Fabrication Techniques and the Formation Mechanism of Nanoparticles and Nanoclusters in Metal Materials

Abstract

:1. Introduction

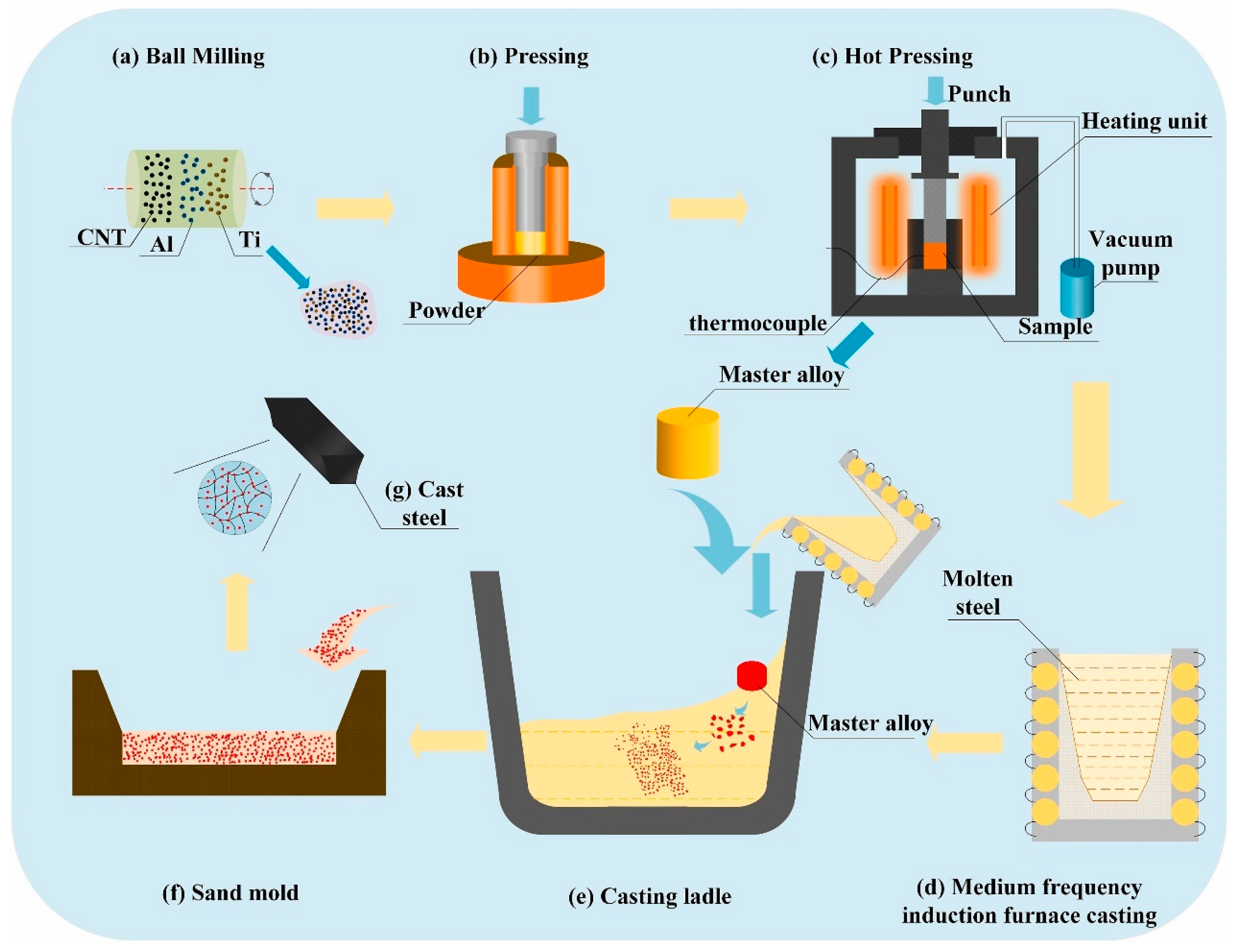

2. Formation of Nanoparticles and Nanoclusters

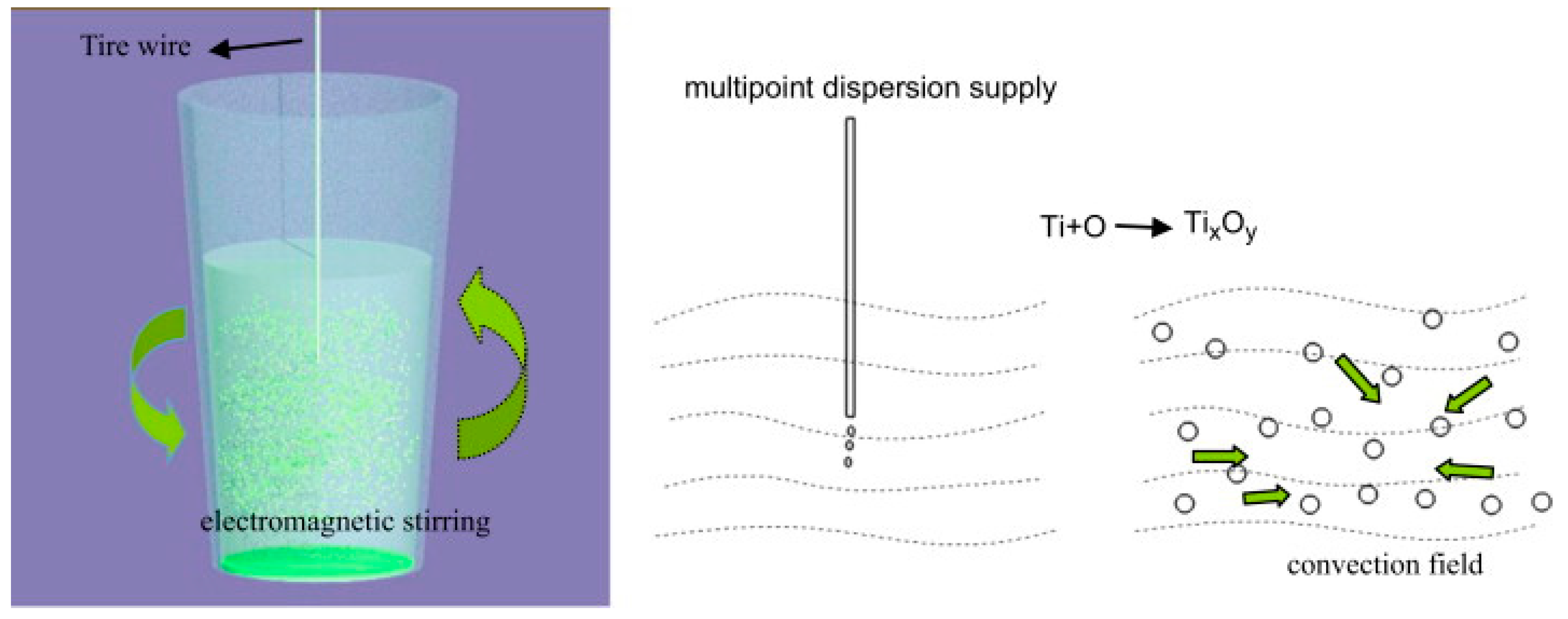

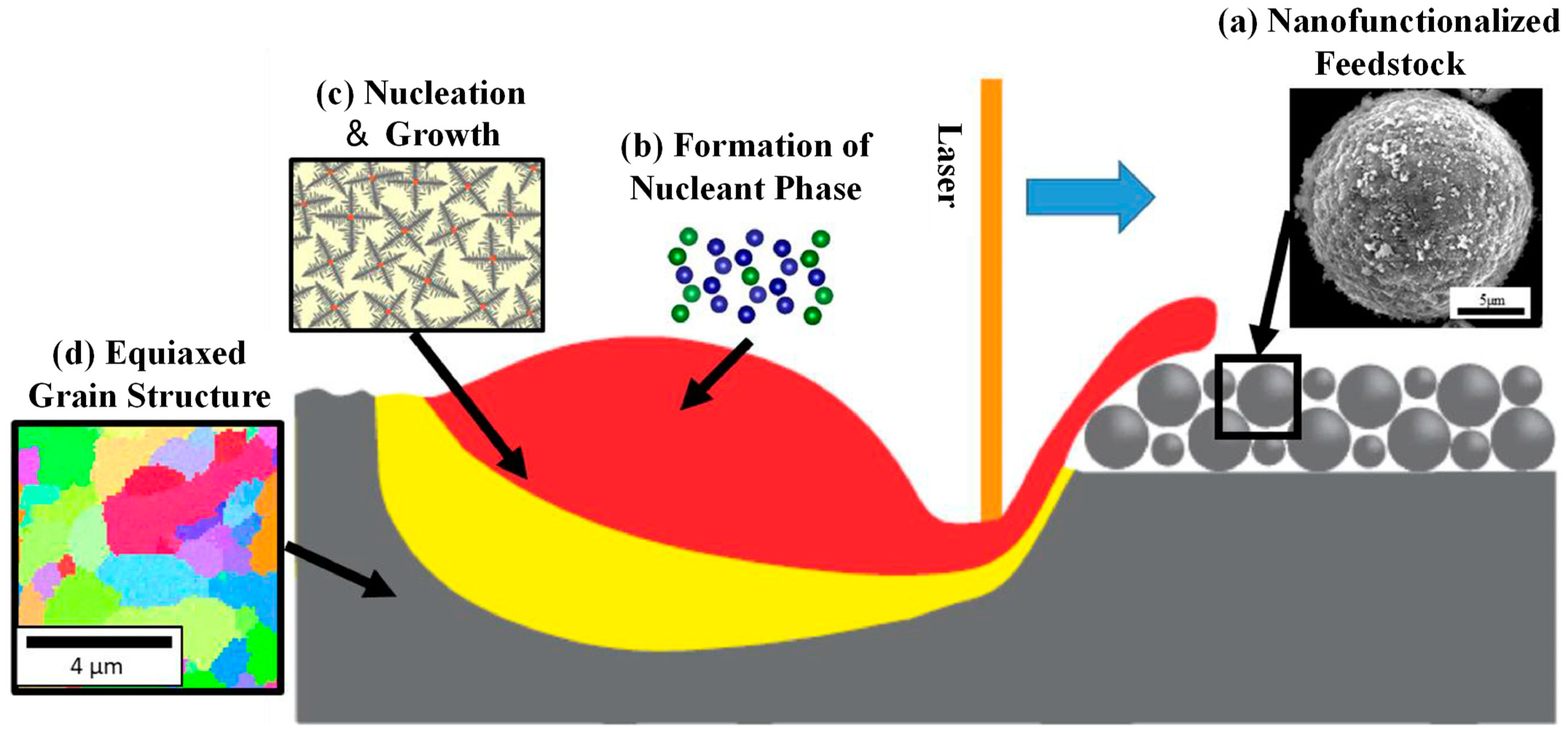

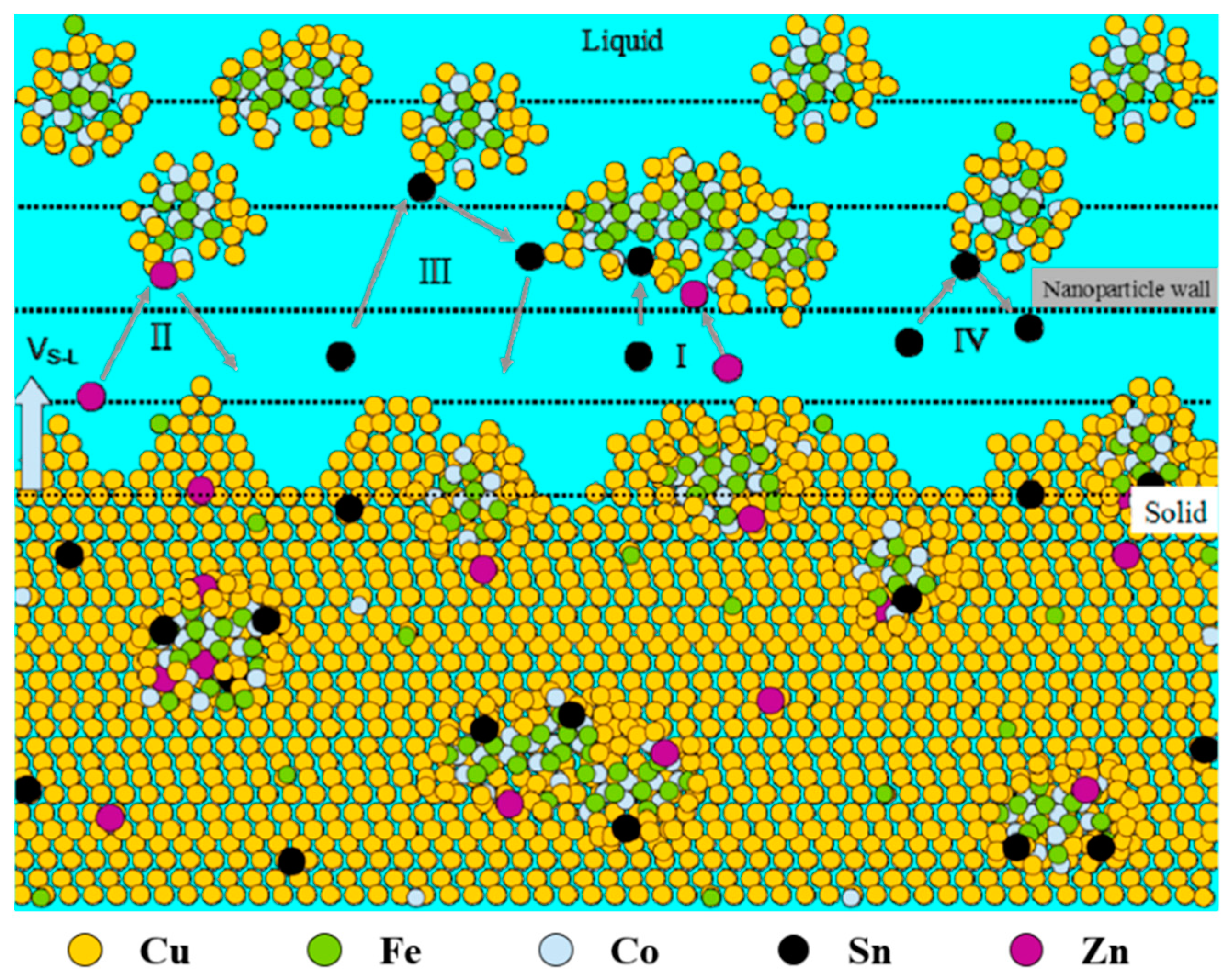

2.1. Formation Mechanism of In Situ Nanoparticles during Solidification

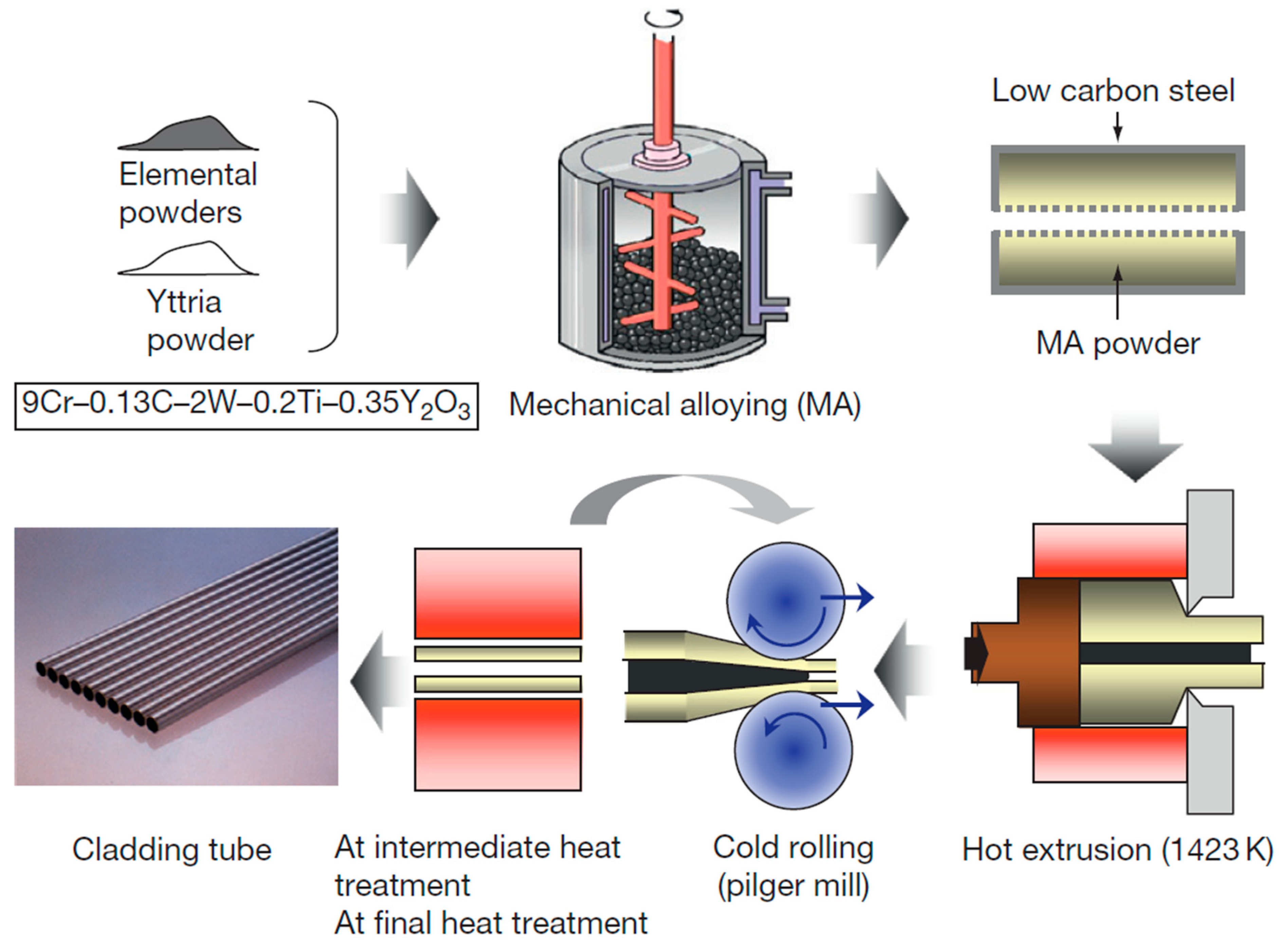

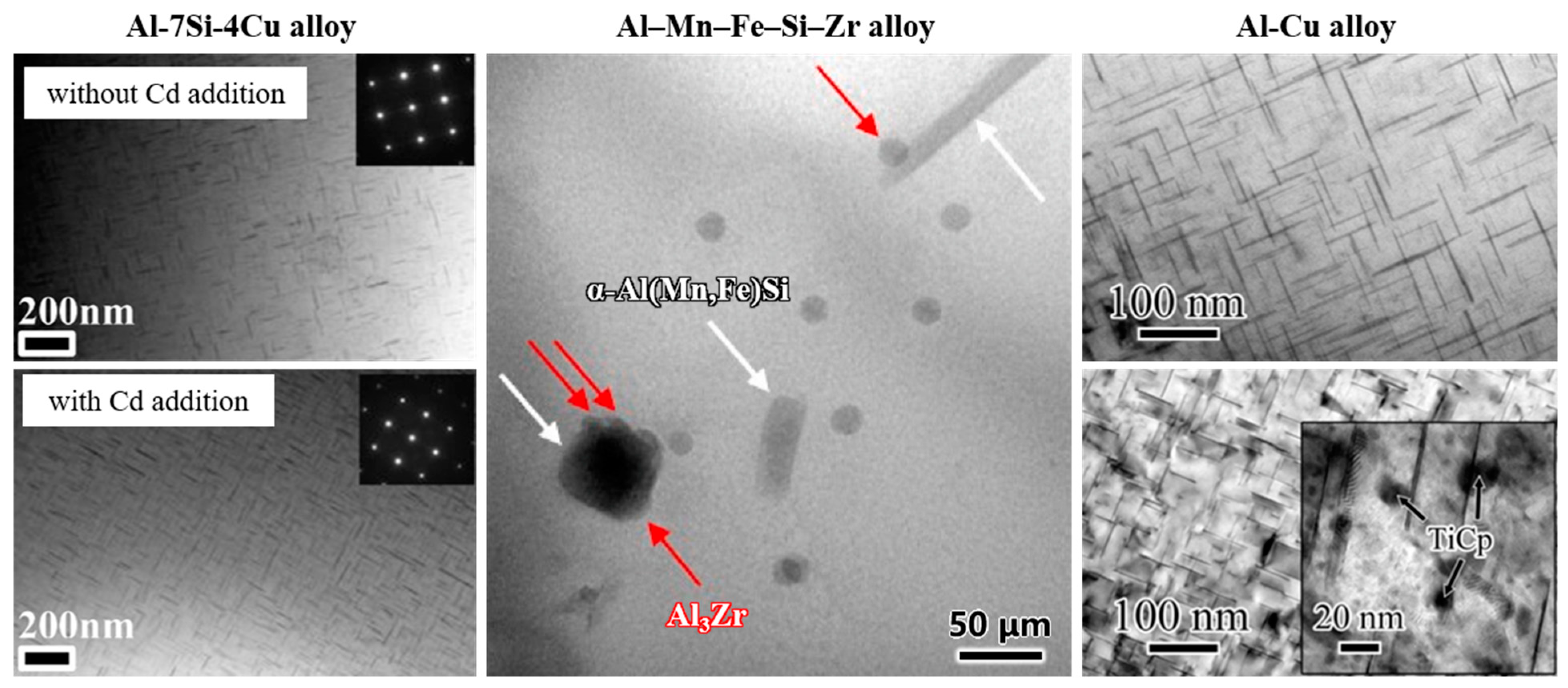

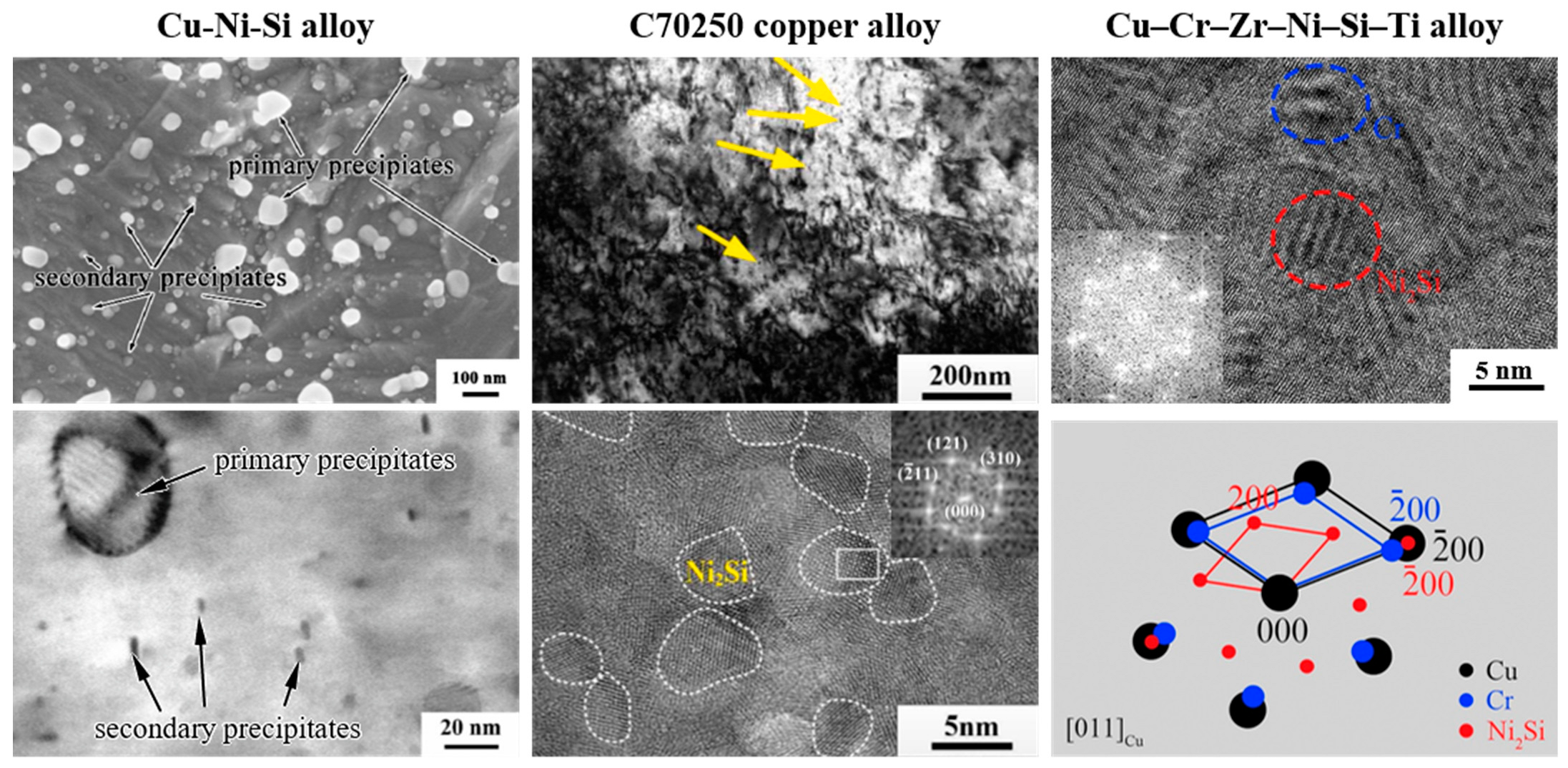

2.2. Formation of In Situ Nanoparticles during Deformation and Heat Treatment

2.3. Technology of Introducing Ex Situ Nanoparticles into Metallic Materials

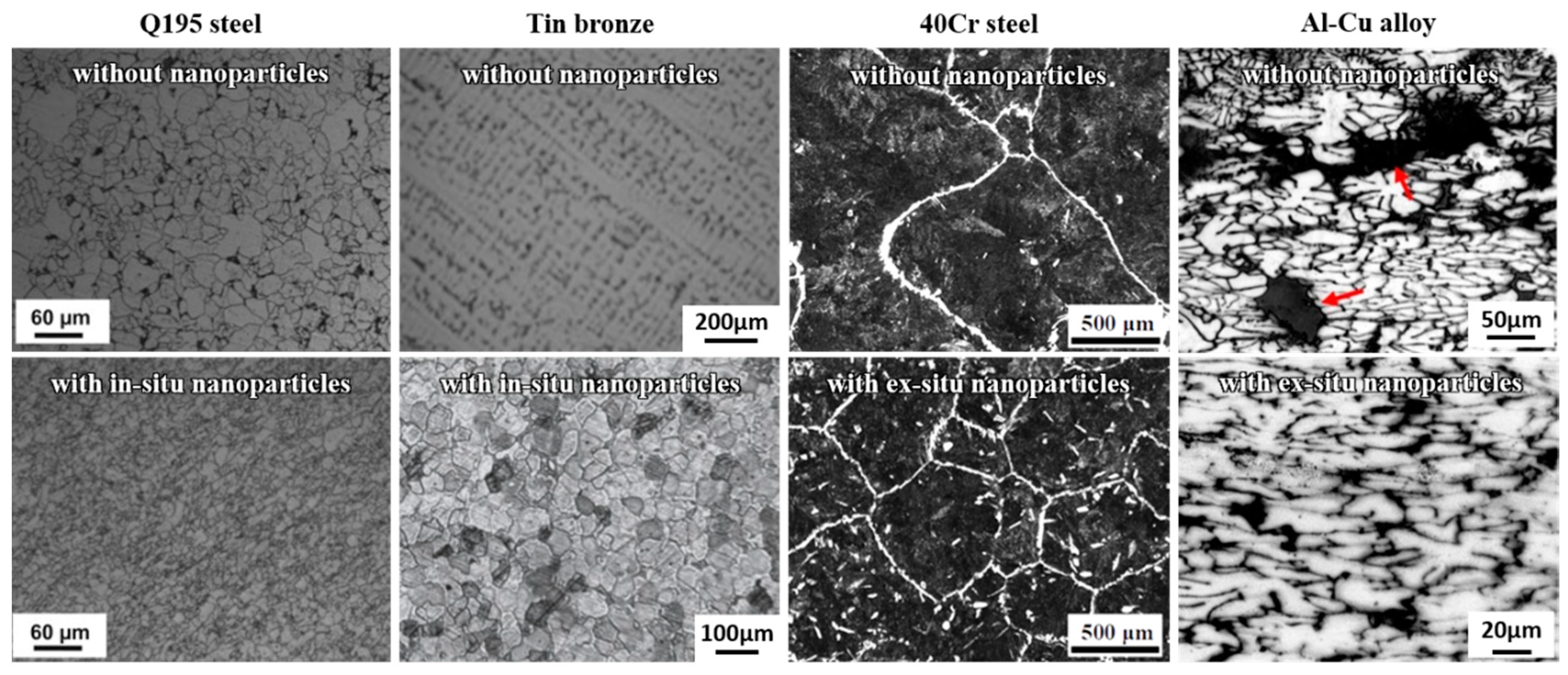

3. Optimization of Microstructure

3.1. Grain Refinement

3.2. Inhibiting Segregation

3.3. Refinement of Second Phases and Inclusions

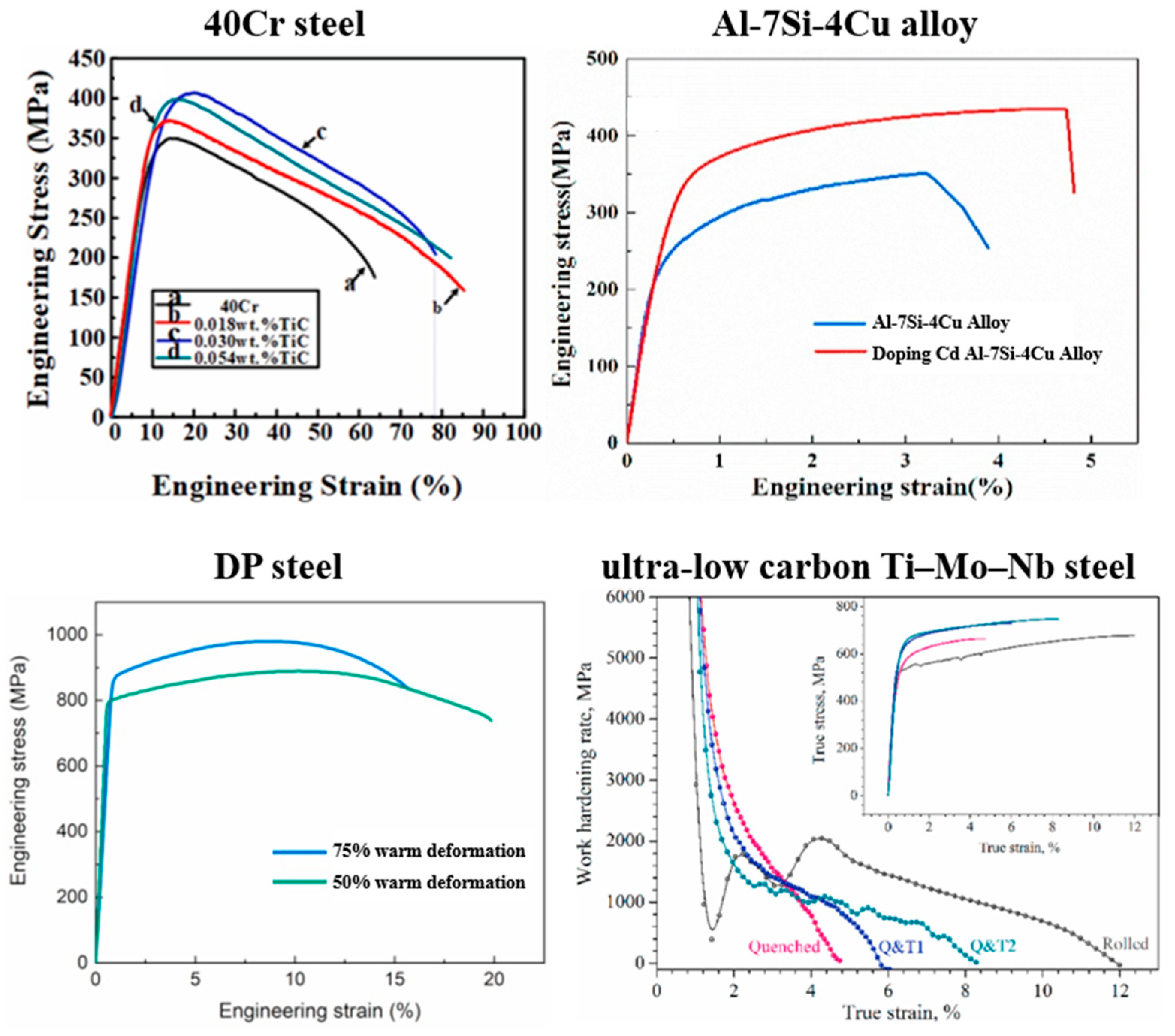

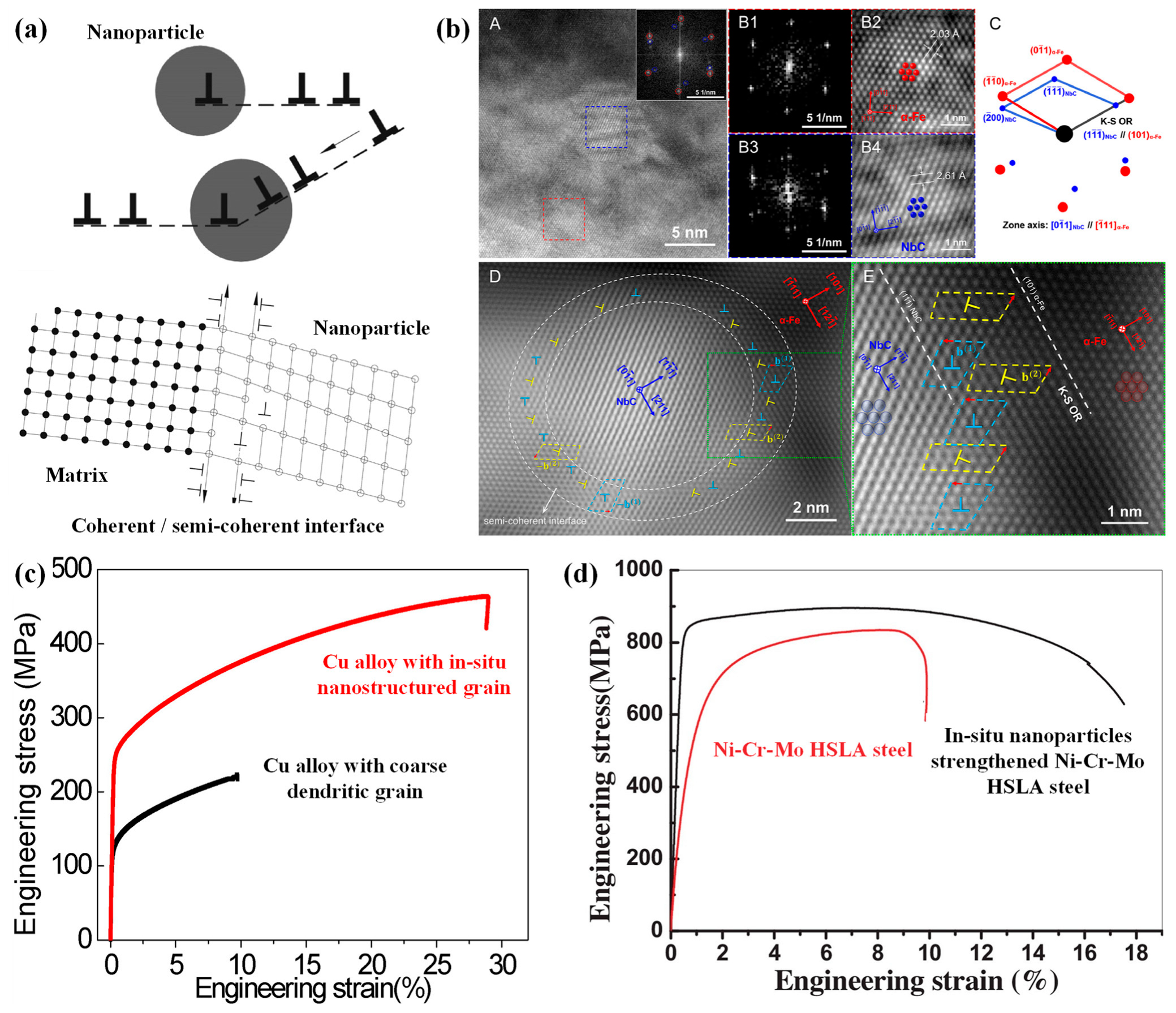

4. Enhancement of Mechanical Properties

5. Conclusions and Prospect

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dutta, R.K.; Petrov, R.H.; Delhez, R.; Hermans, M.J.M.; Richardson, I.M.; Böttger, A.J. The effect of tensile deformation by in situ ultrasonic treatment on the microstructure of low-carbon steel. Acta Mater. 2013, 61, 1592–1602. [Google Scholar] [CrossRef]

- Zhou, P.S.; Wang, B.; Wang, L.; Hu, Y.W.; Zhou, L. Effect of welding heat input on grain boundary evolution and toughness properties in CGHAZ of X90 pipeline steel. Mater. Sci. Eng. A 2018, 722, 112–121. [Google Scholar] [CrossRef]

- Chen, K.; Zhang, J.; Chen, X.; Wang, Z.; Shi, R.; Zhang, A. The effect of iron on the microstructure and mechanical properties of a cast Cu–12Sn-1.5Ni (wt.%) alloy. Mater. Sci. Eng. A 2020, 785, 139330. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Q.L.; Ji, Z.W.; Wang, B.; Zhu, Y.L.; Jiang, Q.C. Effectively mitigated macro-segregation and improved tensile properties of twin-roll casting Al-Cu strips via the addition of TiC nanoparticles. J. Mater. Process. Technol. 2021, 296, 117200. [Google Scholar] [CrossRef]

- Zhang, H.T.; Fu, H.D.; Zhu, S.C.; Yong, W.; Xie, J.X. Machine learning assisted composition effective design for precipitation strengthened copper alloys. Acta Mater. 2021, 215, 117118. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, X.; Chen, K.; Wang, Y.; Wang, Z. Quasi in situ observation of twinning evolution during strain path change in magnesium alloy. J. Mater. Res. 2022, 37, 1125–1132. [Google Scholar] [CrossRef]

- Ma, E.; Zhu, T. Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater. Today 2017, 20, 323–331. [Google Scholar] [CrossRef]

- Lu, K. Materials science. The future of metals. Science 2010, 328, 319–320. [Google Scholar] [CrossRef]

- Hall, E.O. The Deformation and Ageing of Mild Steel: III Discussion of Results. Proc. Phys. Soc. Sect. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Shi, R.; Wang, Z.; Qiao, L.; Pang, X. Microstructure evolution of in-situ nanoparticles and its comprehensive effect on high strength steel. J. Mater. Sci. Technol. 2019, 35, 1940–1950. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.; Mayer, J.; Mone, R.; Stonkevitch, E.; Miller, J.; O’Masta, M.R.; Schaedler, T.; Hundley, J.; Callahan, P.; et al. Grain refinement mechanisms in additively manufactured nano-functionalized aluminum. Acta Mater. 2020, 200, 1022–1037. [Google Scholar] [CrossRef]

- Tang, H.; Chen, X.; Luo, X.; Chen, M.; Wang, Z.; Zuo, L. Heterogeneous nucleation effect of in situ nanoparticles on the metal–matrix microstructure. Mater. Lett. 2014, 137, 455–459. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Shaeri, M.H.; Naseri, R.; Gode, C. Equal channel angular extrusion for tube configuration of Al-Zn-Mg-Cu alloy. Mater. Sci. Eng. A 2018, 731, 569–576. [Google Scholar] [CrossRef]

- Muñoz, J.A.; Komissarov, A.; Avalos, M.; Bolmaro, R.E. Mechanical and microstructural behavior of a heterogeneous austenitic stainless steel processed by Equal Channel Angular Sheet Extrusion (ECASE). Mater. Sci. Eng. A 2020, 792, 139779. [Google Scholar] [CrossRef]

- Jiang, Y.; Gu, R.C.; Peterlechner, M.; Liu, Y.W.; Wang, J.T.; Wilde, G. Impurity effect on recrystallization and grain growth in severe plastically deformed copper. Mater. Sci. Eng. A 2021, 824, 141786. [Google Scholar] [CrossRef]

- Oh, J.; Park, S.; Bae, H.J.; Son, S.; Kim, H.S.; Seol, J.B.; Sung, H.; Kim, J.G. Mechanical properties and microstructural evolution of high-pressure torsion-processed Al7075 alloy at elevated temperatures. Mater. Sci. Eng. A 2022, 835, 142692. [Google Scholar] [CrossRef]

- Jang, G.; Kim, J.N.; Lee, H.; Lee, T.; Enikeev, N.; Abramova, M.; Valiev, R.Z.; Kim, H.S.; Lee, C.S. Microstructural evolution and mechanical properties of nanocrystalline Fe–Mn–Al–C steel processed by high-pressure torsion. Mater. Sci. Eng. A 2021, 827, 142073. [Google Scholar] [CrossRef]

- Manjunath, G.A.; Shivakumar, S.; Fernandez, R.; Nikhil, R.; Sharath, P.C. A review on effect of multi-directional forging/multi-axial forging on mechanical and microstructural properties of aluminum alloy. Mater. Today Proc. 2021, 47, 2565–2569. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abou-Ras, D.; Maghsoudi, M.H.; Ghorbani, A.; Kawasaki, M. An investigation into the homogeneity of microstructure, strain pattern and hardness of pure aluminum processed by accumulative back extrusion. Mater. Sci. Eng. A 2014, 595, 179–187. [Google Scholar] [CrossRef]

- Haghdadi, N.; Zarei-Hanzaki, A.; Abou-Ras, D. Microstructure and mechanical properties of commercially pure aluminum processed by accumulative back extrusion. Mater. Sci. Eng. A 2013, 584, 73–81. [Google Scholar] [CrossRef]

- Rao, G.N.M.; Kumar, V.R.M. A review on recent advances in accumulative roll bonding of similar, dissimilar and metal matrix composites. Mater. Today Proc. 2022, 56, A13–A18. [Google Scholar] [CrossRef]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Fang, T.H.; Li, W.L.; Tao, N.R.; Lu, K. Revealing extraordinary intrinsic tensile plasticity in gradient nano-grained copper. Science 2011, 331, 1587–1590. [Google Scholar] [CrossRef]

- Lu, K. Nanomaterials. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef]

- Wu, X.; Jiang, P.; Chen, L.; Yuan, F.; Zhu, Y.T. Extraordinary strain hardening by gradient structure. Proc. Natl. Acad. Sci. USA 2014, 111, 7197–7201. [Google Scholar] [CrossRef]

- Ghosh, S.; Bibhanshu, N.; Suwas, S.; Chatterjee, K. Surface mechanical attrition treatment of additively manufactured 316L stainless steel yields gradient nanostructure with superior strength and ductility. Mater. Sci. Eng. A 2021, 820, 141540. [Google Scholar] [CrossRef]

- Olugbade, T.O.; Lu, J. Literature review on the mechanical properties of materials after surface mechanical attrition treatment (SMAT). Nano Mater. Sci. 2020, 2, 3–31. [Google Scholar] [CrossRef]

- Zhou, X.; Li, X.; Lu, K. 70 nm: The most unstable grain size in Cu prepared by surface mechanical grinding treatment. Nano Mater. Sci. 2020, 2, 32–38. [Google Scholar] [CrossRef]

- Long, J.; Pan, Q.; Tao, N.; Dao, M.; Suresh, S.; Lu, L. Improved fatigue resistance of gradient nanograined Cu. Acta Mater. 2019, 166, 56–66. [Google Scholar] [CrossRef]

- Lei, Y.B.; Wang, Z.B.; Zhang, B.; Luo, Z.P.; Lu, J.; Lu, K. Enhanced mechanical properties and corrosion resistance of 316L stainless steel by pre-forming a gradient nanostructured surface layer and annealing. Acta Mater. 2021, 208, 116773. [Google Scholar] [CrossRef]

- Mei, X.M.; Mei, Q.S.; Li, J.Y.; Li, C.L.; Wan, L.; Chen, F.; Chen, Z.H.; Xu, T.; Wang, Y.C.; Tan, Y.Y. Solid-state alloying of Al-Mg alloys by accumulative roll-bonding: Microstructure and properties. J. Mater. Sci. Technol. 2022, 125, 238–251. [Google Scholar] [CrossRef]

- Edry, I.; Shoihet, A.; Hayun, S. On the effects of electric current intensity and pulse frequency on the solidified structure of pure aluminum subjected to pulse magneto-oscillation treatment. J. Mater. Processing Technol. 2021, 288, 116844. [Google Scholar] [CrossRef]

- Vorontsov, A.; Astafurov, S.; Melnikov, E.; Moskvina, V.; Kolubaev, E.; Astafurova, E. The microstructure, phase composition and tensile properties of austenitic stainless steel in a wire-feed electron beam melting combined with ultrasonic vibration. Mater. Sci. Eng. A 2021, 820, 141519. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, K.; Li, Y.; Feng, X.; Luo, T. Solidification Structure Control by the Interaction of Pulsed Magnetic Field and Melt. Procedia Manuf. 2019, 37, 621–626. [Google Scholar] [CrossRef]

- Stephenson, P.L.; Haghdadi, N.; DeMott, R.; Liao, X.Z.; Ringer, S.P.; Primig, S. Effect of scanning strategy on variant selection in additively manufactured Ti-6Al-4V. Addit. Manuf. 2020, 36, 101581. [Google Scholar] [CrossRef]

- Mostafaei, A.; Hilla, C.; Stevens, E.L.; Nandwana, P.; Elliott, A.M.; Chmielus, M. Comparison of characterization methods for differently atomized nickel-based alloy 625 powders. Powder Technol. 2018, 333, 180–192. [Google Scholar] [CrossRef]

- Sun, L.; Liu, Y.; Li, J.; Chen, K.; Gao, Y.; Yang, G. Morphology and microstructure of Fe–Cr–W–B alloy powders prepared by argon gas atomization. Vacuum 2022, 200, 111046. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Yuan, G.; Zhang, Y.X.; Liu, C.Y.; Fang, F.; Wang, G.D.; Misra, R.D.K. Cu-based amorphous alloy plates fabricated via twin-roll strip casting. Mater. Sci. Eng. A 2021, 828, 142123. [Google Scholar] [CrossRef]

- Fang, F.; Che, S.; Hou, D.; Zhang, Y.; Wang, Y.; Zhang, W.; Yuan, G.; Zhang, X.; Misra, R.D.K.; Wang, G. Thin-gauge non-oriented silicon steel with balanced magnetic and mechanical properties processed by strip casting. Mater. Sci. Eng. A 2022, 831, 142284. [Google Scholar] [CrossRef]

- Geng, Y.; Ban, Y.; Li, X.; Zhang, Y.; Jia, Y.; Tian, B.; Zhou, M.; Liu, Y.; Volinsky, A.A.; Song, K.; et al. Excellent mechanical properties and high electrical conductivity of Cu-Co-Si-Ti alloy due to multiple strengthening. Mater. Sci. Eng. A 2021, 821, 141639. [Google Scholar] [CrossRef]

- Gleiter, H. Nanostructured materials: Basic concepts and microstructure. Acta Mater. 2000, 48, 1–29. [Google Scholar] [CrossRef]

- Cai, M.; Chen, L.; Fang, K.; Huang, H.; Hodgson, P. The effects of a ferritic or martensitic matrix on the tensile behavior of a nano-precipitation strengthened ultra-low carbon Ti–Mo–Nb steel. Mater. Sci. Eng. A 2021, 801, 140410. [Google Scholar] [CrossRef]

- Lei, G.; Wang, B.; Lu, J.; Wang, C.; Li, Y.; Luo, F. Effects of solid solution temperature on the microstructure and properties of 6013 aluminum alloy. Mater. Chem. Phys. 2022, 280, 125829. [Google Scholar] [CrossRef]

- Huang, C.Y.; Yen, H.W. HRTEM investigations on nano precipitates in Custom 475 maraging stainless steel. Mater. Charact. 2021, 178, 111216. [Google Scholar] [CrossRef]

- Gao, X.; Wang, H.; Xing, L.; Ma, C.; Li, Y.; Sha, G.; Ren, H. The synergistic effects of ultrafine grains and nano-size Cu-rich precipitates on the mechanical properties of DP steels. Mater. Sci. Eng. A 2021, 805, 140547. [Google Scholar] [CrossRef]

- Pan, S.; Chen, X.; Zhou, X.; Wang, Z.; Chen, K.; Cao, Y.; Lu, F.; Li, S. Micro-alloying effect of Er and Zr on microstructural evolution and yield strength of Al-3Cu (wt.%) binary alloys. Mater. Sci. Eng. A 2020, 790, 139391. [Google Scholar] [CrossRef]

- Pereira, V.S.M.; Davis, T.P.; Mayoral, M.H.; Kumar, A.; Schut, H.; Sietsma, J. Investigation of coarsening of oxide nanoparticles at 1400 K and its effect on the microstructure formation of an ODS Eurofer steel. Mater. Charact. 2022, 185, 111723. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, W.X.; Chang, F.; Li, C.L.; Shu, S.L.; Wang, Z.F.; Han, X.; Zou, Q.; Qiu, F.; Jiang, Q.C. Microstructure manipulation and strengthening mechanisms of 40Cr steel via trace TiC nanoparticles. Mat. Sci. Eng. A Struct. 2021, 822, 141693. [Google Scholar] [CrossRef]

- Yang, C.; Zhao, Q.; Zhang, Z.; Li, L.; Tian, W.; Liu, R.; Zhang, P.; Xu, Y.; Li, Y.; Zhang, Z.; et al. Nanoparticle additions promote outstanding fracture toughness and fatigue strength in a cast Al–Cu alloy. Mater. Des. 2020, 186, 108221. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef]

- Chen, M.-W.; Jiang, H.; Wang, Y.-L.; Wang, Q.-S.; Wang, Z.-D. The effect of far-field uniform flow on the particle growth in an undercooled alloy melt. J. Cryst. Growth 2011, 318, 145–149. [Google Scholar] [CrossRef]

- Chen, M.W.; Wang, Y.L.; Zhang, H.; Wu, L.Y.; Wang, Z.D. The interface morphology of a spherical crystal in the undercooled melt affected by a far-field uniform flow. J. Appl. Phys. 2011, 109, 103517. [Google Scholar] [CrossRef]

- Chen, M.W.; He, G.W.; Chen, X.Y.; Wang, Z.D. Interfacial evolution of a spherical particle in a uniaximal straining flow. Chin. Phys. B 2012, 21, 106802. [Google Scholar] [CrossRef]

- Chen, M.-W.; Liu, X.-M.; Yang, Z.-C.; Wang, Z.-D. The asymptotic solution of particle growth in the convective undercooled melt driven by a biaxial straining flow. Acta Mech. Sin. 2015, 31, 73–78. [Google Scholar] [CrossRef]

- Gao, J.; Chen, M.; Wang, Z. Shape evolution of a spherical particle growing in supersaturated solution affected by straining flows. Mod. Phys. Lett. B 2016, 30, 1650059. [Google Scholar] [CrossRef]

- Chen, M.; Liu, W.; Wang, Z. The asymptotic solution for the particle growth in the undercooled melt driven by a straining flow. Mod. Phys. Lett. B 2019, 33, 1950398. [Google Scholar] [CrossRef]

- Chen, M.-W.; Wang, X.-F.; Wang, F.; Lin, G.-B.; Wang, Z.-Z. The effect of interfacial kinetics on the morphological stability of a spherical particle. J. Cryst. Growth 2013, 362, 20–23. [Google Scholar] [CrossRef]

- Chen, M.; Ji, X.; Xu, X.; Zheng, Y.; Qian, P.; Wang, Z. The effect of the shear flow on particle growth in the undercooled melt. J. Cryst. Growth 2014, 401, 116–119. [Google Scholar] [CrossRef]

- Chen, M.-W.; Mi, J.-X.; Wang, Z.-D. The effect of oscillatory flow on nucleation and grain growth in the undercooled melt. J. Cryst. Growth 2017, 468, 32–37. [Google Scholar] [CrossRef]

- Chen, M.W.; Li, L.Y.; Guo, H.M. The dynamics of nucleation and growth of a particle in the ternary alloy melt with anisotropic surface tension. J. Chem. Phys. 2017, 147, 084707. [Google Scholar] [CrossRef]

- Chen, M.W.; Wang, Y.X.; Guo, H.M. The effect of anisotropic surface tension on interfacial evolution of a particle in the binary alloy melt. J. Cryst. Growth 2019, 510, 32–39. [Google Scholar] [CrossRef]

- Jiang, H.; Chen, M.W.; Wang, Z.D. Effect of Anisotropic Surface Tension on the Morphological Stability of Deep Cellular Crystal Growth in Directional Solidification. Surf. Rev. Lett. 2019, 26, 1850210. [Google Scholar] [CrossRef]

- Tang, H.; Chen, X.; Chen, M.; Zuo, L.; Hou, B.; Wang, Z. Microstructure and mechanical property of in-situ nano-particle strengthened ferritic steel by novel internal oxidation. Mater. Sci. Eng. A 2014, 609, 293–299. [Google Scholar] [CrossRef]

- Shi, R.; Tu, Y.; Gao, K.; Qiao, L.; Pang, X. High stress corrosion cracking resistance of in-situ nanoparticle strengthened steel. Corros. Commun. 2022, 5, 14–24. [Google Scholar] [CrossRef]

- Pan, P.; Tang, H.; Chen, X.; Wang, Z.; Zuo, L.; Yang, M.; Cao, Y. Effects of direct-quenching and tempering on the microstructure and mechanical properties of an ultra-low carbon Ti containing bainite steel. Mater. Sci. Eng. A 2020, 796, 139987. [Google Scholar] [CrossRef]

- Luo, X.; Xu, G.; Chen, X.; Wang, Z. Effect of undercooled austenite ausforming on the role of the M–A constituents in the CGHAZ toughness of the HSLA steels with bainite structure. Mater. Sci. Eng. A 2022, 833, 142571. [Google Scholar] [CrossRef]

- Luo, X.; Wang, Z.; Chen, X.; Wang, Y.; Xu, G. Modifying of microstructure and toughness in the weld metal prepared by welding wire containing nanosized titanium oxides. Mater. Sci. Eng. A 2021, 807, 140897. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, L.; Tang, H.; Luo, X.; Zuo, L.; Wang, Z.; Wang, Y. Effect of nanoparticles formed in liquid melt on microstructure and mechanical property of high strength naval steel. J. Mater. Process. Technol. 2015, 222, 224–233. [Google Scholar] [CrossRef]

- Niu, Y.; Tang, H.; Wang, Y.; Chen, X.; Wang, Z.; Chen, K.; Wu, Y.; Liu, X. Effect of In Situ Nano-Particles on the Microstructure and Mechanical Properties of Ferritic Steel. Steel Res. Int. 2016, 87, 1389–1394. [Google Scholar] [CrossRef]

- Shi, R.; Ma, Y.; Wang, Z.; Gao, L.; Yang, X.-S.; Qiao, L.; Pang, X. Atomic-scale investigation of deep hydrogen trapping in NbC/α-Fe semi-coherent interfaces. Acta Mater. 2020, 200, 686–698. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Wang, Q.; Shih, I.; Xu, J.J. Fabrication of a nanocomposite from in situ iron nanoparticle reinforced copper alloy. Nanotechnology 2009, 20, 075605. [Google Scholar] [CrossRef]

- Chen, X.H.; Wang, Z.D.; Ding, D.; Tang, H.; Qiu, L.L.; Luo, X.; Shi, G.D. Strengthening and toughening strategies for tin bronze alloy through fabricating in-situ nanostructured grains. Mater. Des. 2015, 66, 60–66. [Google Scholar] [CrossRef]

- Shi, G.; Chen, X.; Jiang, H.; Wang, Z.; Tang, H.; Fan, Y. Strengthening mechanisms of Fe nanoparticles for single crystal Cu–Fe alloy. Mater. Sci. Eng. A 2015, 636, 43–47. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Ding, D.; Shi, G.; Wang, Z. Crystallographic features of iron-rich nanoparticles in cast Cu–10Sn–2Zn–1.5Fe–0.5Co alloy. Mater. Charact. 2016, 113, 34–42. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Ding, D.; Shi, G.; Wang, Z. Formation mechanism of in-situ nanostructured grain in cast Cu–10Sn–2Zn–1.5Fe–0.5Co (wt.%) alloy. Mater. Des. 2016, 94, 338–344. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Ding, D.; Shi, G.; Wang, Z. Heterogeneous nucleation effect of in situ iron-rich nanoparticles on grain refinement of copper alloy. Mater. Lett. 2016, 168, 188–191. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Ding, D.; Wang, Z. Effect of in-situ nanoparticle wall on inhibiting segregation of tin bronze alloy. Mater. Lett. 2016, 175, 148–151. [Google Scholar] [CrossRef]

- Chen, K.; Tang, H.; Chen, X.; Ding, D.; Shi, G.; Wang, Z. Morphological instability of spherical nano iron-rich crystal in copper melt. Mater. Lett. 2016, 172, 125–127. [Google Scholar] [CrossRef]

- Chen, K.; Pan, S.; Zhu, Y.; Cheng, Y.; Chen, X.; Wang, Z. In situ observations of crack propagation in as-cast Cu-1.5Fe-0.5Co (wt%) alloy. Mater. Sci. Eng. A 2017, 706, 211–216. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Wang, Z.; Mao, H.; Sandström, R. Optimization of deformation properties in as-cast copper by microstructural engineering. Part I. microstructure. J. Alloys Compd. 2018, 763, 592–605. [Google Scholar] [CrossRef]

- Chen, K.; Chen, X.; Wang, Z. Precipitates-interaction capture of nano-sized iron-rich precipitates during copper solidification. Mater. Sci. Technol. 2019, 35, 1028–1037. [Google Scholar] [CrossRef]

- Chen, K.X.; Korzhavyi, P.A.; Demange, G.; Zapolsky, H.; Patte, R.; Boisse, J.; Wang, Z.D. Morphological instability of iron-rich precipitates in Cu Fe Co alloys. Acta Mater. 2019, 163, 55–67. [Google Scholar] [CrossRef]

- Chen, K.; Pan, S.; Chen, X.; Wang, Z.; Sandström, R. Optimisation of deformation properties in as-cast copper by microstructural engineering. Part II. Mechanical properties. J. Alloys Compd. 2020, 812, 151910. [Google Scholar] [CrossRef]

- Chen, K.; Wu, X.; Zhang, A.; Zhang, J.; Chen, X.; Zhu, Y.; Wang, Z. Development of wear resistant Cu-12Sn-1.5Ni alloy via minor addition of Fe during casting process. Appl. Surf. Sci. 2022, 573, 151623. [Google Scholar] [CrossRef]

- Xie, Z.J.; Langelier, B.; Tsai, Y.T.; Shang, C.J.; Yang, J.R.; Subramanian, S.V.; Ma, X.P.; Wang, X.L. Characterization of nano-sized precipitation and dislocations and the correlation with mechanical properties of a low alloy TRIP-aided steel. Mater. Sci. Eng. A 2019, 763, 138149. [Google Scholar] [CrossRef]

- Hou, W.; Liu, Q.; Gu, J. Nano-sized austenite and Cu precipitates formed by using intercritical tempering plus tempering and their effect on the mechanical property in a low carbon Cu bearing 7 Ni steel. Mater. Sci. Eng. A 2020, 780, 139186. [Google Scholar] [CrossRef]

- Niu, M.C.; Yang, K.; Luan, J.H.; Wang, W.; Jiao, Z.B. Cu-assisted austenite reversion and enhanced TRIP effect in maraging stainless steels. J. Mater. Sci. Technol. 2022, 104, 52–58. [Google Scholar] [CrossRef]

- Chen, C.-Y.; Chiu, P.-H.; Yang, Y.-L.; Liu, W.-S.; Chen, Z.-W.; Lin, Y.-H.; Kang, Y.-C. Insight on nano-sized precipitate-hardened Ti-Mo 11Cr-11Ni martensitic stainless steel: Experimental Evidence and Related Patents Investigation. Mater. Today Commun. 2022, 31, 103454. [Google Scholar] [CrossRef]

- Jiang, S.; Wang, H.; Wu, Y.; Liu, X.; Chen, H.; Yao, M.; Gault, B.; Ponge, D.; Raabe, D.; Hirata, A.; et al. Ultrastrong steel via minimal lattice misfit and high-density nanoprecipitation. Nature 2017, 544, 460–464. [Google Scholar] [CrossRef]

- Yang, M.; King, D.J.M.; Povstugar, I.; Wen, Y.; Luan, J.; Kuhn, B.; Jiao, Z.; Wang, C.; Wenman, M.R.; Liu, X. Precipitation behavior in G-phase strengthened ferritic stainless steels. Acta Mater. 2021, 205, 116542. [Google Scholar] [CrossRef]

- Cautaerts, N.; Rauch, E.F.; Jeong, J.; Dehm, G.; Liebscher, C.H. Investigation of the orientation relationship between nano-sized G-phase precipitates and austenite with scanning nano-beam electron diffraction using a pixelated detector. Scr. Mater. 2021, 201, 113930. [Google Scholar] [CrossRef]

- Zhou, Q.; Zhao, X.M.; Li, Z.; Cui, X.J. The Influence of Isothermal Holding Times on Microstructural Evolution of X90 Linepipe Steel. Mater. Res.-Ibero.-Am. J. 2019, 22, e20180605. [Google Scholar] [CrossRef]

- Pereloma, E.V.; Kostryzhev, A.G.; AlShahrani, A.; Zhu, C.; Cairney, J.M.; Killmore, C.R.; Ringer, S.P. Effect of austenite deformation temperature on Nb clustering and precipitation in microalloyed steel. Scr. Mater. 2014, 75, 74–77. [Google Scholar] [CrossRef]

- Xiong, Z.; Timokhina, I.; Pereloma, E. Clustering, nano-scale precipitation and strengthening of steels. Prog. Mater. Sci. 2021, 118, 100764. [Google Scholar] [CrossRef]

- Xiong, R.; Peng, H.; Zhang, T.; Bae, J.W.; Kim, H.S.; Wen, Y. Superior strain-hardening by deformation-induced nano-HCP martensite in Fe–Mn–Si–C high-manganese steel. Mater. Sci. Eng. A 2021, 824, 141864. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, Z.; Jiang, Y.; Lei, Q.; Xie, J. Composition design, phase transition and fabrication of copper alloys with high strength and electrical conductivity. Chin. J. Nonferrous Met. 2019, 29, 2009–2049. [Google Scholar]

- Wang, C.; Fu, H.; Zhang, H.; He, X.; Xie, J. Simultaneous enhancement of mechanical and electrical properties of Cu–Ni–Si alloys via thermo-mechanical process. Mater. Sci. Eng. A 2022, 838, 142815. [Google Scholar] [CrossRef]

- Liao, W.; Yang, H.; Yi, C.; Zheng, J. Effect and mechanism of cold rolling and aging process on microstructure and properties of columnar grain C70250 copper alloy. Mater. Sci. Eng. A 2022, 833, 142577. [Google Scholar] [CrossRef]

- Liao, W.; Liu, X.; Yang, Y. Relationship and mechanism between double cold rolling-aging process, microstructure and properties of Cu–Ni–Si alloy prepared by two-phase zone continuous casting. Mater. Sci. Eng. A 2020, 797, 140148. [Google Scholar] [CrossRef]

- Li, J.; Ding, H.; Li, B.; Wang, L. Microstructure evolution and properties of a Cu–Cr–Zr alloy with high strength and high conductivity. Mater. Sci. Eng. A 2021, 819, 141464. [Google Scholar] [CrossRef]

- Fu, S.; Liu, P.; Chen, X.; Zhou, H.; Ma, F.; Li, W.; Zhang, K. Effect of aging process on the microstructure and properties of Cu–Cr–Ti alloy. Mater. Sci. Eng. A 2021, 802, 140598. [Google Scholar] [CrossRef]

- Liu, W.; Chen, X.; Ahmad, T.; Zhou, C.; Xiao, X.; Wang, H.; Yang, B. Microstructures and mechanical properties of Cu–Ti alloys with ultrahigh strength and high ductility by thermo-mechanical treatment. Mater. Sci. Eng. A 2022, 835, 142672. [Google Scholar] [CrossRef]

- Yan, K.; Chen, Z.; Lu, W.; Zhao, Y.; Le, W.; Naseem, S. Nucleation and growth of Al3Sc precipitates during isothermal aging of Al-0.55 wt% Sc alloy. Mater. Charact. 2021, 179, 111331. [Google Scholar] [CrossRef]

- Chen, K.; Wu, X.; Cao, Y.; Wang, Z.; Zhang, X.; Wu, C.; Chen, M. Enhanced strength and ductility in an Al–Cu–Li alloy via long-term ageing. Mater. Sci. Eng. A 2021, 811, 141092. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, X.; Wang, Z.; Chen, K.; Tang, W.; Pan, S.; Yang, X.; Qin, J.; Li, S.; Wang, Y. Effect of Cd micro-addition on microstructure and mechanical properties in ternary Al-Si-Cu alloy. J. Alloys Compd. 2021, 851, 156739. [Google Scholar] [CrossRef]

- Pan, S.; Qian, F.; Li, C.; Wang, Z.; Li, Y. Synergistic strengthening by nano-sized α-Al(Mn,Fe)Si and Al3Zr dispersoids in a heat-resistant Al–Mn–Fe–Si–Zr alloy. Mater. Sci. Eng. A 2021, 819, 141460. [Google Scholar] [CrossRef]

- Zhai, W.; Zhou, W.; Nai, S.M.L. Grain refinement and strengthening of 316L stainless steel through addition of TiC nanoparticles and selective laser melting. Mater. Sci. Eng. A 2022, 832, 142460. [Google Scholar] [CrossRef]

- Doñate-Buendia, C.; Kürnsteiner, P.; Stern, F.; Wilms, M.B.; Streubel, R.; Kusoglu, I.M.; Tenkamp, J.; Bruder, E.; Pirch, N.; Barcikowski, S.; et al. Microstructure formation and mechanical properties of ODS steels built by laser additive manufacturing of nanoparticle coated iron-chromium powders. Acta Mater. 2021, 206, 116566. [Google Scholar] [CrossRef]

- Huang, C.C.; Qi, L.; Chen, J.; Guan, R.; Ojo, O.A.; Wang, Z.G. Effect of TiC nanoparticles on the hot deformation behavior of AA7075 aluminum alloy. Mater. Charact. 2021, 181, 111508. [Google Scholar] [CrossRef]

- Zhu, H.-W.; Xu, K.; Qin, S.; Xiao, F.-R.; Liao, B. Effect of heat treatment on microstructure and properties of 1045 steel modified with (NbTi)C nanoparticles. Mater. Sci. Eng. A 2018, 728, 175–182. [Google Scholar] [CrossRef]

- Dou, P.; Sang, W.; Kimura, A. Morphology, crystal and metal/oxide interface structures of nanoparticles in Fe–15Cr–2W–0.5Ti–7Al–0.4Zr–0.5Y2O3 ODS steel. J. Nucl. Mater. 2019, 523, 231–247. [Google Scholar] [CrossRef]

- Fu, J.; Davis, T.P.; Kumar, A.; Richardson, I.M.; Hermans, M.J.M. Characterisation of the influence of vanadium and tantalum on yttrium-based nano-oxides in ODS Eurofer steel. Mater. Charact. 2021, 175, 111072. [Google Scholar] [CrossRef]

- Fu, J.; Brouwer, J.C.; Richardson, I.M.; Hermans, M.J.M. Effect of mechanical alloying and spark plasma sintering on the microstructure and mechanical properties of ODS Eurofer. Mater. Des. 2019, 177, 107849. [Google Scholar] [CrossRef]

- Ukai, S. Oxide Dispersion Strengthened Steels. Compr. Nucl. Mater. 2012, 4, 241–271. [Google Scholar]

- Wang, B.; Zhang, Y.; Qiu, F.; Cai, G.; Cui, W.; Hu, Z.; Zhang, H.; Tyrer, N.; Barber, G.C. Role of trace nanoparticles in manipulating the widmanstatten structure of low carbon steel. Mater. Lett. 2022, 306, 130853. [Google Scholar] [CrossRef]

- Cao, Y.; Chen, X.; Wang, Z.; Chen, K.; Pan, S.; Zhu, Y.; Wang, Y. Synergistic influence of La and Zr on microstructure and mechanical performance of an Al-Si-Mg alloy at casting state. J. Alloys Compd. 2022, 902, 163829. [Google Scholar] [CrossRef]

- Maruschak, P.; Konovalenko, I.; Chausov, M.; Pylypenko, A.; Panin, S.; Vlasov, I.; Prentkovskis, O. Impact of Dynamic Non-Equilibrium Processes on Fracture Mechanisms of High-Strength Titanium Alloy VT23. Metals 2018, 8, 983. [Google Scholar] [CrossRef]

- Maruschak, P.; Bishchak, R.; Prentkovskis, O.; Poberezhnyi, L.; Danyliuk, I.; Garbinčius, G. Peculiarities of the static and dynamic failure mechanism of long-term exploited gas pipeline steel. Adv. Mech. Eng. 2016, 8, 1687814016641565. [Google Scholar] [CrossRef]

- Wang, P.; Wang, B.; Liu, Y.; Zhang, P.; Luan, Y.; Li, D.; Zhang, Z. Effects of inclusion types on the high-cycle fatigue properties of high-strength steel. Scr. Mater. 2022, 210, 114232. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, J.; Chen, X.; Wang, Y.; Zhu, Y.; Pan, S.; Zhou, W.; Chen, M.; Wang, Z. Fabrication Techniques and the Formation Mechanism of Nanoparticles and Nanoclusters in Metal Materials. Metals 2022, 12, 1420. https://doi.org/10.3390/met12091420

Qin J, Chen X, Wang Y, Zhu Y, Pan S, Zhou W, Chen M, Wang Z. Fabrication Techniques and the Formation Mechanism of Nanoparticles and Nanoclusters in Metal Materials. Metals. 2022; 12(9):1420. https://doi.org/10.3390/met12091420

Chicago/Turabian StyleQin, Junwei, Xiaohua Chen, Yanlin Wang, Yuzhi Zhu, Shiwei Pan, Wei Zhou, Mingwen Chen, and Zidong Wang. 2022. "Fabrication Techniques and the Formation Mechanism of Nanoparticles and Nanoclusters in Metal Materials" Metals 12, no. 9: 1420. https://doi.org/10.3390/met12091420

APA StyleQin, J., Chen, X., Wang, Y., Zhu, Y., Pan, S., Zhou, W., Chen, M., & Wang, Z. (2022). Fabrication Techniques and the Formation Mechanism of Nanoparticles and Nanoclusters in Metal Materials. Metals, 12(9), 1420. https://doi.org/10.3390/met12091420