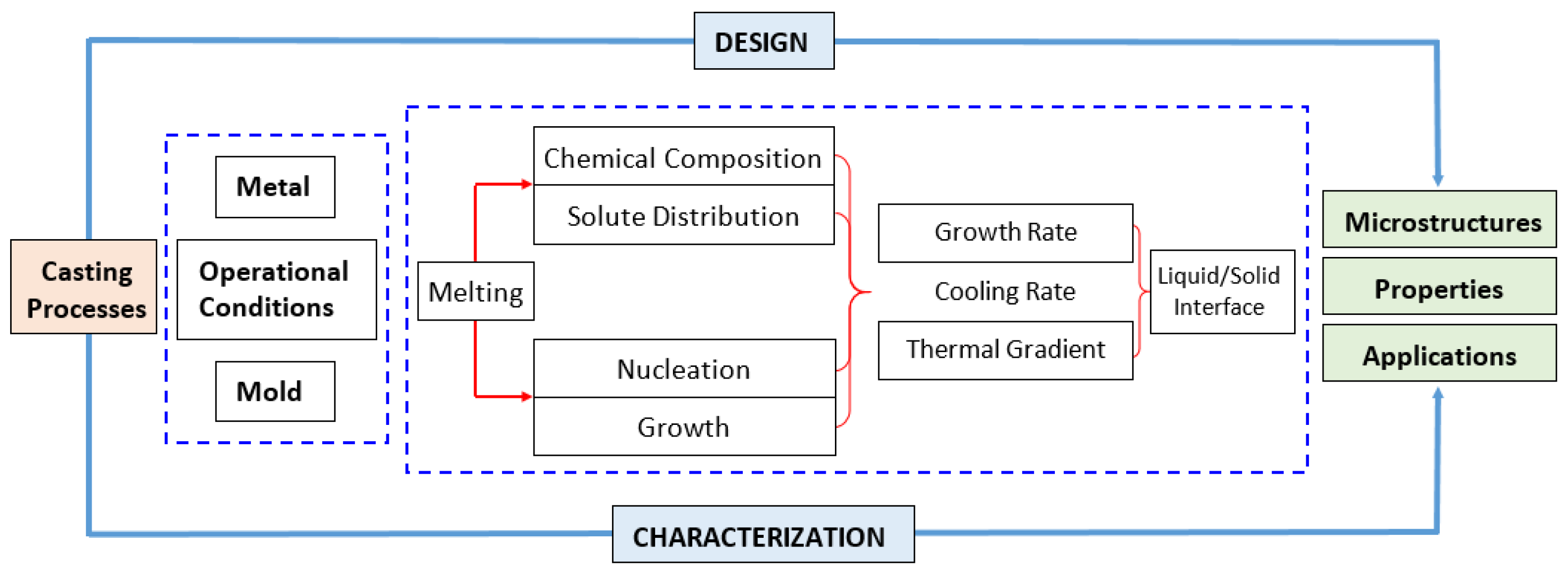

Casting Alloy Design and Characterization

Abstract

:1. Introduction

2. Contributions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Quaresma, J.M.V.; Santos, C.A.; Garcia, A. Correlation between unsteady-state solidification conditions, dendrite spacings, and mechanical properties of Al-Cu alloys. Metall. Mater. Trans. A 2000, 31, 3167–3178. [Google Scholar] [CrossRef]

- Santos, C.A.; Quaresma, J.M.V.; Garcia, A. Determination of transient interfacial heat transfer coefficients in chill mold castings. J. Alloys Compd. 2001, 319, 174–186. [Google Scholar] [CrossRef]

- Barcellos, V.K.; Ferreira, C.R.F.; Santos, C.A.; Spim, J.A. Analysis of metal mould heat transfer coefficients during continuous casting of steel. Ironmak. Steelmak. 2010, 37, 47–56. [Google Scholar] [CrossRef]

- Spinelli, J.E.; Tosetti, J.P.; Santos, C.A.; Spim, J.A.; Garcia, A. Microstructure and solidification thermal parameters in thin strip continuous casting of a stainless steel. J. Mater. Process. Technol. 2004, 150, 255–262. [Google Scholar] [CrossRef]

- Costa, A.M.; Costa, C.E.; Vecchia, F.D.; Ricka, C.; Scherer, M.; Santos, C.A.; Dedavid, B.A. Study of the influence of copper and magnesium additions on the microstructure formation of Zn–Al hypoeutectic alloys. J. Alloys Compd. 2009, 448, 89–99. [Google Scholar] [CrossRef]

- Porás, B.R.; França, R.P.; Spim, J.A.; Garcia, A.; Costa, E.M.; Santos, C.A. The effects of dendrite arm spacings (as-cast) and aging time (solution heat-treated) of Al-Cu alloy on hardness. J. Alloys Compd. 2013, 549, 324–335. [Google Scholar] [CrossRef]

- Chen, R.; Xu, Q.; Guo, H.; Xia, Z.; Wu, Q.; Liu, B. Correlation of solidification microstructure refining scale, Mg composition and heat treatment conditions with mechanical properties in Al-7Si-Mg cast aluminum alloys. Mater. Sci. Eng. A 2017, 685, 391–402. [Google Scholar] [CrossRef]

- Bartex, S.L.T.; Santos, C.A.; Barcellos, V.K.; Schaeffer, L. Effect of solid fraction on microstructures and mechanical properties of a Mg-Al-La-Ca alloy processed by rheocasting. J. Alloys Compd. 2019, 776, 297–305. [Google Scholar] [CrossRef]

- Ferreira, I.L.; Garcia, A. The application of numerical and analytical approaches for the determination of thermophysical properties of Al–Si–Cu–Mg alloys. Contin. Mech. Thermodyn. 2020, 32, 1231–1244. [Google Scholar] [CrossRef]

- Ferreira, I.; Santos, C.A.; Garcia, A.; Voller, V. Analytical, numerical, and experimental analysis of inverse macrosegregation during upward unidirectional solidification of Al-Cu alloys. Metall. Mater. Trans. B 2004, 35, 285–297. [Google Scholar] [CrossRef] [Green Version]

- Jung, I.-H.; Van Ende, M.-A. Computational thermodynamic calculations: FactSage from CALPHAD thermodynamic database to virtual process simulation. Metall. Mater. Trans. B 2020, 51, 1851–1874. [Google Scholar] [CrossRef]

- Santos, C.A.; Spim, J.A.; Ierardi, M.C.F.; Garcia, A. The use of artificial intelligence technique for the optimisation of process parameters used in the continuous casting of steel. Appl. Math. Model. 2002, 26, 1077–1092. [Google Scholar] [CrossRef]

- Santos, C.A.; Fortaleza, E.L.; Frick, C.R.F.; Spim, J.A.; Garcia, A. A solidification heat transfer model and a neural network based algorithm applied to the continuous casting of steel billets and blooms, Model. Simul. Mater. Sci. Eng. 2005, 13, 1071–1087. [Google Scholar] [CrossRef]

- Santos, C.A.; Cheung, N.; Garcia, A.; Spim, J.A. Application of a solidification mathematical model and a genetic algorithm in the optimization of strand thermal profile along the continuous casting of steel. Mater. Manuf. Processes 2005, 20, 421–434. [Google Scholar] [CrossRef]

- Cheung, N.; Santos, C.A.; Spim, J.A.; Garcia, A. Application of a heuristic search technique for the improvement of spray zones cooling conditions in continuously cast steel billets. Appl. Math. Model. 2006, 30, 104–115. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, I.L.; Siqueira, C.A.; Santos, C.A.; Garcia, A. Influence of Metal/Mold Heat Transfer Coefficient on the Inverse Macrosegregation Profile of an Al-6.2wt% Cu Alloy Unidirectionally Solidified. Mater. Sci. Forum 2004, 455-456, 728–731. [Google Scholar] [CrossRef]

- Santos, C.A.; Siqueira, C.A.; Garcia, A.; Quaresma, J.M.V.; Spim, J.A. Metal–mold heat transfer coefficients during horizontal and vertical Unsteady-State solidification of Al–Cu and Sn–Pb Alloys, Inverse Probl. Sci. Eng. 2004, 12, 279–296. [Google Scholar] [CrossRef]

- Souza, E.N.; Cheung, N.; Santos, C.A.; Garcia, A. Factors affecting solidification thermal variables along the cross-section of horizontal cylindrical ingots, Mater. Sci. Eng. A 2005, 397, 239–248. [Google Scholar] [CrossRef]

- Santos, C.A.; Garcia, A.; Frick, C.R.F.; Spim, J.A. Evaluation of heat transfer coefficients along the secondary cooling zones in the continuous casting of steel billets, Inverse Probl. Sci. Eng. 2006, 14, 687–700. [Google Scholar] [CrossRef]

- Melo, M.L.N.; Penhalber, C.L.; Pereira, N.A.; Pelliciari, C.L., Jr.; Santos, C.A. Numerical and experimental analysis of microstructure formation during stainless steels solidification, J. Mater. Sci. 2007, 42, 2267–2275. [Google Scholar] [CrossRef]

- Dedavid, B.A.; Costa, E.M.; Ferreira, C.R.F. A Study of precipitates formation in AA 380.0 aluminium alloys modified by the addition of magnesium. J. Therm. Anal. Calorim. 2002, 67, 473–480. [Google Scholar] [CrossRef]

- Costa, E.M.; Compani, M.; Floriani, A.R.; Dedadvid, B.A. AA 380 Aluminum alloy-based metal matrix composites reinforced with alumina produced by compocasting process. Acta Microsc. 2003, 12, 253–254. [Google Scholar]

- Hönnicke, M.G.; Mazzaro, I.; Manica, J. Structural Characterization of doped GaSb single crystals by X-ray topography. J. Electron. Mater. 2010, 39, 727–731. [Google Scholar] [CrossRef] [Green Version]

- Barcellos, V.K.; Ferreira, C.R.F.; Spim, J.A.; Santos, C.A.; Garcia, A. The Interrelation between casting size, steel grade, and temperature evolution along the mold length and at the strand surface during continuous casting of steel. Mater. Manuf. Processes 2011, 26, 113–126. [Google Scholar] [CrossRef]

- Streicher, M.; Corregidor, V.; Catarino, N.; Alves, L.C.; Franco, N.; Fonseca, M.; Martins, L.; Alves, E.; Costa, E.M.; Dedavid, B.A. Study of In distribution on GaInSb: Al crystals by ion beam techniques. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2016, 371, 278–282. [Google Scholar] [CrossRef]

- Guterres, A.M.; Oliveira, C.A.L.; Santos. C.A. Influence of chemical composition, porosity and aging in the mechanical properties of Al-Si-Mg alloys. Tecnol. Metal. Mater. Min. 2019, 16, 316–324. [Google Scholar] [CrossRef]

- Ribeiro, T.M.; Catellan, E.; Garcia, A.; Santos, C.A. The effects of Cr addition on microstructure, hardness and tensile properties of as-cast Al–3.8wt.%Cu–(Cr) alloys. J. Mater. Res. Technol. 2020, 9, 6620–6631. [Google Scholar] [CrossRef]

- Werlang, A.F.; Souza, B.V.; Santos, C.A. Effect of heat treatments on austempered ductile iron. Mater. Manuf. Processes 2015, 30, 1317–1323. [Google Scholar] [CrossRef]

- Filho, A.W.; Souza, B.V.; Santos, C.A. The Influence of austempering conditions on the machinability of a ductile iron. Mater. Manuf. Processes 2016, 31, 1836–1843. [Google Scholar] [CrossRef]

- Souza, B.V.; Ribeiro, T.M.; Francois, A.; Santos, C.A. Austempering heat treatments of ductile iron using molten metal baths. Mater. Manuf. Processes 2018, 33, 1667–1673. [Google Scholar] [CrossRef]

- Porás, B.R.; Lopes, M.M.; Garcia, A.; Santos, C.A. The correlation of microstructure features, dry sliding wear behavior, hardness and tensile properties of Al-2wt%Mg-Zn alloys. J. Alloys Compd. 2018, 764, 267–278. [Google Scholar] [CrossRef]

- Ache, C.T.; Lopes, M.M.; Porás, B.R.; Garcia, A.; Santos, C.A. Dendritic spacing/columnar grain diameter of Al–2Mg–Zn alloys affecting hardness, tensile properties, and dry sliding wear in the as-cast/heat-treated conditions. Adv. Eng. Mater. 2020, 1, 1901145. [Google Scholar] [CrossRef]

- Bonetti, I.; Almeida, E.A.S.; Costa, C.E.; Paredes, R.S.C.; Sucharski, G.B.; Costa, E.M.; Franco, E.; Milan, J.C. Effect of flame spray deposition parameters on the microstructure, microhardness and corrosion resistance of FeNbC coatings on AISI 1020 steel. Mater. Res. Express 2019, 6, 086530. [Google Scholar] [CrossRef]

- Rosso, E.; Santos, C.A.; Garcia, A. Microstructure, hardness, tensile strength, and sliding wear of hypoeutectic Al–Si cast alloys with small Cr additions and Fe-impurity content. Adv. Eng. Mater. 2021, 1, 2001552. [Google Scholar] [CrossRef]

- Machado, P.A.B.; Quaresma, J.M.V.; Garcia, A.; Santos, C.A. Investigation on machinability in turning of as-cast and T6 heat-treated Al-(3, 7, 12%)Si-0.6%Mg alloys. J. Manuf. Processes 2022, 75, 514–526. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Da Costa, E.M.; Dos Santos, C.A. Casting Alloy Design and Characterization. Metals 2022, 12, 1228. https://doi.org/10.3390/met12071228

Da Costa EM, Dos Santos CA. Casting Alloy Design and Characterization. Metals. 2022; 12(7):1228. https://doi.org/10.3390/met12071228

Chicago/Turabian StyleDa Costa, Eleani Maria, and Carlos Alexandre Dos Santos. 2022. "Casting Alloy Design and Characterization" Metals 12, no. 7: 1228. https://doi.org/10.3390/met12071228

APA StyleDa Costa, E. M., & Dos Santos, C. A. (2022). Casting Alloy Design and Characterization. Metals, 12(7), 1228. https://doi.org/10.3390/met12071228