Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy

Abstract

:1. Introduction

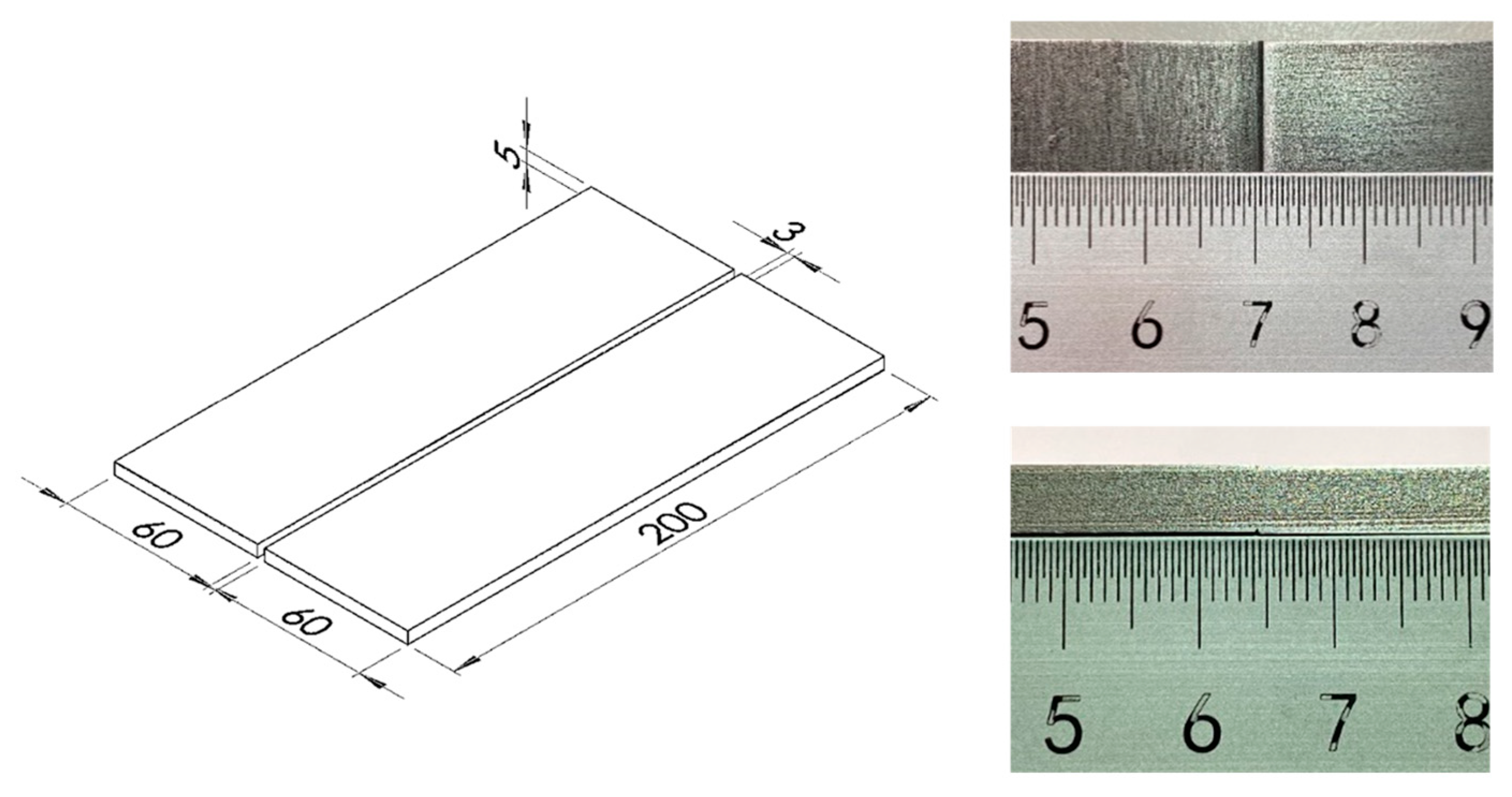

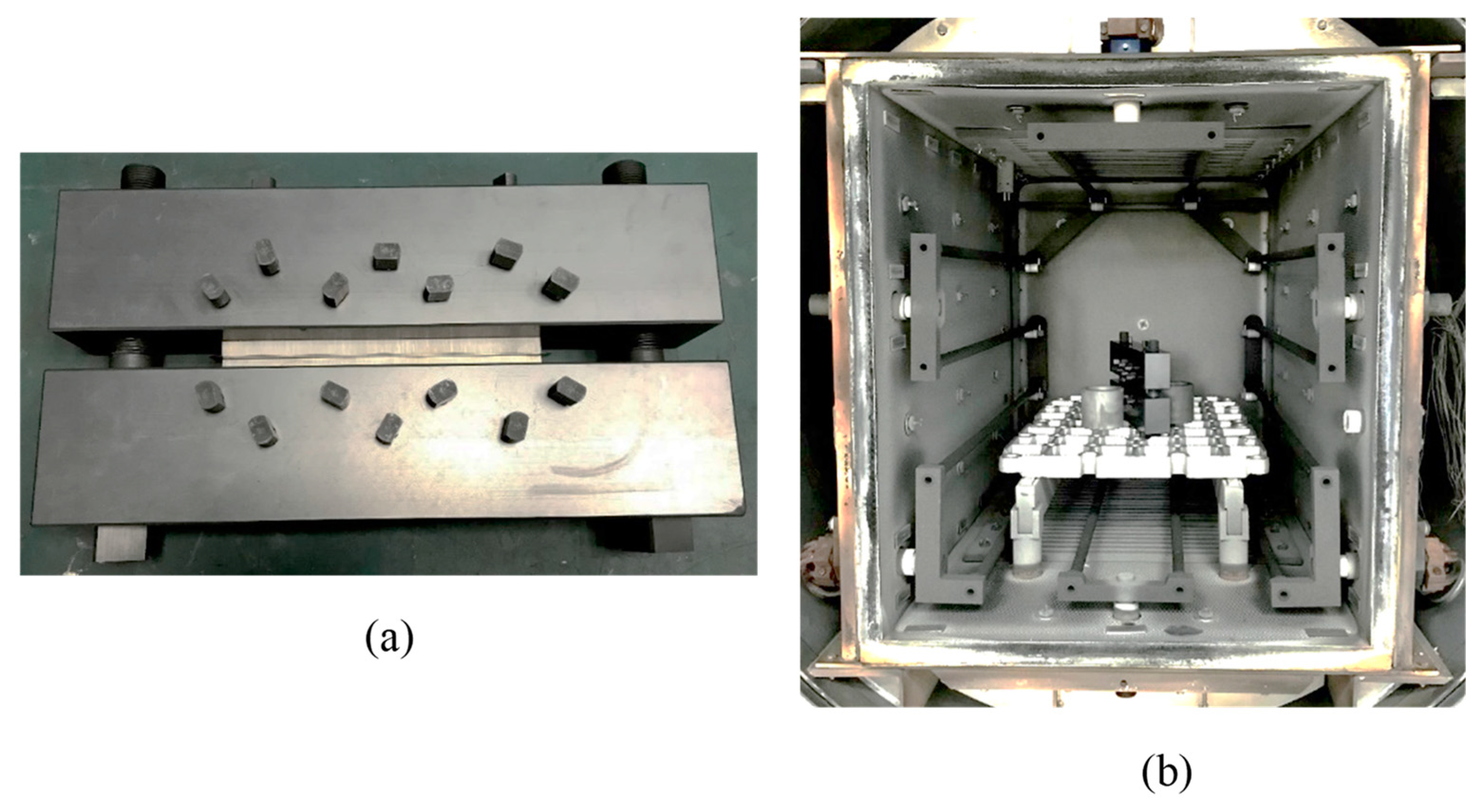

2. Materials and Methods

3. Results and Discussion

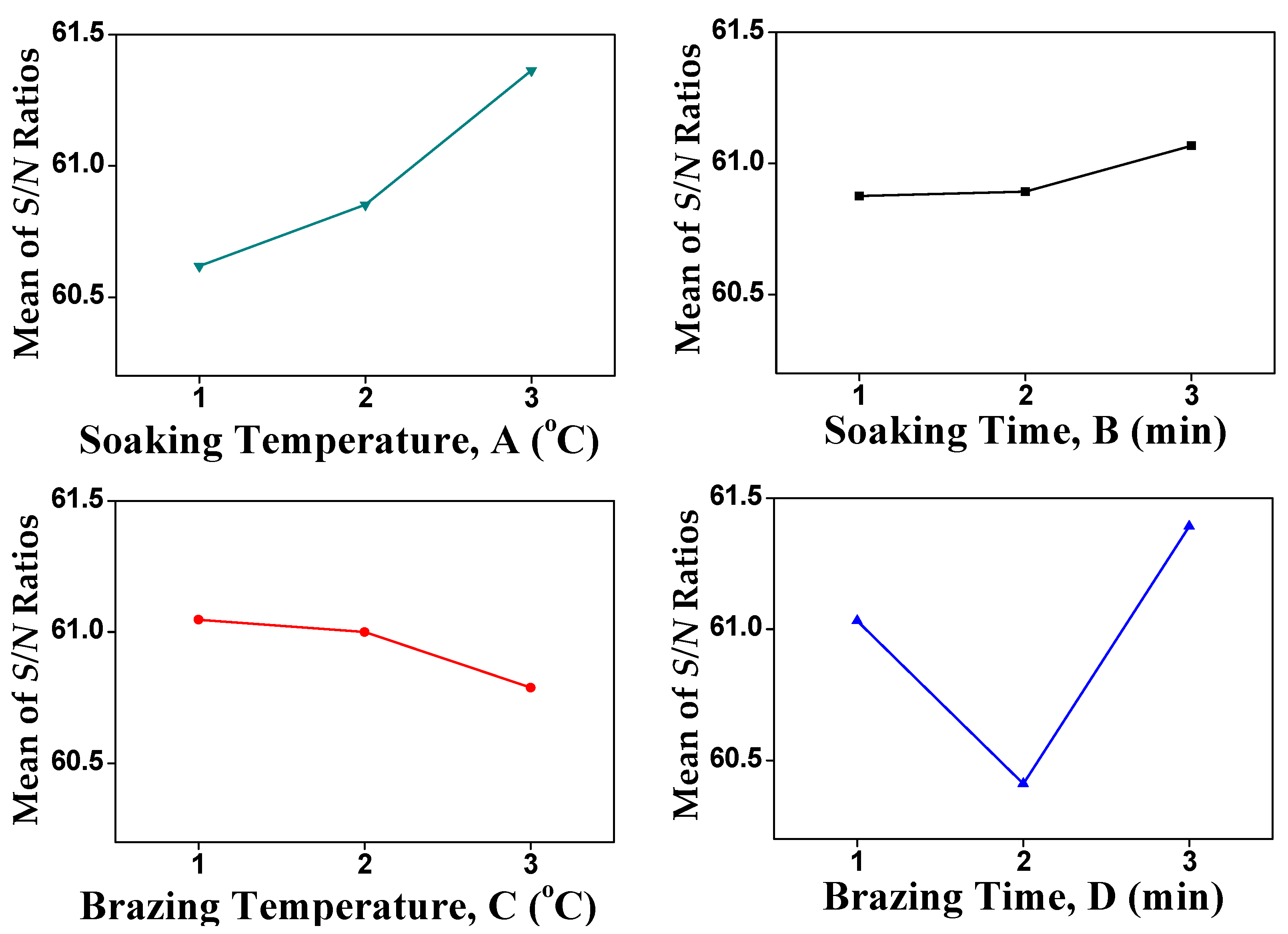

3.1. Process Parameter Optimization

3.2. Variance Analysis (ANOVA)

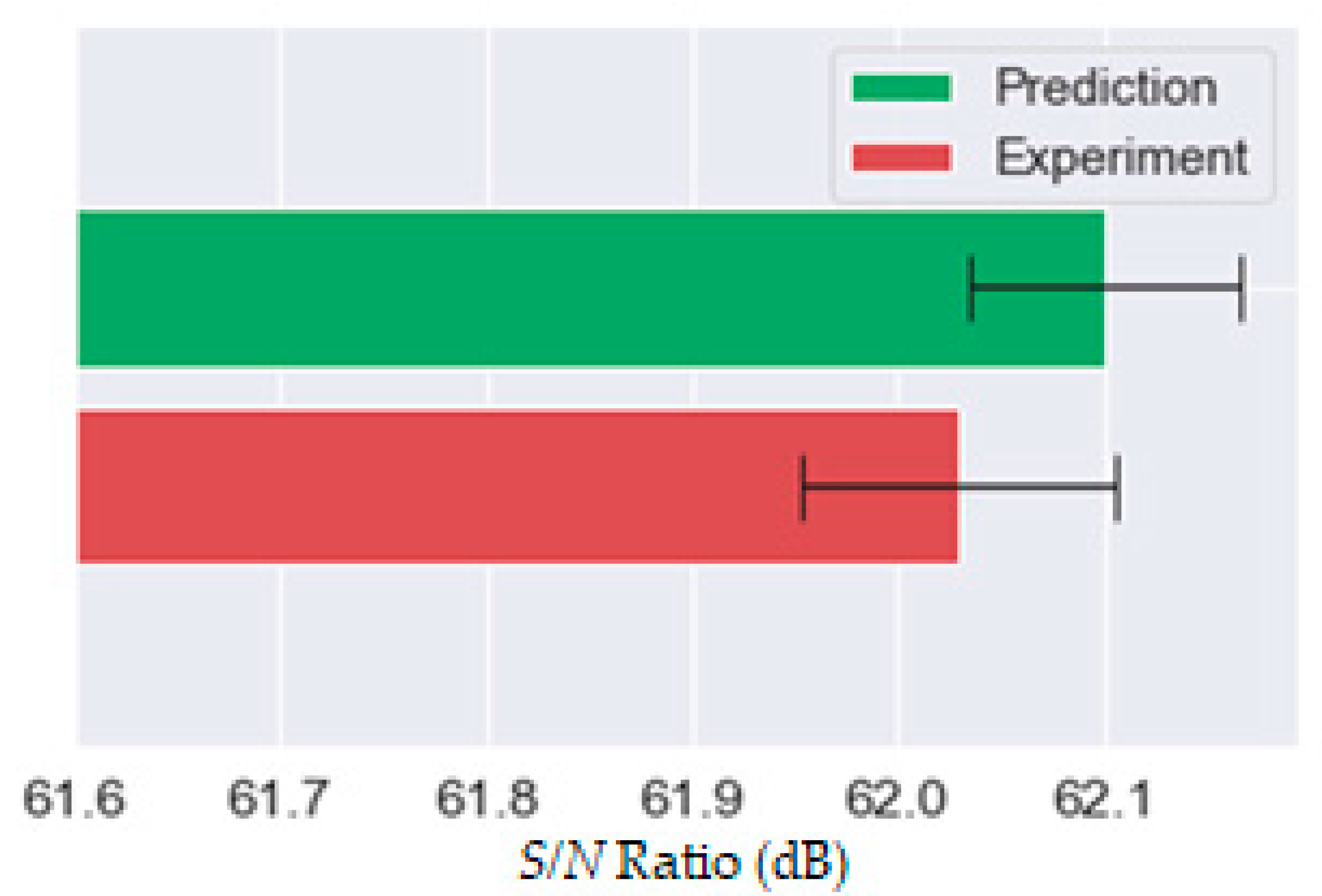

3.3. Confirmation Test

3.4. Microstructures

3.5. Microhardness

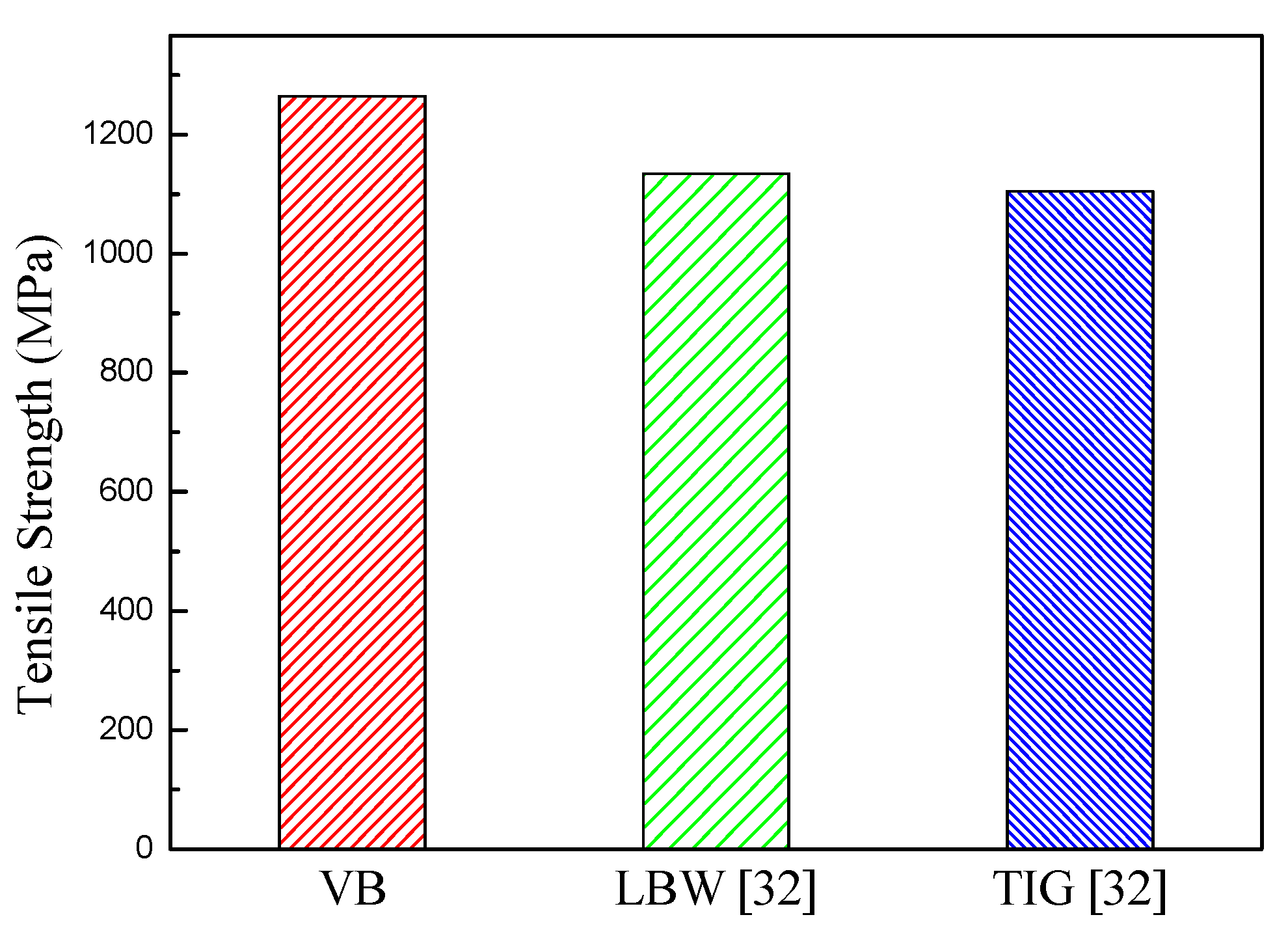

3.6. Tensile Properties

4. Conclusions

- When using the Taguchi method and the quality parameter of tensile strength, the optimal parameters were found to be a soaking temperature of 890 °C, a soaking time of 60 min, a welding temperature of 975 °C, and a holding time of 45 min. According to the ANOVA analysis, the contributing degrees of the four factors were: soaking temperature 27.7%, soaking time 47.3%, brazing temperature 3.6%, and brazing time 21.4%;

- The predicted value of optimal tensile strength was 1262 MPa, with an error value of 0.24%. This demonstrates that the Taguchi method is a feasible means of obtaining the optimal process parameters of titanium vacuum brazed joints;

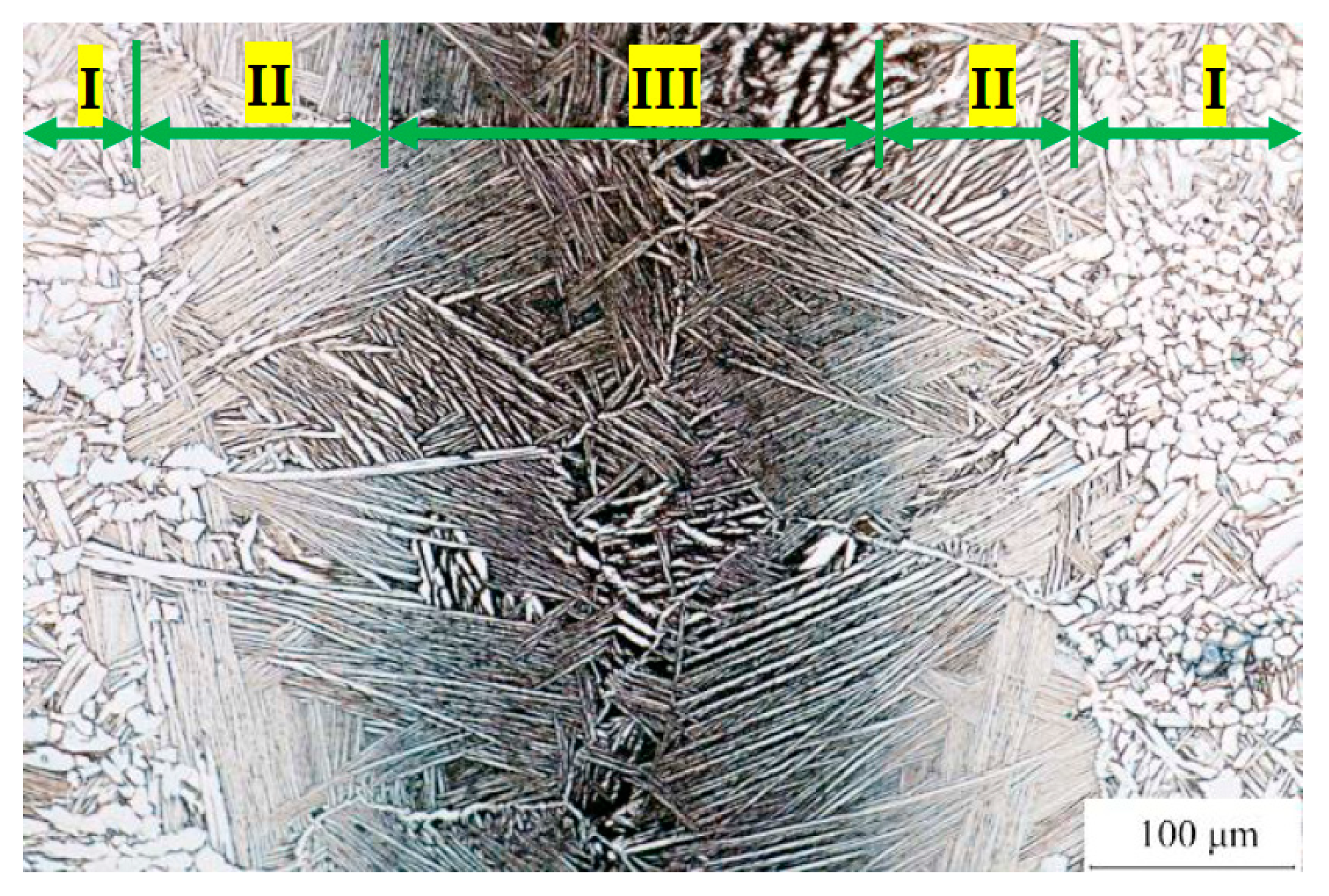

- Under optimum process conditions, the base material of VB weldment is mainly composed of white granular α titanium, slender β titanium, and layered structures interlaced by α and β. The weld bead, composed of Ti-15Cu-15Ni, contains many slender needle-shaped Widmanstätten structures. These structures are commonly found in weld beads which use TiCuNi as a brazing filler and are associated with higher strength and lower ductility;

- The specimen cross-section after vacuum brazing can be divided into three areas: base metal, diffusion zone, and weld bead. The microhardness value of the weld bead was the highest. The base material had the same microhardness as the annealing treatment, which was the lowest. The weld bead hardness of vacuum brazed parts is higher than that of laser beam weldment and gas tungsten arc weldment. The fracture section of the optimized specimens consists of dimples and small cleavage surfaces.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Balasubramanian, T.; Balasubramanian, V.; Muthumanikkam, M. Fatigue performance of gas tungsten arc, electron beam, and laser beam welded Ti-6Al-4V alloy joints. J. Mater. Eng. Perform. 2011, 20, 1620–1630. [Google Scholar] [CrossRef]

- Huang, X.; Richards, N. Activated diffusion brazing technology for manufacture of titanium honeycomb structures-a statistical study. Weld. J. 2004, 83, 73. [Google Scholar]

- Botstein, O.; Rabinkin, A. Brazing of titanium-based alloys with amorphous 25wt.% Ti-25wt.% Zr-50wt.% Cu filler metal. Mater. Sci. Eng. A 1994, 188, 305–315. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Effect of brazing parameters on microstructure and mechanical properties of titanium joints. J. Mater. Process. Technol. 2009, 209, 4842–4849. [Google Scholar] [CrossRef]

- Chang, C.; Du, Y.; Shiue, R.; Chang, C. Infrared brazing of high-strength titanium alloys by Ti-15Cu-15Ni and Ti-15Cu-25Ni filler foils. Mater. Sci. Eng. A 2006, 420, 155–164. [Google Scholar] [CrossRef]

- Ganjeh, E.; Sarkhosh, H. Microstructural, mechanical and fractographical study of titanium-CP and Ti-6Al-4V similar brazing with Ti-based filler. Mater. Sci. Eng. A 2013, 559, 119–129. [Google Scholar] [CrossRef]

- Chiou, C.-Y.; Shiue, R.-K.; Chang, C.S. Infrared brazing titanium alloys using clad Ti-15Cu-15Ni fillers with different clad layers. ISIJ Int. 2009, 49, 605–607. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.Y.; Yeh, T.Y.; Shiue, R.K.; Chang, C.S. The effect of substrate dissolution in brazing CP-Ti and Ti15-3 using clad Ti-15Cu-15Ni Filler. ISIJ Int. 2010, 50, 450–454. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Dong, H.; Li, P. Brazing TC4 titanium alloy/316L stainless steel joint with Ti50-xZrxCu39Ni11 amorphous filler metals. J. Alloy. Compd. 2020, 849, 156650. [Google Scholar] [CrossRef]

- Elrefaey, A.; Tillmann, W. Correlation between microstructure, mechanical properties, and brazing temperature of steel to titanium joint. J. Alloy. Compd. 2009, 487, 639–645. [Google Scholar] [CrossRef]

- Laik, A.; Shirzadi, A.; Tewari, R.; Kumar, A.; Jayakumar, T.; Dey, G. Microstructure and interfacial reactions during active metal brazing of stainless steel to titanium. Metall. Mater. Trans. A 2013, 44, 2212–2225. [Google Scholar] [CrossRef] [Green Version]

- Laik, A.; Shirzadi, A.; Sharma, G.; Tewari, R.; Jayakumar, T.; Dey, G. Microstructure and interfacial reactions during vacuum brazing of stainless steel to titanium using Ag-28 pct Cu alloy. Metall. Mater. Trans. A 2015, 46, 771–782. [Google Scholar] [CrossRef] [Green Version]

- Yue, X.; He, P.; Feng, J.; Zhang, J.; Zhu, F. Microstructure and interfacial reactions of vacuum brazing titanium alloy to stainless steel using an AgCuTi filler metal. Mater. Charact. 2008, 59, 1721–1727. [Google Scholar] [CrossRef]

- J-STAGE. Available online: https://www.jstage.jst.go.jp/article/jwstaikai/2012f/0/2012f_70/_article/-char/ja/ (accessed on 15 March 2022).

- Liu, S.; Suzumura, A.; Ikeshoji, T.-T.; Yamazaki, T. Brazing of stainless steel to various aluminum alloys in air. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2005, 48, 420–425. [Google Scholar] [CrossRef] [Green Version]

- Tamai, F.; Hirano, K. Characteristics of static and fatigue strength of alumina ceramic joints. JSME Int. J. Ser. A Mech. Mater. Eng. 1996, 39, 613–619. [Google Scholar] [CrossRef] [Green Version]

- Shiue, R.-K.; Wu, S.-K.; Liu, C.-K.; Dai, C.-Y. Interfacial reaction and bonding strength of Ti50Ni50 and Inconel 600 dissimilar brazed joints. Mater. Trans. 2017, 58, 1308–1312. [Google Scholar] [CrossRef] [Green Version]

- AlHazaa, A.; Haneklaus, N. Diffusion bonding and transient liquid phase (TLP) bonding of type 304 and 316 austenitic stainless steel—A review of similar and dissimilar material joints. Metals 2020, 10, 613. [Google Scholar] [CrossRef]

- Liaw, D.W.; Wu, Z.Y.; Shiue, R.K.; Chang, C.S. Microstructural analysis of infrared brazed Ti-6Al-4V and Nb using the Ti-15Cu-25Ni foil. ISIJ Int. 2007, 47, 869–874. [Google Scholar] [CrossRef] [Green Version]

- Elrefaey, A.; Tillmann, W. Brazing of titanium to steel with different filler metals: Analysis and comparison. J. Mater. Sci. 2010, 45, 4332–4338. [Google Scholar] [CrossRef]

- J-STAGE. Available online: https://www.jstage.jst.go.jp/article/denkiseiko/74/4/74_4_267/_article/-char/ja/ (accessed on 15 March 2022).

- Yan, G.; Tan, M.J.; Crivoi, A.; Li, F.; Kumar, S.; Chia, C.H.N. Improving the mechanical properties of TIG welding Ti-6Al-4V by post weld heat treatment. Procedia Eng. 2017, 207, 633–638. [Google Scholar] [CrossRef]

- Karna, S.K.; Sahai, R. An overview on Taguchi method. Int. J. Eng. Sci. Math. 2012, 1, 11–18. [Google Scholar]

- Qazi, M.I.; Abas, M.; Khan, R.; Saleem, W.; Pruncu, C.I.; Omair, M. Experimental investigation and multi-response optimization of machinability of AA5005H34 using composite desirability coupled with PCA. Metals 2021, 11, 235. [Google Scholar] [CrossRef]

- Kuo, C.-H.; Lin, Z.-Y. Optimizing the high-performance milling of thin aluminum alloy plates using the Taguchi method. Metals 2021, 11, 1526. [Google Scholar] [CrossRef]

- Lin, H.; Hwang, J.-R.; Fung, C.-P. Fatigue properties of 6061-T6 aluminum alloy T-joints processed by vacuum brazing and TIG welding. Mater. Trans. 2016, 57, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Liu, S.; Miao, J.; Zhang, W.; Wei, R.; Chen, C.; Wang, T.; Zhao, W.; Jing, Z.; Li, F. Interfacial microstructure and shear strength of TC4 alloy joints vacuum brazed with Ti-Zr-Ni-Cu filler metal. Mater. Sci. Eng. A 2020, 775, 138990. [Google Scholar] [CrossRef]

- Pang, S.; Sun, L.; Xiong, H.; Chen, C.; Liu, Y.; Li, H.; Zhang, T. A multicomponent TiZr-based amorphous brazing filler metal for high-strength joining of titanium alloy. Scr. Mater. 2016, 117, 55–59. [Google Scholar] [CrossRef]

- Xia, Y.; Dong, H.; Hao, X.; Li, P.; Li, S. Vacuum brazing of Ti6Al4V alloy to 316L stainless steel using a Ti-Cu-based amorphous filler metal. J. Mater. Process. Technol. 2019, 269, 35–44. [Google Scholar] [CrossRef]

- Wu, B.; Li, J.; Tang, Z. Study on the electron beam welding process of ZTC4 titanium alloy. Rare Metal Mat. Eng. 2014, 43, 786–790. [Google Scholar] [CrossRef]

- Zhang, H.-H.; Cui, Z.-D.; Zhu, S.-L.; Guo, S.-W.; Yang, X.-J.; Inoue, A. Microstructure and mechanical properties of TC4 joints brazed with Ti–Zr–Cu–Sn amorphous filler alloy. Rare Metals 2021, 40, 1881–1889. [Google Scholar] [CrossRef]

- Gao, X.-L.; Zhang, L.-J.; Liu, J.; Zhang, J.-X. A comparative study of pulsed Nd: YAG laser welding and TIG welding of thin Ti6Al4V titanium alloy plate. Mater. Sci. Eng. A 2013, 559, 14–21. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Development of strength-hardness relationships in additively manufactured titanium alloys. Mater. Sci. Eng. A 2017, 693, 214–224. [Google Scholar] [CrossRef] [Green Version]

- Zou, Z.; Zeng, F.; Wu, H.; Liu, J.; Li, Y.; Gu, Y.; Yuan, T.; Zhang, F. The joint strength and fracture mechanisms of TC4/TC4 and TA0/TA0 brazed with Ti-25Cu-15Ni braze alloy. J. Mater. Eng. Perform. 2017, 26, 2079–2085. [Google Scholar] [CrossRef]

| Material | Al | V | Cr | Fe | Ni | Ti | Cu | Ni |

|---|---|---|---|---|---|---|---|---|

| Ti-6Al-4V | 5.88 | 3.60 | 0 | 0.08 | 0.08 | Bal. | 0 | 0 |

| TiCuNi | 0 | 0 | 0 | 0 | 0 | 70 | 15 | 15 |

| Specifications of the Vacuum Brazing Furnace | |

|---|---|

| Chamber Size (mm) | 600 (W) × 600 (H) × 900 (L) |

| Vacuum Level (torr) | Up to 5 × 10−5 |

| Operation Temperature Range (°C) | From 350 to 1250 |

| Maximum Loading Weight (kgf) | Up to 500 |

| Level | Control Factor | |||

|---|---|---|---|---|

| A | B | C | D | |

| Soaking Temperature (°C) | Soaking Time (min) | Brazing Temperature (°C) | Brazing Time (min) | |

| 1 | 850 | 30 | 975 | 15 |

| 2 | 870 | 45 | 990 | 30 |

| 3 | 900 | 60 | 1005 | 45 |

| Trial | Specimen ID | Control Factor and Level | Tensile Strength (MPa) | S/N Ratio (dB) | |||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | No. 1 | No. 2 | No. 3 | |||

| 1 | T1 | 1 | 1 | 1 | 1 | 1103 | 1075 | 1089 | 60.73 |

| 2 | T2 | 1 | 2 | 2 | 2 | 1073 | 957 | 1024 | 60.09 |

| 3 | T3 | 1 | 3 | 3 | 3 | 1117 | 1130 | 1132 | 61.03 |

| 4 | T4 | 2 | 3 | 2 | 1 | 1167 | 1115 | 1131 | 61.12 |

| 5 | T5 | 2 | 1 | 3 | 2 | 989 | 1090 | 965 | 60.09 |

| 6 | T6 | 2 | 2 | 1 | 3 | 1133 | 1253 | 1130 | 61.35 |

| 7 | T7 | 3 | 2 | 3 | 1 | 1163 | 1160 | 1139 | 61.24 |

| 8 | T8 | 3 | 3 | 1 | 2 | 1144 | 1128 | 1115 | 61.05 |

| 9 | T9 | 3 | 1 | 2 | 3 | 1224 | 1209 | 1258 | 61.80 |

| Level | Control Factor | |||

|---|---|---|---|---|

| A | B | C | D | |

| 1 | 60.619 | 60.875 | 61.047 | 61.032 |

| 2 | 60.852 | 60.893 | 61.000 | 60.410 |

| 3 | 61.364 | 61.067 | 60.789 | 61.393 |

| Delta | 0.745 | 0.192 | 0.258 | 0.983 |

| Rank | 2 | 4 | 3 | 1 |

| Control Factor | DF | SST | SSE | MST | MSE | F | Pi (%) |

|---|---|---|---|---|---|---|---|

| Soaking Temperature, A | 2 | 0.871 | 1.664 | 0.436 | 0.277 | 1.571 | 27.7 |

| Soaking Time, B | 2 | 1.482 | 1.048 | 0.741 | 0.175 | 4.243 | 47.3 |

| Brazing Temperature, C | 2 | 0.113 | 2.422 | 0.057 | 0.404 | 0.140 | 3.6 |

| Brazing Time, D | 2 | 0.673 | 2.467 | 0.034 | 0.411 | 0.082 | 21.4 |

| Total | 8 | 3.139 | - | - | - | - | 100 |

| Specimen (A3 B3 C1 D3) | Tensile Strength (MPa) |

|---|---|

| 1 | 1302 |

| 2 | 1224 |

| 3 | 1268 |

| Mean | 1265 |

| Predicted | 1262 |

| Error | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.-D.; Hwang, J.-R.; Huang, J.-Y. Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy. Metals 2022, 12, 974. https://doi.org/10.3390/met12060974

Huang C-D, Hwang J-R, Huang J-Y. Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy. Metals. 2022; 12(6):974. https://doi.org/10.3390/met12060974

Chicago/Turabian StyleHuang, Chou-Dian, Jiun-Ren Hwang, and Jiunn-Yuan Huang. 2022. "Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy" Metals 12, no. 6: 974. https://doi.org/10.3390/met12060974

APA StyleHuang, C.-D., Hwang, J.-R., & Huang, J.-Y. (2022). Optimization of Vacuum Brazing Process Parameters in Ti-6Al-4V Alloy. Metals, 12(6), 974. https://doi.org/10.3390/met12060974