Literature Review on the Fatigue Properties of Materials Processed by Surface Mechanical Attrition Treatment (SMAT)

Abstract

1. Introduction

1.1. Basic Elements of SMAT

1.2. Surface Modification Induced by SMAT

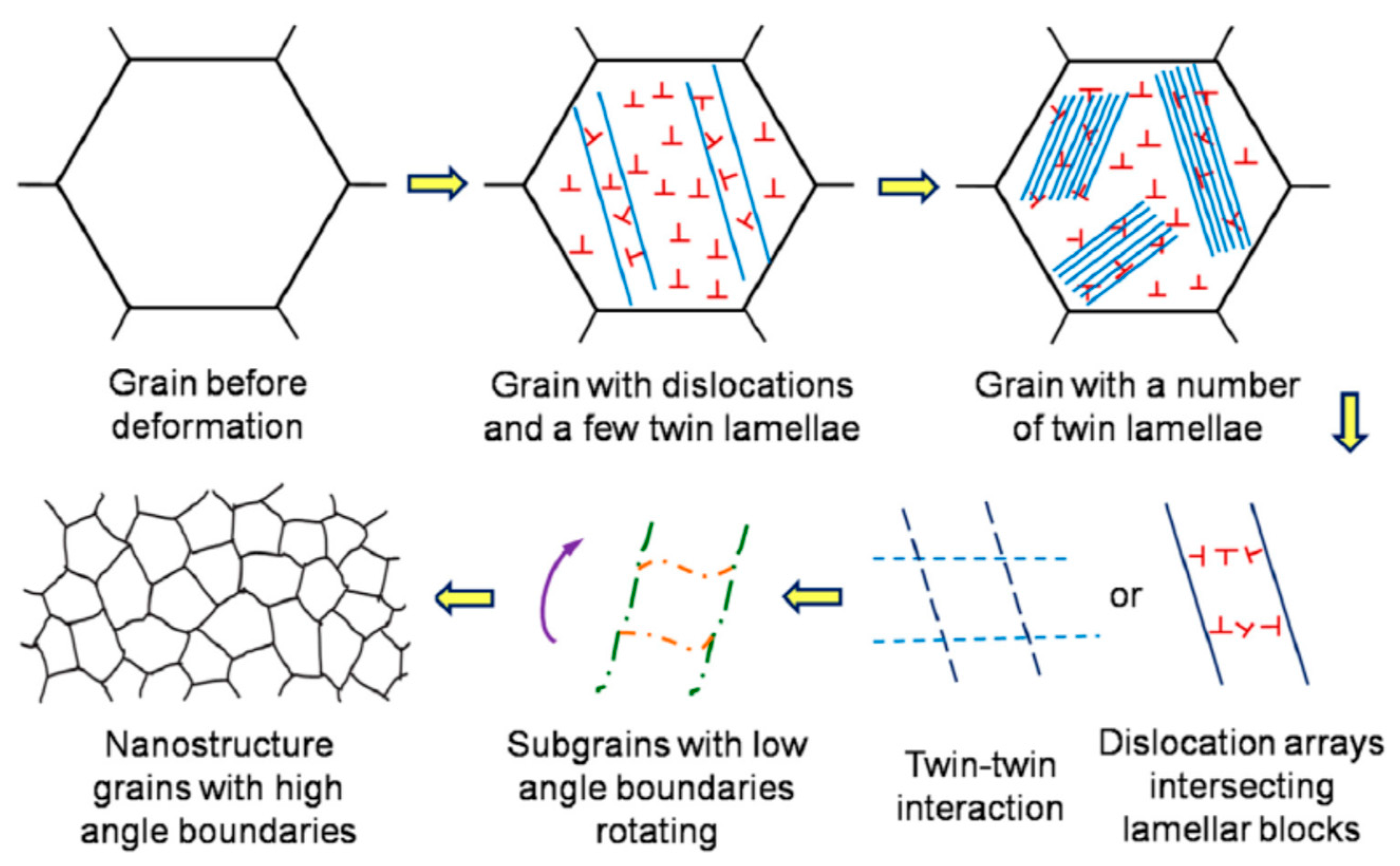

1.2.1. Microstructure and Nanocrystallization

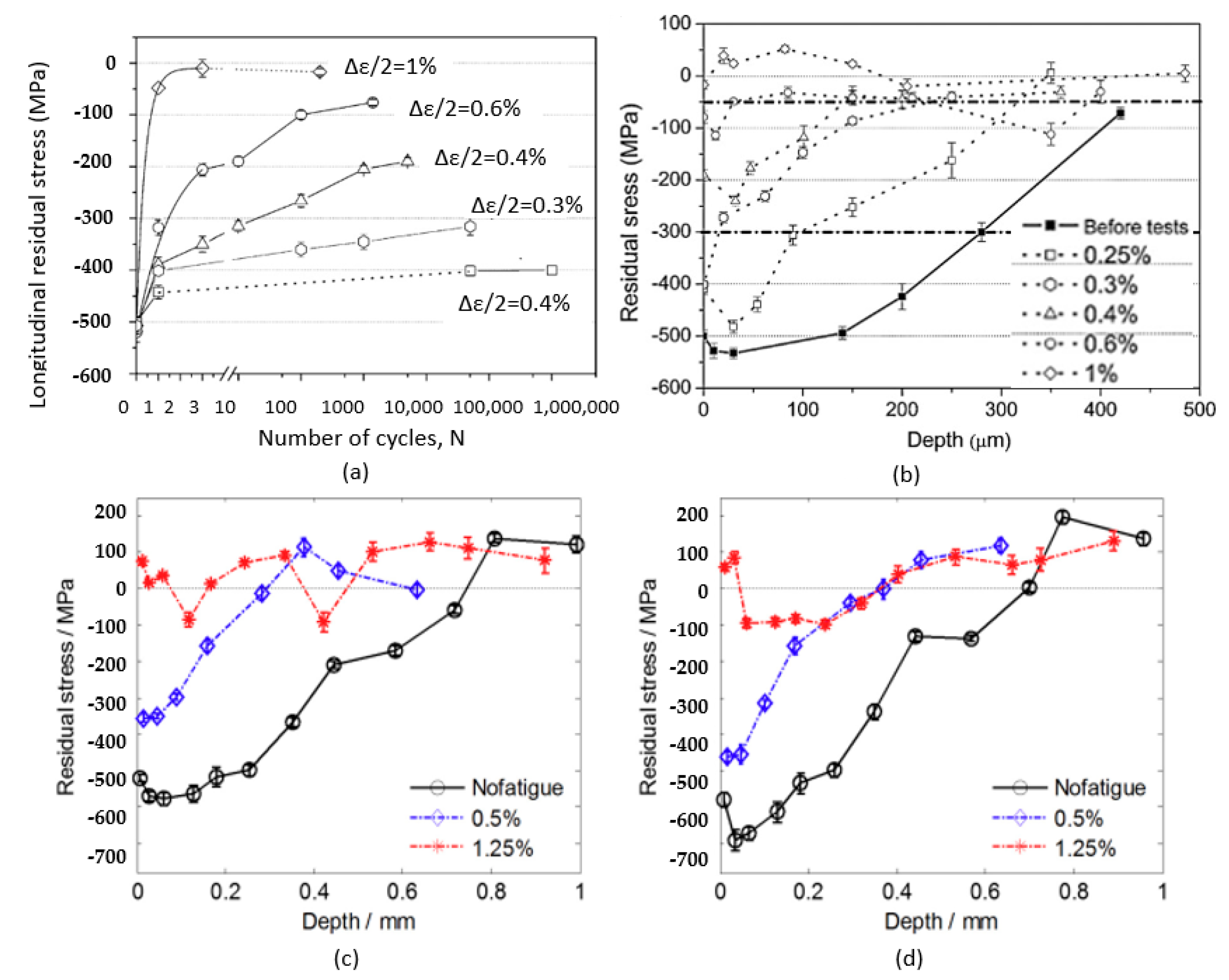

1.2.2. Residual Stress

1.2.3. Surface Hardness and Roughness

2. Fatigue Strength Affected by SMAT

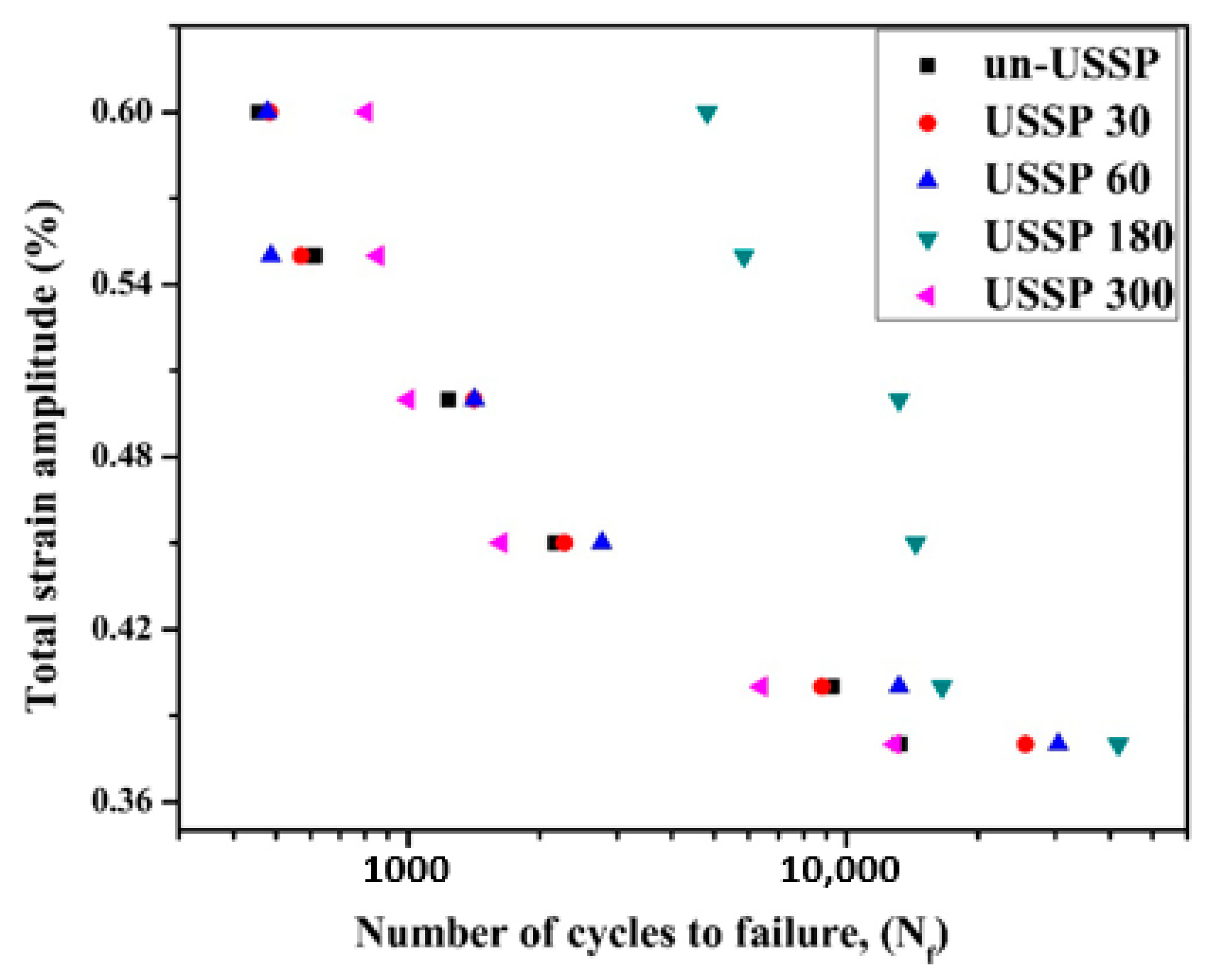

2.1. Low-Cycle Fatigue after SMAT

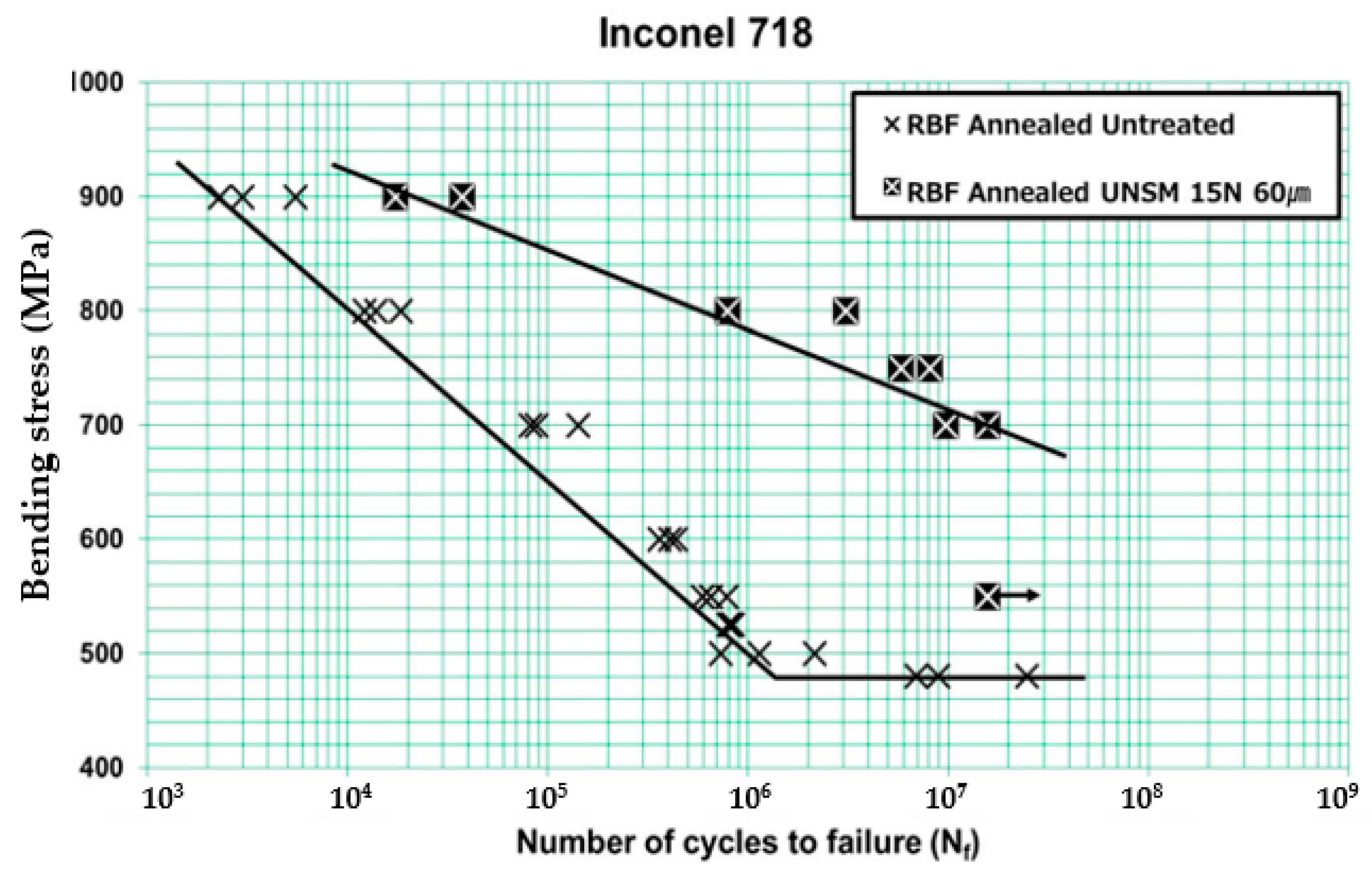

2.2. High-Cycle Fatigue after SMAT

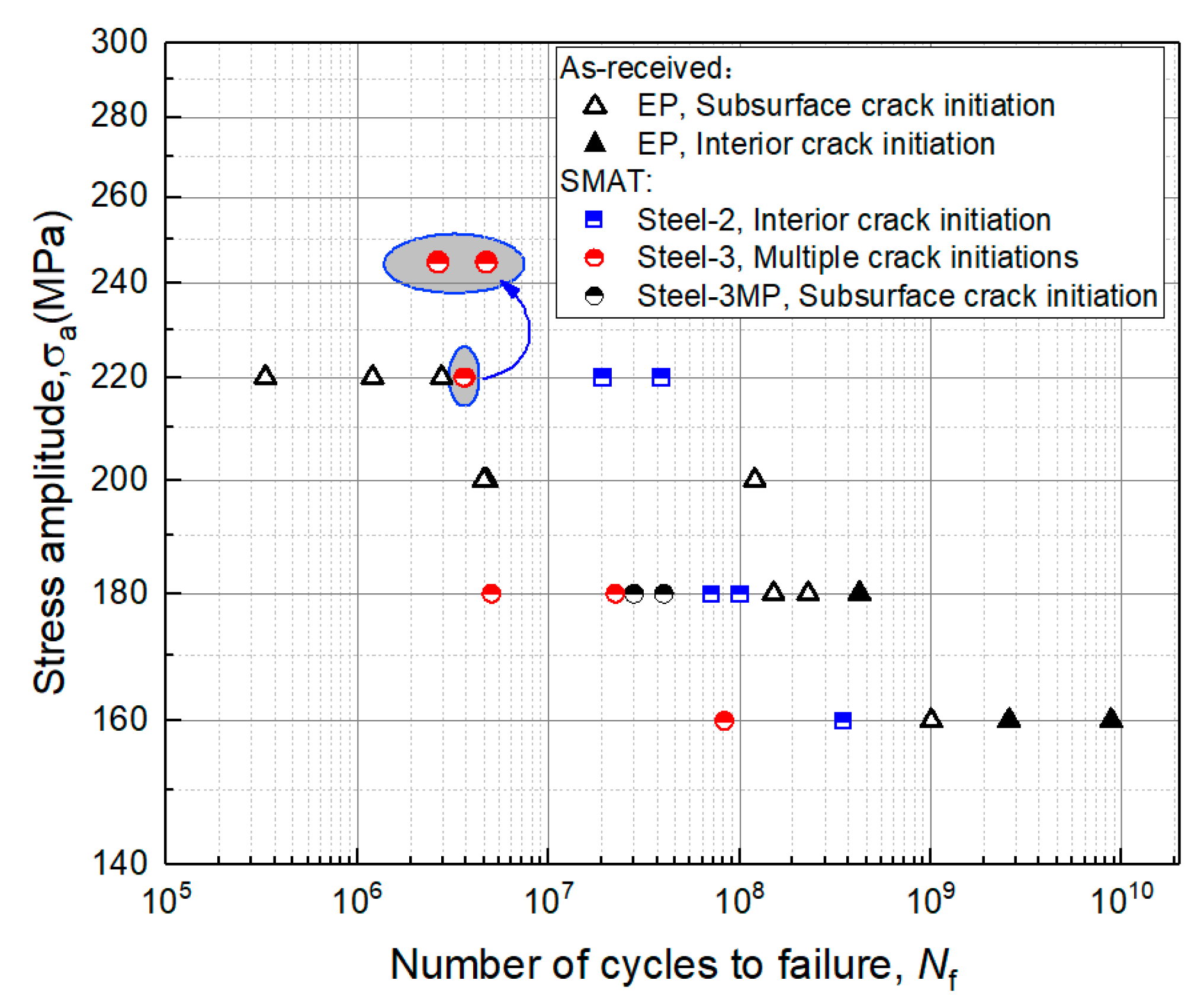

2.3. Very-High-Cycle Fatigue after SMAT

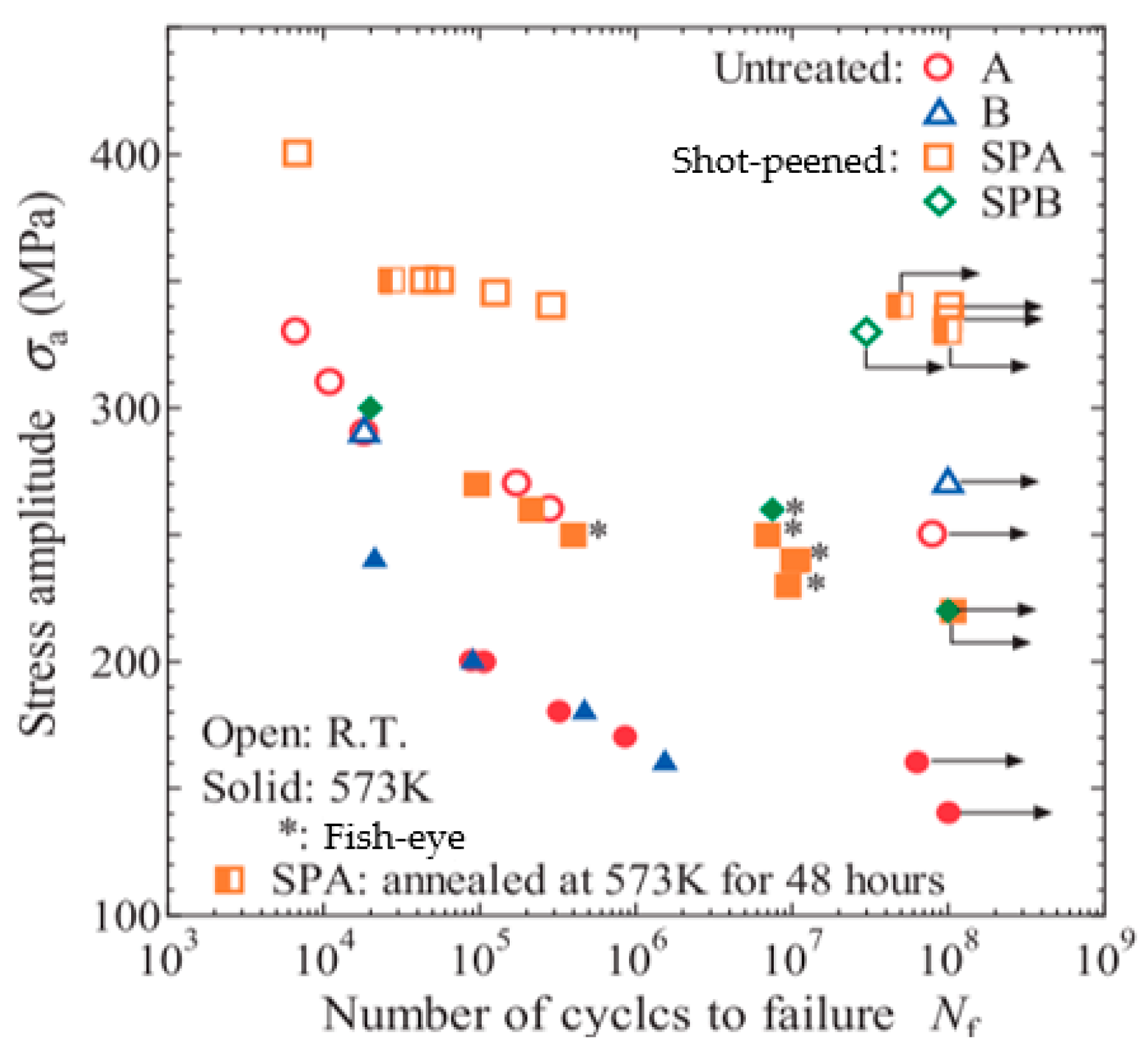

2.4. SMAT-Affected Fatigue at Elevated Temperature

3. Factors Contributing to the Effect of SMAT on Fatigue Strength

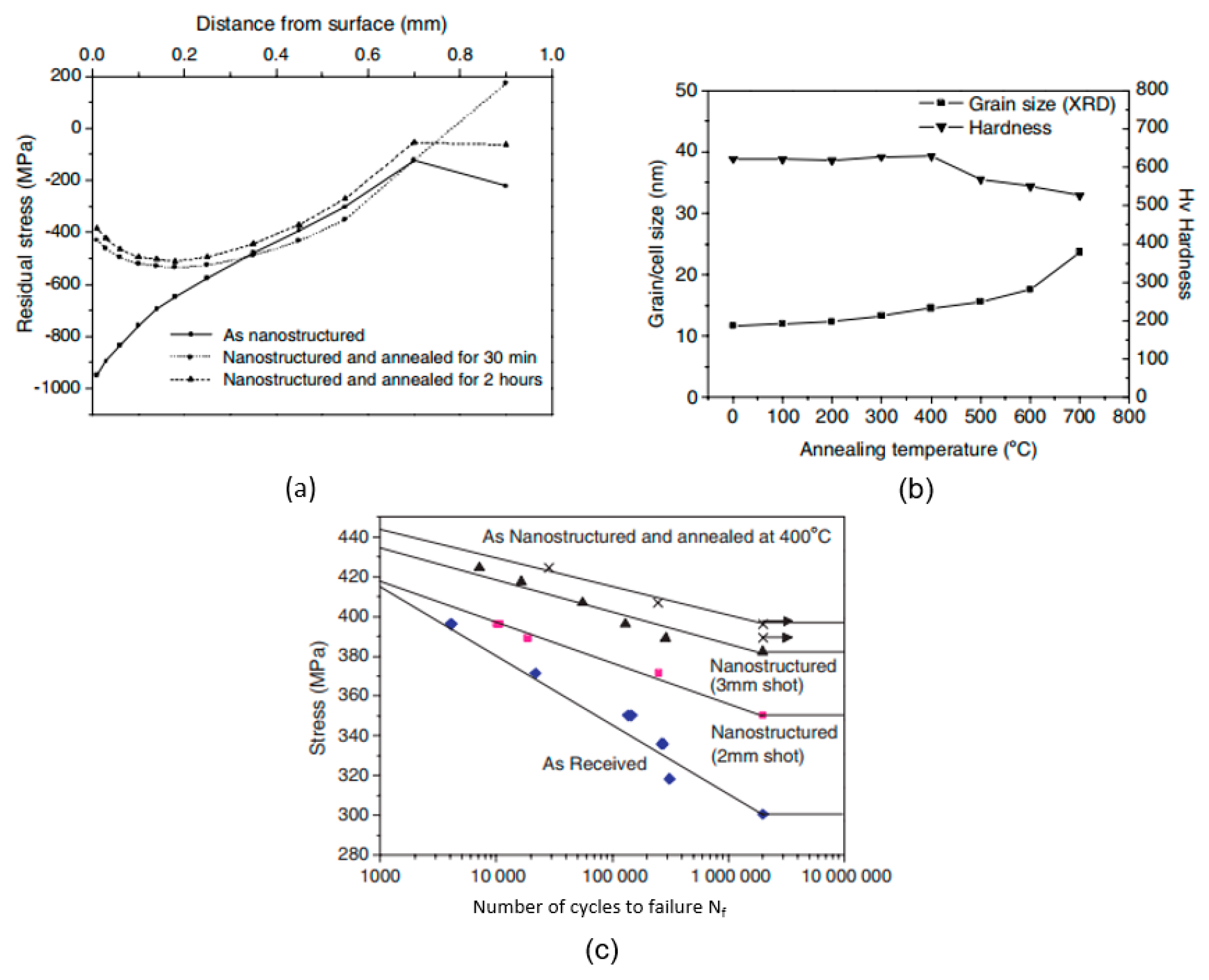

3.1. Residual Stress and Its Relaxation

3.2. Surface Quality

3.3. Nanocrystalline Layer

3.4. Phase Transformation

4. Effects of SMAT Coupled with Other Processes

4.1. Heat Treatment

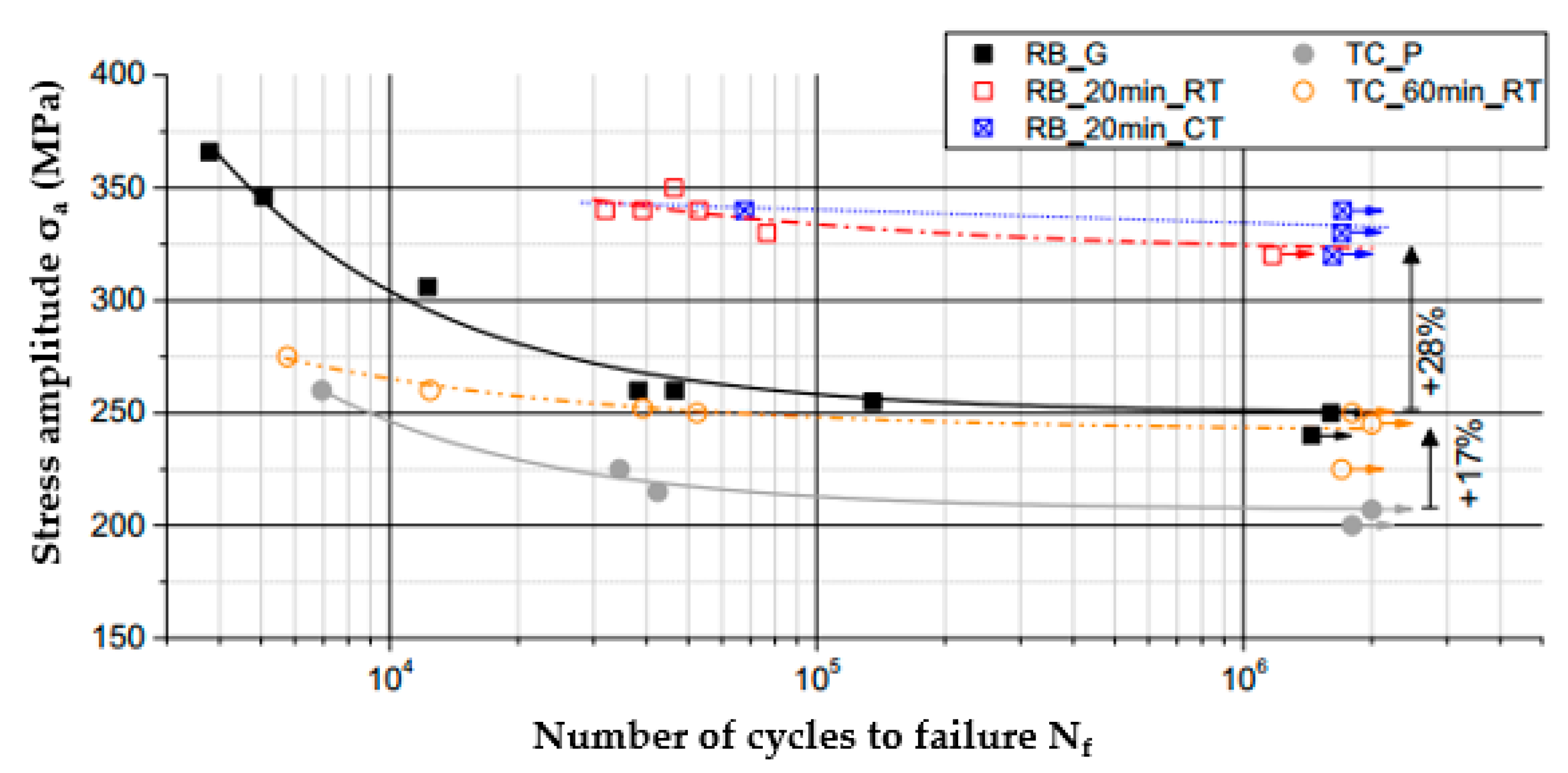

4.2. Cryogenic Temperature

4.3. Other Surface Mechanical Treatments

4.4. Nitriding

5. Conclusions and Prospects

- SMAT has been widely applied to a large variety of metallic materials with different loading conditions, including LCF, HCF and VHCF. The loading conditions are not limited to uniaxial loading. In general, an enhancement in fatigue strength after SMAT can be observed compared to the untreated state if the SMAT conditions are optimized. However, the enhancement of SMAT can be more significant in the HCF regime than the LCF or VHCF regimes. Moreover, SMAT is also reported to have negative effects on fatigue strength for some materials in the LCF and VHCF regimes.

- The enhancement or deterioration of the fatigue strength after SMAT can be attributed to the combined effect of a top surface nanocrystalline layer, superficial compressive residual stress and surface integrity. The nanocrystalline layer can play a crucial role of enhancing fatigue strength by retarding the initiation and propagation of cracks. Superficial compressive residual stress is also reputed to be a beneficial factor when the load level is not too high or too low. As for surface integrity, it is the main detrimental factor. Hence, to achieve an enhancement in fatigue strength, process parameters should be properly determined.

- Combined with other processes such as heat treatment, cryogenic condition, other mechanical surface treatments and nitriding, the effect of SMAT on fatigue strength can be further reinforced or weakened, depending on whether the balanced effect of the nanocrystalline layer, residual stress and surface integrity is changed.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, H.W.; Wang, L.; Hei, Z.K.; Liu, G.; Lu, J.; Lu, K. Low-Temperature Plasma Nitriding of AISI 304 Stainless Steel with Nano-Structured Surface Layer. Z. Meter. Res. Adv. Tech. 2003, 94, 1143–1147. [Google Scholar] [CrossRef]

- Novelli, M.; Fundenberger, J.J.; Bocher, P.; Grosdidier, T. On the Effectiveness of Surface Severe Plastic Deformation by Shot Peening at Cryogenic Temperature. Appl. Surf. Sci. 2016, 389, 1169–1174. [Google Scholar] [CrossRef]

- Unal, O.; Varol, R. Surface Severe Plastic Deformation of AISI 304 via Conventional Shot Peening, Severe Shot Peening and Repeening. Appl. Surf. Sci. 2015, 351, 289–295. [Google Scholar] [CrossRef]

- Merwin, J.E.; Johnson, K.L. An Analysis of Plastic Deformation in Rolling Contact. Proc. Inst. Mech. Eng. 1963, 177, 676–690. [Google Scholar] [CrossRef]

- Wong, C.C.; Hartawan, A.; Teo, W.K. Deep Cold Rolling of Features on Aero-Engine Components. Procedia CIRP 2014, 13, 350–354. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Fatigue Life Improvement through Surface Nanostructuring of Stainless Steel by Means of Surface Mechanical Attrition Treatment. Scr. Mater. 2006, 54, 1949–1954. [Google Scholar] [CrossRef]

- Shaw, L.L.; Tian, J.W.; Ortiz, A.L.; Dai, K.; Villegas, J.C.; Liaw, P.K.; Ren, R.; Klarstrom, D.L. A Direct Comparison in the Fatigue Resistance Enhanced by Surface Severe Plastic Deformation and Shot Peening in a C-2000 Superalloy. Mater. Sci. Eng. A 2010, 527, 986–994. [Google Scholar] [CrossRef]

- Tian, J.W.; Villegas, J.C.; Yuan, W.; Fielden, D.; Shaw, L.; Liaw, P.K.; Klarstrom, D.L. A Study of the Effect of Nanostructured Surface Layers on the Fatigue Behaviors of a C-2000 Superalloy. Mater. Sci. Eng. A 2007, 468–470, 164–170. [Google Scholar] [CrossRef]

- Dai, K.; Shaw, L. Analysis of Fatigue Resistance Improvements via Surface Severe Plastic Deformation. Int. J. Fatigue 2008, 30, 1398–1408. [Google Scholar] [CrossRef]

- Umemoto, M.; Todaka, Y.; Tsuchiya, K. Formation of Nanocrystalline Structure in Steels by Air Blast Shot Peening. Mater. Trans. 2003, 44, 1488–1493. [Google Scholar] [CrossRef]

- Wang, T.; Yu, J.; Dong, B. Surface Nanocrystallization Induced by Shot Peening and Its Effect on Corrosion Resistance of 1Cr18Ni9Ti Stainless Steel. Surf. Coatings Technol. 2006, 200, 4777–4781. [Google Scholar] [CrossRef]

- Tao, N.R.; Wang, Z.B.; Tong, W.P.; Sui, M.L.; Lu, J.; Lu, K. An Investigation of Surface Nanocrystallization Mechanism in Fe Induced by Surface Mechanical Attrition Treatment. Acta Mater. 2002, 50, 4603–4616. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured Surface Layer on Metallic Materials Induced by Surface Mechanical Attrition Treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef]

- Samih, Y.; Beausir, B.; Bolle, B.; Grosdidier, T. In-Depth Quantitative Analysis of the Microstructures Produced by Surface Mechanical Attrition Treatment (SMAT). Mater. Charact. 2013, 83, 129–138. [Google Scholar] [CrossRef]

- Sun, Z.; Retraint, D.; Baudin, T.; Helbert, A.L.; Brisset, F.; Chemkhi, M.; Zhou, J.; Kanouté, P. Experimental Study of Microstructure Changes Due to Low Cycle Fatigue of a Steel Nanocrystallised by Surface Mechanical Attrition Treatment (SMAT). Mater. Charact. 2017, 124, 117–121. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Z.; Kanouté, P.; Retraint, D. Effect of Surface Mechanical Attrition Treatment on Low Cycle Fatigue Properties of an Austenitic Stainless Steel. Int. J. Fatigue 2017, 103, 309–317. [Google Scholar] [CrossRef]

- Lu, J.; Lu, K. 8.14—Surface Nanocrystallization (SNC) of Materials and Its Effect on Mechanical Behavior. Compr. Struct. Integr. 2007, 8, 495–528. [Google Scholar] [CrossRef]

- Wen, M.; Wen, C.; Peter, H.; Li, Y. Wear Behaviour of Pure Ti with a Nanocrystalline Surface Layer. Appl. Mech. Mater. 2011, 66–68, 1500–1504. [Google Scholar] [CrossRef]

- Yang, X.F.; Lu, J. A New Way to Synthesize Carbon Nanofiber Film on Bulk Titanium via Hybrid Surface Mechanical Attrition Treatment. Appl. Surf. Sci. 2013, 264, 191–196. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, H.; Lin, Q. Surface Nanocrystallization of Commercial Pure Titanium Induced by SMAT and Its Properties. J. Mater. Sci. Technol. 2004, 20, 716–718. [Google Scholar]

- Sun, J.; Yao, Q.T.; Zhang, Y.H.; Du, X.D.; Wu, Y.C.; Tong, W.P. Simultaneously Improving Surface Mechanical Properties and in Vitro Biocompatibility of Pure Titanium via Surface Mechanical Attrition Treatment Combined with Low-Temperature Plasma Nitriding. Surf. Coatings Technol. 2017, 309, 382–389. [Google Scholar] [CrossRef]

- Liu, Y.; Jin, B.; Lu, J. Mechanical Properties and Thermal Stability of Nanocrystallized Pure Aluminum Produced by Surface Mechanical Attrition Treatment. Mater. Sci. Eng. A 2015, 636, 446–451. [Google Scholar] [CrossRef]

- Darling, K.A.; Tschopp, M.A.; Roberts, A.J.; Ligda, J.P.; Kecskes, L.J. Enhancing Grain Refinement in Polycrystalline Materials Using Surface Mechanical Attrition Treatment at Cryogenic Temperatures. Scr. Mater. 2013, 69, 461–464. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, L.; Lu, J.; Zhang, W. Thermal Stability and Corrosion Resistance of Nanocrystallized Zirconium Formed by Surface Mechanical Attrition Treatment. J. Mater. Res. 2009, 24, 3136–3145. [Google Scholar] [CrossRef]

- Liu, X.; Nakatani, M.; Gao, H.; Sharma, B.; Pan, H.; Fu, Z.; Li, X.; Ameyama, K.; Zhu, X. Effect of Stacking Fault Energy on Deformation Mechanisms in Cu and Cu-30% Zn Alloy with Gradient Structure Obtained by SMAT. J. Alloys Compd. 2021, 865, 158863. [Google Scholar] [CrossRef]

- Gallitelli, D.; Retraint, D.; Rouhaud, E. Comparison between Conventional Shot Peening (SP) and Surface Mechanical Attrition Treatment (SMAT) on a Titanium Alloy. Adv. Mater. Res. 2014, 996, 964–968. [Google Scholar] [CrossRef]

- Wu, X.; Tao, N.; Hong, Y.; Xu, B.; Lu, J.; Lu, K. Microstructure and Evolution of Mechanically-Induced Ultrafine Grain in Surface Layer of AL-Alloy Subjected to USSP. Acta Mater. 2002, 50, 2075–2084. [Google Scholar] [CrossRef]

- Pandey, V.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Role of Ultrasonic Shot Peening on Low Cycle Fatigue Behavior of 7075 Aluminium Alloy. Int. J. Fatigue 2017, 103, 426–435. [Google Scholar] [CrossRef]

- An, X.; Rodopoulos, C.A.; Statnikov, E.S.; Vitazev, V.N.; Komlkov, O.V. Study of the Surface Nanocrystallization Induced by the Esonix Ultrasonic Impact Treatment on the Near-Surface of 2024-T351 Aluminum Alloy. J. Mater. Eng. Perform. 2006, 15, 355–364. [Google Scholar] [CrossRef]

- Liao, M.; Chen, W.R.; Bellinger, N.C. Effects of Ultrasonic Impact Treatment on Fatigue Behavior of Naturally Exfoliated Aluminum Alloys. Int. J. Fatigue 2008, 30, 717–726. [Google Scholar] [CrossRef]

- Todaka, Y.; Umemoto, M.; Tsuchiya, K. Comparison of Nanocrystalline Surface Layer in Steels Formed by Air Blast and Ultrasonic Shot Peening. Mater. Trans. 2004, 45, 376–379. [Google Scholar] [CrossRef]

- Pour-Ali, S.; Kiani-Rashid, A.R.; Babakhani, A. Surface Nanocrystallization and Gradient Microstructural Evolutions in the Surface Layers of 321 Stainless Steel Alloy Treated via Severe Shot Peening. Vacuum 2017, 144, 152–159. [Google Scholar] [CrossRef]

- Li, Y.R.; Lin, W.M.; Wei, Y.H.; Hou, L.F.; Du, H.Y. Characteristic and Properties of Nanocrystalline Surface Layer in Cu-10wt%Ni Alloy Induced by Surface Mechanical Attrition Treatment. Gongneng Cailiao/J. Funct. Mater. 2011, 42, 766–769. [Google Scholar]

- Liu, Y.; Jin, B.; Li, D.J.; Zeng, X.Q.; Lu, J. Wear Behavior of Nanocrystalline Structured Magnesium Alloy Induced by Surface Mechanical Attrition Treatment. Surf. Coatings Technol. 2015, 261, 219–226. [Google Scholar] [CrossRef]

- Shi, X.Y.; Liu, Y.; Li, D.J.; Chen, B.; Zeng, X.Q.; Lu, J.; Ding, W.J. Microstructure Evolution and Mechanical Properties of an Mg-Gd Alloy Subjected to Surface Mechanical Attrition Treatment. Mater. Sci. Eng. A 2015, 630, 146–154. [Google Scholar] [CrossRef]

- Joshi, M.D.; Kumar, V.; Litoria, A.K.; Singh, D.; Hosmani, S.S. Effect of Surface Mechanical Attrition Treatment on Tribological Behavior of AISI 2205 Steel. Mater. Today Proc. 2020, 33, 4919–4926. [Google Scholar] [CrossRef]

- Huang, J.Y.; Zhu, Y.T.; Jiang, H.; Lowe, T.C. Microstructures and Dislocation Configurations in Nanostructured Cu Processed by Repetitive Corrugation and Straightening. Acta Mater. 2001, 49, 1497–1505. [Google Scholar] [CrossRef]

- Sun, H.Q.; Shi, Y.N.; Zhang, M.X.; Lu, K. Plastic Strain-Induced Grain Refinement in the Nanometer Scale in a Mg Alloy. Acta Mater. 2007, 55, 975–982. [Google Scholar] [CrossRef]

- Bay, B.; Hansen, N.; Hughes, D.A.; Kuhlmann-Wilsdorf, D. Overview No. 96 Evolution of f.c.c. Deformation Structures in Polyslip. Acta Metall. Mater. 1992, 40, 205–219. [Google Scholar] [CrossRef]

- Christian, J.W.; Mahajan, S. Deformation Twinning. Prog. Mater. Sci. 1995, 39, 1–157. [Google Scholar] [CrossRef]

- Zhu, Y.T.; Liao, X.Z.; Wu, X.L. Deformation Twinning in Nanocrystalline Materials. Prog. Mater. Sci. 2012, 57, 1–62. [Google Scholar] [CrossRef]

- Li, Y.S.; Tao, N.R.; Lu, K. Microstructural Evolution and Nanostructure Formation in Copper during Dynamic Plastic Deformation at Cryogenic Temperatures. Acta Mater. 2008, 56, 230–241. [Google Scholar] [CrossRef]

- Meyers, M.A.; Vöhringer, O.; Lubarda, V.A. The Onset of Twinning in Metals: A Constitutive Description. Acta Mater. 2001, 49, 4025–4039. [Google Scholar] [CrossRef]

- Gatey, A.M.; Hosmani, S.S.; Figueroa, C.A.; Arya, S.B.; Singh, R.P. Role of Surface Mechanical Attrition Treatment and Chemical Etching on Plasma Nitriding Behavior of AISI 304L Steel. Surf. Coatings Technol. 2016, 304, 413–424. [Google Scholar] [CrossRef]

- Yasuoka, M.; Wang, P.; Zhang, K.; Qiu, Z.; Kusaka, K.; Pyoun, Y.S.; Murakami, R. ichi Improvement of the Fatigue Strength of SUS304 Austenite Stainless Steel Using Ultrasonic Nanocrystal Surface Modification. Surf. Coatings Technol. 2013, 218, 93–98. [Google Scholar] [CrossRef]

- Pandey, V.; Rao, G.S.; Chattopadhyay, K.; Santhi Srinivas, N.C.; Singh, V. Effect of Surface Nanostructuring on LCF Behavior of Aluminum Alloy 2014. Mater. Sci. Eng. A 2015, 647, 201–211. [Google Scholar] [CrossRef]

- Anand Kumar, S.; Ganesh Sundara Raman, S.; Sankara Narayanan, T.S.N.; Gnanamoorthy, R. Influence of Surface Mechanical Attrition Treatment on Fretting Wear Behaviour of Ti-6Al-4V. Adv. Mater. Res. 2012, 463–464, 316–320. [Google Scholar] [CrossRef]

- Ortiz, A.L.; Tian, J.W.; Shaw, L.L.; Liaw, P.K. Experimental Study of the Microstructure and Stress State of Shot Peened and Surface Mechanical Attrition Treated Nickel Alloys. Scr. Mater. 2010, 62, 129–132. [Google Scholar] [CrossRef]

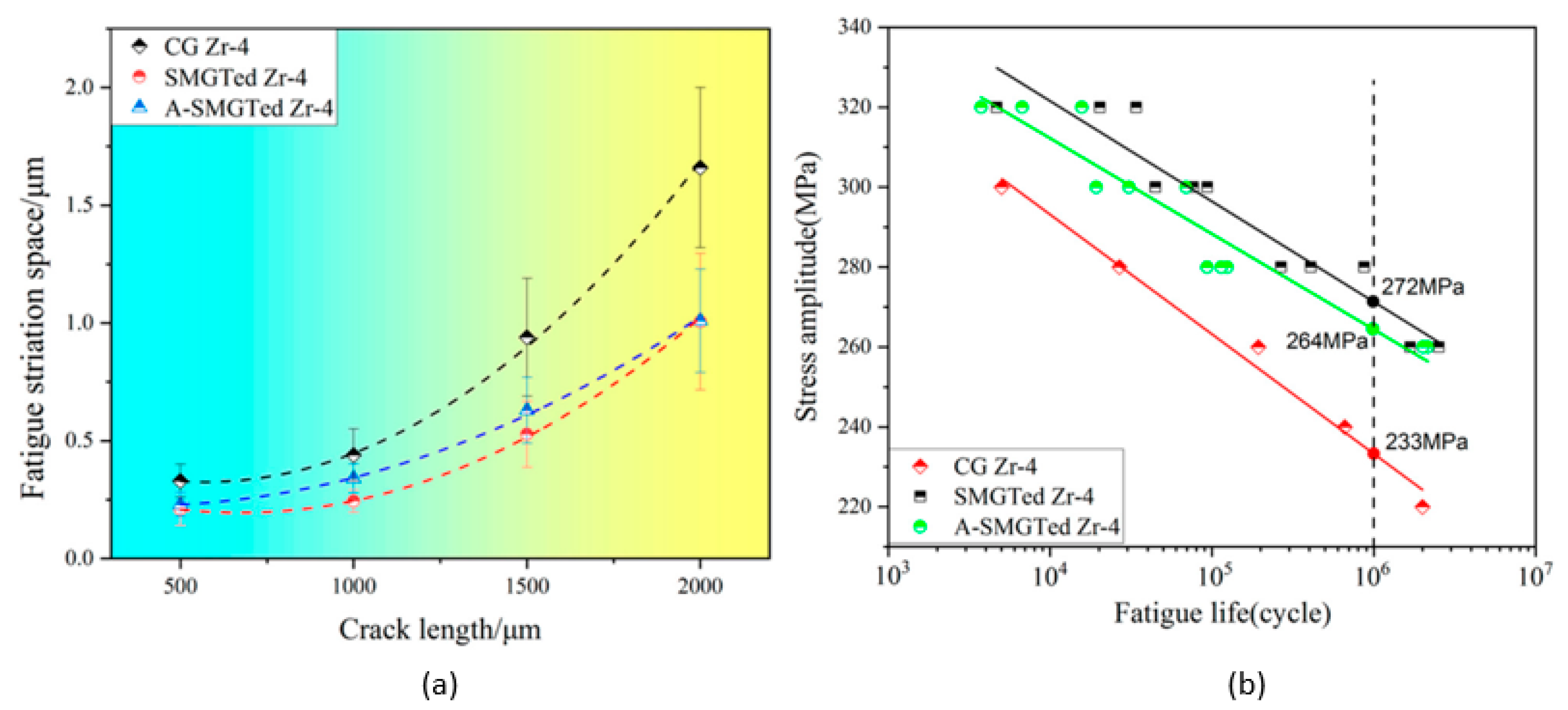

- Geng, D.; Sun, Q.; Xin, C.; Xiao, L. Contribution to Improvement of Fatigue Properties of Zr-4 Alloy: Gradient Nanostructured Surface Layer versus Compressive Residual Stress. Nanomaterials 2021, 11, 3125. [Google Scholar] [CrossRef]

- Ren, J.; Shan, A.; Zhang, J.; Song, H.; Liu, J. Surface Nanocrystallization of Ni3Al by Surface Mechanical Attrition Treatment. Mater. Lett. 2006, 60, 2076–2079. [Google Scholar] [CrossRef]

- Gao, T.; Sun, Z.; Xue, H.; Retraint, D. Effect of Surface Mechanical Attrition Treatment on High Cycle and Very High Cycle Fatigue of a 7075-T6 Aluminium Alloy. Int. J. Fatigue 2020, 139. [Google Scholar] [CrossRef]

- Zhou, J.; Retraint, D.; Sun, Z.; Kanouté, P. Comparative Study of the Effects of Surface Mechanical Attrition Treatment and Conventional Shot Peening on Low Cycle Fatigue of a 316L Stainless Steel. Surf. Coatings Technol. 2018, 349, 556–566. [Google Scholar] [CrossRef]

- Maawad, E.; Brokmeier, H.G.; Wagner, L.; Sano, Y.; Genzel, C. Investigation on the Surface and Near-Surface Characteristics of Ti-2.5Cu after Various Mechanical Surface Treatments. Surf. Coatings Technol. 2011, 205, 3644–3650. [Google Scholar] [CrossRef]

- Miková, K.; Bagherifard, S.; Bokuvka, O.; Guagliano, M.; Trško, L. Fatigue Behavior of X70 Microalloyed Steel after Severe Shot Peening. Int. J. Fatigue 2013, 55, 33–42. [Google Scholar] [CrossRef]

- Zhang, C.; Duan, X.; Zhou, L.; Lan, X. Surface Nanocrystallization of Zircaloy-4 by Surface Mechanical Attrition Treatment. Mater. Sci. Forum 2010, 658, 452–455. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, H.; Yan, Z.; Liaw, P.K.; Dong, P. Cyclic Deformation and Fatigue Behavior of 7075-T651 Al Alloy with a Gradient Structure. Mater. Sci. Eng. A 2021, 822. [Google Scholar] [CrossRef]

- Chen, Y.; Liu, F.; He, C.; Li, L.; Wang, C.; Liu, Y.; Wang, Q. Effect of Ultrasonic Peening Treatment on the Fatigue Behaviors of a Magnesium Alloy up to Very High Cycle Regime. J. Magnes. Alloy. 2022, 10, 614–626. [Google Scholar] [CrossRef]

- Kumar, S.; Chattopadhyay, K.; Singh, V. Effect of Ultrasonic Shot Peening on LCF Behavior of the Ti–6Al–4V Alloy. J. Alloys Compd. 2017, 724, 187–197. [Google Scholar] [CrossRef]

- Kumar, S.; Chattopadhyay, K.; Singh, V.; Satyanarayana, D.V.V.; Kumar, V. Low Cycle Fatigue Life of the Alloy IN718 Enhanced through Surface Nanostructuring. Mater. Charact. 2020, 159. [Google Scholar] [CrossRef]

- Chen, G.; Gao, J.; Cui, Y.; Gao, H.; Guo, X.; Wu, S. Effects of Strain Rate on the Low Cycle Fatigue Behavior of AZ31B Magnesium Alloy Processed by SMAT. J. Alloys Compd. 2018, 735, 536–546. [Google Scholar] [CrossRef]

- Yan, X.; Yin, S.; Chen, C.; Jenkins, R.; Lupoi, R.; Bolot, R.; Ma, W.; Kuang, M.; Liao, H.; Lu, J.; et al. Fatigue Strength Improvement of Selective Laser Melted Ti6al4v Using Ultrasonic Surface Mechanical Attrition. Mater. Res. Lett. 2019, 7, 327–333. [Google Scholar] [CrossRef]

- Carneiro, L.; Wang, X.; Jiang, Y. Cyclic Deformation and Fatigue Behavior of 316L Stainless Steel Processed by Surface Mechanical Rolling Treatment. Int. J. Fatigue 2020, 134. [Google Scholar] [CrossRef]

- Ramos, R.; Ferreira, N.; Ferreira, J.A.M.; Capela, C.; Batista, A.C. Improvement in Fatigue Life of Al 7475-T7351 Alloy Specimens by Applying Ultrasonic and Microshot Peening. Int. J. Fatigue 2016, 92, 87–95. [Google Scholar] [CrossRef]

- Uusitalo, J.; Karjalainen, L.P.; Retraint, D.; Palosaari, M. Fatigue Properties of Steels with Ultrasonic Attrition Treated Surface Layers. Mater. Sci. Forum 2009, 604–605, 239–248. [Google Scholar] [CrossRef]

- Dureau, C.; Novelli, M.; Arzaghi, M.; Massion, R.; Bocher, P.; Nadot, Y.; Grosdidier, T. On the Influence of Ultrasonic Surface Mechanical Attrition Treatment (SMAT) on the Fatigue Behavior of the 304L Austenitic Stainless Steel. Metals (Basel) 2020, 10, 100. [Google Scholar] [CrossRef]

- Li, D.; Chen, H.N.; Xu, H. The Effect of Nanostructured Surface Layer on the Fatigue Behaviors of a Carbon Steel. Appl. Surf. Sci. 2009, 255, 3811–3816. [Google Scholar] [CrossRef]

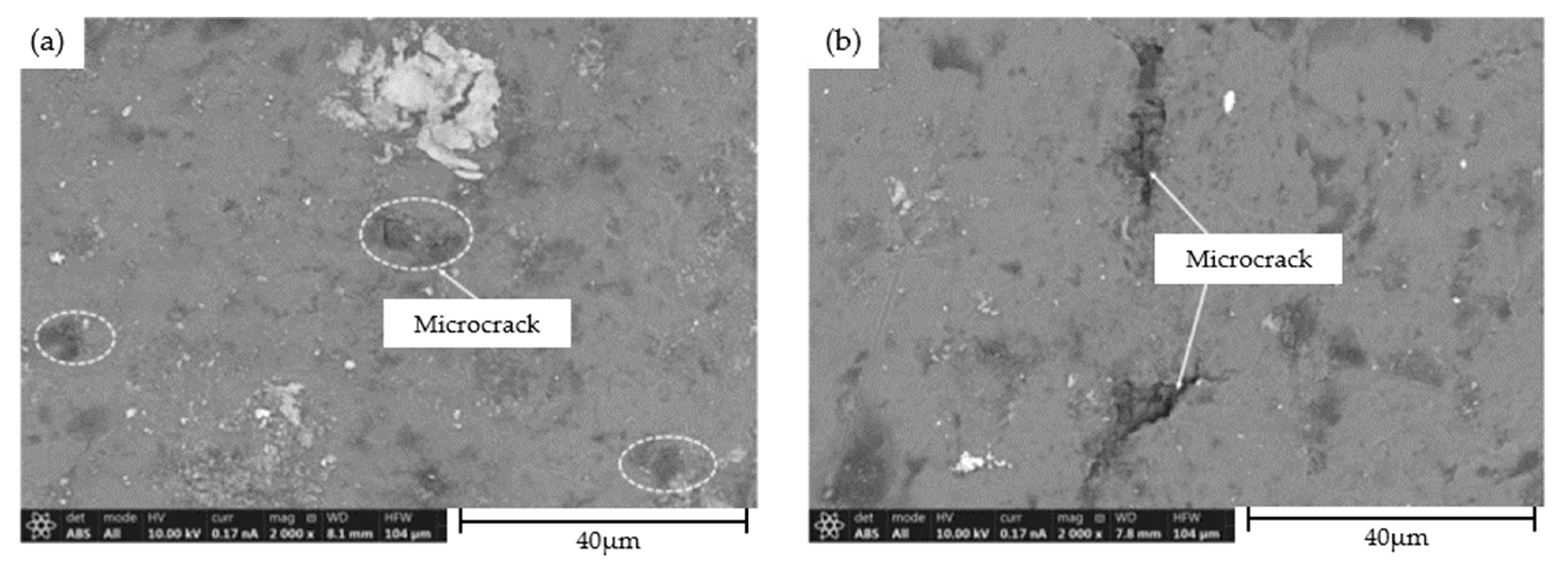

- Zhang, C.; Song, G.; Wang, Y.; Zheng, M.; Xiao, G.; Yang, J. Effect of Surface Nanocrystallization on Fatigue Crack Initiation and Propagation Behavior in Pure Zr. Mater. Sci. Eng. A 2020, 794. [Google Scholar] [CrossRef]

- Li, D.; Chen, H.N.; Xu, H. Comparative Responses of Welded Joints to Surface Mechanical Attrition Treatment and Shot Peening. Surf. Eng. 2009, 25, 15–20. [Google Scholar] [CrossRef]

- Yin, D.; Wang, D.; Jing, H.; Huo, L. The Effects of Ultrasonic Peening Treatment on the Ultra-Long Life Fatigue Behavior of Welded Joints. Mater. Des. 2010, 31, 3299–3307. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, M.; Zhou, L.; Cong, Z.; Gao, H. Improved Fatigue Behavior of Pipeline Steel Welded Joint by Surface Mechanical Attrition Treatment (SMAT). J. Mater. Sci. Technol. 2009, 25, 513–515. [Google Scholar]

- Zhao, X.; Wang, D.; Huo, L. Analysis of the S-N Curves of Welded Joints Enhanced by Ultrasonic Peening Treatment. Mater. Des. 2011, 32, 88–96. [Google Scholar] [CrossRef]

- Lago, J.; Trško, L.; Jambor, M.; Nový, F.; Bokůvka, O.; Mičian, M.; Pastorek, F. Fatigue Life Improvement of the High Strength Steel Welded Joints by Ultrasonic Impact Peening. Metals (Basel) 2019, 9, 619. [Google Scholar] [CrossRef]

- An, L.; Sun, Y.T.; Lu, S.P.; Wang, Z.B. Enhanced Fatigue Property of Welded S355J2W Steel by Forming a Gradient Nanostructured Surface Layer. Acta Metall. Sin. (English Lett.) 2020, 33, 1252–1258. [Google Scholar] [CrossRef]

- Wu, B.; Zhang, J.; Zhang, L.; Pyoun, Y.S.; Murakami, R.I. Effect of Ultrasonic Nanocrystal Surface Modification on Surface and Fatigue Properties of Quenching and Tempering S45C Steel. Appl. Surf. Sci. 2014, 321, 318–330. [Google Scholar] [CrossRef]

- Kakiuchi, T.; Uematsu, Y.; Hasegawa, N.; Kondoh, E. Effect of Ultrasonic Shot Peening on High Cycle Fatigue Behavior in Type 304 Stainless Steel at Elevated Temperature. Zair. Soc. Mater. Sci. Japan 2016, 65, 325–330. [Google Scholar] [CrossRef][Green Version]

- Amanov, A.; Pyun, Y.S.; Kim, J.H.; Suh, C.M.; Cho, I.S.; Kim, H.D.; Wang, Q.; Khan, M.K. Ultrasonic Fatigue Performance of High Temperature Structural Material Inconel 718 Alloys at High Temperature after UNSM Treatment. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1266–1273. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Bandini, M.; Taylor, D. Multiaxial Fatigue Resistance of Shot Peened High-Strength Aluminum Alloys. Int. J. Fatigue 2014, 61, 271–282. [Google Scholar] [CrossRef]

- Benedetti, M.; Fontanari, V.; Allahkarami, M.; Hanan, J.C.; Bandini, M. On the Combination of the Critical Distance Theory with a Multiaxial Fatigue Criterion for Predicting the Fatigue Strength of Notched and Plain Shot-Peened Parts. Int. J. Fatigue 2016, 93, 133–147. [Google Scholar] [CrossRef]

- Wang, Q.; Xin, C.; Sun, Q.; Xiao, L.; Sun, J. Biaxial Tension-Torsion Fatigue Behavior of Gradient Nano-Grained Pure Titanium Fabricated by Surface Nanocrystallization. Mater. Sci. Eng. A 2017, 702, 125–132. [Google Scholar] [CrossRef]

- Suh, M.S.; Suh, C.M.; Pyun, Y.S. Very High Cycle Fatigue Characteristics of a Chrome-Molybdenum Steel Treated by Ultrasonic Nanocrystal Surface Modification Technique. Fatigue Fract. Eng. Mater. Struct. 2013, 36, 769–778. [Google Scholar] [CrossRef]

- Khan, M.K.; Liu, Y.J.; Wang, Q.Y.; Pyun, Y.S.; Kayumov, R. Effect of Ultrasonic Nanocrystal Surface Modification on the Characteristics of AISI 310 Stainless Steel up to Very High Cycle Fatigue. Fatigue Fract. Eng. Mater. Struct. 2016, 39, 427–438. [Google Scholar] [CrossRef]

- Wu, B.; Wang, P.; Pyoun, Y.S.; Zhang, J.; Murakami, R. ichi Effect of Ultrasonic Nanocrystal Surface Modification on the Fatigue Behaviors of Plasma-Nitrided S45C Steel. Surf. Coatings Technol. 2012, 213, 271–277. [Google Scholar] [CrossRef]

- Ochi, Y.; Masaki, K.; Matsumura, T.; Sekino, T. Effect of Shot-Peening Treatment on High Cycle Fatigue Property of Ductile Cast Iron. Int. J. Fatigue 2001, 23, 441–448. [Google Scholar] [CrossRef]

- Arakawa, J.; Kakuta, M.; Hayashi, Y.; Tanegashima, R.; Akebono, H.; Kato, M.; Sugeta, A. Fatigue Strength of USP Treated ASTM CA6NM for Hydraulic Turbine Runner. Surf. Eng. 2014, 30, 662–669. [Google Scholar] [CrossRef]

- Dalaei, K.; Karlsson, B.; Svensson, L.E. Stability of Shot Peening Induced Residual Stresses and Their Influence on Fatigue Lifetime. Mater. Sci. Eng. A 2011, 528, 1008–1015. [Google Scholar] [CrossRef]

- Shimatani, Y.; Shiozawa, K.; Nakada, T.; Yoshimoto, T.; Lu, L. The Effect of the Residual Stresses Generated by Surface Finishing Methods on the Very High Cycle Fatigue Behavior of Matrix HSS. Int. J. Fatigue 2011, 33, 122–131. [Google Scholar] [CrossRef]

- Zhou, J.; Sun, Z.; Kanouté, P.; Retraint, D. Reconstruction of Residual Stress and Work Hardening and Their Effects on the Mechanical Behaviour of a Shot Peened Structure. Mech. Mater. 2018, 127, 100–111. [Google Scholar] [CrossRef]

- Kumar, S.A.; Raman, S.G.S.; Narayanan, T.S.N.S. Influence of Surface Mechanical Attrition Treatment Duration on Fatigue Lives of Ti-6Al-4V. Trans. Indian Inst. Met. 2014, 67, 137–141. [Google Scholar] [CrossRef]

- Huang, G.R.; Tsai, W.Y.; Huang, J.C.; Hu, C.K. Analytical Modelling for Ultrasonic Surface Mechanical Attrition Treatment. AIP Adv. 2015, 5. [Google Scholar] [CrossRef]

- Shamsaei, N.; Fatemi, A. Effect of Microstructure and Hardness on Non-Proportional Cyclic Hardening Coefficient and Predictions. Mater. Sci. Eng. A 2010, 527, 3015–3024. [Google Scholar] [CrossRef]

- Maurel, P.; Weiss, L.; Grosdidier, T.; Bocher, P. How Does Surface Integrity of Nanostructured Surfaces Induced by Severe Plastic Deformation Influence Fatigue Behaviors of Al Alloys with Enhanced Precipitation? Int. J. Fatigue 2020, 140. [Google Scholar] [CrossRef]

- Trško, L.; Guagliano, M.; Bokůvka, O.; Nový, F.; Jambor, M.; Florková, Z. Influence of Severe Shot Peening on the Surface State and Ultra-High-Cycle Fatigue Behavior of an AW 7075 Aluminum Alloy. J. Mater. Eng. Perform. 2017, 26, 2784–2797. [Google Scholar] [CrossRef]

- Amanov, A.; Karimbaev, R.; Maleki, E.; Unal, O.; Pyun, Y.S.; Amanov, T. Effect of Combined Shot Peening and Ultrasonic Nanocrystal Surface Modification Processes on the Fatigue Performance of AISI 304. Surf. Coatings Technol. 2019, 358, 695–705. [Google Scholar] [CrossRef]

- Hanlon, T.; Tabachnikova, E.D.; Suresh, S. Fatigue Behavior of Nanocrystalline Metals and Alloys. Int. J. Fatigue 2005, 27, 1147–1158. [Google Scholar] [CrossRef]

- Hanlon, T.; Kwon, Y.N.; Suresh, S. Grain Size Effects on the Fatigue Response of Nanocrystalline Metals. Scr. Mater. 2003, 49, 675–680. [Google Scholar] [CrossRef]

- Novelli, M.; Bocher, P.; Grosdidier, T. Effect of Cryogenic Temperatures and Processing Parameters on Gradient-Structure of a Stainless Steel Treated by Ultrasonic Surface Mechanical Attrition Treatment. Mater. Charact. 2018, 139, 197–207. [Google Scholar] [CrossRef]

- Roland, T.; Retraint, D.; Lu, K.; Lu, J. Enhanced Mechanical Behavior of a Nanocrystallised Stainless Steel and Its Thermal Stability. Mater. Sci. Eng. A 2007, 445–446, 281–288. [Google Scholar] [CrossRef]

- Bagherifard, S.; Guagliano, M. Fatigue Behavior of a Low-Alloy Steel with Nanostructured Surface Obtained by Severe Shot Peening. Eng. Fract. Mech. 2012, 81, 56–68. [Google Scholar] [CrossRef]

- Maurel, P.; Weiss, L.; Bocher, P.; Grosdidier, T. Effects of SMAT at Cryogenic and Room Temperatures on the Kink Band and Martensite Formations with Associated Fatigue Resistance in a β-Metastable Titanium Alloy. Mater. Sci. Eng. A 2021, 803. [Google Scholar] [CrossRef]

- Tong, W.P.; Han, Z.; Wang, L.M.; Lu, J.; Lu, K. Low-Temperature Nitriding of 38CrMoAl Steel with a Nanostructured Surface Layer Induced by Surface Mechanical Attrition Treatment. Surf. Coatings Technol. 2008, 202, 4957–4963. [Google Scholar] [CrossRef]

- Sun, J.; Tong, W.P.; Zhang, H.; Du, X.D.; Wu, Y.C. Enhanced Strength and Plasticity of Gas Nitrided Iron by Surface Mechanical Attrition Pretreatment. Surf. Coatings Technol. 2016, 286, 279–284. [Google Scholar] [CrossRef]

- Stinville, J.C.; Cormier, J.; Templier, C.; Villechaise, P. Monotonic Mechanical Properties of Plasma Nitrided 316L Polycrystalline Austenitic Stainless Steel: Mechanical Behaviour of the Nitrided Layer and Impact of Nitriding Residual Stresses. Mater. Sci. Eng. A 2014, 605, 51–58. [Google Scholar] [CrossRef]

| Material | Type of Treatment | Grain Size (nm) | Reference |

|---|---|---|---|

| AA 2014 | SMAT—10 min | 31 | [46] |

| AA 7075 | SMAT—300 s | 16 ± 3 | [28] |

| SS 316L | SMAT—15 min | 20 | [6] |

| SUS 304 | UNSM-90 N | ~10 | [45] |

| Ti-6Al-4V | SMAT | 115 | [47] |

| C-2000 alloy | SMAT | ~12 | [48] |

| Zr-4 alloy | SMGT * | 161 | [49] |

| AZ91D alloy | SMAT | 30 ± 5 | [38] |

| Ni3Al | SMAT | 45 | [50] |

| Material | Type of Treatment | Microhardness | Surface Roughness Ra (μm) | ||

|---|---|---|---|---|---|

| Bulk | Surface | Initial | Treated | ||

| AA 7075-T6 [51] | SMAT | 157 HV0.025 | 180 HV0.025 | 0.35 | 1.11 |

| AA 2014 [46] | SMAT | 190 HV | 246 HV | - | - |

| SUS 304 [45] | UNSM | 250 HV | 540 HV | 0.35 | 0.95 |

| SS 316L [52] | SMAT | 200 HV0.025 | 380 HV0.025 | ~2 | ~1.5 ~3.3 |

| CSP | 200 HV0.025 | 430 HV0.025 | ~2 | ||

| Ti-6Al-4V [47] | SMAT | ~3.2 GPa * | ~6.9 GPa * | 0.1 | 0.63 |

| X70 micro alloyed steel [54] | CSP | ~215 HV0.05 | ~237 HV0.05 | 2.58 | 3.15 8.39 |

| SSP | ~215 HV0.05 | ~244 HV0.05 | 2.58 | ||

| Ni3Al [50] | SMAT | ~4 GPa * | ~12 GPa * | - | - |

| Zircaloy-4 [55] | SMAT | 165 HV | 215 HV | - | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, P.; Sun, Z.; Retraint, D. Literature Review on the Fatigue Properties of Materials Processed by Surface Mechanical Attrition Treatment (SMAT). Metals 2022, 12, 775. https://doi.org/10.3390/met12050775

Gao P, Sun Z, Retraint D. Literature Review on the Fatigue Properties of Materials Processed by Surface Mechanical Attrition Treatment (SMAT). Metals. 2022; 12(5):775. https://doi.org/10.3390/met12050775

Chicago/Turabian StyleGao, Pengfei, Zhidan Sun, and Delphine Retraint. 2022. "Literature Review on the Fatigue Properties of Materials Processed by Surface Mechanical Attrition Treatment (SMAT)" Metals 12, no. 5: 775. https://doi.org/10.3390/met12050775

APA StyleGao, P., Sun, Z., & Retraint, D. (2022). Literature Review on the Fatigue Properties of Materials Processed by Surface Mechanical Attrition Treatment (SMAT). Metals, 12(5), 775. https://doi.org/10.3390/met12050775