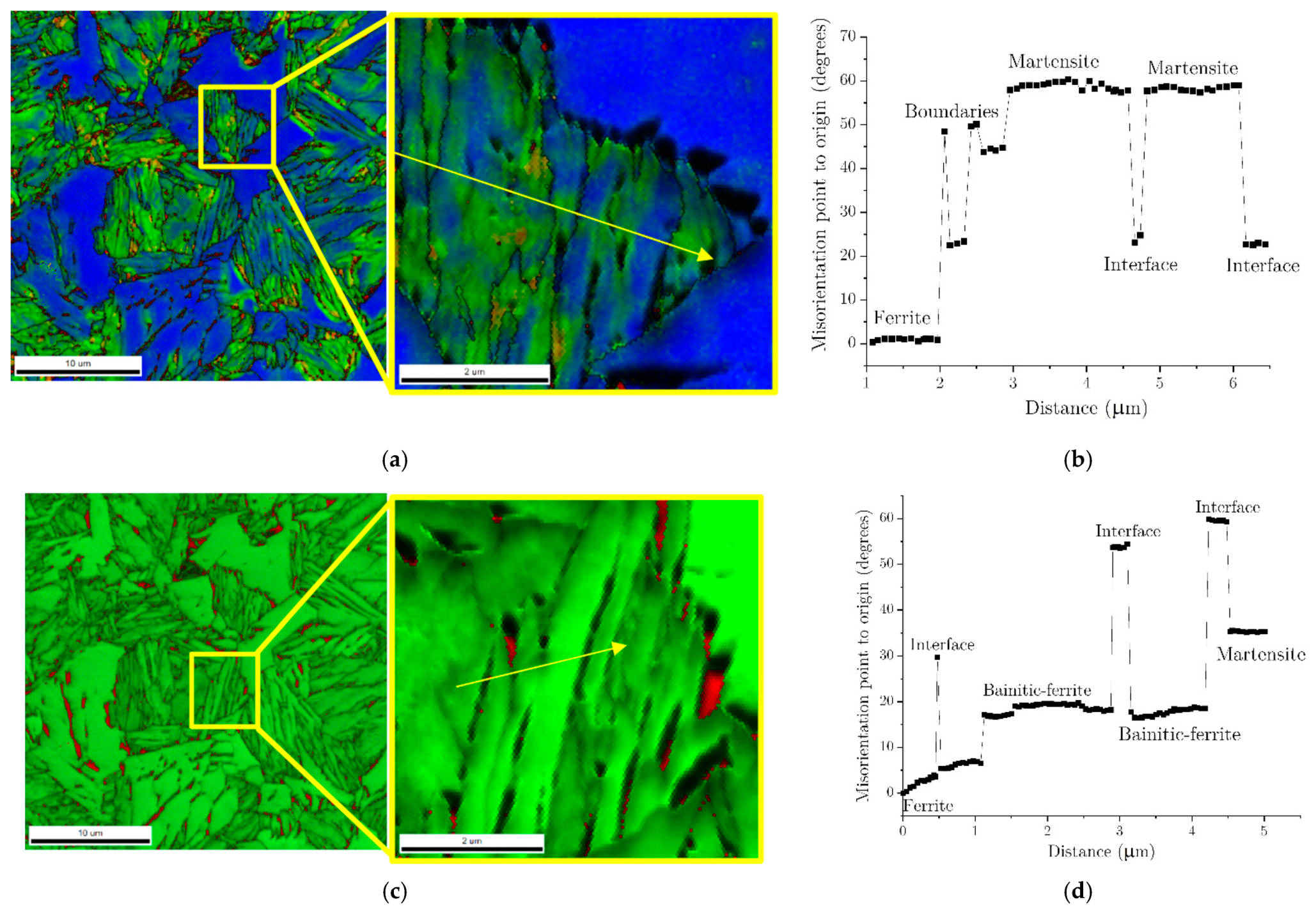

- From the EBSD results, it was possible to distinguish different morphologies of the retained austenite, which appeared in the form of equiaxed blocks (preexisting austenite grains) distributed along the martensite packages and close to the ferrite boundaries; films between the martensite laths and between the bainitic-ferrite plates; and embedded in the ferrite grains. Additionally, the combination of the quality map with the orientation map allowed us to observe that the austenite islands belonging to the same grain have the same crystallographic orientation, indicating that this retained austenite originated from the same previous austenite grain.

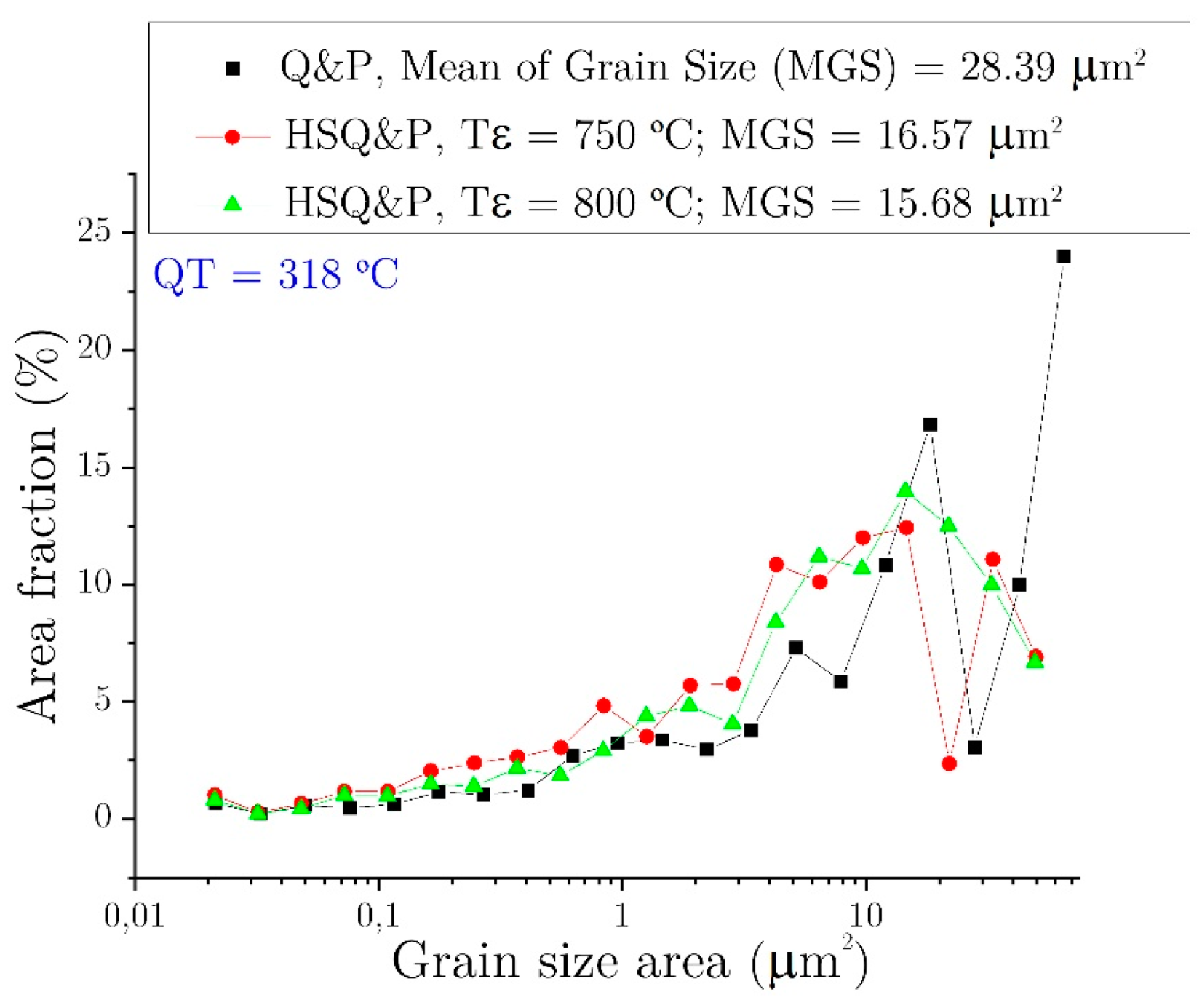

- For the Q&P sample quenched at 318 °C and partitioned at 400 °C for 100 s, the average grain size value was 28 μm2, while the HSQ&P samples deformed by 30%, quenched at 318 °C and partitioned at 400 °C for 100 s showed medium values around 16 µm2. This suggested that the transformation of austenite into ferrite produced by deformation (DIFT-effect) and dynamic recrystallization would be the main mechanisms contributing to the formation of refined ferrite grains.

- In the HSQ&P samples, some ferrite/ferrite interfaces were analyzed using Kernel Average Misorientation (KAM) maps. Due to the variation in the misorientation results for this type of interface, the formation and identification of two types of ferrites can be proposed: the ferrite generated by the DIFT effect, which has lower KAM values, and the higher KAM values ferrite formed during the intercritical step, which was deformed mainly at the grain boundaries, and therefore, presents higher values of KAM in this region.

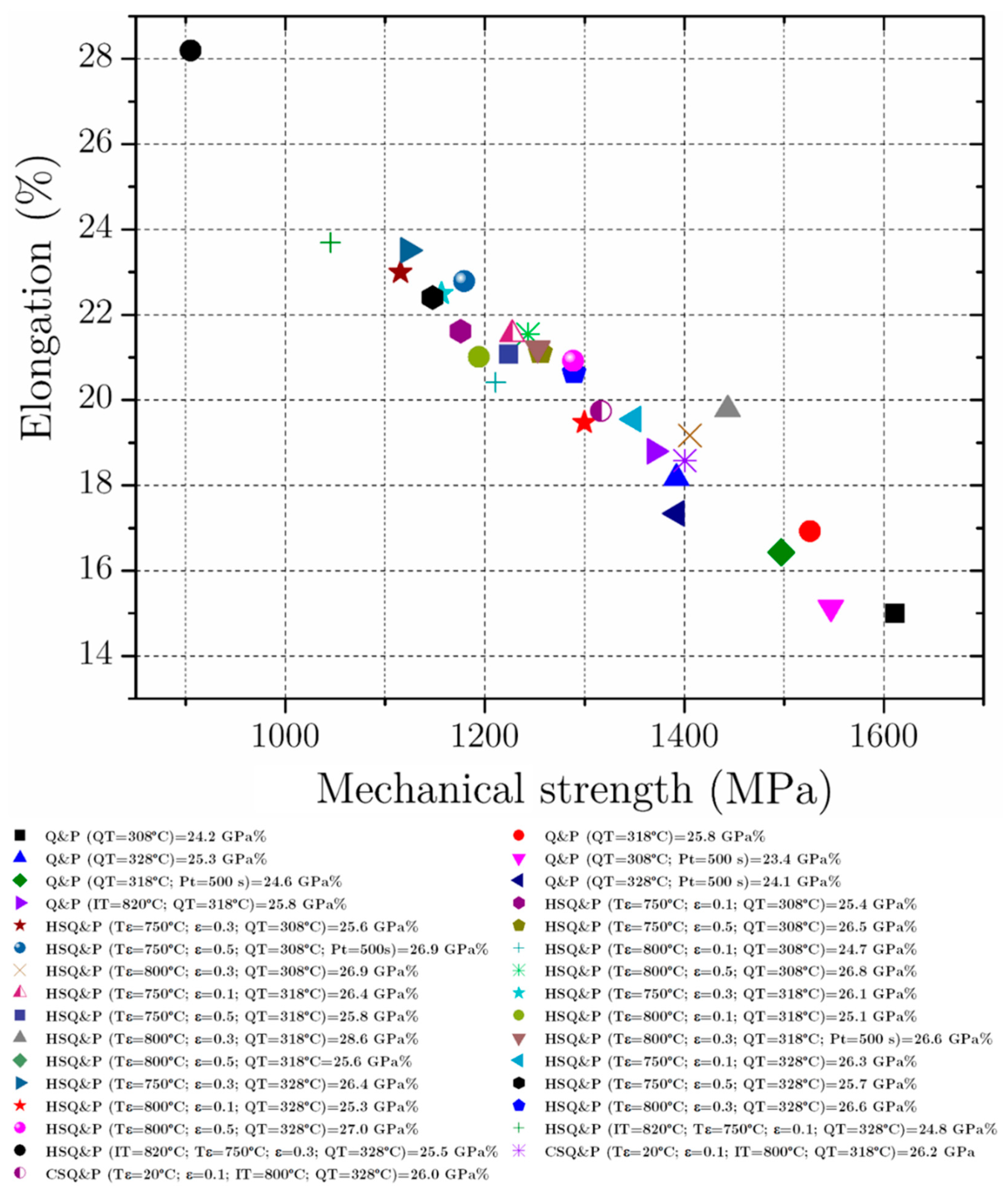

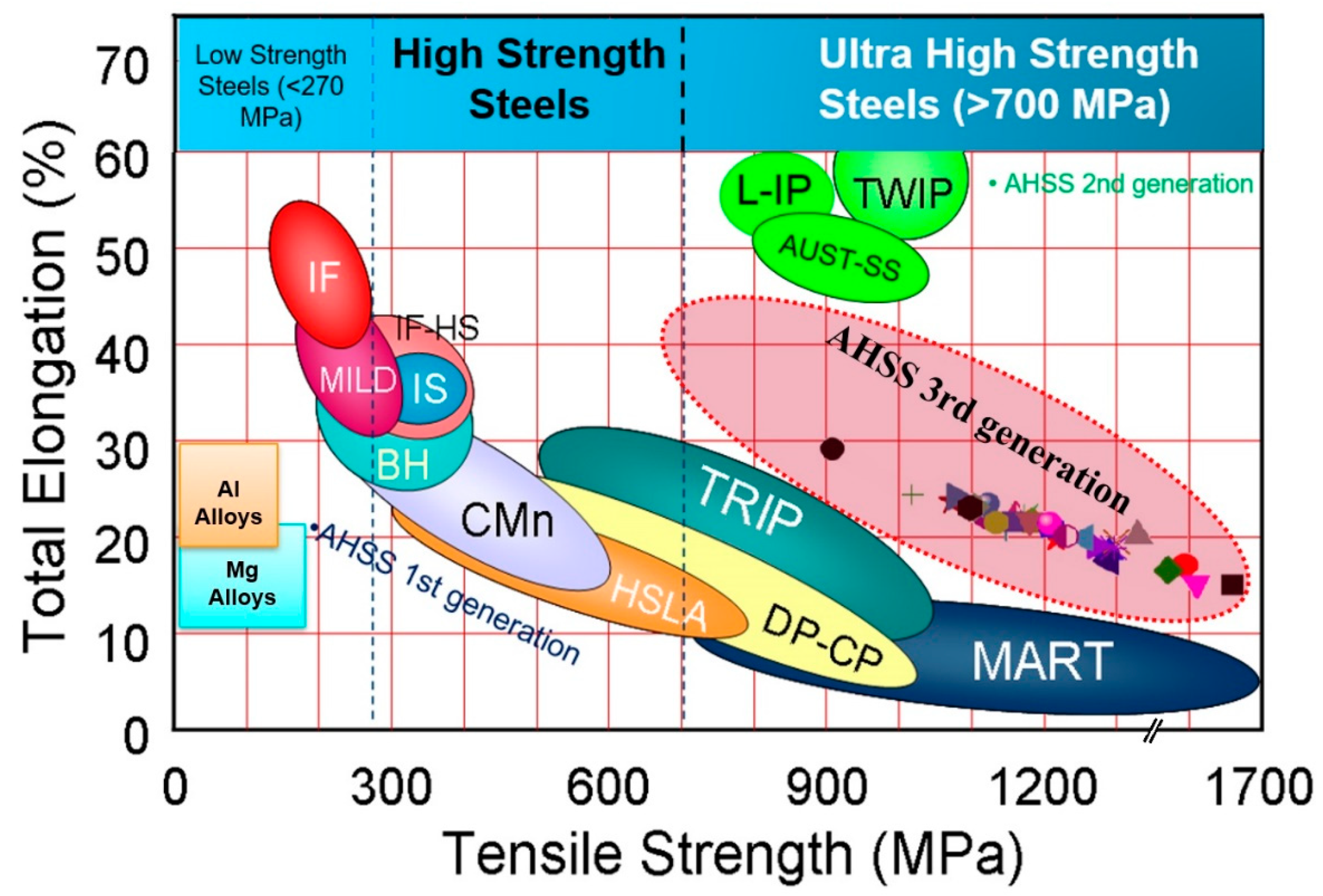

- Using the rule of mixtures, it was possible to build an elongation-mechanical strength diagram to identify and correlate the heat or thermomechanical treatment conditions that lead to an increase in ductility or strength according to the volume fractions of the resulting phases. Comparing the results for the HSQ&P treatments, it was observed that isothermal strains at higher temperatures (≥ 800 °C) are more advantageous to increase mechanical strength, while non-isothermal strains (starting at 750 °C) are suggested, if the objective is the increase in ductility, with mechanical strength being sacrificed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hu, P.; Shi, D.; Ying, L.; Shen, G.; Liu, W. The finite element analysis of ductile damage during hot stamping of 22MnB5 steel. Mater. Des. 2015, 69, 141–152. [Google Scholar] [CrossRef]

- WORLDAUTOSTEEL. Future Steel Vehicle—Final Engineering Report. Available online: http://www.autosteel.org/Programs/FutureSteelVehicle.aspx (accessed on 7 October 2021).

- UltraLight Steel Auto Body Consortium. ULSAB-AVC—Advanced Vehicle Concepts Overview Report; ULSAB-AVC Consortium: Troy, MI, USA, 2002. [Google Scholar]

- Fonstein, N. Advanced High Strength Sheet Steels; Springer: Chicago, IN, USA, 2015; ISBN 9783319191645. [Google Scholar]

- Wang, X.; Ma, F.; Liu, Q.; Zhao, F. Research on Holding Pressure and Cooling Process During Hot Forming of Ultra-High Strength Steel 22MnB5. In Proceedings of the FISITA 2012 World Automotive Congress, Beijing, China, 27–30 November 2012; Springer: Berlin/Heidelberg, Germany, 2013; pp. 123–131. [Google Scholar]

- Yan, S.; Liu, X.; Liu, W.J.; Liang, T.; Zhang, B.; Liu, L.; Zhao, Y. Comparative study on microstructure and mechanical properties of a C-Mn-Si steel treated by quenching and partitioning (Q&P) processes after a full and intercritical austenitization. Mater. Sci. Eng. A 2017, 684, 261–269. [Google Scholar] [CrossRef]

- Liu, H.; Jin, X.; Dong, H.; Shi, J. Martensitic microstructural transformations from the hot stamping, quenching and partitioning process. Mater. Charact. 2011, 62, 223–227. [Google Scholar] [CrossRef]

- Lora, F.; Meza-García, E.; Rautenstrauch, A.; Mosel, A.; Silva, B.; Müller, R.; Ladgrebe, D.; Coelho, R. Press Hardening Technology: Current Challenges and Potential for Expansion in the Brazilian Industrial Sector. In Proceedings of the SENAFOR 35th, Porto Alegre, Brazil, 7 October 2015; p. 8. [Google Scholar]

- Windmann, M.; Röttger, a.; Theisen, W. Formation of intermetallic phases in Al-coated hot-stamped 22MnB5 sheets in terms of coating thickness and Si content. Surf. Coat. Technol. 2014, 246, 17–25. [Google Scholar] [CrossRef]

- Lei, C.; Cui, J.; Xing, Z.; Fu, H.; Zhao, H. Investigation of Cooling Effect of Hot-stamping Dies by Numerical Simulation. Phys. Procedia 2012, 25, 118–124. [Google Scholar] [CrossRef][Green Version]

- Wang, S.; Lee, P. Investigation of Die Quench Properties of Hot Stamping. China Steel Tech. Rep. 2013, 2, 22–31. [Google Scholar]

- Okitsu, Y.; Takata, N.; Tsuji, N. Mechanical properties of ultrafine grained ferritic steel sheets fabricated by rolling and annealing of duplex microstructure. J. Mater. Sci. 2008, 43, 7391–7396. [Google Scholar] [CrossRef]

- Fereiduni, E.; Ghasemi Banadkouki, S.S. Improvement of mechanical properties in a dual-phase ferrite-martensite AISI4140 steel under tough-strong ferrite formation. Mater. Des. 2014, 56, 232–240. [Google Scholar] [CrossRef]

- Karmakar, A.; Misra, R.D.K.; Neogy, S.; Chakrabarti, D. Development of Ultra-Fine Grained Dual-Phase Steels: Mechanism of Grain Refinement during Inter-Critical Deformation. Mater. Sci. Forum 2014, 783–786, 674–678. [Google Scholar] [CrossRef]

- Matsumara, O.; Sakuma, T.; Ishi, Y.; Zhao, J. Etfect of Retained Austenite on Formability of High Strength Sheet Steels. ISIJ Int. 1992, 32, 1110–1116. [Google Scholar] [CrossRef]

- Yin, H.; Zhao, A.; Zhao, Z.; Li, X.; Li, S.; Hu, H.; Xia, W. Influence of original microstructure on the transformation behavior and mechanical properties of ultra-high-strength TRIP-aided steel. Int. J. Miner. Metall. Mater. 2015, 22, 262–271. [Google Scholar] [CrossRef]

- Gibbs, P.J.; De Moor, E.; Merwin, M.J.; Clausen, B.; Speer, J.G.; Matlock, D.K. Austenite Stability Effects on Tensile Behavior of Manganese-Enriched-Austenite Transformation-Induced Plasticity Steel. Metall. Mater. Trans. A 2011, 42, 3691–3702. [Google Scholar] [CrossRef]

- Han, H.N.; Oh, C.S.; Kim, G.; Kwon, O. Design method for TRIP-aided multiphase steel based on a microstructure-based modelling for transformation-induced plasticity and mechanically induced martensitic transformation. Mater. Sci. Eng. A 2009, 499, 462–468. [Google Scholar] [CrossRef]

- Young, C.H.; Bhadeshia, H.K.D.H. Strength of mixtures of bainite and martensite. Mater. Sci. Technol. 1994, 10, 209–214. [Google Scholar] [CrossRef]

- Hase, K.; Garcia-Mateo, C.; Bhadeshia, H.K.D.H. Bainite formation influenced by large stress. Mater. Sci. Technol. 2004, 20, 1499–1505. [Google Scholar] [CrossRef]

- Hell, J.-C.; Dehmas, M.; Allain, S.; Prado, J.M.; Hazotte, A.; Chateau, J.-P. Microstructure—Properties Relationships in Carbide-free Bainitic Steels. ISIJ Int. 2011, 51, 1724–1732. [Google Scholar] [CrossRef]

- Andrea Di Schino Analysis of Phase Transformation in High Strength Low Alloyed Steels. Metalurgija 2017, 56, 349–352.

- Cornide, J.; Miyamoto, G.; Caballero, F.G.; Furuhara, T.; Miller, M.K.; García-Mateo, C. Distribution of Dislocations in Nanostructured Bainite. Solid State Phenom. 2011, 172–174, 117–122. [Google Scholar] [CrossRef]

- Gong, W.; Tomota, Y.; Harjo, S.; Su, Y.H.; Aizawa, K. Effect of prior martensite on bainite transformation in nanobainite steel. Acta Mater. 2015, 85, 243–249. [Google Scholar] [CrossRef]

- Caballero, F.G.; Garcia-Mateo, C.; Miller, M.K. Design of novel bainitic steels: Moving from ultrafine to nanoscale structures. Jom 2014, 66, 747–755. [Google Scholar] [CrossRef]

- Speer, J.; Matlock, D.K.; De Cooman, B.C.; Schroth, J.G. Carbon partitioning into austenite after martensite transformation. Acta Mater. 2003, 51, 2611–2622. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Sietsma, J. Microstructural evolution of a low-carbon steel during application of quenching and partitioning heat treatments after partial austenitization. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2009, 40, 46–57. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Zhao, L.; Petrov, R.; Kwakernaak, C.; Sloof, W.G.; Sietsma, J. Microstructural development during the quenching and partitioning process in a newly designed low-carbon steel. Acta Mater. 2011, 59, 6059–6068. [Google Scholar] [CrossRef]

- Steineder, K.; Schneider, R.; Krizan, D.; Béal, C.; Sommitsch, C. Comparative Investigation of Phase Transformation Behavior as a Function of Annealing Temperature and Cooling Rate of Two Medium-Mn Steels. Steel Res. Int. 2015, 86, 1179–1186. [Google Scholar] [CrossRef]

- Grajcar, A.; Kilarski, A.; Radwanski, K.; Swadzba, R. Microstructural Features of Strain-Induced Martensitic Transformation in Medium-Mn Steels with Metastable Retained Austenite. Arch. Metall. Mater. 2014, 59, 12–14. [Google Scholar] [CrossRef]

- Aydin, H.; Essadiqi, E.; Jung, I.-H.; Yue, S. Development of 3rd generation AHSS with medium Mn content alloying compositions. Mater. Sci. Eng. A 2013, 564, 501–508. [Google Scholar] [CrossRef]

- Narayanaswamy, B.; Hodgson, P.; Beladi, H. Comparisons of the two-body abrasive wear behaviour of four different ferrous microstructures with similar hardness levels. Wear 2016, 350–351, 155–165. [Google Scholar] [CrossRef]

- Han, W.; Li, Y.; Chen, G.; Yang, Q. Effect of sintering additive composition on microstructure and mechanical properties of silicon nitride. Mater. Sci. Eng. A 2017, 700, 19–24. [Google Scholar] [CrossRef]

- Speer, J.G.; Assunção, F.C.R.; Matlock, D.K.; Edmonds, D.V. The “quenching and partitioning” process: Background and recent progress. Mater. Res. 2005, 8, 417–423. [Google Scholar] [CrossRef]

- Di Schino, A.; Gaggiotti, M.; Testani, C. Heat Treatment Effect on Microstructure Evolution in a 7% Cr Steel for Forging. Metals 2020, 10, 808. [Google Scholar] [CrossRef]

- Choi, K.S.; Soulami, A.; Liu, W.N.; Sun, X.; Khaleel, M.A. Influence of various material design parameters on deformation behaviors of TRIP steels. Comput. Mater. Sci. 2010, 50, 720–730. [Google Scholar] [CrossRef]

- Wang, J.; van der Zwaag, S. Stabilization Mechanisms of Retained Austenite in Transformation-Induced Plasticity Steel. Metall. Mater. Trans. A 2001, 32, 1527–1539. [Google Scholar] [CrossRef]

- Yi, H.L.; Lee, K.Y.; Bhadeshia, H.K.D.H. Mechanical stabilisation of retained austenite in δ-TRIP steel. Mater. Sci. Eng. A 2011, 528, 5900–5903. [Google Scholar] [CrossRef]

- Shen, Y.F.; Qiu, L.N.; Sun, X.; Zuo, L.; Liaw, P.K.; Raabe, D. Effects of retained austenite volume fraction, morphology, and carbon content on strength and ductility of nanostructured TRIP-assisted steels. Mater. Sci. Eng. A 2015, 636, 551–564. [Google Scholar] [CrossRef]

- Seol, J.B.; Raabe, D.; Choi, P.P.; Im, Y.R.; Park, C.G. Atomic scale effects of alloying, partitioning, solute drag and austempering on the mechanical properties of high-carbon bainitic-austenitic TRIP steels. Acta Mater. 2012, 60, 6183–6199. [Google Scholar] [CrossRef]

- Cai, Z.H.; Ding, H.; Misra, R.D.K.; Ying, Z.Y. Austenite stability and deformation behavior in a cold-rolled transformation-induced plasticity steel with medium manganese content. Acta Mater. 2015, 84, 229–236. [Google Scholar] [CrossRef]

- Ariza, E.A.; Poplawsky, J.; Guo, W.; Unocic, K.; Ramirez, A.J.; Tschiptschin, A.P.; Babu, S.S. Evaluation of Carbon Partitioning in New Generation of Quench and Partitioning (Q&P) Steels. Metall. Mater. Trans. A 2018, 49, 4809–4823. [Google Scholar] [CrossRef]

- Eghbali, B. Study on the ferrite grain refinement during intercritical deformation of a microalloyed steel. Mater. Sci. Eng. A 2010, 527, 3407–3410. [Google Scholar] [CrossRef]

- Ariza, E.A.; Nishikawa, A.S.; Goldenstein, H.; Tschiptschin, A.P. Characterization and methodology for calculating the mechanical properties of a TRIP-steel submitted to hot stamping and quenching and partitioning (Q&P). Mater. Sci. Eng. A 2016, 671, 54–69. [Google Scholar] [CrossRef]

- Ariza-Echeverri, E.A.; Masoumi, M.; Nishikawa, A.S.; Mesa, D.H.; Marquez-Rossy, A.E.; Tschiptschin, A.P. Development of a new generation of quench and partitioning steels: Influence of processing parameters on texture, nanoindentation, and mechanical properties. Mater. Des. 2020, 186, 108329. [Google Scholar] [CrossRef]

- Bardelcik, A.; Worswick, M.J.; Wells, M.A. The influence of martensite, bainite and ferrite on the as-quenched constitutive response of simultaneously quenched and deformed boron steel—Experiments and model. Mater. Des. 2014, 55, 509–525. [Google Scholar] [CrossRef]

- Faria, G.A. Exploring Metallic Materials Behavior Through In Situ Crystallographic Studies by Synchrotron Radiation. Master’s Thesis, State University of Campinas, Sao Paulo, Brazil, 2014. [Google Scholar]

- De Knijf, D.; Nguyen-Minh, T.; Petrov, R.H.; Kestens, L.A.I.; Jonas, J.J. Orientation dependence of the martensite transformation in a quenched and partitioned steel subjected to uniaxial tension. J. Appl. Crystallogr. 2014, 47, 1261–1266. [Google Scholar] [CrossRef]

- Available online: http://lnnano.cnpem.br/laboratories/cpm/facilities/xtms (accessed on 31 August 2021).

- Suwanpinij, P. The Synchrotron Radiation for Steel Research. Adv. Mater. Sci. Eng. 2016, 2016, 1–6. [Google Scholar] [CrossRef]

- Babu, S.S.; Specht, E.D.; David, S.A.; Karapetrova, E.; Zschack, P.; Peet, M.; Bhadeshia, H.K.D.H. In-situ observations of lattice parameter fluctuations in austenite and transformation to bainite. Metall. Mater. Trans. A 2005, 36, 3281–3289. [Google Scholar] [CrossRef]

- Gnäupel-Herold, T.; Creuziger, A. Diffraction study of the retained austenite content in TRIP steels. Mater. Sci. Eng. A 2011, 528, 3594–3600. [Google Scholar] [CrossRef]

- Dickson, M.J. The Significance of Texture Parameters in Phase Analysis by X-Ray Diffraction. J. Appl. Crystallogr. 1969, 2, 176–180. [Google Scholar] [CrossRef]

- Fielding, L.C.D.; Jones, N.G.; Walsh, J.; Van Boxel, S.; Blackmur, M.S.; Lee, P.D.; Withers, P.J.; Stone, H.J.; Bhadeshia, H.K.D.H. Synchrotron analysis of toughness anomalies in nanostructured bainite. Acta Mater. 2016, 105, 52–58. [Google Scholar] [CrossRef]

- Van Bohemen, S.M.C. The nonlinear lattice expansion of iron alloys in the range 100–1600 K. Scr. Mater. 2013, 69, 315–318. [Google Scholar] [CrossRef]

- Dyson, D.J.; Holmes, B. Effect of alloying additions on the lattice parameter of austenite. J. Iron Steel Inst. 1970, 208, 469–474. [Google Scholar]

- Mola, J.; Cooman, B.C. Quenching and Partitioning (Q&P) Processing of Martensitic Stainless Steels. Metall. Mater. Trans. A 2012, 44, 946–967. [Google Scholar] [CrossRef]

- Speer, J.G.; Matlock, D.K.; Decooman, B.C. Analysis of Lattice Parameter Changes Following Induced Plasticity Sheet Steel. Met. Mater Trans A 2005, 36, 907–918. [Google Scholar]

- Fultz, B.; Howe, J. Diffraction and the X-Ray Powder Diffractometer. In Transmission Electron Microscopy and Diffractometry of Materials; Graduate Texts in Physics; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–57. ISBN 978-3-642-29760-1. [Google Scholar]

- ASTM Standard. ASTM E562-08; Standard Test Method for Determining Volume Fraction by Systematic Manual Point Count. 1–7. ASTM International: West Conshohocken, PA, USA, 2002.

- Koistinen, D.P.; Marburger, R.E. A general equation prescribing the extent of the austenite-martensite transformation in pure iron-carbon alloys and plain carbon steels. Acta Metall. 1959, 7, 59–60. [Google Scholar] [CrossRef]

- van Bohemen, S.M.C. Bainite and martensite start temperature calculated with exponential carbon dependence. Mater. Sci. Technol. 2012, 28, 487–495. [Google Scholar] [CrossRef]

- Andrews, K. Empirical Formulae for the Calculation of Some Transformation Temperatures. J. Iron Steel Inst. 1965, 203, 721–727. [Google Scholar]

- Speer, J.G.; Edmonds, D.V.; Rizzo, F.C.; Matlock, D.K. Partitioning of carbon from supersaturated plates of ferrite, with application to steel processing and fundamentals of the bainite transformation. Curr. Opin. Solid State Mater. Sci. 2004, 8, 219–237. [Google Scholar] [CrossRef]

- Rizzo, F.C.; Martins, A.R.; Speer, J.G.; Matlock, D.K.; Clarke, a.; De Cooman, B.C. Quenching and Partitioning of Ni-Added High Strength Steels. Mater. Sci. Forum 2007, 539–543, 4476–4481. [Google Scholar] [CrossRef]

- Matlock, D.K.; Bräutigam, V.E.; Speer, J.G. Application of the Quenching and Partitioning (Q&P) Process to a Medium-Carbon, High-Si Microalloyed Bar Steel. Mater. Sci. Forum 2003, 426–432, 1089–1094. [Google Scholar] [CrossRef]

- Rollett, A.; Humphreys, F.; Rohrer, G.S.; Hatherly, M. Recrystallization and Related Annealing Phenomena, 2nd ed.; Pergamon: Stanmore, UK, 2004; ISBN 9780080441641. [Google Scholar]

- Cheng, L.; Chen, Y.; Cai, Q.; Yu, W.; Han, G.; Dong, E.; Li, X. Precipitation enhanced ultragrain refinement of Ti-Mo microalloyed ferritic steel during warm rolling. Mater. Sci. Eng. A 2017, 698, 117–125. [Google Scholar] [CrossRef]

- Shen, X.J.; Tang, S.; Chen, J.; Liu, Z.Y.; Misra, R.D.K.; Wang, G.D. Grain refinement in surface layers through deformation-induced ferrite transformation in microalloyed steel plate. Mater. Des. 2017, 113, 137–141. [Google Scholar] [CrossRef]

- Liu, H.; Sun, H.; Liu, B.; Li, D.; Sun, F.; Jin, X. An ultrahigh strength steel with ultrafine-grained microstructure produced through intercritical deformation and partitioning process. Mater. Des. 2015, 83, 760–767. [Google Scholar] [CrossRef]

- Ghosh, C.; Aranas, C.; Jonas, J.J. Dynamic transformation of deformed austenite at temperatures above the Ae3. Prog. Mater. Sci. 2016, 82, 151–233. [Google Scholar] [CrossRef]

- Nikravesh, M.; Naderi, M.; Akbari, G.H. Influence of hot plastic deformation and cooling rate on martensite and bainite start temperatures in 22MnB5 steel. Mater. Sci. Eng. A 2012, 540, 24–29. [Google Scholar] [CrossRef]

- Wang, H.-Z.; Yang, P.; Mao, W.-M.; Lu, F.-Y. Effect of hot deformation of austenite on martensitic transformation in high manganese steel. J. Alloys Compd. 2013, 558, 26–33. [Google Scholar] [CrossRef]

- He, B.B.; Xu, W.; Huang, M.X. Increase of martensite start temperature after small deformation of austenite. Mater. Sci. Eng. A 2014, 609, 141–146. [Google Scholar] [CrossRef]

- Han, Q.; Kang, Y.; Zhao, X.; Stanford, N.; Cai, M. Suppression of Ms temperature by carbon partitioning from carbon-supersaturated ferrite to metastable austenite during intercritical annealing. Mater. Des. 2013, 51, 409–414. [Google Scholar] [CrossRef]

- Ariza, E.A.; Tschiptschin, A.P.; Azevedo, C.R.F. Failure analysis of a martensitic stainless steel (CA-15M) roll manufactured by centrifugal casting. Part II: Thermal stress analysis by FEA. Eng. Fail. Anal. 2015, 48, 78–93. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Y.H.; Zheng, C.L.; Zhang, F.C.; Wang, T.S. Austenite deformation behaviour and effect of ausforming process on starting martensite microstructure in medium-carbon S-Al-rich alloy steel. Mater. Sci. Eng. A 2014, 596, 9–14. [Google Scholar] [CrossRef]

- Luo, H.; Zhao, L.; Kruijver, S.O.; Sietsma, J.; Zwaag, S. Van Der Effect of Intercritical Deformation on Bainite Formation in Al-containing TRIP Steel. ISIJ Int. 2003, 43, 1219–1227. [Google Scholar] [CrossRef][Green Version]

- Garcia-Mateo, C.; Caballero, F.G.; Capdevila, C.; De Andres, C.G. Estimation of dislocation density in bainitic microstructures using high-resolution dilatometry. Scr. Mater. 2009, 61, 855–858. [Google Scholar] [CrossRef]

- Fan, D.W.; Park, R.B.; Cho, Y.R.; De Cooman, B.C. Influence of isothermal deformation conditions on the mechanical properties of 22mnb5 hpf steel. Steel Res. Int. 2010, 81, 292–298. [Google Scholar] [CrossRef]

- Hosseini, S.M.K.; Zarei-Hanzaki, A.; Yue, S. The Effect of Intercritical Deformation on Microstructure Development in Thermomechanically-Processed Low-Silicon TRIP-Assisted Steels. Adv. Mater. Res. 2013, 856, 251–256. [Google Scholar] [CrossRef]

- Lawrynowicz, Z. Rationalisation of Austenite Transformation to Upper or Lower Bainite in Steels. Adv. Mater. Sci. 2014, 14, 14–23. [Google Scholar] [CrossRef][Green Version]

- Santofimia, M.J.; Nguyen-Minh, T.; Zhao, L.; Petrov, R.; Sabirov, I.; Sietsma, J. New low carbon Q&P steels containing film-like intercritical ferrite. Mater. Sci. Eng. A 2010, 527, 6429–6439. [Google Scholar] [CrossRef]

- Zaefferer, S.; Ohlert, J.; Bleck, W. A study of microstructure, transformation mechanisms and correlation between microstructure and mechanical properties of a low alloyed TRIP steel. Acta Mater. 2004, 52, 2765–2778. [Google Scholar] [CrossRef]

- Yang, J.; Liu, Q.; Sun, D.; Li, X. Microstructure and Transformation Characteristics of Acicular Ferrite in High Niobium-Bearing Microalloyed Steel. J. Iron Steel Res. Int. 2010, 17, 53–59. [Google Scholar] [CrossRef]

- Li, Z.D.; Yang, Z.G.; Zhang, C.; Liu, Z.Q. Influence of austenite deformation on ferrite growth in a Fe-C-Mn alloy. Mater. Sci. Eng. A 2010, 527, 4406–4411. [Google Scholar] [CrossRef]

- Hurley, P.J.; Muddle, B.C.; Hodgson, P.D. The production of ultrafine ferrite during hot torsion testing of a 0.11 wt pct C steel. Metall. Mater. Trans. A 2002, 33, 2985–2993. [Google Scholar] [CrossRef]

- De Knijf, D.; Petrov, R.; Föjer, C.; Kestens, L.A.I. Effect of fresh martensite on the stability of retained austenite in quenching and partitioning steel. Mater. Sci. Eng. A 2014, 615, 107–115. [Google Scholar] [CrossRef]

- Hsu, T.Y. Additivity hypothesis and effects of stress on phase transformations in steel. Curr. Opin. Solid State Mater. Sci. 2005, 9, 256–268. [Google Scholar] [CrossRef]

- Shi, Z.; Liu, K.; Wang, M.; Shi, J.; Dong, H.; Pu, J.; Chi, B.; Zhang, Y.; Jian, L. Effect of non-isothermal deformation of austenite on phase transformation and microstructure of 22SiMn2TiB steel. Mater. Sci. Eng. A 2012, 535, 290–296. [Google Scholar] [CrossRef]

- Sun, J.; Yu, H.; Wang, S.; Fan, Y. Study of microstructural evolution, microstructure-mechanical properties correlation and collaborative deformation-transformation behavior of quenching and partitioning (Q&P) steel. Mater. Sci. Eng. A. 2014, 596, 89–97. [Google Scholar] [CrossRef]

- Somani, M.C.; Porter, D.A.; Karjalainen, L.P.; Misra, D.K. Designing a Novel DQ&P Process through Physical Simulation Studies. Mater. Sci. Forum 2013, 762, 83–88. [Google Scholar] [CrossRef]

- Humphreys, F.J.; Hatherly, M. Hot Deformation and Dynamic Restoration. In Recrystallization and Related Annealing Phenomena; Elsevier: Oxford, UK, 2004; pp. 415–450. [Google Scholar]

- Siciliano, F. Recuperação e recristalização durante a deformação a quente. In Textura e Relações de Orientação; EPUSP: São Paulo, Brazil, 2001; pp. 93–108. [Google Scholar]

- Hidaka, K.; Takemoto, Y.; Senuma, T. Microstructural Evolution of Carbon Steels in Hot Stamping Processes. ISIJ Int. 2012, 52, 688–696. [Google Scholar] [CrossRef][Green Version]

- Rasouli, D.; Khameneh Asl, S.; Akbarzadeh, A.; Daneshi, G.H. Effect of cooling rate on the microstructure and mechanical properties of microalloyed forging steel. J. Mater. Process. Technol. 2008, 206, 92–98. [Google Scholar] [CrossRef]

- Santofimia, M.J.; Petrov, R.H.; Zhao, L.; Sietsma, J. Microstructural analysis of martensite constituents in quenching and partitioning steels. Mater. Charact. 2014, 92, 91–95. [Google Scholar] [CrossRef]

- Baltazar Hernandez, V.H.; Panda, S.K.; Kuntz, M.L.; Zhou, Y. Nanoindentation and microstructure analysis of resistance spot welded dual phase steel. Mater. Lett. 2010, 64, 207–210. [Google Scholar] [CrossRef]

- de Diego-Calderón, I.; De Knijf, D.; Monclús, M.A.; Molina-Aldareguia, J.M.; Sabirov, I.; Föjer, C.; Petrov, R.H. Global and local deformation behavior and mechanical properties of individual phases in a quenched and partitioned steel. Mater. Sci. Eng. A 2015, 630, 27–35. [Google Scholar] [CrossRef]

- Park, H.S.; Han, J.C.; Lim, N.S.; Park, C.G. Nano-scale observation on the transformation behavior and mechanical stability of individual retained austenite in CMnSiAl TRIP steels. Mater. Sci. Eng. A 2015, 627, 262–269. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Venkatsurya, P.; Wu, K.M.; Karjalainen, L.P. Ultrahigh strength martensite–austenite dual-phase steels with ultrafine structure: The response to indentation experiments. Mater. Sci. Eng. A 2013, 560, 693–699. [Google Scholar] [CrossRef]

- Furnémont, Q.; Kempf, M.; Jacques, P.J.; Göken, M.; Delannay, F. On the measurement of the nanohardness of the constitutive phases of TRIP-assisted multiphase steels. Mater. Sci. Eng. A 2002, 328, 3–20. [Google Scholar] [CrossRef]

- Rios, P.R.; Padilha, A.F. Transformações de Fase; Artliber Editora Ltd.: São Paulo, Brazil, 2007. [Google Scholar]

- Gadelrab, K.R.; Li, G.; Chiesa, M.; Souier, T. Local characterization of austenite and ferrite phases in duplex stainless steel using MFM and nanoindentation. J. Mater. Res. 2012, 27, 1573–1579. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X. Revealing the Intrinsic Nanohardness of Lath Martensite in Low Carbon Steel. Metall. Mater. Trans. A 2014, 46, 688–694. [Google Scholar] [CrossRef]

- Blondé, R.; Jimenez-Melero, E.; Huizenga, R.; Zhao, L.; Wright, J.; Bruck, E.; van der Zwaag, S.; van Dijk, N. High-resolution X-ray diffraction investigation on the evolution of the substructure of individual austenite grains in TRIP steels during tensile deformation. Mater. Sci. Eng. A 2014, 47, 965–973. [Google Scholar] [CrossRef]

- Bernier, N.; Bracke, L.; Malet, L.; Godet, S. Crystallographic Reconstruction Study of the Effects of Finish Rolling Temperature on the Variant Selection During Bainite Transformation in C-Mn High-Strength Steels. Metall. Mater. Trans. A 2014, 45, 5937–5955. [Google Scholar] [CrossRef]

- Tirumalasetty, G.K.; van Huis, M.; Kwakernaak, C.; Sietsma, J.; Sloof, W.G.; Zandbergen, H.W. Deformation-induced austenite grain rotation and transformation in TRIP-assisted steel. Acta Mater. 2012, 60, 1311–1321. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Stress and Strain Effects. In Bainite in Steels; IOM Communications: London, UK, 2001; pp. 201–224. [Google Scholar]

- Chaouch, D.; Guessasma, S.; Sadok, A. Finite Element simulation coupled to optimisation stochastic process to assess the effect of heat treatment on the mechanical properties of 42CrMo4 steel. Mater. Des. 2012, 34, 679–684. [Google Scholar] [CrossRef]

- Nayak, S.S.; Anumolu, R.; Misra, R.D.K.; Kim, K.H.; Lee, D.L. Microstructure–hardness relationship in quenched and partitioned medium-carbon and high-carbon steels containing silicon. Mater. Sci. Eng. A 2008, 498, 442–456. [Google Scholar] [CrossRef]

- Matlock, D.; Speer, J. Design Considerations for the Next Generation of Advanced High Strength Sheet Steels. In Proceedings of the 3rd International Conference on Structural Steels, Gyeongju, Korea, 22–24 August 2006; Lee, H.C., Ed.; The Korean Institute of Metals and Materials: Seoul, Korea, 2006; pp. 774–781. [Google Scholar]

- Davies, R.G. The deformation behavior of a vanadium-strengthened dual phase steel. Metall. Mater. Trans. A 1978, 9, 41–52. [Google Scholar] [CrossRef]

- Davies, R.G. Influence of martensite composition and content on the properties of dual phase steels. Metall. Trans. A 1978, 9, 671–679. [Google Scholar] [CrossRef]

- Ojima, M.; Inoue, J.; Nambu, S.; Xu, P.; Akita, K.; Suzuki, H.; Koseki, T. Stress partitioning behavior of multilayered steels during tensile deformation measured by in situ neutron diffraction. Scr. Mater. 2012, 66, 139–142. [Google Scholar] [CrossRef]

- Mileiko, S. The Tensile Strength and Ductility of Continuous Fibre Composites. J. Mater. Sci. 1969, 4, 974–977. [Google Scholar] [CrossRef]

- Matlock, D.K.; Speer, J.G.; De Moor, E.; Gibbs, P.J. Recent developments in Advanced High Strength Sheet Steels for automotive applications: An overview. Jestech 2012, 15, 1–12. [Google Scholar]

- Srikanth, S.; Saravanan, P.; Kumar, V.; Saravanan, D.; Sivakumar, L.; Sisodia, S.; Ravi, K.; Jha, B. Property Enhancement in MetasTable 301LN Austenitic Stainless Steel through Strain-Induced Martensitic Transformation and its Reversion (SIMTR) for Metro Coach Manufacture. Int. J. Metall. Eng. 2013, 2, 203–213. [Google Scholar] [CrossRef]

- Jiao, Z.; Liu, C.-T. Research and development of advanced nano-precipitate strengthened ultra-high strength steels. Mater. China 2011, 30, 1–7. [Google Scholar]

- International Energy Agency. Key World Energy Statistics; International Energy Agency: Paris, France, 2016. [Google Scholar]

| C | Si | Mn | Cr |

|---|---|---|---|

| 0.23 | 1.23 | 1.5 | 0.02 |

| Heat Treatment | QT (°C) | Pt (s) | HV0.5 | α (%) | γ (%) |

|---|---|---|---|---|---|

| Q&P (IT = 800 °C) | 308 | 100 | 380 ± 13 | 18.3 | 5.7 |

| 308 | 500 | 355 ± 17 | 23.7 | 3.7 | |

| 318 | 100 | 373 ± 13 | 21.4 | 8.1 | |

| 318 | 500 | 352 ± 6 | 25.1 | 5.6 | |

| 328 | 100 | 348 ± 11 | 30.4 | 6.7 | |

| 328 | 500 | 338 ± 14 | 32.3 | 4.3 | |

| Q&P (IT = 820 °C) | 328 | 100 | 321 ± 15 | 30.9 | 7.7 |

| Thermomechanical Treatment | QT (°C) | Pt (s) | ε = 10% | ε = 30% | ε = 50% | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HV0.5 | α (%) | γ (%) | HV0.5 | α (%) | γ (%) | HV0.5 | α (%) | γ (%) | |||

| HSQ&P; IT = 800 °C; Tε = 750 °C | 308 | 100 | 310 ± 7 | 41.6 | 8.6 | 296 ± 8 | 43.8 | 10.3 | 329 ± 5 | 35.7 | 10.1 |

| 308 | 500 | 287 ± 10 | 31.2 | 309 ± 5 | 37.3 | ||||||

| 318 | 100 | 315 ± 7 | 37.2 | 10.3 | 306 ± 9 | 41.3 | 10.4 | 361 ± 7 | 38.6 | 8.8 | |

| 318 | 500 | 298 ± 7 | 31.8 | 304 ± 13 | 38.6 | 12.1 | |||||

| 328 | 100 | 324 ± 20 | 31.0 | 9.1 | 303 ± 8 | 41.9 | 12.1 | 333 ± 12 | 42.3 | 9.8 | |

| 328 | 500 | 282 ± 8 | 35.7 | 10.3 | 310 ± 4 | 48.9 | |||||

| HSQ&P; IT = 800 °C; Tε = 800 °C | 308 | 100 | 336 ± 13 | 41.3 | 6.4 | 324 ± 7 | 26.9 | 10.1 | 310 ± 9 | 35.8 | 10.9 |

| 318 | 100 | 314 ± 7 | 41.4 | 7.5 | 341 ± 11 | 22.1 | 13.3 | 302 ± 9 | 41.5 | 10.3 | |

| 318 | 500 | 336 ± 19 | 22.4 | 304 ± 9 | 25.9 | ||||||

| 328 | 100 | 320 ± 13 | 35.6 | 7.0 | 340 ± 14 | 33.8 | 10.0 | 300 ± 9 | 33.2 | 10.8 | |

| 328 | 500 | 334 ± 10 | 21.9 | 305 ± 15 | 29.9 | ||||||

| HSQ&P; IT = 820 °C; Tε = 750 °C | 328 | 100 | 319 ± 11 | 48.4 | 9.7 | 322 ± 15 | 50.4 | 17.5 | |||

| CSQ&P; IT = 800 °C; Tε = 20 °C | 318 | 100 | 339 ± 10 | 28.7 | 8.2 | ||||||

| 328 | 100 | 313 ± 11 | 33.5 | 8.4 | |||||||

| Constituent | UTS (MPa) | Uniform Elongation (%) |

|---|---|---|

| Ferrite | 300 | 0.3 |

| Austenite | 640 | 0.6 |

| Martensite | 2000 | 0.008 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Echeverri, E.A.A.; Nishikawa, A.S.; Masoumi, M.; Pereira, H.B.; Marulanda, N.G.; Rossy, A.M.; Goldenstein, H.; Tschiptschin, A.P. In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching & Partitioning Processing for Development of Third-Generation Advanced High Strength Steels. Metals 2022, 12, 174. https://doi.org/10.3390/met12020174

Echeverri EAA, Nishikawa AS, Masoumi M, Pereira HB, Marulanda NG, Rossy AM, Goldenstein H, Tschiptschin AP. In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching & Partitioning Processing for Development of Third-Generation Advanced High Strength Steels. Metals. 2022; 12(2):174. https://doi.org/10.3390/met12020174

Chicago/Turabian StyleEcheverri, Edwan Anderson Ariza, Arthur Seiji Nishikawa, Mohammad Masoumi, Henrique Boschetti Pereira, Nelson Granda Marulanda, Andrés Márquez Rossy, Hélio Goldenstein, and André Paulo Tschiptschin. 2022. "In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching & Partitioning Processing for Development of Third-Generation Advanced High Strength Steels" Metals 12, no. 2: 174. https://doi.org/10.3390/met12020174

APA StyleEcheverri, E. A. A., Nishikawa, A. S., Masoumi, M., Pereira, H. B., Marulanda, N. G., Rossy, A. M., Goldenstein, H., & Tschiptschin, A. P. (2022). In Situ Synchrotron X-ray Diffraction and Microstructural Studies on Cold and Hot Stamping Combined with Quenching & Partitioning Processing for Development of Third-Generation Advanced High Strength Steels. Metals, 12(2), 174. https://doi.org/10.3390/met12020174