Laser Powder Bed Fusion of K418 Superalloy: Process, Microstructure, Texture Feature, and Mechanical Property

Abstract

:1. Introduction

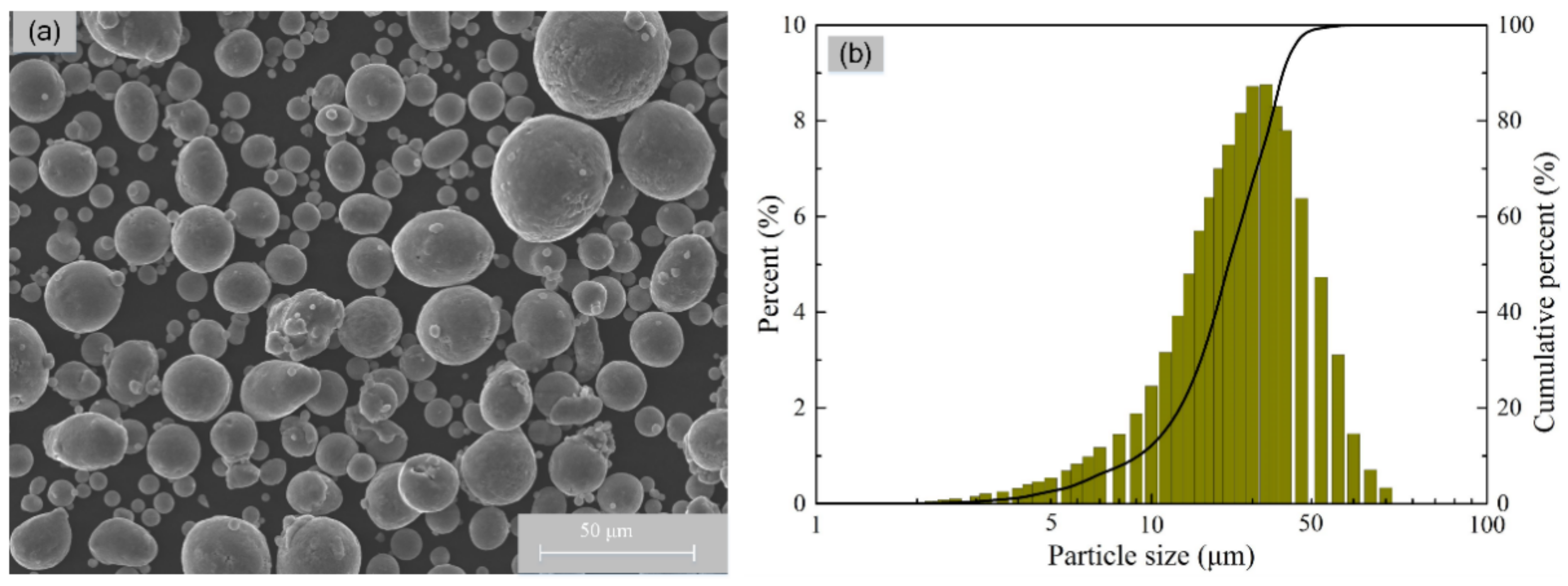

2. Materials and Methods

2.1. Materials

2.2. Specimens Preparation

2.3. Experimental Test

3. Results and Discussion

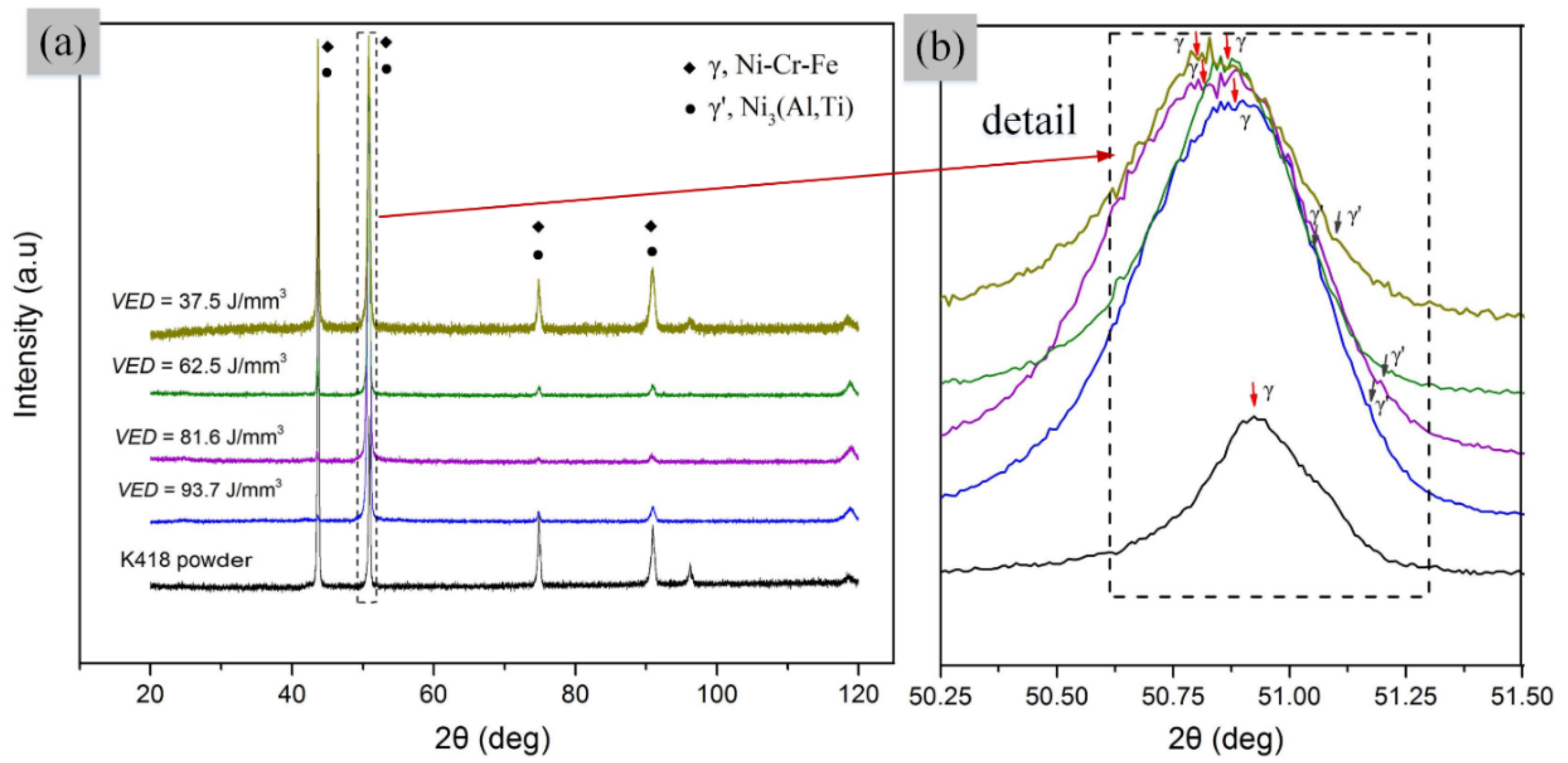

3.1. Phases

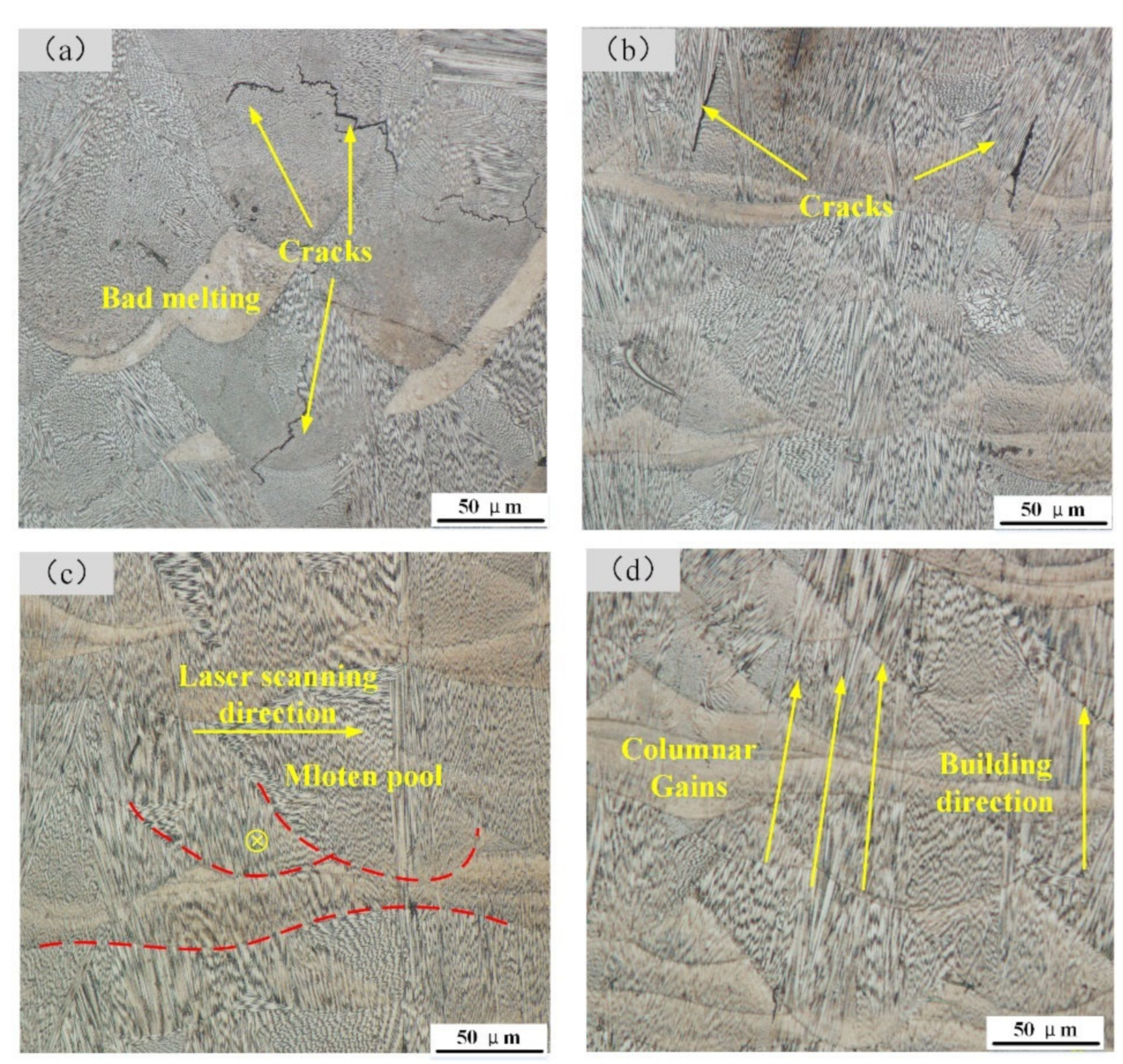

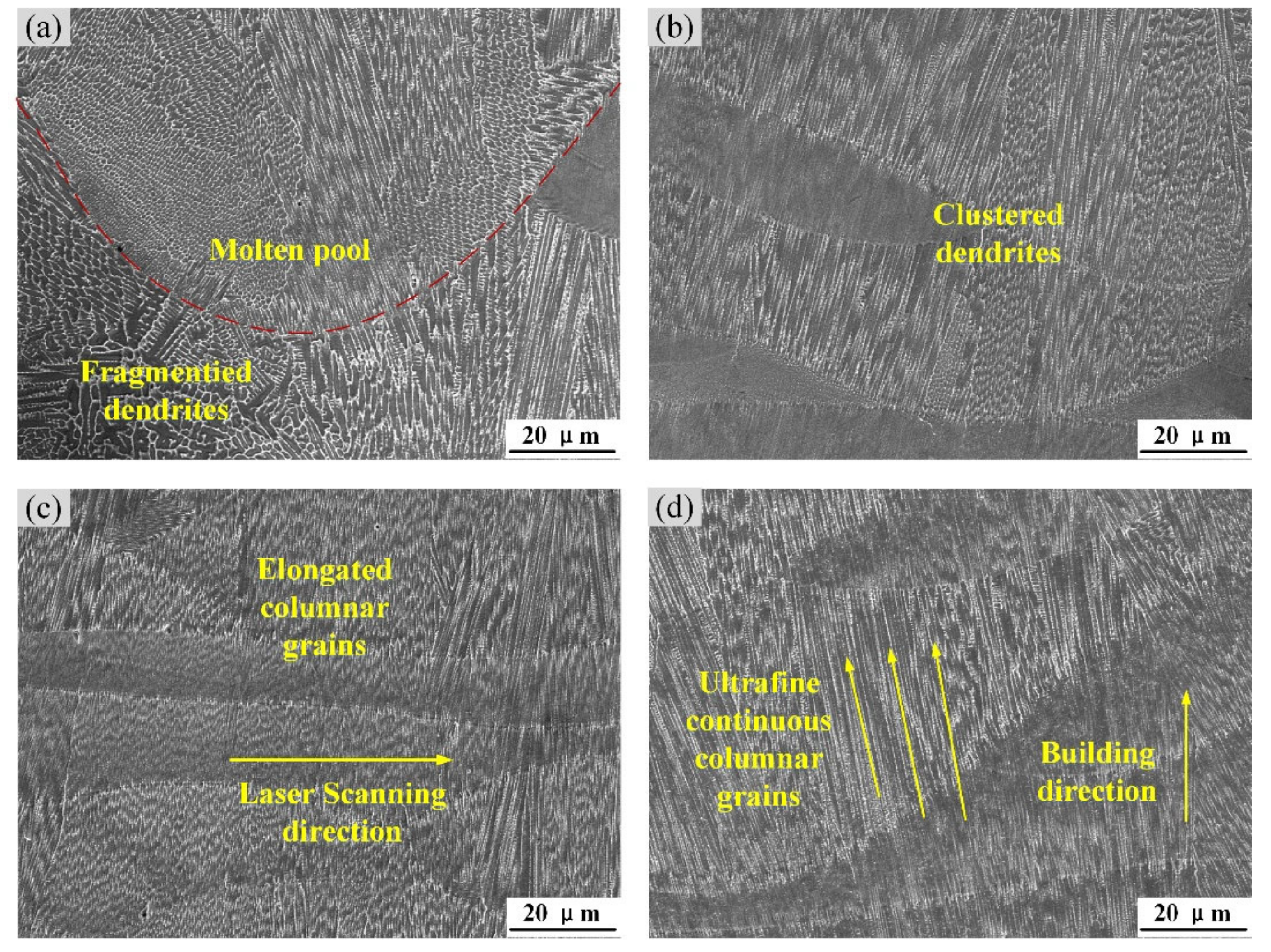

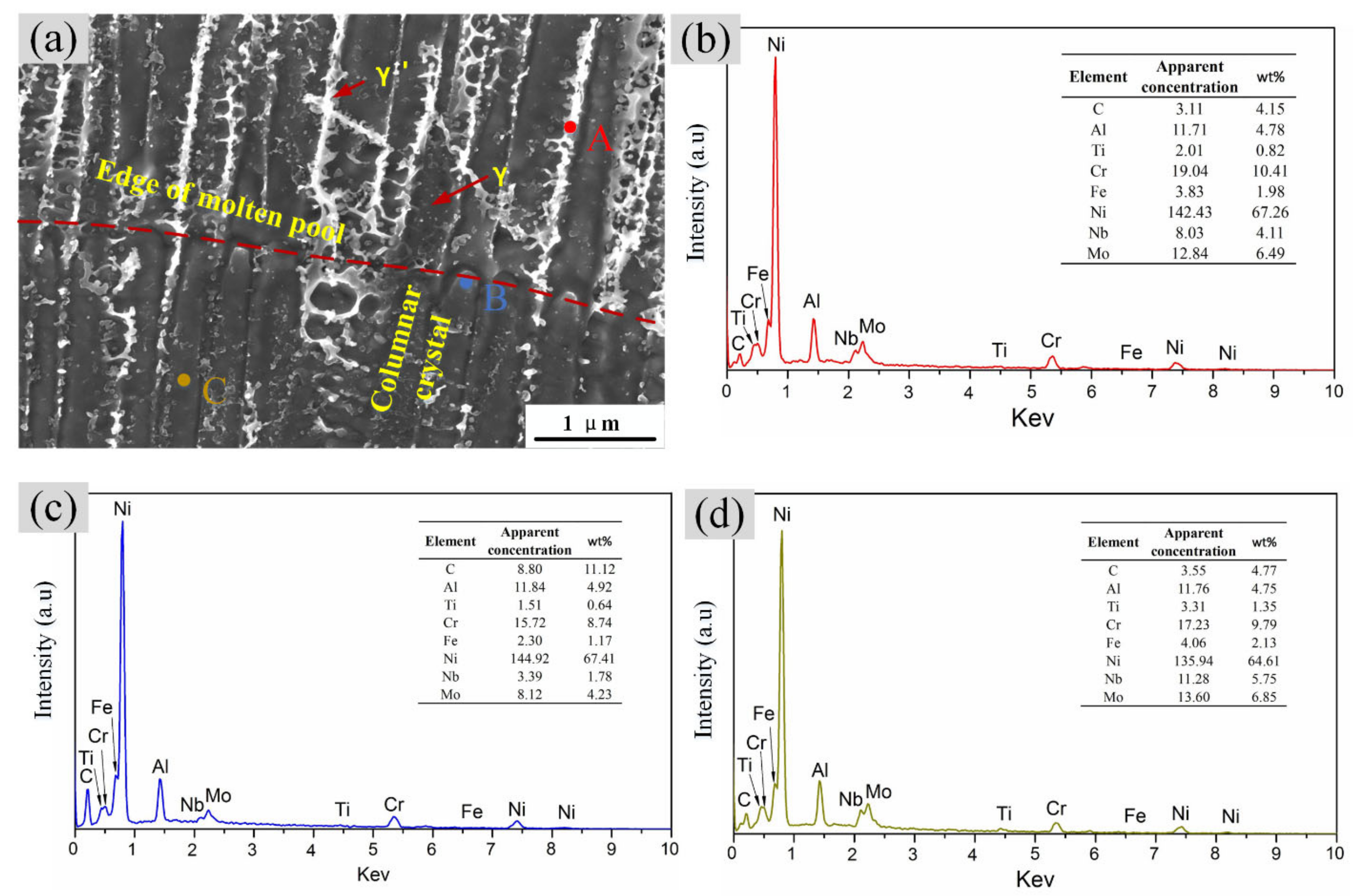

3.2. Microstructure

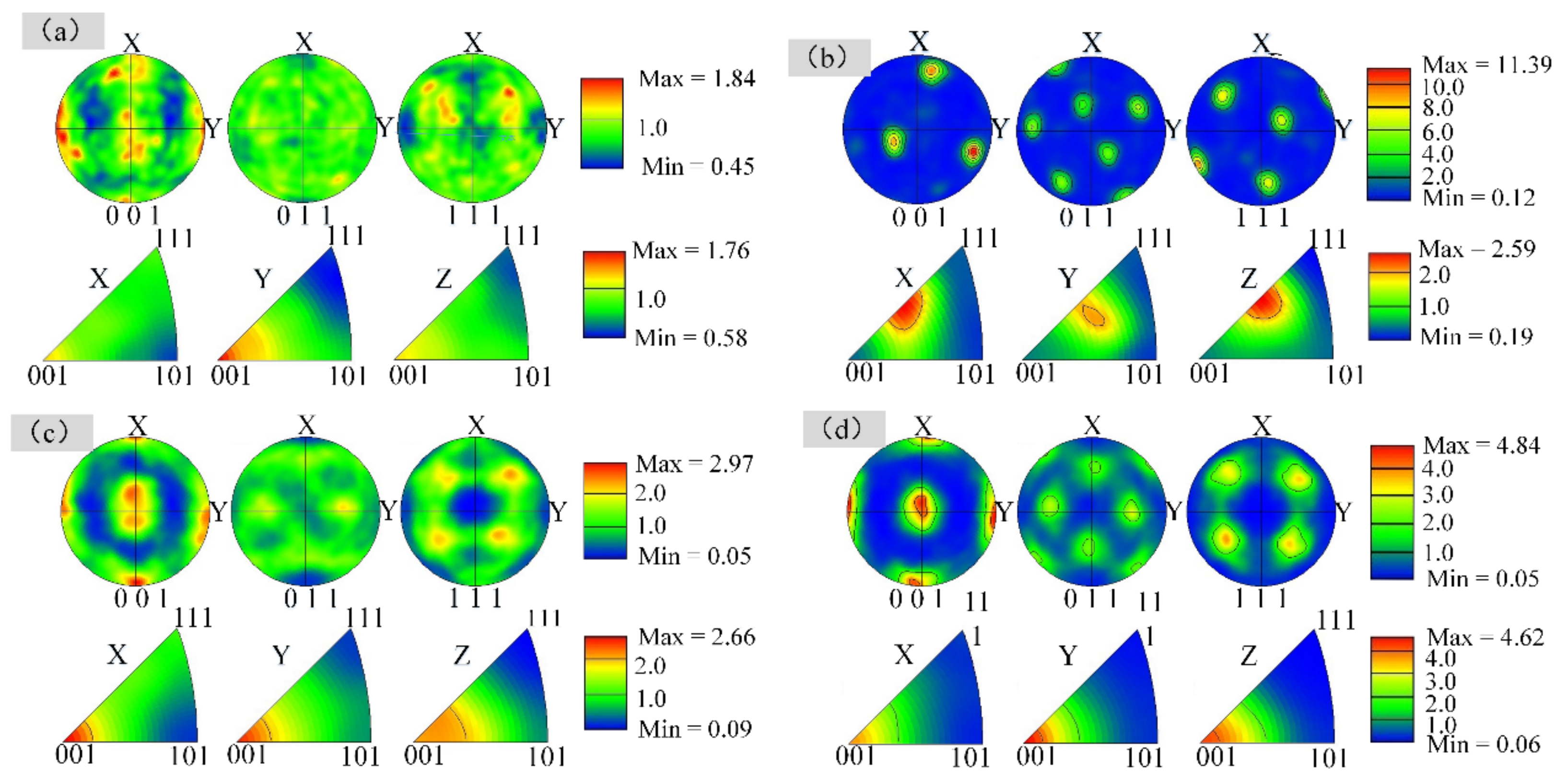

3.3. Texture

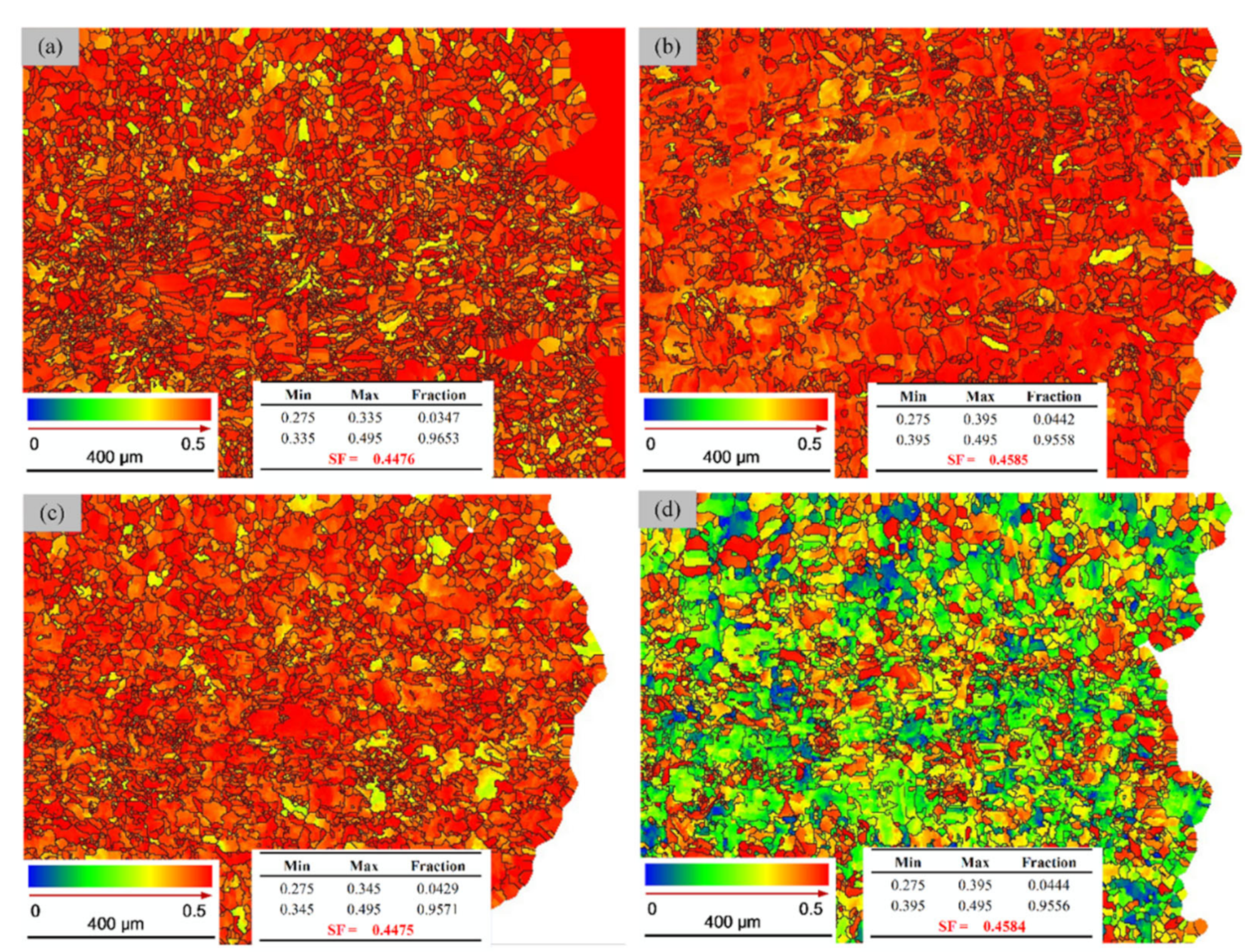

3.4. Mechanical Properties

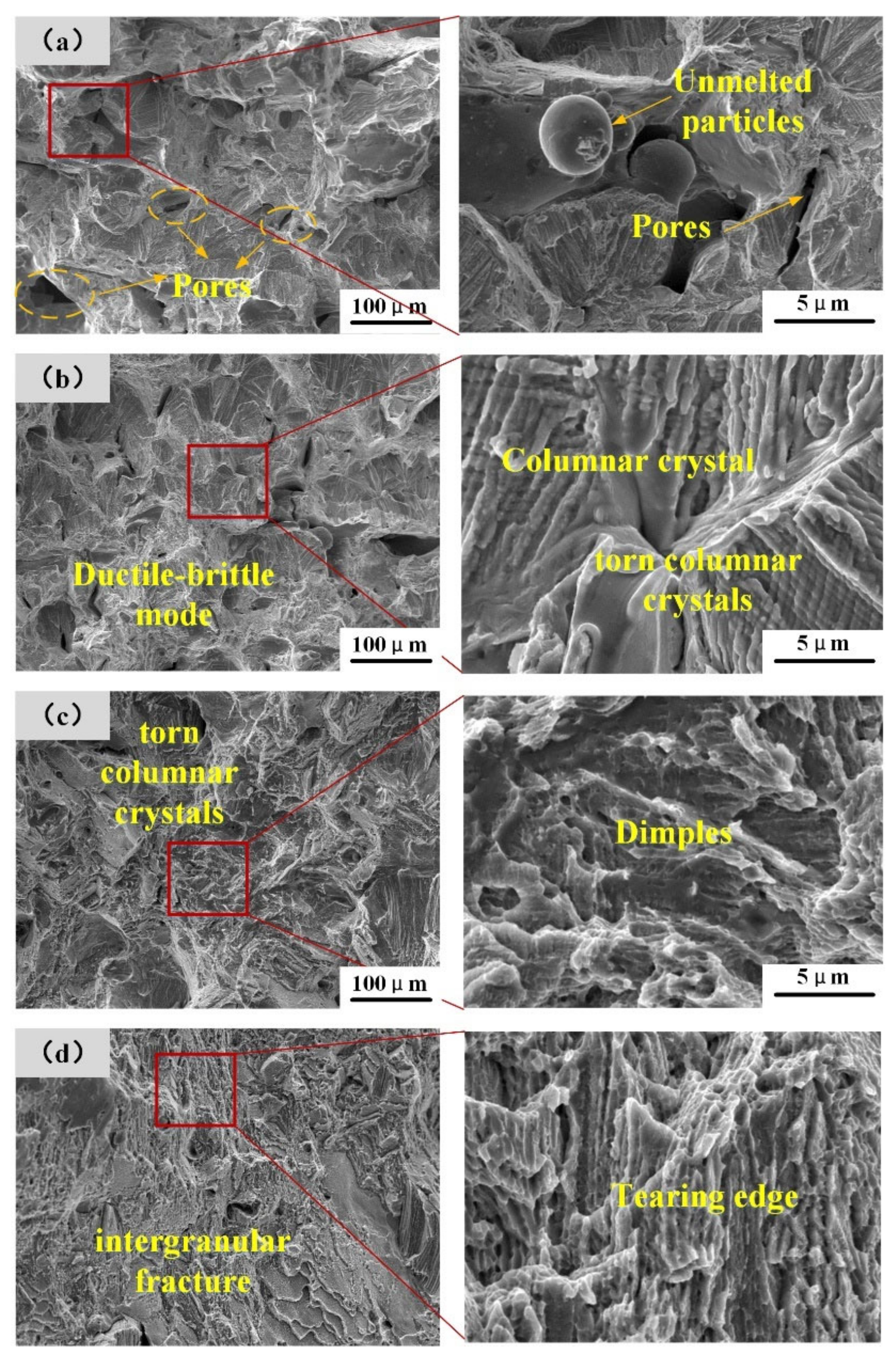

3.5. Fracture Morphology

4. Conclusions

- (The mechanical properties of the LPBF-manufactured K418 sample are determined by the solidification microstructures, which are governed by the local solidification conditions (G/V) of the molten pool, with the value of G/V being primarily controlled by the process parameters. As a result, the process parameters during LPBF are responsible for the evolution of the solidification microstructures and properties.

- As the volumetric energy density increased, the typical microstructures of the LPBF-manufactured K418 samples evolved sequentially: clustered columnar grains→coarsened columnar grains→ultrafine elongated columnar grains.

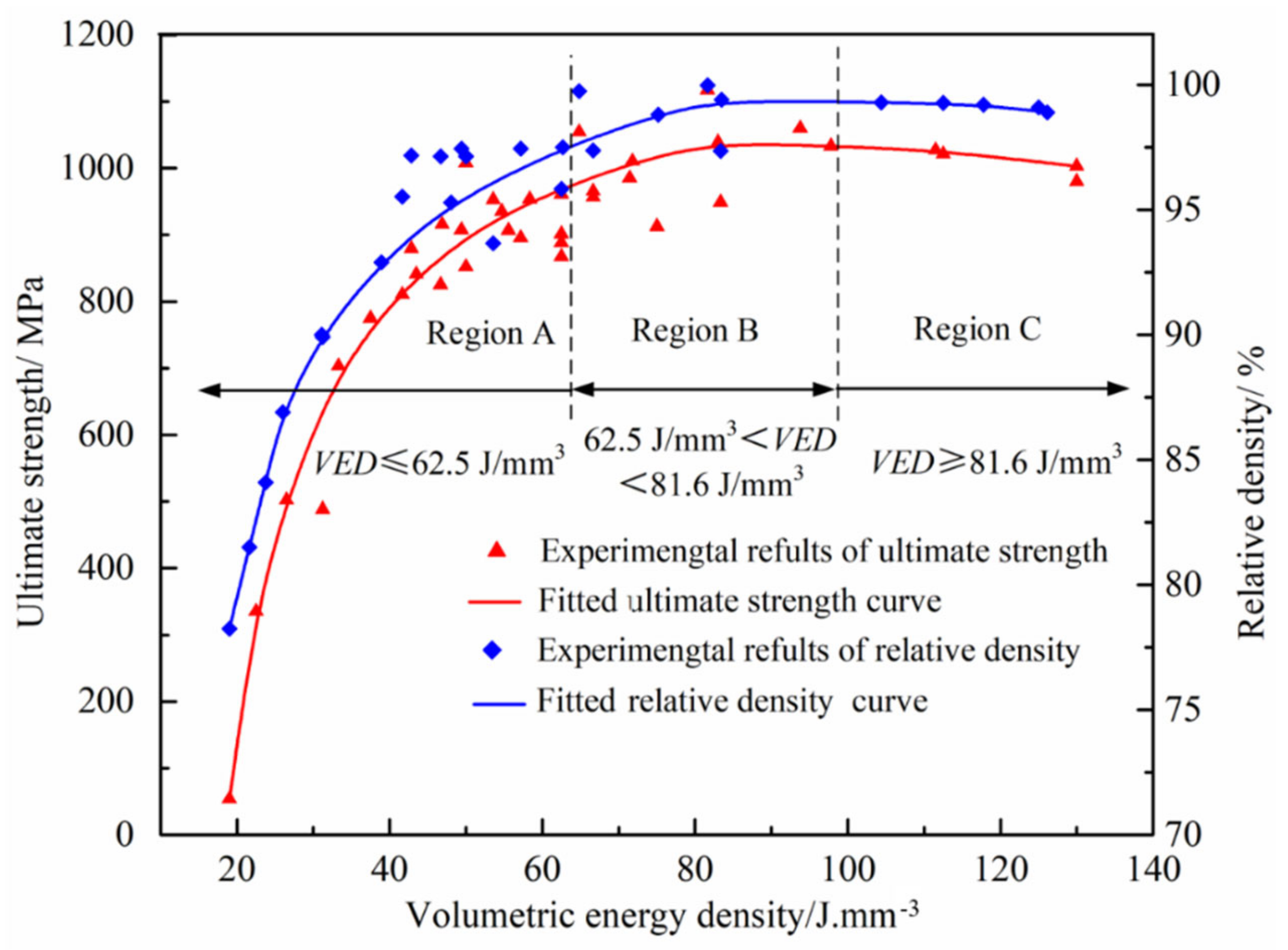

- As the volumetric energy density VED increases from 37.5 J/mm3 to 93.7 J/mm3, the mechanical strength initially increases and then decreases reaching a maximum of 1117 MPa at the VED of 81.6 J/mm3, owing to the ultrafine elongated columnar grains and a strong {001} <100> cubic texture.

- The fracture mechanism of the LPBF-manufactured K418 components changes from brittle fracture to ductile-brittle hybrid fracture to transgranular ductile fracture as the volumetric energy density VED increases.

- The solidification microstructure characteristics, grain orientation, low-angle grain boundaries, grain size, and internal defects comprehensively determine the final mechanical properties of the LPBF-manufactured K418 parts, and their respective influences on the properties are different under various process conditions.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- China Aviation Materials Manual Committee. China Aviation Materials Manual. Volume II: Superalloy; China Standards Press: Beijing, China, 2002; ISBN 7-5066-2439-7. [Google Scholar]

- Shi, Z.; Dong, J.; Zhang, M.; Zheng, L. Solidification characteristics and segregation behavior of Ni-based superalloy K418 for auto turbocharger turbine. J. Alloys Compd. 2013, 571, 168–177. [Google Scholar] [CrossRef]

- Durand-Charre, M.; Davidson, J.H. The Microstructure of Superalloys; Routledge: London, UK, 2017. [Google Scholar]

- Kianian, B. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry; Annual Worldwide Progress Report; Wohlers Associates: Fort Collins, CO, USA, 2016; ISBN 978-0-9913332-2-6. [Google Scholar]

- Gu, D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Calignano, F.; Manfredi, D.; Ambrosio, E.; Biamino, S.; Pavese, M.; Fino, P. Direct Fabrication of Joints based on Direct Metal Laser Sintering in Aluminum and Titanium Alloys. Procedia CIRP 2014, 21, 129–132. [Google Scholar] [CrossRef] [Green Version]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431, Erratum in 2016, 32, e1. [Google Scholar] [CrossRef]

- Li, S.; Wei, Q.; Shi, Y.; Zhu, Z.; Zhang, D.J. Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting. J. Mater. Sci. Technol. 2015, 31, 946–952. [Google Scholar] [CrossRef]

- Luo, Y.W.; Ma, T.; Shao, W.W.; Zhang, G.P.; Zhang, B. Effects of heat treatment on microstructures and mechanical properties of GH4169/K418 functionally graded material fabricated by laser melting deposition. Mater. Sci. Eng. A. 2021, 821, 141601. [Google Scholar] [CrossRef]

- Yang, F.; Wang, J.; Yu, J.B.; Zhou, Z.H.; Wang, B.J.; Tu, T.S.; Ren, X.F.; Deng, K.; Ren, Z.M. Microstructure and Mechanical Properties of Ni-based Superalloy K418 Produced by the Continuous Unidirectional Solidification Process. J. Mater. Eng. Perform. 2019, 28, 6483–6491. [Google Scholar] [CrossRef]

- Thijs, L.; Kempen, K.; Kruth, J.P.; Humbeeck, J.V. Fine-structured aluminium products with controllable texture by selective laser melting of pre-alloyed AlSi10Mg powder. Acta Mater. 2013, 61, 1809–1819. [Google Scholar] [CrossRef] [Green Version]

- Suwas, S.; Gurao, N.P. Crystallographic texture of materials. J. Indian Inst. Sci. 2008, 88, 151–177. [Google Scholar]

- Jia, Q.; Gu, D. Selective laser melting additive manufacturing of Inconel 718 superalloy parts: Densification, microstructure and properties. J. Alloys Compd. 2014, 585, 713–721. [Google Scholar] [CrossRef]

- Mumtaz, K.A.; Erasenthiran, P.; Hopkinson, N. High density selective laser melting of Waspaloy. J. Mater. Process. Technol. 2008, 195, 77–87. [Google Scholar] [CrossRef]

- Strner, J.; Terock, M.; Glatzel, U. Mechanical and Microstructural Investigation of Nickel-Based Superalloy IN718 Manufactured by Selective Laser Melting (SLM). Adv. Eng. Mater. 2015, 17, 1099–1105. [Google Scholar] [CrossRef]

- Shi, Q.; Gu, D.; Gu, R.; Chen, W.; Dai, D.; Chen, H. Thermophysical mechanism of selective laser melting of TiC/Inconel 718 Composites. Rare Met. Mater. Eng. 2017, 46, 1543–1550. [Google Scholar]

- Geiger, F.; Kunze, K.; Etter, T. Tailoring the texture of IN738LC processed by selective laser melting (SLM) by specific scanning strategies. Mater. Sci. Eng. A 2016, 661, 240–246. [Google Scholar] [CrossRef]

- Tomus, D.; Tian, Y.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting. Mater. Sci. Eng. A 2016, 667, 42–53. [Google Scholar] [CrossRef]

- Gong, H.; Rafi, K.; Gu, H.; Starr, T.; Stucker, B. Analysis of defect generation in Ti–6Al–4V parts made using powder bed fusion additive manufacturing processes. Addit. Manuf. 2014, 1–4, 87–98. [Google Scholar] [CrossRef]

- Yan, A.; Wang, Z.; Yang, T.; Wang, Y.; Ma, Z. Microstructure, thermal physical property and surface morphology of W-Cu composite fabricated via selective laser melting. Mater. Des. 2016, 109, 79–87. [Google Scholar] [CrossRef]

- Pollock, T.M.; Tin, S. Nickel-based superalloys for advanced turbine engines: Chemistry, microstructure and properties. J. Propul. Power 2016, 22, 361–374. [Google Scholar] [CrossRef]

- Vilaro, T.; Colin, C.; Bartout, J.D.; Naze, L.; Sennour, M. Microstructural and mechanical approaches of the selective laser melting process applied to a nickel-base superalloy. Mater. Sci. Eng. A 2012, 534, 446–451. [Google Scholar] [CrossRef]

- Chen, Z.; Xiang, Y.; Wei, Z.Y.; Wei, P.; Lu, B.H.; Zhang, L.J.; Du, J. Thermal dynamic behavior during selective laser melting of K418 superalloy: Numerical simulation and experimental verification. Appl. Phys. A 2018, 124, 313. [Google Scholar] [CrossRef]

- Kvick, Å. X-ray Diffraction, Materials Science Applications. In Encyclopedia of Spectroscopy and Spectrometry, 3rd ed.; Lindon, J.C., Tranter, G.E., Koppenaal, D.W., Eds.; Academic Press: Oxford, UK, 2017; pp. 648–655. [Google Scholar]

- Wang, H.Y.; Wang, B.B.; Wang, L.; Cui, R.; Luo, L.S.; Su, Y.Q. Impact of laser scanning speed on microstructure and mechanical properties of Inconel 718 alloys by selective laser melting. China Foundry. 2021, 18, 170–179. [Google Scholar] [CrossRef]

- Song, B.; Wang, Z.; Yan, Q. Integral method of preparation and fabrication of metal matrix composite: Selective laser melting of in-situ nano/submicro-sized carbides reinforced iron matrix composites. Mater. Sci. Eng. A 2017, 707, 478–807. [Google Scholar] [CrossRef]

- Liu, X.-B.; Yu, G.; Guo, J.; Gu, Y.-J.; Pang, M.; Zheng, C.-Y.; Wang, H.-H. Research on laser welding of cast ni-based superalloy K418 turbo disk and alloy steel 42crmo shaft. J. Alloys Compd. 2008, 453, 371–378. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Pei, W.; Zhang, S.; Lu, B.; Zhang, L.; XigangYang, X.; Huang, K.; Huang, Y.; Li, X.; Zhao, Q. Graphene reinforced nickel-based superalloy composites fabricated by additive manufacturing. Mater. Sci. Eng. A 2019, 769, 138484. [Google Scholar] [CrossRef]

- Chen, Z.; Chen, S.; Wei, Z.; Zhang, L.; Wei, P.; Lu, B.; Zhang, S.; Xiang, Y. Anisotropy of nickel-based superalloy K418 fabricated by selective laser melting. Prog. Nat. Sci. Mater. Int. 2018, 4, 28. [Google Scholar] [CrossRef]

- Hosford, W.F. Mechanical Behavior of Materials, 2nd ed.; Cambridge University Press: Cambridge, UK, 2009. [Google Scholar]

- Zhang, Z.; Sheng, H.; Wang, Z.; Gludovatz, B.; Zhang, Z.; George, E.P. Dislocation mechanisms and 3d twin architectures generate exceptional strength-ductility-toughness combination in crconi medium-entropy alloy. Nat. Commun. 2017, 8, 14390. [Google Scholar] [CrossRef]

- Hansen, N. Hall-Petch relation and boundary strengthening. Scr. Mater. 2004, 51, 801–806. [Google Scholar] [CrossRef]

- Hall, E.O. The deformation and aging of mild steel. Proc. Phys. Soc. London B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N.J. The cleavage strength of polycrystals. J. Iron Steel Inst. 1953, 174, 25. [Google Scholar]

- Koyama, M.; Zhang, Z.; Wang, M.; Ponge, D.; Raabe, D.; Tsuzaki, K. Bone-like crack resistance in hierarchical metastable nanolaminate steels. Science 2017, 355, 1055–1057. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Kai, G.; Ming, G.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-in718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

| Element | Ni | Cr | Al | Mo | Nb | Ti | Fe | B | C |

|---|---|---|---|---|---|---|---|---|---|

| Std. (wt%) | Balance | 11–13.5 | 5.5–6.4 | 3.8–4.8 | 1.8–2.8 | 0.5–1 | ≤1.0 | 0.008–0.02 | 0.08–0.16 |

| Actual (wt%) | Balance | 12.5 | 6.2 | 4.3 | 2.1 | 0.7 | 1.0 | 0.014 | 0.12 |

| Samples NO. | Laser Power P, W | Scanning Speed v, mm/s | Hatch Spacing H, mm | Layer Thickness t, mm | Volumetric Energy Density VED, J/mm3 | Relative Density η, % |

|---|---|---|---|---|---|---|

| 1 | 360 | 2400 | 0.08 | 0.05 | 37.5 | 94.78 |

| 2 | 360 | 2400 | 0.08 | 0.03 | 62.5 | 98.04 |

| 3 | 320 | 2800 | 0.07 | 0.02 | 81.6 | 99.94 |

| 4 | 360 | 2400 | 0.08 | 0.02 | 93.7 | 98.29 |

| VED | γ-Phase | γ’-Phase | ||

|---|---|---|---|---|

| 2θ/° | Intensity/CPS | 2θ/° | Intensity/CPS | |

| 37.5 J/mm3 | 50.78 | 1825 | 50.82 | 1900 |

| 62.5 J/mm3 | 50.80 | 1788 | 50.85 | 1824 |

| 81.6 J/mm3 | 50.83 | 1903 | 50.87 | 1926 |

| 93.7 J/mm3 | 50.85 | 2185 | 50.90 | 2171 |

| Ultimate Strength UTS/(Mpa) | Yield Strength YS(Mpa) | Elongation (%) | Grain Size (μm) | Aspect Ratio | Reference | |

|---|---|---|---|---|---|---|

| As-cast | 875 | 735 | 7.6 | -- | -- | [1] |

| Sample 1 | 775 | 687 | 2.94 | 18.32 | 2.09 | This work |

| Sample 2 | 961 | 824 | 4.48 | 23.23 | 2.17 | This work |

| Sample 3 | 1117 | 912 | 5.67 | 21.53 | 1.94 | This work |

| Sample 4 | 1060 | 875 | 7.31 | 22.26 | 1.96 | This work |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Wei, P.; Chen, H.; Chen, X.; Ruan, Y.; Zhou, W.; Lu, S. Laser Powder Bed Fusion of K418 Superalloy: Process, Microstructure, Texture Feature, and Mechanical Property. Metals 2022, 12, 611. https://doi.org/10.3390/met12040611

Chen Z, Wei P, Chen H, Chen X, Ruan Y, Zhou W, Lu S. Laser Powder Bed Fusion of K418 Superalloy: Process, Microstructure, Texture Feature, and Mechanical Property. Metals. 2022; 12(4):611. https://doi.org/10.3390/met12040611

Chicago/Turabian StyleChen, Zhen, Pei Wei, Hanfeng Chen, Xinggang Chen, Yi Ruan, Wenzheng Zhou, and Sujun Lu. 2022. "Laser Powder Bed Fusion of K418 Superalloy: Process, Microstructure, Texture Feature, and Mechanical Property" Metals 12, no. 4: 611. https://doi.org/10.3390/met12040611