Microstructure and Fracture Performance of Wire Arc Additively Manufactured Inconel 625 Alloy by Hot-Wire GTAW

Abstract

:1. Introduction

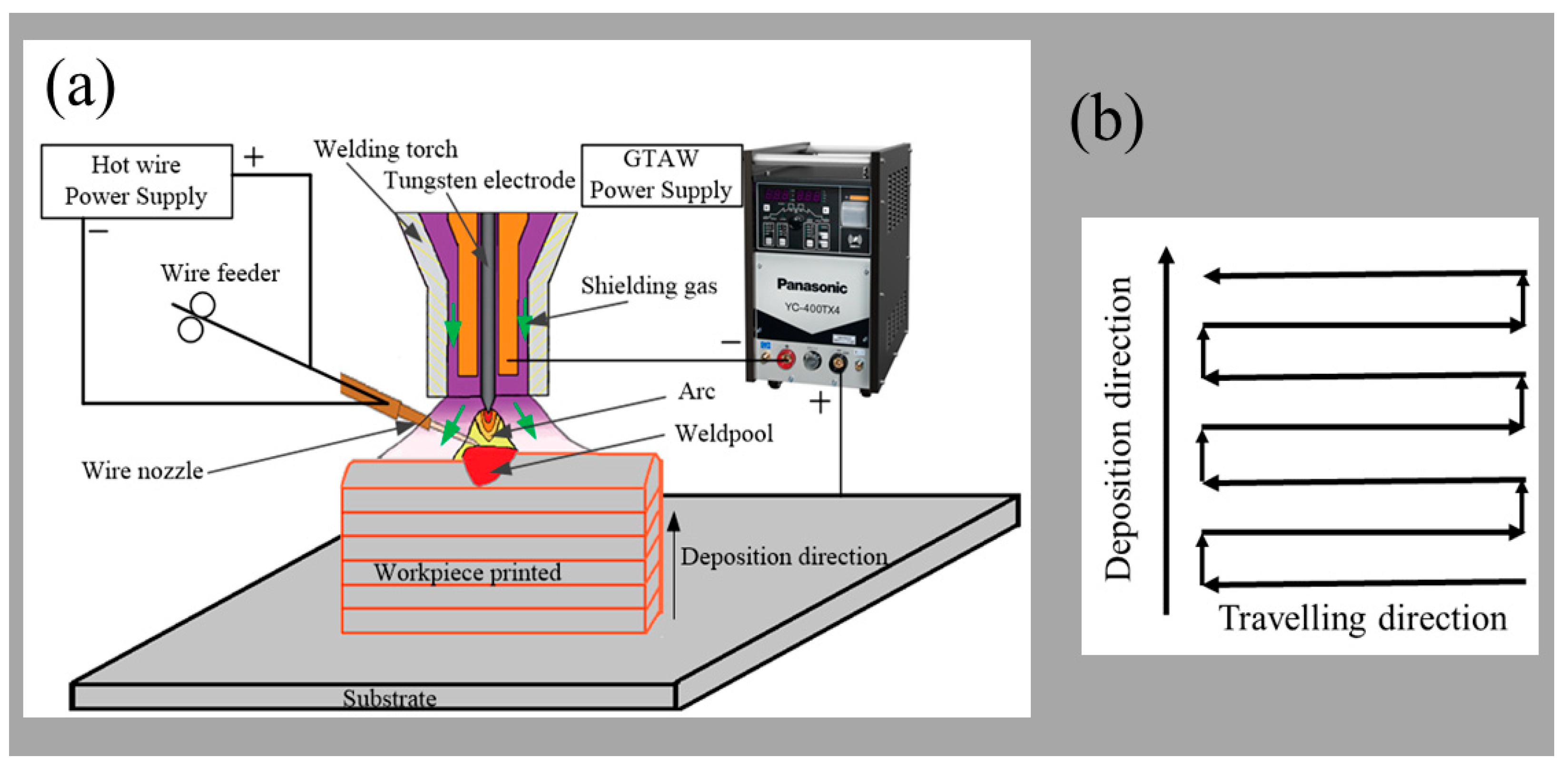

2. Materials and Methods

2.1. Materials and Equipment

2.2. Material Characterization

3. Results Analysis

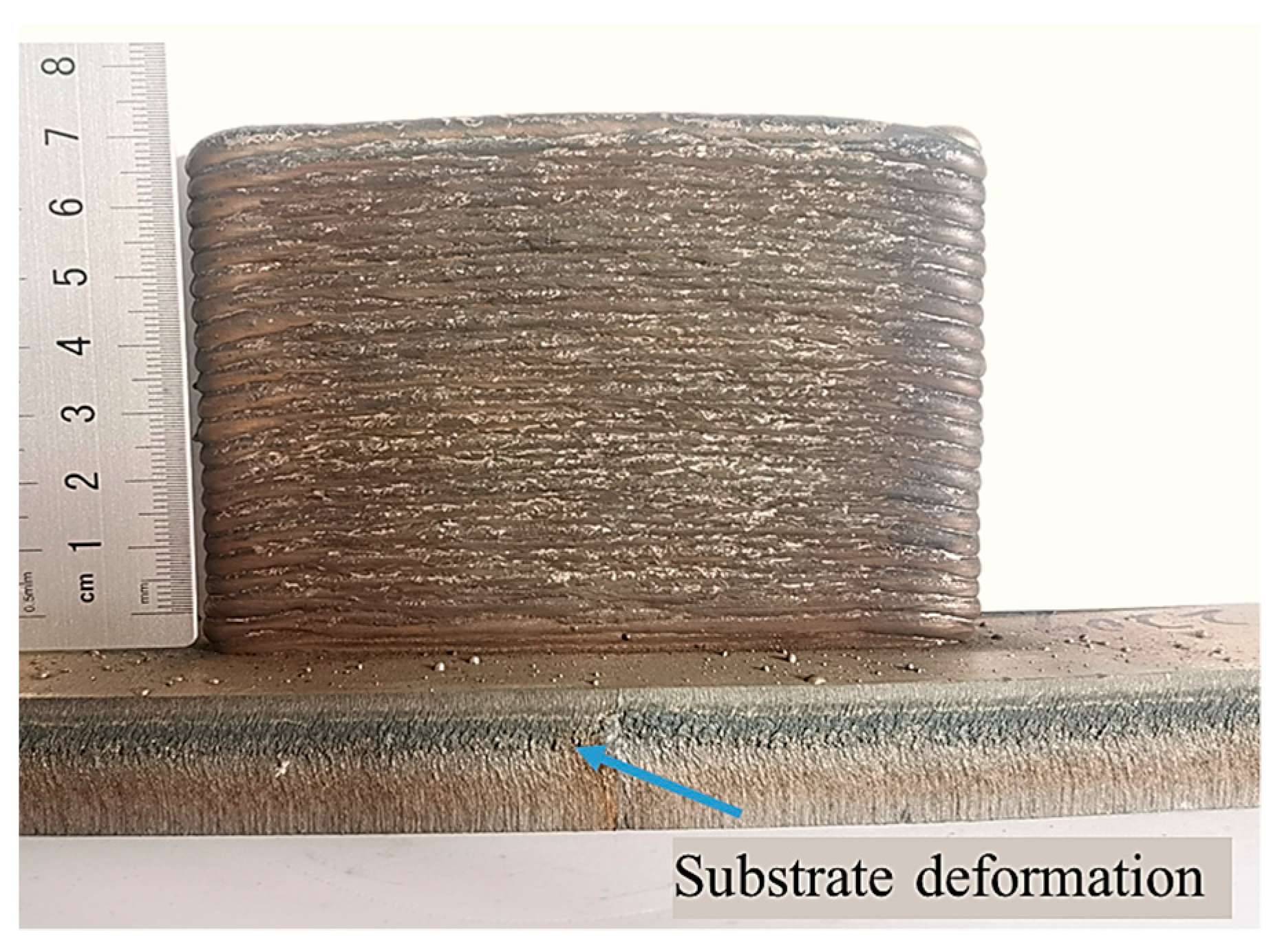

3.1. Macrostructure

3.2. Microstructure Observation

3.3. Mechanical Property Analysis

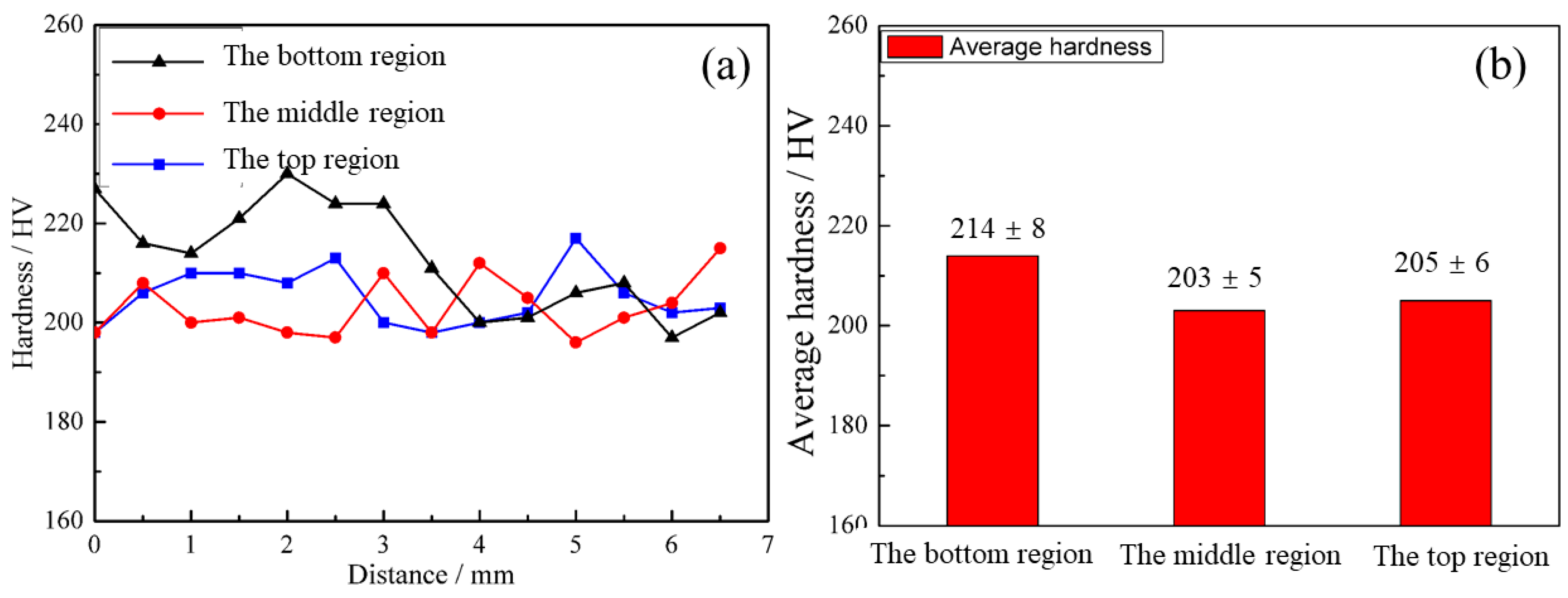

3.3.1. Hardness

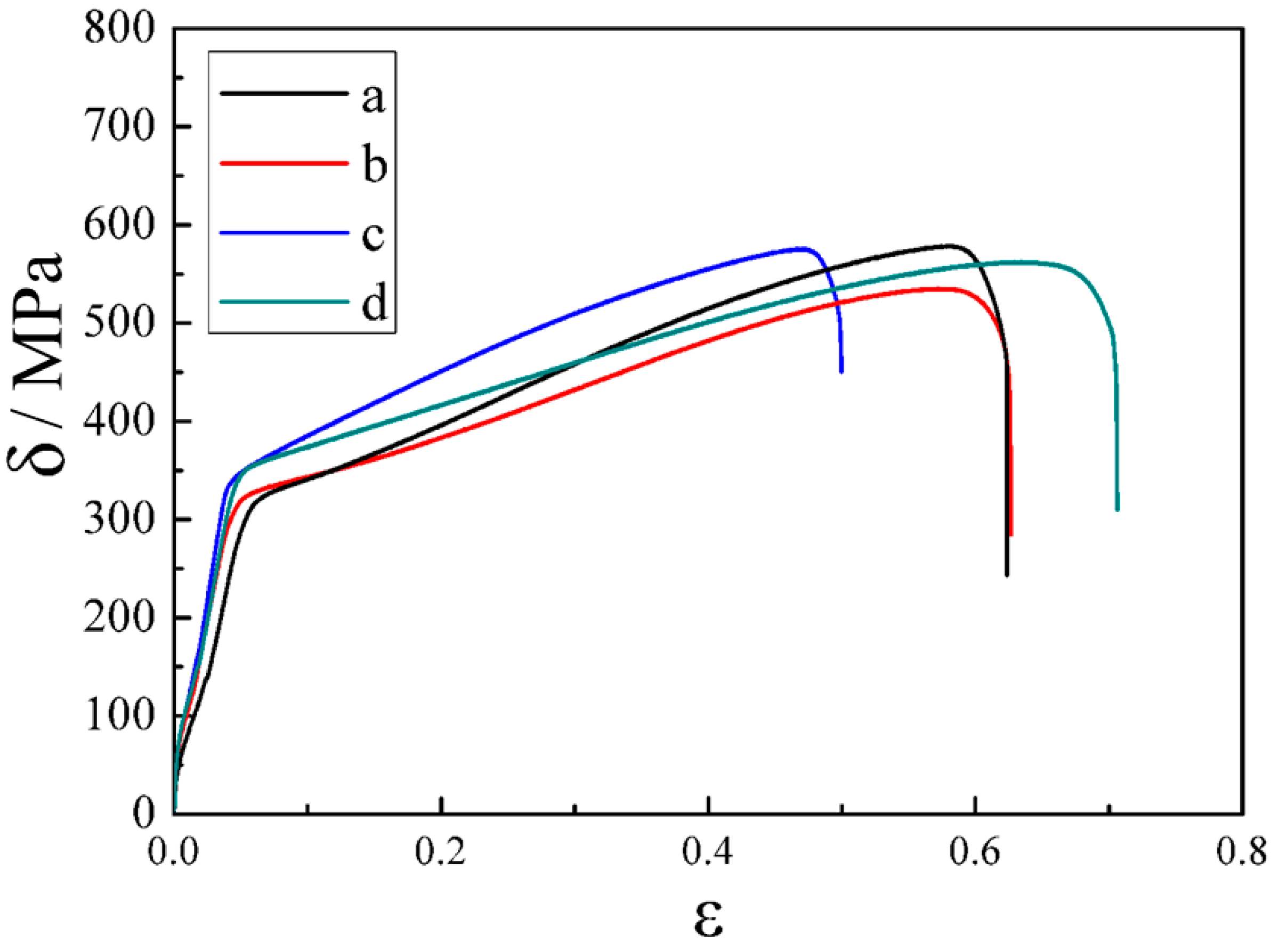

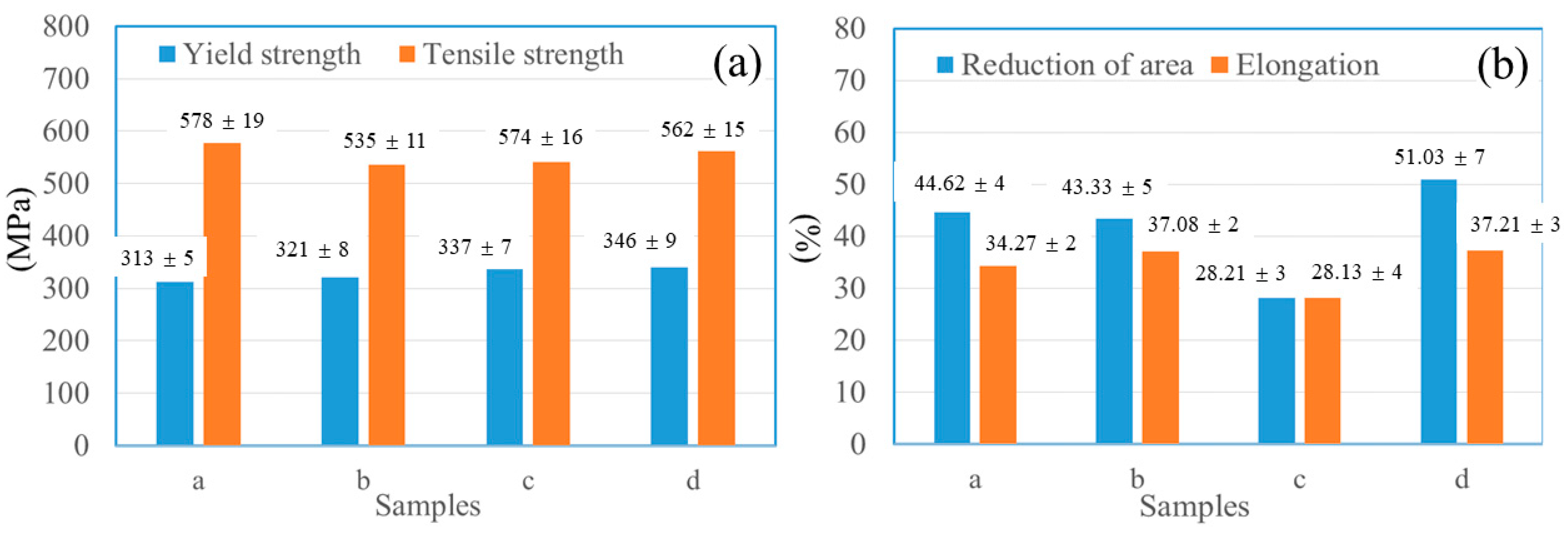

3.3.2. Tensile Strength

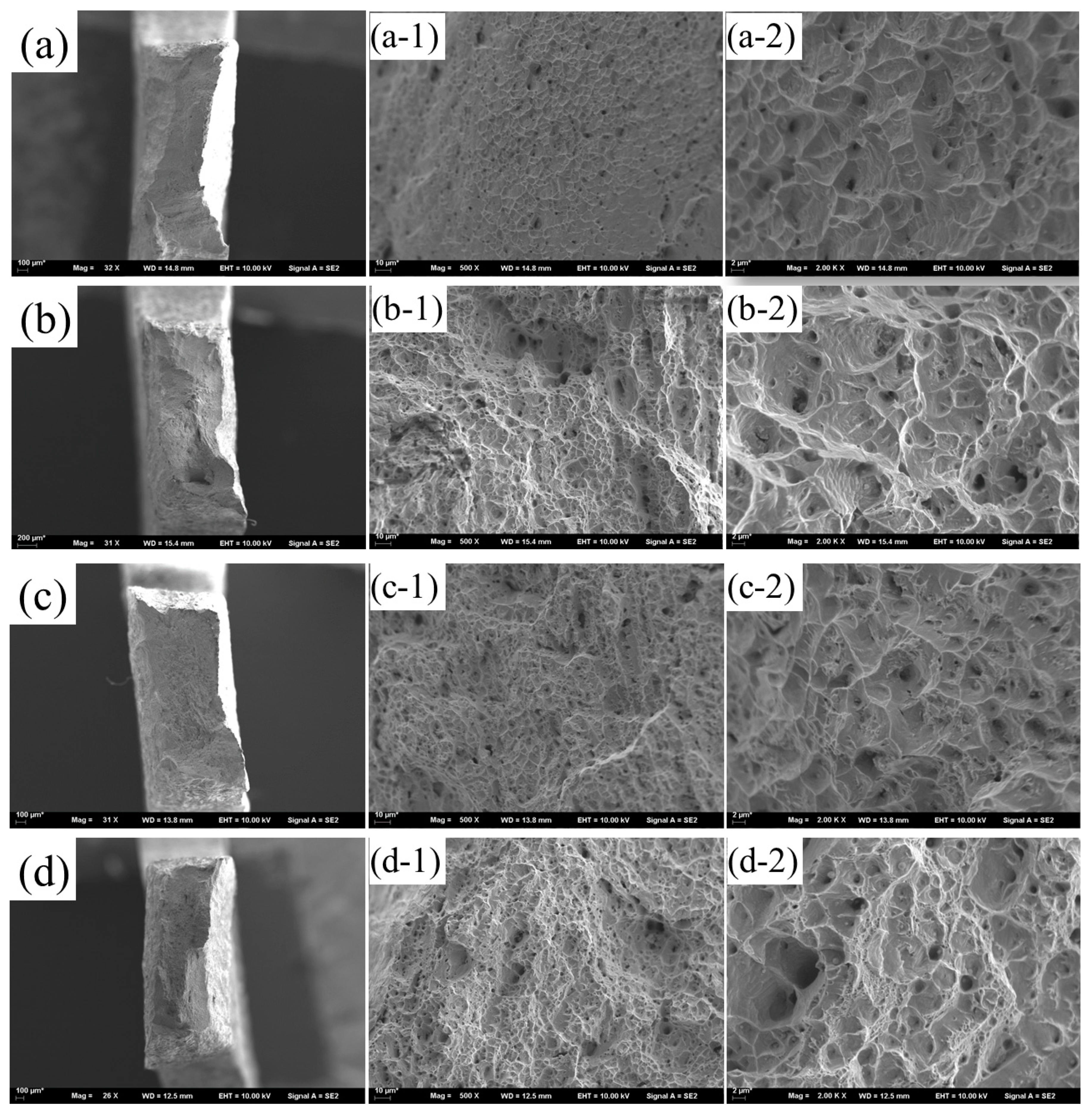

3.3.3. Fracture Behavior Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramkumar, K.D.; Abraham, W.S.; Viyash, V.; Arivazhagan, N.; Rabel, A.M. Investigations on the microstructure, tensile strength and high temperature corrosion behaviour of Inconel 625 and Inconel 718 dissimilar joints. J. Manuf. Process. 2017, 25, 306–322. [Google Scholar] [CrossRef]

- Huebner, J.; Kata, D.; Kusiński, J.; Rutkowski, P.; Lis, J. Microstructure of laser cladded carbide reinforced Inconel 625 alloy for turbine blade application. Ceram. Int. 2017, 43, 8677–8684. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D. Microstructure characteristics of Inconel 625 superalloy manufactured by selective laser melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Xiong, J.; Zhang, G.; Qiu, Z.; Li, Y. Vision-sensing and bead width control of a single-bead multi-layer part: Material and energy savings in GMAW-based rapid manufacturing. J. Clean Prod. 2012, 41, 82–88. [Google Scholar] [CrossRef]

- Colegrove, P.A.; Coules, H.E.; Fairman, J.; Martina, F.; Kashoob, T.; Mamash, H. Microstructure and residual stress improvement in wire and arc additively manufactured parts through high-pressure rolling. J. Mater. Process. Technol. 2013, 213, 1782–1791. [Google Scholar] [CrossRef]

- Basmachi, A.; Erkoyuncu, J.; Colegrover, P.; Martina, F.; Ding, J. Designing a WAAM based manufacturing system for defense applications. Procedia CIRP 2015, 37, 48–53. [Google Scholar]

- Donoghue, J.; Antonysamy, A.A.; Martina, F.; Colegrove, P.A.; Williams, S.W.; Prangnell, P.B. The effectiveness of combining rolling deformation with Wire–Arc Additive Manufacture on β-grain refinement and texture modification in Ti–6Al–4V. Mater. Charact. 2016, 114, 103–114. [Google Scholar] [CrossRef]

- Martina, F.; Mehnen, J.; Williams, S.W.; Colegrove, P.A.; Wang, F. Investigation of the benefits of plasma deposition for the additive layer manufacture of Ti-6Al-4V. J. Mater. Process. Technol. 2012, 212, 1377–1386. [Google Scholar] [CrossRef] [Green Version]

- Geng, H.B.; Li, J.L.; Xiong, J.T.; Lin, X.; Zhang, F.S. Optimization of wire feed for gtaw based additive manufacturing. J. Mater. Process. Technol. 2017, 243, 40–47. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhang, H.; Zhang, G.Y.; Xu, J.N. Precision rapid prototyping of steel parts using TIG depositision technology. Welding 2009, 30, 37–41. [Google Scholar]

- Ouyang, J.H.; Wang, H.; Kovacevic, R. Rapid prototyping of 5356-aluminum alloy based on variable polarity gas tungsten arc welding: Process control and microstructure. Mater. Manuf. Process. 2002, 17, 103–124. [Google Scholar] [CrossRef]

- Hu, Q.X.; Wang, X.L.; Shen, X.W.; Tan, Z.M. Microstructure and corrosion resistance in bimetal materials of Q345 and 308 steel wire-arc additive manufacturing. Crystals 2021, 11, 1401. [Google Scholar] [CrossRef]

- Tabernero, I.; Paskual, A.; Álvarez, P.; Suárez, A. Study on arc welding processes for high deposition rate additive manufacturing. Procedia CIRP 2018, 68, 358–362. [Google Scholar]

- Chen, J.S.; Lu, Y.; Li, X.R.; Zhang, Y.M. Gas Tungsten Arc Welding Using an Arcing wire. Weld. J. 2012, 91, 261–269. [Google Scholar]

- Ueguri, S.; Tabata, Y.; Shimizu, T.; Mizuno, T. A study on control of deposition rate in hot-wire TIG welding. Q. J. J. W. Soc. 1986, 4, 678–684. [Google Scholar] [CrossRef] [Green Version]

- Frei, J.; Alexandrov, B.T.; Rethmeier, M. Low heat input gas metal arc welding for dissimilar metal weld overlays part Ⅱ: The transition zone. Weld. World 2018, 62, 317–324. [Google Scholar] [CrossRef]

- Fu, R.; Tang, S.Y.; Lu, J.P.; Cui, Y.N.; Li, Z.X.; Zhang, H.R.; Xu, T.Q.; Chen, Z.; Liu, C.M. Hot-wire arc additive manufacturing of aluminum alloy with reduced porosity and high deposition rate. Mater. Des. 2021, 199, 109370. [Google Scholar] [CrossRef]

- Hu, Q.X.; Miao, J.Y.; Wang, X.L.; Li, C.T.; Fang, K.W. Microstructure and properties of ER50-6 steel fabricated by wire arc additive manufacturing. Scanning 2021, 2021, 7846116. [Google Scholar] [CrossRef] [PubMed]

- Hack, H.; Link, R.; Knudsen, E.; Baker, B.; Olig, S. Mechanical properties of additive manufactured nickel alloy 625. Addit. Manuf. 2017, 14, 105–115. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Dadbakhsh, S.; Rashid, A. Contouring strategies to improve the tensile properties and quality of EBM printed Inconel 625 parts. J. Manuf. Process. 2021, 62, 418–429. [Google Scholar] [CrossRef]

- Li, R.F.; Yuan, W.Y.; Yue, H.Y.; Zhu, Y.Y. Study on microstructure and properties of Fe-based amorphous composite coating by high-speed laser cladding. Opt. Laser Technol. 2022, 146, 107574. [Google Scholar] [CrossRef]

- Luo, S.X.; Li, R.F.; He, P.Y.; Yue, H.Y.; Gu, J.Y. Investigation on the microstructure and mechanical properties of CNTs-AlSi10Mg composites fabricated by selective laser melting. Materials 2021, 14, 838. [Google Scholar] [CrossRef] [PubMed]

- Tao, J.; Yao, Z.J.; Xue, F. Material Science Foundation; Chemical Industry Press: Beijing, China, 2015; pp. 180–191. [Google Scholar]

- Brandl, E.; Baufeld, B.; Leyens, C.; Gault, R. Additive manufactured Ti-6Al-4V using welding wire: Comprision of laser and arc beam deposition and evaluation with respect to aerospace material specifications. Phys. Procedia 2010, 5, 595–606. [Google Scholar] [CrossRef] [Green Version]

- Baufeld, B. Effect of deposition parameters on mechanical properties of shaped metal deposition parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 126–136. [Google Scholar] [CrossRef]

- Wang, F.; Williams, S.; Colegrove, P.; Antonysamy, A.A. Microstructure and mechanical properties of wire and arc additive manufactured Ti-6Al-4V. Metal. Mater. Trans. A 2013, 44, 968–977. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Mo | Nb | Al | Ti | Cu | Fe |

|---|---|---|---|---|---|---|---|---|

| wt.% | ≥58 | 20.0–23.0 | 8.0–10.0 | 3.0–4.2 | ≤0.4 | ≤0.4 | ≤0.5 | ≤5.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Hu, Q.; Li, T.; Liu, W.; Tang, D.; Hu, Z.; Liu, K. Microstructure and Fracture Performance of Wire Arc Additively Manufactured Inconel 625 Alloy by Hot-Wire GTAW. Metals 2022, 12, 510. https://doi.org/10.3390/met12030510

Wang X, Hu Q, Li T, Liu W, Tang D, Hu Z, Liu K. Microstructure and Fracture Performance of Wire Arc Additively Manufactured Inconel 625 Alloy by Hot-Wire GTAW. Metals. 2022; 12(3):510. https://doi.org/10.3390/met12030510

Chicago/Turabian StyleWang, Xiaoli, Qingxian Hu, Tianqing Li, Wenkang Liu, Douxi Tang, Zichen Hu, and Kang Liu. 2022. "Microstructure and Fracture Performance of Wire Arc Additively Manufactured Inconel 625 Alloy by Hot-Wire GTAW" Metals 12, no. 3: 510. https://doi.org/10.3390/met12030510