On the Short-Term Creep Response at 482 °C (900 °F) of the 17-4PH Steel Produced by Bound Metal Deposition

Abstract

:1. Introduction

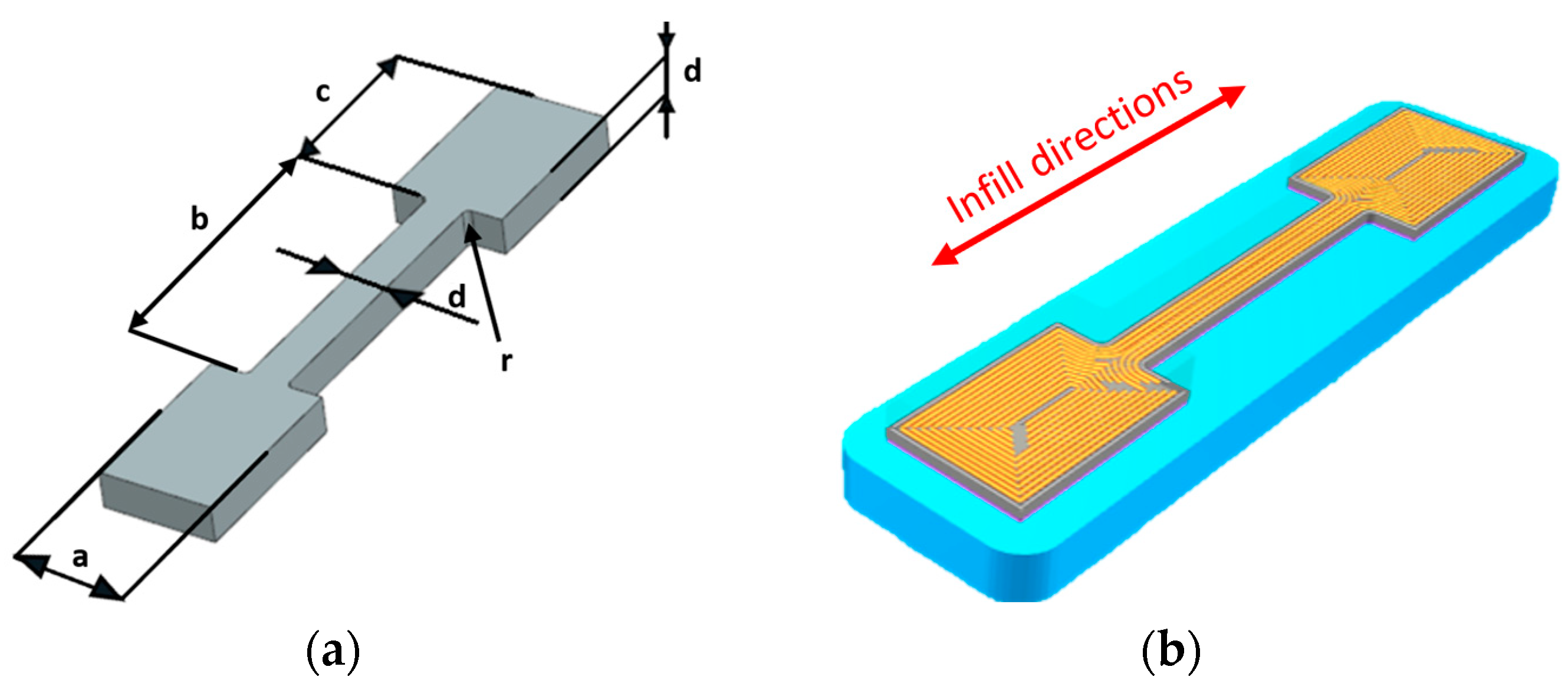

2. Materials and Methods

3. Results and Discussion

3.1. Hardness Results

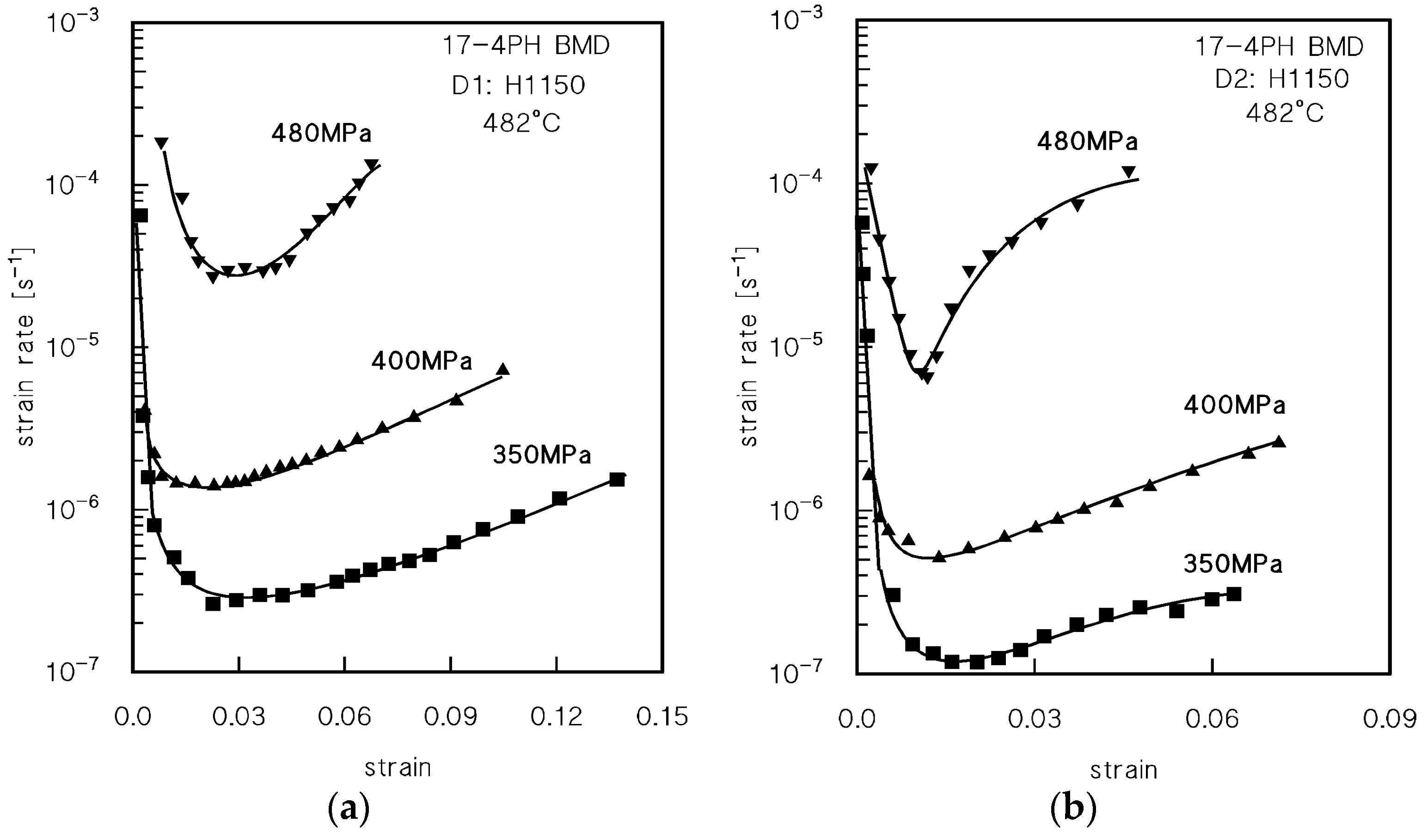

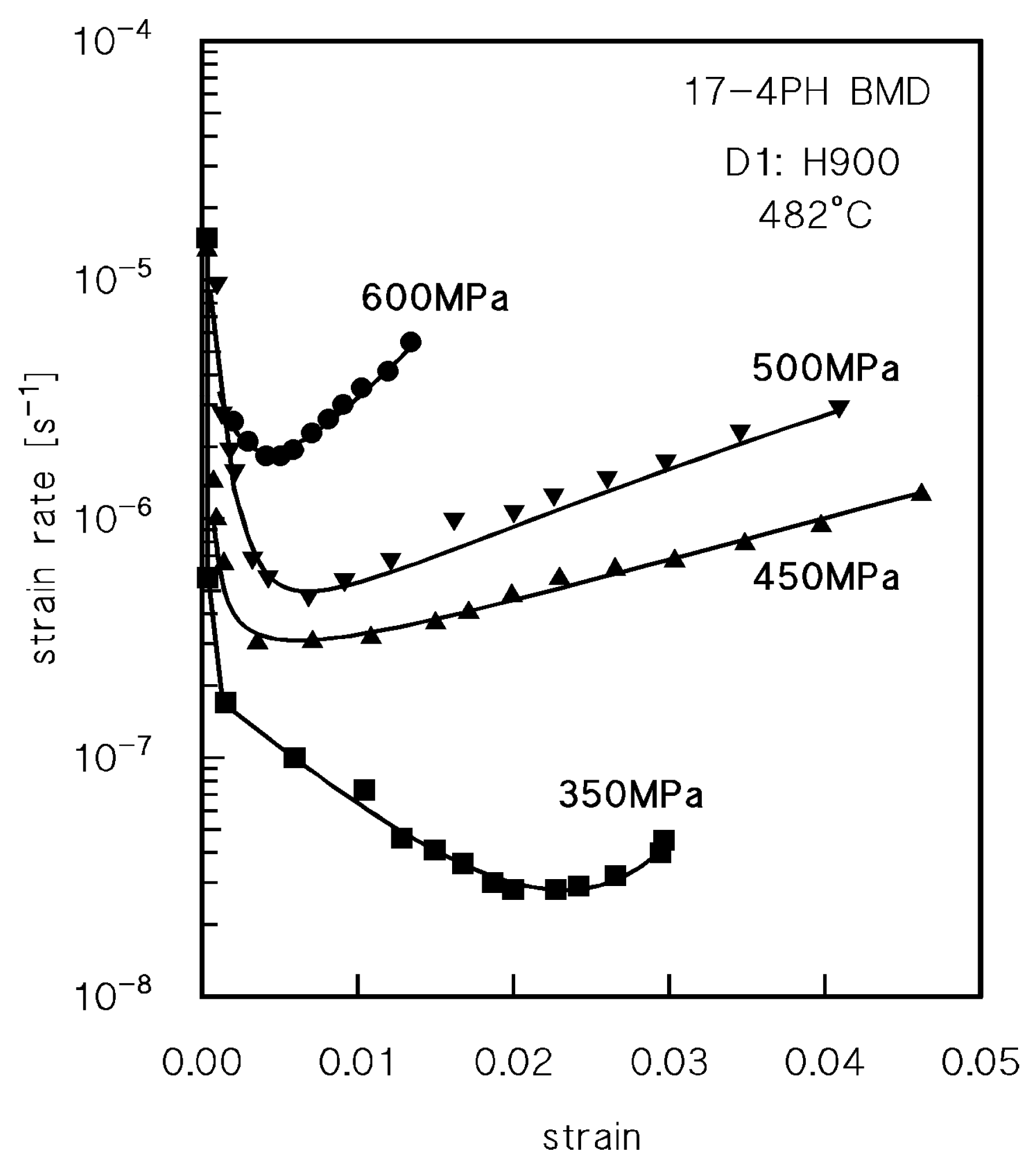

3.2. Creep Results

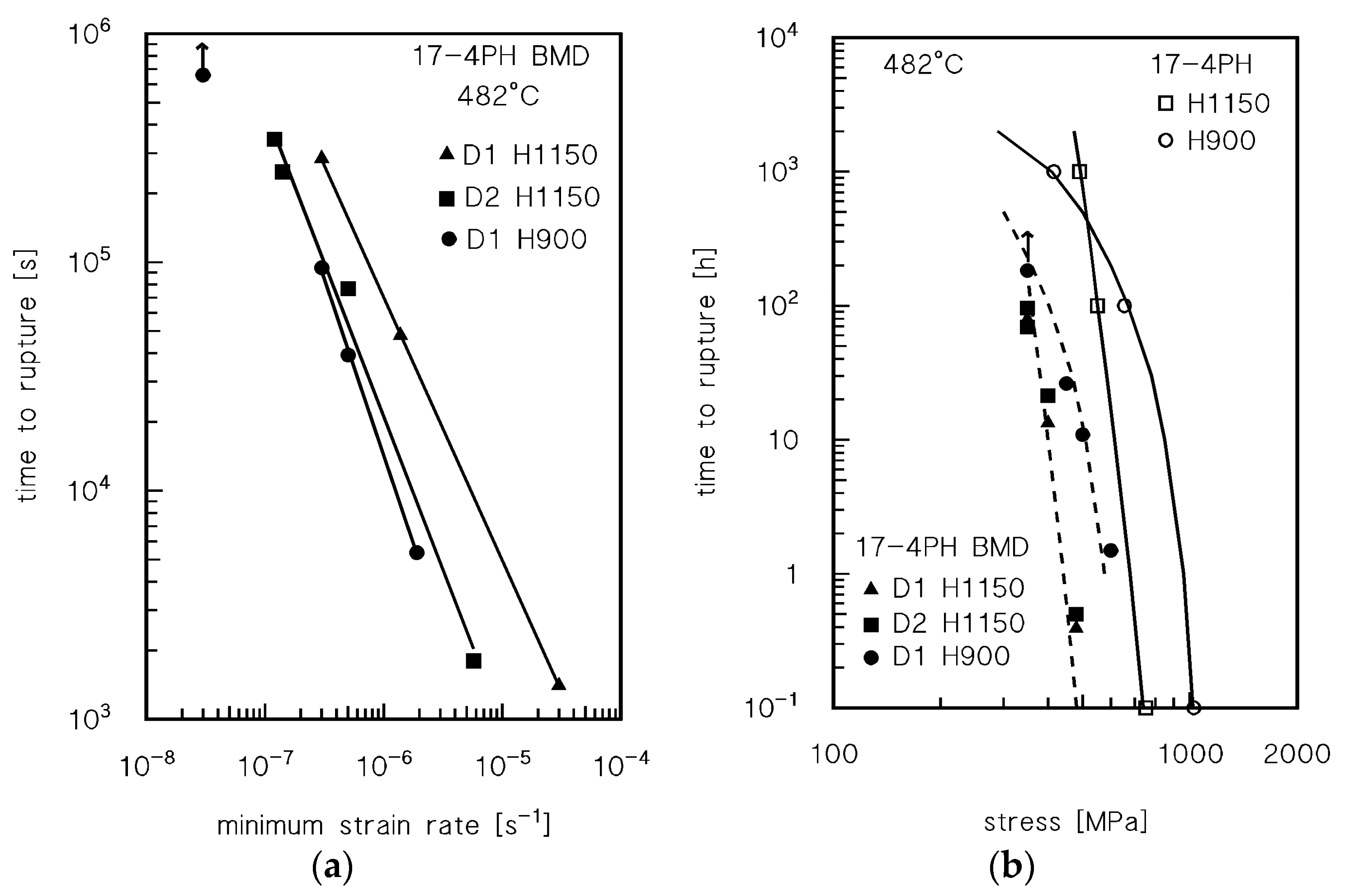

3.3. Time to Fracture

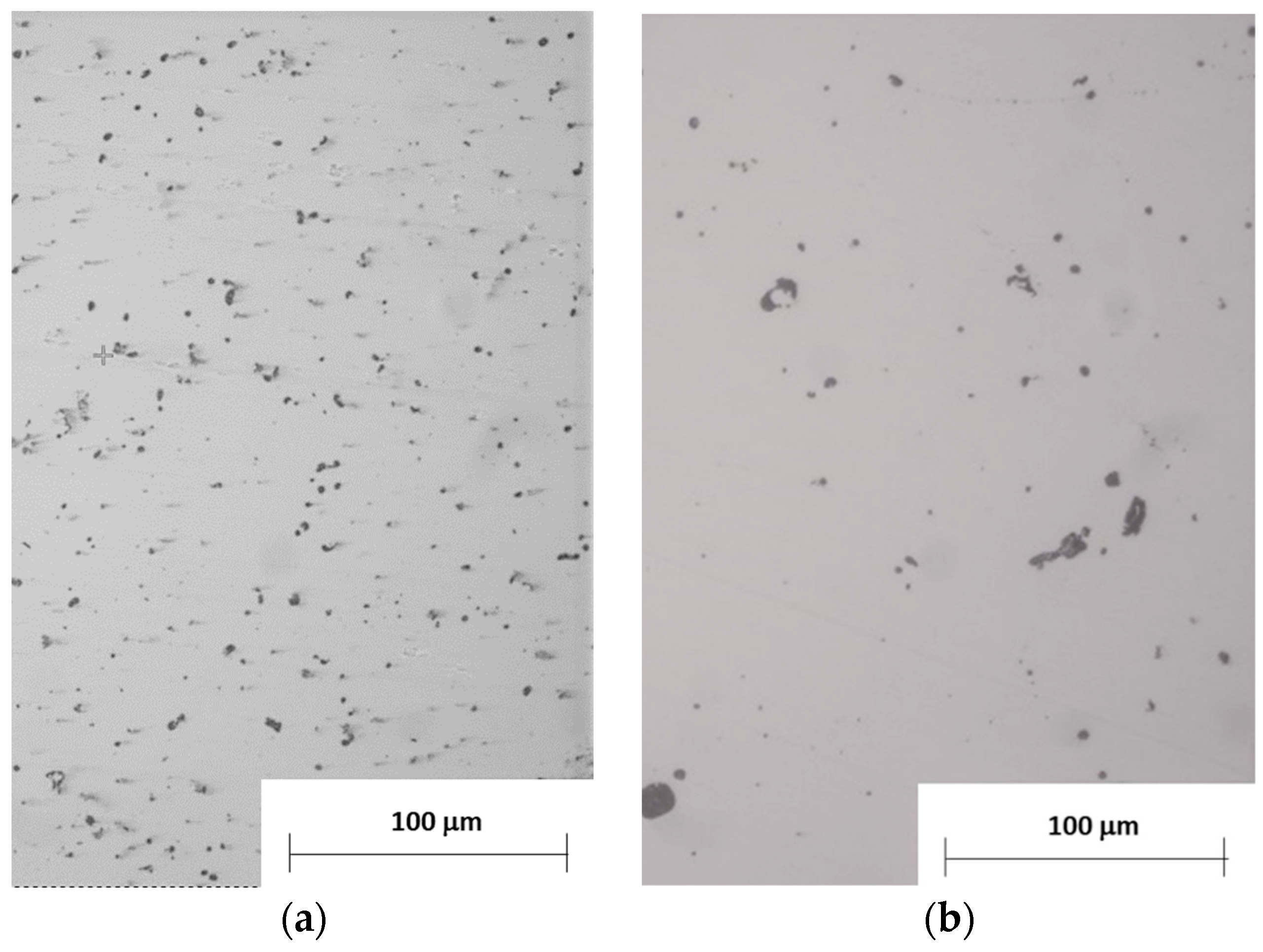

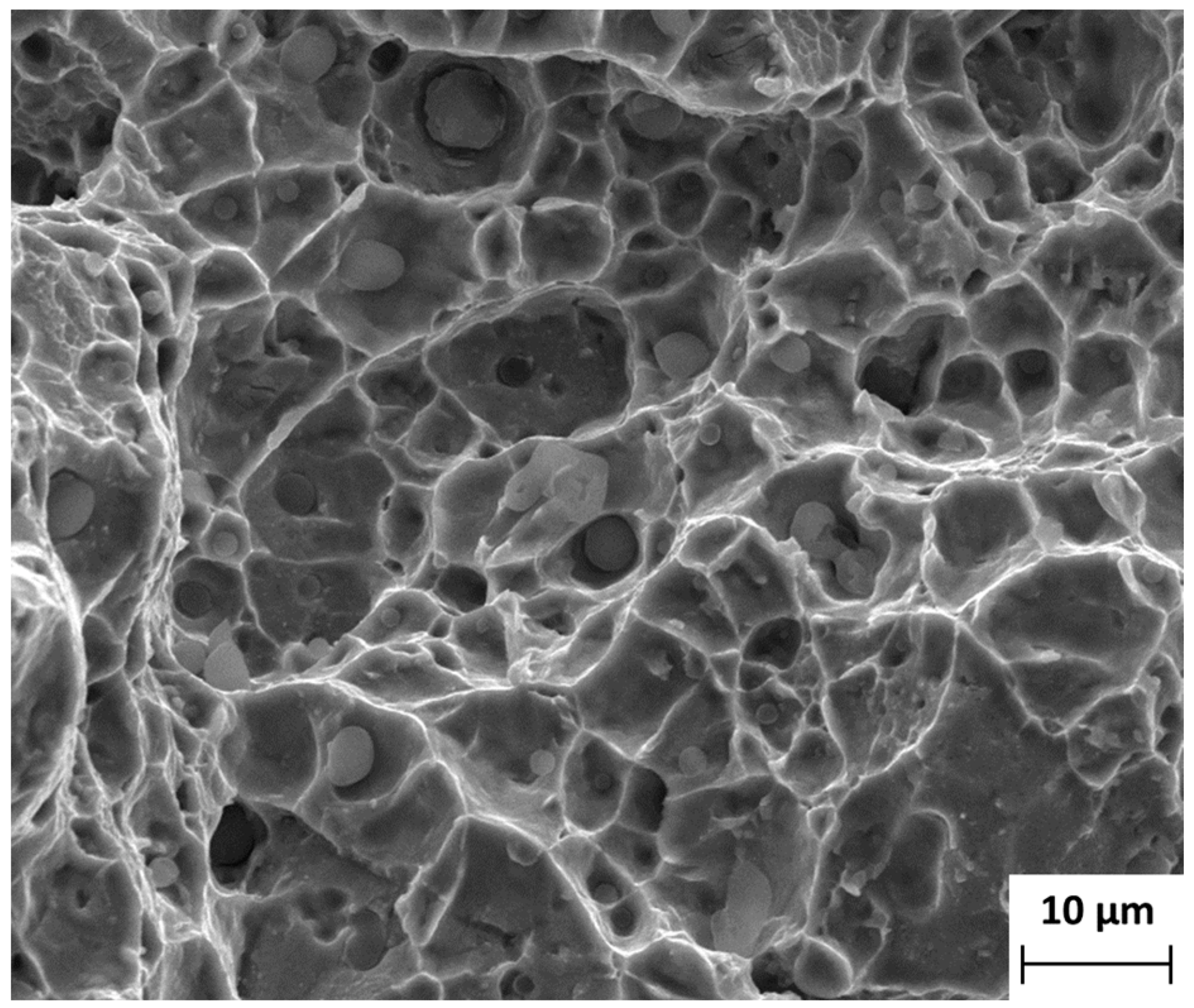

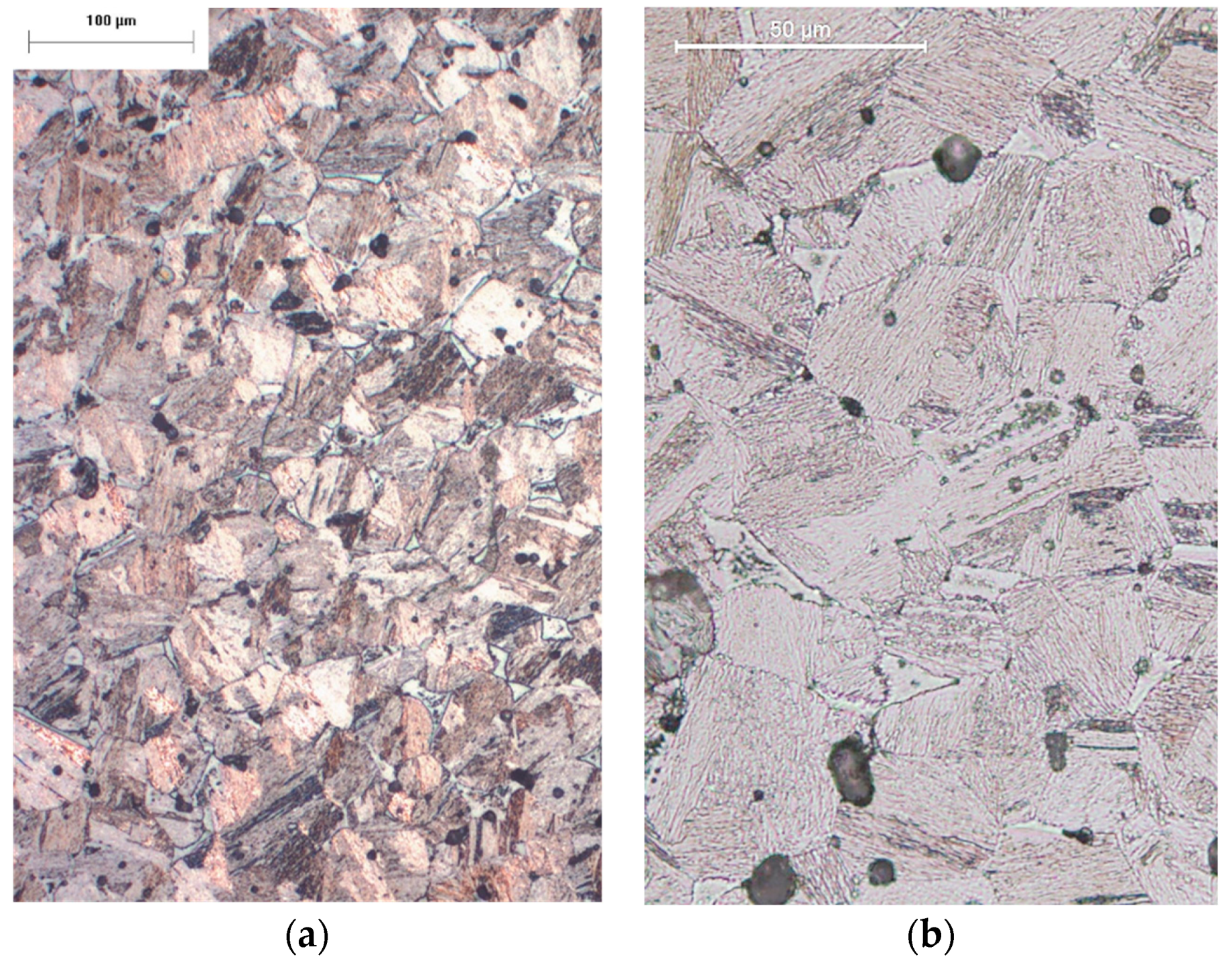

3.4. Source of Reduction in Strength: Analysis of Defects

3.5. Creep Mechanisms

4. Conclusions

- In H900 state, the BMD steel exhibits, as expected, a higher creep strength than in H1150 state, although the difference in response gradually vanishes as stress decreases, i.e., time of exposure increases. This behavior can be attributed to progressive overageing of the H900 samples;

- An extensive population of defects (porosity and silicon-rich oxides) can be observed in the BMD samples; these defects cause an early onset of tertiary stage, and lead to a reduction in the creep life;

- Comparison with the admittedly scant literature evidence, suggests that the defects above-mentioned cause a 35% reduction in the stress for a given time to rupture for the H1150 state. The reduction was marginally higher (40%) in H900 state;

- As a whole, the 17-4PH steel remains a material whose creep response is scarcely known. This fact suggests that substantial studies on this subject are required.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Singh, S.; Singh, G.; Prakash, C.; Ramakrishna, S. Current status and future directions of fused filament fabrication. J. Manuf. Process. 2020, 55, 288–306. [Google Scholar] [CrossRef]

- Montani, M.; Demir, A.G.; Mostaed, E.; Vedani, M.; Previtali, B. Processability of pure Zn and pure Fe by SLM for biodegradable metallic implant manufacturing. Rapid Prototyp. J. 2017, 23, 514–523. [Google Scholar] [CrossRef]

- Bouaziz, M.A.; Djouda, J.M.; Chemkhi, M.; Rambaudon, M.; Kauffmann, J.; Hild, F. Heat treatment effect on 17-4PH stainless steel manufactured by Atomic Diffusion Additive Manufacturing (ADAM). Procedia CIRP 2021, 104, 935–938. [Google Scholar] [CrossRef]

- Nagarajan, B.; Hu, Z.; Song, X.; Zhai, W.; Wei, J. Development of Micro Selective Laser Melting: The State of the Art and Future Perspectives. Engineering 2019, 5, 702–720. [Google Scholar] [CrossRef]

- Chemkhi, M.; Djouda, J.M.; Bouaziz, M.A.; Kauffmann, J.; Hild, F.; Retraint, D. Effects of Mechanical Post-Treatments on Additive Manufactured 17-4PH Stainless Steel Produced by Bound Powder Extrusion. Procedia CIRP 2021, 104, 957–961. [Google Scholar] [CrossRef]

- Desktop Metal Site. Available online: www.desktopmetal.com (accessed on 21 February 2022).

- Di Pompeo, V.; Forcellese, A.; Mancia, T.; Simoncini, M.; Vita, A. Effect of Geometric Parameters and Moisture Content on the Mechanical Performances of 3D-Printed Isogrid Structures in Short Carbon Fiber-Reinforced Polyamide. J. Mater. Eng. Perform. 2021, 30, 5100–5107. [Google Scholar] [CrossRef]

- Parenti, P.; Puccio, D.; Colosimo, B.M.; Semeraro, Q. A new solution for assessing the printability of 17-4 PH gyroids produced via extrusion-based metal AM. J. Manuf. Process. 2022, 74, 557–572. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Sun, Y.; Hebert, R.J.; Aindow, M. Effect of heat treatments on microstructural evolution of additively manufactured and wrought 17-4PH stainless steel. Mater. Des. 2018, 156, 429–440. [Google Scholar] [CrossRef]

- Sabooni, S.; Chabok, A.; Feng, S.C.; Blaauw, H.; Pijper, T.C.; Yang, H.J.; Pei, Y.T. Laser powder bed fusion of 17–4 PH stainless steel: A comparative study on the effect of heat treatment on the microstructure evolution and mechanical properties. Addit. Manuf. 2021, 46, 102176. [Google Scholar] [CrossRef]

- Mutlu, I.; Oktay, E. Characterization of 17-4 PH stainless steel foam for biomedical applications in simulated body fluid and artificial saliva environments. Mater. Sci. Eng. C 2013, 33, 1125–1131. [Google Scholar] [CrossRef] [PubMed]

- Lumley, R.N.; Morton, A.J.; Polmear, I.J. Enhanced creep performance in an Al-Cu-Mg-Ag alloy through underageing. Acta Mater. 2002, 50, 3597–3608. [Google Scholar] [CrossRef]

- Kloc, L.; Spigarelli, S.; Cerri, E.; Evangelista, E.; Langdon, T.G. Creep behavior of an aluminum 2024 alloy produced by powder metallurgy. Acta Mater. 1997, 45, 529–540. [Google Scholar] [CrossRef]

- Lin, Y.C.; Xia, Y.C.; Ma, X.S.; Jiang, Y.Q.; Chen, M.S. High-temperature creep behavior of Al-Cu-Mg alloy. Mater. Sci. Eng. A 2012, 550, 125–130. [Google Scholar] [CrossRef]

- Harvey, P.D. Engineering Properties of Steel; ASM International: Almere, The Netherlands, 1982; ISBN 9781621984801. [Google Scholar]

- Yeli, G.; Auger, M.A.; Wilford, K.; Smith, G.D.W.; Bagot, P.A.J.; Moody, M.P. Sequential nucleation of phases in a 17-4PH steel: Microstructural characterisation and mechanical properties. Acta Mater. 2017, 125, 38–49. [Google Scholar] [CrossRef]

- Murayama, M.; Katayama, Y.; Hono, K. Microstructural evolution in a 17-4 PH stainless steel after aging at 400 °C. Metall. Mater. Trans. 1999, 30A, 345–353. [Google Scholar] [CrossRef]

- Cerri, E.; Evangelista, E.; Spigarelli, S.; Bianchi, P. Evolution of microstructure in a modified 9Cr-1Mo steel during short term creep. Mater. Sci. Eng. A 1998, 245, 285–292. [Google Scholar] [CrossRef]

- Spigarelli, S. Microstructure-based assessment of creep rupture strength in 9Cr steels. Int. J. Press. Vessel. Pip. 2013, 101, 64–71. [Google Scholar] [CrossRef]

| Fe | Cr | Cu | Ni | Ni + Ta | Mn | Si | C | S | O | N |

|---|---|---|---|---|---|---|---|---|---|---|

| Bal. | 16.7 | 4.0 | 4.5 | 0.29 | 0.12 | 0.45 | 0.031 | 0.001 | 0.0095 | 0.029 |

| Set | Parameters | ||||

|---|---|---|---|---|---|

| Infill | Layer Height [mm] | Line Width [mm] | Overlap | Printing Speed [mm/s] | |

| Standard (D1) | 100% | 0.2 | 0.40 | 0% | 30 |

| Dense (D2) | 100% | 0.15 | 0.44 | 0% | 60 |

| Condition | Temperature | Dwell Time, hours | Hardness, HRC [16] |

|---|---|---|---|

| H900 | 900 °F (482 °C) | 1 | 42.7–44.5 |

| H1150 | 1150 °F (621 °C) | 4 | 31–32.5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Di Pompeo, V.; Santoni, A.; Santecchia, E.; Spigarelli, S. On the Short-Term Creep Response at 482 °C (900 °F) of the 17-4PH Steel Produced by Bound Metal Deposition. Metals 2022, 12, 477. https://doi.org/10.3390/met12030477

Di Pompeo V, Santoni A, Santecchia E, Spigarelli S. On the Short-Term Creep Response at 482 °C (900 °F) of the 17-4PH Steel Produced by Bound Metal Deposition. Metals. 2022; 12(3):477. https://doi.org/10.3390/met12030477

Chicago/Turabian StyleDi Pompeo, Valerio, Alberto Santoni, Eleonora Santecchia, and Stefano Spigarelli. 2022. "On the Short-Term Creep Response at 482 °C (900 °F) of the 17-4PH Steel Produced by Bound Metal Deposition" Metals 12, no. 3: 477. https://doi.org/10.3390/met12030477