Biodegradable WE43 Magnesium Alloy Produced by Selective Laser Melting: Mechanical Properties, Corrosion Behavior, and In-Vitro Cytotoxicity

Abstract

:1. Introduction

2. Materials and Methods

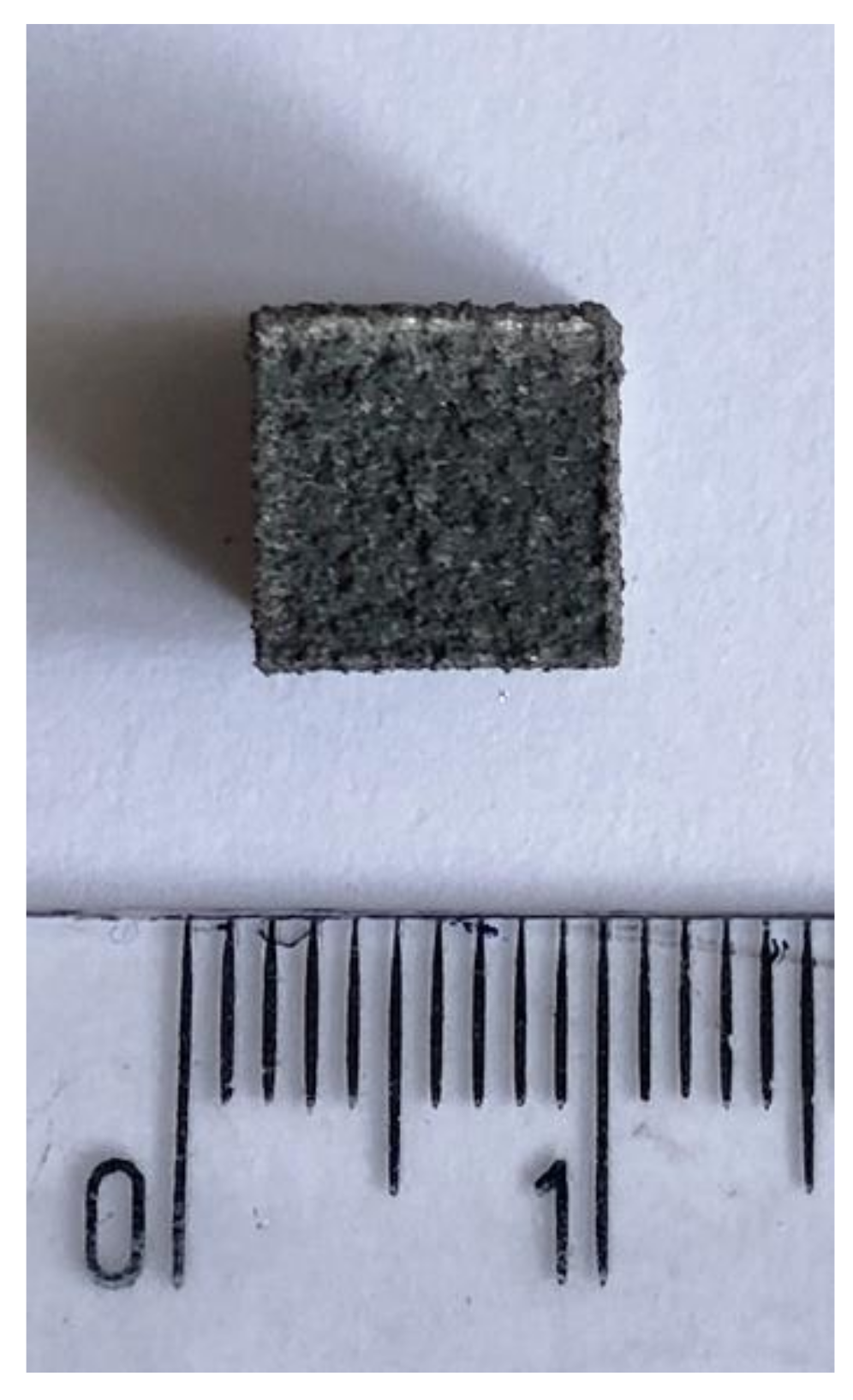

2.1. Material Preparation

2.2. Microstructure Characterization

2.3. Mechanical Testing

2.4. Corrosion Properties

2.5. Cytotoxicity Test

3. Results and Discussion

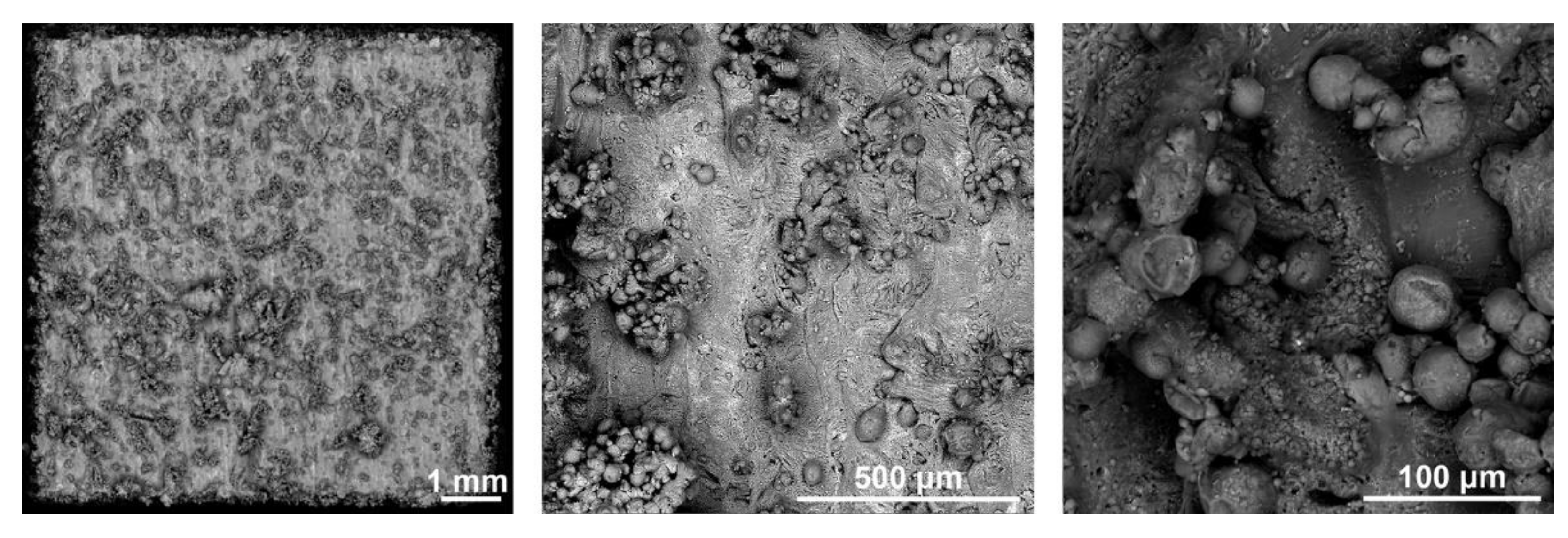

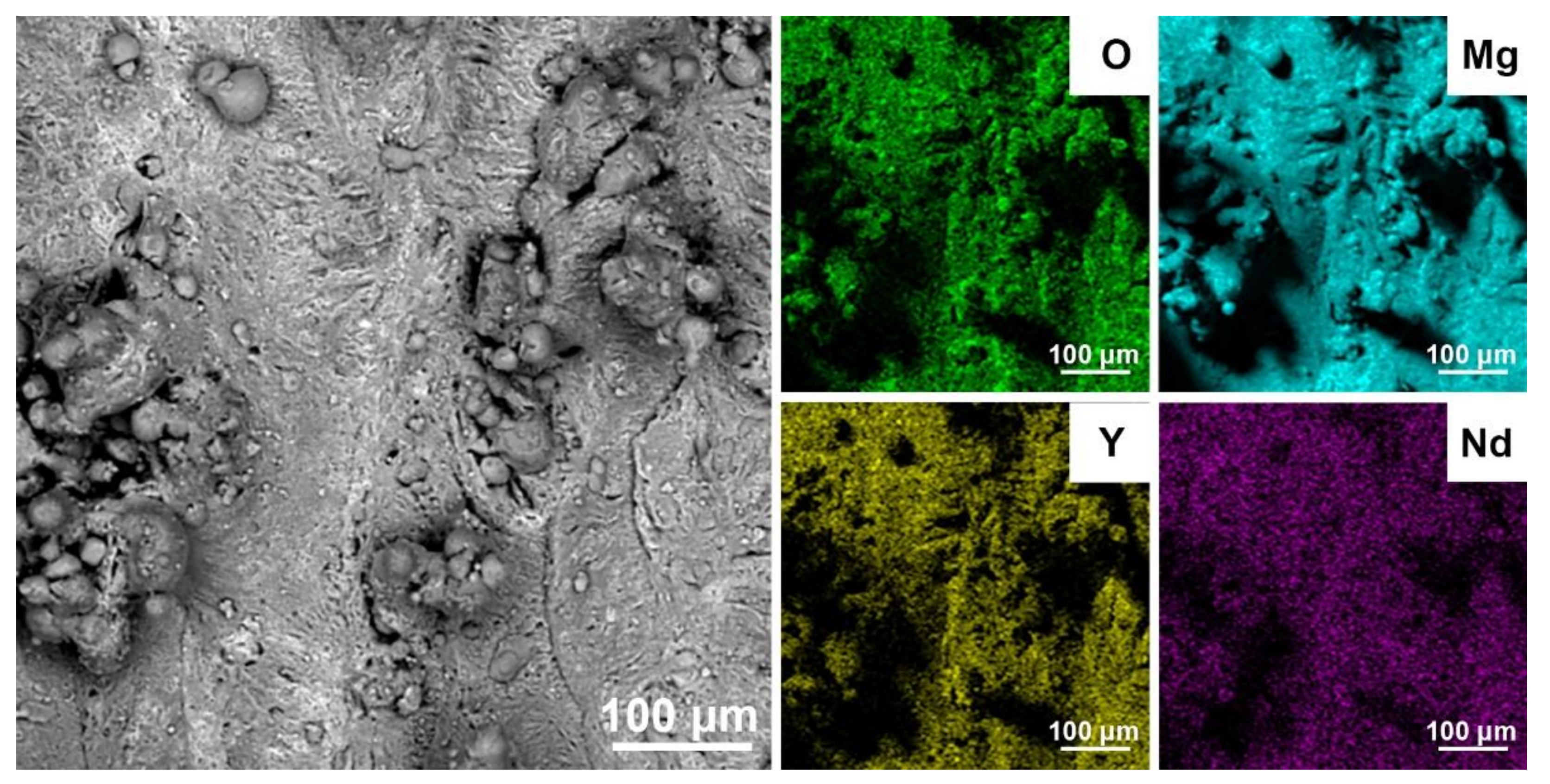

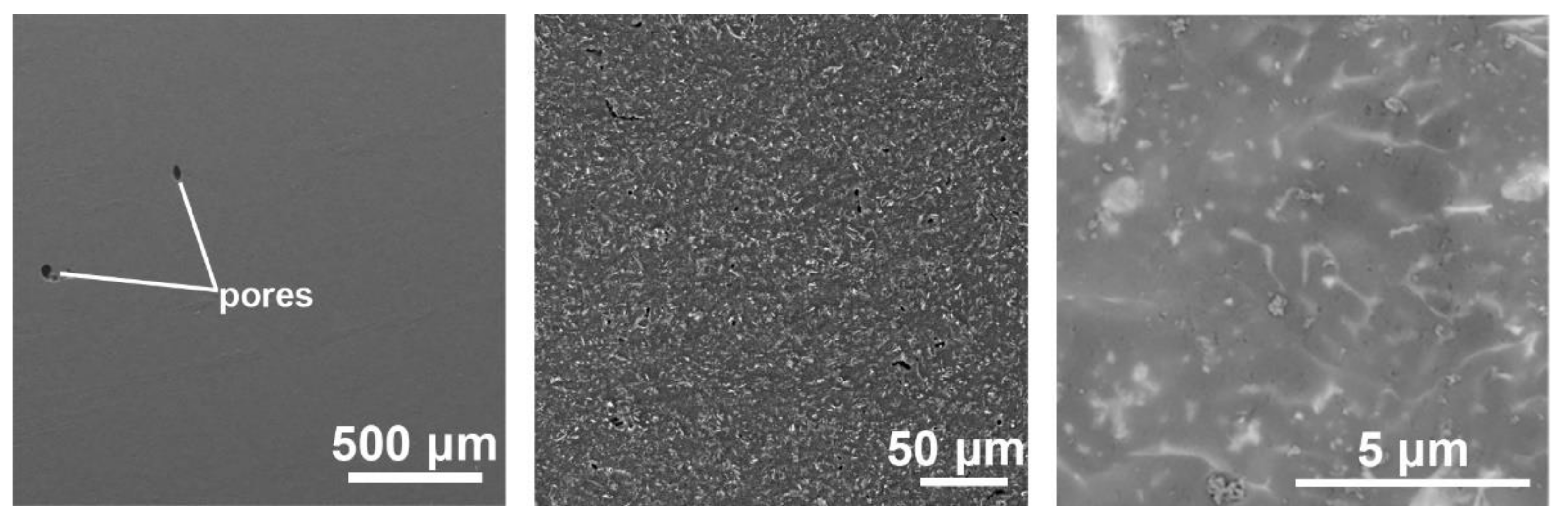

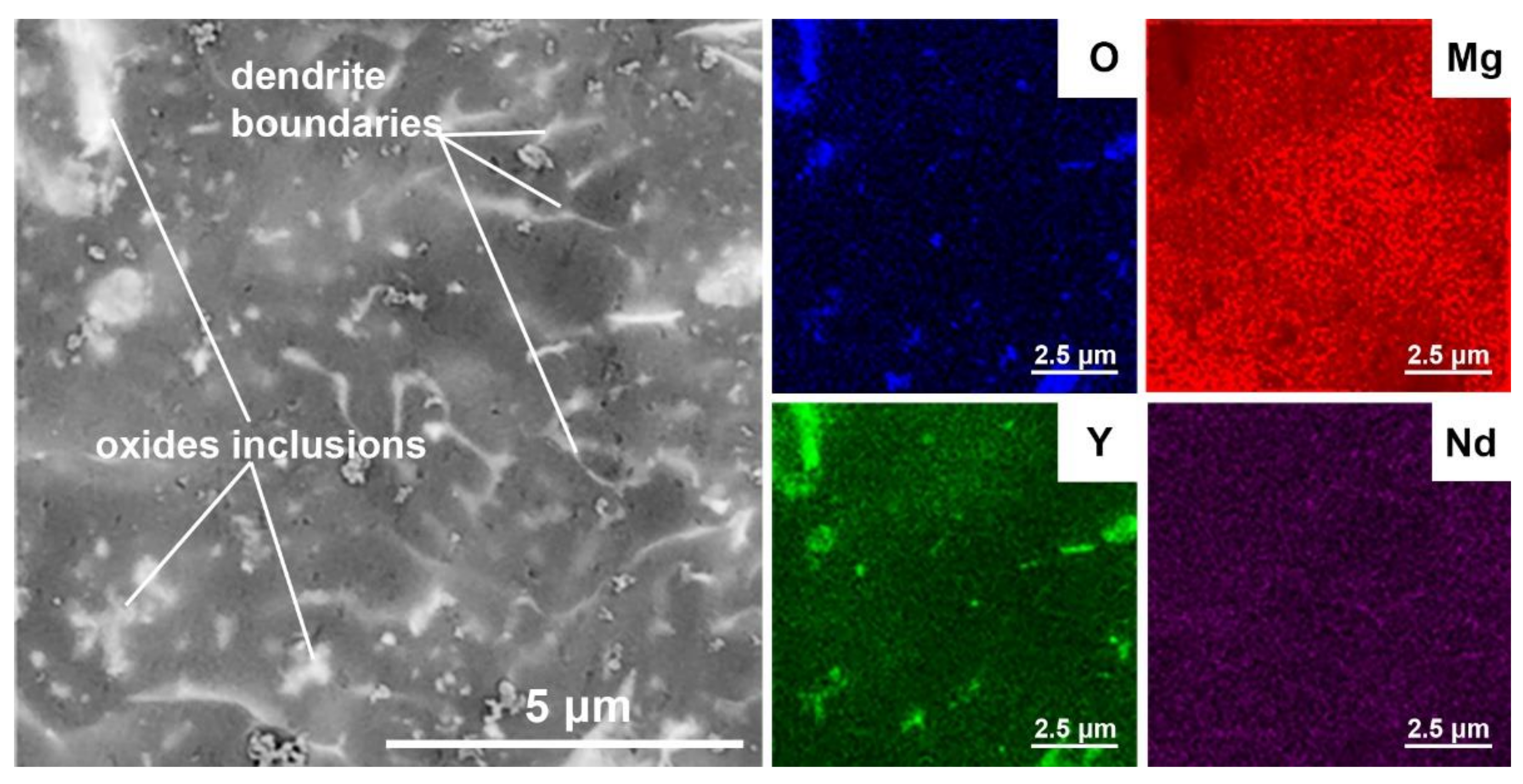

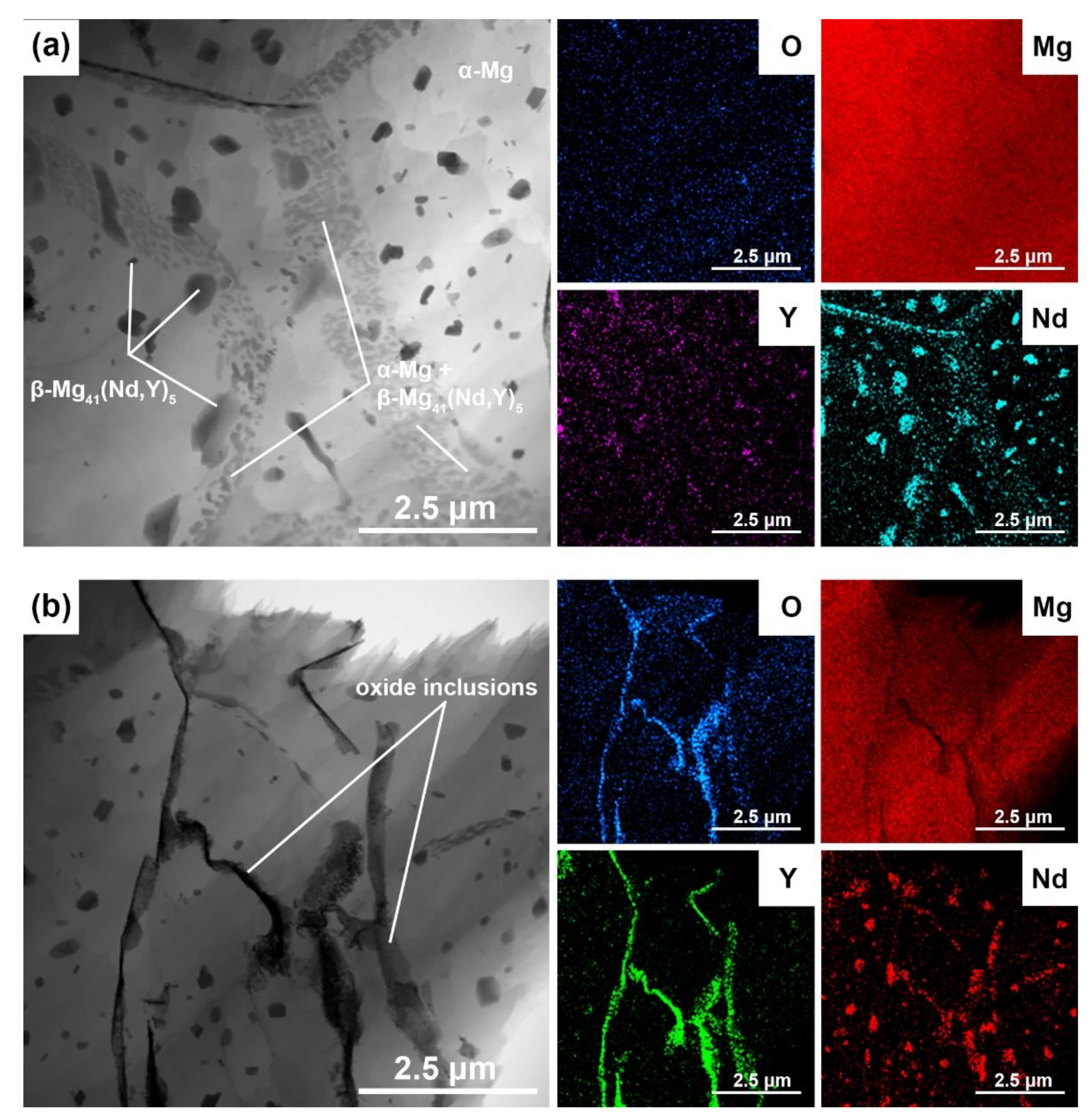

3.1. Microstructure and Chemical Composition

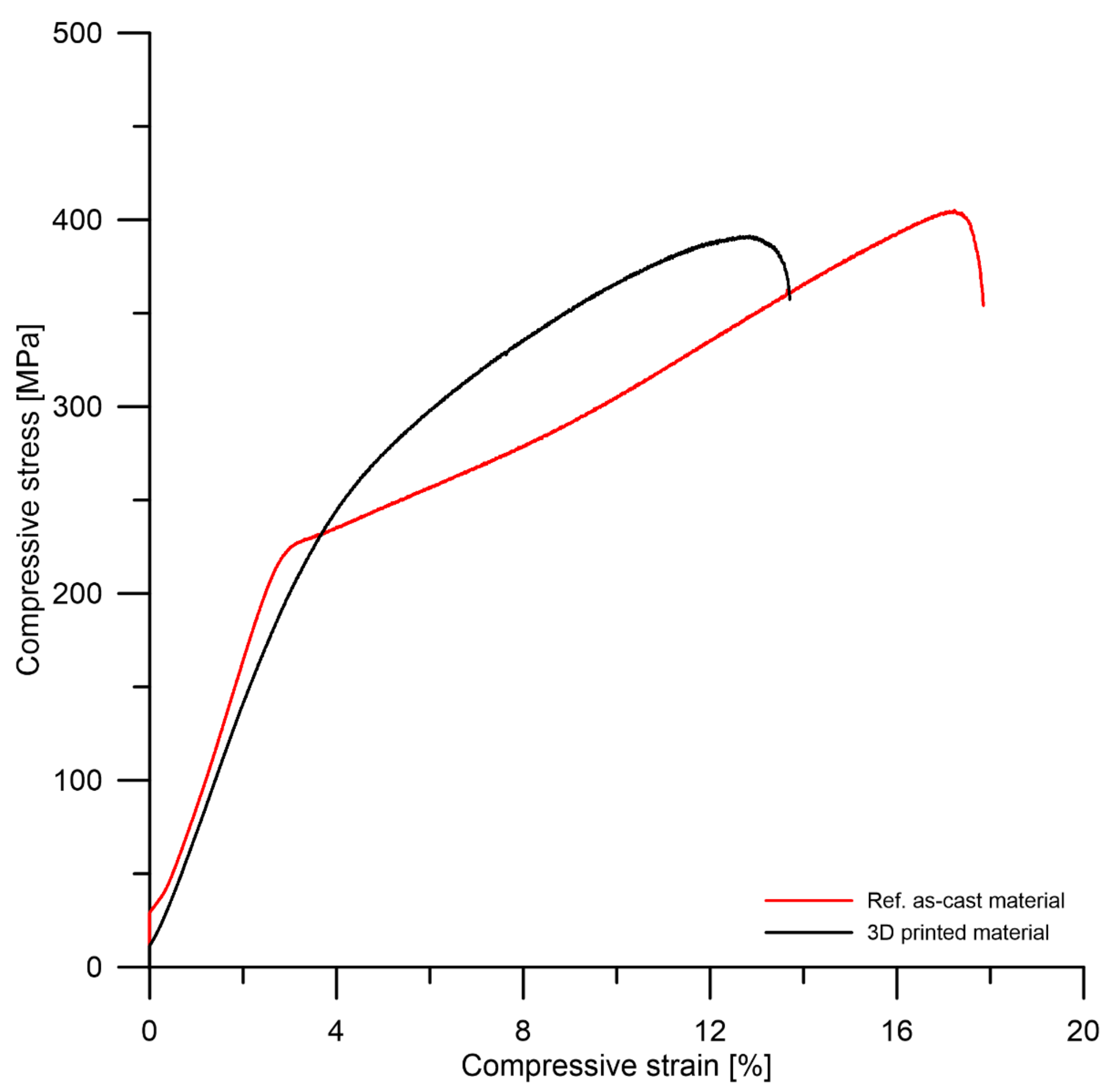

3.2. Mechanical Properties

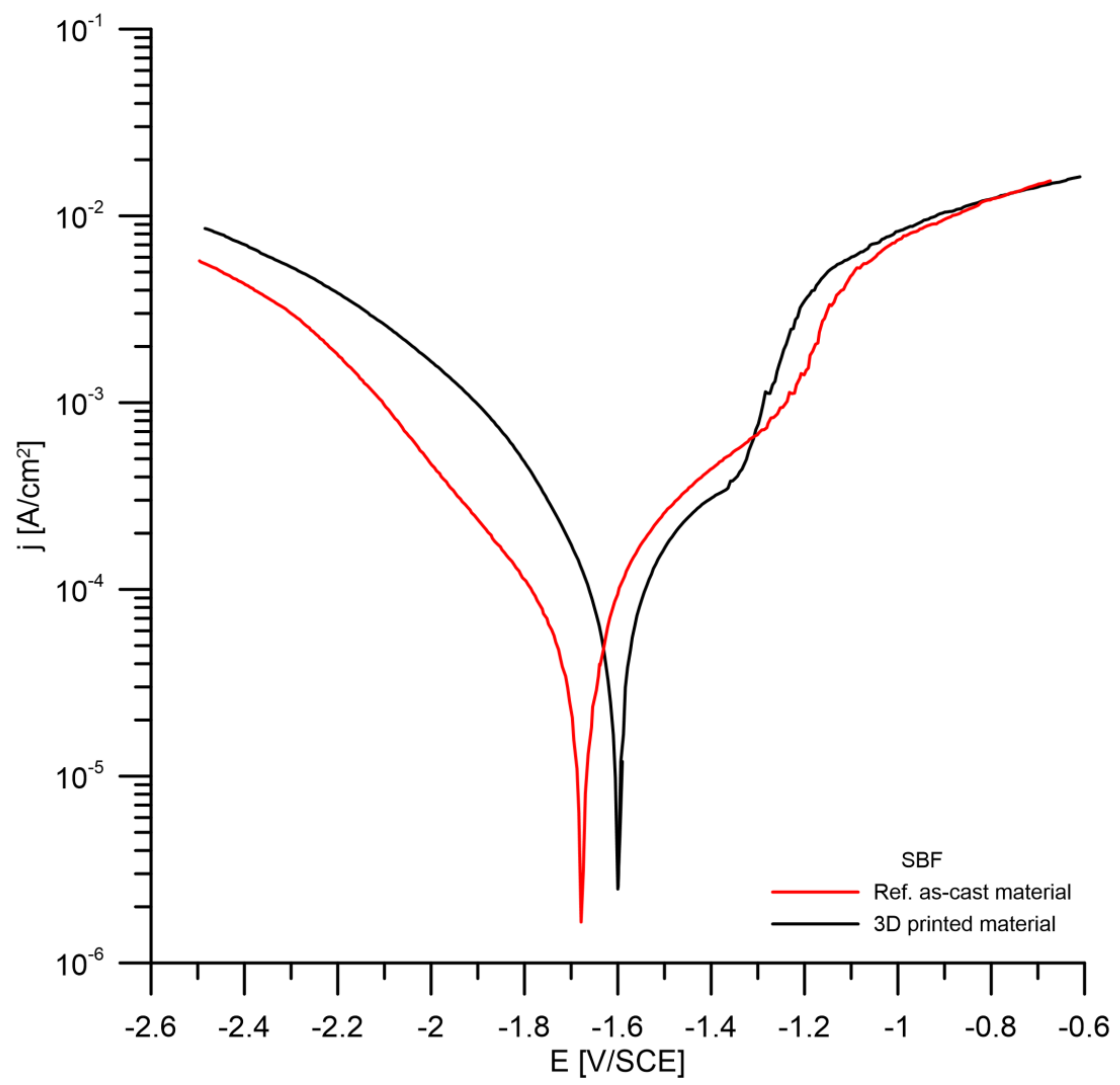

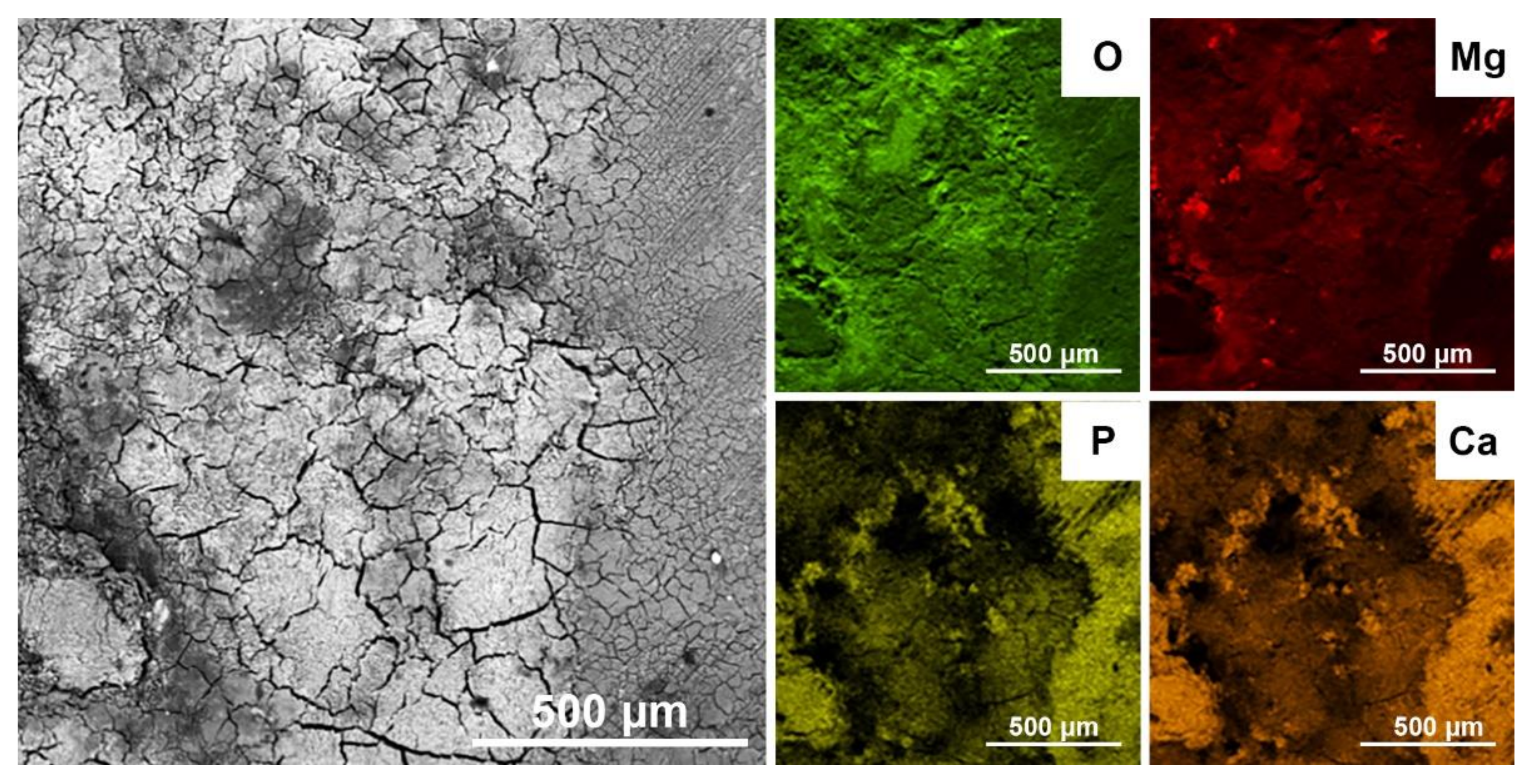

3.3. Corrosion Properties

3.4. In-Vitro Cytotoxicity According to ISO 10993-5

4. Conclusions

- Great attention should be paid to the surface state of the 3D-printed alloy. Unmelted and only partially adherent spherical particles of the initial powder alloy were found on the surface. These particles are undesirable because they are detrimental to the surrounding tissue and negatively affect the mechanical (especially fatigue) properties.

- The microstructure of the material is very fine and contains α-Mg dendritic matrix, β-Mg41(Nd, Y)5 intermetallic phase, Y2O3 inclusions, and 0.6 vol.% of residual porosity.

- Thanks to the fine microstructure, the hardness, compressive yield strength, ultimate compressive strength, and maximum compressive strain showed values similar to those of a conventional casting.

- An in vitro corrosion rate of 2.6 mm/year was obtained in the SBF immersion test. This value may be acceptable for some implant types. Despite the satisfactory results of the corrosion experiments, it seems that further improvement of the corrosion properties of the material is necessary for future applications. This improvement can be achieved, for example, by appropriate control of the SLM process, reduction of the oxidation rate, surface treatment, etc.

- Standard in vitro cytotoxicity tests indicated good biocompatibility of the 3D-printed WE43 alloy studied in this work.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Hermawan, H. Updates on the research and development of absorbable metals for biomedical applications. Prog. Biomater. 2018, 7, 93–110. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sezer, N.; Evis, Z.; Koç, M. Additive manufacturing of biodegradable magnesium implants and scaffolds: Review of the recent advances and research trends. J. Magnes. Alloy. 2021, 9, 392–415. [Google Scholar] [CrossRef]

- Ascencio, M.; Pekguleryuz, M.; Omanovic, S. An investigation of the corrosion mechanisms of WE43 Mg alloy in a modified simulated body fluid solution: The influence of immersion time. Corros. Sci. 2014, 87, 489–503. [Google Scholar] [CrossRef]

- Putra, N.E.; Mirzaali, M.J.; Apachitei, I.; Zhou, J.; Zadpoor, A.A. Multi-material additive manufacturing technologies for Ti-, Mg-, and Fe-based biomaterials for bone substitution. Acta Biomater. 2020, 109, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Pereira, G.S.; Koga, G.Y.; Avila, J.A.; Bittencourt, I.M.; Fernandez, F.; Miyazaki, M.H.; Botta, W.J.; Bose Filho, W.W. Corrosion resistance of WE43 Mg alloy in sodium chloride solution. Mater. Chem. Phys. 2021, 272, 124930. [Google Scholar] [CrossRef]

- Staiger, M.P.; Pietak, A.M.; Huadmai, J.; Dias, G. Magnesium and its alloys as orthopedic biomaterials: A review. Biomaterials 2006, 27, 1728–1734. [Google Scholar] [CrossRef]

- Zhou, H.; Li, J.; Li, J.; Ruan, Q.; Peng, X.; Li, S.; Jin, W.; Yu, Z.; Chu, P.K.; Li, W. A composite coating with physical interlocking and chemical bonding on WE43 magnesium alloy for corrosion protection and cytocompatibility enhancement. Surf. Coat. Technol. 2021, 412, 127078. [Google Scholar] [CrossRef]

- Velásquez-García, L.F.; Kornbluth, Y. Biomedical Applications of Metal 3D Printing. Annu. Rev. Biomed. Eng. 2021, 23, 307–338. [Google Scholar] [CrossRef]

- Esmaily, M.; Zeng, Z.; Mortazavi, A.N.; Gullino, A.; Choudhary, S.; Derra, T.; Benn, F.; D’Elia, F.; Müther, M.; Thomas, S.; et al. A detailed microstructural and corrosion analysis of magnesium alloy WE43 manufactured by selective laser melting. Addit. Manuf. 2020, 35, 101321. [Google Scholar] [CrossRef]

- Dvorský, D.; Kubásek, J.; Roudnická, M.; Průša, F.; Nečas, D.; Minárik, P.; Stráská, J.; Vojtěch, D. The effect of powder size on the mechanical and corrosion properties and the ignition temperature of WE43 alloy prepared by spark plasma sintering. J. Magnes. Alloy. 2021, 9, 1349–1362. [Google Scholar] [CrossRef]

- He, W.; Zhang, E.; Yang, K. Effect of Y on the bio-corrosion behavior of extruded Mg–Zn–Mn alloy in Hank’s solution. Mater. Sci. Eng. C 2010, 30, 167–174. [Google Scholar] [CrossRef]

- Gangireddy, S.; Gwalani, B.; Liu, K.; Faierson, E.J.; Mishra, R.S. Microstructure and mechanical behavior of an additive manufactured (AM) WE43-Mg alloy. Addit. Manuf. 2019, 26, 53–64. [Google Scholar] [CrossRef]

- Yang, J.; Blawert, C.; Lamaka, S.V.; Yasakau, K.A.; Wang, L.; Laipple, D.; Schieda, M.; Di, S.; Zheludkevich, M.L. Corrosion inhibition of pure Mg containing a high level of iron impurity in pH neutral NaCl solution. Corros. Sci. 2018, 142, 222–237. [Google Scholar] [CrossRef]

- Kalb, H.; Rzany, A.; Hensel, B. Impact of microgalvanic corrosion on the degradation morphology of WE43 and pure magnesium under exposure to simulated body fluid. Corros. Sci. 2012, 57, 122–130. [Google Scholar] [CrossRef]

- Yu, L.; Subodh, D.; Ian, J.; Yu-Lung, C. Biodegradable magnesium alloys for orthopedic applications. Biomater. Transl. 2021, 2, 214–235. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, J.; Pavanram, P.; Leeflang, M.A.; Fockaert, L.I.; Pouran, B.; Tümer, N.; Schröder, K.U.; Mol, J.M.C.; Weinans, H.; et al. Additively manufactured biodegradable porous magnesium. Acta Biomater. 2018, 67, 378–392. [Google Scholar] [CrossRef]

- Kharitonov, D.S.; Zimowska, M.; Ryl, J.; Zieliński, A.; Osipenko, M.A.; Adamiec, J.; Wrzesińska, A.; Claesson, P.M.; Kurilo, I.I. Aqueous molybdate provides effective corrosion inhibition of WE43 magnesium alloy in sodium chloride solutions. Corros. Sci. 2021, 190, 109664. [Google Scholar] [CrossRef]

- Kong, D.; Ni, X.; Dong, C.; Lei, X.; Zhang, L.; Man, C.; Yao, J.; Cheng, X.; Li, X. Bio-functional and anti-corrosive 3D printing 316L stainless steel fabricated by selective laser melting. Mater. Des. 2018, 152, 88–101. [Google Scholar] [CrossRef]

- Suryawanshi, J.; Prashanth, K.G.; Ramamurty, U. Mechanical behavior of selective laser melted 316L stainless steel. Mater. Sci. Eng. A 2017, 696, 113–121. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Nie, M.; Chen, Y.; Yang, S.; Gao, N. Microstructure and corrosion performance of 316L stainless steel fabricated by Selective Laser Melting and processed through high-pressure torsion. J. Alloy. Compd. 2018, 763, 360–375. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Ahmed Obeidi, M.; Uí Mhurchadha, S.M.; Raghavendra, R.; Conway, A.; Souto, C.; Tormey, D.; Ahad, I.U.; Brabazon, D. Comparison of the porosity and mechanical performance of 316L stainless steel manufactured on different laser powder bed fusion metal additive manufacturing machines. J. Mater. Res. Technol. 2021, 13, 2361–2374. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Simonelli, M.; Parry, L.; Ashcroft, I.; Tuck, C.; Hague, R. 3D printing of Aluminium alloys: Additive Manufacturing of Aluminium alloys using selective laser melting. Prog. Mater. Sci. 2019, 106, 100578. [Google Scholar] [CrossRef]

- Buttard, M.; Chehab, B.; Shahani, R.; Robaut, F.; Renou, G.; Tassin, C.; Rauch, E.; Donnadieu, P.; Deschamps, A.; Blandin, J.-J.; et al. Multi-scale microstuctural investigation of a new Al-Mn-Ni-Cu-Zr aluminium alloy processed by laser powder bed fusion. Materialia 2021, 18, 101160. [Google Scholar] [CrossRef]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal powders in additive manufacturing: A review on reusability and recyclability of common titanium, nickel and aluminum alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Li, X.P.; Wang, X.J.; Saunders, M.; Suvorova, A.; Zhang, L.C.; Liu, Y.J.; Fang, M.H.; Huang, Z.H.; Sercombe, T.B. A selective laser melting and solution heat treatment refined Al–12Si alloy with a controllable ultrafine eutectic microstructure and 25% tensile ductility. Acta Mater. 2015, 95, 74–82. [Google Scholar] [CrossRef]

- Simonelli, M.; Tse, Y.Y.; Tuck, C. Effect of the build orientation on the mechanical properties and fracture modes of SLM Ti–6Al–4V. Mater. Sci. Eng. A 2014, 616, 1–11. [Google Scholar] [CrossRef] [Green Version]

- Yang, Y.; Wang, G.; Liang, H.; Gao, C.; Peng, S.; Shen, L.; Shuai, C. Additive manufacturing of bone scaffolds. Int. J. Bioprint. 2019, 5, 148. [Google Scholar] [CrossRef]

- Fousová, M.; Stejskalova, T.; Vojtěch, D. Metallographic and Fractographic Evaluation of 3D-Printed Titanium Samples to Eliminate Unsatisfactory Mechanical Properties. Solid State Phenom. 2017, 270, 212–217. [Google Scholar] [CrossRef]

- Khanna, N.; Zadafiya, K.; Patel, T.; Kaynak, Y.; Rahman Rashid, R.A.; Vafadar, A. Review on machining of additively manufactured nickel and titanium alloys. J. Mater. Res. Technol. 2021, 15, 3192–3221. [Google Scholar] [CrossRef]

- Bär, F.; Berger, L.; Jauer, L.; Kurtuldu, G.; Schäublin, R.; Schleifenbaum, J.H.; Löffler, J.F. Laser additive manufacturing of biodegradable magnesium alloy WE43: A detailed microstructure analysis. Acta Biomater. 2019, 98, 36–49. [Google Scholar] [CrossRef]

- Salehi, M.; Maleksaeedi, S.; Farnoush, H.; Nai, M.L.S.; Meenashisundaram, G.K.; Gupta, M. An investigation into interaction between magnesium powder and Ar gas: Implications for selective laser melting of magnesium. Powder Technol. 2018, 333, 252–261. [Google Scholar] [CrossRef]

- Kopp, A.; Derra, T.; Müther, M.; Jauer, L.; Schleifenbaum, J.H.; Voshage, M.; Jung, O.; Smeets, R.; Kröger, N. Influence of design and postprocessing parameters on the degradation behavior and mechanical properties of additively manufactured magnesium scaffolds. Acta Biomater. 2019, 98, 23–35. [Google Scholar] [CrossRef] [PubMed]

- Krištofová, P.; Kubásek, J.; Vojtěch, D.; Paloušek, D.; Suchý, J. Microstructure of the Mg-4Y-3RE-Zr (WE43) Magnesium Alloy Produced by 3D Printing. Manuf. Technol. 2019, 19, 89–94. [Google Scholar] [CrossRef]

- Suchý, J.; Klakurková, L.; Man, O.; Remešová, M.; Horynová, M.; Paloušek, D.; Koutný, D.; Krištofová, P.; Vojtěch, D.; Čelko, L. Corrosion behaviour of WE43 magnesium alloy printed using selective laser melting in simulation body fluid solution. J. Manuf. Process. 2021, 69, 556–566. [Google Scholar] [CrossRef]

- Jones, D.A. Principles and Prevention of Corrosion, 2nd ed.; Prentice Hall: Hoboken, NJ, USA, 1996. [Google Scholar]

- Fischer, J.; Pröfrock, D.; Hort, N.; Willumeit, R.; Feyerabend, F. Reprint of: Improved cytotoxicity testing of magnesium materials. Mater. Sci. Eng. B 2011, 176, 1773–1777. [Google Scholar] [CrossRef]

- Riss, T.L.; Moravec, R.A.; Niles, A.L.; Benink, H.A.; Worzella, T.J.; Minor, L. The Assay Guidance Manual; Cell Viability Assays; Eli Lily and Co., National Center for Advancing Translsational Sciences: Bethesda, MD, USA, 2016. [Google Scholar]

- Kubásek, J.; Vojtěch, D.; Martínek, M. Structural characteristics and elevated temperature mechanical properties of AJ62 Mg alloy. Mater. Charact. 2013, 86, 270–282. [Google Scholar] [CrossRef]

- Zhang, J.; Amini, N.; Morton, D.A.V.; Hapgood, K.P. 3D printing with particles as feedstock materials. Adv. Powder Technol. 2021, 32, 3324–3345. [Google Scholar] [CrossRef]

- Chu, F.; Zhang, K.; Shen, H.; Liu, M.; Huang, W.; Zhang, X.; Liang, E.; Zhou, Z.; Lei, L.; Hou, J.; et al. Influence of satellite and agglomeration of powder on the processability of AlSi10Mg powder in Laser Powder Bed Fusion. J. Mater. Res. Technol. 2021, 11, 2059–2073. [Google Scholar] [CrossRef]

- Aboulkhair, N.T.; Everitt, N.M.; Maskery, I.; Ashcroft, I.; Tuck, C. Selective laser melting of aluminum alloys. MRS Bull. 2017, 42, 311–319. [Google Scholar] [CrossRef]

- Olakanmi, E.O.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Benson, G.; McWilliams, B.; Cho, K.; Sohn, Y. Additive manufacturing of dense WE43 Mg alloy by laser powder bed fusion. Addit. Manuf. 2020, 33, 101123. [Google Scholar] [CrossRef]

- Zou, J.; Zhu, B.; Zhang, G.; Guo, S.; Xiao, R. Power density effect on the laser beam-induced eruption of spatters in fiber laser keyhole welding. Opt. Laser Technol. 2022, 147, 107651. [Google Scholar] [CrossRef]

- Lazov, L.; Teirumnieks, E.; Karadzhov, T.; Angelov, N. Influence of power density and frequency of the process of laser marking of steel products. Infrared Phys. Technol. 2021, 116, 103783. [Google Scholar] [CrossRef]

- Majeed, A.; Zhang, Y.; Lv, J.; Peng, T.; Atta, Z.; Ahmed, A. Investigation of T4 and T6 heat treatment influences on relative density and porosity of AlSi10Mg alloy components manufactured by SLM. Comput. Ind. Eng. 2020, 139, 106194. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Li, H.; Guo, G.; Wang, L.; Rong, Y. The effect of porosity on the mechanical property of metal-bonded diamond grinding wheel fabricated by selective laser melting (SLM). Mater. Sci. Eng. A 2019, 743, 697–706. [Google Scholar] [CrossRef]

- Ng, C.C.; Savalani, M.M.; Lau, M.L.; Man, H.C. Microstructure and mechanical properties of selective laser melted magnesium. Appl. Surf. Sci. 2011, 257, 7447–7454. [Google Scholar] [CrossRef]

- Menshikova, S.G.; Shirinkina, I.G.; Brodova, I.G.; Brazhkin, V.V.; Lad’yanov, V.I.; Pushkarev, B.E. Morphological features of crystal growth in the Al87Ni8Y5 alloy on rapid cooling of the melt under high pressure. J. Cryst. Growth 2019, 525, 125206. [Google Scholar] [CrossRef]

- Lejček, P.; Roudnická, M.; Čapek, J.; Dvorský, D.; Drahokoupil, J.; Šimek, D.; Čížek, J.; Svora, P.; Molnárová, O.; Vojtěch, D. Selective laser melting of pure iron: Multiscale characterization of hierarchical microstructure. Mater. Charact. 2019, 154, 222–232. [Google Scholar] [CrossRef]

- Bendoumi, A.; Makuch, N.; Chegroune, R.; Kulka, M.; Keddam, M.; Dziarski, P.; Przestacki, D. The effect of temperature distribution and cooling rate on microstructure and microhardness of laser re-melted and laser-borided carbon steels with various carbon concentrations. Surf. Coat. Technol. 2020, 387, 125541. [Google Scholar] [CrossRef]

- Liu, W.; Ren, X.; Li, N.; Gao, C.; Xiong, H. Rapid directionally solidified microstructure characteristic and fracture behaviour of laser melting deposited Nb–Si–Ti alloy. Prog. Nat. Sci. Mater. Int. 2021, 31, 113–120. [Google Scholar] [CrossRef]

- Fousová, M.; Dvorský, D.; Michalcová, A.; Vojtěch, D. Changes in the microstructure and mechanical properties of additively manufactured AlSi10Mg alloy after exposure to elevated temperatures. Mater. Charact. 2018, 137, 119–126. [Google Scholar] [CrossRef]

- Li, M.; Benn, F.; Derra, T.; Kröger, N.; Zinser, M.; Smeets, R.; Molina-Aldareguia, J.M.; Kopp, A.; Llorca, J. Microstructure, mechanical properties, corrosion resistance and cytocompatibility of WE43 Mg alloy scaffolds fabricated by laser powder bed fusion for biomedical applications. Mater. Sci. Eng. C 2021, 119, 111623. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.-W.; Han, H.-S.; Han, K.-J.; Park, J.; Jeon, H.; Ok, M.-R.; Seok, H.-K.; Ahn, J.-P.; Lee, K.E.; Lee, D.-H.; et al. Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy. Proc. Natl. Acad. Sci. USA 2016, 113, 716. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mohan Sathyaraj, P.; Ravichandran, K.; Sankara Narayanan, T.S.N. Controlling the rate of degradation of Mg using magnesium fluoride and magnesium fluoride-magnesium phosphate duplex coatings. J. Magnes. Alloy. 2021, 10, 295–312. [Google Scholar] [CrossRef]

- Sezer, N.; Evis, Z.; Kayhan, S.M.; Tahmasebifar, A.; Koç, M. Review of magnesium-based biomaterials and their applications. J. Magnes. Alloy. 2018, 6, 23–43. [Google Scholar] [CrossRef]

- Mena-Morcillo, E.; Veleva, L.P.; Wipf, D.O. Multi-Scale Monitoring the First Stages of Electrochemical Behavior of AZ31B Magnesium Alloy in Simulated Body Fluid. J. Electrochem. Soc. 2018, 165, C749–C755. [Google Scholar] [CrossRef]

- Bütev Öcal, E.; Esen, Z.; Aydınol, K.; Dericioğlu, A.F. Comparison of the short and long-term degradation behaviors of as-cast pure Mg, AZ91 and WE43 alloys. Mater. Chem. Phys. 2020, 241, 122350. [Google Scholar] [CrossRef]

- Galli, S.; Stocchero, M.; Andersson, M.; Karlsson, J.; He, W.; Lilin, T.; Wennerberg, A.; Jimbo, R. The effect of magnesium on early osseointegration in osteoporotic bone: A histological and gene expression investigation. Osteoporos. Int. 2017, 28, 2195–2205. [Google Scholar] [CrossRef] [Green Version]

- Kowalewicz, K.; Vorndran, E.; Feichtner, F.; Waselau, A.-C.; Brueckner, M.; Meyer-Lindenberg, A. In-Vivo Degradation Behavior and Osseointegration of 3D Powder-Printed Calcium Magnesium Phosphate Cement Scaffolds. Materials 2021, 14, 946. [Google Scholar] [CrossRef] [PubMed]

- Vojtěch, D.; Kubásek, J.; Čapek, J.; Pospíšilová, I. Magnesium zinc and iron alloys for medical applications in biodegradable implants. In Proceedings of the 23rd International Conference on Metallurgy and Materials, Brno, Czech Republic, 21–23 May 2014. [Google Scholar]

- Charyeva, O.; Dakischew, O.; Sommer, U.; Heiss, C.; Schnettler, R.; Lips, K.S. Biocompatibility of magnesium implants in primary human reaming debris-derived cells stem cells in vitro. J. Orthop. Traumatol. 2016, 17, 63–73. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kraus, T.; Fischerauer, S.F.; Hänzi, A.C.; Uggowitzer, P.J.; Löffler, J.F.; Weinberg, A.M. Magnesium alloys for temporary implants in osteosynthesis: In vivo studies of their degradation and interaction with bone. Acta Biomater. 2012, 8, 1230–1238. [Google Scholar] [CrossRef]

- Witte, F.; Hort, N.; Vogt, C.; Cohen, S.; Kainer, K.U.; Willumeit, R.; Feyerabend, F. Degradable biomaterials based on magnesium corrosion. Curr. Opin. Solid State Mater. Sci. 2008, 12, 63–72. [Google Scholar] [CrossRef] [Green Version]

| Compound | Concentration (g/L) |

|---|---|

| KCl | 0.3 |

| NaCl | 5.84 |

| NaHCO3 | 2.29 |

| MgSO4·7H2O | 0.25 |

| CaCl2 | 0.28 |

| TRIS | 6.06 |

| KH2PO4 | 0.14 |

| 3D Printed Material | Reference As-Cast Material | |

|---|---|---|

| HV 0.1 | 88 ± 7 | 96 ± 12 |

| 3D-Printed Material | Reference As-Cast Material | |

|---|---|---|

| Compressive yield strength (MPa) | 201 | 220 |

| Ultimate compressive strength (MPa) | 394 | 405 |

| Maximum compressive strain (%) | 14 | 18 |

| Ecorr (V/SCE) | RP (ohm·m2) | vcorr (mm/Year) | |

|---|---|---|---|

| Reference as-cast material | −1.67 | 0.070 | 1.27 |

| 3D-printed material | −1.59 | 0.058 | 1.30 |

| 3D-Printed Material | Reference As-Cast Material | |

|---|---|---|

| Corrosion rate (mm/year) | 2.6 ± 1.9 | 1.0 ± 0.5 |

| Element | O | Mg | Ca | P | Y | Nd | Na | Cl | K |

|---|---|---|---|---|---|---|---|---|---|

| wt.% | 50.0 | 17.2 | 13.1 | 7.9 | 5.2 | 3.6 | 0.6 | 0.4 | 0.1 |

| Y | Nd | Gd | Dy | Mg | |

|---|---|---|---|---|---|

| Sample 1 | 148 ng/mL | 168 ng/mL | 40.4 ng/mL | 7.20 ng/mL | 185.000 ng/mL |

| Sample 2 | 120 ng/mL | 128 ng/mL | 30.0 ng/mL | 5.00 ng/mL | 178.000 ng/mL |

| Medium | - | - | - | - | 19.800 ng/mL |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lovašiová, P.; Lovaši, T.; Kubásek, J.; Jablonská, E.; Msallamová, Š.; Michalcová, A.; Vojtěch, D.; Suchý, J.; Koutný, D.; Ghassan Hamed Alzubi, E. Biodegradable WE43 Magnesium Alloy Produced by Selective Laser Melting: Mechanical Properties, Corrosion Behavior, and In-Vitro Cytotoxicity. Metals 2022, 12, 469. https://doi.org/10.3390/met12030469

Lovašiová P, Lovaši T, Kubásek J, Jablonská E, Msallamová Š, Michalcová A, Vojtěch D, Suchý J, Koutný D, Ghassan Hamed Alzubi E. Biodegradable WE43 Magnesium Alloy Produced by Selective Laser Melting: Mechanical Properties, Corrosion Behavior, and In-Vitro Cytotoxicity. Metals. 2022; 12(3):469. https://doi.org/10.3390/met12030469

Chicago/Turabian StyleLovašiová, Patrícia, Tomáš Lovaši, Jiří Kubásek, Eva Jablonská, Šárka Msallamová, Alena Michalcová, Dalibor Vojtěch, Jan Suchý, Daniel Koutný, and Enas Ghassan Hamed Alzubi. 2022. "Biodegradable WE43 Magnesium Alloy Produced by Selective Laser Melting: Mechanical Properties, Corrosion Behavior, and In-Vitro Cytotoxicity" Metals 12, no. 3: 469. https://doi.org/10.3390/met12030469

APA StyleLovašiová, P., Lovaši, T., Kubásek, J., Jablonská, E., Msallamová, Š., Michalcová, A., Vojtěch, D., Suchý, J., Koutný, D., & Ghassan Hamed Alzubi, E. (2022). Biodegradable WE43 Magnesium Alloy Produced by Selective Laser Melting: Mechanical Properties, Corrosion Behavior, and In-Vitro Cytotoxicity. Metals, 12(3), 469. https://doi.org/10.3390/met12030469