Microstructure, Inclusions, and Elemental Distribution of a Compacted Graphite Iron Alloyed by Ce and La Rare Earth (RE) Elements

Abstract

:1. Introduction

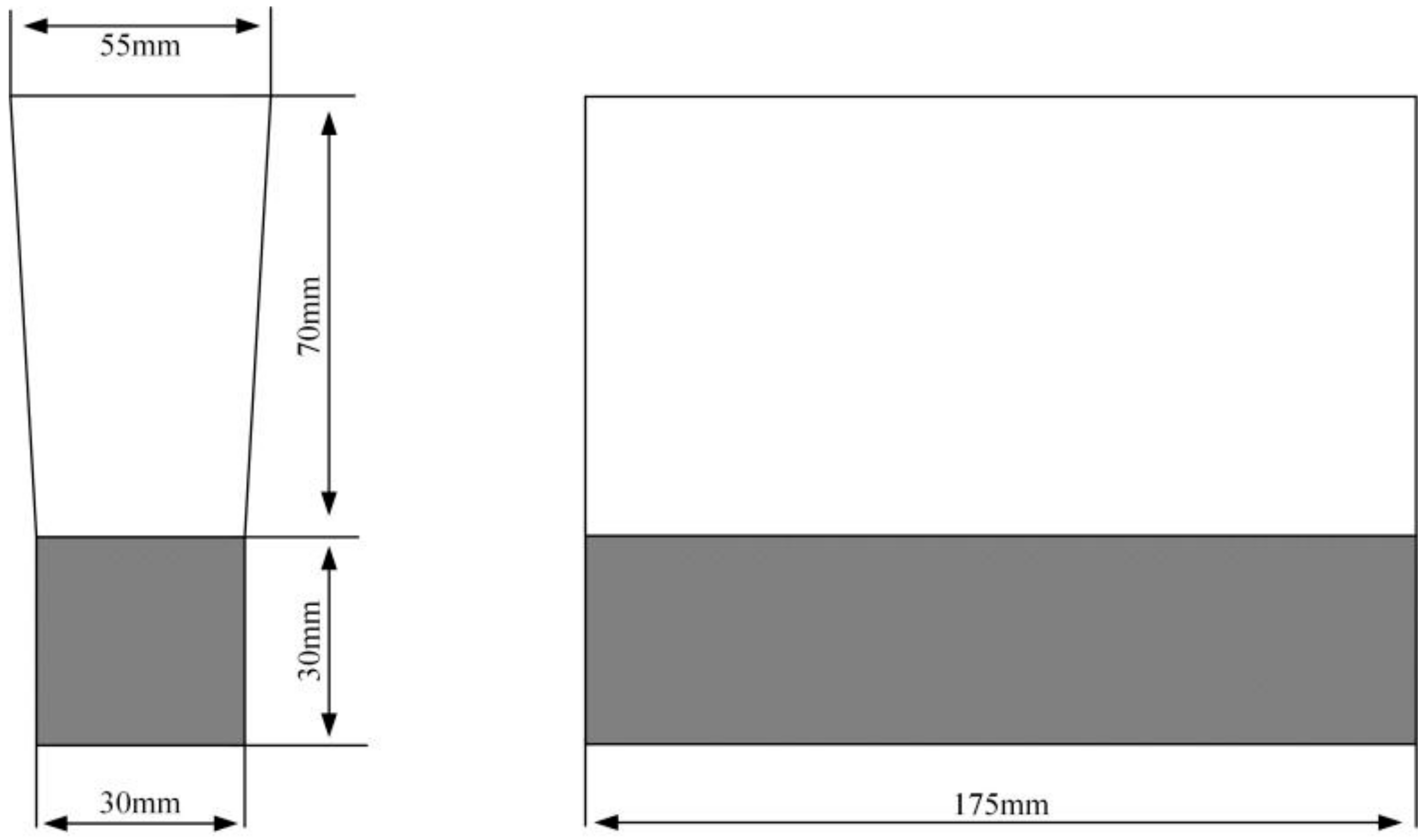

2. Materials and Methods

3. Results and Discussions

3.1. Microstructure

3.2. Inclusions

3.3. Graphite Nucleation and Growth

3.4. Distribution of Alloying Elements

3.4.1. Distribution of C, Si, and Mn

3.4.2. Distribution of Cr and V

3.4.3. Distribution of Cu and P

3.4.4. Distribution of RE Element

4. Conclusions

- (1)

- The addition of RE into CGI formed several kinds of inclusions that were determined as RE(Ce,La)2S3, MgS, carbides, and aggregated composite inclusions. These inclusions, containing elements such as S, Ce, La, and Mg, provided heterogeneous nucleation cores for graphite.

- (2)

- Significant solute clustering in the matrix, coupled with the segregation of the solute to grain boundaries, was observed in CGI alloyed by RE. Cr and V from raw materials promoted cementite precipitation, while a Cu-rich atom cluster was found towards the phase boundary, stabilizing pearlite. P, as a segregation element, was observed to be enriched at the ferrite/ cementite boundaries continuously.

- (3)

- RE had three main roles in the modified CGI.: RE participated in the formation of relatively regular inclusions containing RE and consumed harmful elements, such as S, As, and P. In addition, the heterogeneous nucleation of the graphite was promoted by RE inclusion nuclei, and the growth of vermicular graphite was deeply altered by the segregation of RE towards the graphite/ferrite or cementite phase boundaries. Moreover, the segregation of RE, in the form of solute atoms towards the grain or phase boundaries, could eliminate the harmful effects of the residual elements, which benefited the strength of the grain boundary.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Morrogh, H.; Williams, W. The production of nodular graphite structures in cast iron. J. Iron Steel Inst. 1948, 158, 306–322. [Google Scholar]

- Qiu, H.; Chen, Z. The forty years of vermicular graphite cast iron development in China (Part III). China Foundry 2007, 4, 261–269. [Google Scholar]

- Alonso, G.; Stefanescu, D.M.; Larrañaga, P.; Suarez, R. Graphite Nucleation in Compacted Graphite Cast Iron. Int. J. Metalcast. 2020, 14, 1162–1171. [Google Scholar] [CrossRef]

- Gregorutti, R.W.; Grau, J.E. Mechanical properties of compacted graphite cast iron with different microstrucures. Int. J. Cast Met. Res. 2014, 27, 275–281. [Google Scholar] [CrossRef]

- König, M.; Wessén, M. Influence of alloying elements on microstrucure and mechanical properties of CGI. Int. J. Cast Met. Res. 2010, 23, 97–110. [Google Scholar] [CrossRef]

- Almanza, A.; Pérez, M.J.; Almanza, E. Microstructure and Mechanical Properties of Gray Iron Cylinder Blocks Casting. Int. J. Metalcast. 2015, 9, 84–86. [Google Scholar] [CrossRef]

- Antoni-Zdziobek, A.; Shen, Y.J.; Durand-Charre, M. About one stable and three metastable eutectic microconstituents in the Fe-W-C system. Int. J. Refract. Met. Hard Mater. 2008, 26, 372–382. [Google Scholar] [CrossRef]

- Brauer, S.A.; Whittington, W.R.; Johnson, K.L.; Li, B.; Rhee, H.; Allison, P.G.; Crane, C.K.; Horstemeyer, M.F. Strain rate and stress state dependence of gray cast iron. J. Eng. Mater. Technol. ASME 2017, 139, 021013. [Google Scholar] [CrossRef] [Green Version]

- Domeij, B.; Diószegi, A. The distribution of carbon in austenite studied on a water-quenched compacted graphite iron using electron probe microanalysis. Int. J. Metalcast. 2020, 14, 782–793. [Google Scholar] [CrossRef] [Green Version]

- Boeri, R.; Weinberg, F. Microsegregation of alloying elements in cast iron. Cast Met. 1993, 6, 153–158. [Google Scholar] [CrossRef]

- Boudot, A.; Gerval, V.; Oquab, D.; Lacaze, J.; Santos, H. The role of manganese and copper in the eutectoid transformation of spheroidal graphite cast iron. Metall. Mater. Trans. A 1997, 28, 2015–2025. [Google Scholar] [CrossRef]

- Gundlach, R.; Meyer, M.; Winardi, L. Influence of Mn and S on the Properties of Cast Iron Part III—Testing and Analysis. Int. J. Metalcast. 2015, 9, 69–82. [Google Scholar] [CrossRef]

- Meyer, M.; Gundlach, R.; Williams, D.; Winardi, L. Influence of Mn and S on the Properties of Cast Iron Part II—Experimental Design: Aspects of Melting and Pouring. AFS Trans. 2014, 122, 273–278. [Google Scholar]

- Shyrokov, V.V.; Arendar, L.A.; Rytsar, D.I. Tribological properties of gray cast irons alloyed with phosphorus. Mater. Sci. 2004, 40, 512–517. [Google Scholar] [CrossRef]

- Abbasi, H.R.; Bazdar, M.; Halvaee, A. Effect of phosphorus as an alloying element on microstrucure and mechanical properties of pearlitic gray cast iron. Mater. Sci. Eng. A 2007, 444, 314–317. [Google Scholar] [CrossRef]

- Shibata, E.; Egawa, S.; Nakamura, T. Reduction behavior of chromium oxide in molten slag using aluminum, ferrosilicon and graphite. ISIJ Int. 2002, 42, 609–613. [Google Scholar] [CrossRef]

- Li, Y.; Li, P.; Wang, K.; Li, H.; Gong, M.; Tong, W. Microstrucutre and mechanical properties of a Mo alloyed high chromium cast iron after different heat treatment. Vacuum 2018, 156, 59–67. [Google Scholar] [CrossRef]

- König, M.; Wessén, M. The influence of copper on microstructure and mechanical properties of compacted graphite iron. Int. J. Cast Met.al Res. 2009, 22, 164–167. [Google Scholar] [CrossRef]

- Xu, D.M.; Wang, G.Q.; Chen, X.; Li, Y.X.; Liu, Y.; Zhang, H. Effects of Mo and Ni on the thermal conductivity of compacted graphite iron. Int. J. Cast Met. Res. 2019, 32, 243–251. [Google Scholar] [CrossRef]

- Upadhyay, S.; Saxena, K.K. Effect of Cu and Mo addition on mechanical properties and microstructure of grey cast iron: An overview. Mater. Today Proc. 2020, 26, 2462–2470. [Google Scholar] [CrossRef]

- Deng, X.X.; Jiang, M.; Wang, X.H. Mechanisms of inclusion evolution and intra-granular acicular ferrite formation in steels containing rare earth elements. Acta Metal. Sin. Engl. 2012, 25, 241–248. [Google Scholar]

- Yi, D.W.; Xing, J.D.; Fu, H.G.; Ma, S.Q.; Liu, Z.X. Effect of Rare Earth-Al Additions on the Structural Variations of Medium Carbon Fe-B Cast Alloy. Key Eng. Mater. 2011, 457, 213–218. [Google Scholar] [CrossRef]

- Guzik, E.; Dzik, S. Structure and mechanicalproperties of vermicaluar cast iron in cylinder head casting. Arch. Foundry Eng. 2009, 9, 175–180. [Google Scholar]

- He, Z.R.; Lin, G.X.; Ji, S. A new understanding on the relation among microstructure micro interfacial mechanical behaviours and macro mechanical properties in cast iron. Mater. Sci. Eng. A 1997, 234–236, 161–164. [Google Scholar] [CrossRef]

- Lekakh, S.N. Effect of nonmetallic inclusions on solidification of inoculated spheroidal graphite iron. Int. J. Metalcast. 2019, 13, 47–57. [Google Scholar] [CrossRef]

- Liu, H.H.; Fu, P.X.; Liu, H.W.; Cao, Y.F.; Sun, C.; Du, N.Y.; Li, D.Z. Effects of Rare Earth elements on microstructure evolution and mechanical properties of 718H pre-hardened mold steel. J. Mater. Sci. Technol. 2020, 50, 245–256. [Google Scholar] [CrossRef]

- Yang, C.Y.; Luan, Y.K.; Li, D.Z.; Li, Y.Y. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel. J. Mater. Sci. Technol. 2019, 35, 1298–1308. [Google Scholar] [CrossRef]

- Taşgin, Y.; Kaplan, M.; Yaz, M. Investigation of effects of boron additives and heat treatment on carbides and phase transition of highly alloyed duplex cast iron. Mater. Des. 2009, 30, 3174–3179. [Google Scholar] [CrossRef]

- Wang, L.P.; Guo, E.; Chen, H.B.; Wang, J.Z.; Li, D.Y. Effects of light and heavy rare earths on anti-degradation of nodular cast iron. J. Rare Earth 2006, 24, 103–107. [Google Scholar] [CrossRef]

- Hao, F.F.; Li, D.; Dan, T.; Ren, X.J.; Liao, B.; Yang, Q.X. Effect of rare earth oxides on the morphology of carbides in hardfaxing metal of high chromium cast iron. J. Rare Earth 2011, 2, 168–172. [Google Scholar] [CrossRef]

- Shi, G.Q.; Yang, Z.; Li, J.P.; Tao, D.; Ma, Z.J. Investigation on the graphite nucleation and growth mechanism of the compacted graphite iron. J. Mater. Res. Technol. 2020, 9, 8186–8196. [Google Scholar] [CrossRef]

- Vicente, A.; Moreno, J.S.; Santos, T.; Espinosa, D.; Tenório, J.A.S. Nucleation and growth of graphite particles in ductile cast iron. J. Alloy. Compd. 2019, 775, 1230–1234. [Google Scholar] [CrossRef]

- Miao, B.; Wood, D.O.N.; Bian, W.; Fang, K.; Fan, M.H. Structure and growth of platelets in graphite spherulites in cast iron. J. Mater. Sci. 1994, 29, 255–261. [Google Scholar] [CrossRef]

- Theuwissen, K.; Lacaze, J.; Laffont, L.; Zollinger, J.; Daloz, D. Effect of Ce and Sb on primary graphite growth in cast irons. Trans. Indian Inst. Met. 2012, 65, 707–712. [Google Scholar] [CrossRef] [Green Version]

- Double, D.D.; Hellawell, A. The nucleation and growth of graphite—The modification of cast iron. Acta Metall. Mater. 1995, 43, 2435–2442. [Google Scholar] [CrossRef]

- Lian, X.T.; Zhu, J.N.; Dong, H.; Wang, Y.M.; Liu, J.D. Effects of micro-alloying elements on microstructure, element distribution and mechanical properties in gray irons. Int. J. Metalcast. 2020, 14, 1025–1032. [Google Scholar] [CrossRef]

- Zhu, J.N.; Lian, X.T.; Lu, H.C.; Liu, Q.Y.; Jiang, A.L.; Fang, D.; Dong, H.; Xu, D.X. Effects of rare earth elements (Ce, La) on microstructure and mechanical properties in compacted graphite iron. Philos. Mag. 2020, 101, 354–368. [Google Scholar] [CrossRef]

- Wu, J.H.; Zhang, S.H.; Chen, Y.; Li, H.H.; Song, H.W.; Cheng, M.; Liu, J.S. Microstructure and properties of TP2 copper tube with La microalloying by horizontal continuous casting. China Foundry 2018, 15, 31–36. [Google Scholar] [CrossRef] [Green Version]

| Element | Si | Al | Ca | Ba | Mg | RE | Fe |

|---|---|---|---|---|---|---|---|

| Inoculant | 68.23 | 0.93 | 2.04 | 4.15 | - | - | Bal. |

| Vermiculizer | 45.11 | 0.74 | 2.05 | - | 5.11 | 4.51 | Bal. |

| Element | C | Si | Mn | Cu | Cr | P | S | Ce | La | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| Investigated CGI | 3.37 | 2.12 | 0.33 | 0.51 | 0.020 | 0.039 | 0.020 | 0.026 | 0.015 | Bal. |

| Original CGI | 3.35 | 2.04 | 0.33 | 0.50 | 0.025 | 0.040 | 0.017 | 0.008 | 0.006 | Bal. |

| Sample | RE Content/wt.% | Vermicular Graphite/% | Spheroidal Graphite/% |

|---|---|---|---|

| Investigated CGI | 0.041 | 79 | 21 |

| Original CGI | 0.014 | 88 | 12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fan, Z.; Zhu, J.; Lian, X.; Liu, T.; Xu, D.; Wei, X.; Dong, H. Microstructure, Inclusions, and Elemental Distribution of a Compacted Graphite Iron Alloyed by Ce and La Rare Earth (RE) Elements. Metals 2022, 12, 779. https://doi.org/10.3390/met12050779

Fan Z, Zhu J, Lian X, Liu T, Xu D, Wei X, Dong H. Microstructure, Inclusions, and Elemental Distribution of a Compacted Graphite Iron Alloyed by Ce and La Rare Earth (RE) Elements. Metals. 2022; 12(5):779. https://doi.org/10.3390/met12050779

Chicago/Turabian StyleFan, Zengwei, Jianan Zhu, Xintong Lian, Tengshi Liu, Dexiang Xu, Xicheng Wei, and Han Dong. 2022. "Microstructure, Inclusions, and Elemental Distribution of a Compacted Graphite Iron Alloyed by Ce and La Rare Earth (RE) Elements" Metals 12, no. 5: 779. https://doi.org/10.3390/met12050779

APA StyleFan, Z., Zhu, J., Lian, X., Liu, T., Xu, D., Wei, X., & Dong, H. (2022). Microstructure, Inclusions, and Elemental Distribution of a Compacted Graphite Iron Alloyed by Ce and La Rare Earth (RE) Elements. Metals, 12(5), 779. https://doi.org/10.3390/met12050779