Abstract

In many machining operations, metalworking fluids (MWFs) play an invaluable role. Often, proper application of an intelligent MWF strategy allows manufacturing processes to benefit from a multitude of operational incentives, not least of which are increased tool life, improved surface integrity and optimised chip handling. Despite these clearly positive implications, current MWF strategies are often unable to accommodate the environmental, economic and social conscience of industrial environments. In response to these challenges, CO2 coolants are postulated as an operationally viable, environmentally benign MWF solution. Given the strong mechanistic rationale and historical evidence in support of cryogenic coolants, this review considers the technological chronology of cryogenic MWF’s in addition to the current state-of-the-art approaches. The review also focuses on the use of CO2 coolants in the context of the machining of a multitude of material types in various machining conditions. In doing so, cryogenic assisted machining is shown to offer a litany of performance benefits for both conventional emulsion (flood) cooling and near dry strategies, i.e., minimum quantity lubrication (MQL), as well as aerosol dry lubrication (ADL).

1. Introduction

In order to accommodate the demands of the current technological landscape, engineers have developed novel materials that meet an increasingly expansive range of lofty performance indices. One pertinent example is that of an aero-engine disk. In such an application, the subject material must exhibit high flexural rigidity, fatigue strength and creep resistance, all whilst being exposed to operating temperatures in excess of 800 °C [1]. In this case, it crucial that the material chosen exhibits both high shear strength and low thermal conductivity. Whilst these properties serve a clear purpose in an aeroengine, they generate a challenging machining environment, which must be met with a robust metalworking fluid (MWF) strategy. Unfortunately, however, whilst they remain an operational necessity, the use of conventional MWF strategies is accompanied by a series of negative environmental, social and ergonomic implications. To elaborate, their disposal is not only unsustainable, but both extremely costly and time consuming; they pose a health risk to machine operators and their maintenance requires a significant time commitment that could be allocated to more productive tasks. In contrast, whilst cryogenic and CO2 cutting fluids have their own limitations, they offer markedly improved sustainability (Section 4); they have been shown (situationally) to produce significantly improved machinability outcomes (Section 5), and by virtue of their return to the atmosphere post machining cycle, they remove the burden of fluid maintenance and disposal.

Despite the prospective benefits of cryogenic and CO2 MWF strategies, the use of CO2 as an MWF remains confined to niche applications. This is due to the fact that whilst LN2 is, at this point, extensively researched, the available literature on CO2 is (comparatively) very much in its infancy. As such, if CO2 MWF strategies are to become commonplace, it is crucial that the body of literature is compiled in a means that is both accessible and categorised according to research interest. With this in mind, the proceeding review looks to outline the scenarios in which CO2 MWF strategies have, at this stage, been employed, and further, serves to identify avenues for future research.

2. Review Structure

Given the extensive research that focuses upon the use of liquid nitrogen (LN2) MWFs, the proceeding text is primarily focused upon the emerging use of CO2 coolants, with only an ancillary consideration of LN2. The review first provides a background (Section 3) on the subject matter of cryogenic and CO2 MWFs, focusing foremost upon the historical use of cryogenic MWF’s (Section 3.1) followed by their motivation for use (Section 3.2) and the mechanism of action for scCO2 coolants specifically (Section 3.3). Thereafter, the document considers the sustainability of CO2 coolants in lieu of conventional MWFs (Section 4), giving primary consideration to the environmental, social and ergonomic implications of the widespread disruptive use of CO2 coolants. The review next focuses upon the current state-of-the-art by way of outlining the available literature on CO2 MWFs, categorizing said literature foremost according to the workpiece material considered (Section 5) and then according to a range of other operational variables (Section 6), i.e., feeds and speeds, tool design, etc. Finally, the document is brought to a conclusion (Section 7). When locating research for this review article, the following search terms were used: “CO2”, “Machining”, “Cryogenic”, “MQL”, “Milling” and “Turning”.

3. Background

3.1. History of Cryogenic MWFs

In many regards, formal research on cryogenic cutting fluids began in 1967, when Okoshi [2] observed, and later went on to present the chip handling benefits of LN2 at the annual general meeting of the Japan Society of Precision Engineers (JSPE). Despite sparking interest, it was not until 1969 that the first journal articles were published in the field. In the original paper on cryogenic machining, Uehara and Kumagai [3] examined the variability of cutting temperature, chip formation and tool force with workpiece temperature for plain carbon steel, stainless steel and commercially pure titanium. In their research, Uehara and Kumagai employed a simple turning model where LN2 was applied in situ to the three workpiece materials. Thereafter, two separate thermocouples were employed to measure temperature (at the workpiece and chip-tool interface), and a dynamometer utilised to measure force components. The ultimate findings of the paper noted that whilst the cryogenic machining strategy led to an improved surface finish in the carbon steel workpiece, in the stainless steel and titanium samples, surface roughness was either comparable or worsened by the application of LN2. Moreover, the paper found that during the machining of titanium sample, workpiece temperature and cutting force followed a negative correlation. The authors went on to conclude that the variability with which the different materials responded to reduced workpiece temperature was largely due to the extent to which a given material exhibited low temperature brittleness. As the amount of shear flow stress implicit during low temperature machining increases, surface roughness is worsened and cutting force is generally increased (if not offset by increased brittleness).

In their following paper, Uehara and examined the tool life implications of a cryogenic, workpiece cooling strategy [4]. In this regard, the first truly promising tool life rationale for the use of cryogenic coolants was made, where tool wear was noted to decrease at reduced temperatures in both the carbon steel and titanium test pieces. Moreover, this paper went on to define the conditionality of cryogenic cooling strategies, noting that the extent of flank wear in the stainless steel workpiece followed the reverse trend to that of both carbon steel and titanium. As was the case in their original paper, this article again concludes by defining three variables responsible for the observed phenomenon: the temperature dependency of tool wear, low temperature brittleness of the workpiece and the protective effect of built-up edge (BUE) against tool wear (the latter being heavily cited in the authors reasoning for the conditionality of recorded results). Interestingly, whilst both titanium and stainless steel failed to exhibit low temperature brittleness, the impact of workpiece temperature on tool life differed dramatically between the two materials. The authors went on to state that this discrepancy is likely a consequence of the protective effect of a BUE having a much more significant impact on tool life in the machining of stainless steel (then titanium), and as such, the extinguishment of the BUE at cryogenic temperatures was a more relevant phenomenon in the machining of stainless steel. Additionally, it can be argued that in the machining of titanium, temperature dependency of tool wear is higher based upon the low thermal conductivity of titanium and the known susceptibility of titanium and titanium alloys to diffusion dominated wear mechanisms such as crater wear.

Given the early research of Uehara and Kumagai, many authors have since followed suit in the study of cryogenic MWF’s. Generally, much of this research has historically focused upon the use of LN2 coolants. Whilst these articles are the subject of a great deal of academic interest, much of their contents have already been previously considered in earlier review papers [5,6]. Additionally, it is the rationale of the author that the significant incentives offered by CO2 MWFs (Section 3.2 and Section 4) make further LN2 focused reviews inconsistent with the current research trend of the cryogenic machining community. Given this statement, a case is thus made in support of the proceeding work’s focus upon CO2 (rather than LN2) MWF’s.

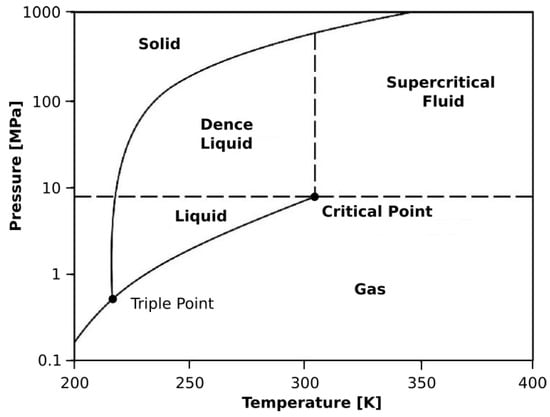

3.2. CO2 Mechanism of Action

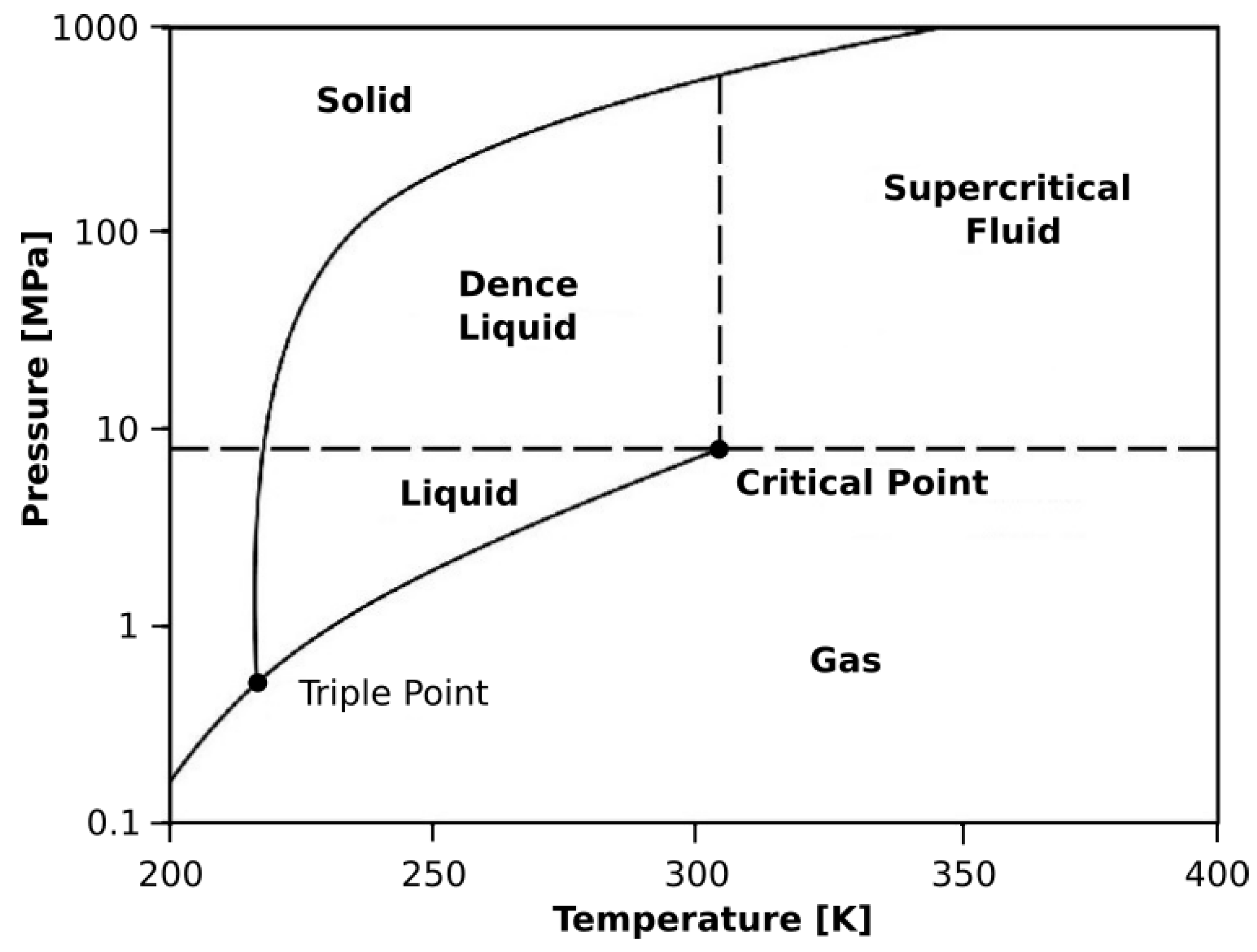

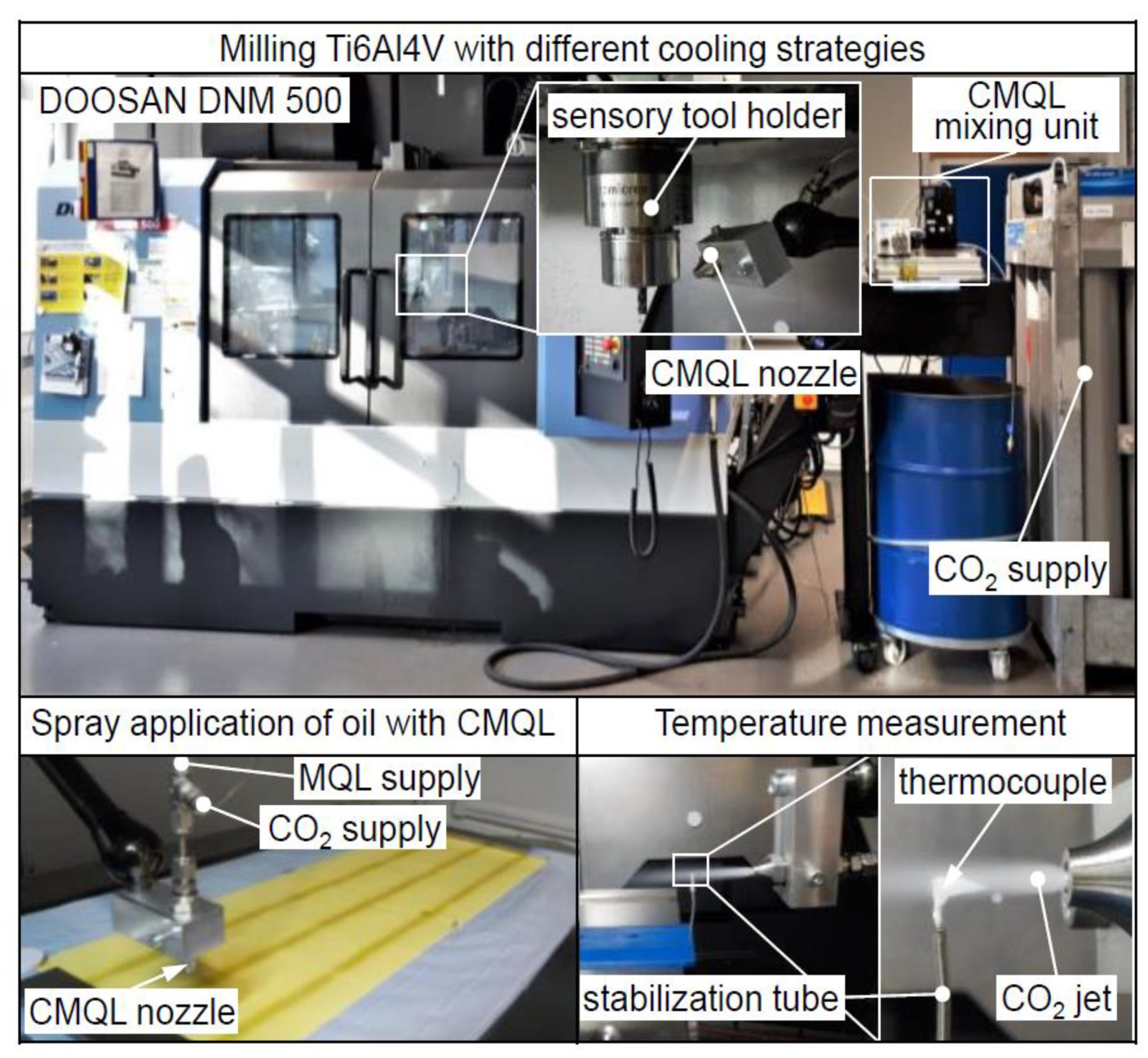

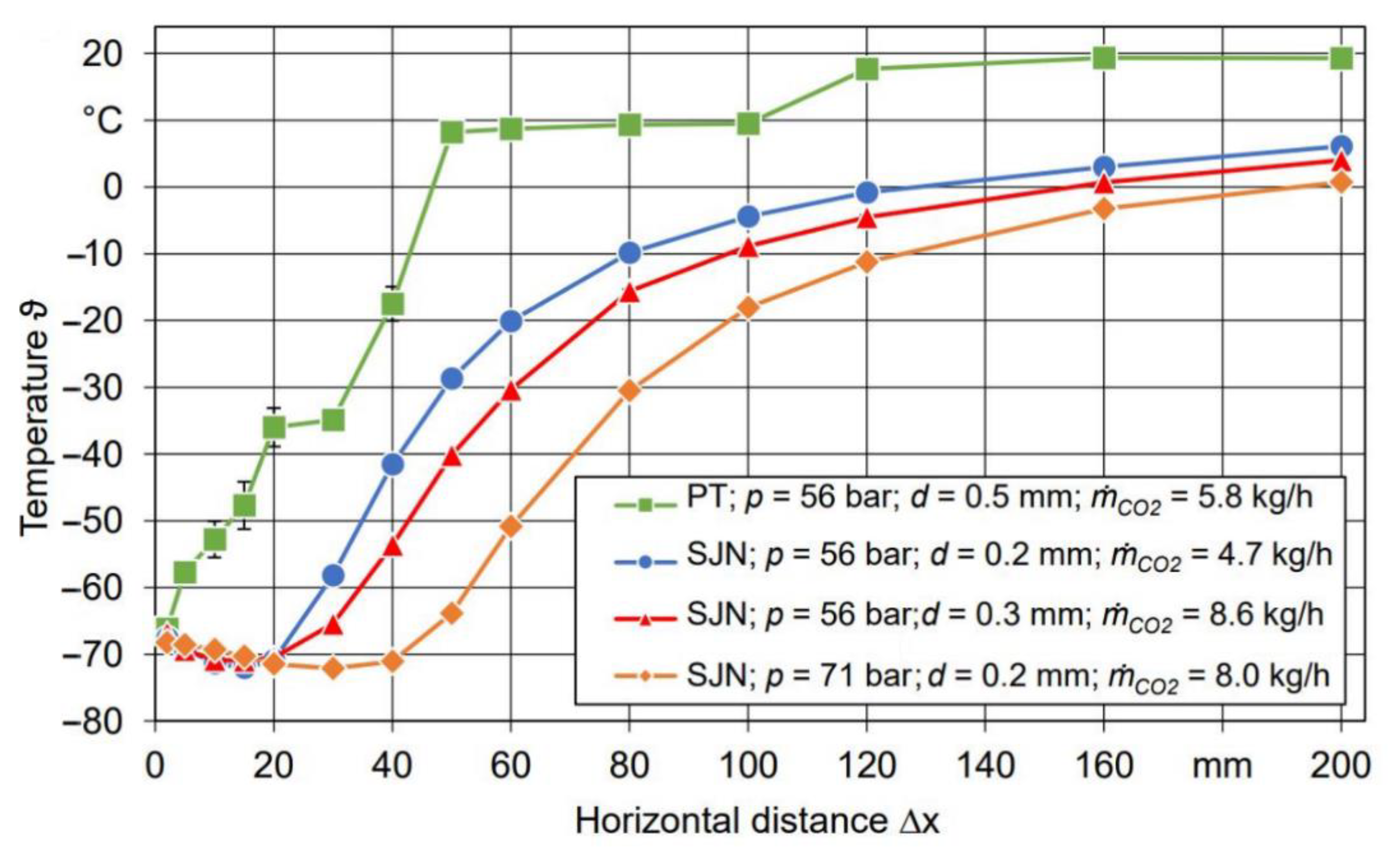

In a conventional LN2 cryogenic machining strategy, the tool is cooled by proximity to the cryogenic medium. In such a scenario, the extremely cold fluid serves to function as a heat sink, cooling the tool primarily by convection, driven by temperature gradient (between the tool and cryogen). CO2 coolants on the other hand are delivered at ambient temperature (Figure 1), and as such, their function as a coolant is not a consequence of their cryogenic temperature at delivery, but rather, the Joule–Thomson effect. In a Joule–Thomson expansion, the fluid is adiabatically throttled through the exit valve of the coolant system. As the gas is throttled, it undergoes a sudden drop in pressure. This reduction in pressure is accompanied by an increase in the potential energy of the fluid owing to the increasing Van der Waals attraction at a larger atomic separation. As such, in order for enthalpy to remain constant across the throttle (which is observed in a Joule–Thomson expansion), the thermal kinetic energy of the fluid post throttle must reduce to accommodate this increase in potential energy, ultimately generating a cooling effect in the system. The throttling process also corresponds a phase-transformation where, in the case of CO2, LCO2 becomes a combination of 60% solid (generally in the form of CO2 “snow”) and 40% gas [7], which equally has a novel impact upon the mode of cooling, and the machining process in general.

Figure 1.

Adapted CO2 pressure–temperature phase diagram. Reprinted from reference [8].

3.3. Motivation for CO2 Coolants

Whilst LN2 can be shown to outperform conventional MWF’s across a broad range of performance indices (i.e., demonstrated improvements to tool life, surface integrity, etc.), the current research landscape has largely made strides to transition away from LN2, and instead focus upon CO2; this is likely a consequence of the following factors:

- By using CO2 coolants, there is a reduced risk of cold burns to the operator due to their delivery at ambient temperature.

- CO2 coolant strategies do not create the same work-holding complexities as LN2 coolant strategies owing to their higher temperature and more localised application.

- LN2 coolants can impede the normal operation of the machining centre, i.e., by freezing the lubricating grease on the spindle; CO2 is not associated with the same risks.

- CO2 storage does not require the use of an insulated pressure vessel and pipe network, making the process of designing and retrofitting machining centres with CO2 more convenient than is the case with LN2.

- Due to the extreme cold, there is a risk of near surface microstructural transformation when using LN2 coolants, this may be mitigated with CO2.

4. Sustainability of CO2 Coolants

Although the performance benefits of cryogenic cooling strategies are highly contingent upon a range of a factors, from a sustainability standpoint, their benefits are much more widespread. Whilst emulsion cooling has been able to meet a range of performance indices (i.e., long tool life, low surface roughness and cutting forces), it remains a highly imperfect solution from an ergonomic and environmental perspective. So much so that a large portion of the research into cryogenic cutting fluids is primarily motivated by the ultimate unsustainability of conventional MWF’s rather than a commercial desire to reduce operating costs (although, this is clearly a significant auxiliary benefit). As such, the following section examines a range of cited sustainability issues associated with the use of conventional MWF’s, and thereafter explores the ways in which these issues are entirely, or partially, mitigated by cryogenic MWF strategies. Moreover, the section will additionally outline the processing route by which CO2 is obtained, as well as address any concerns associated with the abundant release of CO2 into the atmosphere (as is associated with its use as an MWF).

4.1. Environmental Implications of CO2 Coolants

Given that CO2 is a greenhouse gas, it is reasonable to assume that should it displace conventional emulsion coolant strategies, the net release of CO2 into the atmosphere would invariably increase in concert. This is a particularly concerning proposition given that the UN’s Intergovernmental Panel on Climate Change (IPCC) has stated that a 45% reduction in global net CO2 emission is necessary (by 2030) to meet global warming targets [9]. Clearly, on the surface, these concerns make intuitive sense. Unrestricted CO2 usage would seem to be a significant backwards step in meeting the UN’s lofty climate change goals; however, it is the argument of the author that these concerns are a consequence of a fundamental misunderstanding of the CO2 processing route. If CO2 was indeed purposefully generated in order to meet coolant needs, this would be a pertinent point; however, this is not the case. In reality, CO2 is generated in a range of essential industrial processes (i.e., in the production of ammonia and alcohol), and is ordinarily released into the atmosphere at the point of production. By instead reclaiming this CO2 for use in MWF’s (amongst other things), the rate of CO2 production is unchanged relative to its baseline industrial production, and as such, the otherwise wasted CO2 now serves a purpose prior to being released into the atmosphere (as it ordinarily would be). Ultimately, the only additional energy expenditure associated with CO2 as an MWF comes from that which is consumed in the recycling process; otherwise, its use corresponds to a net zero change in emissions relative to the industrial baseline. The use of CO2 coolants could also lead to an overall lower carbon footprint of the machining process, since the targeted application of such coolants could lead to increased throughput of the machining process. Furthermore, carbon capture techniques could be used to recycle and reuse the CO2 used in the machining process.

In contrast with the sentiments of the previous paragraph, the use of emulsion and oil-based coolants can be extremely problematic from an environmental sustainability standpoint. Whilst mineral oils were once regarded as an inconvenient by-product of petroleum production, this is no longer the case. In fact, it can be reasonably suggested that the vast demand for mineral oils serves as an ancillary driving force for the crude oil industry. Of course, many of the concerns associated with the crude oil industry can be subverted by formulating MWF’s that are comprised of oils which are non-derivative of mineral oil, i.e., vegetable oils and synthetic formulations. Indeed, whilst synthetic and vegetable oil-based MWF’s are generally more expensive, this statement is largely correct, and in fact, many high performance MWF’s are formulated without the use of mineral oil. Despite the improved solution offered by synthetic oil formulations, there nonetheless persists a range of problems that apply to both synthetic, mineral and vegetable oil-based MWF’s, not least of which the issue of their ultimate disposal.

Whilst cryogenic MWF’s re-enter the atmosphere after a given machining cycle, conventional MWF’s are repeatedly recirculated in the machining centre. Although this is a comparatively environmentally frugal system of coolant delivery relative to single use, oil-based coolant strategies, it fails to address the issue of the ultimate disposal of the MWF. This disposal becomes necessary as the coolant is recycled throughout the machine owing to a degradation in quality by means of microbial, and processing by-product contamination [10]. In fact, in a 1988 article, this degradation is explained as an intuitive consequence of the underlying MWF chemistry, whereby “mineral oil base stocks, glycols, fatty acid soaps, amines and other metalworking fluid concentrates” are said to “provide all of the essential nutrients required for growth” of bacterial and fungal organisms [11]. Whilst this ultimate microbial spoilage is necessary to facilitate the ultimate biodegradation of the fluid, it equally accompanies a range of adverse implications for machine operation, some of which include:

- Reduction in emulsion stability.

- Increased propensity to contribute to workpiece, or machine corrosion.

- Decrease in MWF pH (and thereby, increased alkalinity of the fluid).

- Clogging of coolant delivery system including MWF lines and screens.

- Reductions in tool life.

- Development of an unpleasant odour.

In addition to these consequences, microbial spoilage corresponds to an increased incidence of dermatitis and skin irritation; however, this is explored in greater detail in Section 4.2.

Evidently there exists a range of problems associated with the prolonged use of spent coolant. In order to subvert these concerns, machine coolant reservoirs must frequently be drained, cleaned and replenished with fresh MWF, whilst the spent coolant should be disposed of, or recycled in an environmentally cognisant manner. The process of cleaning an MWF system is, however, not without its concerns. A common cleaning protocol involves the use of compressed airlines and/or the administration of synthetic cleaning products, which are often harmful to life [12]. Whilst this use of compressed air is effective in displacing MWF biofilm and clogged particulates, it equally leads to the mobilising of a rancid MWF mist, corresponding to the generally poor ergonomics of the cleaning process. This phenomenon is equally concerning given the often small, or confined working areas associated with machine shop floors, whereby fresh, uncontaminated air is often unable to easily recirculate. Moreover, this cleaning protocol is generally iterative and may have to be repeated several times until the extent of bacterial contamination is satisfactorily reduced (as tested by a dip slide). In addition to the challenging cleaning protocol, the recycling process by which MWFs are treated is typically extremely convoluted and, in general, requires the adoption of a robust separation procedure. Whilst there are currently a range of developments being explored in the treatment of spent MWF (i.e., nanofiltration, ion exchange resins, etc.), the general processing route by which spent MWF’s are treated still largely fails to generate a reusable MWF, but rather, a less hazardous waste substance which can be disposed of in a more financially, or environmentally sustainable manner [13]. For these reasons, the use of cryogenic MWFs, which return to the atmosphere post use, is of clear benefit in terms of the relative reduction in environmental, financial and time cost to the manufacturing sector.

4.2. Social Implications of CO2 Coolants

As an aside to the environmental limitations of conventional MWFs, their usage is equally accompanied by a range of negative health repercussions, persisting during handling, use and ultimate disposal. Whilst it is true that CO2 usage as an MWF (and elsewhere) creates a non-negligible risk of asphyxiation, this health concern can largely be mitigated by reasonable precaution such as the use of proper ventilation and local O2/CO2 monitoring systems. By contrast, conventional MWFs present a much broader encompassing range of health concerns, elevated in part by their capacity for contact exposure via a range of media (primarily dermal, ocular and via inhalation). As dermal contact has been shown to account for as much as 80% of the occupational risk of MWFs [14], it is unsurprising that research into the negative health implications of cutting fluids has, historically, been heavily focused upon the deleterious effect of MWFs on skin health. One 2014 systematic review [15] notes currently established causal links between cutting fluids and the following skin conditions: irritant contact dermatitis, allergic contact dermatitis, folliculitis, oil acne, keratosis and carcinomas. Despite these concerns, much of the risk to skin health can effectively be mitigated by the combined protocol of wearing suitable gloves and adopting a thorough hand cleanliness routine. Whilst this strategy is simple, skin conditions such as those outlined previously are often extremely prevalent in the manufacturing sector. This is likely a consequence of poor adherence to the PPE guidelines, an assertion supported by a 2012 survey that found that 82% of safety professionals had observed a failure to use the requisite PPE in their workplace [16]. Clearly it is unrealistic to expect universal adherence to even the simplest of PPE guidelines, and as such, the negative dermal implications of conventional MWF’s persist where they could otherwise be avoided by employing cryogenic cooling strategies.

In addition to the development of skin conditions, MWFs are linked to a range of ocular and respiratory conditions of varying severity. In general, the respiratory conditions associated with MWFs exposure are primarily a consequence of the inhalation of a fine particulate mist, which is generated as the MWF evaporates. Thereafter, either the MWF suspension or a fine atomised aerosol of non-aqueous MWF constituents (as water and water-soluble constituents are vaporised) is inhaled by individuals proximal to the machine. The consequences of which manifest as a range of negative health implications largely, but not entirely, focused upon the respiratory tract, including: airway irritation, chronic bronchitis, asthma, laryngeal cancer, alveolitis, and more abstractly, cancers of the pancreas, rectum and prostate [15]. Although these concerns could, in part, be addressed by the implementation of respirators, or even by assuring proper machine shop ventilation, this remains far from the industrial norm, with respirator use in machining typically being confined to grinding scenarios, wherein the goal is simply to filter out machined chips/dust, rather than MWF mist. Although these issues are perhaps the most severe of the negative health implications associated with MWF exposure, eye irritation, though non-permanent, is equally common amongst machinists. This ocular exposure to MWF can be extremely painful, particularly when contact results from direct splashing of the eye (as opposed to airborne particulates) [17], and necessitates the use of safety glasses. Whilst the use of safety glasses should equally be encouraged during cryogenic machining (owing to the risk of swarf projection), it is reasonable to assume that both the respiratory and ocular risks of cryogenic MWFs are invariably reduced.

4.3. Economic Implications of CO2 Coolants

Whilst the use of cryogenic MWFs is incentivised by a multiplicity of environmental, operational and social factors, their widespread adoption in industry will of course be subject to their financial viability. Indeed, if a company is to convert to, or supplement their existing MWF strategies with, CO2, there are a range of set-up and running costs that have to be weighed against the relative benefits of the strategy. With regard to set-up, at the moment, each machine must be retrofitted with a CO2 coolant delivery system and both volumetric and Coriolis flow meters (i.e., Fusion Coolant Systems Pure Cut ©); of course, the cost of which is, at this point, relatively significant. With that being said, it is almost always the case that the early adoption and implementation of an emerging technology is costly; however this is not likely to be restrictive in the long term for two primary reasons. Foremost, it seems likely that the initial capital outlay will reduce as machining centres begin to be built from stock with integrated CO2 coolant systems, or equivalently, as the option to incorporate a CO2 coolant system as a manufacturer add-on becomes available (in the same way that high pressure coolant is often available as an add-on). Secondly, and perhaps most importantly, it is clear that if marginal improvements can be made to the productivity of the manufacturing sector, i.e., by reducing lead time via the use of more aggressive feeds and speeds or, equally by reducing machine down time via fewer tool changes, the cost saving incurred by adopters of the technology would invariably far surpass this initial capital outlay.

In addition to the initial capital outlay associated with the purchase of the coolant system, it is also important to consider the operating costs associated with large-scale CO2 consumption and, additionally, the practicalities associated with the supply of suitable tooling. On the topic of CO2 consumption, the cost of small-scale CO2 usage is generally relatively high compared to the low cost of conventional MWFs. As such, it would likely be the case that the machine shop would be supported by a large cryogenic tanker retrofitted to the externalities of the premises. The tanker would thereafter be filled on site by a CO2 supplier. In adopting this strategy, the machine shop would be able to benefit from significant economies of scale relative to small scale purchase of CO2 pallets, wherein pallet rental, refill and delivery costs become significantly cost restrictive. With regard to the availability of tooling, in much of the cryogenic machining research, bespoke tool holders are employed to accommodate the CO2 nozzle. Whilst this is suitable for small scale research, it is unsurprisingly not cost effective. This, however, is again a consequence of the infancy of the technology and the limited demand placed upon tooling manufacturers to produce tool holders capable of CO2 cooling. It is thus likely that, as CO2 cooling strategies become more commonplace, new ‘off the shelf’ tooling will be developed in concert: a hypothesis supported by patents filed by both SECO [18] and Kennametal [19] to protect their prospective tool holders and the novel CO2 nozzle configurations that they will employ.

Although the initial capital outlay associated with the use of CO2 cooling strategies is non-trivial, it is worthwhile to consider the multitude of ways in which these costs can be recouped. As such, it is important to outline the ways in which CO2 MWF strategies can avoid the operational shortcomings of conventional MWFs and subsequently benefit from improved economic sustainability. With this in mind, it is noteworthy that one of the primary driving forces of cryogenic MWF research is an intent to find operationally superior MWFs, so that tool life can be prolonged. It thus follows that more aggressive feeds and speeds may be employed, and subsequently cycle time significantly reduced. In doing so, it is likely that less energy would be consumed in the machining process, and by proxy, both expenditure and carbon footprint should be reduced in kind.

Another benefit of CO2 MWF strategies is the avoidance of post-process cleaning. This has the potential to incur a significant cost saving as, in many safety critical applications, parts are unable to enter service with a cutting fluid residue. There are a range of reasons for this, primarily focused upon the altered component tribology as well as general cleanliness and ease of handling. These cleaning procedures generally add a significant amount of lead time to the (often) already sedate process of manufacturing safety critical components, and as such, have a clear downstream impact upon the supply chain, and subsequently the cost per component (and ultimate cost of the overall system). This is a factor that can be entirely subverted by the preferential use of cryogenic cooling strategies (in lieu of conventional MWFs), wherein no residue remains post machining, but rather the coolant dissolves and returns to the atmosphere. Moreover, this benefit of cryogenic machining strategies may persist even in cases of machining with CO2 + MQL, where, by design, MQL leaves little to no residue on the final machined component.

Evidently, the range of problems discussed makes for a compelling argument for the deracination of conventional MWFs (in favour of cryogenic fluids). Although the current widespread use of conventional cutting fluids is born of necessity, it is clear that such strategies are not only unsustainable, but equally, are potentially operationally sub-optimal across a range of performance indices (Section 5).

5. Applications of CO2 MWF Strategies

The following work has been categorised according to the workpiece materials that are considered in a given article, such that the first section focuses upon the use of CO2 MWFs for the machining of steels, the second section focuses upon titanium alloys and the third considers any other material species that have been the subject of research. The order is of materials is chosen to be coincident with the volume of research that is available on a given material, wherein steels and titanium alloys are subject to the most research in the field. In addition to the research outlined in Section 5.1, Section 5.2 and Section 5.3, there are a small number of articles that consider multiple materials [20,21,22]. As these articles serve as important case studies for use in determining the relative cryogenic machinability of a given material (and do not easily fit into the proceeding sections), they are retained for Section 6.

5.1. CO2 Machining of Steels

For almost two centuries, steels have found a broad range of applications owing to their high strength and durability. For these reasons, it is intuitive that a significant portion of the cryogenic research landscape would be focused upon the machining of steel, and indeed this has historically proven to be the case. In recent times, these articles have generally focused upon the use of CO2 cooling to improve the machinability otherwise generated by conventional MWFs. Such research is often motivated by the early success of LN2 as an MWF for the machining of steel. Some of these trials are discussed in the following section, where they have been selected to provide a variety of steel species and to cover a range of research interests within the field of cryogenic machining.

In order to understand the fundamental physics of CO2 as an MWF, it is useful to adopt a reductionist strategy towards the employed machining model. This approach was recently undertaken by Rahim et al. [23], who examined the impact of a scCO2 MWF in the context of the orthogonal cutting of AISI 1045 medium carbon steel. The performance of said cryogenic coolant was thereafter measured across four primary performance indices (cutting force, chip thickness, tool-chip contact length and cutting temperature) and compared to an equivalent machining trial undertaken with MQL (where MQL was chosen as a competitive sustainable machining strategy). The paper notes that the scCO2 machining strategy leads to 5–14% lower cutting forces, 0.5–2.5% thinner chips, 1–10% shorter tool-chip contact length and 15–30% lower cutting temperature than the MQL condition. Each of these variables is heavily correlated to machinability. Foremost, lower cutting forces are beneficial for a range of reasons including improving system dynamics and reducing tool holder deflection (thereby improving dimensional accuracy); thinner chips tend to be more breakable and, as such, pose a significant chip handling benefit. A shorter tool-chip contact length infers lower friction (and thus, superior lubricity). Finally, lower cutting temperature corresponds to the reduced severity of diffusion dominated wear mechanisms and allows the retention of a strong cutting edge. These findings make for a strong mechanistic rationale for the use of CO2 as a cutting fluid, and further, leave a strong foundation upon which research with a higher degree of specificity to real, practical machining set-ups can be built.

A preceding paper by the same authors [24] utilised a similar set-up to trial the effectiveness of scCO2 and scCO2 + MQL as an MWF strategy for the turning of, again, AISI 1045 medium carbon steel. In this trial, the performance of the coolant was quantified according to the cutting temperature, cutting force and the surface roughness. Again, performance was compared to MQL in isolation. The paper noted that the use of a scCO2 coolant was able to generate a reduction in cutting temperature of 6–30%, dependent upon presence (or lack thereof) of MQL, nozzle configuration and proximity to the cut, where the tool cooled with scCO2 in isolation generated a lower cutting temperature. Despite scCO2 in isolation generating the lowest temperature of the three coolant configurations trialled, the scCO2 + MQL strategy corresponded to the lowest cutting force and surface roughness of the three strategies trialled. These findings further build upon the prospective positive impact of the usage of scCO2 as an MWF, or in supplement to the use of MQL.

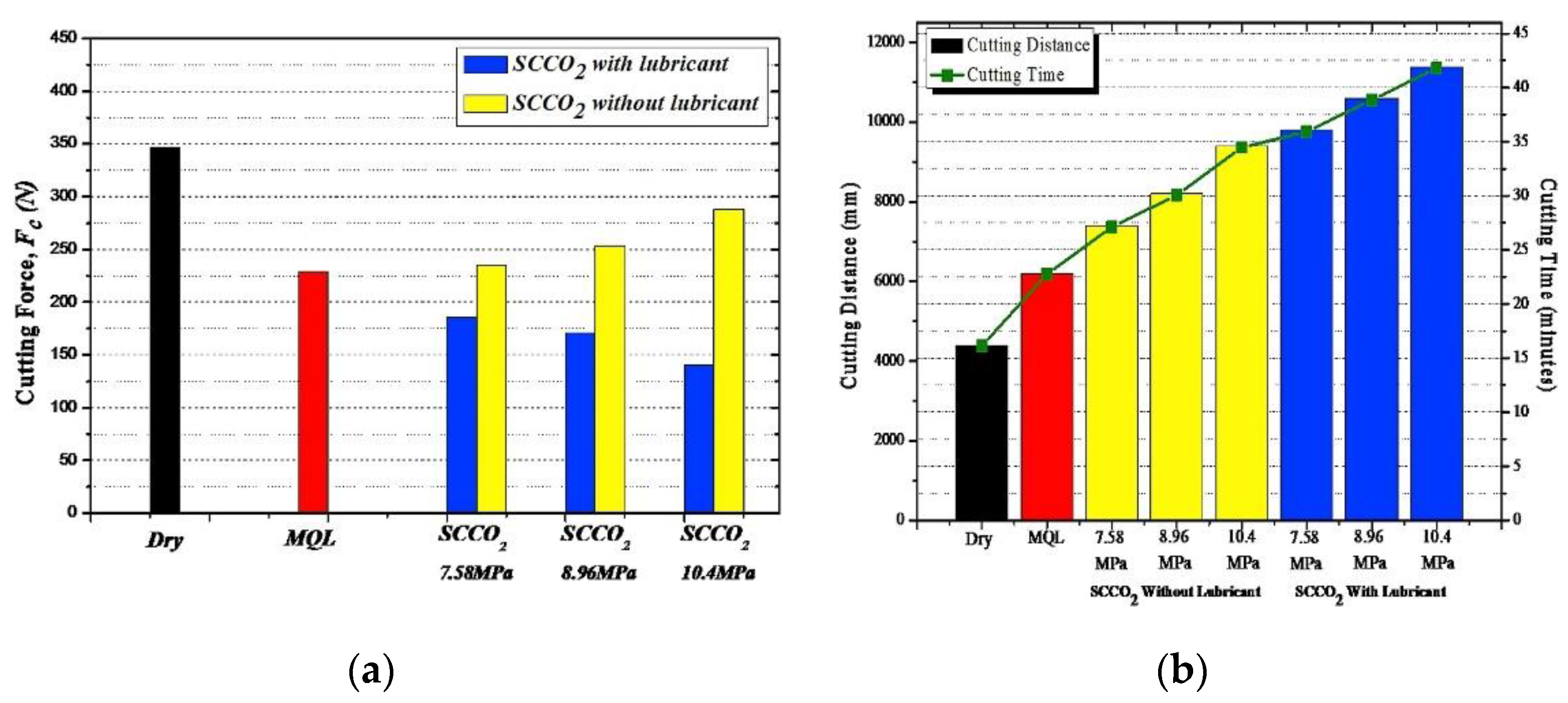

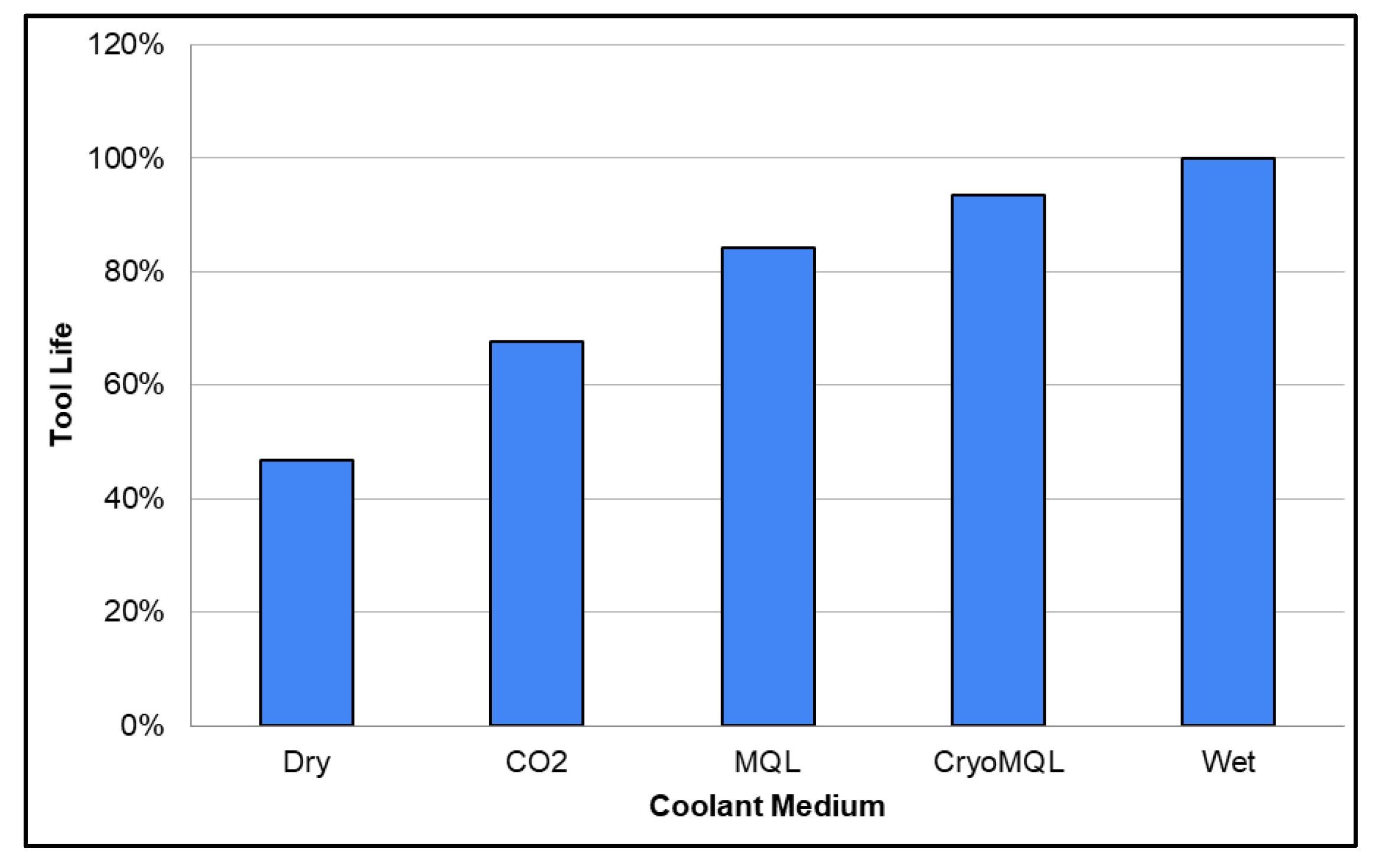

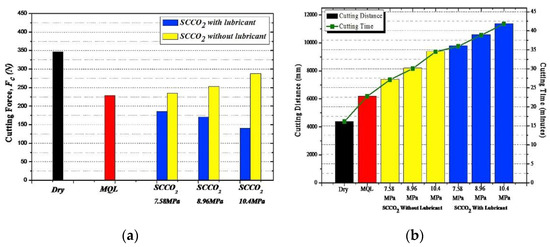

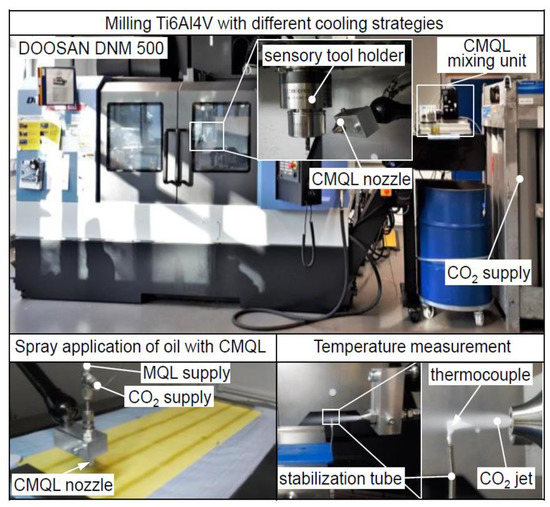

Whilst AISI 1045 steel is extremely well researched, other steel species are increasingly being considered, one such novel species being that of high thermal conductivity steel (HTCS). As part of their 2017 paper, Mulyana et al. [25] compared the performance of scCO2 to MQL and dry machining in the milling of HTCS. In accordance with the previous research undertaken by Rahim et al. [23], the authors considered the impact of cutting fluid on temperature, cutting force and tool wear in addition to considering the underlying wear mechanisms associated with the machining process (by the assigned MWF). The author noted that across all major performance metrics, MQL, scCO2 and scCO2 + MQL outperformed dry machining and, further, each cryogenic strategy outperformed MQL in isolation. With regard to both cutting force and tool life, the scCO2 + MQL strategy led to the best performance, generating 28–64% lower cutting forces and 60–85% longer tool life relative to MQL in isolation (Figure 2). Moreover, in each of the three performance indices considered in the paper (cutting force, tool life and cutting temperature), elevated scCO2 input chamber pressure corresponded to superior performance. The author reasons that this phenomenon is a consequence of the elevated density of scCO2 and higher volumetric flow rate of MQL.

Figure 2.

Graphs to show the variation in: (a) cutting force, (b) cutting distance with coolant and scCO2 input chamber pressure. Reprinted with permission from reference [25], Copyright 2000 Elsevier.

In a 2014 conference proceeding, Cordes et al. [26] outlined a novel strategy for the internal, selective, multi-channel supply of LCO2, MQL or a combination of the two. As part of the proceedings, they trialled their tool holder configuration in the machining of 1.4962 stainless steel. The article employed a “radial multiaxial turn milling strategy” (as is common in the roughing of aerofoils), where the extent of tool wear was measured at the end of the roughing cycle of one blade and thereafter compared to dry machining. Ultimately the obtained tool life was inferred to be vastly increased by the application of a CO2 coolant. This inference came as a consequence of the cryogenic cooling strategy corresponding to a 63% lower flank wear (after one pass). Interestingly, the authors then went on to increase the cutting speed and feed rate of the cryogenic machining strategy to the point of which flank wear (after one pass) was equivalent to that which was observed in dry machining. They note that a 37.5% increase in feed rate and a 25% increase in cutting speed were required to elevate flank wear to that of the dry machining trial. In such a scenario, material removal rate (MRR) was increased by 72%, outlining the potential of CO2 cooling in increasing the productivity of the manufacturing sector.

Similarly, in 2019, Fernández et al. [20] published a paper considering the application of CO2 as an MWF in the cryogenic face milling of hard-to-cut materials. As part of their research, they undertook tool life testing on grade EA1N steel when machined with gaseous CO2, indexing its performance against the tool life obtained by a Hysol XF (6–8%) emulsion. The authors noted that whilst the underlying wear mechanism, which led to tool failure, was, in both cases, abrasion, the rate at which the tool became abrasively worn was significantly reduced in the cryogenic trial. Moreover, in accordance with ISO 8688-1:1989, the authors utilised a tool life criterion wherein tool failure was inferred by insert fracture. As such, the article notes that CO2 cooling is able to generate a 175% longer tool life than that obtained by a conventional emulsion strategy. This finding is of particular interest owing to the authors observing a favourable comparison between the performance of CO2 and emulsion (rather than dry machining), which is generally best practice for the machining of most materials.

As is outlined in the proceeding work, much of the research that has thus far been conducted has focused upon the machining of steels, and although there remains a great deal of novelty yet to be explored, the field is becoming increasingly well understood. Whilst this is of great utility in the sense that steel is an extremely popular engineering material, it fails to address the demands of many performance-driven engineering sectors, namely aerospace, motorsport and biomedical. In many of these scenarios, weight restrictions are implicated into the design process and, as such, specific, rather than generic, mechanical properties are of great importance. As these applications are (in general) driven by factors such as performance and lead time (as opposed to cost and durability), they are generally better positioned to become early adopters of technological advancements in the manufacturing sector or elsewhere. For this reason, it is intuitive that early research efforts focus more heavily upon high-performance materials such as titanium alloys, nickel-based superalloys, composites, etc. Consequently, the proceeding work examines CO2 as an MWF in the context of these aforementioned materials.

5.2. CO2 Machining of Titanium Alloys

As a consequence of their remarkable mechanical properties, corrosion resistance and ability to function effectively at elevated temperatures, titanium alloys have become commonplace at the high-performance end of the engineering sector. Although these exceptional properties allow titanium alloys to serve a broad range of demanding applications, they equally correspond to poor machinability. For this reason, it is intuitive that titanium alloys would be the focus of a great deal of cryogenic machining research, and indeed this has proven to be the case. Whilst the cryogenic machining of titanium is undoubtedly an area of significant research, many of the articles published focus specifically on Ti-6Al-4V [27,28,29,30]. Although this research direction is intuitive based upon Ti-6Al-4V being the most popular titanium alloy (accounting for 50% of titanium production worldwide as of April 2020) [31], there remains a great degree of novelty to be explored in the machining of more exotic titanium alloys. The proceeding section is dedicated to the current portion of the research landscape focused upon the cryogenic machining of titanium alloys with CO2 MWF strategies.

In much of the cryogenic machining research currently available, there is significant variance in the relative performance of the coolant strategies employed. To give an example, in 2016, Sadik et al. [32] published an article examining the use of LCO2 as an MWF for the cryogenic face milling of Ti-6Al-4V. In the article, the authors note a tool life increase of 250–350% when LCO2 was applied in lieu of an emulsion flood cooling strategy. In contrast, to the strong performance of CO2 in the research of Sadik et al., the later work of Tapoglou and colleagues [7] noted that CO2 failed to compare favourably to conventional (emulsion based) MWF strategies. In their research, Tapoglou and colleagues undertook shoulder end-milling trials on a Starrag LX051, 5-axis horizontal milling centre employing a LCO2 cooling strategy. In contrast with the significant tool life improvements experienced by Sadik et al., Tapoglou observed markedly inferior tool life when utilizing both CO2 in isolation and CO2 + MQL strategies (in comparison to a both a flood and medium pressure through tool emulsion cooling strategy). Tapoglou did, however, note that the use of a CO2 + MQL MWF strategy corresponded to an increase in tool life relative to both MQL and CO2 in isolation.

Further to the variability of the data, An et al. [33] undertook side-milling trials on Ti-64 with three CO2 MWF strategies: scCO2 in isolation, scCO2 with water based MQL and scCO2 with vegetable oil-based MQL. As part of the trial, An and colleagues measured (and simulated) flank wear, cutting torque and surface morphology, indexing performance against dry cutting conditions. The authors noted that the scCO2 strategy generated the most flank wear, followed by dry, scCO2 with water-based MQL and, finally, scCO2 with vegetable oil-based MQL. In the paper, An et al. hypothesises that the elevated wear state experienced during scCO2-only machining strategy is likely a consequence of increased friction at the tool-workpiece interface, thermal cyclic fatigue and adhered chips accumulating on the tool. Interestingly, the extent to which flank wear was reduced by the scCO2 + MQL strategies, relative to dry machining, was extremely marginal, wherein the difference in flank wear between the three strategies fell within the variance of the data set.

It is clear that, whilst there are non-trivial differences in the experimental design of the three papers in question (differing cutting speeds, CO2 rather than LCO2, end-milling/side-milling rather than face milling, etc.), their nonetheless exists a clear variance in the findings of Sadik, Tapoglou and An et al. It is thus the opinion of the author that this is illustrative of the conditionality of the machinability outcomes that are achieved when employing CO2 MWF strategies. Further to this point, it is not immediately obvious as to which variables are of the most importance in manipulating performance indices such as tool life. For this reason, a compelling case is made to work towards establishing an appropriate processing window for CO2 MWF strategies in a range of different machining context. In doing so, the processing parameters that allow the cryogenic media to offer comparative (or superior) tool life to conventional means would be outlined, thereby allowing manufacturers to employ the most appropriate MWF strategy for a given application.

One of the few articles to consider non Ti-6Al-4V titanium alloy (CO2) machining was published in 2018 by Kaynak and Gharibi [34]. The paper was published with the outlook of examining the impact of LN2 and CO2 as MWF’s for the turning of Ti-5553 and as such, undertook trials with the following performance indices in mind: cutting temperature, tool wear and dimensional accuracy. Thereafter, the performance of each of the two media was compared against each other, in addition to a dry machining baseline. The authors observed that in both the CO2 and LN2 trials, the measured maximum temperature was shown to be significantly decreased relative to the dry machining trials, whilst LN2 cooling generally corresponded to a marginally lower maximum temperature than was observed in CO2 machining. Moreover, the authors observed a general trend in both cryogenic media reducing the extent of flank wear, noting that this effect was particularly exaggerated at elevated cutting speeds, where, at the maximum trialled cutting speed, CO2 cooling lead to a 22% reduction in flank wear (relative to dry machining) and LN2 a 59% reduction in flank wear. In addition, although both of the cryogenic media trialled led to improvements in dimensional accuracy, LN2 cooling corresponded to a lower maximum deviation from the nominal diameter than the CO2 strategy. Whilst this article generally points to the superior performance of LN2 (relative to CO2) in this context, it is important to note that both cutting force and feed force were most optimally reduced by the CO2 cooling strategy, whereby a noteworthy reduction was observed across the majority of cutting speeds. This reduction in feed force provides further evidence of the excellent lubricity, which can be obtained by employing CO2 cooling strategy in a machining context.

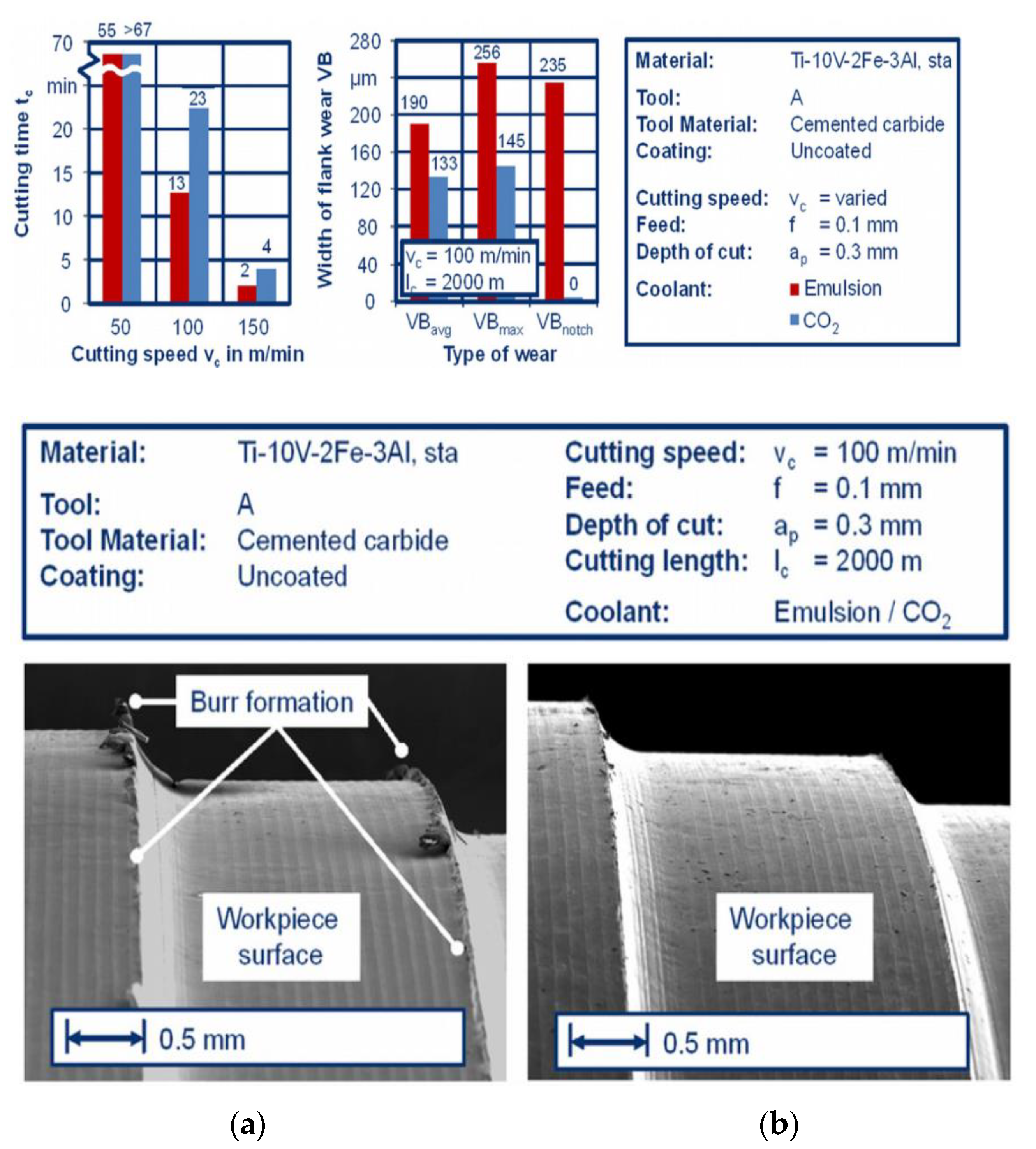

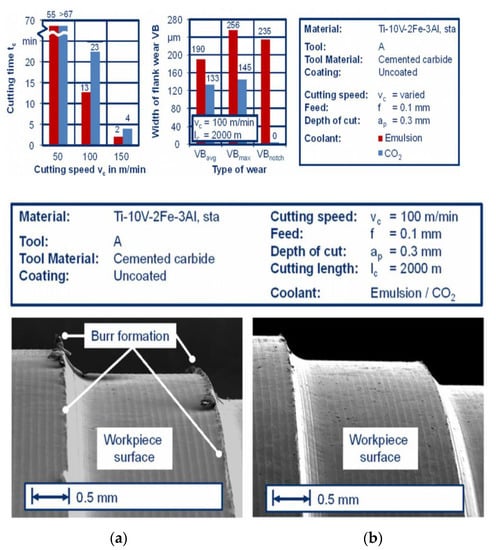

In addition to the work of Kaynak and Gharibi, Machai and Biermann [35] undertook cryogenic OD turning trails on Ti-10V-2Fe-3Al. The authors compared the tool life performance of CO2 snow (as a coolant) to an emulsion, flood coolant strategy. Moreover, Machai and Biermann went on to outline the transient wear progression of the cutting insert when subject to each media, as well as discuss the inherent mechanisms associated with said wear progression. The authors observed that the CO2 cooling strategy corresponded to increased tool life at each of the cutting speeds trialled (Figure 3); moreover, whilst the emulsion-cooled tool was subject to significant notch wear, the CO2 cooled tool was entirely devoid of notching. Moreover, CO2 cooling additionally contributed to reduced feed force during later machining passes, despite initially generating elevated radial forces, findings that have been observed elsewhere in the literature. In addition to the positive tool wear implications of CO2 cooling, Machai and Biermann observed that, during the later passes with emulsion cooling, burrs formed at the tools’ exit from the cutting zone; in contrast, no such burrs were observed during the CO2 machining trials (Figure 3). The authors went on to suggest that the presence of burrs (or lack thereof) was a consequence of the periodic impact of a worn, notched tool, and in this sense, the lack of burr formation in the CO2 trials is an intuitive finding.

Figure 3.

Tool wear and burr formation during the cryogenic machining of Ti-10V-2Fe-3Al. (a) Emulsion; (b) CO2. Reprinted with permission from reference [35], Copyright 2011 Elsevier.

In conclusion, the current landscape of the literature around titanium alloy machining remains, at this stage, inconclusive. Although some of the variability between the current research is undoubtedly a result of the differences in employed processing parameters (Section 6), the significant contrast between otherwise experimentally similar remains a challenge that must be addressed by the research community. Clearly, it is possible to establish a range of operating conditions with which CO2, or CO2 + MQL could be rendered the optimal MWF strategy for a given material; however, in the available research, the efficacy of CO2 cooling remains subjective. Further work should thus focus upon establishing a suitable operating range (for multiple titanium alloys), whereby CO2 is able to function as a suitable coolant. Moreover, should future research become more aligned with the findings of Tapoglou, it would undoubtedly be beneficial for researchers, who have an interest in the adoption of cryogenic machining technologies to further develop the consortium of literature studying the auxiliary benefits of CO2 as an MWF, rather than simply focusing upon tool life. Alternatively, it may also be beneficial to consider directing further research towards the cryogenic machining of alternative titanium alloys or even entirely new material species. With this recommendation in mind, the following section will consider current examples of CO2 usage as an MWF for the machining of various other material species.

5.3. Additional Applications of CO2 MWFs

Although steel and titanium alloys are the focus of a large portion of the current cryogenic machining literature, CO2 is speculated to function as a potentially efficacious MWF strategy for a range of other materials. As an example, in nickel-based superalloys, the combination of high hardness and low thermal conductivity leads to excessive heat forming in the cutting zone, and by proxy, the tool. This, in turn, leads to a litany of problems, not least of which are reduced tool life and thermally induced geometric distortion. Despite presenting a clear cause for concern, these challenges are certainly not unique to nickel-based superalloys, and in fact are commonplace in titanium alloy machining. Given this realisation, it is rational to extrapolate the potential benefits of CO2 in the machining of titanium alloys to a prospective application in the machining of nickel-based superalloys. Whilst this reasoning is undoubtedly useful in deciding upon the most likely avenues for future research, prior machining trials on mechanistically similar materials of course cannot be regarded as a direct citation of the efficacy of CO2 for new, unproven material species. For this reason, the use of CO2 as an MWF for the machining of nickel-based superalloys, whilst currently in its infancy, is proving to be a burgeoning field of cryogenic machining research.

Whilst superalloys have, in recent times, been the subject of an increasing number of promising cryogenic machining trials (with LN2) [36], CO2 trials are, despite being supported by a strong mechanistic rationale, relatively unexplored. Of the limited research that is currently available, results are generally mixed. In 2016, Busch et al. [21] undertook turning trials with coated CNMG 120,408 cemented carbide inserts on Inconel 718. The authors went on to compare the performance of both CO2 in isolation, and ADL + CO2 to a high-pressure emulsion coolant strategy, as is regarded as the current best practice for the machining of this material. The performance of the three coolant strategies were thereafter assessed primarily according to tool life, specific energy consumption and general machined surface quality. Whilst the authors noted a generally invariable energy consumption across each of the trialled media, both the CO2 and ADL + CO2 strategies generated markedly lower tool life relative to the use of high-pressure coolant. In addition to the poor tool life, the authors observed no clear chip handling benefit of ADL + CO2 and further went on to note the presence of adhered material at the machined surface when CO2 cooling was applied in isolation. Whilst the article makes note of the operational convenience of retrofitting a CO2 coolant delivery system, and equally the benefits of oil residue free machining, the paper states that any scope for the future efficacy of these CO2 cooling strategies will be reliant upon future optimisation to the delivery of the cryogenic media (and the ADL).

In addition to these findings, Patil et al. [37] also conducted CO2-assisted machining trials on Inconel 718. In accordance with the work of Bush et al. [21], the authors employed an OD turning model utilising TiAlN-coated SNMG120408-cemented carbide inserts. Thereafter, the authors examined both cutting forces and surface phenomena over a range of feeds and speeds, ultimately comparing the performance of CO2 cooling to a dry machining condition. Whilst the authors observed an increase in both cutting and feed forces when CO2 assistance was applied, this effect was observed to be of a much smaller magnitude than the impact of cutting speed and feed rate on tool force. Moreover, when compared to dry cutting, the presence of a CO2 MWF led to a reduced surface roughness. This effect is visible across all feeds and speeds; however, it was most pronounced at 0.1 mm/rev, 100 m/min. When surface integrity was further analysed (by way of taking microhardness measurements of the machined surfaces), the CO2 assisted trials corresponded to an increase in surface hardness (relative to bulk), whilst the dry machined surfaces were of equal or lesser hardness to the as-supplied bulk. The authors note that this finding is likely a consequence of the cold work hardening of the workpiece in the presence of CO2, presumably in lieu of the elevated microstructural recovery, which would otherwise be observed at elevated temperatures (as in dry machining). This increase in hardness is regarded, by both the authors of the study and others [6], to be a desirable outcome for improved surface integrity. Further, where increased surface and subsurface hardness has previously been observed (in the LN2 machining of Inconel 718) [38], it has been accompanied by higher compressive residual stress, which makes positive implications for fatigue life (via the inhibition of crack propagation).

Given the research of Busch and Patil [21,37], the holistic impact of CO2 coolants in the machining of Inconel 718 remains uncertain. Clearly, future research is necessary to optimise the operational parameters used in the CO2 machining of each workpiece material. This will likely involve optimising variables such as nozzle position, coolant flow rate, feed rate, cutting speed, tool material, tool geometry, etc. over a range of machining operations (Section 5). Moreover, whilst material classifications are helpful when analysing the density of research in a given domain, there remains no guarantee that similar species of material will behave similarly in an equivalent cryogenic machining context. In the case of superalloys specifically, although iron-, nickel- and cobalt-based superalloys are often employed in similar roles, their machinability is likely to vary in accordance with their metallurgical differences. Whilst this variability is likely to be most noticeable amongst dissimilarly based alloys, it will undoubtedly persist within each species. As an example, nickel-based superalloys used in aero-engine disks (i.e., RR1000) may, and likely will, exhibit markedly different machinability to alloys used in aero-engine turbine blades (i.e., Inconel 738LC) owing to their variation in mechanical, and thermal properties. For this reason, whilst a CO2 MWF may not be regarded as efficacious for one alloy, it may be wholly suitable for another.

Whilst the cryogenic machining of superalloys is a burgeoning field of research, there remains a mechanistic rationale for many other materials. In fact, many of the most thought-provoking avenues for future cryogenic machining research will invariably focus upon materials that otherwise are ineffectively machined by way of their material properties; one pertinent example being that of viscoelastic polymers such as polydimethylsiloxane (PDMS) or ultra-high molecular weight polyethylene (UHMWPE). In general, the high elasticity and susceptibility to adhesion make for a material that is challenging to machine by conventional means. These properties correspond to a litany of adverse machining outcomes including geometric deformation of the workpiece material and undesirable chip formation. Moreover, the propensity of polymeric material to adhere to the cutting tool often corresponds to an increase in effective edge radius, which in turn corresponds to a ploughed, rough surface (owing to the size effect). Despite this, with the rise of the burgeoning field of microfluidics, small scale, geometrically accurate polymeric chips are becoming increasingly necessitated, not least of which within the pharmaceutical industry, wherein they serve a range of roles including drug screening and metabolic research [39]. Currently, microfluidic chips are manufactured via micromolding techniques, whereby the micromolds are photolithographically formed in the polymeric substrate. Whilst this technique allows for accurate fabrication, the process is not easily customisable. As such, future iterations of a chip, or equally new chip geometries, generally necessitate the development of a new, bespoke mould. Given this reality, and with the rise of micromachining technology, cryogenic machining may prove to become a cost-effective strategy for the manufacture of viscoelastic polymers.

Where the cryogenic machining of polymers has been undertaken, the strategy generally involves either a workpiece pre-cooling strategy or, further, the submersion of the polymer during the machining process. This strategy takes advantage of the changed chip-formation mechanisms that occur below the glass transition temperature (Tg) of the polymer. In a 2015 paper by Aldwell et al. [40], UHMWPE was submerged in a vat of liquid nitrogen for a period of 24 h prior to turning. Thereafter, cutting force, surface roughness and chip morphology were measured in both the pre-cooled and room temperature billets. As a consequence of the elevated elastic modulus of the polymer (sub-Tg), cutting force was elevated when cryogenic-assisted machining was applied. Ordinarily, increased cutting force has negative implications for productivity; however, as tool life is of limited relevance in the small batch machining of polymers, surface quality is a much more vital parameter. In this regard, cryogenic pre-cooling was shown to be efficacious from a surface finish perspective, whereby mean surface roughness was reduced by more than 20% in the pre-cooled material. In addition, the authors generally observed a greater propensity to produce chips (rather than dust) when LN2 pre-cooling was employed. Although this effect was more apparent when worn tools were used, the finding is of potential utility to the manufacturing sector as, an inability to form chips is, in general, accompanied by an inability to dispel heat, which, particularly in the machining of polymers, can become extremely problematic.

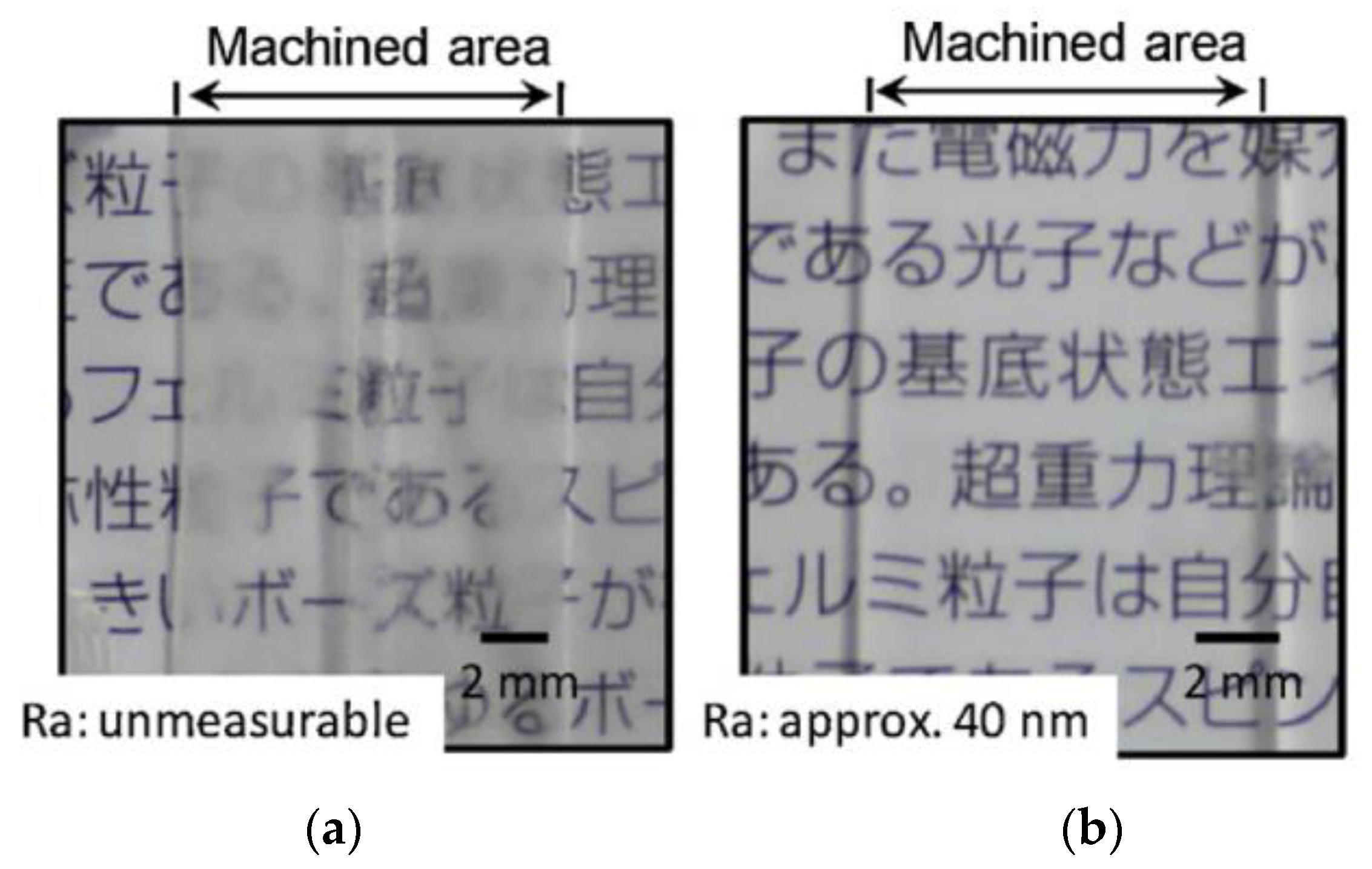

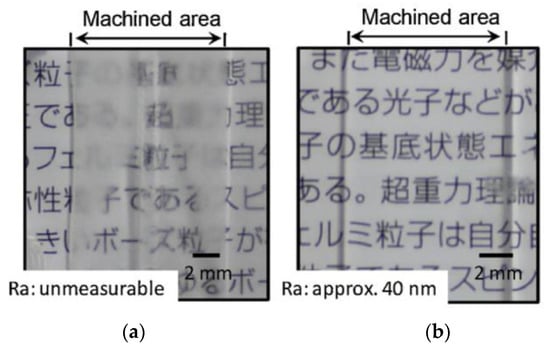

In addition to the research of Aldwell and colleagues, Kakinuma et al. published an article employing the micro-end milling of cryogenically cooled PDMS [41]. The authors utilised a complete emersion strategy wherein the both the (single crystal diamond) milling cutter and PDMS workpiece were submerged in a vat of liquid nitrogen; thereafter, a ductile mode milling strategy was employed with a varying depth of cut. By employing such a strategy, the PDMS workpiece is held below the glass transition temperature such that it retains properties of low adhesion and elasticity. In abstract, this allows the thermal deformation (which is implicit during a machining operation) to be suppressed, and thus form inaccuracies to be minimised. When machining trials were conducted, the authors observed that the large quantity of heat generated in the cutting operation was sufficient to vaporise the proximal LN2 and, subsequently, that the generated surface transparency was unsatisfactory. In response to this realisation, Kakinuma and colleagues went on to additionally apply cryogen directly to the cutting zone by way of LN2 jet. In doing so, heat flux into the workpiece was minimised, and subsequently a high-quality surface with lower opacity and surface roughness was generated (Figure 4). Given this success, the authors went on to machine a series of microfluidic chips with the outlined approach, noting benefits over micromolding processes such as a comparative ease in forming stepped channels and a generally far reduced lead time.

Figure 4.

A demonstration of machined surface quality in micro-milled PDMS. (a) LN2 immersion method; (b) LN2 immersion + external supply cooling method. Reprinted with permission from reference [41], Copyright 2012 Elsevier.

Ultimately, although cryogenic MWFs are mostly well researched in the context of steels and titanium alloys, it is apparent that their early success has birthed widespread interest. In addition to the strides that have been made in researching the cryogenic machining of superalloys and polymers, cryogenic methods have already been applied to magnesium alloys [42], cobalt-chromium alloys [43] and composites [44], garnering generally positive results. Moreover, with the current pace of research, it is likely that trials will expand further into various other niche materials and manufacturing processes. Fortunately, in this regard, various avenues of research still exist. As an example, one material that may be suitable for future machining trials is that of oxygen free copper (OFC). Whilst OFC parts are in demand as high-conductivity electronic components, they are often extremely difficult to machine owing to poor chip handling and subsequent surface integrity. Given the prior use of cryogenic-assisted machining for chip-breaking purposes in other materials, it is reasonable to foresee future machining trials on OFC. In addition to examining novel materials, it may be equally worthwhile to consider alternative manufacturing process (to those commonly employed in a cryogenic machining context) as an example, rather than turning and milling, broaching has the scope to be significantly augmented by the addition of cryogenic cooling. By way of an explanation, in many articles researching the effects of CO2 as an MWF, benefits (over flood coolant) are often relatively incremental. This incremental improvement in operational efficiency may be insufficient to justify the purchase of a CO2 delivery system to an SME manufacturing company with a turning or milling focus. In contrast, broaching operations generally feature extremely expensive tooling, and create a great deal of added value. As such, if incremental process improvements can be made (i.e., to tool life) by cryogenic assisted machining, ample financial motivation may be available for early adoption of the technology. To summarise, cryogenic-assisted machining is an extremely interesting field of research, which, given its current promise, has scope to become a disruptive technology in the near future.

6. Practical Factors Impacting the Performance of Cryogenic and CO2 MWFs

6.1. Workpiece and Tool Material

When reviewing cryogenic machining research, one of the most superficially apparent variables that dictates trial performance is the choice of workpiece material. In fact, it is reasonable to assume that the perception of success of a given research paper is, in absence of other compelling evidence, generally thought of as a consequence of the suitability, or lack thereof, of said workpiece material. Whilst this perception is somewhat short-sighted (given the extent to which cryogenic assisted machining trials can vary), the choice of machined material invariably plays a significant role in determining which MWF strategy is preferential for a given trial. Given this fact, it is unsurprising that this most fundamental dependency has been observed since the earliest iterations of cryogenic machining research. To be specific, the aforementioned work of Uehara and Kumagai [3,4] notes that a strategy of cryogenic pre and intra workpiece cooling lead to tool life improvements in both carbon steel and commercially pure titanium workpieces despite presenting no clear performance benefit in the context of stainless steel.

Needless to say, the trend of differing machining trial performance by workpiece material persists into the modern day and is in fact a topic of discussion in most, if not all, journal articles published in the field (not least of which this one). Despite this, it is also true that conclusions of workpiece suitability should not be equitably drawn from each cryogenic machining article on the basis of a lack of experimental control. In order to illustrate this point, take the example of two machining trials that both employ jet cooling, utilise equivalent feed rates, cutting speeds and depths of cut and consider two different workpiece materials (one per paper). In this example, it may seem appropriate to draw like for like comparisons between the two papers, particularly given their stark similarity. Whilst the results of these two papers would likely share some commonality, the problem with a direct comparison in this context is the invariable fact that across some parameters (i.e., tool nozzle diameter, or means/standards of measuring tool life), the employed experimental practice of the two papers will differ. Taking this into consideration, the most academically rigorous way to analyse the relative cryogenic machinability of different materials would involve the analysis of research papers that examine various material species in the one paper, or equivalently, those papers published as part of a research chronology by one set of authors (where DOE is unaltered). For this reason, Section 5, whilst citing papers utilising various materials, does not effectively serve to illustrate which materials are suited to cryogenic machining strategies. With this in mind, the following section employs such an approach with the outlook of understanding the conditionality with which different materials can be cryogenically machined.

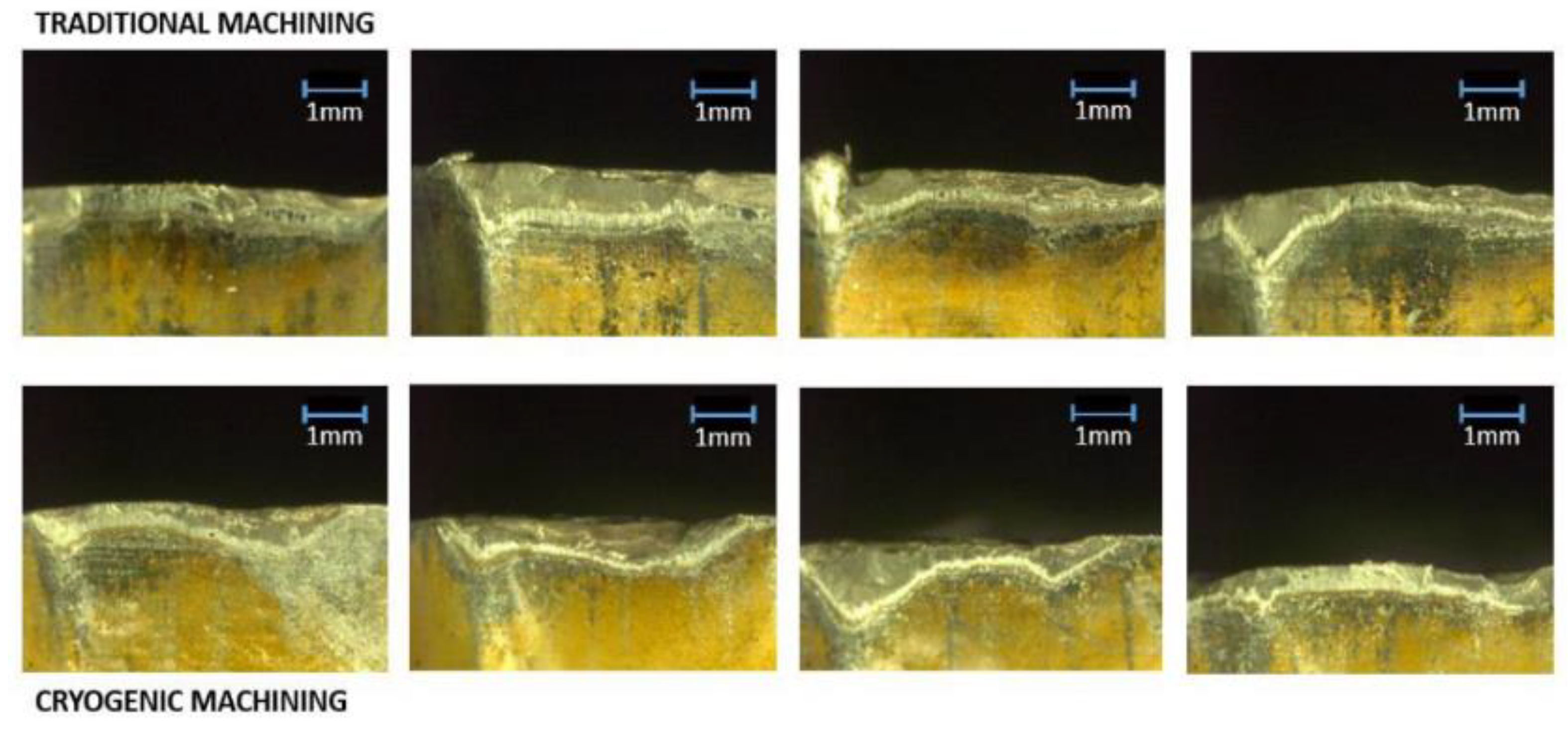

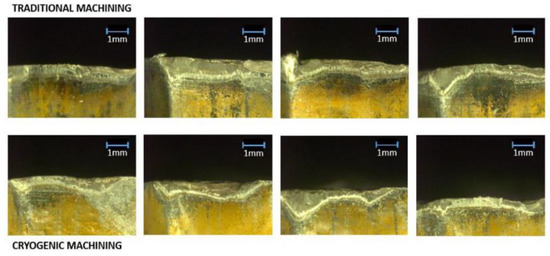

One paper that considered various materials was the aforementioned work of Fernández et al. [20]. In their article, Fernández and colleagues undertook the cryogenic face milling of three challenging-to-machine materials: Grade EA1N steel, gamma Ti-Al and Inconel 718. Interestingly, the authors observed markedly different (tool life) performance across each trialled material. In the case of Inconel 718, both the CO2 and emulsion strategies lead to equivalent tool life, such that the tools in both trials failed in each case after two machining passes (and a tool life of 5.3 min). Moreover, in both trials, the tools failed via a similar cracking mechanism said to be a consequence to the combined effects of abrasion adhesion and microchipping (Figure 5). In contrast, during the gamma Ti-Al trials, the authors observed that conventional emulsion cooling led to tool failure after the first machining pass, whilst the CO2 cooled tools generally had not failed prior to undertaking the second machining pass and thus achieved a projected 100% increase in tool life. This performance was shown to extend to the EA1N steel trials, wherein the cryogenic cooling strategy led to a 175% increase in tool life relative to emulsion flood cooling. Moreover, despite this significantly reduced rate of tool wear, wear mechanisms were, in both cases, found to be predominantly abrasive despite being markedly more aggressive in the emulsion cooled trials. Ultimately the results of this paper would seem to suggest that both EA1N steel and gamma Ti-Al may be more suitable for CO2-assisted machining than Inconel 718; however, this should be developed upon with further research.

Figure 5.

Worn inserts (at tool failure) during the machining of Inconel 718. Reprinted from reference [20].

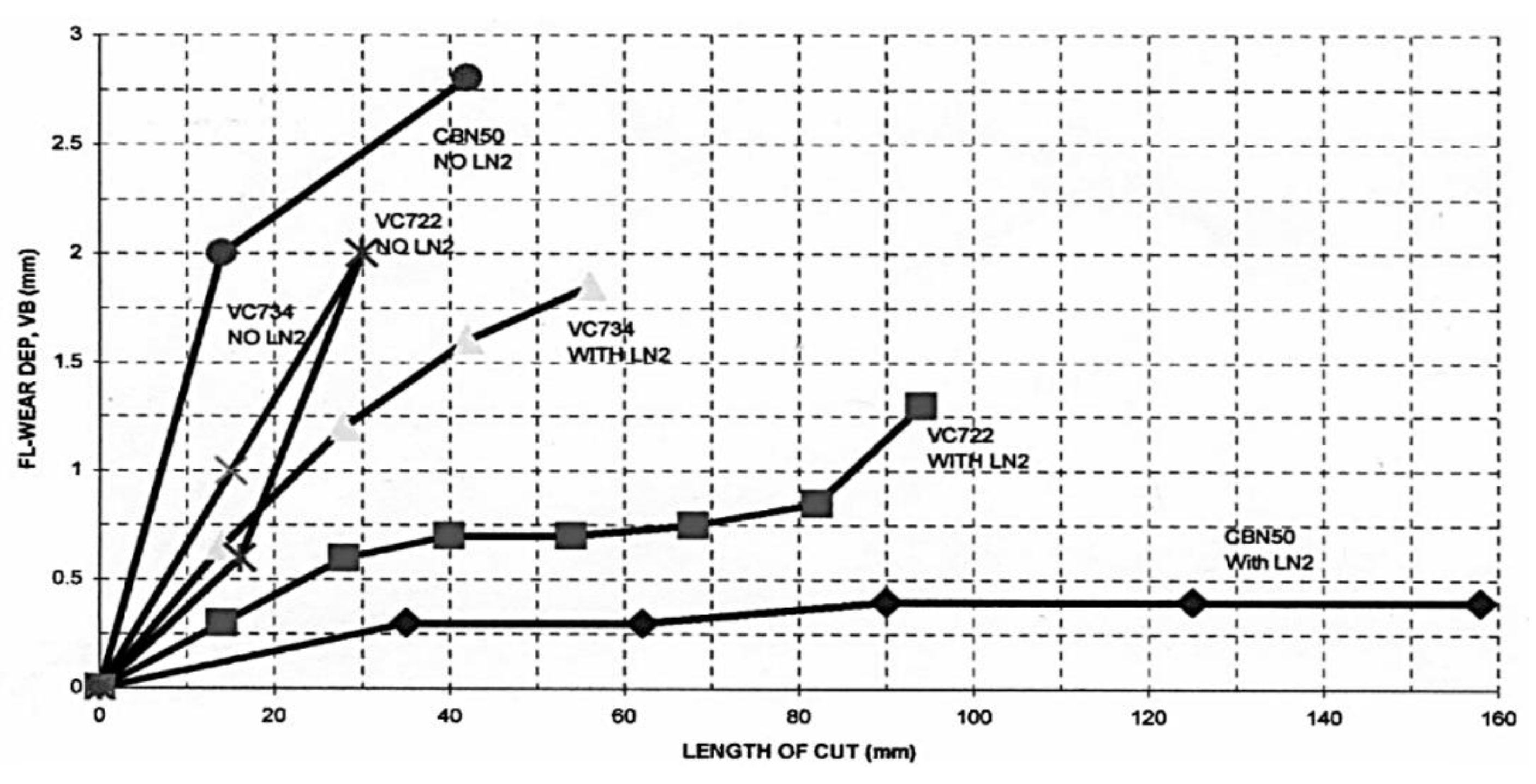

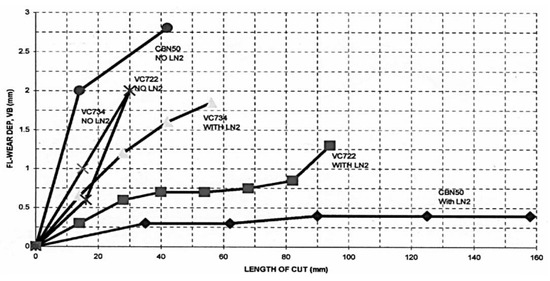

In addition to the work of Fernández and colleagues, an earlier paper by Wang and Rajurka [22] was published examining the cryogenic machinability of Ti-6Al-4V, Inconel 718, Reaction Bonded Silicon-Nitride (RBSN) and (commercially pure) Tantalum. The paper employed a simple turning model with two different tool materials, Cubic Boron Nitride and Cemented Tungsten Carbide (WC-8 wt%Co). In contrast to the more recent research of Fernández, the authors employed a LN2 remote-cooling strategy wherein LN2 was recirculated in close proximity to the cutting edge via a network of copper tubes in a proximal tool cover. As part of their research, the authors primarily focused upon tool life, in addition to cutting temperature (via a mounted thermocouple), surface roughness and cutting force.

During the machining of RBSN, three different varieties of CBN tools were employed, in all cases showing prolonged tool life during LN2 remote cooling (relative to dry machining). Despite this commonality, not all tools were equally positively implicated by the LN2 cooling strategy (Figure 6). Specifically, despite wearing most aggressively during dry machining, the CBN50 tool (produced by Sandvik) was most drastically impacted by LN2 cooling, wherein after completing the 158 mm cutting length (which was allocated to each tool), a sub 0.5 mm flank wear was observed. These promising results equally persisted during the turning of Ti-6Al-4V (with H13A WC-8 wt%Co tools), whereby an over five times increased cutting length was required of the LN2 cooled inserts to generate the equivalent flank wear to an ‘oil cooled’ equivalent.

Figure 6.

Wear progress curves during the machining of RBSN with three different CBN tools. Reprinted with permission from reference [22], Copyright 2000 Elsevier.

In addition to the trials conducted on RBSN and Ti-6Al-4V the author also considered the cryogenic machinability of Inconel 718 and Tantalum (with a H13A tool), again observing a markedly reduced rate of tool wear when LN2 cooling was employed (in lieu of dry machining). Despite this clear trend, it is difficult to accurately extrapolate tool life from the figures present in the report. In the case of Tantalum, at the points where the tools were equivalently worn, the magnitude of flank wear was extremely low, which of course raises questions as to the efficacy of any conclusions which are drawn. With this limitation in mind, it was nonetheless observed that the LN2-cooled tool required an approximately 90 mm cutting length to reach a flank wear of approximately 0.15 mm, whilst the uncooled tool reached such a wear state after only 20 mm (with LN2 cooling). Unfortunately, however, when Inconel 718 is considered, the scope to predict the impact of cutting fluid on tool life is further hampered, wherein the available data are not at any point coincident and thus insufficient to make a sober estimate.

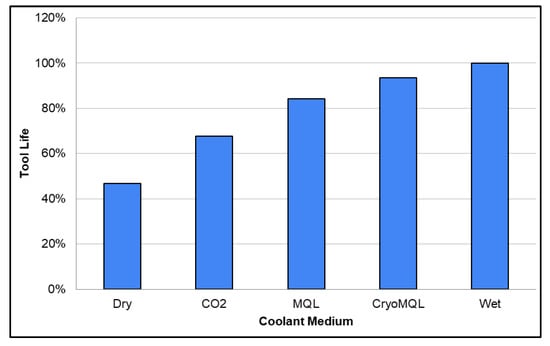

Whilst there are a limited number of papers to consider multiple workpiece materials, there are, of course, a few other examples of similarly inclined research, one such paper being that of Busch et al. [21], who conducted CO2-assisted OD turning of Inconel 718 and Ti-6Al-4V. In contrast to some of the earlier promising research, Busch and colleagues observed generally poor performance markers for CO2 cooling. The key observation made in this article (from a cryogenic machining perspective) was one of reduced tool life when CO2 cooling was used in lieu of high-pressure (HP) coolant. This phenomenon was somewhat more pronounced during their Inconel 718 trials. Specifically, the tool life obtained during the CO2 machining of Inconel 718 was almost 70% reduced relative to HP coolant, whilst the equivalent figure was closer to 60% in the Ti-6Al-4V trials. In this regard, the findings of Busch and colleagues are largely in keeping with the work of Wang and Rajurka, as both papers contribute to a future lack of candidacy of Inconel 718 for cryogenic machining research.

In summation, current research implies that Inconel 718 has, so far, not shown itself to be a particularly compelling candidate for future cryogenic machining research owing to generally poor susceptibility to cryogenic cooling, at least from a tool life perspective. Mechanistically, this may be a consequence of the markedly low thermal conductivity of Ni-based superalloys impeding the success with which CO2 is able to effectively cool the cutting zone; however, this of course must be supported by more substantive data. Importantly however, although Inconel 718 is not shown to be particularly promising in any of the previously considered research, the suitability or lack thereof of superalloys remains to be seen. In contrast, cryogenic machining strategies are, at this stage, shown to have some scope to improve the machinability of both titanium alloys and steels.

6.2. Feeds and Speeds

One of the most critical aspects in machining is the appropriate selection of cutting parameters in order to optimise the overall efficiency of a production process. This selection must take into consideration not only the material that is being processed, but also other factors including the cutting tool characteristics and more importantly the lubri-cooling technique employed and the delivery method. Different cooling techniques would result in different cutting temperatures and loads on the cutting tool; therefore, the cutting parameters would need to be adjusted to allow for optimal cutting conditions. Given this complexity, it is often desirable to encompass various feed rates and cutting speeds centred around estimated best practice data established in the literature, or via practical machining guidelines.

It is undeniable that the success (or lack thereof) a machining trial is highly contingent upon the operational parameters employed during said trial. It follows that the way in which cryogenic coolants are perceived in a trial could, and likely would, equally be dependent upon the use of appropriate feeds and speeds. It is also apparent that any feed rate and cutting speed data will be incredibly specific to the material being machined. As way of an example, one online machining data base [45] recommends a cutting speed of 175 m/min for the turning of austenitic stainless steel, whilst equivalently recommending speeds as high as 860 m/min for wrought aluminium alloys. Although this effect is quite clearly exaggerated by the choice of materials, similar implications would undoubtedly persist across more (mechanically) similar species, i.e., titanium and nickel alloys. Given this, it is thus crucial that an extensive dataset of cryogenic machining performance is developed for a range of feeds, speeds and materials. Unfortunately, such data are not currently available in the public domain, and as such, investment into CO2 cooling systems remains speculative until the research landscape is able to catch up.

6.3. Tool/Nozzle Design

When designing an experiment within the domain of machining science, one of the most important variables to optimise is the cutting tool. Often this takes the form of optimisation across parameters such as cutting insert material, tool geometry, tool holder design or nozzle configuration. Practically however, some of these variables are more easily established during experimentation. For example, if an experiment is not being run with the express intent of establishing novel tool materials (for use in a given context), it is likely that the chemical composition of the tool material is decided upon by external actors. To give a specific case, it is often taken as a given that the current best practice for the machining of challenging materials such as titanium and nickel alloys are cemented carbide tools. Of course, there remains a significant scope to optimise the specifics of the tool chemistry (e.g., WC-(Ti,Ta,Nb)C-(Co,Ni)); however, the nuance of tool composition is often removed from the experimental process by instead following the recommendations of a tool supplier (i.e., Sandvik, Seco or Kennametal), who generally offer tool compositions that have been optimised via extensive R&D to meet a range of similar machining challenges. With this in mind, and given both the relative complexity and financial (and informative) barriers to entry associated with tool composition optimisation, this section considers composition only in passing, instead focusing upon variables such as nozzle, tool and tool holder geometry.

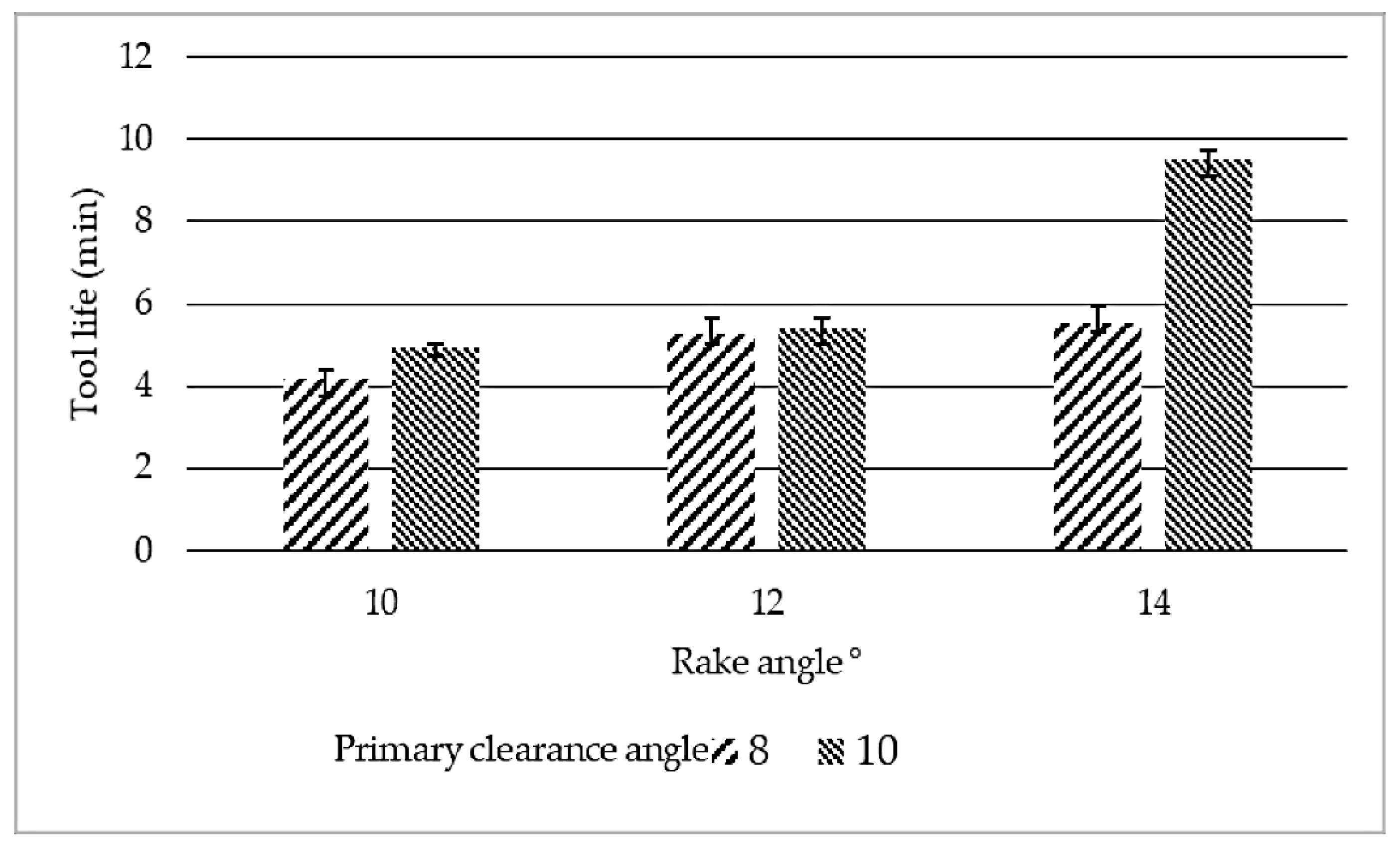

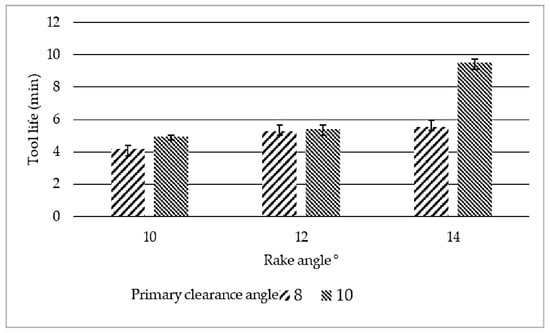

Given this focus, one such article that considers the problem of tool design was recently published by Shokrani and Newman [46]. As part of their research, the authors focused upon the relationship between cutting insert geometry and tool life in the context of the cryogenic end milling of Ti-6Al-4V. Specifically, Shokrani and Newman mapped the relationship between both the rake and primary clearance angle on tool life, tool wear and surface roughness. The authors utilised 12 mm diameter solid WC end mills coated with TiSN-TiN to a thickness of approximately 3 µm. They employed a constant LN2 nozzle position and flow rate (20 kg/h) throughout the trials. Within this experimental design, Shokrani and Newman noted the positive implications of both primary clearance angle and rake angle (Figure 7) on tool life. Moreover, they observed that, although the impact of increased clearance angle persisted across each rake angle, the effect was most pronounced at the highest rake angle, and likewise, the correlation between rake angle and tool life was most exaggerated at the higher clearance angle. Although these observations are of clear value, the authors do however note that (despite not being manifested in their trial) excessively increasing either rake, or clearance angle, can lead to weakening of the cutting edge and ultimately premature tool failure.

Figure 7.

A graph to show the relationship between tool life and tool geometries during the cryogenic end milling of Ti-6Al-4V. Reprinted from reference [46].

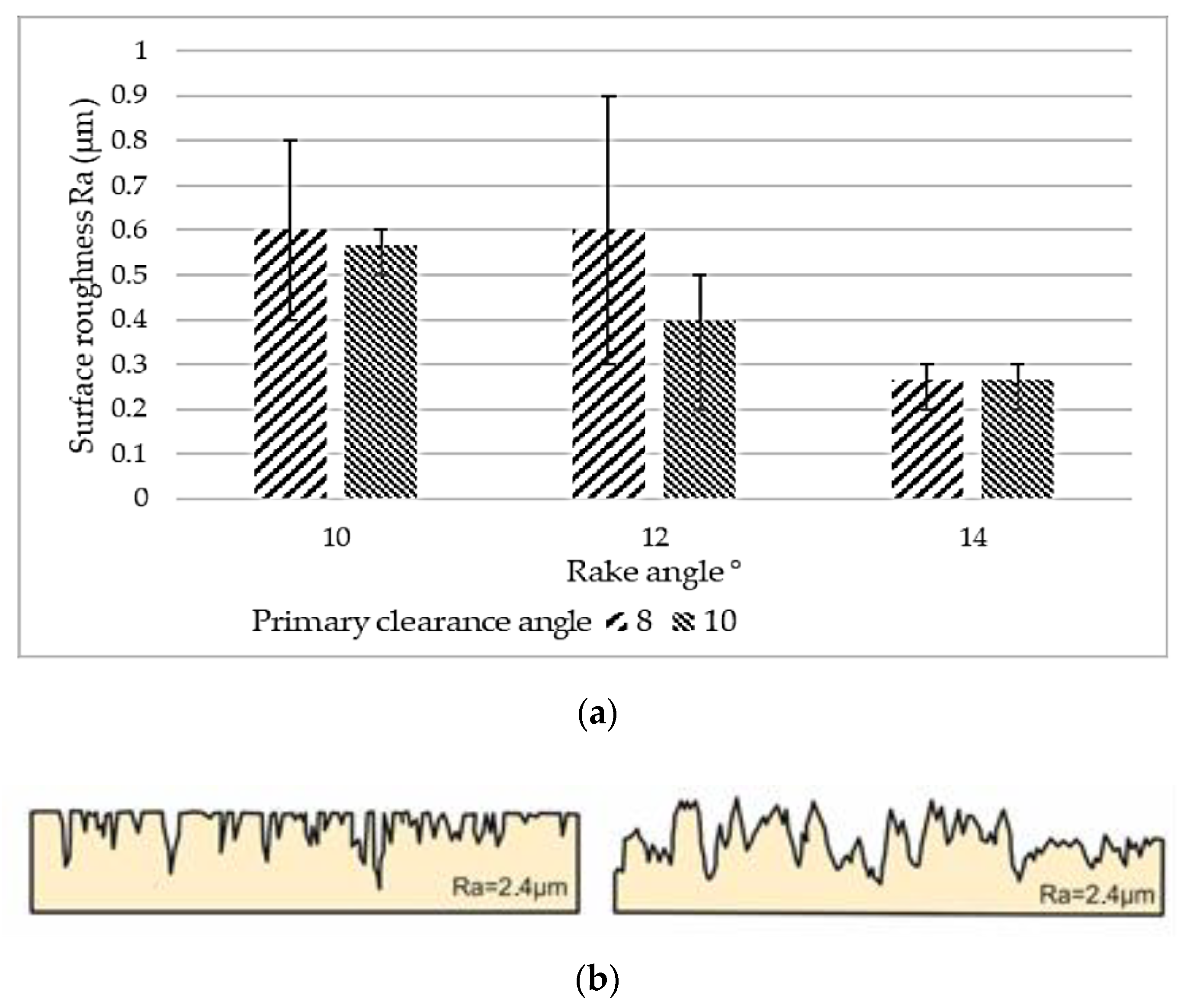

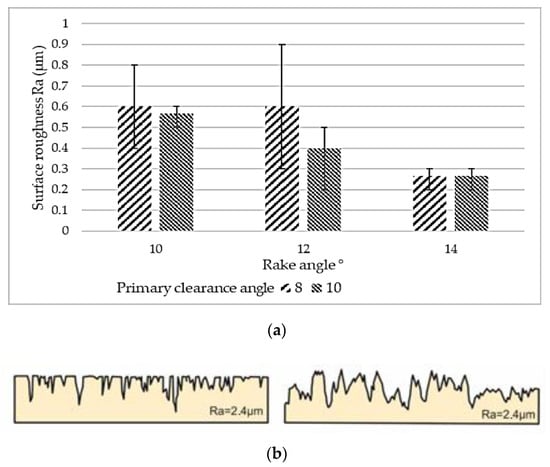

In addition to the tool life implications of manipulating clearance and rake angle, the relationship between surface roughness and insert geometry was also considered. In order to realise these goals Shokrani and Newman took readings at the start of experimentation in order to remove the impact of tool wear on average surface roughness (Ra). In doing so, the authors again noted the positive implications of both increased primary clearance and rake angles such that a tool with a sharper cutting edge corresponded to an equivalent or reduced surface roughness across the entirety of the data set (Figure 8a). Whilst it is difficult to qualitatively assess the relative effect of rake and primary clearance angle on this phenomenon, it is true that the lowest surface roughness was generated at a rake angle of 14° regardless of the primary clearance angle. Given this observation, it is also apparent that the impact of primary clearance angle is most significant at a rake angle of 12°. Whilst these observations make a compelling case for the use of steeper rake and clearance angles, it is important to note that the true impact of cutting edge geometry (on the surface mechanics of the machined workpiece) is not fully captured via Ra measurement. Rather, it is often true that two surfaces with an equivalent centre line average will exhibit varying degrees of asperity, and thus vastly different tribological performance [47] (Figure 8b).

Figure 8.

(a) A graph to show Ra and tool geometry during the cryogenic end milling of Ti-6Al-4V. Reprinted from reference [46]. (b) Schematic illustration of machined surfaces with equivalent values of Ra.