Observation of Microstructure and Mechanical Properties in Heat Affected Zone of As-Welded Carbon Steel by Using Plasma MIG Welding Process

Abstract

:1. Introduction

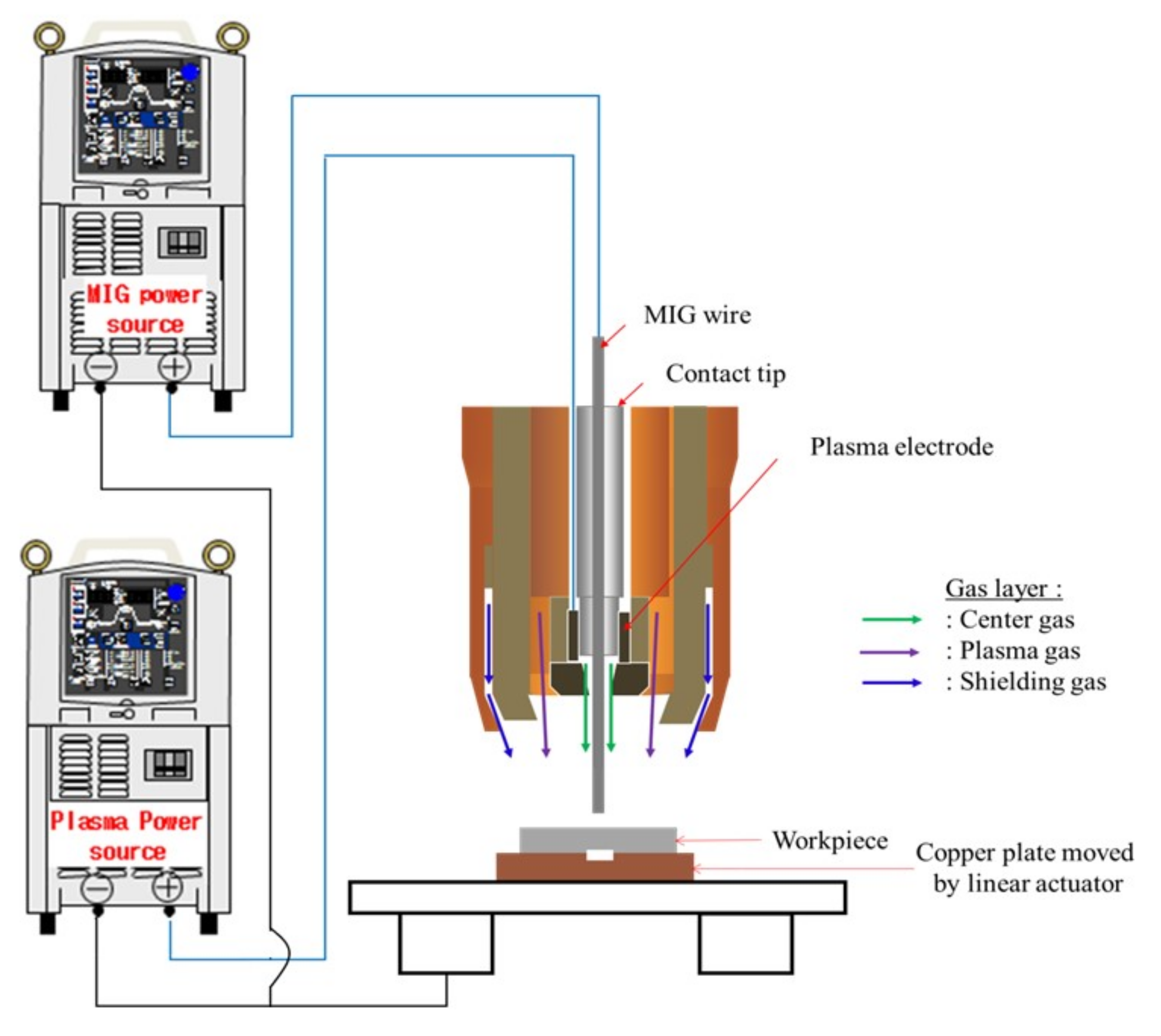

2. Experimental Method

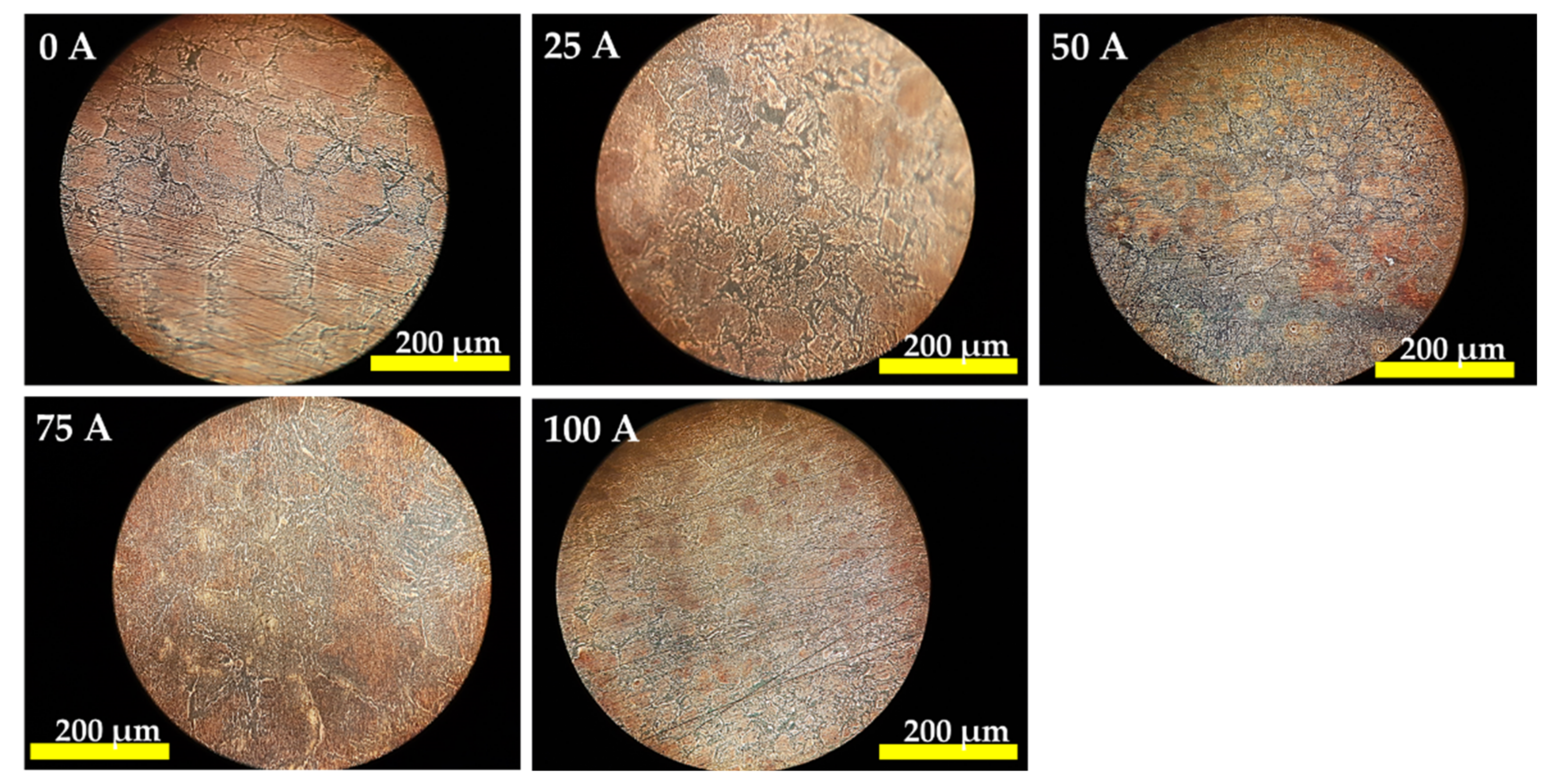

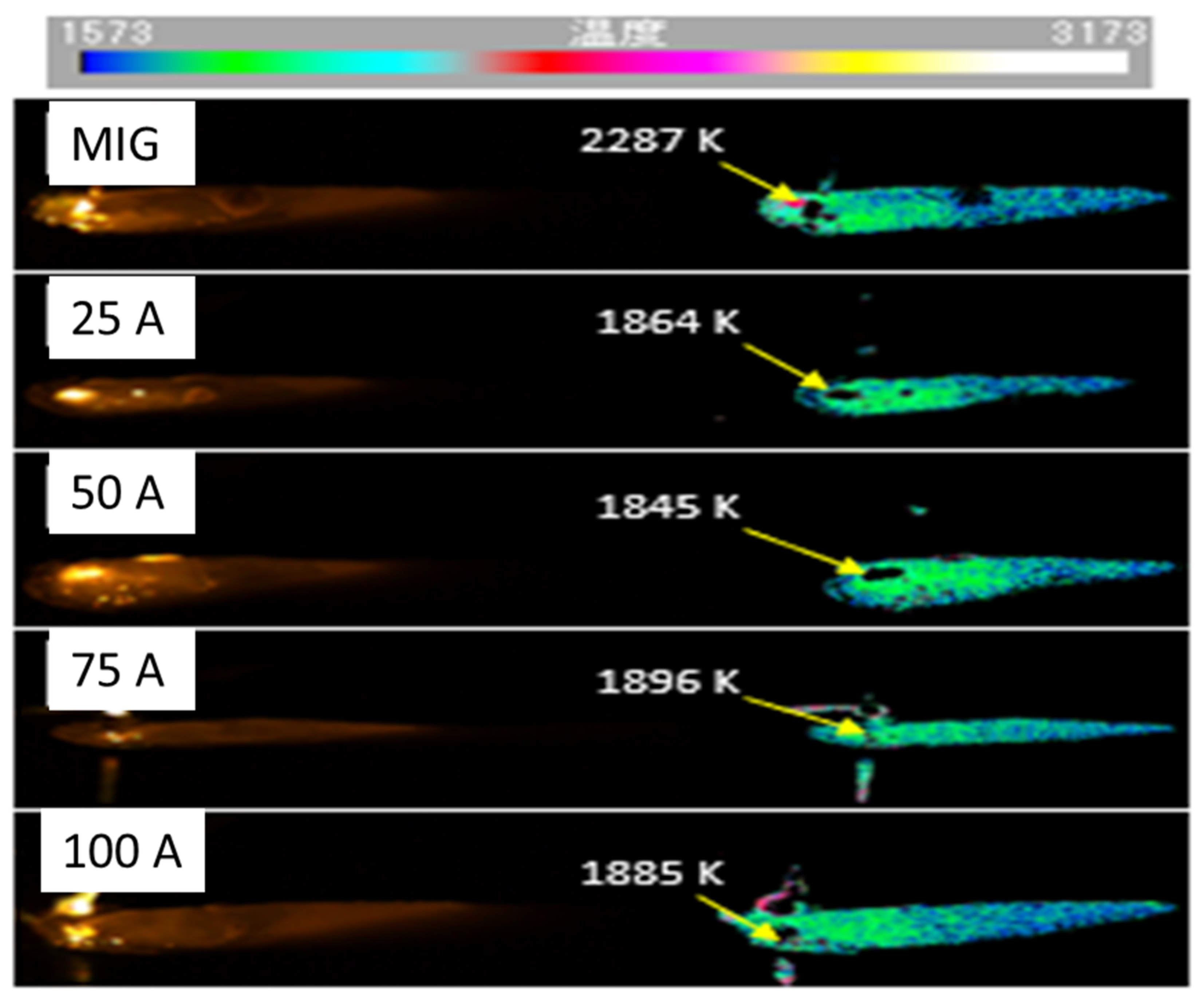

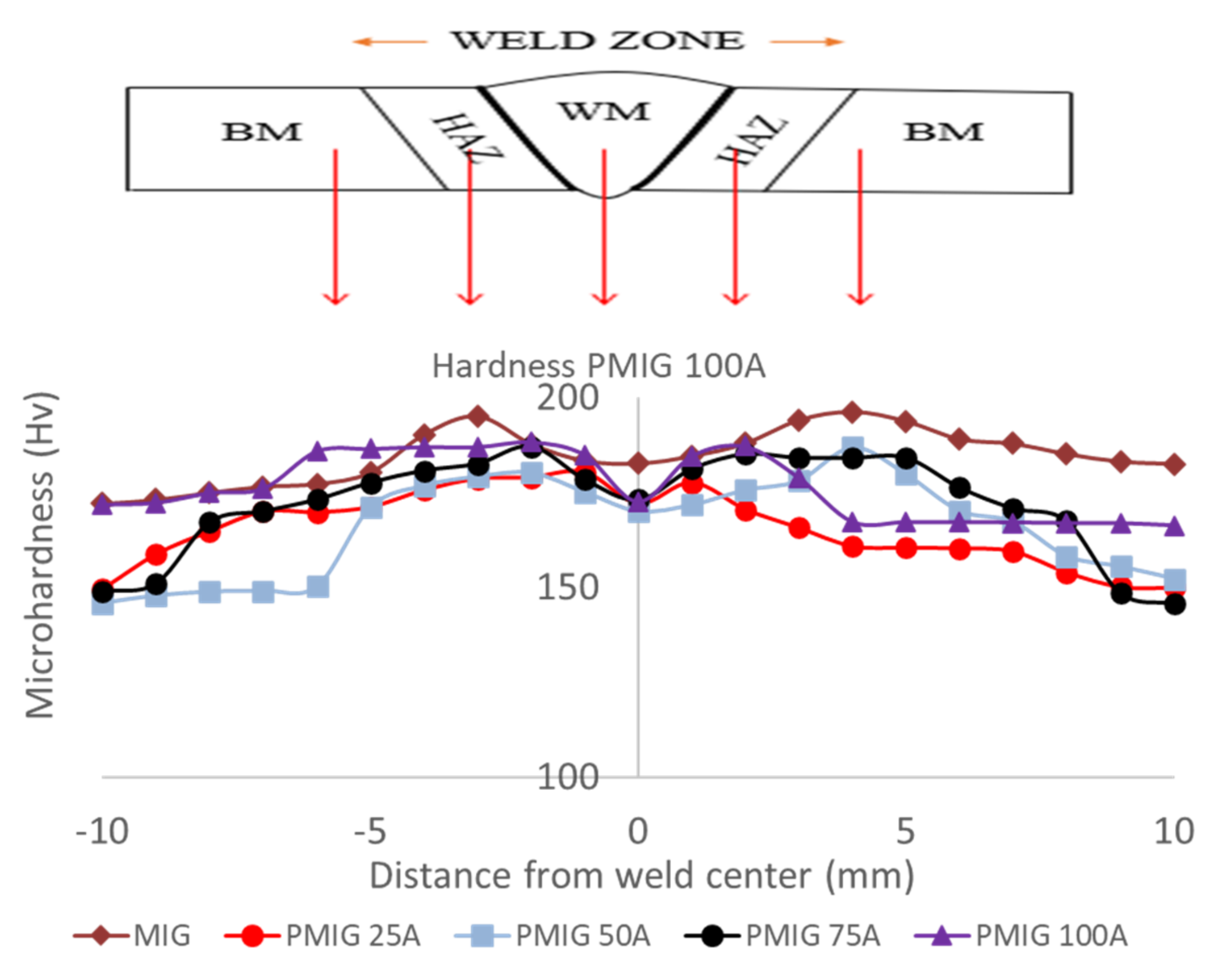

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sen, M.; Mukherjee, M.; Pal, T.K. Evaluation of correlations between DP-GMAW process parameters and bead geometry. Weld. J. 2015, 94, 265s–279s. [Google Scholar]

- Modenesi, P.J.; Nixon, J.H. Arc instability phenomena in GMA welding. Weld. Res. Suppl. 1994, 9, 219s–224s. [Google Scholar]

- Gao, M.; Zeng, X.Y.; Hu, Q.W. Effects of welding parameters on melting energy of CO2 laser—GMA hybrid welding. Sci. Technol. Weld. Join. 2006, 11, 517–522. [Google Scholar] [CrossRef]

- Gao, M.; Zeng, X.; Yan, J.; Hu, Q. Microstructure characteristics of laser—MIG hybrid welded mild steel. Appl. Surf. Sci. 2008, 254, 5715–5721. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Mishima, H.; Tashiro, S.; Tanaka, M. Study for TIG—MIG hybrid welding process. Weld World 2014, 58, 11–18. [Google Scholar] [CrossRef]

- Kanemaru, S.; Sasaki, T.; Sato, T.; Era, T.; Tanaka, M. Study for the mechanism of TIG—MIG hybrid welding process. Weld World 2015, 59, 261–268. [Google Scholar] [CrossRef]

- Zong, R.; Chen, J.; Wu, C. A comparison of TIG—MIG hybrid welding with conventional MIG welding in the behaviors of arc, droplet and weld pool. J. Mater. Processing Tech 2019, 270, 345–355. [Google Scholar] [CrossRef]

- Ono, K.; Lie, Z.; Era, T.; Ueono, T.; Ueyama, T.; Tanaka, M.; Nakata, K. Development of a plasma MIG welding system for aluminum. Weld. Int. 2019, 23, 805–809. [Google Scholar] [CrossRef]

- Bin Mamat, S.S.; Tashiro, M.; Tanaka, M. Study on factors affecting the droplet temperature in plasma MIG welding process. J. Phys. D. Appl. Phys. 2018, 51, 135206. [Google Scholar] [CrossRef]

- Tsujimura, Y.; Tanaka, M. Numerical Simulation of heat source property with metal vapor behavior in GMA Welding. J. Japan Weld. Soc. 2012, 30, 68–76. (In Japanese) [Google Scholar] [CrossRef] [Green Version]

- Valensi, F.; Pellerin, S.; Castillon, Q.; Boutaghane, A.; Dzierzega, K.; Zielinska, S.; Pellerin, N.; Briand, F. Study of the spray to globular transition in gas metal arc welding: A spectroscopic investigation. J. Phys. D Appl. Phys. 2013, 46, 1–12. [Google Scholar] [CrossRef]

- Mamat, S.; Afandi, A.A.M.; Abu Bakar, M.B.; Masri, M.N.; Mohamed, M.; Abdul Razab, M.K.A.; Yuji, T.; Tashiro, S.; Tanaka, M. Effect of plasma flow in plasma mig welding process to the microstructure refinement at heat affected zone of as-welded carbon steel. Mater. Sci. Forum 2020, 1010, 15–20. [Google Scholar] [CrossRef]

- Long, N.P.; Katada, Y.; Tanaka, Y. Cathode diameter and operating parameter effects on hafnium cathode evaporation for oxygen plasma cutting arc. J. Phys. D. Appl. Phys. 2012, 45, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Bin Mamat, S.; Tashiro, S.; Masri, M.N.; Hong, S.M.; Bang, H.S.; Tanaka, M. Application of pulse plasma MIG welding process to Al/steel dissimilar joining. Weld. World 2020, 64, 857–871. [Google Scholar] [CrossRef]

- Essers, W.G.; Walter, A.R. Heat Transfer and Penetration Mechanisms with GMA and Plasma-GMA Welding. Weld. Res. Suppl. 1981, 2, 37s–42s. [Google Scholar]

- Seri, M.; Mukerjee, M.; Sigh, S.K.; Pal, T.K. Effect of double-pulsed gas metal arc welding (DP-GMAW) process variables on microstructural constituents and hardness of low carbon steel weld deposits. J. Manuf. Processes 2018, 13, 424–439. [Google Scholar]

| Element | C | Mn | P | S | Cu | Fe |

|---|---|---|---|---|---|---|

| Composition (%) | 0.018 | 0.206 | 0.092 | 0.004 | 0.051 | Bal |

| Wire Type | Wire Diameter (mm) | Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|---|

| C | Mn | Si | P | S | Ni | ||

| JIS YGW11 | Ø 1.2 | 0.07 | 0.90–1.40 | 0.40–0.70 | 0.025 max | 0.035 max | 0.15 max |

| Cr | Mo | V | Cu | Ti | Al | ||

| 0.15 max | 0.15 max | 0.03 max | 0.50 max | 0.05–0.15 | 0.05–0.15 | ||

| Parameters | Values |

|---|---|

| Polarity | DCEP |

| Filler wire | JIS YGW Ø 1.2 mm |

| Wire feeding speed | 980 cm/min |

| MIG current | 200 A |

| MIG voltage | 25 V |

| Welding speed | 50 cm/min |

| Contact tip to work distance | 20 mm |

| Plasma current | Conventional MIG: 0 A Plasma MIG: 25 A, 50 A, 75 A, 100 A |

| Argon gas flow rate | Center gas: 5 L/min |

| Plasma gas: 10 L/min | |

| Shielding gas: 10 L/min |

| Plasma Current (A) | HAZ Width (mm) | Weld Bead Size (mm) |

|---|---|---|

| 0 | 3.5 | 9.6 |

| 25 | 4.5 | 5.7 |

| 50 | 5.0 | 6.6 |

| 75 | 6.0 | 7.4 |

| 100 | 7.0 | 7.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamat, S.; Sidek, N.A.; Afandi, N.A.A.M.; Roslan, R.A.E.; Ter, T.P.; Yuji, T.; Tashiro, S.; Tanaka, M. Observation of Microstructure and Mechanical Properties in Heat Affected Zone of As-Welded Carbon Steel by Using Plasma MIG Welding Process. Metals 2022, 12, 315. https://doi.org/10.3390/met12020315

Mamat S, Sidek NA, Afandi NAAM, Roslan RAE, Ter TP, Yuji T, Tashiro S, Tanaka M. Observation of Microstructure and Mechanical Properties in Heat Affected Zone of As-Welded Carbon Steel by Using Plasma MIG Welding Process. Metals. 2022; 12(2):315. https://doi.org/10.3390/met12020315

Chicago/Turabian StyleMamat, Sarizam, Nur Azmina Sidek, Nur Aina Aqilah Mohd Afandi, Rose Alifah Ellyana Roslan, Teo Pao Ter, Toshifumi Yuji, Shinichi Tashiro, and Manabu Tanaka. 2022. "Observation of Microstructure and Mechanical Properties in Heat Affected Zone of As-Welded Carbon Steel by Using Plasma MIG Welding Process" Metals 12, no. 2: 315. https://doi.org/10.3390/met12020315

APA StyleMamat, S., Sidek, N. A., Afandi, N. A. A. M., Roslan, R. A. E., Ter, T. P., Yuji, T., Tashiro, S., & Tanaka, M. (2022). Observation of Microstructure and Mechanical Properties in Heat Affected Zone of As-Welded Carbon Steel by Using Plasma MIG Welding Process. Metals, 12(2), 315. https://doi.org/10.3390/met12020315