Prediction of Work Hardening in Bearing Steels Undergoing Rolling Contact Loading with a Dislocation-Based Model

Abstract

:1. Introduction

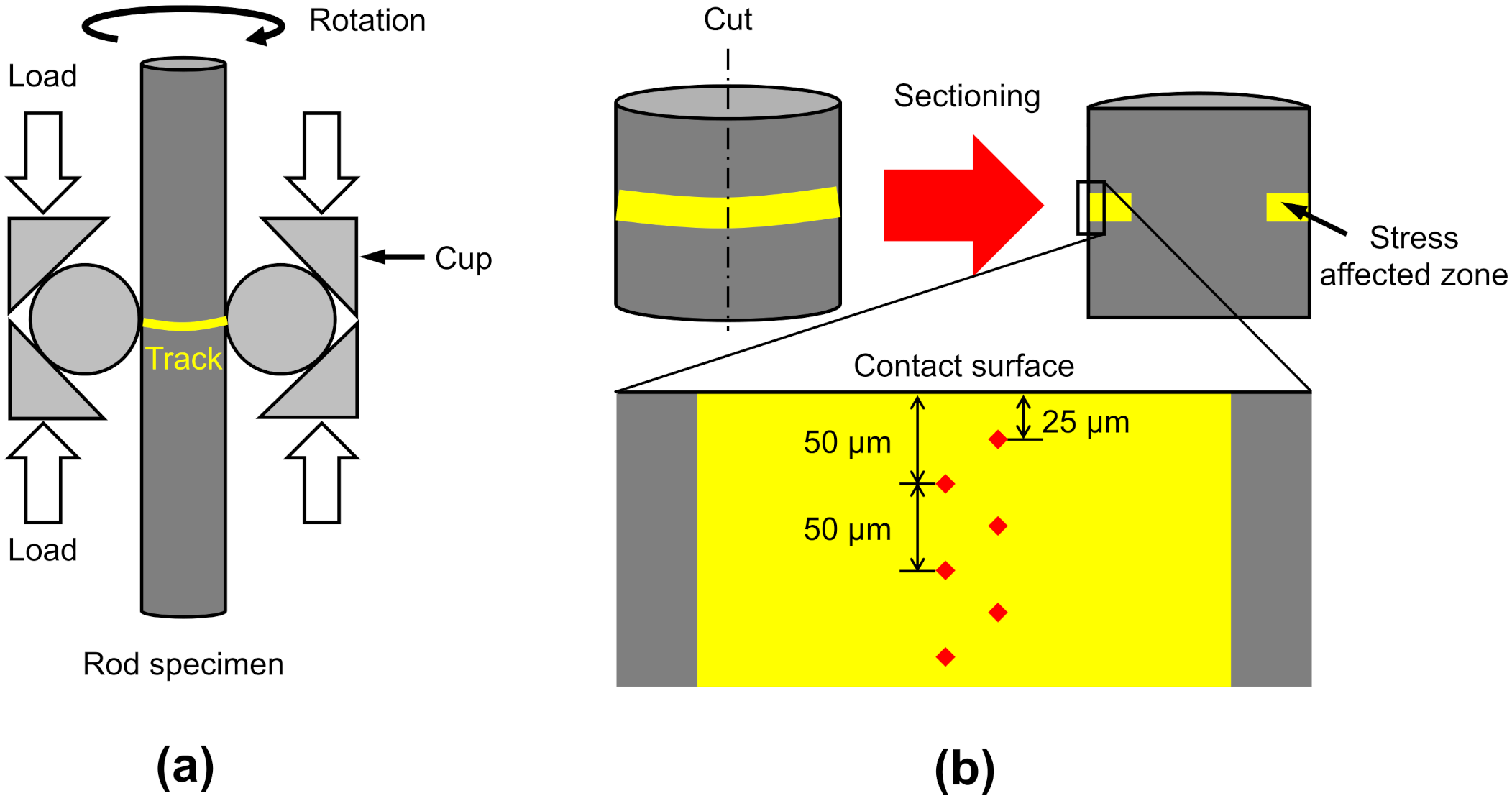

2. Material and Methods

3. Results and Discussion

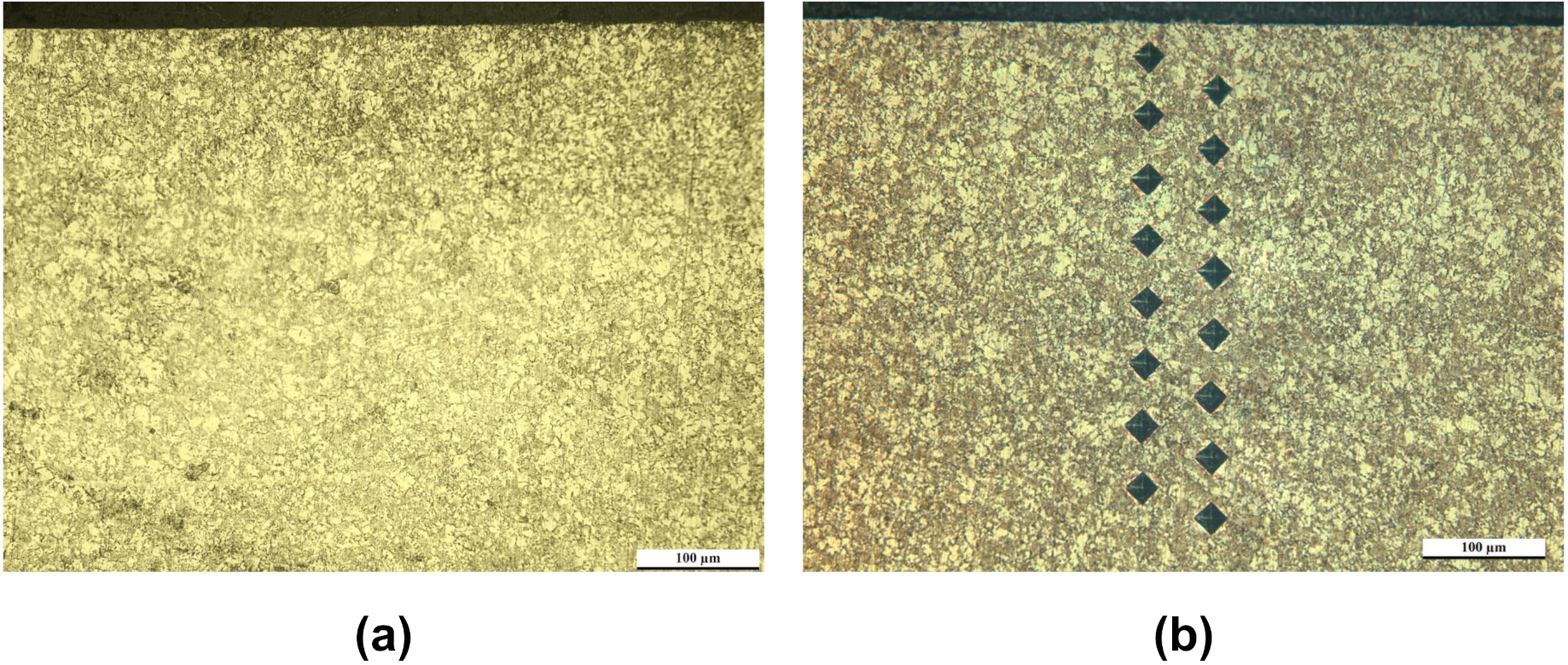

3.1. Characterisation and Hardness Profiles

3.2. Stress State under Hertzian Contact

3.3. Work Hardening Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fu, H.; Rivera-Díaz-del Castillo, P.E.J. Approaches to model structural and contact fatigue. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 576–588. [Google Scholar]

- Johnson, K. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1987. [Google Scholar]

- Bhadeshia, H.K.D.H. Steels for Bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Fu, H.; Rivera-Díaz-del Castillo, P.E. Evolution of white etching bands in 100Cr6 bearing steel under rolling contact-fatigue. Metals 2019, 9, 491. [Google Scholar] [CrossRef] [Green Version]

- Arakere, N.K.; Subhash, G. Work hardening response of M50-NiL case hardened bearing steel during shakedown in rolling contact fatigue. Mater. Sci. Technol. 2012, 28, 34–38. [Google Scholar] [CrossRef]

- Warhadpande, A.; Sadeghi, F.; Evans, R.D. Microstructural Alterations in Bearing Steels under Rolling Contact Fatigue Part 1—Historical Overview. Tribol. Trans. 2013, 56, 349–358. [Google Scholar] [CrossRef]

- Fu, H.; Rydel, J.J.; Gola, A.M.; Yu, F.; Geng, K.; Lau, C.; Luo, H.; Rivera-Díaz-del Castillo, P.E.J. The relationship between 100Cr6 steelmaking, inclusion microstructure and rolling contact fatigue performance. Int. J. Fatigue 2019, 129, 104899. [Google Scholar] [CrossRef]

- Kang, J.H.; Vegter, R.H.; Rivera-Díaz-del Castillo, P.E.J. Rolling contact fatigue in martensitic 100Cr6: Subsurface hardening and crack formation. Mater. Sci. Eng. A 2014, 607, 328–333. [Google Scholar] [CrossRef]

- Liang, X.; Zhao, G.H.; Owens, J.; Gong, P.; Rainforth, W.M.; Rivera-Díaz-del Castillo, P.E.J. Hydrogen-assisted microcrack formation in bearing steels under rolling contact fatigue. Int. J. Fatigue 2020, 134, 105485. [Google Scholar] [CrossRef]

- Kang, J.H.; Rivera-Díaz-del Castillo, P.E.J. Fatigue in martensitic 100Cr6: Relationship between rolling contact fatigue microstructural transitions and repetitive push testing. Mater. Sci. Eng. A 2014, 614, 214–222. [Google Scholar] [CrossRef]

- Christ, H.J.; Sommer, C.; Mughrabi, H.; Voskamp, A.P.; Beswick, J.M.; Hengerer, F. Fatigue behaviour of three variants of the roller bearing steel SAE 52100. Fatigue Fract. Eng. Mater. Struct. 1992, 15, 855–870. [Google Scholar] [CrossRef]

- Hahn, G.T.; Bhargava, V.; Chen, Q. The cyclic stress-strain properties, hysteresis loop shape, and kinematic hardening of two high-strength bearing steels. Metall. Trans. A 1990, 21, 653. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Subhash, G.; Arakere, N. Evolution of subsurface plastic zone due to rolling contact fatigue of M-50 NiL case hardened bearing steel. Int. J. Fatigue 2014, 59, 102–113. [Google Scholar] [CrossRef]

- Merwin, J.E.; Johnson, K.L. An analysis of plastic deformation in rolling contact. Proc. Inst. Mech. Eng. 1963, 177, 676–690. [Google Scholar]

- Bhargava, V.; Hahn, G.T.; Rubin, C.A. An elastic-plastic finite element model of rolling contact. II: Analysis of repeated contacts. J. Appl. Mech. 1985, 52, 75–82. [Google Scholar] [CrossRef]

- Bhargava, V.; Hahn, G.T.; Rubin, C.A. Analysis of rolling contact with kinematic hardening for rail steel properties. Wear 1988, 122, 267–283. [Google Scholar] [CrossRef]

- Hahn, G.; Bhargava, V.; Rubin, C.A.; Chen, Q.; Kim, K. Analysis of the rolling contact residual stresses and cyclic plastic deformation of SAE 52100 steel ball bearings. J. Tribol. 1987, 109, 618–626. [Google Scholar] [CrossRef]

- Bower, A.F. Cyclic hardening properties of hard-drawn copper and rail steel. J. Mech. Phys. Solids 1989, 37, 455–470. [Google Scholar] [CrossRef]

- Howell, M.; Hahn, G.T.; Rubin, C.A.; McDowell, D.L. Finite element analysis of rolling contact for nonlinear kinematic hardening bearing steel. J. Tribol. 1995, 117, 729–736. [Google Scholar] [CrossRef]

- Pandkar, A.S.; Arakere, N.; Subhash, G. Microstructure-sensitive accumulation of plastic strain due to ratcheting in bearing steels subject to rolling contact fatigue. Int. J. Fatigue 2014, 63, 191–202. [Google Scholar] [CrossRef]

- Fu, H.; Galindo-Nava, E.; Rivera-Díaz-del Castillo, P.E.J. Modelling and characterisation of stress-induced carbide precipitation in bearing steels under rolling contact fatigue. Acta Mater. 2017, 128, 176–187. [Google Scholar] [CrossRef]

- Sackfield, A.; Hills, D.A.; Nowell, D. Mechanics of Elastic Contacts; Elsevier: Amsterdam, The Netherlands, 2013. [Google Scholar]

- Kocks, U.; Mecking, H. Physics and phenomenology of strain hardening: The FCC case. Prog. Mater. Sci. 2003, 48, 171–273. [Google Scholar] [CrossRef]

- Galindo-Nava, E.I.; Sietsma, J.; Rivera-Díaz-del Castillo, P.E.J. Dislocation annihilation in plastic deformation: II. Kocks-Mecking Analysis. Acta Mater. 2012, 60, 2615–2624. [Google Scholar] [CrossRef]

- Nabarro, F.R.N.; Basinski, Z.S.; Holt, D.B. The plasticity of pure single crystals. Adv. Phys. 1964, 13, 193–323. [Google Scholar] [CrossRef]

- Tabor, D. The hardness and strength of metals. J. Inst. Met. 1951, 79, 1. [Google Scholar]

- Fu, H.; Song, W.; Galindo-Nava, E.I.; Rivera-Díaz-del Castillo, P.E.J. Strain-induced martensite decay in bearing steels under rolling contact fatigue: Modelling and atomic-scale characterisation. Acta Mater. 2017, 139, 163–173. [Google Scholar] [CrossRef]

- Slack, T.S.; Raje, N. A Review of Rolling Contact Fatigue. J. Tribol. 2009, 131, 041403. [Google Scholar]

- Fu, H.; Rivera-Díaz-del Castillo, P.E.J. A unified theory for microstructural alterations in bearing steels under rolling contact fatigue. Acta Mater. 2018, 155, 43–55. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, H.; Bai, X.; Fu, H. Prediction of Work Hardening in Bearing Steels Undergoing Rolling Contact Loading with a Dislocation-Based Model. Metals 2022, 12, 555. https://doi.org/10.3390/met12040555

Yin H, Bai X, Fu H. Prediction of Work Hardening in Bearing Steels Undergoing Rolling Contact Loading with a Dislocation-Based Model. Metals. 2022; 12(4):555. https://doi.org/10.3390/met12040555

Chicago/Turabian StyleYin, Hongxiang, Xue Bai, and Hanwei Fu. 2022. "Prediction of Work Hardening in Bearing Steels Undergoing Rolling Contact Loading with a Dislocation-Based Model" Metals 12, no. 4: 555. https://doi.org/10.3390/met12040555

APA StyleYin, H., Bai, X., & Fu, H. (2022). Prediction of Work Hardening in Bearing Steels Undergoing Rolling Contact Loading with a Dislocation-Based Model. Metals, 12(4), 555. https://doi.org/10.3390/met12040555