Comparative Evaluation of the TRIP Effect in Steels with Different Contents of Mn and Al

Abstract

:1. Introduction

- −

- Not to increase the hardness too much, with Mn being an element that still increases the hardenability;

- −

- Not to form a large amount of complex carbides, such as FeMn3C;

- −

- Carbon, a strong gammageneous element, should not negatively influence, together with Mn, the appearance of a quantity higher than the optimal value (10–15%) of retained austenite.

2. Materials and Methods

2.1. Production of Studied TRIP Steels

2.2. Heat Treatments

2.3. TRIP Steels Testing

2.3.1. Impact Bending Test

2.3.2. Hardness Test

2.3.3. Microstructural Analysis

- -

- Cr Kα radiation, (λ = 2.29092 Å);

- -

- X radiation beam parameters: 40 kV, 40 mA, irradiated area = 1.15 × 1.15 mm2;

- -

- Detector: D/teX Ultra 2000 silicon strip (Rigaku Corporation, Tokyo, Japan).

- Rα = correction corresponding to the diffraction line α(211); Rα = 190.8;

- Iγ = integrated intensity of the diffraction line γ(220);

- Rγ = correction corresponding to the diffraction line γ(220); Rγ = 47.88.

3. Results and Discussion

- -

- Qualitatively, using electron microscopy images of the samples before and after the impact bending test;

- -

- Quantitatively, by establishing the volume of retained austenite (also before and after the impact bending test).

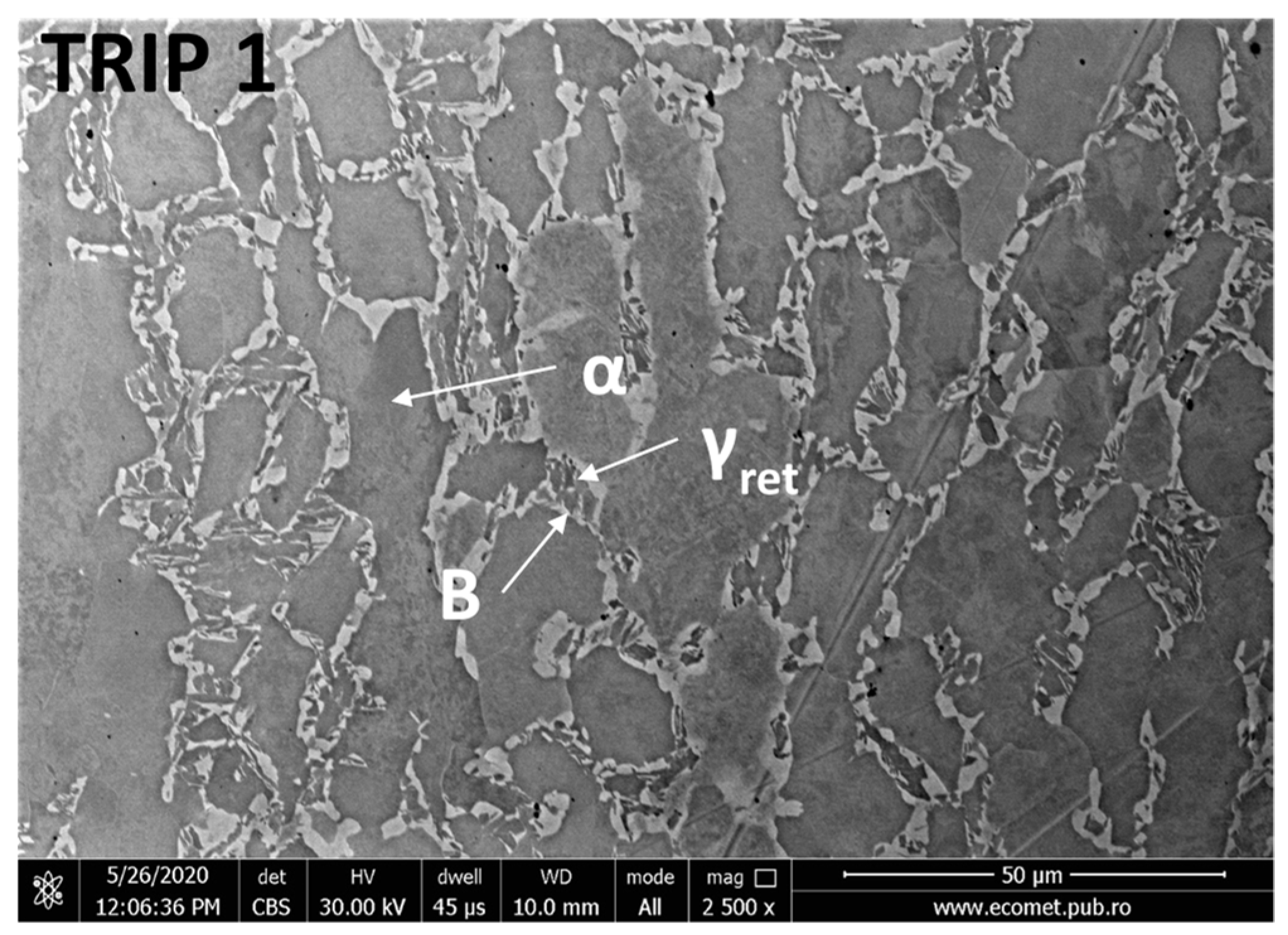

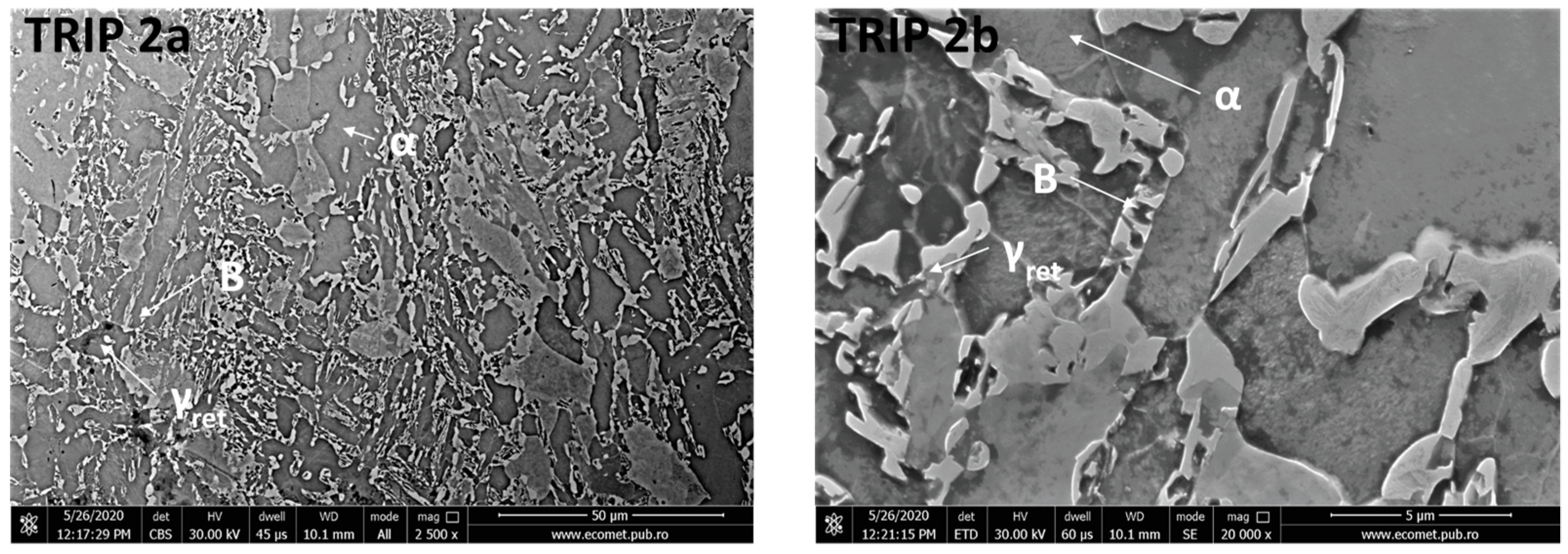

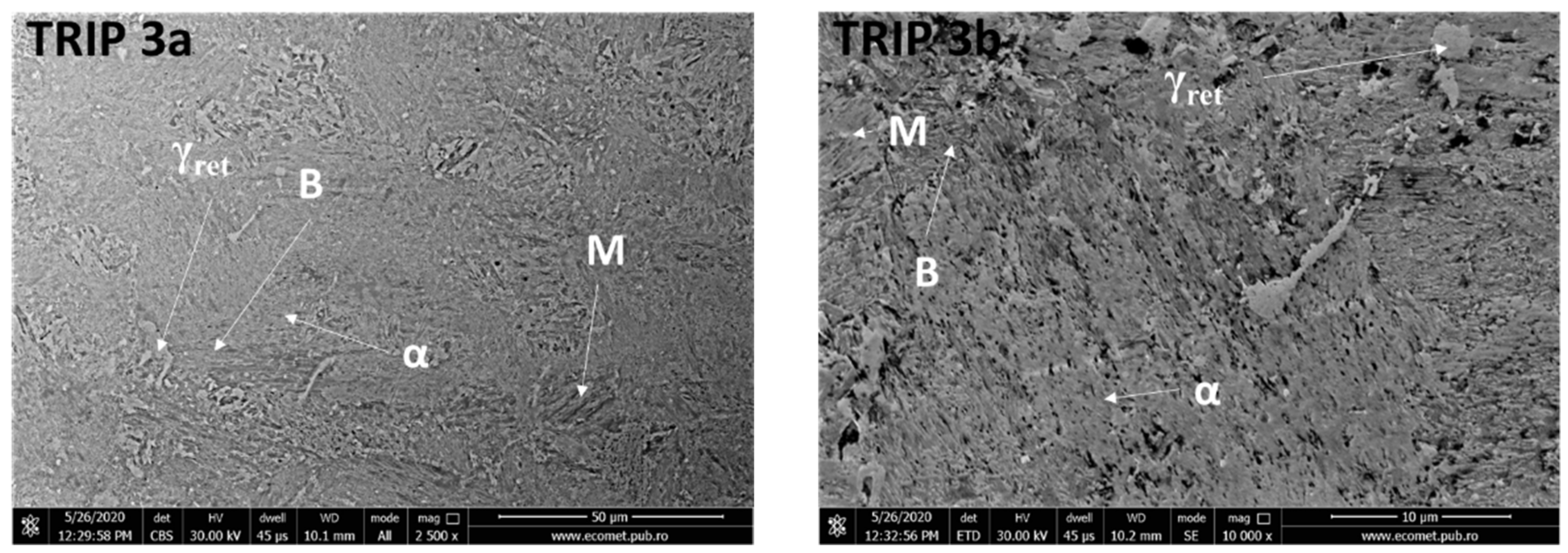

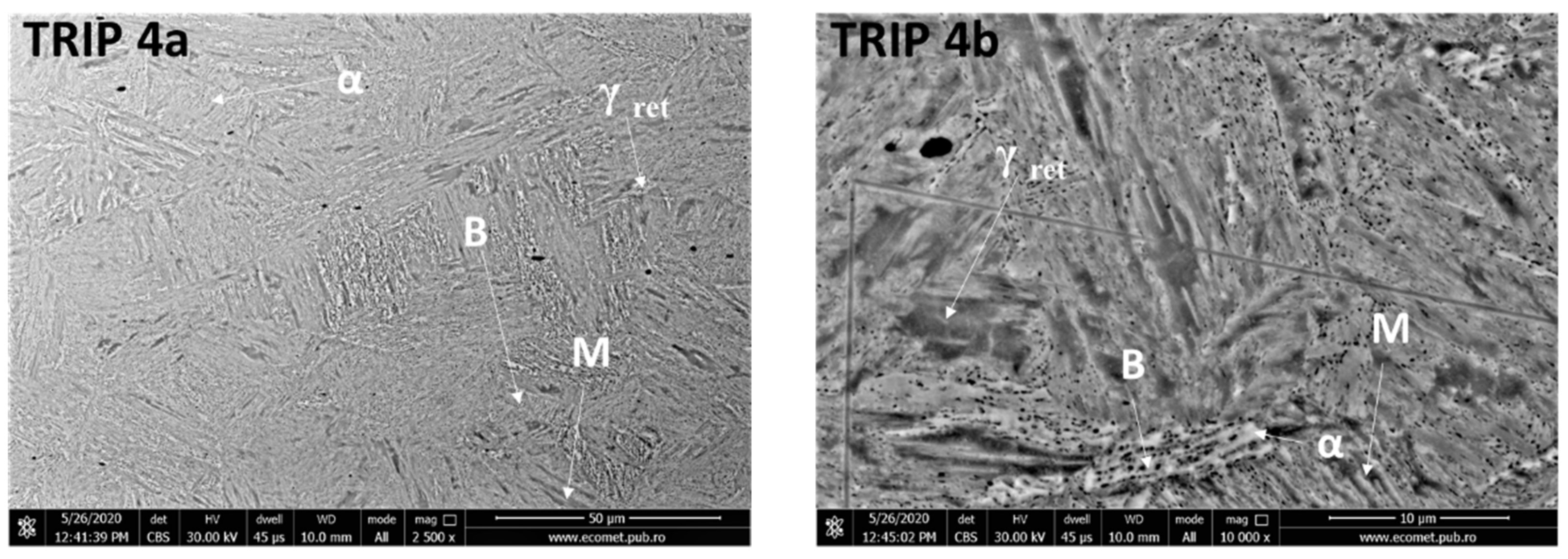

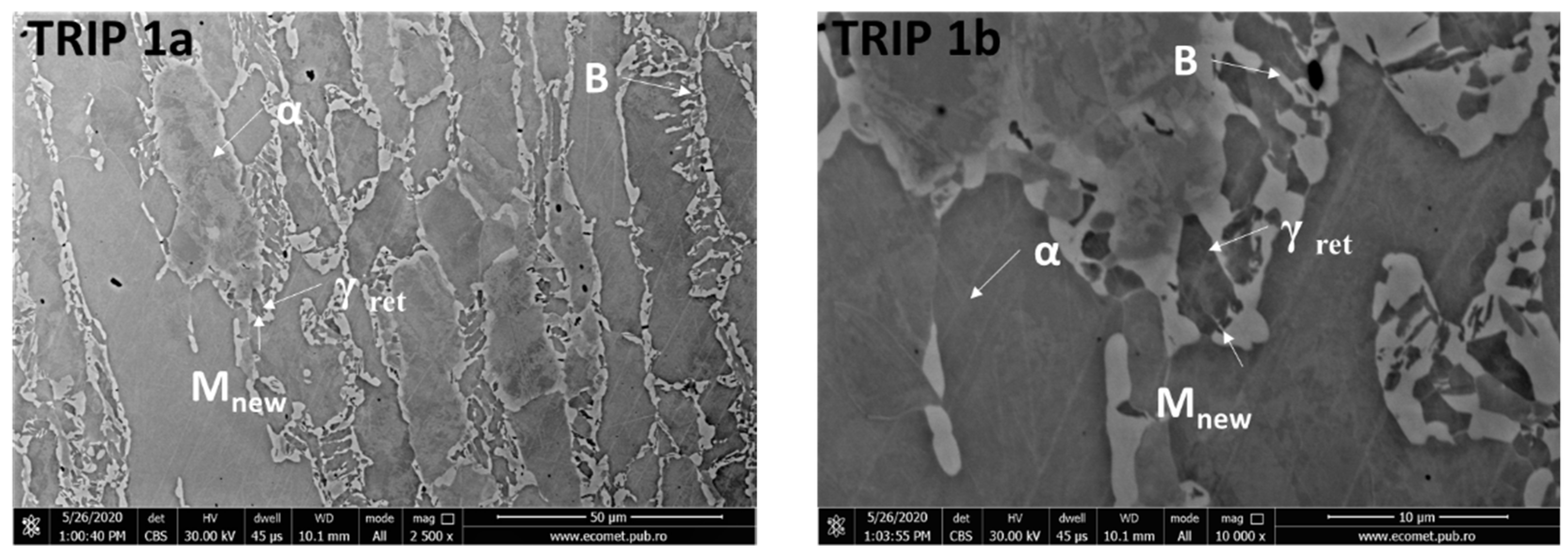

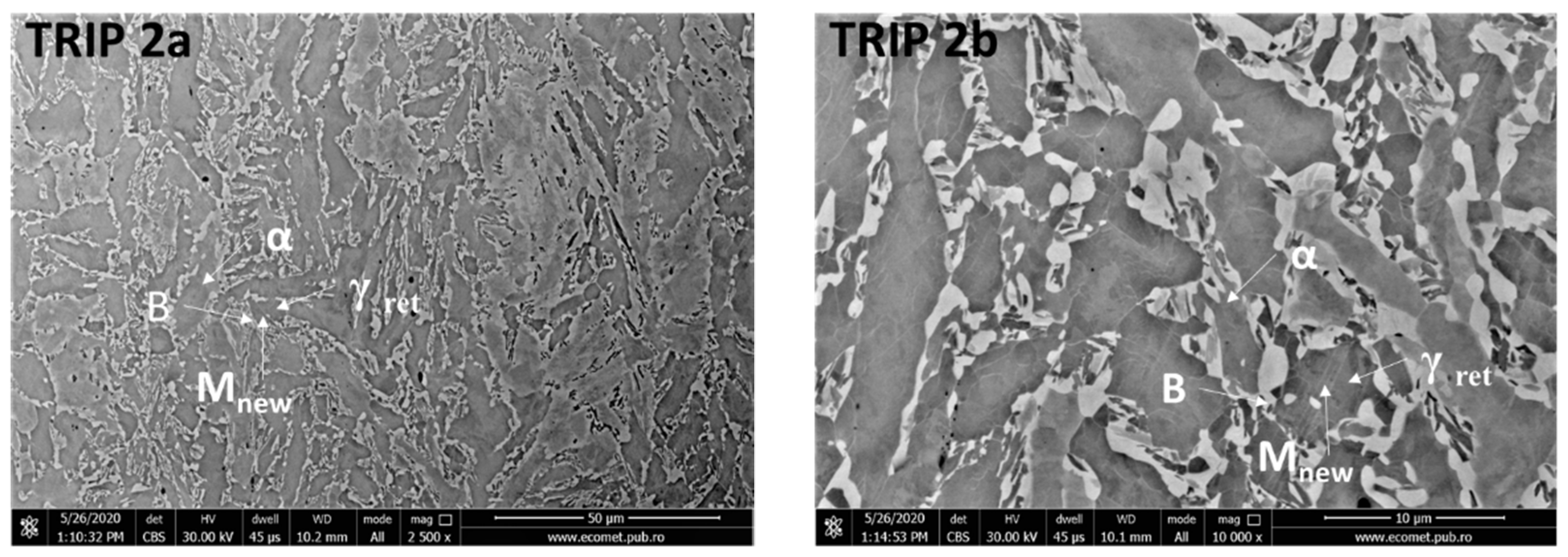

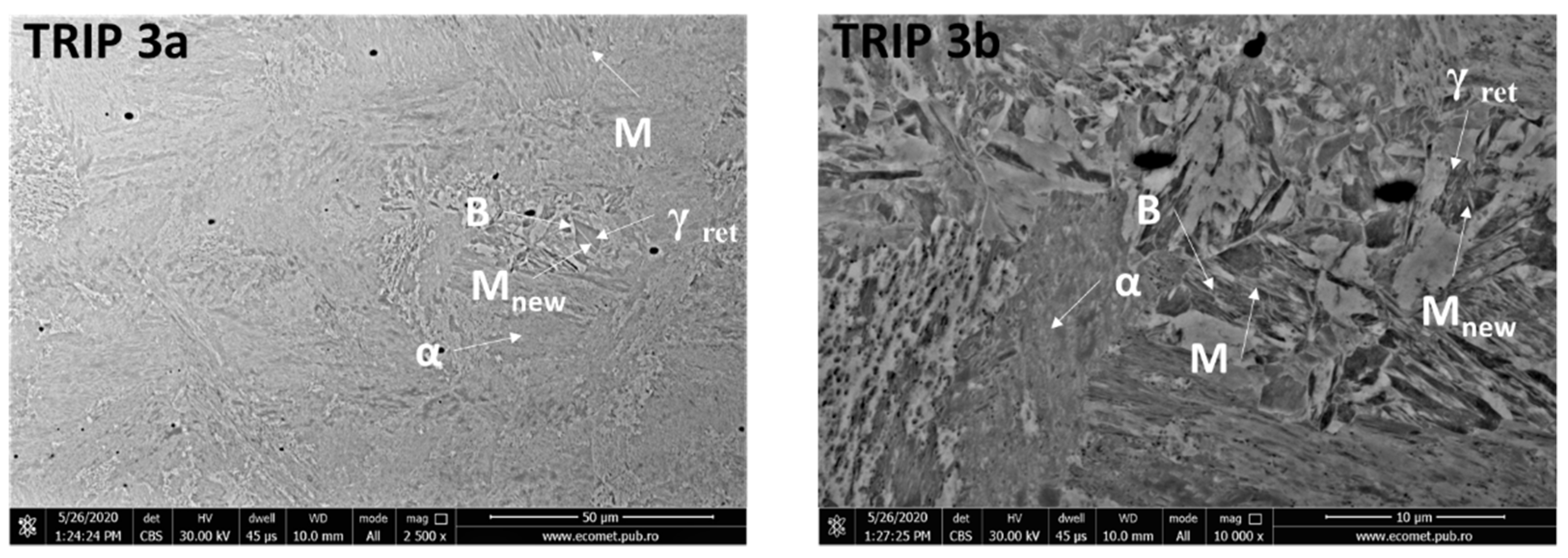

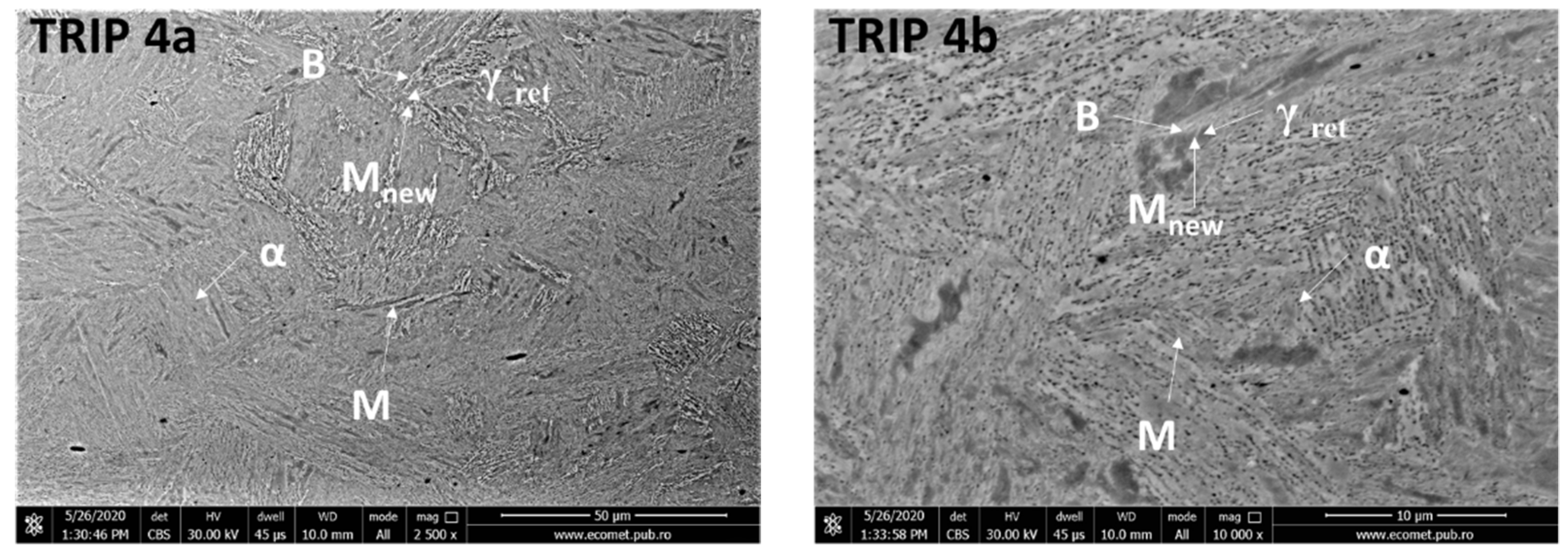

3.1. Scanning Electron Microscopy (SEM)

- -

- Accentuation of the ferrite oriented disposition, especially the bainitic one;

- -

- The trend of orderly disposal of lath martensite inside austenite islands.

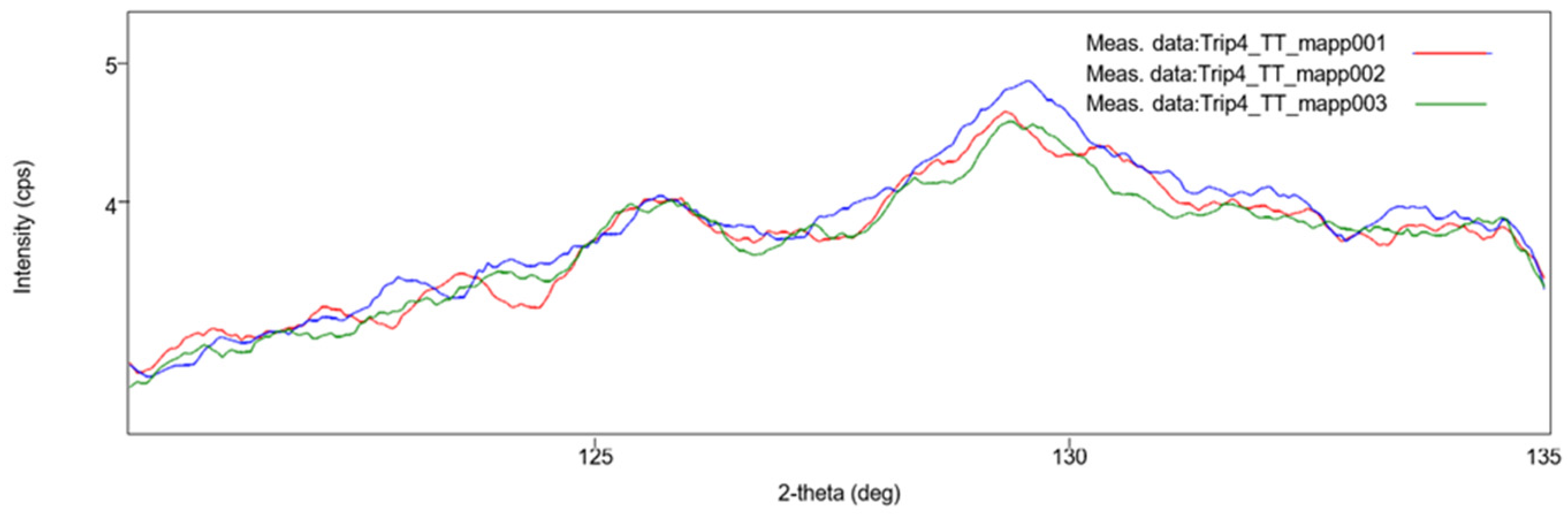

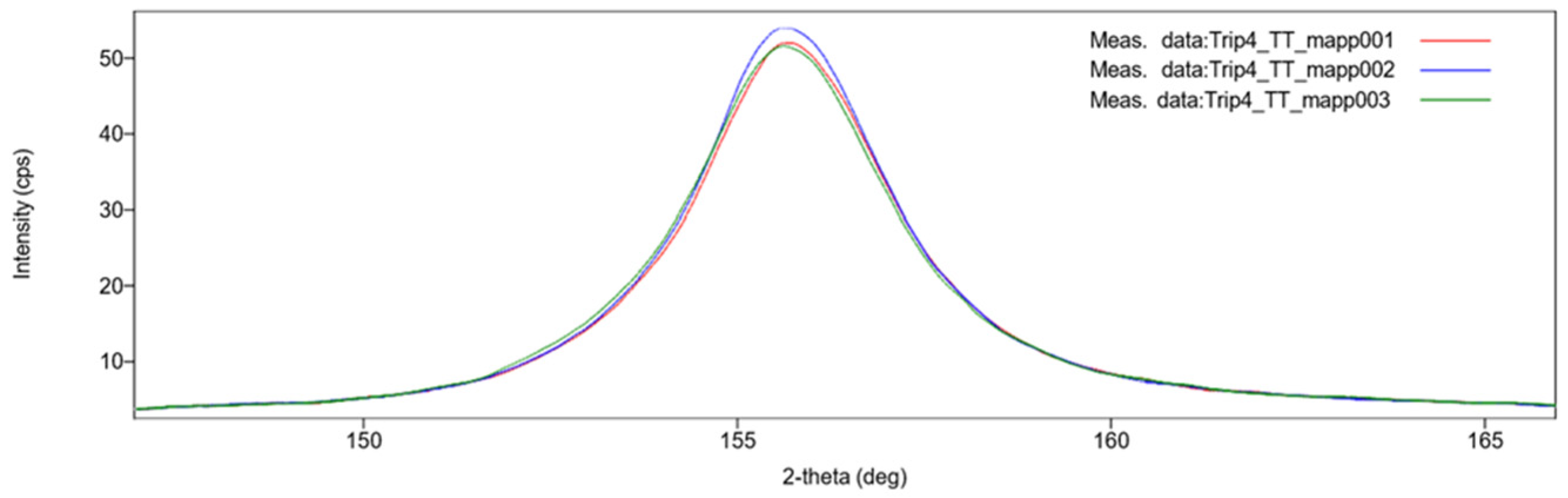

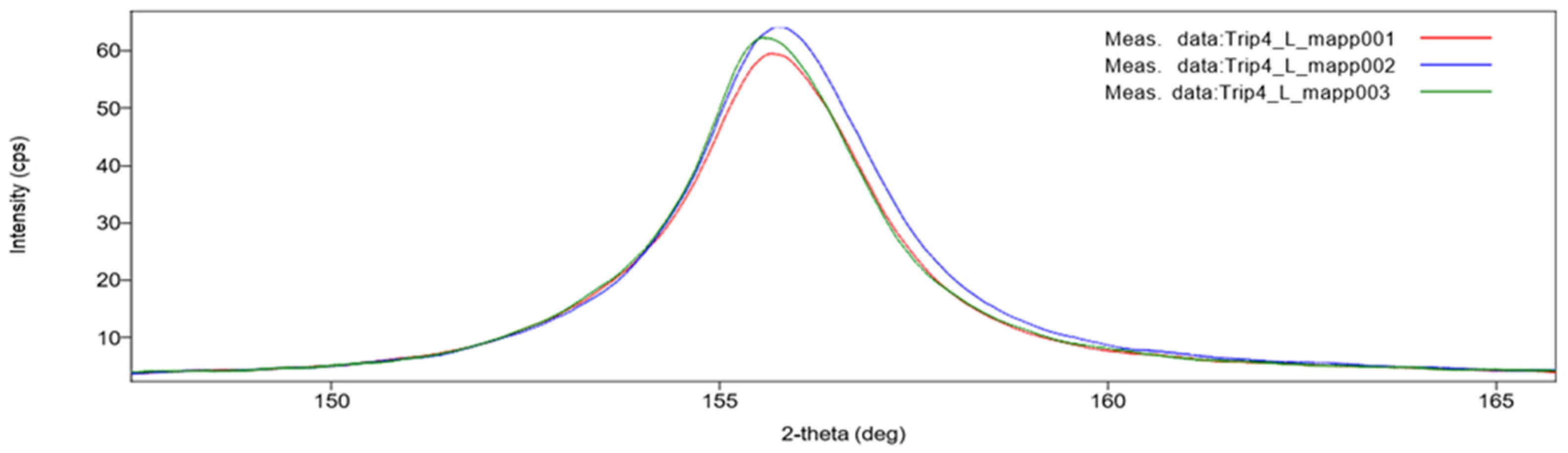

3.2. Determination of Retained Austenite by X-ray Diffraction

- -

- The highest amount of retained austenite was found in TRIP 4 steel (10.63%) due to it having the highest percentage of Mn and an Al content of 0.6%. Manganese was gammageneous and determined the improvement of the hardenability, which, at the same time, was correlated with the presence of an important fraction of retained austenite. The stabilization of austenite was thus due to alloying with both Mn and Al and was also achieved according to Bhadeshia’s theory [23];

- -

- A similar amount of retained austenite was also noticeable in TRIP 1 steel, probably due to it having a doubled percentage of C (0.2% vs. 0.1%) as well as the highest percentage of Al (1.8%). All alloying elements acted synergistically in terms of stabilizing austenite, with the high amount of Al causing the Mn deficiency of this steel (1.6%) as compared to the TRIP 4 sample (Mn = 6.1%);

- -

- A lower fraction of retained austenite was found in TRIP 2 steel, which, despite having a C content almost identical to that of TRIP 1 steel, had a lower amount of Al (1.3%), which was correlated with a slightly higher percentage of Mn (1.8%). It can be stated in this case that increasing the amount of Mn by 0.2% did not have the expected effect on the austenite stabilization (counteracting the Al decrease by 0.5%);

- -

- The lowest fraction of retained austenite was observed, as expected, in TRIP 3 steel, which had a low C content (0.1%) as well as the lowest percentage of Al (negligible when compared to the other steels). The high content of Mn (5.18%) led to the predominance of the bainite fraction, but could not stabilize higher fractions of austenite at the top of the ferrite laths, most likely due to the steel’s small number of alloying elements (including C).

- -

- Regarding the steels belonging to the first compositional group, characterized by lower percentages of Mn and higher percentages of Al and C, the highest amount of martensite obtained by the TRIP effect was found in the TRIP 2 sample (2.08%), although it did not have the highest amount of retained austenite after heat treatment; on the other hand, the TRIP 1 sample, which had a similar chemical composition and a higher amount of austenite prior to the test, showed a slightly lower fraction of martensite. A possible explanation could be a better chemical homogeneity of austenite in the TRIP 2 sample when compared to TRIP 1 steel: the segregation of Al in austenite is known to be influenced by the presence of other chemical elements and is even more pronounced when the percentage of Mn is lower [24].

- -

- The TRIP effect was most pronounced in the case of TRIP 4 steel, from the second compositional group, characterized by high Mn and low Al and C contents, respectively. This steel had the highest percentage of Mn (6.1%). This was correlated with a sufficient amount of Al (0.6%) to stabilize the highest fraction of retained austenite (10.63%), which, following the mechanical shock, had the best transformation ratio. Thus, the amount of martensite obtained after the impact bending test (2.17%) was higher than in all the other analyzed steels, regardless of the compositional group. It can be stated that percentages of Mn of over 6% were associated with amounts of Al that were slightly higher than 0.5%, even when the C percentage was low, ensuring an optimal fraction of retained austenite, characterized by a good chemical homogeneity and an appropriate ratio of austenite-to-martensite transformation by plastic deformation. In addition, the low C content ensured high plasticity and superior weldability to the steels of the first compositional group, both of which are requirements that are imposed on TRIP steels;

- -

- TRIP 3 had the lowest fraction of martensite obtained by the transformation induced by plastic deformation, and also had the lowest amount of retained austenite. In the case of steels belonging to the second compositional group, TRIP 3 and TRIP 4, it can be stated that the TRIP effect was enhanced only by the presence of an Al percentage of more than 0.5%. In fact, Table 6 shows that the highest values of ΔVM were recorded for the TRIP 3 and TRIP 4 steels (1.23%). Only relatively high amounts of Mn (over 5%), without being associated with a percentage of over 0.5% Al and/or with a higher percentage of C, were sufficient neither to obtain a high fraction of retained austenite nor for its transformation into martensite in a significant amount.

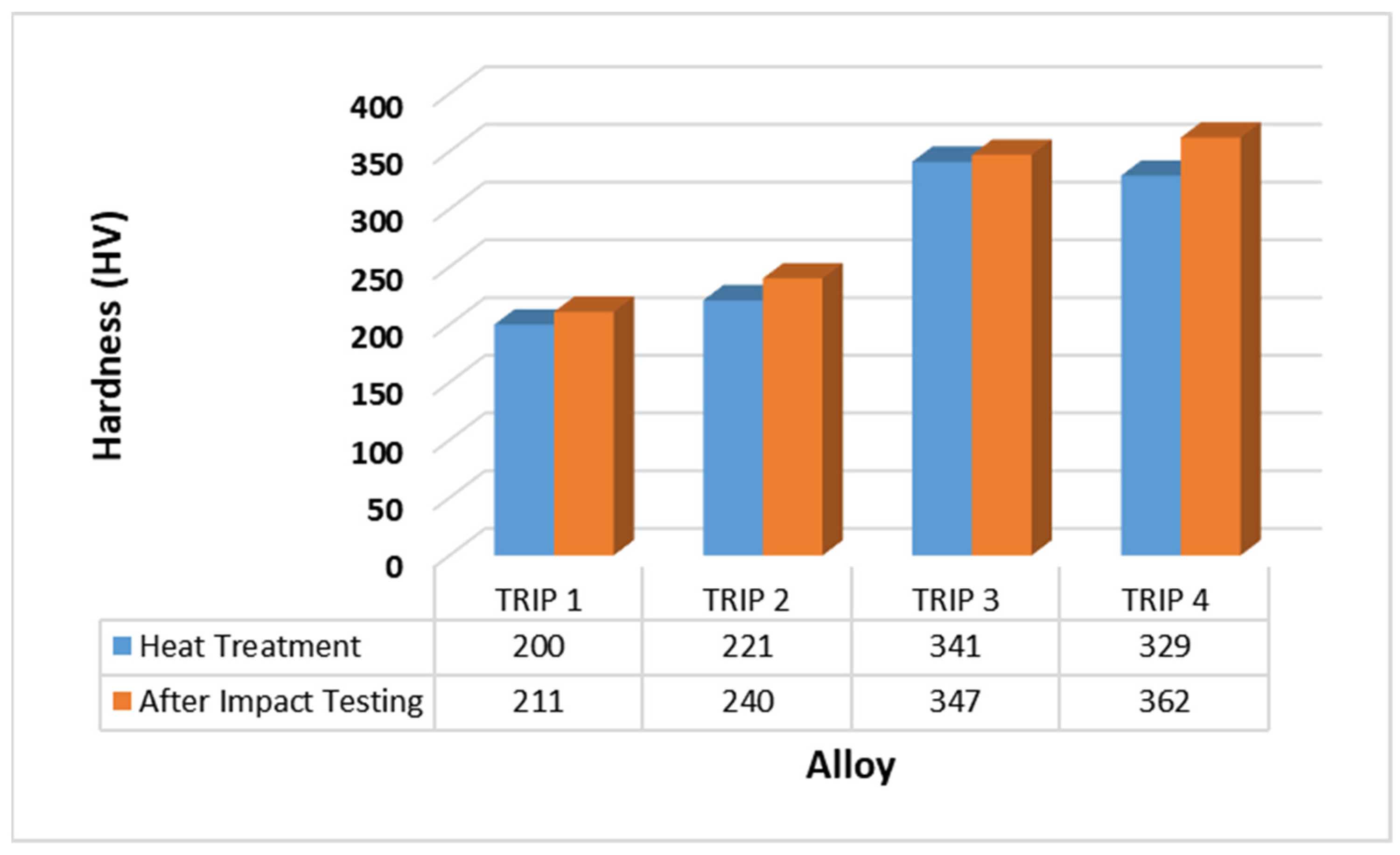

3.3. Hardness Tests

- -

- Cold-working, produced by plastic deformation in the impact bending test;

- -

- Structural hardening, which occurred as a result of obtaining martensite via the γret → M phase transformation.

4. Conclusions

- The highest fraction of retained austenite after heat treatment was found in the TRIP 4 steel (10.63%); a close value (9.29%) was determined in the TRIP 1 steel, while smaller amounts were found in the TRIP 2 (7.40%) and TRIP 3 (4.63%) steels. Therefore, TRIP 4 steel is the most promising in terms of the extent of the transformation underlying the TRIP effect. The highest content of Mn (6.1%), which was correlated with an Al percentage of 0.6%, contributed to the stabilization of austenite and, thus, to the obtaining of the highest fraction of retained phase that was able to be transformed after impact.

- The deformation-induced martensite fractions were: TRIP 1—1.96%; TRIP 2—2.08%; TRIP 3—0.94%; TRIP 4—2.17%. Given that the highest amount of martensite was obtained in TRIP 4, this steel is the optimal solution in impact situations.

- The increases in hardness after impact were correlated with the martensite fractions obtained after the impact bending test. In this respect, the highest hardness was recorded in TRIP 4 steel (362 HV).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Soleimani, M.; Kalhor, A.; Mirzadeh, H. Transformation-induced plasticity (TRIP) in advanced steels: A review. Mater. Sci. Eng. A 2020, 795, 140023. [Google Scholar] [CrossRef]

- Ríos-Diez, O.; Aristizábal-Sierra, R.; Serna-Giraldo, C.; Jimenez, J.A.; Garcia-Mateo, C. Development of Nanobainitic Microstructures in Carbo-Austempered Cast Steels: Heat Treatment, Microstructure and Properties. Metals 2020, 10, 635. [Google Scholar] [CrossRef]

- Salinas, A.; Celentano, D.; Carvajal, L.; Artigas, A.; Monsalve, A. Microstructure-Based Constitutive Modelling of Low-Alloy Multiphase TRIP Steels. Metals 2019, 9, 250. [Google Scholar] [CrossRef] [Green Version]

- Kozłowska, A.; Radwański, K.; Matus, K.; Samek, L.; Grajcar, A. Mechanical stability of retained austenite in aluminum-containing medium-Mn steel deformed at different temperatures. Arch. Civ. Mech. Eng. 2021, 21, 324–338. [Google Scholar] [CrossRef]

- Sugimoto, K.; Usui, N.; Kobayashi, M.; Hashimoto, S. Effects of volume fraction and stability of retained austenite on ductility of TRIP-aided dual-phase steels. ISIJ Int. 1992, 32, 1311–1318. [Google Scholar] [CrossRef]

- Speer, J.G.; Streicher, A.M.; Matlock, D.K.; Rizzo, F.C.; Krauss, G. Quenching and partitioning: A fundamentally new process to create high strength trip sheet microstructures. In Proceedings of the Materials Science & Technology 2003, Chicago, IL, USA, 9–12 November 2003; pp. 505–522. [Google Scholar]

- Traint, S.; Pichler, A.; Hauzenberger, K.; Stiaszny, P.; Werner, E. Influence of silicon, aluminium, phosphorus and copper on the phase transformations of low alloyed TRIP steels. Steel Res. 2002, 73, 259–266. [Google Scholar] [CrossRef]

- Li, L.; De Cooman, B.C.; Wollants, P.; He, Y.L.; Zhou, X.D. Effect of aluminum and silicon on transformation induced plasticity of the TRIP steel. J. Mater. Sci. Technol. 2004, 20, 135–138. [Google Scholar]

- Gomez, M.; Garcia, C.I.; Haezebrouck, D.; Deardo, A. Design of composition in (Al/Si)-alloyed TRIP steels. ISIJ Int. 2009, 49, 302–311. [Google Scholar] [CrossRef] [Green Version]

- Lim, N.S.; Park, H.S.; Kim, S.; Park, C.G. Effects of aluminum on the microstructure and phase transformation of TRIP steels. Met. Mater. Int. 2012, 18, 647–654. [Google Scholar] [CrossRef]

- Cai, M.; Li, Z.; Chao, Q.; Hodgson, P. A novel Mo and Nb microalloyed medium Mn TRIP Steel with maximal ultimate strength and moderate ductility. Metall. Mater. Trans. A 2014, 45, 5624–5634. [Google Scholar] [CrossRef]

- Tian, J.; Xu, G.; Jiang, Z.; Wan, X.; Hu, H.; Yuan, Q. Transformation Behavior and Properties of Carbide-Free Bainite Steels with Different Si Contents. Steel Res. Int. 2019, 90, 1800474. [Google Scholar] [CrossRef] [Green Version]

- Caballero, F.; García-Mateo, C.; Chao, J.; Santofimia, M.J.; Capdevila, C.; García de Andrés, C. Effects of Morphology and Stability of Retained Austenite on the Ductility of TRIP-aided Bainitic Steels. ISIJ Int. 2008, 48, 1256–1262. [Google Scholar] [CrossRef] [Green Version]

- Salinas, A.; Artigas, A.; Perez-Ipiña, J.; Castro-Cerda, F.; Garza-Montes-de-Oca, N.; Colás, R.; Petrov, R.; Monsalve, A. Effects of Heat Treatment on Morphology, Texture, and Mechanical Properties of a MnSiAl Multiphase Steel with TRIP Behavior. Metals 2018, 8, 1021. [Google Scholar] [CrossRef] [Green Version]

- Tan, X.; He, H.; Lu, W.; Yang, L.; Tang, B.; Yan, J.; Xu, Y.; Wu, D. Effect of matrix structures on TRIP effect and mechanical properties of low-C low-Si Al-added hot-rolled TRIP steels. Mater Sci. Eng. A 2019, 771, 138629. [Google Scholar] [CrossRef]

- Kruijver, S.O.; Zhao, L.; Sietsma, J.; Offerman, S.E.; Van Dijk, N.H.; Lauridsen, E.M.; Margulies, L.; Grigull, S.; Poulsen, H.F.; Van der Zwaag, S. In situ observations on the mechanical stability of austenite in TRIP-steel. J. Phys. IV 2003, 104, 499–502. [Google Scholar] [CrossRef]

- Kumar Srivastava, A.; Jha, G.; Gope, N.; Singh, S.B. Effect of heat treatment on microstructure and mechanical properties of cold rolled C–Mn–Si TRIP-aided steel. Mater Charact. 2006, 57, 127–135. [Google Scholar] [CrossRef]

- Merwin, M.J. Low-Carbon Manganese TRIP Steels. Mater. Sci. Forum. 2007, 539, 4327–4332. [Google Scholar] [CrossRef]

- Pantilimon, M.C. Modern Steel Concepts for the Roadworthiness Structure of Road Vehicles. Ph.D. Thesis, Doctoral School of Materials Science and Engineering, University Politehnica of Bucharest, Bucharest, Romania, 2020. [Google Scholar]

- Grange, R.A. Estimating Critical Ranges in Heat Treatment. Met. Prog. 1961, 79, 73–75. [Google Scholar]

- Mertens, A.; Jacques, P.; Lazarova, R.; Zhao, L.; Sietsma, J.; Delannay, F. On the influence of aluminium content on the stability of retained austenite in multiphase TRIP-assisted steels. J. Phys. IV 2001, 11, Pr8-223–Pr8-228. [Google Scholar] [CrossRef] [Green Version]

- Tian, J.; Xu, G.; Zhou, M.; Hu, H.; Xue, Z. Effects of Al addition on bainite transformation and properties of high-strength carbide-free bainitic steels. J. Iron Steel Res. Int. 2019, 26, 846–855. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H.; Christian, J.W. Bainite in steels. Metall Trans. A 1990, 21, 767–797. [Google Scholar] [CrossRef]

- Palizdar, Y. Understanding the Effect of Aluminium on the Microstructure on Low Level Nitrogen Steel. Ph.D. Thesis, School of Process, Environmental and Materials Engineering, The University of Leeds, Leeds, UK, 2011. [Google Scholar]

| Raw Materials’ Element Contents, wt% | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C | Mn | Si | S | P | Cu | Al | Fe | Ca | Cr | Ni | Ti | |

| ARMCO | 0.005 | 0.047 | 0.043 | 0.02 | 0.006 | 0.01 | 0.004 | bal. | - | 0.006 | 0.01 | - |

| FeSi | 0 | 0.659 | 68.18 | 0.002 | 0.027 | 0.049 | 1.589 | 28.39 | 0.049 | 0.244 | 0.067 | 0.148 |

| FeMn | 1.2 | 78.22 | 1.832 | 0.004 | 0.187 | 0.093 | 0.056 | 17.97 | 0.017 | 0.197 | 0.147 | 0.019 |

| Mn | - | 99.8 | - | - | - | - | - | - | - | - | - | - |

| Al | - | - | - | - | - | - | 99.99 | - | - | - | - | - |

| Element Contents, wt% | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Steel | C | Mn | Si | S | P | Cu | Al | B | Mo | Cr | Ni | Ti | |

| TRIP 1 | Ref. [10] | 0.2 | 1.6 | 0.3 | - | - | - | 1.8 | - | - | - | - | - |

| Cast | 0.199 | 1.58 | 0.281 | 0.035 | 0.023 | 0.020 | 1.77 | 0.003 | 0.002 | 0.016 | 0.024 | 0.014 | |

| TRIP 2 | Ref. [11] | 0.25 | 1.8 | 0.3 | - | 0.021 | - | 1.3 | - | - | - | - | - |

| Cast | 0.251 | 1.81 | 0.307 | 0.029 | 0.024 | 0.033 | 1.29 | 0.003 | 0.005 | 0.028 | 0.030 | 0.080 | |

| TRIP 3 | Ref. [12] | 0.1 | 5.18 | 0.2 | 0.008 | 0.015 | 0.03 | 0.026 | - | 0.02 | 0.04 | 0.03 | - |

| Cast | 0.105 | 5.20 | 0.213 | 0.007 | 0.019 | 0.016 | 0.002 | 0.002 | 0.001 | 0.012 | 0.020 | 0.008 | |

| TRIP 4 | Ref. [13] | 0.1 | 6.1 | 0.3 | - | - | - | 0.6 | - | - | - | - | - |

| Cast | 0.097 | 6.11 | 0.324 | 0.028 | 0.022 | 0.016 | 0.616 | 0.002 | 0.001 | 0.012 | 0.018 | 0.009 | |

| Steel | Ac1 (°C) | Ac3 (°C) | TT = (Ac1 + Ac3)/2 (°C) |

|---|---|---|---|

| TRIP 1 | 750 | 813 | 781.5 |

| TRIP 2 | 737 | 800 | 768.5 |

| TRIP 3 | 659 | 773 | 716 |

| TRIP 4 | 661 | 766 | 713.5 |

| Sample Code | Retained Austenite Fraction, Vγ1 (%) |

|---|---|

| TRIP 1 | 9.29 |

| TRIP 2 | 7.40 |

| TRIP 3 | 4.63 |

| TRIP 4 | 10.63 |

| Sample Code | Retained Austenite Fraction, Vγ2 (%) |

|---|---|

| TRIP 1 | 7.33 |

| TRIP 2 | 5.32 |

| TRIP 3 | 3.69 |

| TRIP 4 | 8.46 |

| Sample Code | Martensite Fraction, VM (%) | The Difference between the Martensite Fractions, ΔVM (%) |

|---|---|---|

| TRIP 1 | 1.96 | 0.12 |

| TRIP 2 | 2.08 | |

| TRIP 3 | 0.94 | 1.23 |

| TRIP 4 | 2.17 |

| TRIP Steel | Vickers Hardness | |||

|---|---|---|---|---|

| HV1 | Stdev 1 | HV2 | Stdev 2 | |

| TRIP 1 | 200 | 3 | 211 | 26 |

| TRIP 2 | 221 | 4 | 240 | 29 |

| TRIP 3 | 341 | 11 | 347 | 25 |

| TRIP 4 | 329 | 2 | 362 | 20 |

| TRIP Steel | γret Volume Transformed in M (%) | Vickers Hardness Increase (ΔHV) |

|---|---|---|

| TRIP 1 | 1.96 | 11 |

| TRIP 2 | 2.08 | 19 |

| TRIP 3 | 0.94 | 6 |

| TRIP 4 | 2.17 | 33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pantilimon, M.C.; Berbecaru, A.C.; Gherghescu, I.A.; Coman, G.; Ciucă, S.; Grecu, A.; Sohaciu, M.G.; Dumitrescu, R.E.; Predescu, C. Comparative Evaluation of the TRIP Effect in Steels with Different Contents of Mn and Al. Metals 2022, 12, 443. https://doi.org/10.3390/met12030443

Pantilimon MC, Berbecaru AC, Gherghescu IA, Coman G, Ciucă S, Grecu A, Sohaciu MG, Dumitrescu RE, Predescu C. Comparative Evaluation of the TRIP Effect in Steels with Different Contents of Mn and Al. Metals. 2022; 12(3):443. https://doi.org/10.3390/met12030443

Chicago/Turabian StylePantilimon, Mircea Cristian, Andrei Constantin Berbecaru, Ioana Arina Gherghescu, George Coman, Sorin Ciucă, Andrei Grecu, Mirela Gabriela Sohaciu, Ruxandra Elena Dumitrescu, and Cristian Predescu. 2022. "Comparative Evaluation of the TRIP Effect in Steels with Different Contents of Mn and Al" Metals 12, no. 3: 443. https://doi.org/10.3390/met12030443

APA StylePantilimon, M. C., Berbecaru, A. C., Gherghescu, I. A., Coman, G., Ciucă, S., Grecu, A., Sohaciu, M. G., Dumitrescu, R. E., & Predescu, C. (2022). Comparative Evaluation of the TRIP Effect in Steels with Different Contents of Mn and Al. Metals, 12(3), 443. https://doi.org/10.3390/met12030443