Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels

Abstract

:1. Introduction

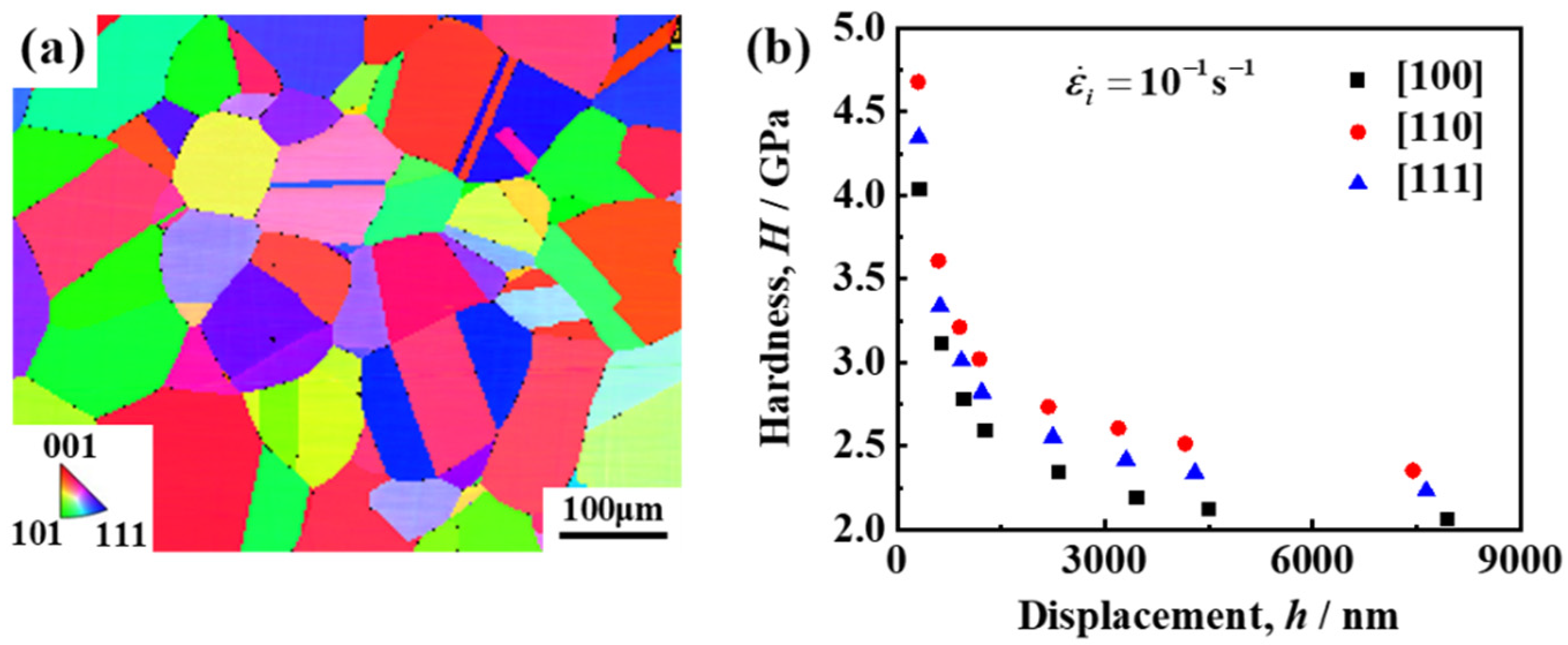

2. Materials and Methods

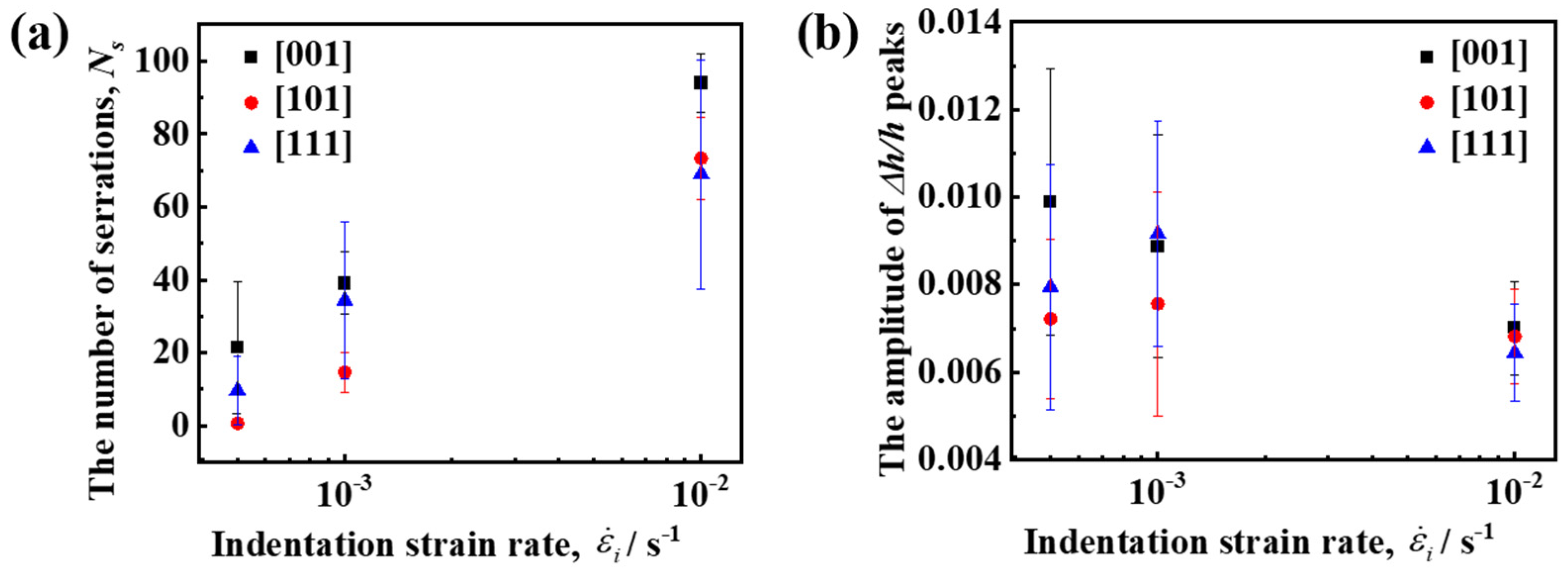

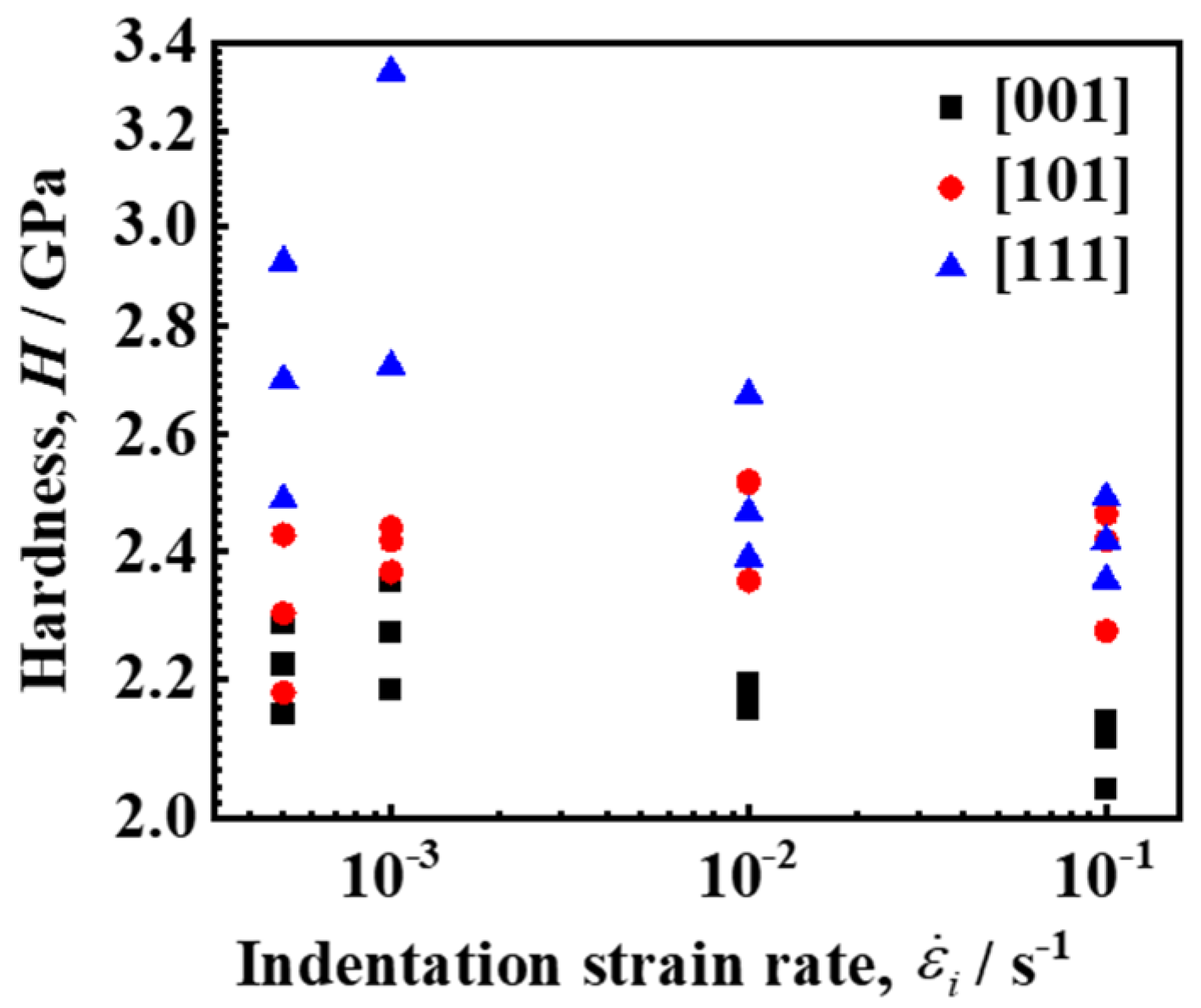

3. Results

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Le Chatelier, A. Influence du temps et de la température sur les essais au choc. Rev. Métall. 1909, 6, 914–917. [Google Scholar] [CrossRef]

- Yilmaz, A. The Portevin–Le Chatelier effect: A review of experimental findings. Sci. Technol. Adv. Mater. 2011, 12, 063001. [Google Scholar] [CrossRef] [PubMed]

- Curtin, W.A.; Olmsted, D.L.; Hector, L.G. A predictive mechanism for dynamic strain ageing in Aluminium–Magnesium alloys. Nat. Mater. 2006, 5, 875–880. [Google Scholar] [CrossRef] [PubMed]

- Van den Beukel, A. Theory of the effect of dynamic strain aging on mechanical properties. Phys. Status Solidi 1975, 30, 197–206. [Google Scholar] [CrossRef]

- Lee, S.-J.; Kim, J.; Kane, S.N.; De Cooman, B.C. On the origin of dynamic strain aging in twinning-induced plasticity steels. Acta Mater. 2011, 59, 6809–6819. [Google Scholar] [CrossRef]

- De Almeida, L.H.; Le May, I.; Emygdio, P.R.O. Mechanistic modeling of dynamic strain aging in austenitic stainless steels. Mater. Charact. 1998, 41, 137–150. [Google Scholar] [CrossRef]

- Van den Beukel, A.; Kocks, U.F. The strain dependence of static and dynamic strain-aging. Acta Metall. 1982, 30, 1027–1034. [Google Scholar] [CrossRef]

- McCormick, P.G.; Ling, C.P. Numerical modelling of the Portevin–Le Chatelier effect. Acta Metall. Mater. 1995, 43, 1969–1977. [Google Scholar] [CrossRef]

- Canadinc, D.; Efstathiou, C.; Sehitoglu, H. On the negative strain rate sensitivity of Hadfield steel. Scr. Mater. 2008, 59, 1103–1106. [Google Scholar] [CrossRef] [Green Version]

- Picu, R.C.; Vincze, G.; Ozturk, F.; Gracio, J.J.; Barlat, F.; Maniatty, A.M. Strain rate sensitivity of the commercial aluminum alloy AA5182-O. Mater. Sci. Eng. A 2005, 390, 334–343. [Google Scholar] [CrossRef]

- McCormigk, P.G. A model for the Portevin-Le Chatelier effect in substitutional alloys. Acta Metall. 1972, 20, 351–354. [Google Scholar] [CrossRef]

- Cheng, X.M.; Morris, J.G. The anisotropy of the portevin-le chatelier effect in aluminum alloys. Scr. Mater. 2000, 43, 651–658. [Google Scholar] [CrossRef]

- Mizera, J.; Kurzydlowski, K.J. On the anisotropy of the Portevin–Le Chatelier plastic instabilities in Al–Li–Cu–Zr alloy. Scr. Mater. 2001, 45, 801–806. [Google Scholar] [CrossRef]

- Nayan, N.; Mishra, S.; Prakash, A.; Sarkar, R.; Murty, S.; Yadava, M.; Prasad, M.; Samajdar, I. Origin of through-thickness serrated tensile flow behavior in Al–Cu–Li (AA2195) alloy: Effect of microstructure and texture. Materialia 2019, 5, 100180. [Google Scholar] [CrossRef]

- Shabadi, R.; Kumar, S.; Roven, H.J.; Dwarakadasa, E.S. Effect of specimen condition, orientation and alloy composition on PLC band parameters. Mater. Sci. Eng. A 2004, 382, 203–208. [Google Scholar] [CrossRef]

- Shen, Y.Z.; Oh, K.H.; Lee, D.N. The effect of texture on the Portevin–Le Chatelier effect in 2090 Al–Li alloy. Scr. Mater. 2004, 51, 285–289. [Google Scholar] [CrossRef]

- Hu, Z.; Qi, Y.; Nie, X.; Zhang, H.; Zhu, H. The Portevin-Le Chatelier (PLC) effect in an Al-Cu aluminum alloy fabricated by selective laser melting. Mater. Charact. 2021, 178, 111198. [Google Scholar] [CrossRef]

- Kumar, S.; Pink, E. Serrated flow in aluminium alloys containing lithium. Acta Mater. 1997, 45, 5295–5301. [Google Scholar] [CrossRef]

- Pink, E.; Bruckbauer, P.; Weinhandl, H. Stress-drop rates in serrated flow of aluminium alloys. Scr. Mater. 1998, 38, 945–951. [Google Scholar] [CrossRef]

- Kalk, A.; Nortmann, A.; Schwink, C. Dynamic strain ageing and the boundaries of stable plastic deformation in Cu-Mn single crystals. Philos. Mag. A 1995, 72, 1239–1259. [Google Scholar] [CrossRef]

- Kovács, Z.; Chinh, N.Q.; Lendvai, J. Orientation dependence of Portevin–Le Châtelier plastic instabilities in depth-sensing microindentation. J. Mater. Res. 2001, 16, 1171–1177. [Google Scholar] [CrossRef]

- Ovri, H.; Steglich, D.; Dieringa, H.; Lilleodden, E.T. Grain-scale investigation of the anisotropy of Portevin-Le Chatelier effect in Mg AZ91 alloy. Mater. Sci. Eng. A 2019, 740, 226–234. [Google Scholar] [CrossRef]

- Zhou, P.; Huang, M.X. On the mechanisms of different work-hardening stages in twinning-induced plasticity steels. Metall. Mater. Trans. A 2015, 46, 5080–5090. [Google Scholar] [CrossRef]

- Lucas, B.N.; Oliver, W.C. Indentation power-law creep of high-purity indium. Metall. Mater. Trans. A 1999, 30, 601–610. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Nohava, J.; Randall, N.X.; Conté, N. Novel ultra nanoindentation method with extremely low thermal drift: Principle and experimental results. J. Mater. Res. 2009, 24, 873–882. [Google Scholar] [CrossRef] [Green Version]

- Bei, H.; Gao, Y.F.; Shim, S.; George, E.P.; Pharr, G.M. Strength differences arising from homogeneous versus heterogeneous dislocation nucleation. Phys. Rev. B 2008, 77, 060103. [Google Scholar] [CrossRef]

- Shim, S.; Bei, H.; George, E.P.; Pharr, G.M. A different type of indentation size effect. Scr. Mater. 2008, 59, 1095–1098. [Google Scholar] [CrossRef]

- Ahn, T.H.; Oh, C.S.; Kim, D.H.; Oh, K.H.; Bei, H.; George, E.P.; Han, H.N. Investigation of strain-induced martensitic transformation in metastable austenite using nanoindentation. Scr. Mater. 2010, 63, 540–543. [Google Scholar] [CrossRef]

- He, B.B.; Huang, M.X.; Liang, Z.Y.; Ngan, A.H.W.; Luo, H.W.; Shi, J.; Cao, W.Q.; Dong, H. Nanoindentation investigation on the mechanical stability of individual austenite grains in a medium-Mn transformation-induced plasticity steel. Scr. Mater. 2013, 69, 215–218. [Google Scholar] [CrossRef]

- Seo, E.J.; Kim, J.K.; Cho, L.; Mola, J.; Oh, C.Y.; De Cooman, B.C. Micro-plasticity of medium Mn austenitic steel: Perfect dislocation plasticity and deformation twinning. Acta Mater. 2017, 135, 112–123. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Q.; Chen, X.; Chen, Z.; Jiang, Z.; Wu, X.; Fan, J. Three types of Portevin–Le Chatelier effects: Experiment and modelling. Acta Mater. 2007, 55, 2219–2228. [Google Scholar] [CrossRef]

- Takagi, H.; Fujiwara, M. Set of conversion coefficients for extracting uniaxial creep data from pseudo-steady indentation creep test results. Mater. Sci. Eng. A 2014, 602, 98–104. [Google Scholar] [CrossRef]

- Bower, A.F.; Fleck, N.A.; Needleman, A.; Ogbonna, N.; Enderby, J.E. Indentation of a power law creeping solid. Proc. R. Soc. Lond. Ser. A Math. Phys. Sci. 1993, 441, 97–124. [Google Scholar]

- Chinh, N.Q.; Gubicza, J.; Kovács, Z.; Lendvai, J. Depth-sensing indentation tests in studying plastic instabilities. J. Mater. Res. 2004, 19, 31–45. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, J.; ul Hassan, H.; Zhang, J.; Yan, Y.; Hartmaier, A.; Sun, T. Coupled effect of crystallographic orientation and indenter geometry on nanoindentation of single crystalline copper. Int. J. Mech. Sci. 2018, 148, 531–539. [Google Scholar] [CrossRef]

- Liu, M.; Tieu, A.K.; Peng, C.-T.; Zhou, K. Explore the anisotropic indentation pile-up patterns of single-crystal coppers by crystal plasticity finite element modelling. Mater. Lett. 2015, 161, 227–230. [Google Scholar] [CrossRef]

- Chen, S.; Miyahara, Y.; Nomoto, A. Crystallographic orientation dependence of nanoindentation hardness in austenitic phase of stainless steel. Philos. Mag. Lett. 2018, 98, 473–485. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, X.; Wang, L.; Xu, W.; Liang, Z. Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels. Metals 2022, 12, 439. https://doi.org/10.3390/met12030439

Peng X, Wang L, Xu W, Liang Z. Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels. Metals. 2022; 12(3):439. https://doi.org/10.3390/met12030439

Chicago/Turabian StylePeng, Xiuxing, Lingyu Wang, Wei Xu, and Zhiyuan Liang. 2022. "Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels" Metals 12, no. 3: 439. https://doi.org/10.3390/met12030439

APA StylePeng, X., Wang, L., Xu, W., & Liang, Z. (2022). Crystal Orientation Dependence of the Portevin–Le Chatelier Effect in Instrumented Indentation: A Case Study in Twinning-Induced Plasticity Steels. Metals, 12(3), 439. https://doi.org/10.3390/met12030439