Influence of Chromium Atoms on the Shear-Coupled Motion of [110] Symmetric Tilt Grain Boundary in α-Iron: Atomic Simulation

Abstract

:1. Introduction

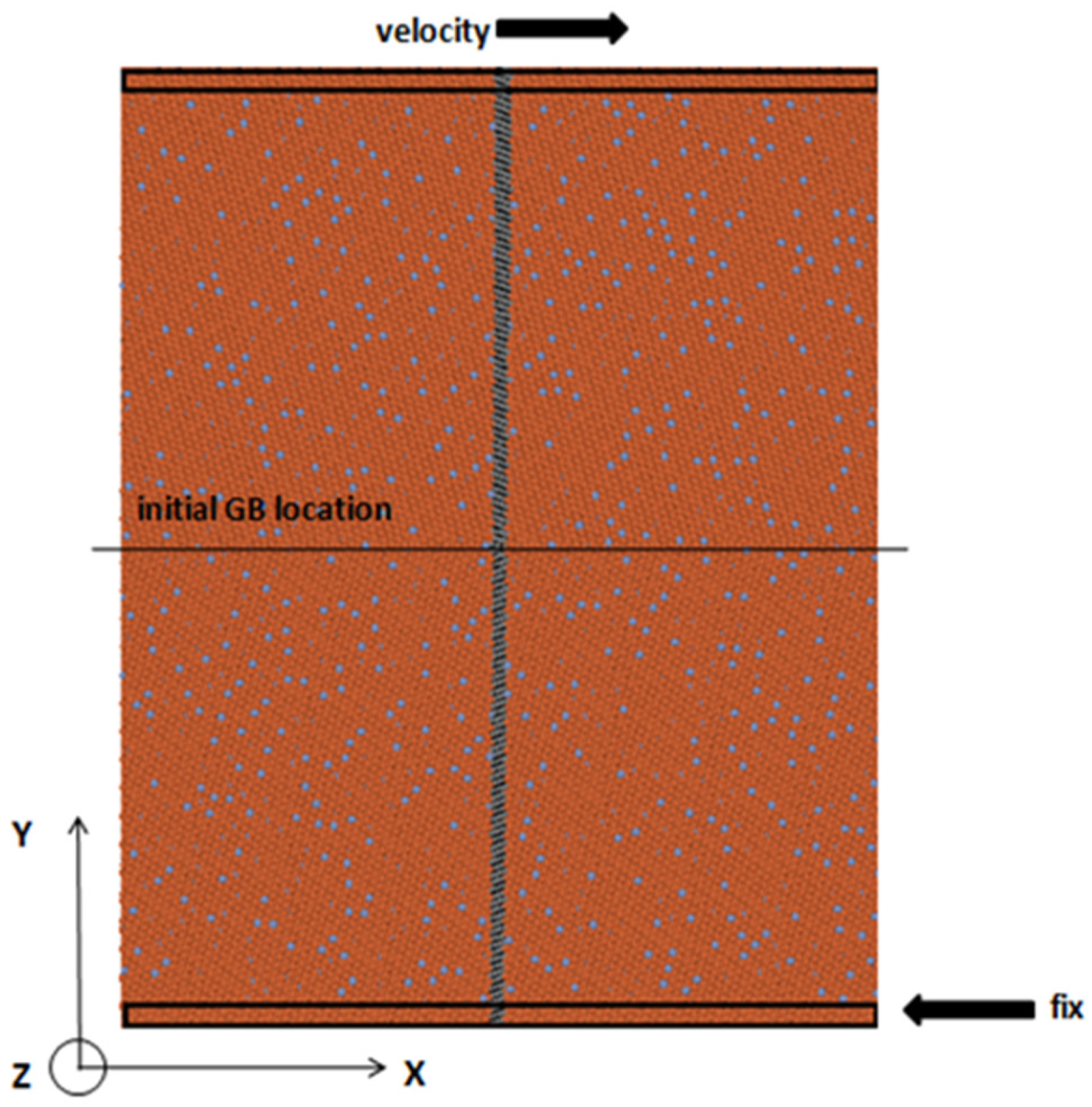

2. Computational Model

3. Results

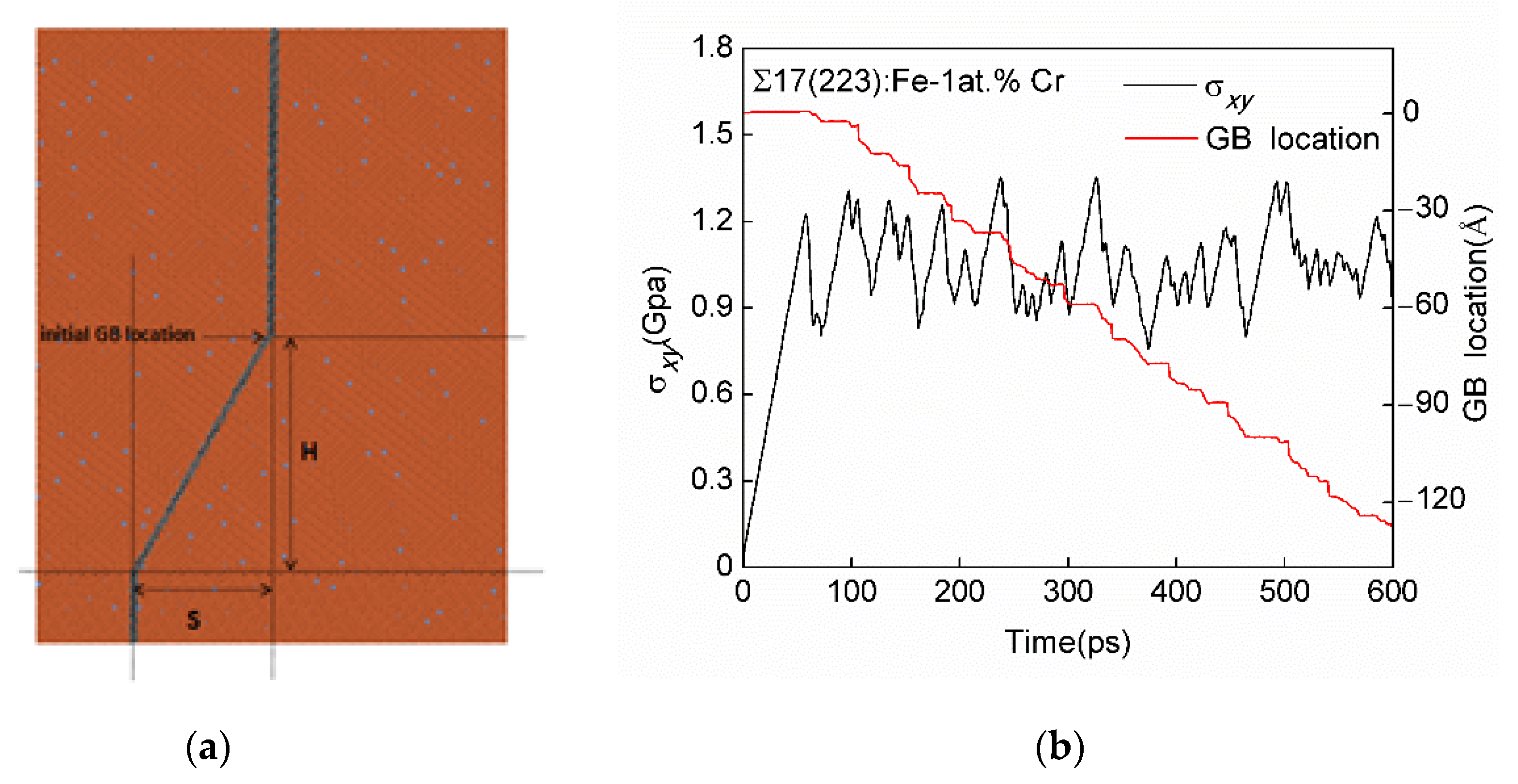

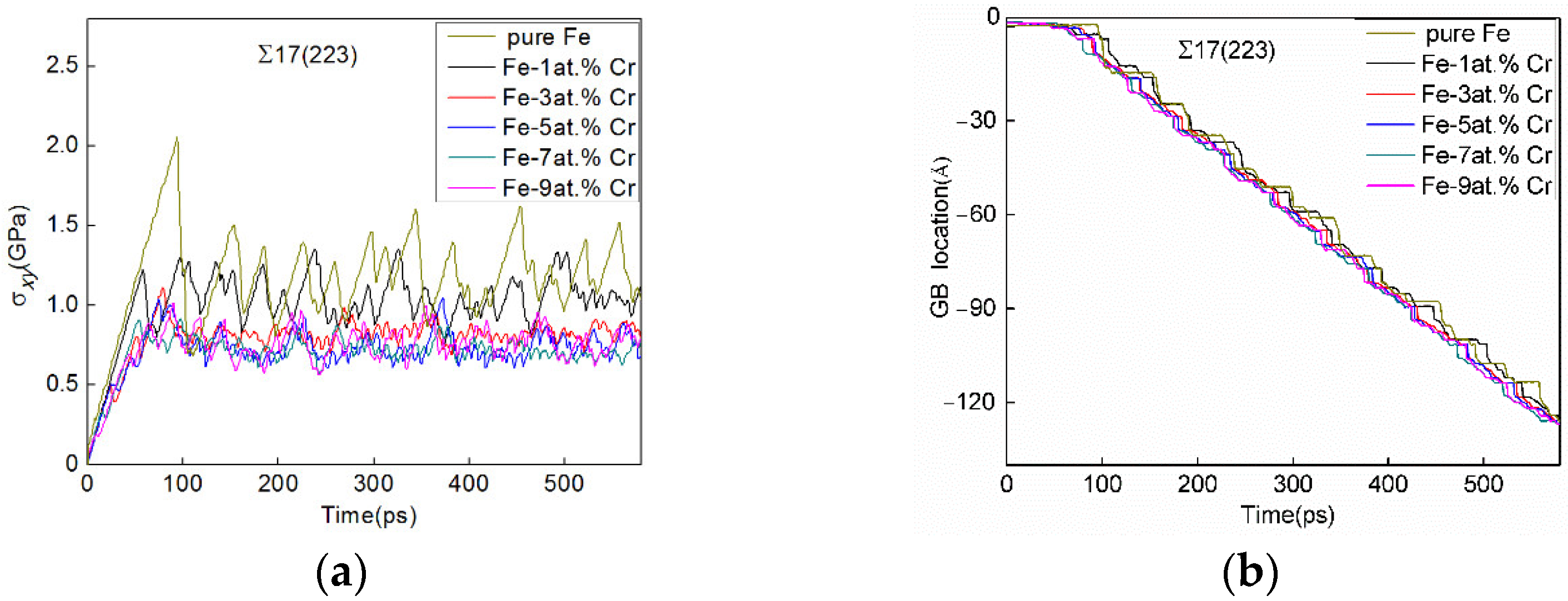

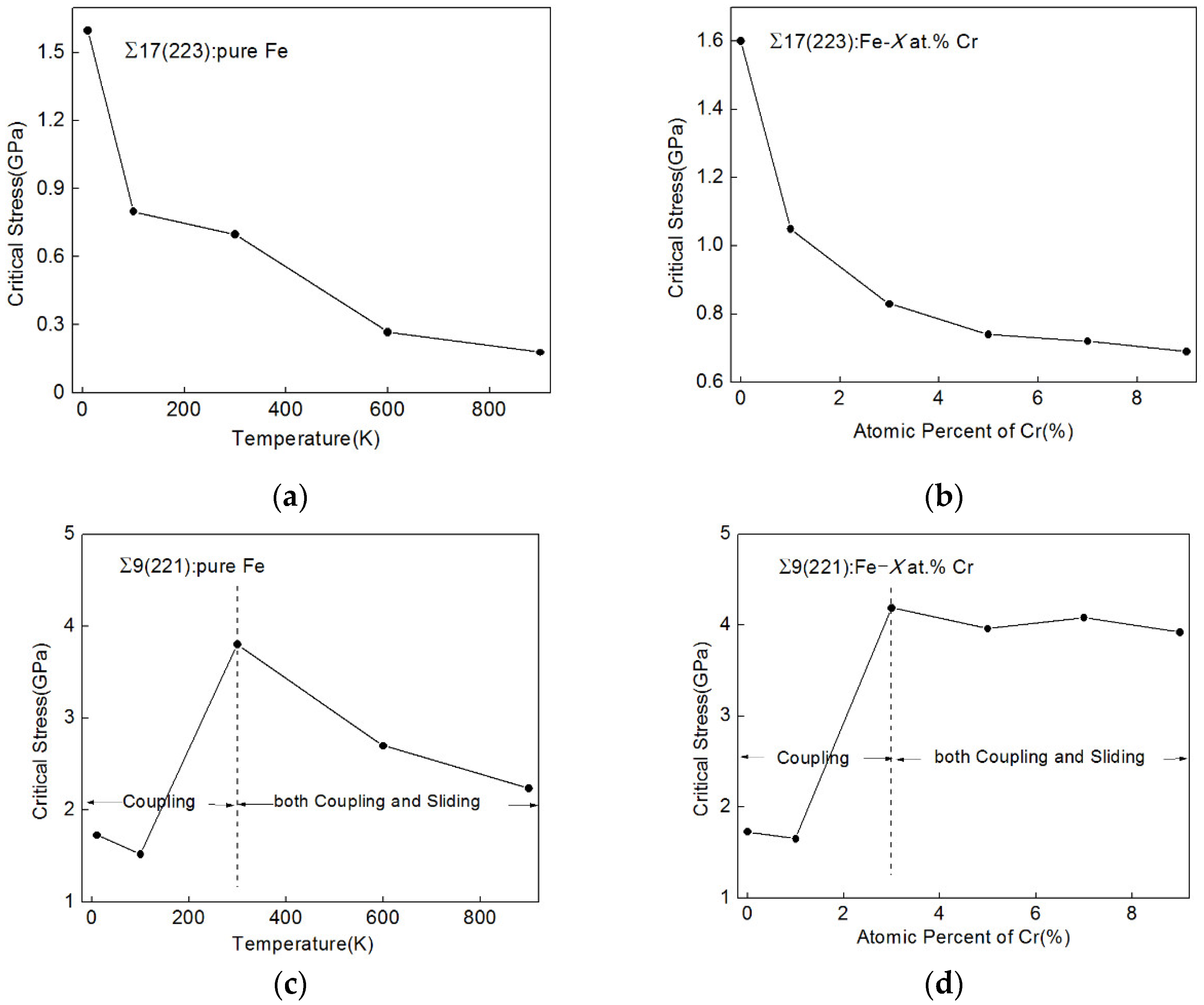

3.1. SCGBM of Σ17[110](223) GBs in the Fe-X at.% Cr Alloys (X = 1, 3, 5, 7, and 9)

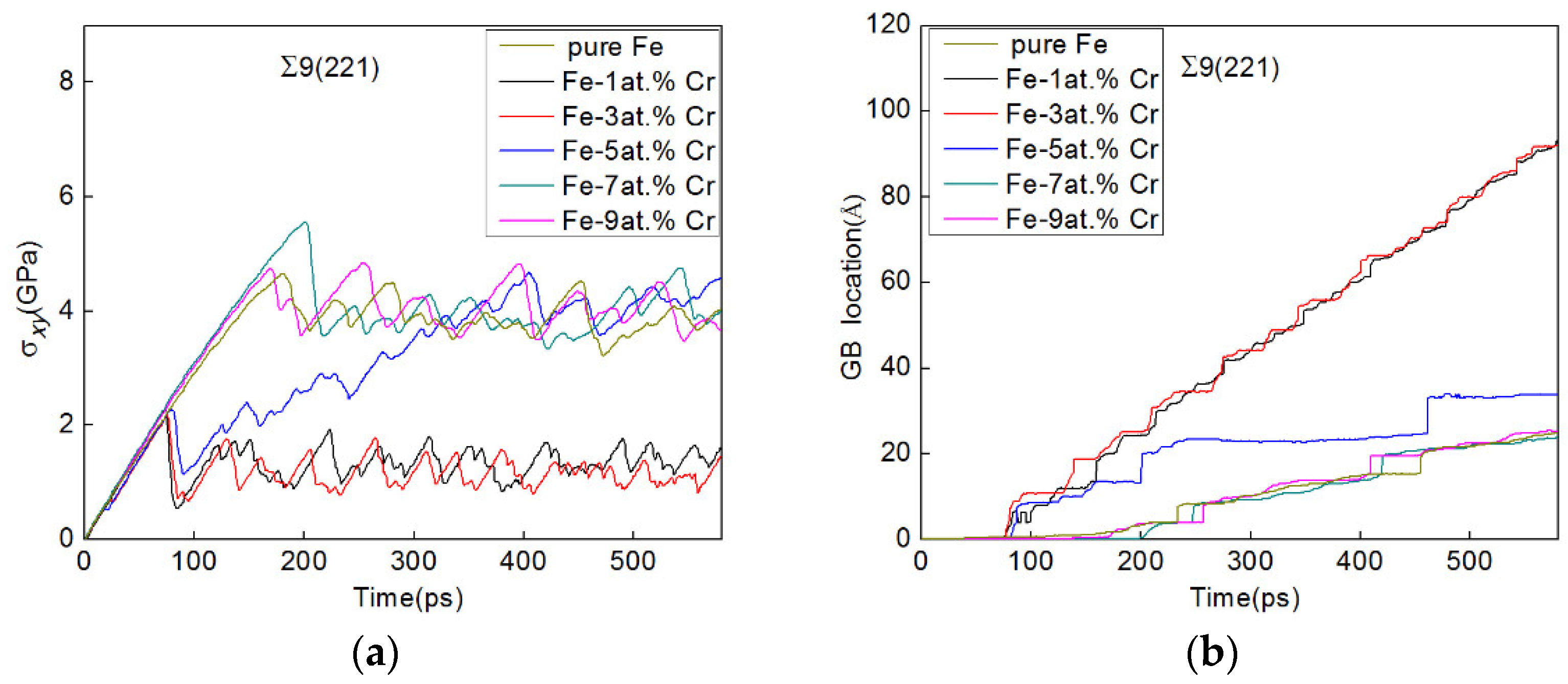

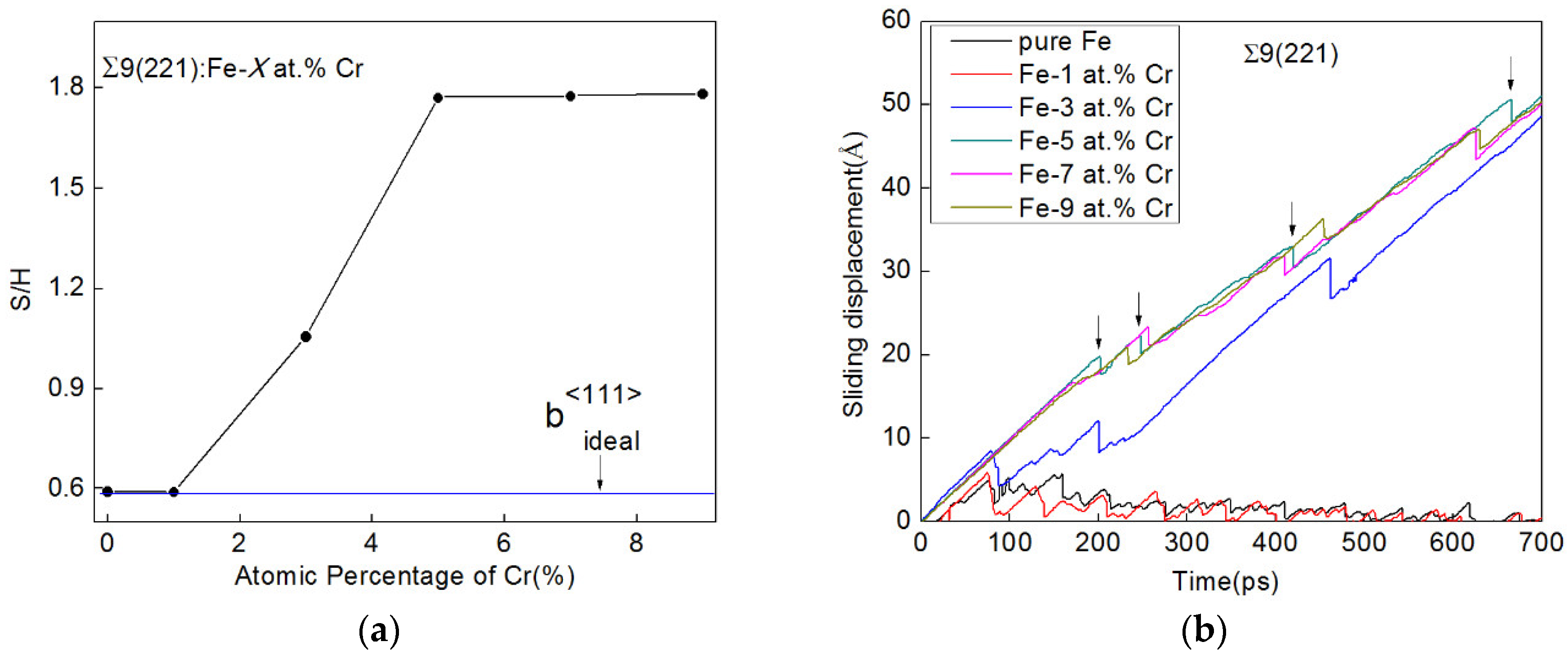

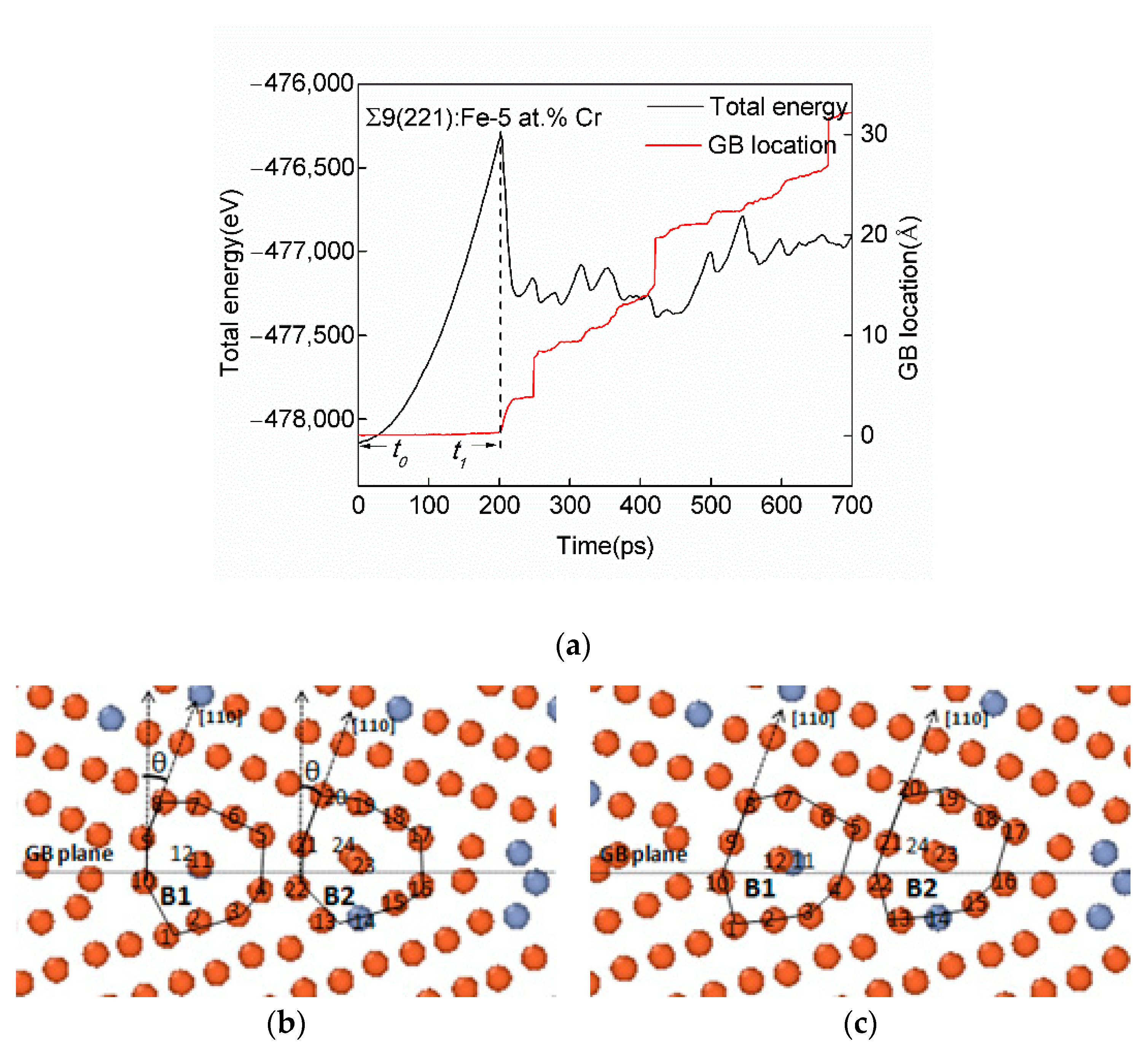

3.2. SCGBM of Σ9[110](221) GBs in Fe-X at.% Cr Alloys (X = 1, 3, 5, 7, and 9)

4. Discussion

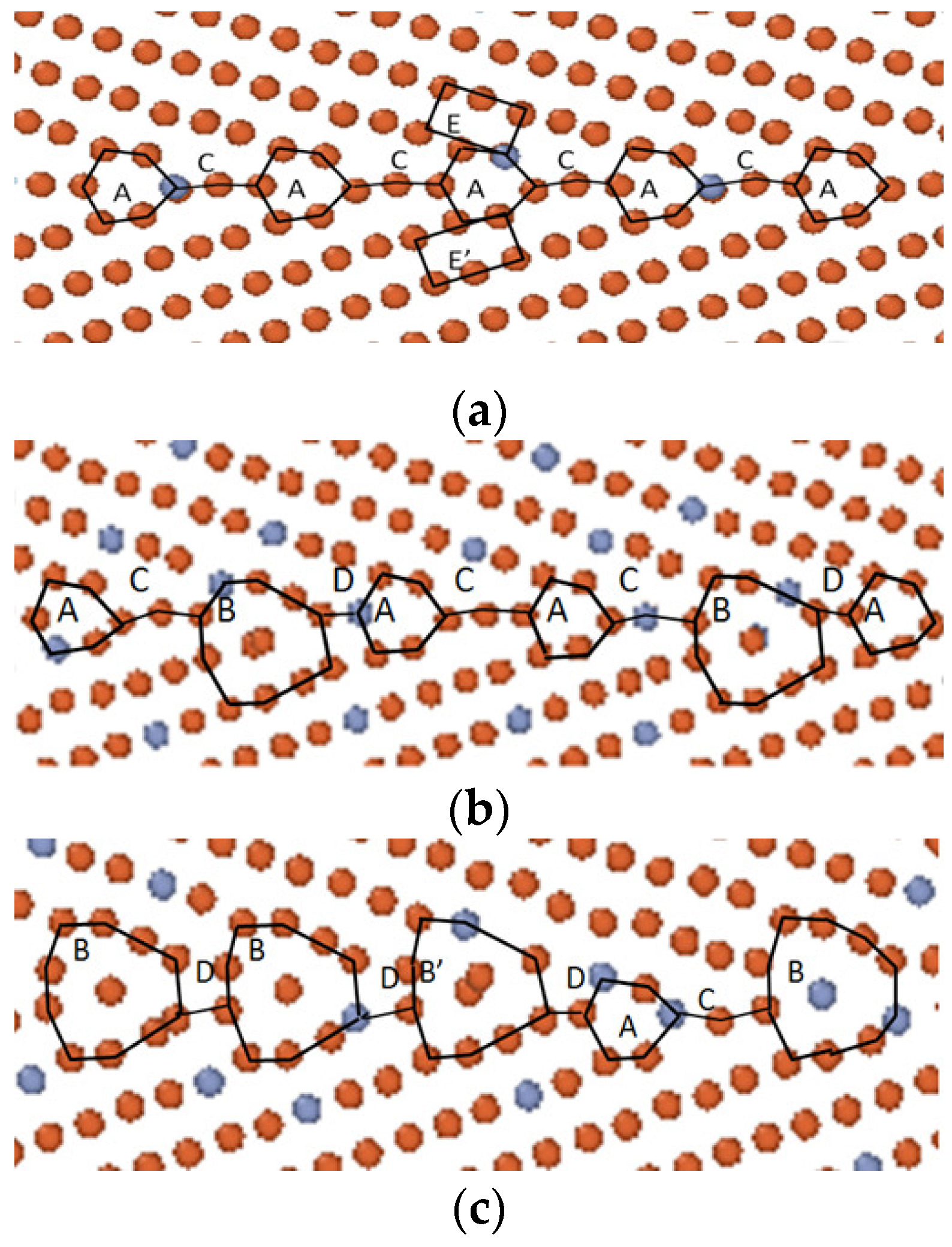

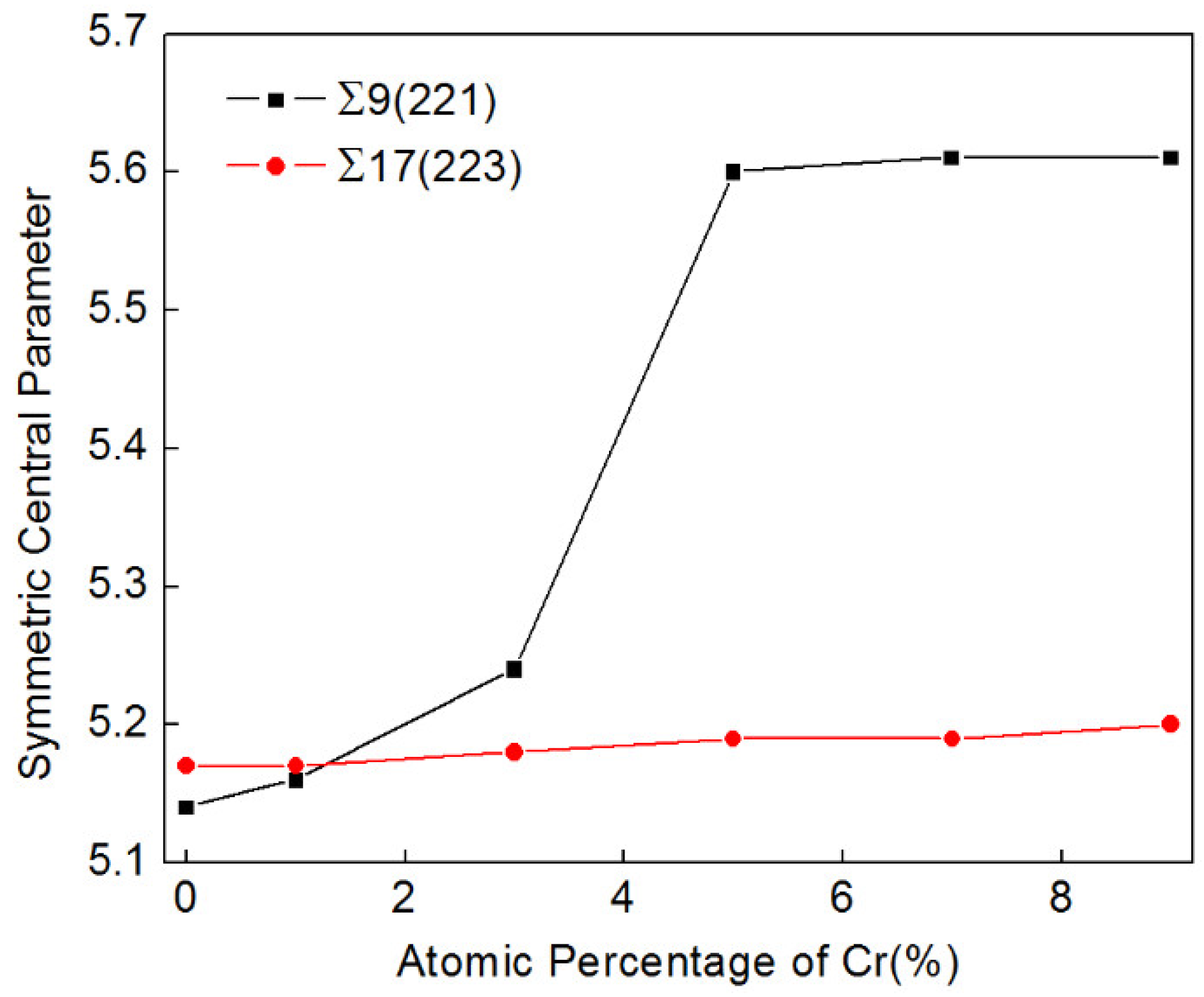

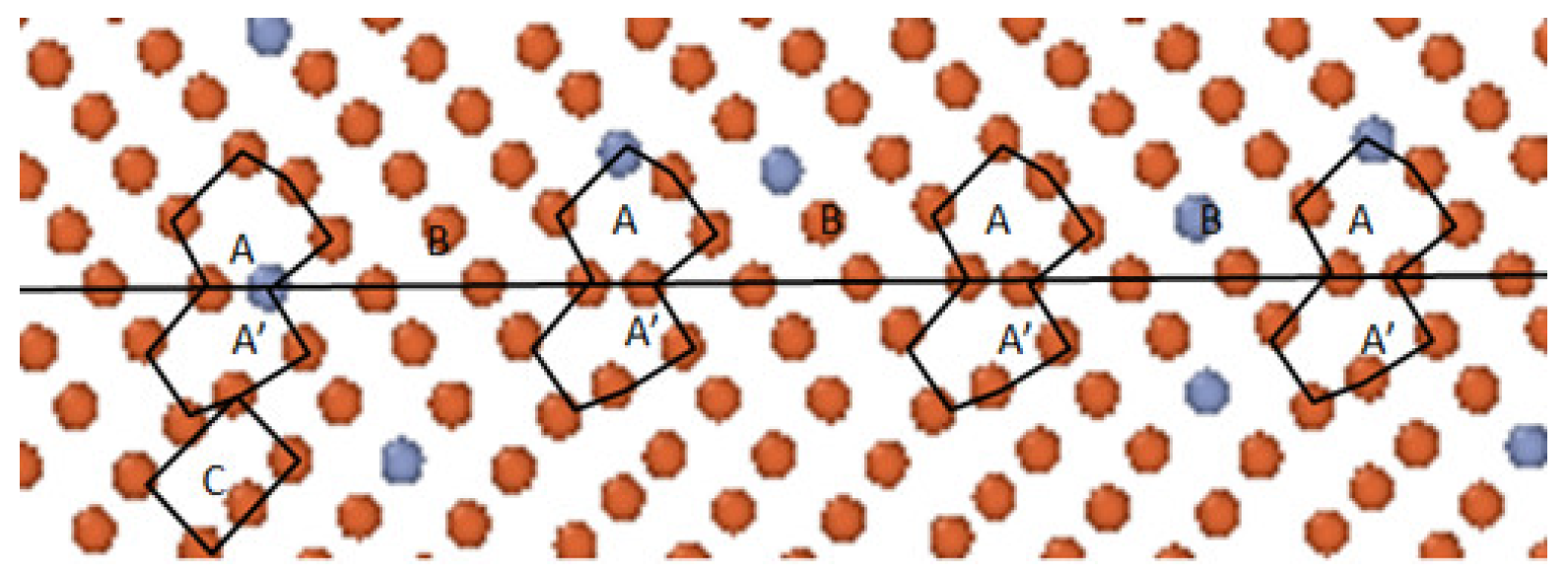

4.1. Relationship between GB Structure and GB Motion

4.2. Comparison of the Effects of Impurities and Temperature on SCGBM

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, C.H.; Edwards, E.H.; Washburn, J.; Parker, E.R. Stress-induced movement of crystal boundaries. Acta Metall. 1953, 1, 223–229. [Google Scholar] [CrossRef]

- Molodov, D.A.; Mishin, Y. Chapter 9: Plastic Deformation by Grain Boundary Motion: Experiments and Simulations. In Microstructural Design of Advanced Engineering Materials; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2013; pp. 201–233. [Google Scholar]

- Rupert, T.J.; Gianola, D.S.; Gan, Y.; Hemker, K.J. Experimental observations of stress-driven grain boundary migration. Science 2009, 326, 1686–1690. [Google Scholar] [CrossRef] [PubMed]

- Niu, L.L.; Zhang, Y.; Shu, X.; Gao, F.; Jin, S.; Zhou, H.B.; Lu, G.H. Shear-coupled grain boundary migration assisted by unusual atomic shuffling. Sci. Rep. 2016, 6, 23602. [Google Scholar] [CrossRef] [PubMed]

- Mompiou, F.; Caillard, D.; Legros, M. Grain boundary shear–migration coupling—I. In situ TEM straining experiments in Al polycrystals. Acta Mater. 2009, 57, 2198–2209. [Google Scholar] [CrossRef]

- Caillard, D.; Mompiou, F.; Legros, M. Grain-boundary shear-migration coupling. II. Geometrical model for general boundaries. Acta Mater. 2009, 57, 2390–2402. [Google Scholar] [CrossRef]

- Berbenni, S.; Paliwal, B.; Cherkaoui, M. A micromechanics-based model for shear-coupled grain bondary migration in bicrystals. Int. J. Plast. 2013, 44, 68–94. [Google Scholar] [CrossRef]

- Cahn, J.W.; Mishin, Y.; Suzuki, A. Coupling grain boundary motion to shear deformation. Acta Mater. 2006, 54, 4953–4975. [Google Scholar] [CrossRef]

- Cahn, J.W.; Taylor, J.E. A unified approach to motion of grain boundaries, relative tangential translation along grain boundaries, and grain rotation. Acta Mater. 2004, 52, 4887–4898. [Google Scholar] [CrossRef]

- Hoyt, J.J. Atomistic simulations of grain and interphase boundary mobility. Model. Simul. Mater. Sci. Eng. 2014, 22, 033001. [Google Scholar] [CrossRef]

- Ivanov, V.A.; Mishin, Y. Dynamics of grain boundary motion coupled to shear deformation: An analytical model and its verification by molecular dynamics. Phys. Rev. B Condens. Matter 2008, 78, 064106. [Google Scholar] [CrossRef] [Green Version]

- Trautt, Z.T.; Adland, A.; Karma, A.; Mishin, Y. Coupled motion of asymmetrical tilt grain boundaries: Molecular dynamics and phase field crystal simulations. Acta Mater. 2012, 60, 6528–6546. [Google Scholar] [CrossRef]

- Aramfard, M.; Deng, C. Interaction of shear-coupled grain boundary motion with crack: Crack healing, grain boundary decohesion, and sub-grain formation. J. Appl. Phys. 2016, 119, 085308. [Google Scholar] [CrossRef]

- Bringuier, S.; Manga, V.R.; Runge, K.; Deymier, P.; Muralidharan, K. An atomic scale characterization of coupled grain boundary motion in silicon bicrystals. Philos. Mag. 2015, 95, 4118–4129. [Google Scholar] [CrossRef]

- Wan, L.; Wang, S. Shear response of the Σ11<100>{131} symmetric tilt grain boundary studied by molecular dynamics. Model. Simul. Mater. Sci. Eng. 2009, 17, 45008–45025. [Google Scholar] [CrossRef]

- Wan, L.; Wang, S. Shear response of the Σ9<100> {221} symmetric tilt grain boundary in fcc metals studied by atomistic simulation methods. Phys. Rev. B 2010, 82, 214112. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Tieu, K.; Zhao, X.; Pei, L. The shear response of copper bicrystals with Σ11 symmetric and asymmetric tilt grain boundaries by molecular dynamics simulation. Nanoscale 2015, 7, 7224–7233. [Google Scholar] [CrossRef] [PubMed]

- Gorkaya, T.; Molodov, D.A.; Gottstein, G. Stress-driven migration of symmetrical <1 0 0> tilt grain boundaries in Al bicrystals. Acta Mater. 2009, 57, 5396–5405. [Google Scholar] [CrossRef]

- Shiga, M.; Shinoda, W. Stress-assisted grain boundary sliding and migration at finite temperature: A molecular dynamics study. Phys. Rev. B 2004, 70, 054102. [Google Scholar] [CrossRef]

- Huang, B.W.; Shang, J.X.; Liu, Z.H.; Chen, Y. Atomic simulation of bcc niobium Σ5 <001> {310} grain boundary under shear deformation. Acta Mater. 2014, 77, 258–268. [Google Scholar] [CrossRef]

- Dmitriev, A.I.; Nikonov, A.Y. Features of the behavior of symmetrical tilt grain boundaries in BCC and FCC metals under shear loading. Molecular dynamics study. AIP Conf. Proc. 2014, 1623, 127–130. [Google Scholar]

- Yin, J.; Wang, Y.; Yan, X.; Hou, H.; Wang, J.T. Atomistic simulation of shear-coupled motion of [110] symmetric tilt grain boundary in α-iron. Comput. Mater. Sci. 2018, 148, 141–148. [Google Scholar] [CrossRef]

- Zhang, L.; Lu, C.; Michal, G.; Tieu, K.; Zhao, X.; Deng, G. Influence of temperature and local structure on the shear-coupled grain boundary migration. Phys. Status Solidi B 2017, 254, 1600477. [Google Scholar] [CrossRef]

- Gao, F.; Yang, L.; Heinisch, H.L.; Kurtz, R.J. Dynamics of Helium-Loaded Grain Boundaries under Shear Deformation in α-Fe; US Department of Energy: Washington, DC, USA, 2014.

- Shibuta, Y.; Takamoto, S.; Suzuki, T. Dependence of the grain boundary energy on the alloys composition in the bcc iron–chromium alloys: A molecular dynamics study. Comput. Mater. Sci. 2009, 44, 1025–1029. [Google Scholar] [CrossRef]

- Bonny, G.; Pasianot, R.C.; Terentyev, D.; Malerba, L. Iron chromium potential to model high-chromium ferritic alloys. Philos. Mag. 2011, 91, 1724–1746. [Google Scholar] [CrossRef]

- Plimpton, S. Fast Parallel Algorithms for Short-Range Molecular Dynamics. J. Comput. Phys. 1995, 117, 1–19. [Google Scholar] [CrossRef]

- Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO-the Open Visualization Tool. IEEE Trans. Fuzzy Syst. 2010, 23, 2154–2162. [Google Scholar] [CrossRef]

- Kelchner, C.L.; Plimpton, S.J.; Hamilton, J.C. Dislocation nucleation and defect structure during surface indentation. Phys. Rev. B 2011, 58, 11085–11088. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, Z.; Yan, X.; Yin, J.; Hou, H. Influence of Chromium Atoms on the Shear-Coupled Motion of [110] Symmetric Tilt Grain Boundary in α-Iron: Atomic Simulation. Metals 2022, 12, 1451. https://doi.org/10.3390/met12091451

Bai Z, Yan X, Yin J, Hou H. Influence of Chromium Atoms on the Shear-Coupled Motion of [110] Symmetric Tilt Grain Boundary in α-Iron: Atomic Simulation. Metals. 2022; 12(9):1451. https://doi.org/10.3390/met12091451

Chicago/Turabian StyleBai, Zhiwen, Xiaohan Yan, Jian Yin, and Huaiyu Hou. 2022. "Influence of Chromium Atoms on the Shear-Coupled Motion of [110] Symmetric Tilt Grain Boundary in α-Iron: Atomic Simulation" Metals 12, no. 9: 1451. https://doi.org/10.3390/met12091451

APA StyleBai, Z., Yan, X., Yin, J., & Hou, H. (2022). Influence of Chromium Atoms on the Shear-Coupled Motion of [110] Symmetric Tilt Grain Boundary in α-Iron: Atomic Simulation. Metals, 12(9), 1451. https://doi.org/10.3390/met12091451