Low Frequency Giant Magneto-Impedance Effect of Co-Rich Ribbons Induced by Joule Annealing Treatment

Abstract

:1. Introduction

2. Experimental Method and Details

3. Results and Discussion

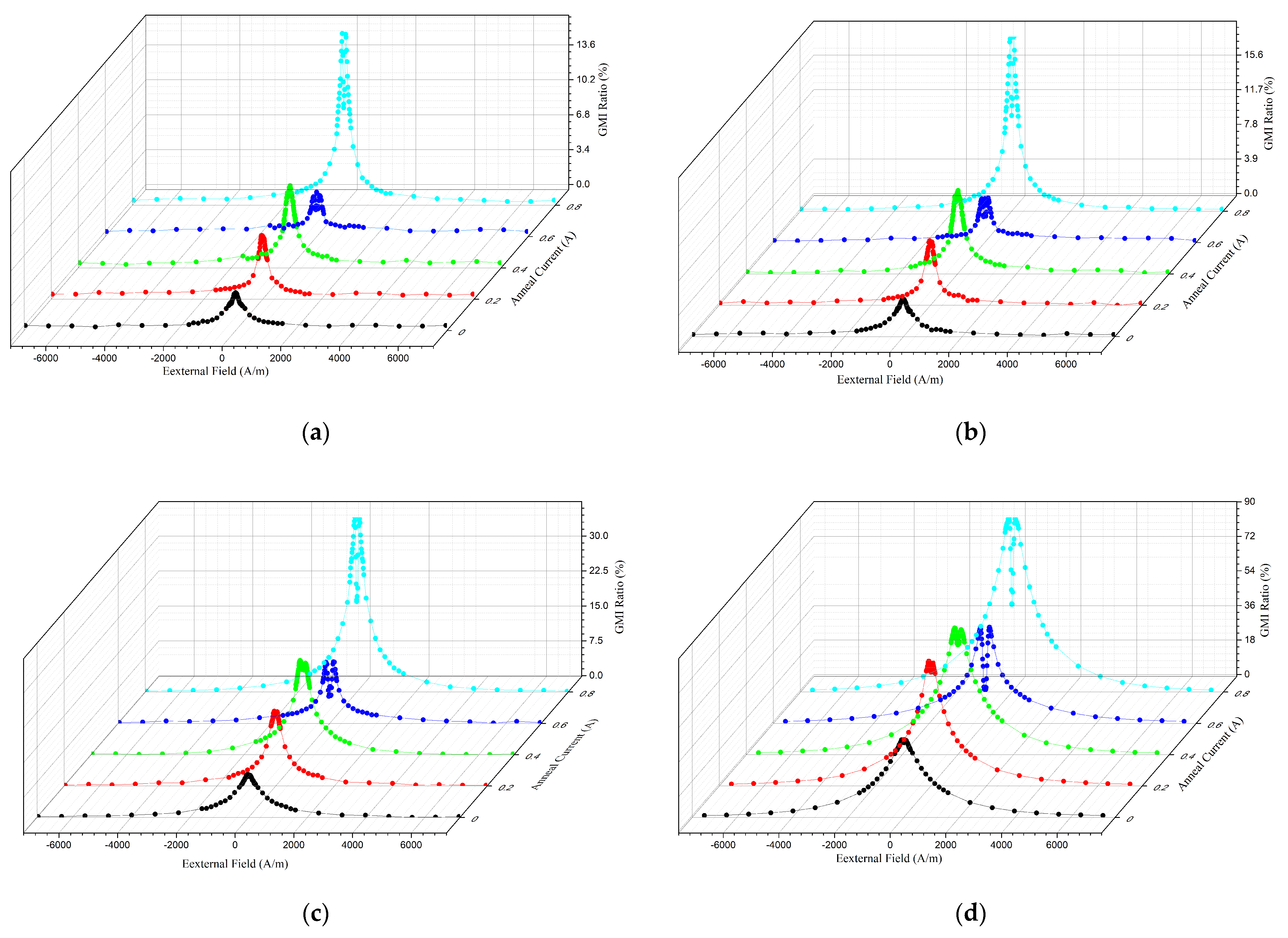

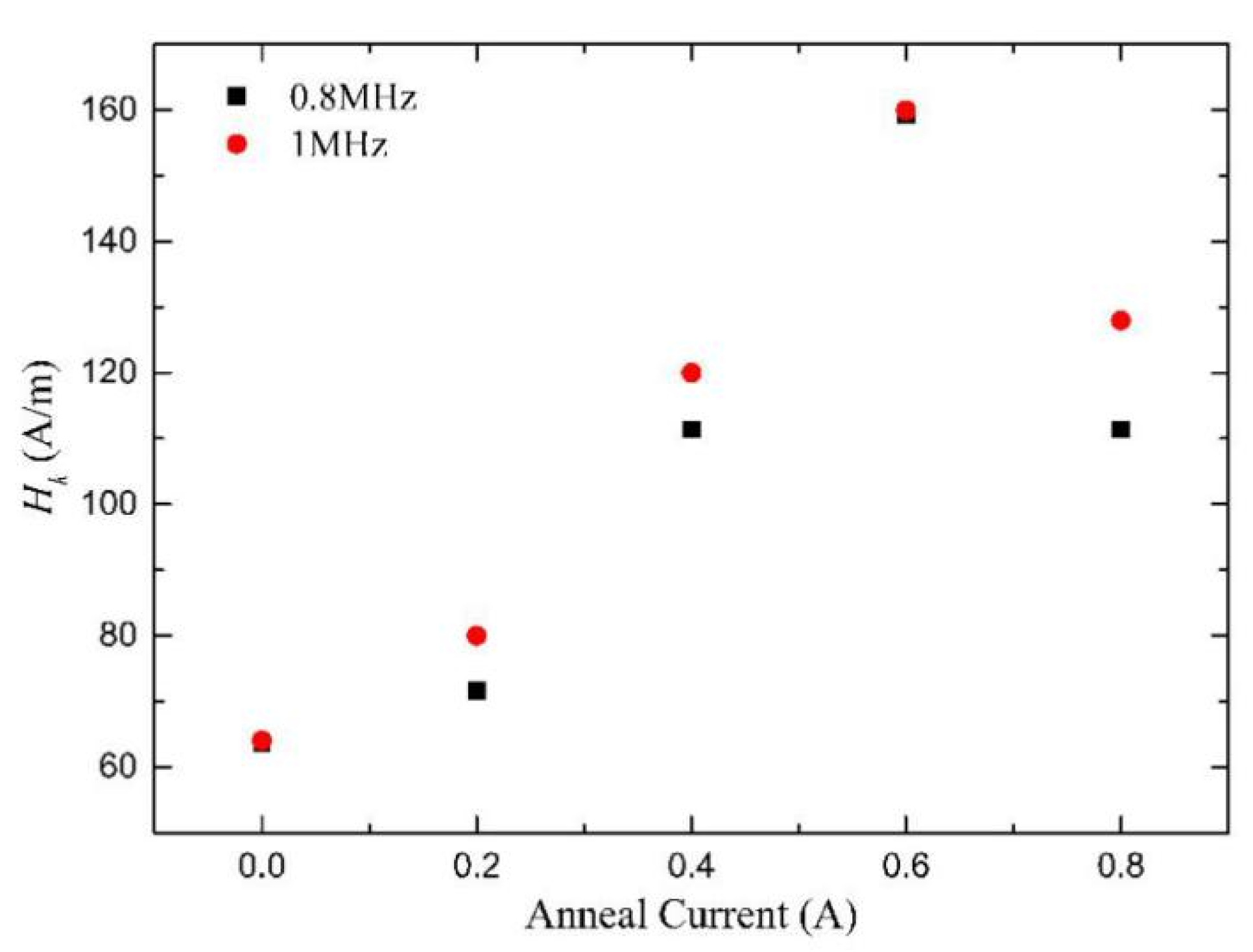

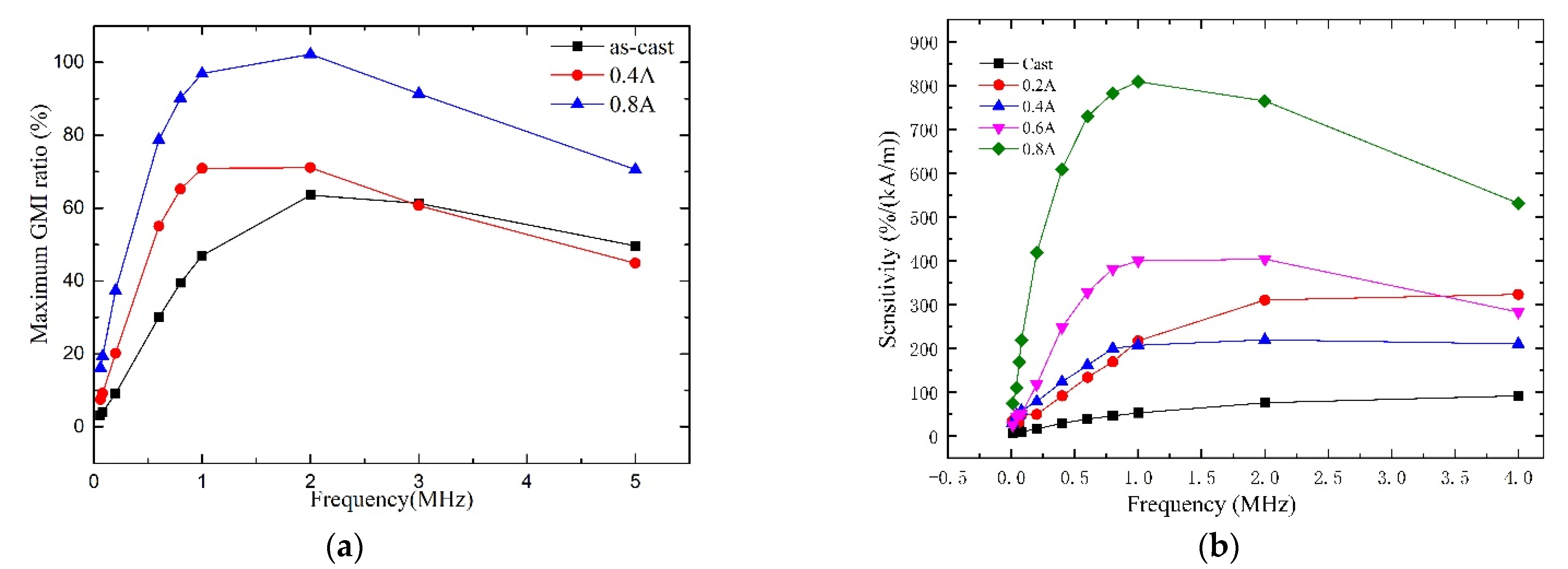

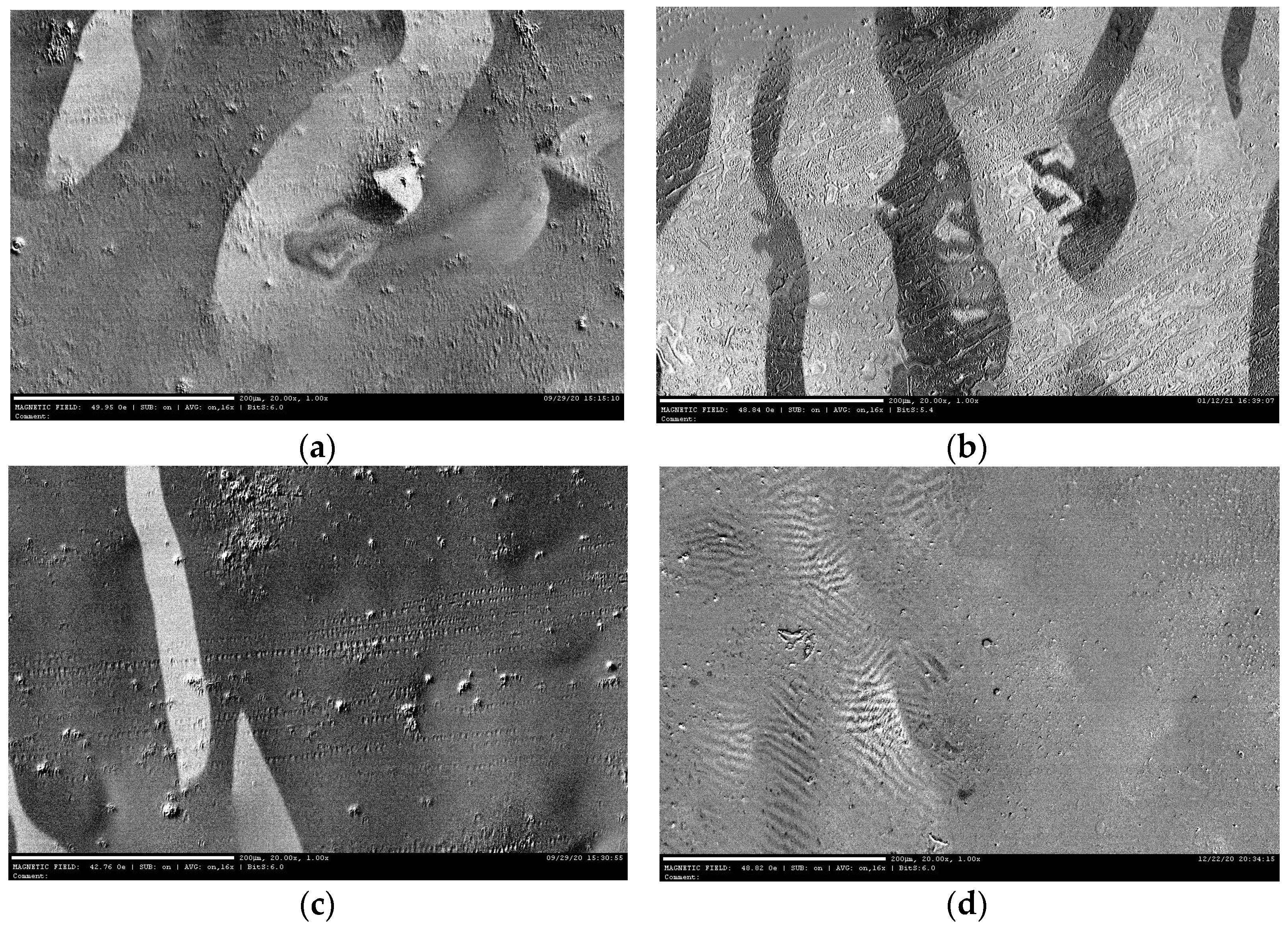

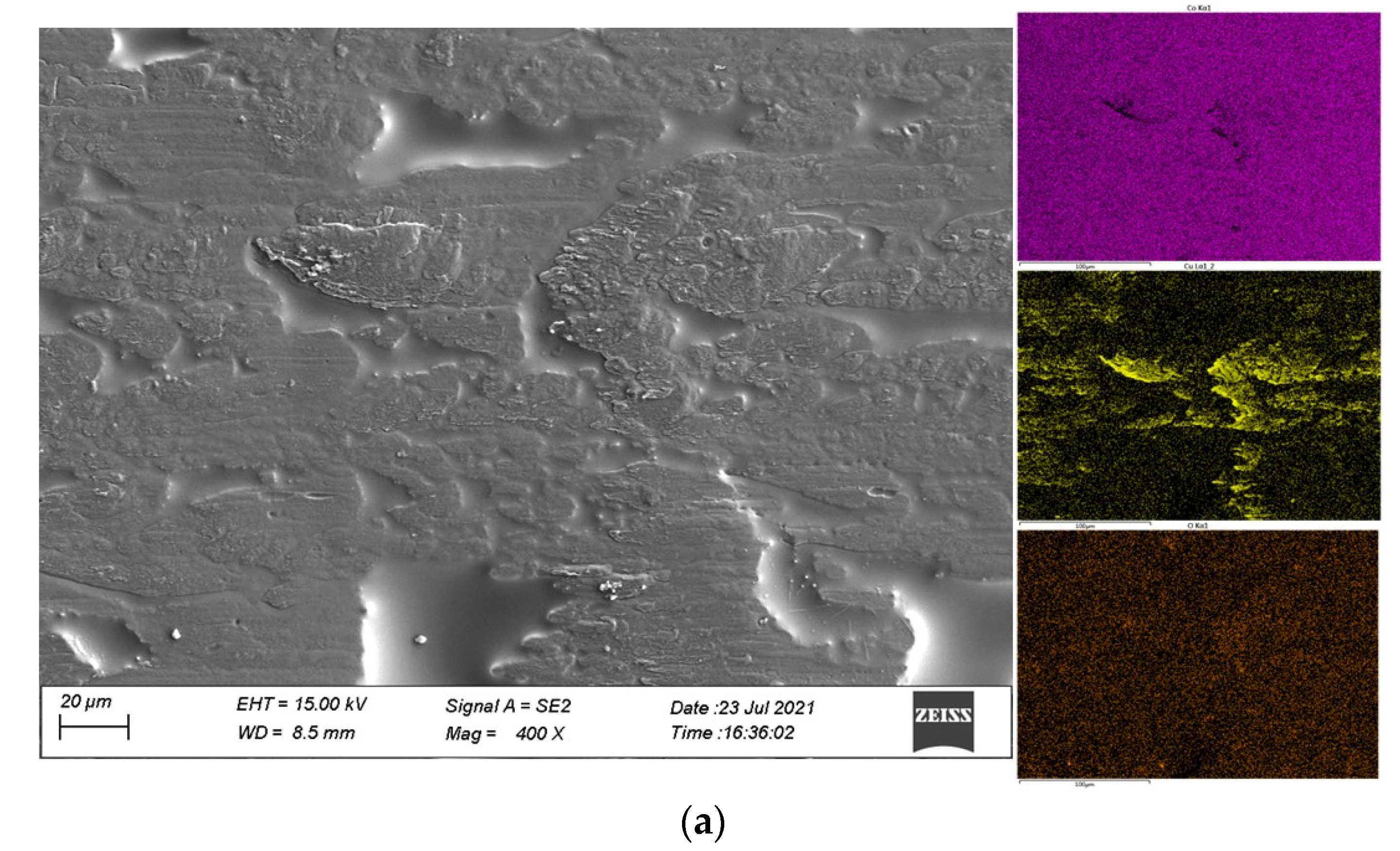

3.1. The Microstructure and GMI Effect

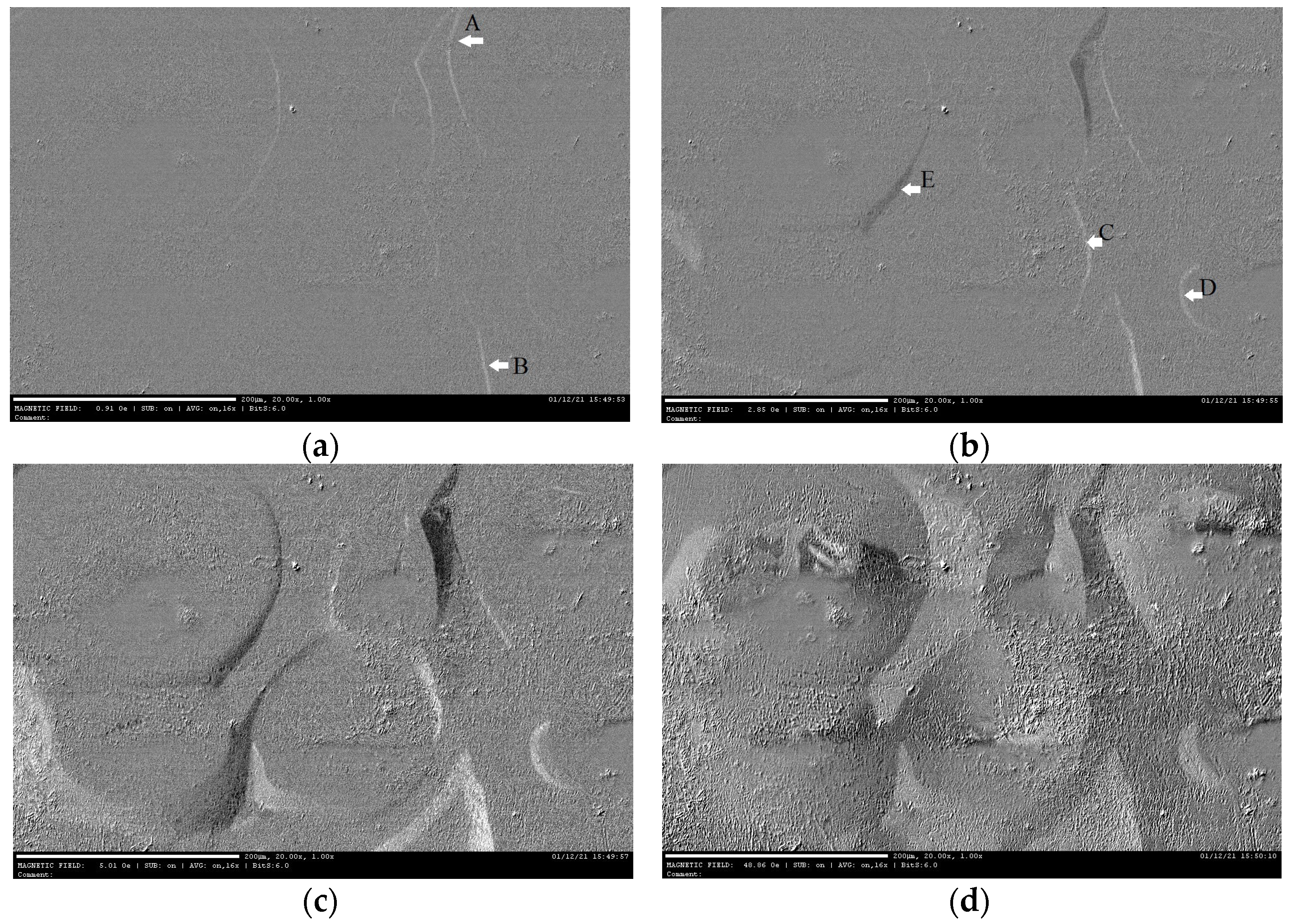

3.2. Domain Structure Transformation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohri, K.; Kohzawa, T.; Kawashima, K.; Yoshida, H.; Panina, L.V. Magneto-inductive effect (MI effect) in amorphous wires. IEEE Trans Magn. 1992, 28, 3150–3152. [Google Scholar] [CrossRef]

- Melo, L.G.C.; Menard, D.; Yelon, A.; Ding, L.; Saez, S.; Dolabdjian, C. Optimization of the magnetic noise and sensitivity of giant magnetoimpedance sensors. J. Appl. Phys. 2008, 103, 033903. [Google Scholar] [CrossRef]

- Phan, M.H.; Peng, H.X. Giant magnetoimpedance materials:Fundamentals and applications. Prog. Mater. Sci. 2008, 53, 323–420. [Google Scholar] [CrossRef]

- Ding, L.; Saez, S.; Dolabdjian, C.; Luiz, G.C.M.; Yelon, A.; Menard, D. Equivalent Magnetic Noise Limit of Low-Cost GMI Magnetometer. IEEE Sens. J. 2009, 9, 159–168. [Google Scholar] [CrossRef]

- Nematov, M.G.; Baraban, I.; Yudanov, N.A.; Rodionova, V.; Qin, F.X.; Peng, H.X.; Panina, L.V. Evolution of the magnetic anisotropy and magnetostriction in Co-based amorphous alloys microwires due to current annealing and stress-sensory applications. J. Alloys Compd. 2020, 837, 155584. [Google Scholar] [CrossRef]

- Kamruzzaman, M.; Rahman, I.Z.; Rahman, M.A. A review on magneto-impedance effect in amorphous magnetic materials. J. Mater. Process. Technol. 2001, 119, 312–317. [Google Scholar] [CrossRef]

- Guo, H.Q.; Kronmuller, H.; Dragon, T.; Chen, C.; Shen, B.G. Transverse domain structure related giant magnetoimpedance in nanocrystalline Fe73.5Cu1Nb3Si13.5B9 ribbons. J. Appl. Phys. 1998, 84, 5673–5676. [Google Scholar] [CrossRef]

- Kraus, L.; Malatek, M.; Postava, K.; Janickovic, P. Asymmetric giant magnetoimpedance in stress-field annealed CoFeBSi amorphous ribbons. J. Magn. Magn. Mater. 2005, 290–291, 1131–1133. [Google Scholar] [CrossRef]

- Turtelli, R.S.; Sinnecker, J.P.; Grossinge, R.; Badurek, G.; Kussbach, C.; Allia, P. Stress dependence of magnetization processes: Reversals and relaxation in FexCo85ÀxB15 amorphous ribbons. Phys. Rev. B 2001, 63, 094427. [Google Scholar] [CrossRef]

- Chizhik, A.; Vega, V.; Mohamed Abd El-Moez, A.; Prida, V.M.; Sanchez, T.; Hernando, B.; Ipatov, M.; Zhukova, V.; Zhukov, A.P.; Stupakiewicz, A.; et al. Surface magnetic properties and giant magnetoimpedance effect in Co-based amorphous ribbons. Intermetallics 2017, 86, 15–19. [Google Scholar] [CrossRef]

- Dastani, M.M.; AL-Ali, M.H.; Moradi, M. Influence of current annealing on the magneto-impedance response of cobased ribbons arising from surface structural improvement. J. Non-Cryst. Solids 2019, 516, 9–13. [Google Scholar] [CrossRef]

- Ozturk, S.; Icin, K.; Gencturk, M.; Gobuluk, M.; Topal, U.; Svec, P. Surface and structural characterization of amorphous Fe, Co-based melt-spun ribbons subjected to heat treatment processes. J. Non-Cryst Solids 2019, 522, 11. [Google Scholar] [CrossRef]

- Brunetti, L.; Tiberto, P.; Vinai, F.; Chiriac, H. High-frequency giant magnetoimpedance in joule-heated Co-based amorphous ribbons and wires. Mater. Sci. Eng. A 2001, 304–306, 961–964. [Google Scholar] [CrossRef]

- Menard, D.; Yelon, A. Theory of longitudinal magnetoimpedance in wires. J. Appl. Phys. 2000, 88, 379–393. [Google Scholar] [CrossRef]

- Hernando, A.; Gonzalez, A.P.; Crespo, M.M. Magnetization fluctuations in random anisotropy ferromagnets. J. Magn. Magn. Mater. 2004, 272–276, 1347–1350. [Google Scholar] [CrossRef]

- Gazda, P.; Szewczyk, R. Influence of Joule-Annealing on Double-Peak GMI Effect in Co-Based Amorphous Ribbons. Acta Phys Pol. A 2020, 137, 818–820. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-Leon, P.; Legarreta, L.G.; Churyukanova, M.; Blanco, J.M.; Gonzalez, J.; Taskaev, S.; Hernando, B.; Zhukova, V. Giant magnetoimpedance in rapidly quenched materials. J. Alloys Compd. 2020, 814, 152225. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Zhukov, A. Effect of Joule heating on giant magnetoimpedance effect and magnetic properties of Co-rich microwires. J. Alloys Compd. 2021, 883, 160778. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Blanco, J.M.; Ipatov, M.; Taskaev, S.; Churyukanova, M.; Gonzalez, J.; Zhukov, A. Engineering of magnetic properties and magnetoimpedance effect in Fe-rich microwires by reversible and irreversible stress-annealing anisotropy. J. Alloys Compd. 2021, 855, 157460. [Google Scholar] [CrossRef]

- Li, X.P.; Zhao, Z.J.; Chua, C.; Seet, H.L.; Lu, L. Enhancement of giant magnetoimpedance effect of electroplated NiFe/Cu composite wires by dc Joule annealing. J. Appl. Phys. 2003, 94, 7626–7630. [Google Scholar] [CrossRef]

- Coisson, M.; Kane, S.N.; Tiberto, P.; Vinai, F. Influence of DC Joule-heating treatment on magnetoimpedance effect in amorphous Co64Fe21B15 alloy. J. Magn. Magn. Mater. 2004, 271, 312–317. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Gonzalez, J.; Zhukov, A. Engineering of magnetic properties of Co-rich microwires by joule heating. Intermetallics 2019, 105, 92–98. [Google Scholar] [CrossRef]

- Gonzalez-Alonso, D.; Gonzalez-Legarreta, L.; Corte-Leon, P.; Zhukova, V.; Ipatov, M.; Blanco, J.M.; Zhukov, A. Magnetoimpedance Response and Field Sensitivity in Stress-Annealed Co-Based Microwires for Sensor Applications. Sensors 2020, 20, 3227. [Google Scholar] [CrossRef] [PubMed]

- Celegato, F.; Coisson, M.; Kane, S.N.; Tiberto, P.; Vinai, F. High-frequency magnetoimpedance on annealed amorphous magnetic wires with different magnetostriction constants. J. Non-Cryst. Solids 2007, 353, 919–921. [Google Scholar] [CrossRef]

- Dwevedi, S.; Markandeyulu, G.; Ohodnicki, P.R.; Leary, A.; McHenry, M.E. Stress-MI and domain studies in Co-based nanocrystalline ribbons. J. Magn. Magn. Mater. 2011, 323, 1929–1933. [Google Scholar] [CrossRef]

- Ipatov, M.; Gonzalez-Legarreta, L.; Garcia, J.; Chizhik, A.; Dominguez, L.; Zhukova, V.; Zhukov, A.; Hernando, B.; Gonzalez, J. Induced Giant Magnetoimpedance Effect by Current Annealing in Ultra Thin Co-Based Amorphous Ribbons. IEEE Trans. Magn. 2013, 49, 1009–1012. [Google Scholar] [CrossRef]

- Hoa, N.Q.; Thanh, P.Q.; Yu, S.; Chau, N.; Gam, D.T.H. Large Enhancement of the GMI Effect in Multi-Ferromagnetic Ribbons. J. Korean Phys. Soc. 2009, 54, 2349–2352. [Google Scholar] [CrossRef]

- Corte-Leon, P.; Zhukova, V.; Dominquez, L.; Blanco, J.M.; Ipatov, M.; Chizhik, A.; Zhukov, A.; Gonzalez, J. Giant magnetoimpedance and magneto-optical Kerr effects in (Co63Ni37)(75)Si15B10 amorphous ribbon. Intermetallics 2020, 125, 6. [Google Scholar] [CrossRef]

- Zhukova, V.; Blanco, J.M.; Ipatov, M.; Gonzalez, J.; Churyukanova, M.; Zhukov, A. Engineering of magnetic softness and giant magnetoimpedance effect in Fe-rich microwires by stress-annealing. Scr. Mater. 2018, 142, 10–14. [Google Scholar] [CrossRef]

- Qikui, M.; Yunzhang, F.; Huaijun, S.; Fangmin, Y. A new type of longitudinally driven GMI effect of FeCo-based alloy. Chin. Sci. Bull. 2008, 53, 329–334. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Gan, Z.; Chen, W.; Zhao, D. Low Frequency Giant Magneto-Impedance Effect of Co-Rich Ribbons Induced by Joule Annealing Treatment. Metals 2023, 13, 28. https://doi.org/10.3390/met13010028

Zhang S, Gan Z, Chen W, Zhao D. Low Frequency Giant Magneto-Impedance Effect of Co-Rich Ribbons Induced by Joule Annealing Treatment. Metals. 2023; 13(1):28. https://doi.org/10.3390/met13010028

Chicago/Turabian StyleZhang, Shuling, Zhiying Gan, Weiye Chen, and Dawei Zhao. 2023. "Low Frequency Giant Magneto-Impedance Effect of Co-Rich Ribbons Induced by Joule Annealing Treatment" Metals 13, no. 1: 28. https://doi.org/10.3390/met13010028