On the Generation of Excess Solid Fraction in the RheoMetal Process

Abstract

:1. Introduction

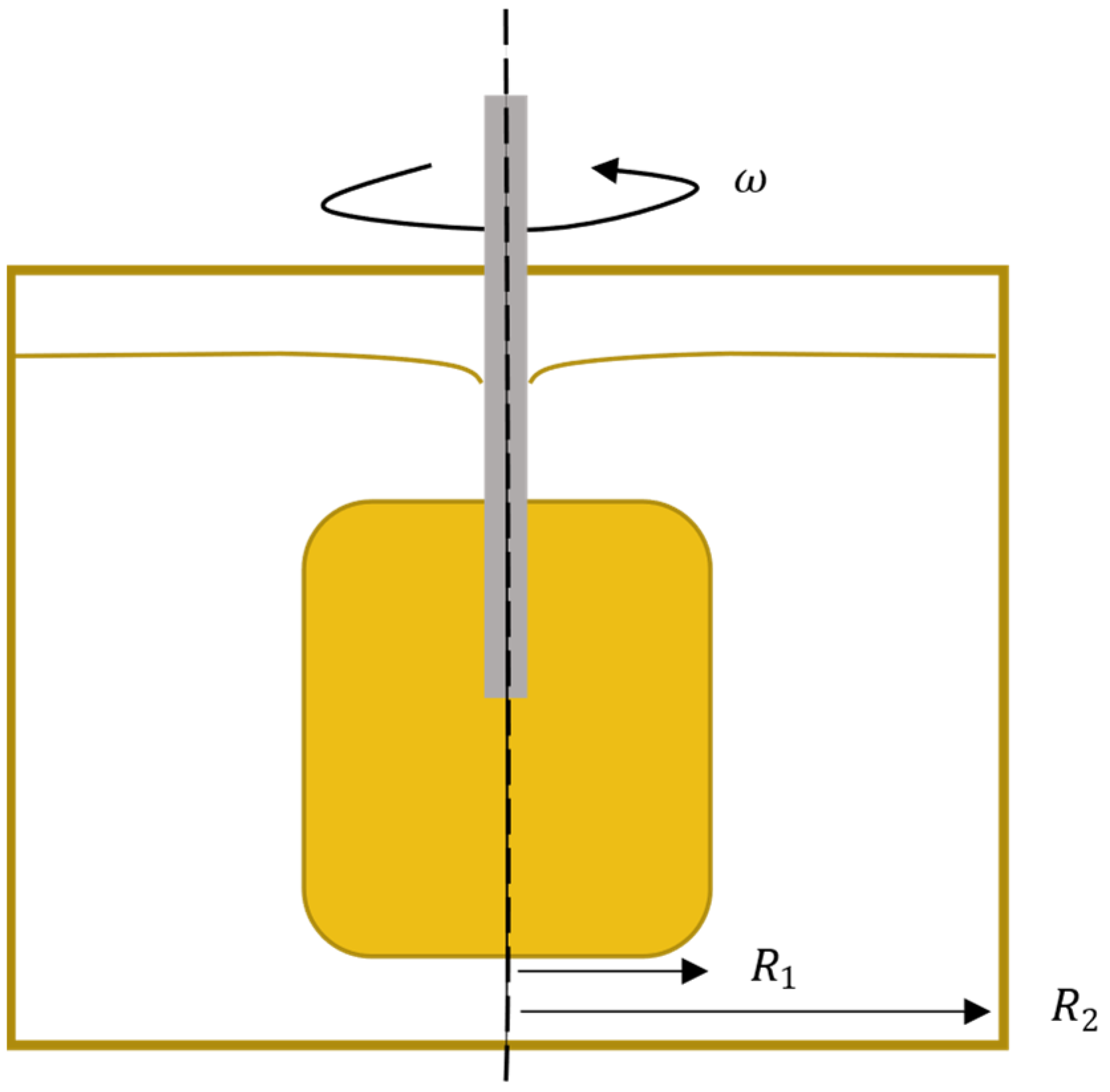

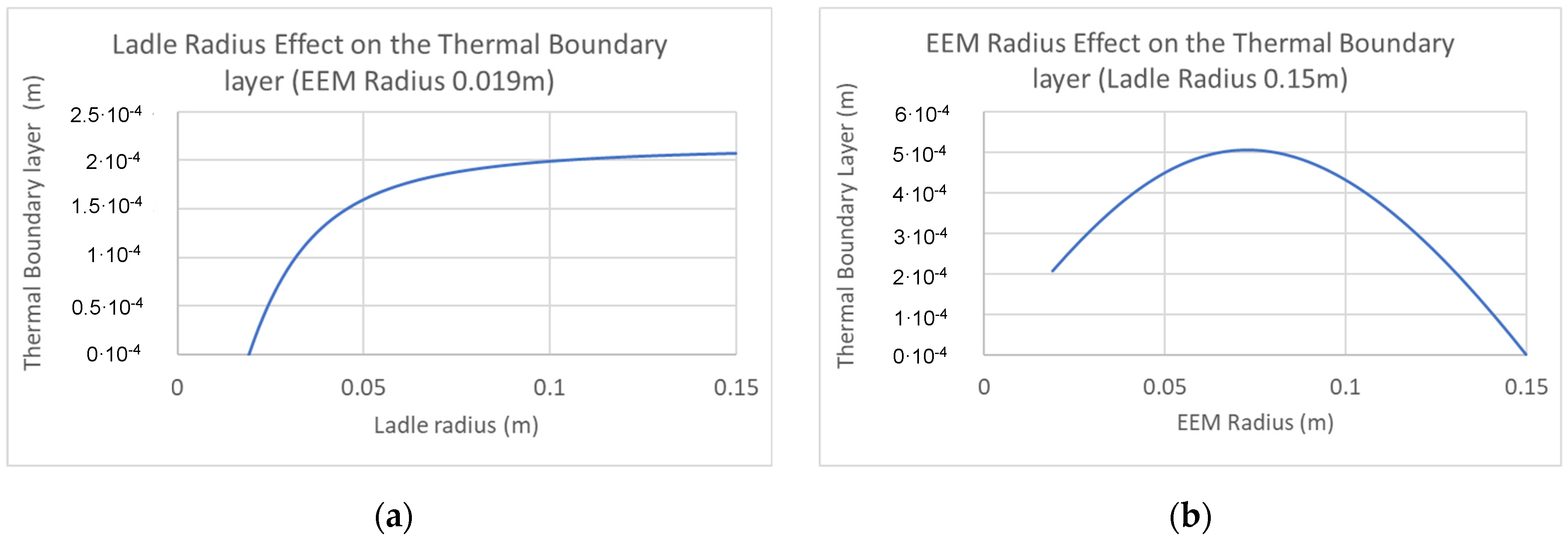

2. Methodology

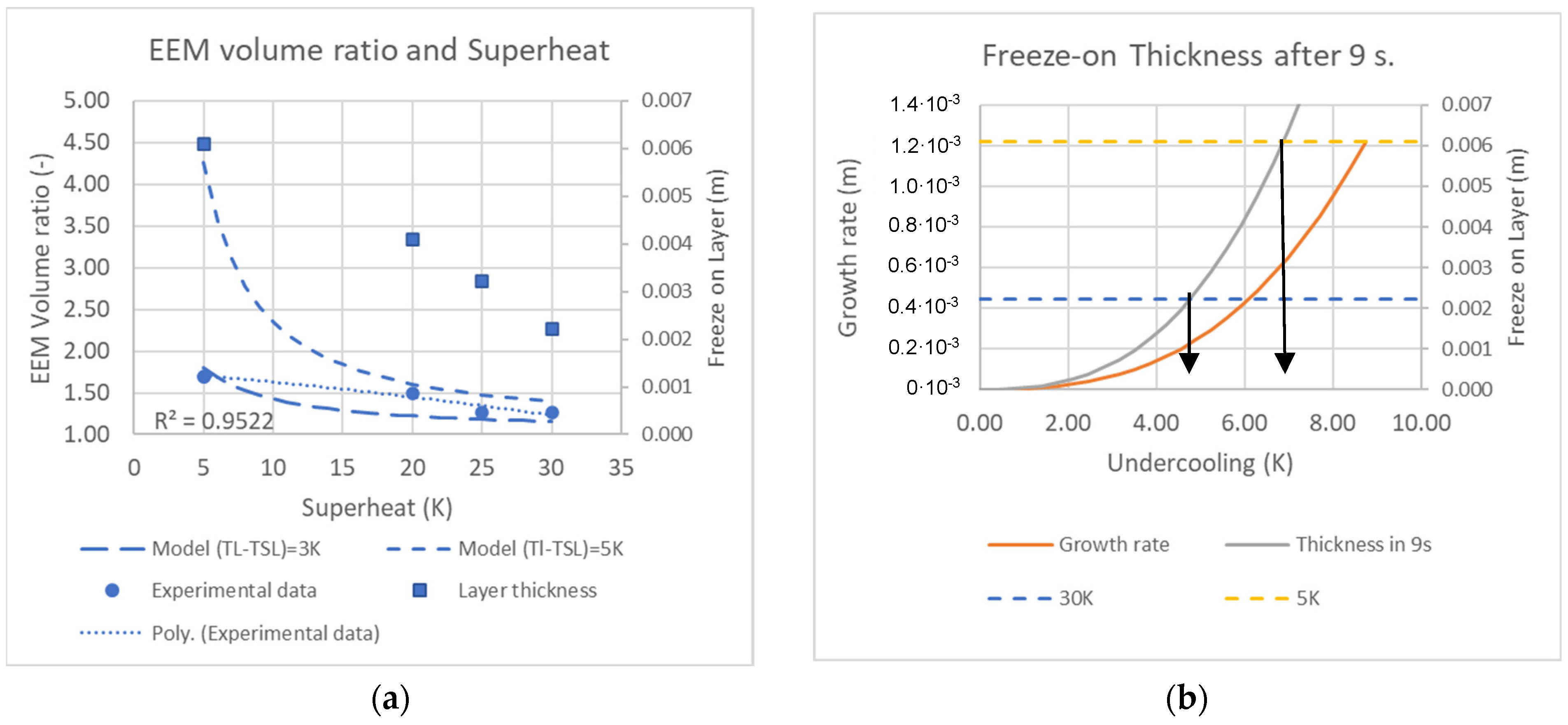

3. Model Development and Discussion

4. Conclusions

- The model developed allows for the estimation of the maximum amounts of freeze-on layer formation as a function of the superheat.

- The model confirms that the process is far from equilibrium and that the dendrite tip growth undercooling determines the final slurry temperature.

- This further implies that the assumption that the slurry is in thermal equilibrium is not valid, explaining the reasons why attempts to use macroscopic thermal balances fail to predict the slurry temperature and the solid fraction.

- The freeze-on layer formed and the contribution from the primary precipitated phase in the EEM can explain the additional solid fraction formed.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Serrenho, A.C.; Norman, J.B.; Allwood, J.M. The impact of reducing car weight on global emissions: The future fleet in Great Britain. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2017, 375, 20160364. [Google Scholar] [CrossRef] [PubMed]

- Jarfors, A.E.W.; Zheng, J.C.; Chen, L.; Yang, J. Recent Advances in Commercial Application of the Rheometal Process in China and Europe. Solid State Phenom. 2019, 285, 405–410. [Google Scholar] [CrossRef]

- Li, G.; Luo, M.; Qu, W.Y.; Lu, H.X.; Hu, X.G.; Zhu, Q. Progress of Semi-Solid Processing of Alloys and Composites in China. Solid State Phenom. 2022, 327, 178–188. [Google Scholar] [CrossRef]

- Modigell, M.; Pola, A.; Tocci, M. Rheological Characterization of Semi-Solid Metals: A Review. Metals 2018, 8, 245. [Google Scholar] [CrossRef]

- Tocci, M.; Pola, A.; Modigell, M. Visco-Elastic Properties of Semi-Solid Alloys. Solid State Phenom. 2022, 327, 119–126. [Google Scholar] [CrossRef]

- Ma, Z.; Zhang, H.; Fu, H.; Fonseca, J.; Yang, Y.; Du, M.; Zhang, H. Modelling flow-induced microstructural segregation in semi-solid metals. Mater. Des. 2022, 213, 110364. [Google Scholar] [CrossRef]

- Jarfors, A.E.W.; Jafari, M.; Aqeel, M.; Liljeqvist, P.; Jansson, P. In-Production Rheometry of Semi-Solid Metal Slurries. Metals 2022, 12, 1221. [Google Scholar] [CrossRef]

- Jarfors, A.E.W. A comparison between semisolid casting methods for aluminium alloys. Metals 2020, 10, 1368. [Google Scholar] [CrossRef]

- Santos, J.; Kallien, L.H.; Jarfors, A.E.W.; Dahle, A.K. Influence of Grain Refinement on Slurry Formation and Surface Segregation in Semi-solid Al-7Si-0.3Mg Castings. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 4871–4883. [Google Scholar] [CrossRef]

- Payandeh, M.; Jarfors, A.E.W.; Wessén, M. Effect of Superheat on Melting Rate of EEM of Al Alloys during Stirring Using the RheoMetal Process. Solid State Phenom. 2012, 192–193, 392–397. [Google Scholar] [CrossRef]

- Payandeh, M.; Sabzevar, M.H.; Jarfors, A.E.W.; Wessén, M. Solidification and Re-melting Phenomena during Slurry Preparation Using the RheoMetalTM Process. Metall. Mater. Trans. B Process Metall. Mater. Process. Sci. 2017, 48, 2836–2848. [Google Scholar] [CrossRef]

- Payandeh, M.; Jarfors, A.E.W.; Wessén, M. Solidification Sequence and Evolution of Microstructure during Rheocasting of Four Al-Si-Mg-Fe Alloys with Low Si Content. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2015, 47, 1215–1228. [Google Scholar] [CrossRef]

- Santos, J.; Jarfors, A.E.W.; Dahle, A.K. Tag-and-Trace Method of a -Al Crystals Applied to Study Solidification and Casting of Aluminum Alloys. Metall. Mater. Trans. A 2020, 53, 3311–3320. [Google Scholar] [CrossRef]

- Yih, C.-S. Fluid Mechanics; West River Press: Ann Arbor, MI, USA, 1977; ISBN 0-9602190-0-5. [Google Scholar]

- Dinsdale, A.T.; Quested, P.N. The viscosity of aluminium and its alloys—A review of data and models. J. Mater. Sci. 2004, 39, 7221–7228. [Google Scholar] [CrossRef]

- Cho, S.H.; Okane, T.; Umeda, T. The contribution of the nucleation process to grain formation in calculating solidification microstructure by CA-DFD. Sci. Technol. Adv. Mater. 2001, 2, 241–245. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jarfors, A.E.W. On the Generation of Excess Solid Fraction in the RheoMetal Process. Metals 2023, 13, 1644. https://doi.org/10.3390/met13101644

Jarfors AEW. On the Generation of Excess Solid Fraction in the RheoMetal Process. Metals. 2023; 13(10):1644. https://doi.org/10.3390/met13101644

Chicago/Turabian StyleJarfors, Anders E. W. 2023. "On the Generation of Excess Solid Fraction in the RheoMetal Process" Metals 13, no. 10: 1644. https://doi.org/10.3390/met13101644

APA StyleJarfors, A. E. W. (2023). On the Generation of Excess Solid Fraction in the RheoMetal Process. Metals, 13(10), 1644. https://doi.org/10.3390/met13101644