Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel

Abstract

:1. Introduction

2. Experiment

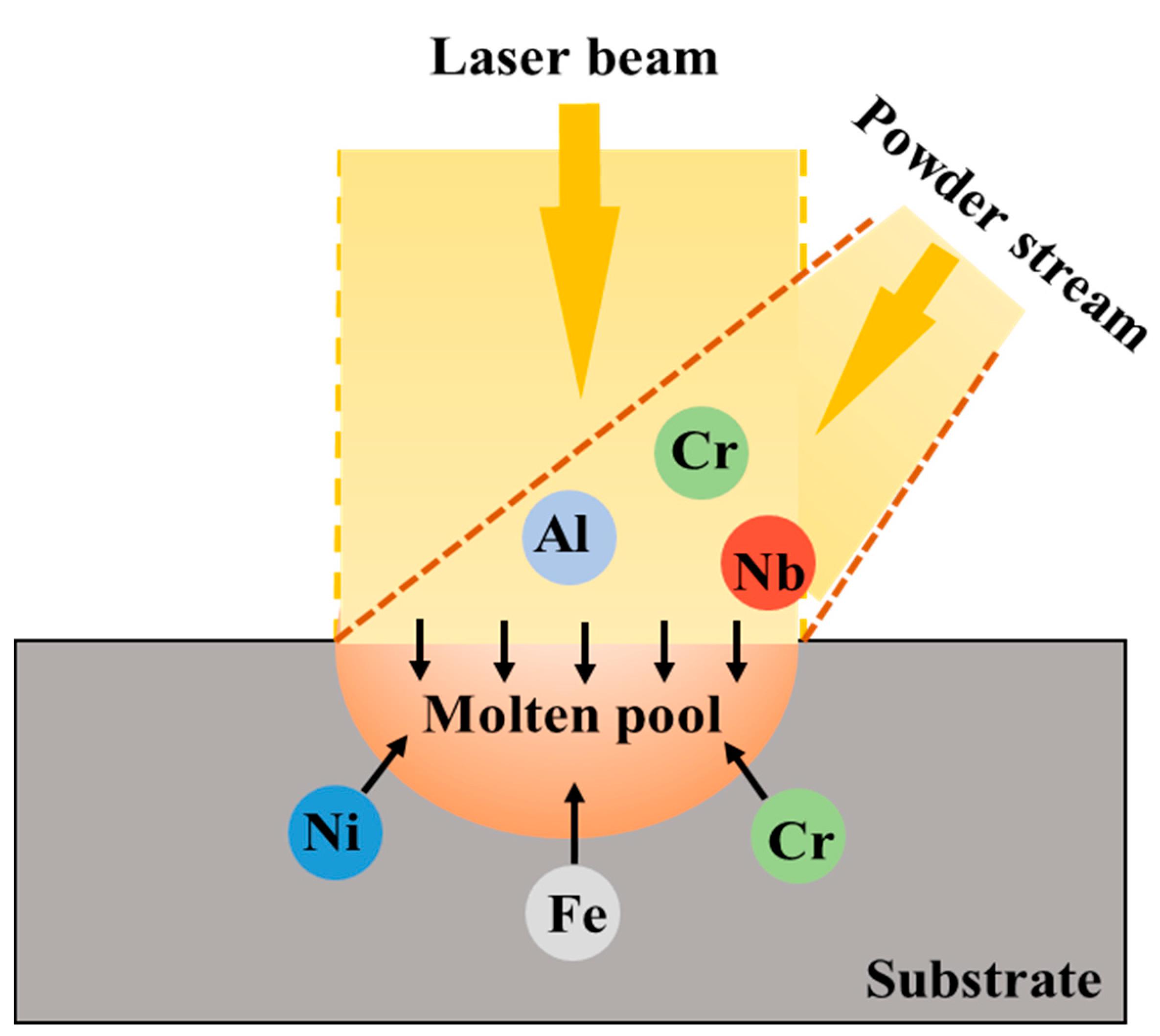

2.1. Preparation of the Simples

2.2. Material Characterization

2.3. Performance Test

3. Results and Discussion

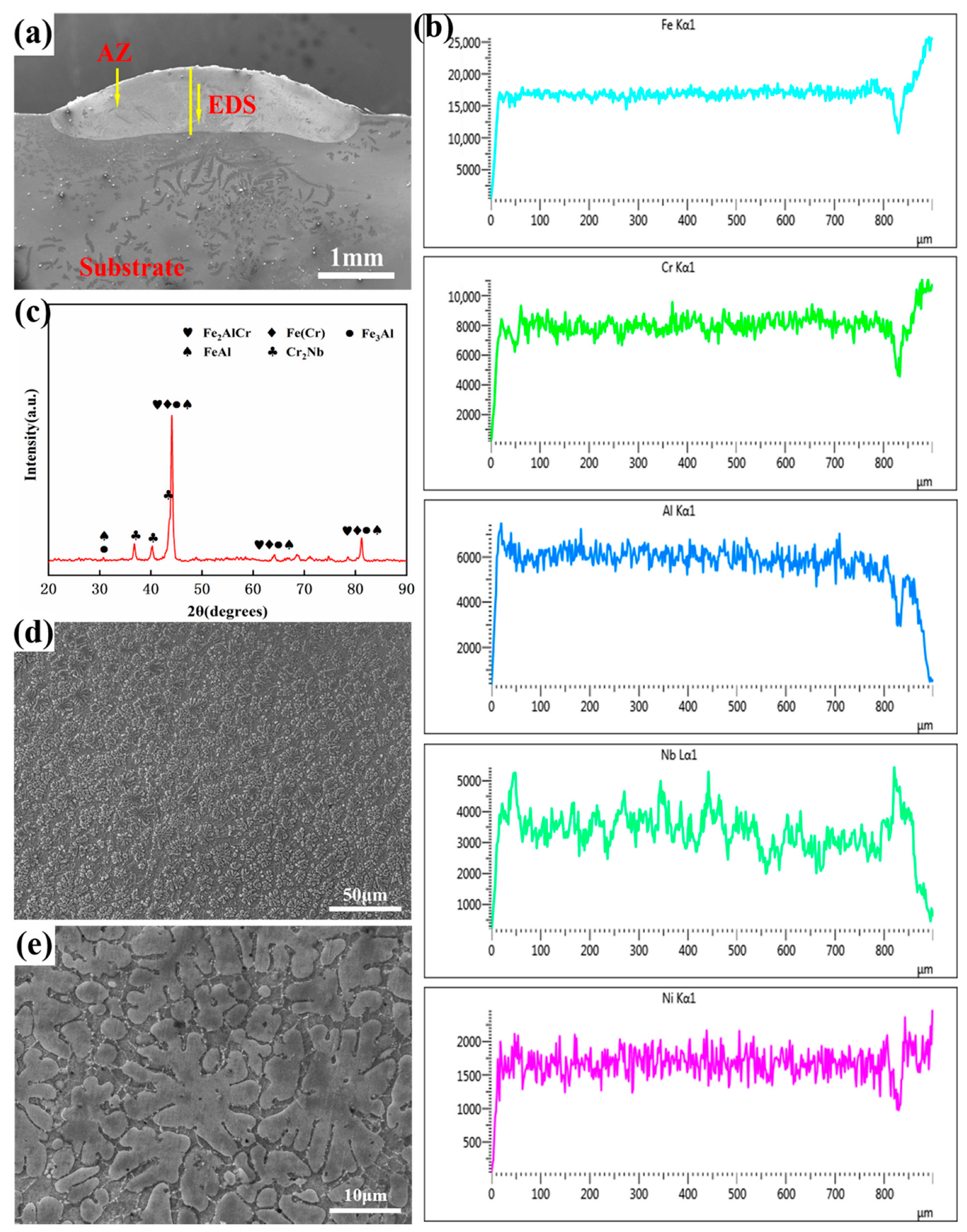

3.1. Macro Morphology and Micro Analysis of the AZ

3.2. Microhardness

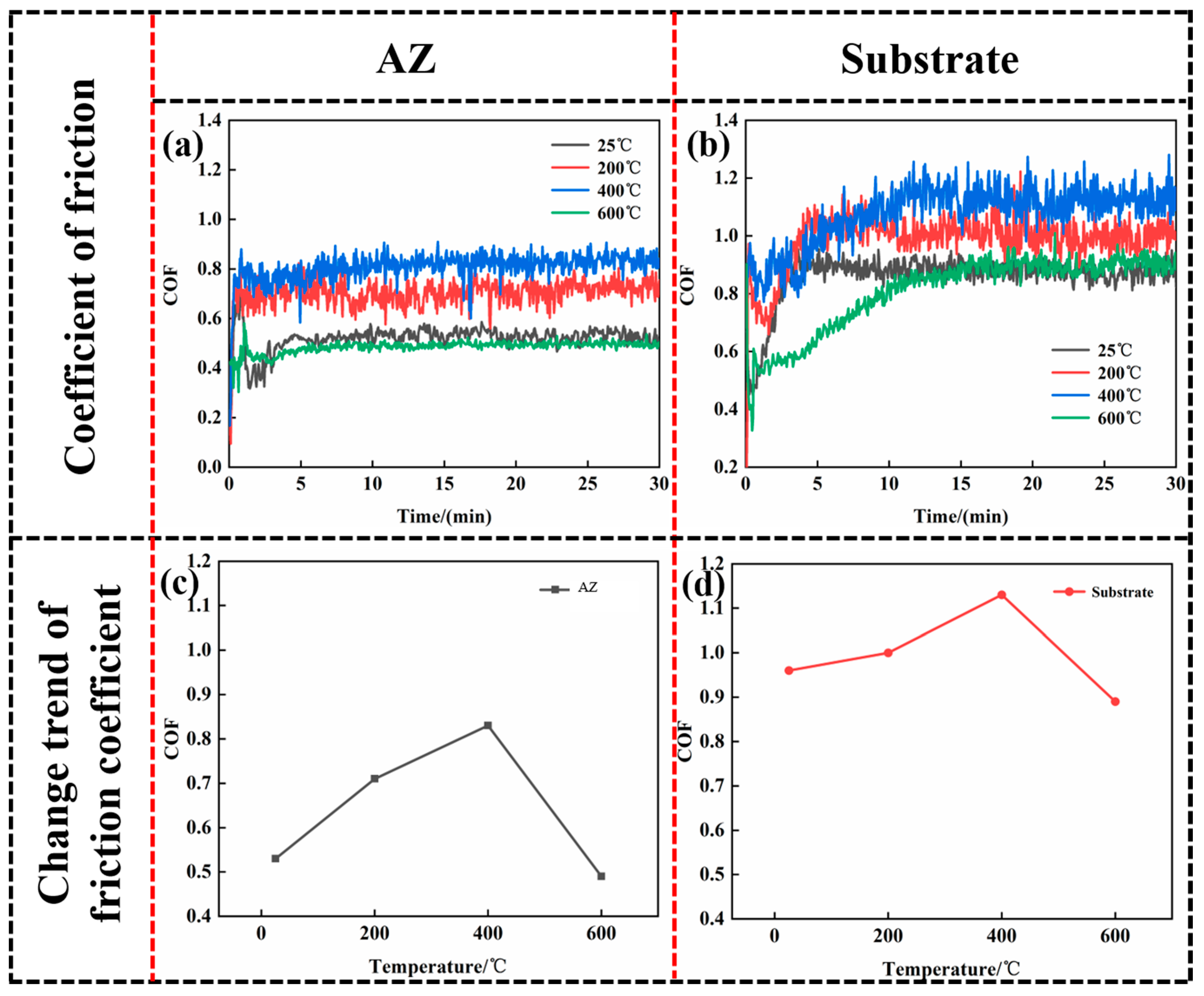

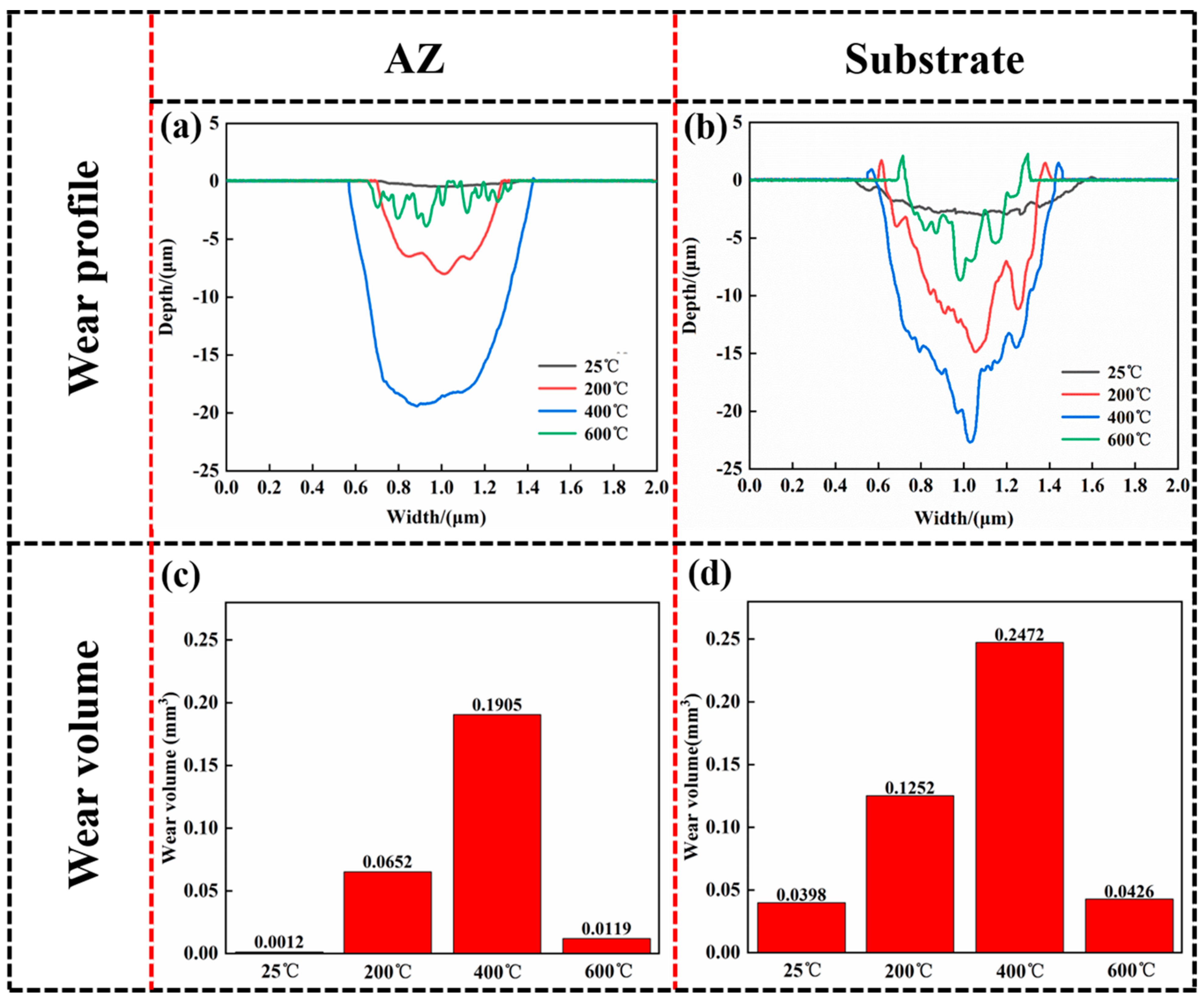

3.3. Friction Coefficient and Wear Volume

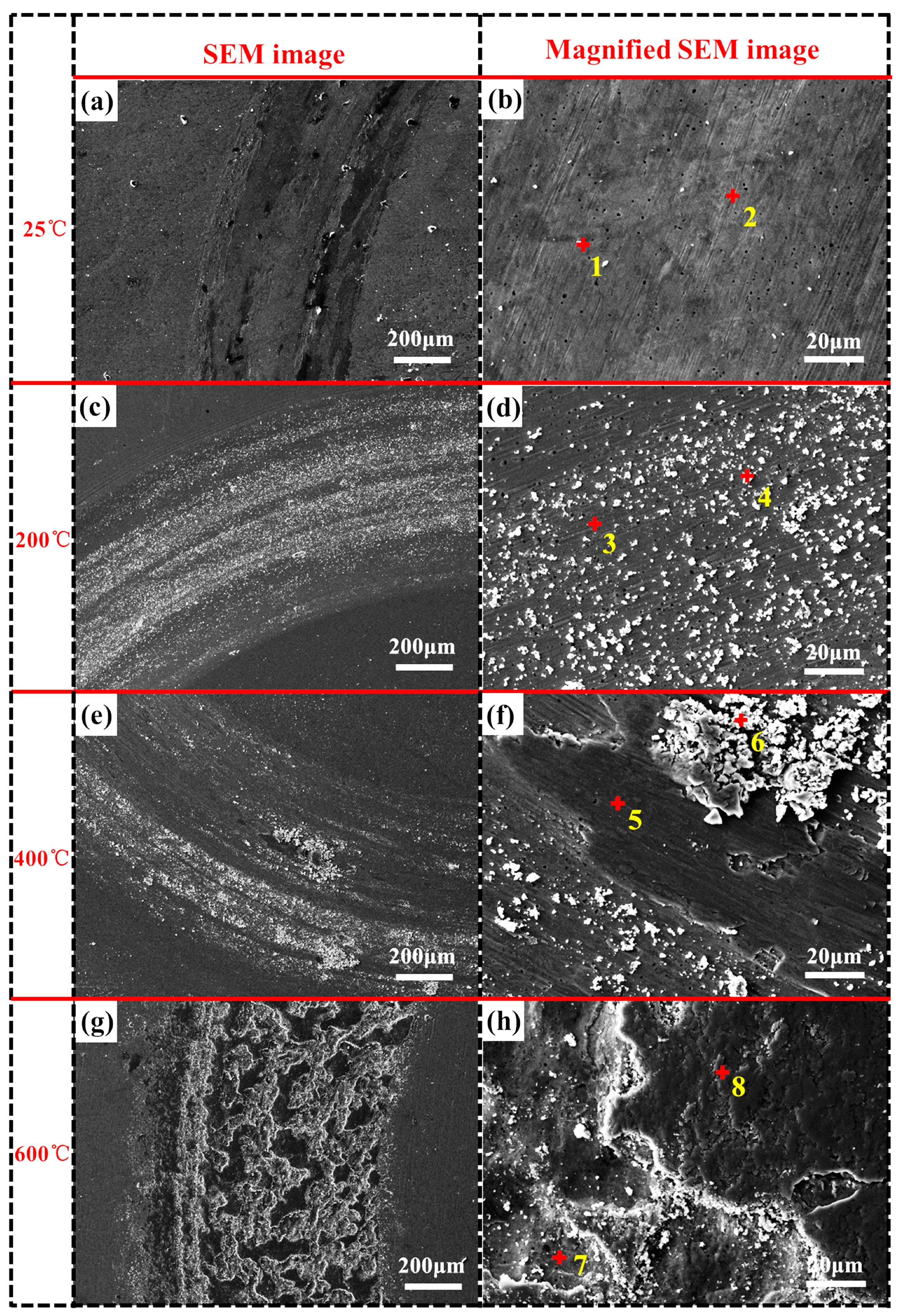

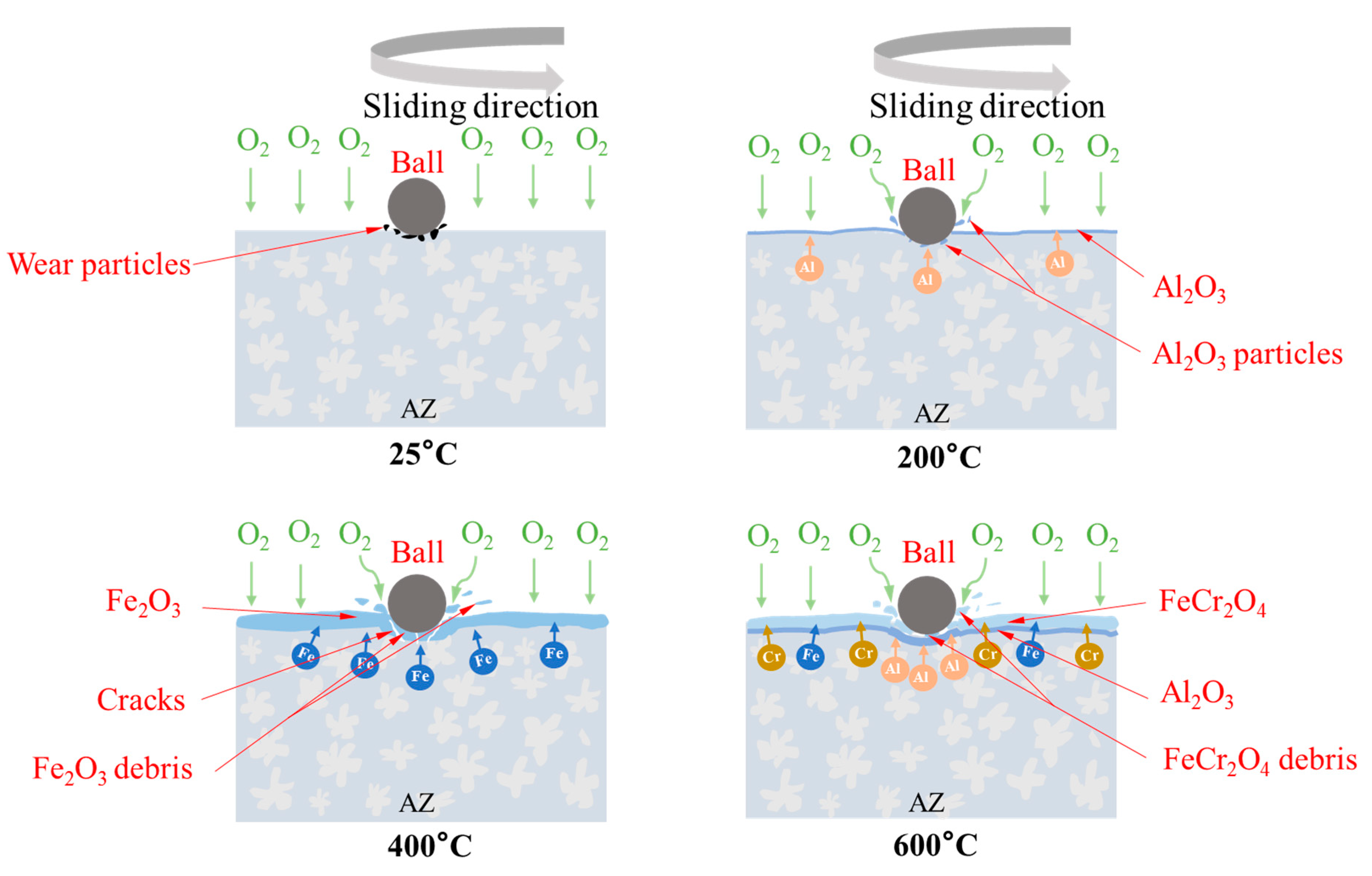

3.4. Wear Mechanism of the AZ

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zalnezhad, E.; Hamouda, A.; Faraji, G.; Shamshirband, S. TiO2 nanotube coating on stainless steel 304 for biomedical applications. Ceram. Int. 2015, 41, 2785–2793. [Google Scholar] [CrossRef]

- Singh, J.; Kumar, S.; Mohapatra, S.K. Tribological analysis of WC–10Co–4Cr and Ni–20Cr2O3 coating on stainless steel 304. Wear 2017, 376–377, 1105–1111. [Google Scholar] [CrossRef]

- Zhao, H.; Duan, L.; Chen, G.; Fan, H.; Wang, J.; Zhou, C. High corrosion resistance performance of 304 stainless steel after liquid nitrocarburization. Compos. Part B Eng. 2018, 155, 173–177. [Google Scholar] [CrossRef]

- Liu, M.J.; Zhang, M.; Zhang, G.Q.; Yang, G.-J.; Li, C.-X.; Li, C.-J. Gaseous material capacity of open plasma jet in plasma spray-physical vapor deposition process. Appl. Surf. Sci. 2018, 428, 877–884. [Google Scholar] [CrossRef]

- Han, Y.-J.; Zhu, Z.-Y.; Li, X.-Q.; Shen, S.-G.; Ye, F.-X. Effects of vacuum pre-oxidation process on thermally-grown oxides layer of CoCrAlY high temperature corrosion resistance coating. Trans. Nonferr. Met. Soc. China 2015, 25, 3305–3314. [Google Scholar] [CrossRef]

- Brandl, W.; Marginean, G.; Maghet, D.; Utu, D. Effects of specimen treatment and surface preparation on the isothermal oxidation behaviour of the HVOF-sprayed MCrAlY coatings. Surf. Coat. Technol. 2004, 188–189, 20–26. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, X.; Xiao, P. Effect of microstructure on early oxidation of MCrAlY coatings. Acta Mater. 2018, 159, 150–162. [Google Scholar] [CrossRef] [Green Version]

- Nie, J.; Li, Y.; Chen, B.; Yang, Y.; Zhang, H.; Liu, S.; Wei, S.; Cai, J.; Guan, Q. Evolution of oxide layer during high-temperature oxidation of NiCoCrAlY coating via laser cladding on 304 stainless steel. Mater. Lett. 2021, 286, 129233. [Google Scholar] [CrossRef]

- Li, Y.; Nie, J.; Liang, Z.; Bai, P.; Yang, Y.; Chen, B.; Liu, S.; Guan, Q.; Cai, J. Microstructure evolution and high-temperature oxidation behavior of FeCrAlNbNi alloyed zone prepared by laser surface alloying on 304 stainless steel. J. Alloys Compd. 2021, 888, 161468. [Google Scholar] [CrossRef]

- Li, Y.; Nie, J.; Yang, Y.; Bai, P.; Zhang, H.; Zhao, Z.; Wei, S.; Cai, J.; Guan, Q. High-Temperature Oxidation Behavior of NiCoCrAlY Coatings Deposited by Laser Cladding on 304 Stainless Steel. Met. Mater. Int. 2021, 28, 412–420. [Google Scholar] [CrossRef]

- Sahoo, C.K.; Masanta, M. Microstructure and mechanical properties of TiC-Ni coating on AISI304 steel produced by TIG cladding process. J. Mater. Process. Technol. 2017, 240, 126–137. [Google Scholar] [CrossRef]

- OuYang, C.-S.; Liu, X.-B.; Luo, Y.-S.; Liang, J.; Wang, M.; Chen, D.-Q. Preparation and high temperature tribological properties of laser in-situ synthesized self-lubricating composite coating on 304 stainless steel. J. Mater. Res. Technol. 2020, 9, 7034–7046. [Google Scholar] [CrossRef]

- Jin, G.; Cai, Z.; Guan, Y.; Cui, X.; Liu, Z.; Li, Y.; Dong, M.; Zhang, D. High temperature wear performance of laser-cladded FeNiCoAlCu high-entropy alloy coating. Appl. Surf. Sci. 2018, 445, 113–122. [Google Scholar] [CrossRef]

- Tang, H.; Zhang, H.; Chen, L.; Guo, S. Novel laser rapidly solidified medium-entropy high speed steel coatings with enhanced hot wear resistance. J. Alloys Compd. 2019, 772, 719–727. [Google Scholar] [CrossRef]

- Wu, L.-K.; Xia, J.-J.; Jiang, M.-Y.; Wang, Q.; Wu, H.-X.; Sun, D.-B.; Yu, H.-Y.; Cao, F.-H. Oxidation behavior of Ti45Al8.5Nb alloy anodized in NH4F containing solution. Corros. Sci. 2020, 166, 108447. [Google Scholar] [CrossRef]

- Chen, G.; Wang, H.; Sun, H.; Zhang, Y.; Cao, P.; Wang, J. Effects of Nb-doping on the mechanical properties and high-temperature steam oxidation of annealing FeCrAl fuel cladding alloys. Mater. Sci. Eng. A 2021, 803, 140500. [Google Scholar] [CrossRef]

- Liu, Z.; Wang, C.; Yi, J.; Yu, Y.; Yu, B.; Yang, G. Microstructure and Mechanical Property of High Strength and High Toughness Titanium Alloy by Laser Deposition Manufacturing. J. Phys. Conf. Ser. 2021, 1965, 012086. [Google Scholar] [CrossRef]

- Lin, C.-W.; Chen, K.-J.; Hung, F.-Y.; Lui, T.-S.; Chen, H.-P. Impact of solid-solution treatment on microstructural characteristics and formability of rotary-swaged 2024 alloy tubes. J. Mater. Res. Technol. 2019, 8, 3137–3148. [Google Scholar] [CrossRef]

- Li, Q.; Lei, Y.; Fu, H. Laser cladding in-situ NbC particle reinforced Fe-based composite coatings with rare earth oxide addition. Surf. Coat. Technol. 2014, 239, 102–107. [Google Scholar] [CrossRef]

- Torres, H.; Varga, M.; Widder, F.; Cihak-Bayr, U.; Viskovic, O.; Ripoll, M.R. Experimental simulation of high temperature sliding contact of hot rolled steel. Tribol. Int. 2016, 93, 745–754. [Google Scholar] [CrossRef]

- Li, Y.; Su, K.; Bai, P.; Wu, L. Microstructure and property characterization of Ti/TiBCN reinforced Ti based composite coatings fabricated by laser cladding with different scanning speed. Mater. Charact. 2020, 159, 110023. [Google Scholar] [CrossRef]

- Yu, P.-C.; Liu, X.-B.; Lu, X.-L.; Qiao, S.-J.; Zhai, Y.-J.; Zhu, G.-X.; Wang, Y.-G.; Chen, Y. Tribology and high-temperature oxidation behaviors of NiCrBSiFe composite coatings on Ti6Al4V alloy by laser cladding. RSC Adv. 2015, 5, 76516–76525. [Google Scholar] [CrossRef]

- Li, Y.; Yang, Y.; Nie, J.; Bai, P.; Liang, Z.; Wei, S.; Cai, J.; Guan, Q. Hot corrosion behavior of a NiCoCrAlY coating fabricated by laser cladding on 17-4PH stainless steel. Eng. Fail. Anal. 2022, 1133, 05962. [Google Scholar] [CrossRef]

- Ziemniak, S.E.; Anovitz, L.M.; Castelli, R.A.; Porter, W.D. Thermodynamics of Cr2O3, FeCr2O4, ZnCr2O4, and CoCr2O4. J. Chem. Thermodyn. 2007, 39, 1474–1492. [Google Scholar] [CrossRef] [Green Version]

- Ramachandran, T.; Hamed, F. The effect of fuel to nitrates ratio on the properties of FeCr2O4 nanopowders. Mater. Res. Bull. 2017, 95, 104–114. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | P | S | Cr | Ni | Fe |

|---|---|---|---|---|---|---|---|---|

| wt.% | 0.040 | 0.378 | 0.903 | 0.040 | 0.004 | 18.330 | 8.110 | Bal. |

| The Parameters | Values |

|---|---|

| Laser output power/W | 1600 |

| Wavelength/nm | 980–1020 |

| Laser scanning speed/(mm/s) | 7 |

| Beam diameter/mm | 4 |

| Focal distance/mm | 40 |

| Overlap rate | 50% |

| Powder feeding speed/(g/min) | 4.5 |

| Argon gas flow rate/(L/min) | 2.5 |

| EDS Point | Composition (At.%) | |||||

|---|---|---|---|---|---|---|

| Fe | Cr | Al | Nb | Ni | O | |

| 1 | 11.79 | 5.30 | 9.89 | 4.47 | 1.26 | 67.29 |

| 2 | 39.31 | 24.65 | 18.48 | 8.79 | 4.56 | 4.21 |

| 3 | 38.22 | 13.78 | 27.36 | 7.15 | 5.76 | 7.73 |

| 4 | 6.92 | 3.53 | 36.15 | 0.22 | 0.86 | 52.32 |

| 5 | 27.12 | 9.81 | 9.48 | 3.07 | 3.40 | 47.12 |

| 6 | 24.91 | 8.70 | 11.85 | 3.38 | 3.41 | 47.75 |

| 7 | 7.90 | 3.62 | 34.01 | 1.96 | 1.25 | 51.26 |

| 8 | 11.42 | 26.68 | 3.31 | 6.26 | 0.58 | 51.75 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, C.; Nie, J.; Li, Y.; Guan, Q.; Cai, J.; Zhang, P.; Wu, J. Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel. Metals 2022, 12, 467. https://doi.org/10.3390/met12030467

Cui C, Nie J, Li Y, Guan Q, Cai J, Zhang P, Wu J. Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel. Metals. 2022; 12(3):467. https://doi.org/10.3390/met12030467

Chicago/Turabian StyleCui, Chunsheng, Jinhao Nie, Yuxin Li, Qingfeng Guan, Jie Cai, Pengfei Zhang, and Jie Wu. 2022. "Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel" Metals 12, no. 3: 467. https://doi.org/10.3390/met12030467

APA StyleCui, C., Nie, J., Li, Y., Guan, Q., Cai, J., Zhang, P., & Wu, J. (2022). Wear Resistance of FeCrAlNbNi Alloyed Zone via Laser Surface Alloying on 304 Stainless Steel. Metals, 12(3), 467. https://doi.org/10.3390/met12030467