Performance of Ni-Based Coatings with Various Additives Fabricated by Cold Gas Spraying

Abstract

:1. Introduction

- The heating of particles occurs due to the conversion of kinetic energy into thermal energy in the process of interaction with an obstacle, i.e., directly during the formation of the coating;

- The ability to obtain coatings that are entirely adequate in composition to the sprayed powder;

- The ability to obtain composite coatings with a constant and adjustable composition over the thickness of the coating;

- No negative thermal effects on the substrate material;

- Relative safety, process economy, and simplicity.

2. Materials and Methods

2.1. Corrosion Tests

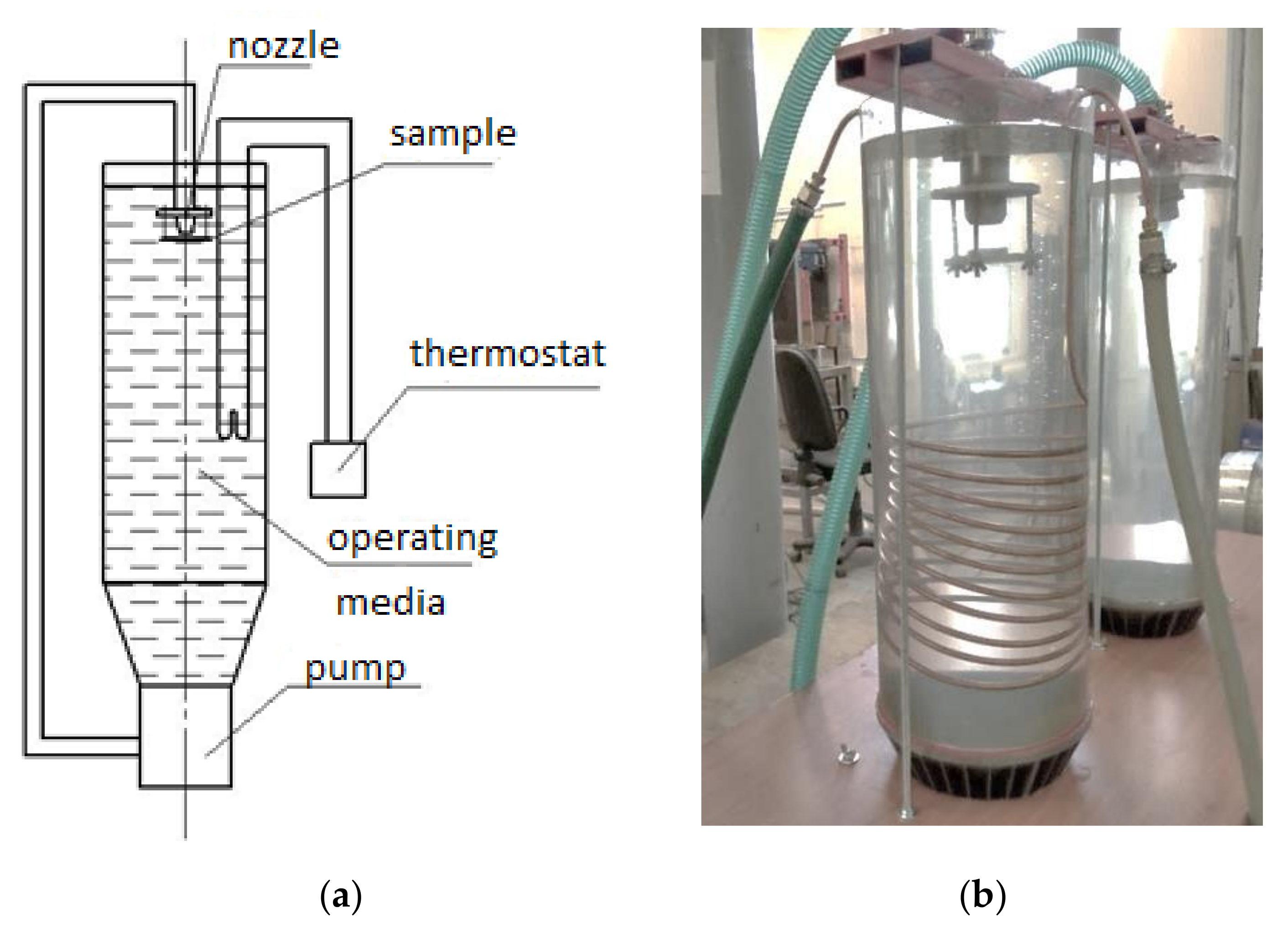

2.2. Hydroabrasive Testing

2.3. Microstructure and Microhardness Investigation

3. Results and Discussion

3.1. Characterization of Initial Powders

3.2. Characterization of the Microstructure of Coatings

3.3. Characterization of Corrosion and Wear Properties

3.4. Characterization of Wear Properties

4. Summary

- It was shown that the coating based on Ni-Zn had the lowest corrosion characteristics (under simulated oilfield conditions, the corrosion rate was 0.17–0.2 mm/year). Despite these coatings having the highest wear resistance characteristics, the protective effect of zinc allows them to be used as corrosion-resistant material, while at the same time being economically attractive.

- The nickel–copper coating samples had high corrosion resistance, but low wear resistance, due to their low hardness. Applying coatings of mechanically alloyed nickel–copper powders is practically impossible without titanium carbide.

- The nickel samples had low corrosion resistance, but high resistance to hydroabrasive wear.

- Nickel coatings can be recommended for use in deposits with a high content of mechanical particles in the fluid, as they are highly resistant to hydroabrasive wear.

- The corrosion resistance of the nickel coatings Ni60-Al2O340 and Ni60-Cu40 under conditions close to operational conditions was less than 0.1 mm/year, so they can be recommended for deposits with a high content of hydrogen sulfide.

- All the studied coating specimens had a sufficiently high adhesion before and after testing in the autoclave.

- A thickness of 40–60 microns provided acceptable performance in the studied coatings.

- The studied nickel coatings had higher wear characteristics than well-known epoxy and silicate enamel coatings.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Heidersbach, R. Metallurgy and Corrosion Control in Oil and Gas Production, 2nd ed.; Wiley Series in Corrosion; John Wiley & Sons: Hoboken, NJ, USA, 2011; 293p, ISBN 13:9780470248485. [Google Scholar]

- Craig, B.D. Oilfield Metallurgy and Corrosion, 3rd ed.; MetCorr: Denver, CO, USA, 2014; 335p, ISBN 0615961355. [Google Scholar]

- Popoola, L.T.; Grema, A.S.; Latinwo, G.K.; Gutti, B.; Balogun, A.S. Corrosion problems during oil and gas production and its mitigation. Int. J. Ind. Chem. 2013, 4, 35. [Google Scholar] [CrossRef] [Green Version]

- Rebak, R.B. Pitting Characteristics of Nickel Alloys—A Review. In Corrosion Conference Proceedings; NACE: Houston, TX, USA, 2016; 7450p. [Google Scholar]

- MacLean, M.; Farhat, Z.; Jarjoura, G.; Fayyad, E.; Abdullah, A.; Hassan, M. Fabrication and investigation of the scratch and indentation behavior of new generation Ni-P-nano-NiTi composite coating for oil and gas pipelines. Wear 2019, 426–427, 265–276. [Google Scholar] [CrossRef]

- Wang, C.; Farhat, Z.; Jarjoura, G.; Hassan, M.K.; Abdullah, A.M. Indentation and erosion behavior of electroless Ni-P coating on pipeline steel. Wear 2017, 376–377, 1630–1639. [Google Scholar] [CrossRef]

- Kumar, P.; Siva, N. Shanmugam Some studies on nickel-based Inconel 625 hard overlays on AISI 316L plate by gas metal arc welding based hardfacing process. Wear 2020, 456–457, 203394. [Google Scholar] [CrossRef]

- Sahoo, C.K.; Masanta, M. Microstructure and mechanical properties of TiC-Ni coating on AISI304 steel produced by TIG cladding process. J. Mater. Processing Technol. 2017, 240, 126–137. [Google Scholar] [CrossRef]

- Pawlowski, L. The Science and Engineering of Thermal Spray Coatings, 2nd ed.; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2008. [Google Scholar] [CrossRef]

- Brandolt, C.S.; Vega, O.; Menezes, M.R.; Schroeder, T.L.; Malfatti, C.F. Corrosion behavior of nickel and cobalt coatings obtained by high-velocity oxy-fuel (HVOF) thermal spraying on API 5CT P110 steel. Mater. Corros. 2016, 67, 368–377. [Google Scholar] [CrossRef]

- Ermakov, B.S.; Alkhimenko, A.A.; Shaposhnikov, N.O.; Ermakov, S.B.; Shatsky, T.E.; Igolkin, A.F. The Use of Sprayed Powders to Create Coatings in the Welds of Oilfield Pipelines. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Chennai, India, 16–17 September 2020; Volume 826. [Google Scholar] [CrossRef]

- Brissonneau, L.; Vahlas, C. Precursors and operating conditions for the metal-organic chemical vapor deposition of nickel films. Ann. Chim. Sci. Matériaux 2000, 25, 81–90. [Google Scholar] [CrossRef]

- Bowden, C.; Matthews, A. A study of the corrosion properties of PVD Zn-Ni coatings. Surf. Coat. Technol. 1995, 76–77, 508–515. [Google Scholar] [CrossRef]

- Geraschenkov, D.A.; Vasiliev, A.F.; Farmakovsky, B.V.; Mashek, A.C.H. Study of the flow temperature in the process of cold gas-dynamic spraying of functional coatings. Mater. Sci. 2014, 1, 87–96. [Google Scholar]

- Gerashchenkov, D.A.; Bobkova, T.I.; Vasiliev, A.F.; Kuznetsov, P.A.; Samodelkin, E.A.; Farmakovsky, B.V. Functional protective coatings of nickel-based alloys. Vopr. Materialoved. 2018, 1, 110–114. (In Russian) [Google Scholar] [CrossRef]

- Alkhimov, A.P.; Klinkov, S.V.; Kosarev, V.F. Investigation of heat transfer of a supersonic plane jet with an obstacle under conditions of gas-dynamic spraying. Therm. Phys. Aeromech. 2000, 7, 389–396. [Google Scholar]

- Parmar, H.; Tucci, F.; Carlone, P.; Sudarshan, T.S. Metallisation of polymers and polymer matrix composites by cold spray: State of the art and research perspectives. Int. Mater. Rev. 2021, 66, 1–24. [Google Scholar] [CrossRef]

- Kumar, S.; Kumar, M.; Jindal, N. Overview of cold spray coatings applications and comparisons: A critical review. World J. Eng. 2020, 17, 27–51. [Google Scholar] [CrossRef]

- Meng, M.; Leech, A.; Le, H. Mechanical properties and tribological behavior of electroless Ni–P–Cu coatings on corrosion-resistant alloys under ultrahigh contact stress with sprayed nanoparticles. Tribol. Int. 2019, 139, 59–66. [Google Scholar] [CrossRef]

- Li, B.; Mei, T.; Li, D.; Du, S.; Zhang, W. Structural and corrosion behavior of Ni-Cu and Ni-Cu/ZrO2 composite coating electrodeposited from sulphate-citrate bath at low Cu concentration with additives. J. Alloys Compd. 2019, 804, 192–201. [Google Scholar] [CrossRef]

- Hammami, O. Influence of Zn-Ni alloy electrodeposition techniques on the coating corrosion behavior in chloride solution. Surf. Coat. Technol. 2009, 203, 2863–2870. [Google Scholar] [CrossRef]

- Shourgeshty, M.; Aliofkhazraei, M.; Karimzadeh, A.; Poursalehi, R. Corrosion and wear properties of Zn-Ni and Zn-Ni-Al2O3 multilayer electrodeposited coatings. Mater. Res. Express 2017, 4, 096406. [Google Scholar] [CrossRef]

- Oryshchenko, A.S.; Gerashchenkov, D.A. Aluminum matrix functional coatings with high microhardness on the basis of Al–Sn + Al2O3 composite powders fabricated by cold gas dynamic spraying. Inorg. Mater. Appl. Res. 2016, 7, 863–867. [Google Scholar] [CrossRef]

- Chen, L.; Wang, L.; Zeng, Z.; Zhang, J. Effect of surfactant on the electrodeposition and wear resistance of Ni-Al2O3 composite coatings. Mater. Sci. Eng. A 2006, 434, 319–325. [Google Scholar] [CrossRef]

- Szczygieł, B.; Kołodziej, M. Corrosion resistance of Ni/Al2O3 coatings in NaCl solution. Trans. Inst. Met. Finish 2005, 83, 181–187. [Google Scholar] [CrossRef]

- Ghaziof, S.; Kilmartin, P.; Gao, W. Electrochemical studies of sol-enhanced Zn-Ni-Al2O3 composite and Zn-Ni alloy coatings. J. Electroanal. Chem. 2015, 755, 63–70. [Google Scholar] [CrossRef]

- Baghery, P.; Farzam, M.; Mousavi, A.B.; Hosseini, M. Ni–TiO2 nanocomposite coating with high resistance to corrosion and wear. Surf. Coat. Technol. 2010, 204, 3804–3810. [Google Scholar] [CrossRef]

- Zimmerman, A. Pulse electrodeposition of Ni–SiC nanocomposite. Mater. Lett. 2002, 52, 85–90. [Google Scholar] [CrossRef]

- Tao, Y.; Xiong, T.; Sun, C.; Jin, H.; Du, H.; Li, T. Effect of α-Al2O3 on the properties of cold sprayed Al/α-Al2O3 composite coatings on AZ91D magnesium alloy. Appl. Surf. Sci. 2009, 256, 261–266. [Google Scholar] [CrossRef]

- Lee, Y.; Jung, A.H.; Lee, S.Y.; You, Y.H.; Ko, K.H. Correlation between Al2O3 particles and interface of Al–Al2O3 coatings by cold spray. Appl. Surf. Sci. 2009, 205, 1891–1898. [Google Scholar] [CrossRef]

- Mondol, D.P.; Das, S.; Jha, A.K.; Yegneswaren, A.H. Abrasive wear of Al alloy–Al2O3 particle composite: A study on the combined effect of load and size abrasive. Wear 1998, 233, 131–138. [Google Scholar] [CrossRef]

- Hodder, K.J.; Izadi, H.; McDonald, A.G.; Gerlich, A.P. Fabrication of aluminum–alumina metal matrix composites via cold gas dynamic spraying at low pressure followed by friction stir processing. Mater. Sci. Eng. 2012, 556, 114–121. [Google Scholar] [CrossRef]

- Alekseeva, E.; Shishkova, M.; Strekalovskaya, D.; Gerashchenkov, D. Ni-Based Coatings for Oil and Gas Industry Fabricated by Cold Gas Spraying. Mater. Proc. 2021, 3, 2. [Google Scholar] [CrossRef]

- Lashkov, B.A. On the experimental determination of the coefficients of recovery of the velocity of the particles of the gas suspension flow upon impact on the surface. Eng. Phys. J. 1991, 60, 197–203. [Google Scholar] [CrossRef]

- ASTM G3-14; Standard Practice for Conventions Applicable to Electrochemical Measurements in Corrosion Testing. ASTM International: Pennsylvania, PA, USA, 2019. [CrossRef]

- Kovalev, M.; Alekseeva, E.; Shaposhnikov, N. Investigation of hydroabrasive resistance of internal anti-corrosion coatings used in the oil and gas industry. IOP Conference Series: Materials Science and Engineering. Int. Sci. Pract. Conf. Mater. Sci. 2020, 889, 012020. [Google Scholar]

- Alekseeva, E.; Galata, L.; Lapechenkov, A.; Kovalev, M. Evaluation of Corrosion Resistance of Nickel-based Alloy EP718 for use in Hydrogen Sulphide Containing Environment. In Proceedings of the E3S Web of Conferences, Corrosion in the Oil & Gas Industry, Saint-Petersburg, Russia, 14–16 December 2020; Volume 225, p. 03001. [Google Scholar] [CrossRef]

| Sample | Chemical Composition, wt.% | Thickness, ±5 μm |

|---|---|---|

| Ni100 | Ni–100% | 30 |

| Ni90-TiC10 | Ni–90%, TiC–10% | 70 |

| Ni60-TiC40 | Ni–60%, TiC–40% | 70 |

| Ni60-Al2O340/60 | Ni–60%, Al2O3–40% | 60 |

| Ni60-Al2O340/130 | Ni–60%, Al2O3–40% | 130 |

| Ni90-Cu10/40 * | Ni–90%, Cu–10% | 40 |

| Ni90-Cu10/150 * | Ni–90%, Cu–10% | 150 |

| Ni60-Cu40/50 * | Ni–60%, Cu–40% | 50 |

| Ni60-Cu40/120 * | Ni–60%, Cu–40% | 120 |

| Ni90-Zn10/50 * | Ni–90%, Zn–10% | 50 |

| Ni90-Zn10/150 * | Ni–90%, Zn–10% | 150 |

| Ni60-Zn40/100 * | Ni–60%, Zn–40% | 100 |

| Ni60-Zn40/200 * | Ni–60%, Zn–40% | 200 |

| Mechanically Alloyed (MA) | ||

| (Ni50-Cu50)60-TiC40 (MA) * | Ni–50%, Cu–50% | 30 |

| Ni50-Cu50 (MA) * | Ni–50%, Cu–50% | - |

| Ni50-Zn50 (MA) * | Ni–50%, Cu–50% | 30 |

| Nickel Coating Type | Porosity, Unit/cm2 | Microhardness, HV |

|---|---|---|

| Ni | 1.1 | 185 |

| Ni-TiC | 1.1 | 90 |

| Ni-Al2O3 | 0.5 | 130 |

| Ni-Cu | 0.6 | 90 |

| Ni-Zn | 2.1 | 170 |

| Ni-Cu-TiC (MA) | 1.2 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alekseeva, E.; Shishkova, M.; Strekalovskaya, D.; Shaposhnikov, N.; Gerashchenkov, D.; Glukhov, P. Performance of Ni-Based Coatings with Various Additives Fabricated by Cold Gas Spraying. Metals 2022, 12, 314. https://doi.org/10.3390/met12020314

Alekseeva E, Shishkova M, Strekalovskaya D, Shaposhnikov N, Gerashchenkov D, Glukhov P. Performance of Ni-Based Coatings with Various Additives Fabricated by Cold Gas Spraying. Metals. 2022; 12(2):314. https://doi.org/10.3390/met12020314

Chicago/Turabian StyleAlekseeva, Ekaterina, Margarita Shishkova, Darya Strekalovskaya, Nikita Shaposhnikov, Dmitry Gerashchenkov, and Pavel Glukhov. 2022. "Performance of Ni-Based Coatings with Various Additives Fabricated by Cold Gas Spraying" Metals 12, no. 2: 314. https://doi.org/10.3390/met12020314

APA StyleAlekseeva, E., Shishkova, M., Strekalovskaya, D., Shaposhnikov, N., Gerashchenkov, D., & Glukhov, P. (2022). Performance of Ni-Based Coatings with Various Additives Fabricated by Cold Gas Spraying. Metals, 12(2), 314. https://doi.org/10.3390/met12020314