Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles

Abstract

:1. Introduction

2. Materials and Methods

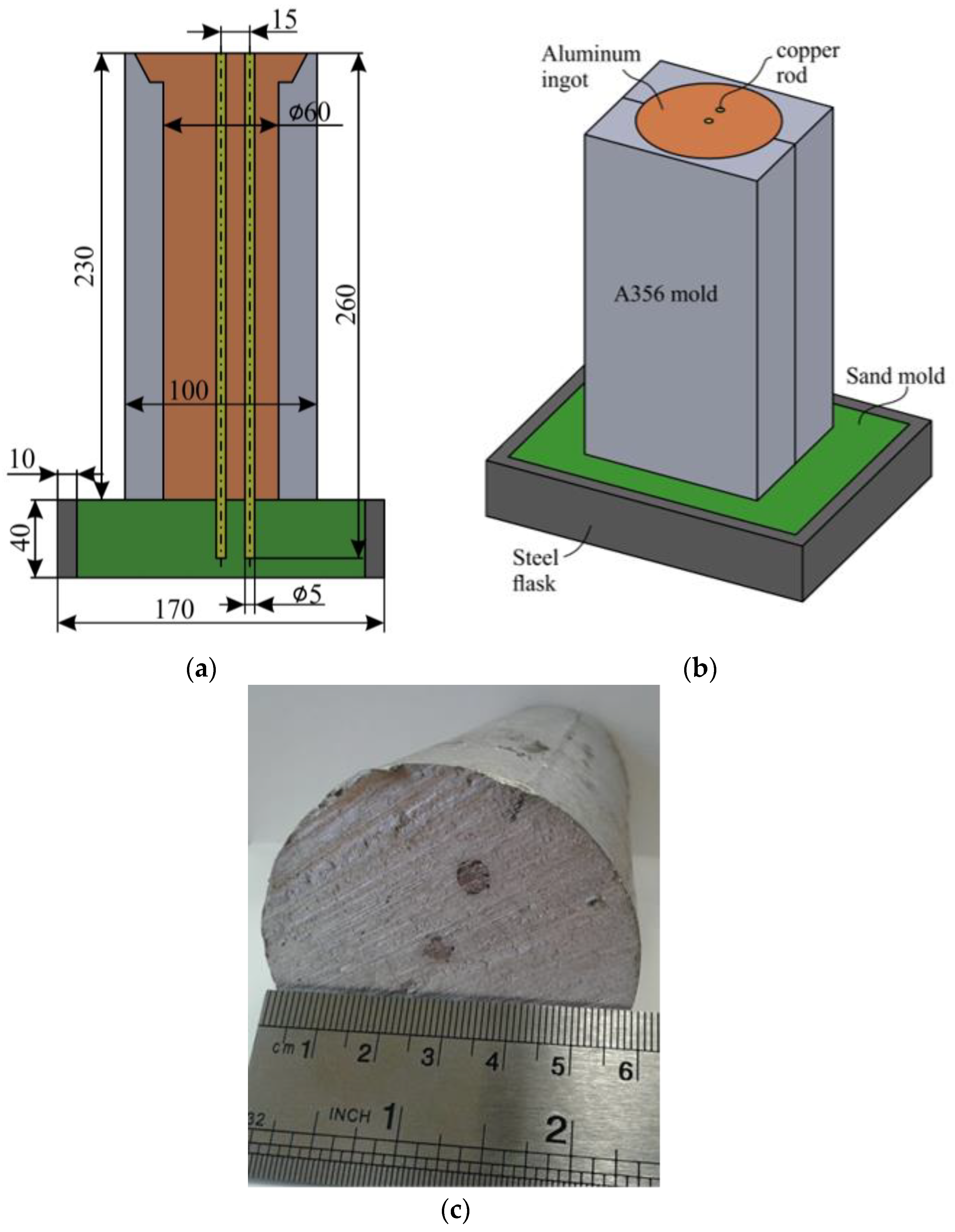

2.1. Method of Fabricating Cast Billet with Inserts

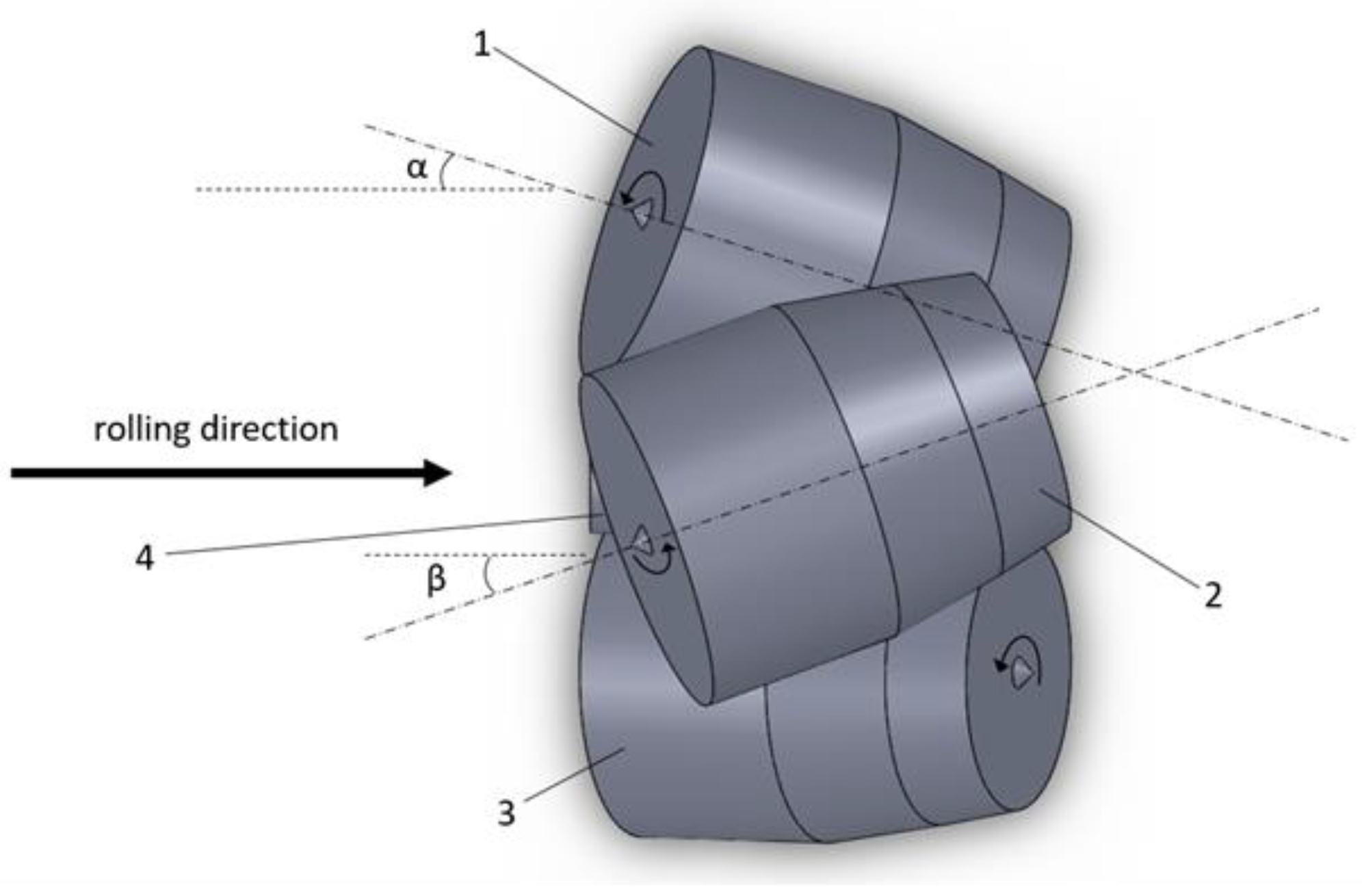

2.2. Experimental Rolling Technique

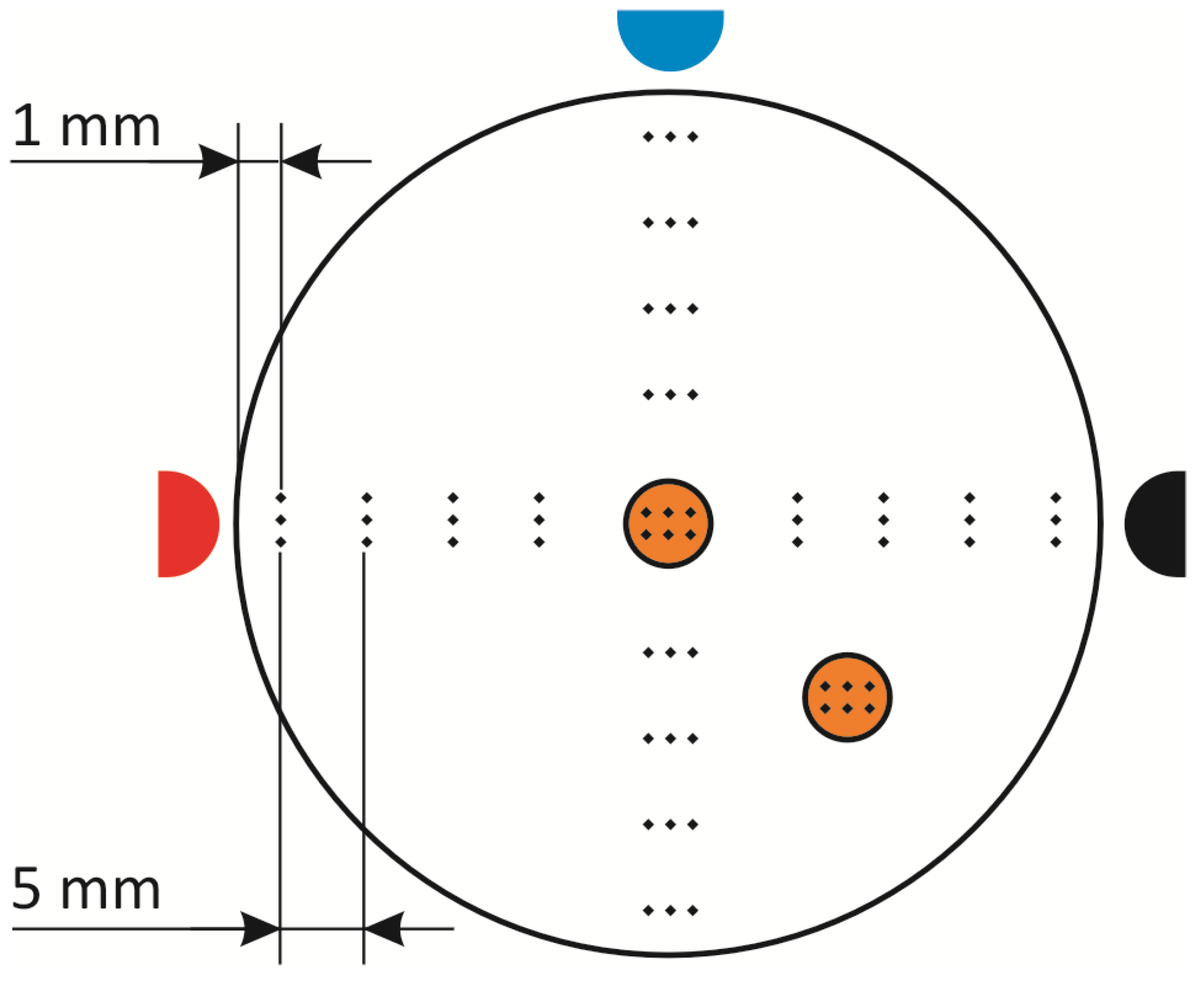

2.3. Hardness Measuring Method

2.4. Microstructure Research Method

2.5. Three-Dimensional Rolled Billets Model Creation Method

3. Results and Discussion

4. Conclusions

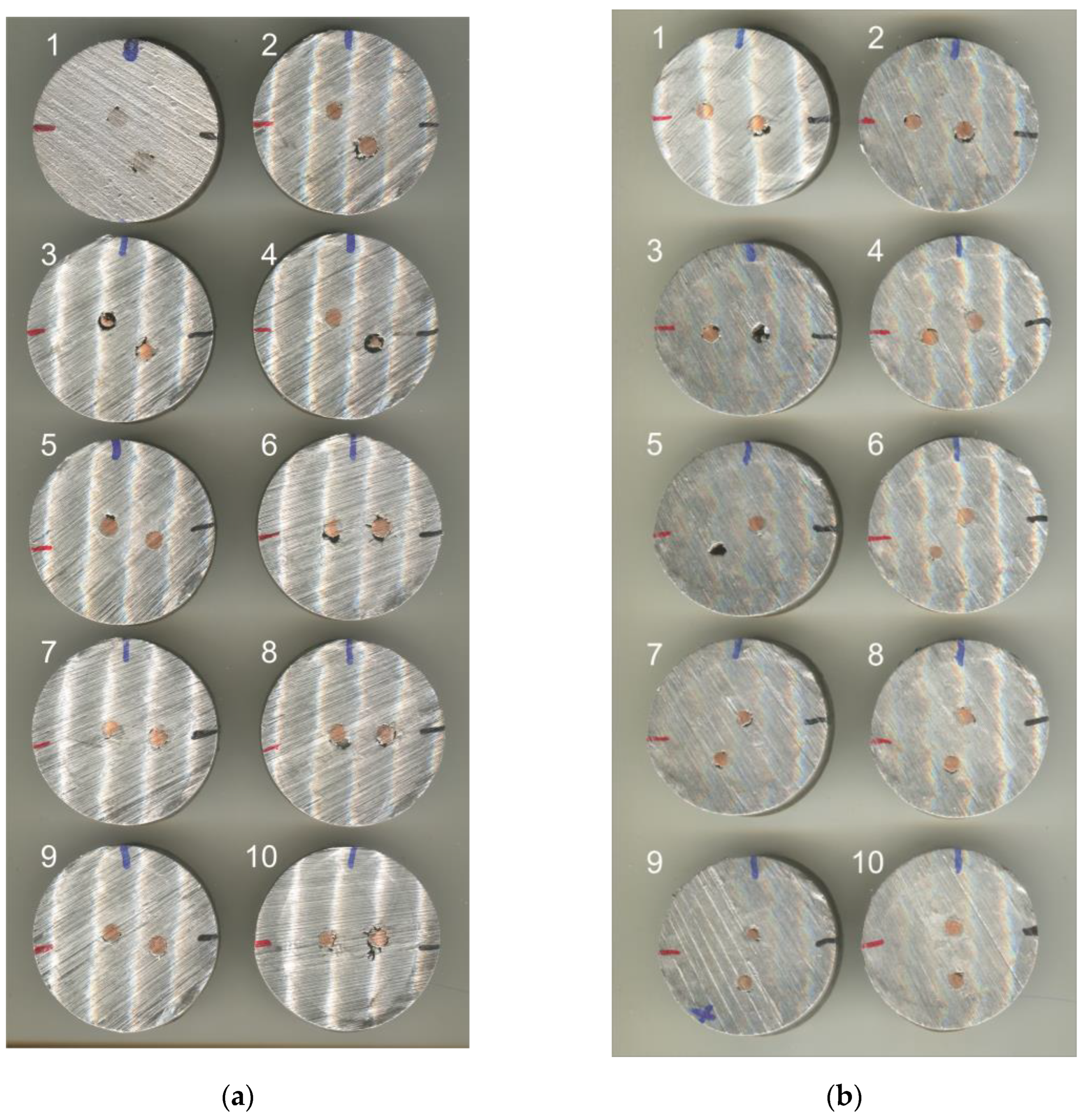

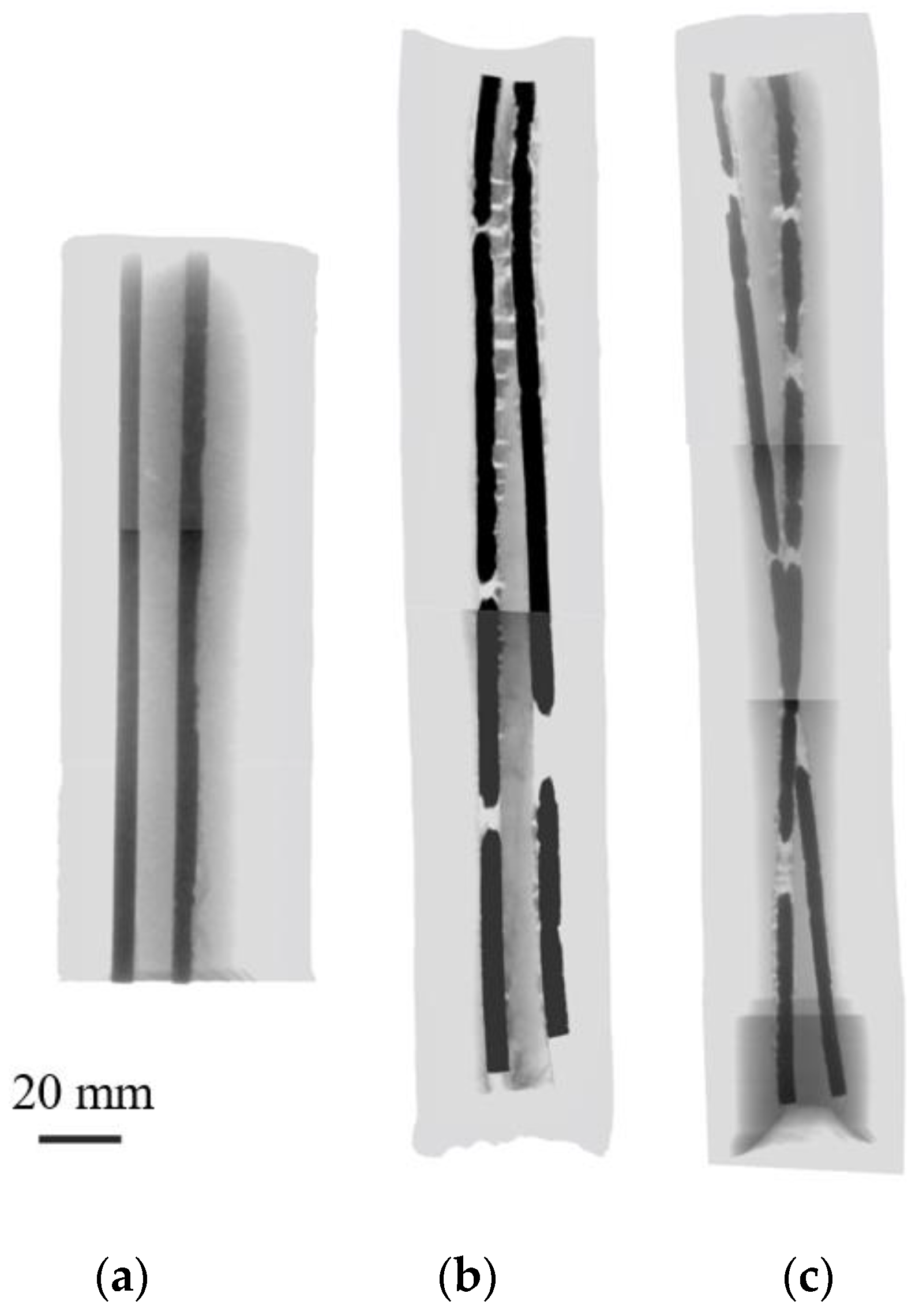

- The copper insert twist angle with respect to the central copper insert was 65 degrees after rolling with a 12-degrees feed angle and 110 degrees after rolling with a 20-degrees feed angle. This illustrates the fact that the helical character of material flow was more clearly expressed at larger rolls feed angles. However, increasing the rolls feed angle led to an increase in the deformation load on the inserts, which, in turn, led to a higher number of breaks in them: four in the center and three at the half-radius at a 20-degrees angle compared to three in the center and one at the half-radius at a 12-degrees angle.

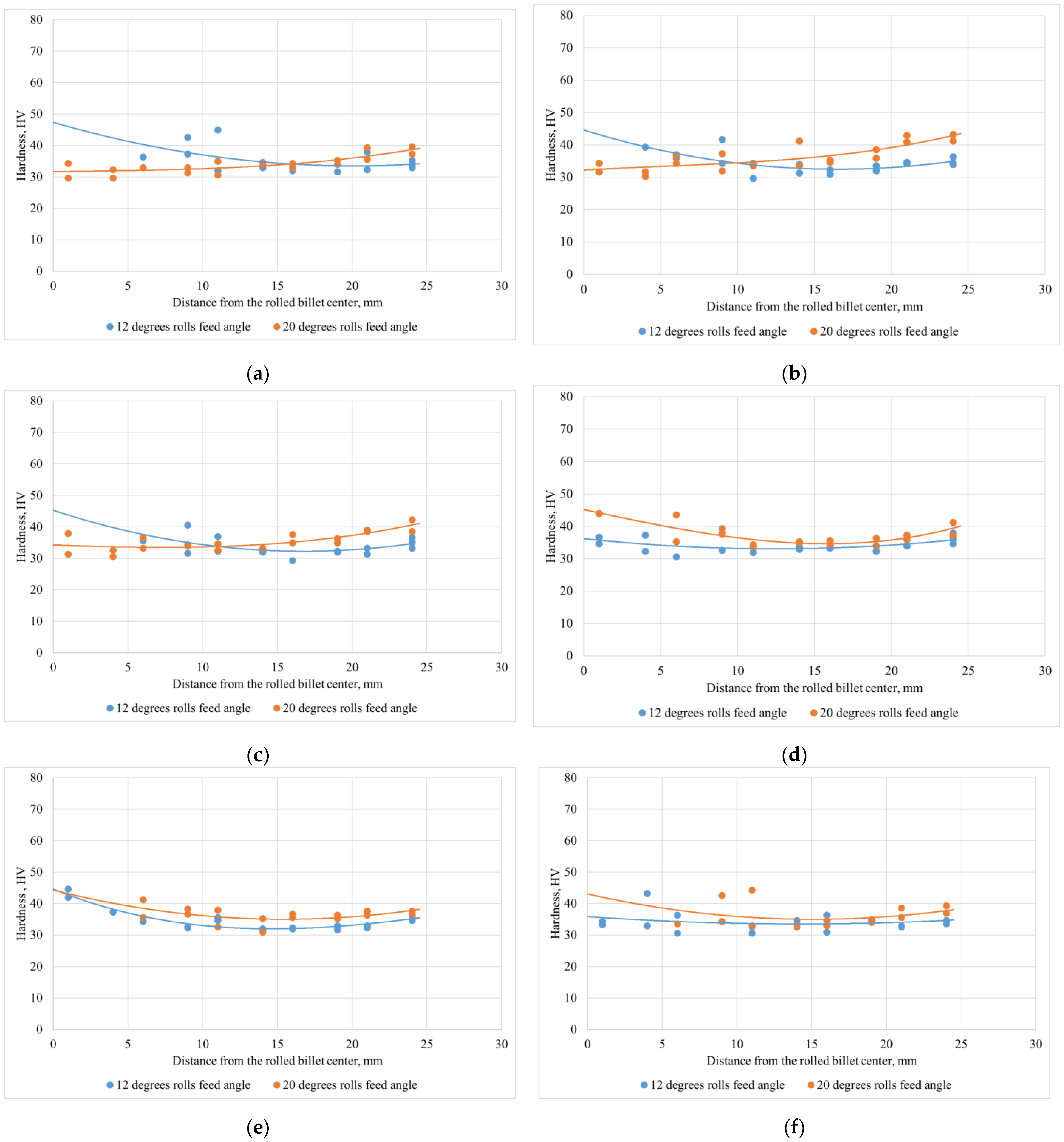

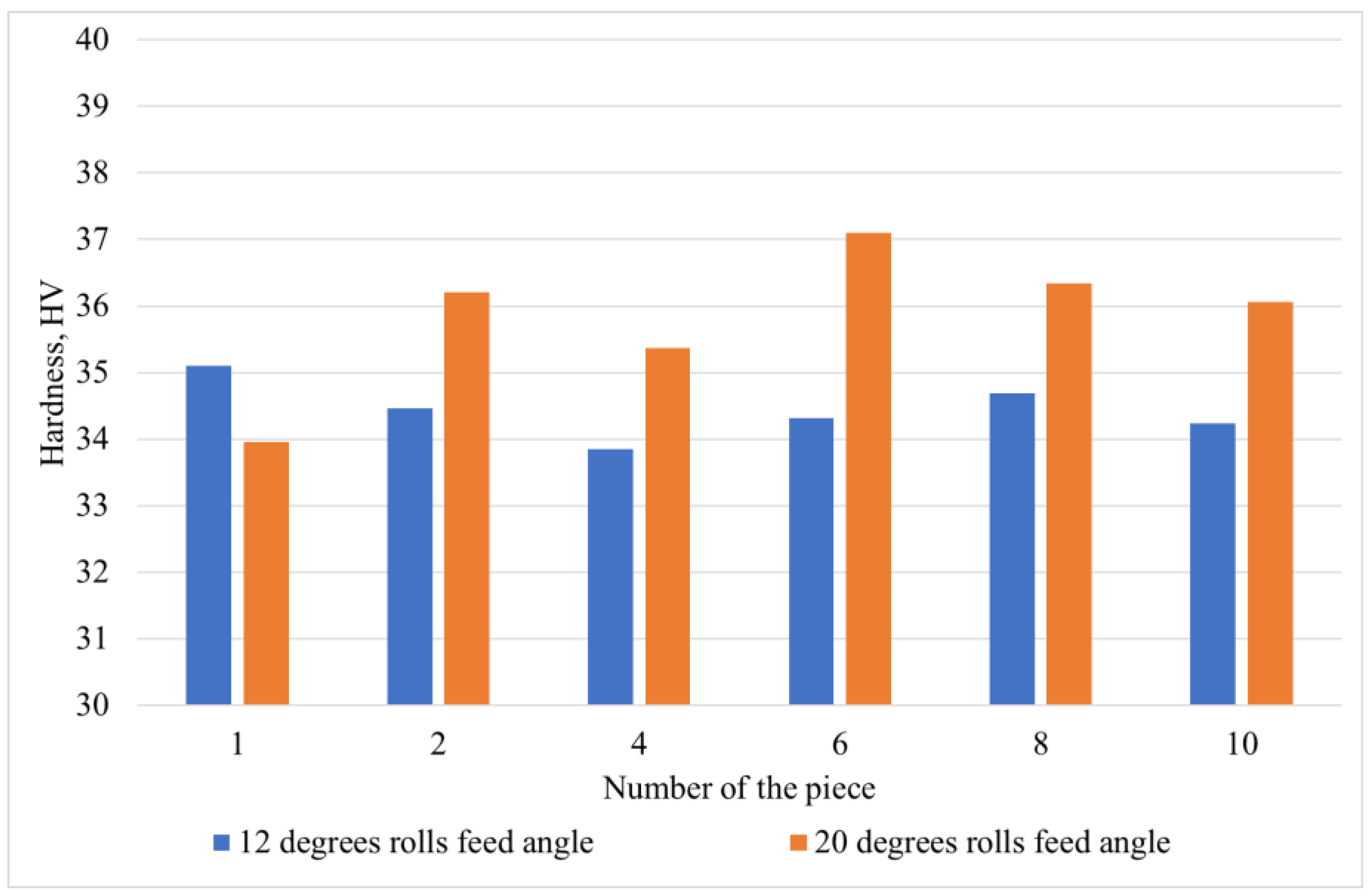

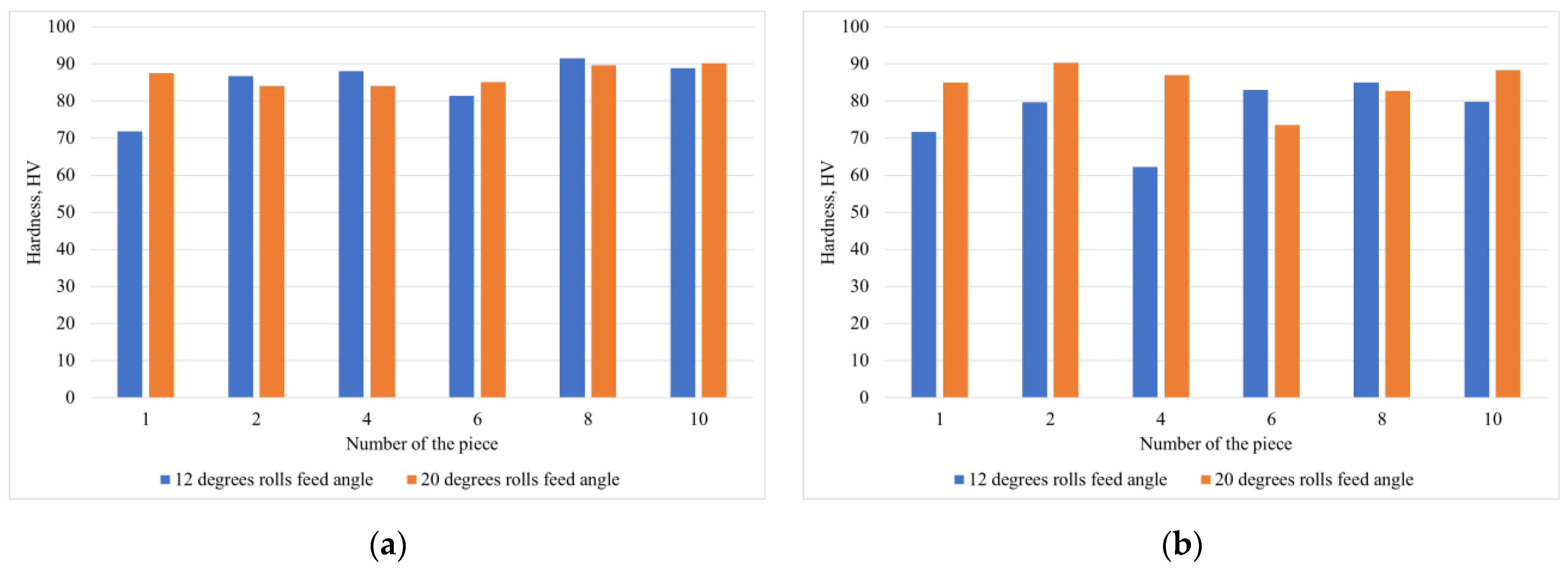

- The increase in hardness of aluminum compared to the original ingot was 8% after rolling at a 12-degrees feed angle and 14% after rolling at a 20-degrees feed angle. There were two patterns of the hardness changing, including: (1) a decrease from the center of the billet till some minimum located at 0.5–0.8 of the billet radius, followed by a monotonous increase till the billet surface; (2) a monotonic increase from the center towards the billet surface. Type one was observed at 12-degrees feed angle rolling and both types were observed at 20-degrees feed angle rolling. The copper insert’s hardness before rolling was 65–71 HV. The central copper insert hardness was 71–91 HV after rolling at a 12-degrees feed angle and 84–90 HV after rolling at a 20-degrees feed angle. The hardness of the copper insert located at the half-radius of the billet was 63–85 after 12-degrees feed angle rolling and 73–90 after 20-degrees feed angle rolling.

- The microstructure of the copper inserts did not change sufficiently after rolling at both feed angles. The aluminum before rolling had a coarse-crystalline, as-cast microstructure, and the grain size was 300–1500 μm. Grains elongated along the billet radius and twisted in one direction after rolling. Considering the results of earlier research, this phenomenon seems to be typical for three-high screw rolling and does not depend either on the forming and temperature regimes or on the billet material.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Romantsev, B.A.; Goncharuk, A.V.; Vavilkin, N.M.; Samusev, S.V. Pipe Manufacture; Izdatelskiy Dom MISiS: Moscow, Russia, 2011; ISBN 978-5-87623-504-6. (In Russian) [Google Scholar]

- Teterin, P.K. Theory of Cross and Screw Rolling; Metallurgija: Moscow, Russia, 1971; 368p. (In Russian) [Google Scholar]

- Chen, C.; Chen, J.; Shuang, Y.; Li, C. Short-flow rolling process and heat treatment of seamless titanium alloy tube. Metals 2023, 13, 527. [Google Scholar] [CrossRef]

- Potapov, I.N.; Polukhin, P.I. Screw Rolling Technology; Metallurgia: Moscow, Russia, 1990; 344p. (In Russian) [Google Scholar]

- Galkin, S.P. Theory and Technology of Steady-State Workpiece and Bar Rolling of Low-Ductility Steels and Alloys; Moscow State Institute of Steel and Alloys: Moscow, Russia, 1998. (In Russian) [Google Scholar]

- Skripalenko, M.M.; Karpov, B.V.; Rogachev, S.O.; Kaputkina, L.M.; Romantsev, B.A.; Skripalenko, M.N.; Huy, T.B.; Fadeev, V.A.; Danilin, A.V.; Gladkov, Y.A. Simulation of the kinematic condition of radial shear rolling and estimation of its influence on a titanium billet microstructure. Materials 2022, 15, 7980. [Google Scholar] [CrossRef] [PubMed]

- Kolobov, Y.R.; Golosova, O.A.; Manokhin, S.S. Regularities of Formation and Degradation of the Microstructure and Properties of New Ultrafine-Grained Low-Modulus Ti–Nb–Mo–Zr Alloys. Russ. J. Non-Ferr. Met. 2017, 59, 393–402. [Google Scholar] [CrossRef]

- Naydenkin, E.V.; Mishin, I.P.; Ratochka, I.V.; Lykova, O.N.; Zabudchenko, O.V. The effect of alpha-case formation on plastic deformation and fracture of near β titanium alloy. Mater. Sci. Eng. A 2020, 769, 138495. [Google Scholar] [CrossRef]

- Ratochka, I.V.; Mishin, I.P.; Lykova, O.N.; Naydenkin, E.V.; Varlamova, N.V. Structural Evolution and Mechanical Properties of a VT22 Titanium Alloy Under High-Temperature Deformation. Russ. Phys. J. 2016, 59, 397–402. [Google Scholar] [CrossRef]

- Ding, X.; Sun, L.; Huang, X.; Zhao, Z. Research on Three-Roll Screw Rolling Process for Ti6Al4V Titanium Alloy Bar. High Temp. Mater. Process. 2018, 38, 178–182. [Google Scholar] [CrossRef]

- Gamin, Y.V.; Muñoz Bolaños, J.A.; Aleschenko, A.S.; Komissarov, A.A.; Bunits, N.S.; Nikolaev, D.A.; Fomin, A.V.; Cheverikin, V.V. Influence of the radial-shear rolling (RSR) process on the microstructure, electrical conductivity and mechanical properties of a Cu–Ni–Cr–Si alloy. Mater. Sci. Eng. A 2021, 822, 141676. [Google Scholar] [CrossRef]

- Dobatkin, S.; Galkin, S.; Estrin, Y.; Serebryany, V.; Diez, M.; Martynenko, N.; Lukyanova, E.; Perezhogin, V. Grain refinement, texture, and mechanical properties of a magnesium alloy after radial-shear rolling. J. Alloys Compd. 2019, 774, 969–979. [Google Scholar] [CrossRef]

- Stefanik, A.; Szota, P.; Mróz, S.; Bajor, T.; Dyja, H. Properties of the AZ31 Magnesium Alloy Round Bars Obtained in Different Rolling Processes/Własności Prętów Okrągłych Ze Stopu Magnezu AZ31 Otrzymanych WRóznych Procesach Walcowania. Arch. Metall. Mater. 2015, 60, 3001–3006. [Google Scholar] [CrossRef]

- Stefanik, A.; Szota, P.; Mróz, S. Analysis of the Effect of Rolling Speed on the Capability to Produce Bimodal-Structure AZ31 Alloy Bars in the Three-High Skew Rolling Mill. Arch. Metall. Mater. 2020, 65, 329–335. [Google Scholar]

- Wang, L.; Zhang, Z.; Zhang, H.; Wang, H.; Shin, K. The dynamic recrystallization and mechanical property responses during hot screw rolling on pre-aged ZM61 magnesium alloys. Mater. Sci. Eng. A 2020, 798, 140126. [Google Scholar] [CrossRef]

- Patrin, P.V.; Karpov, B.V.; Aleshchenko, A.S.; Galkin, S.P. Capability Process Assessment of Radial-Displacement Rolling of Heat-Resistant Alloy HN73MBTYU. Steel Transl. 2020, 50, 42–45. [Google Scholar] [CrossRef]

- Arbuz, A.; Kawalek, A.; Ozhmegov, K.; Daniyeva, N.; Panin, E. Obtaining of UFG Structure of Zr-1% Nb Alloy by Radial-Shear Rolling. In Proceedings of the 29th International Conference on Metallurgy and Materials, Brno, Czech Republic, 20–22 May 2020; pp. 333–338. [Google Scholar]

- Gamin, Y.V.; Akopyan, T.K.; Koshmin, A.N.; Dolbachev, A.P.; Goncharuk, A.V. Microstructure evolution and property analysis of commercial pure Al alloy processed by radial-shear rolling. Arch. Civ. Mech. Eng. 2020, 20, 143. [Google Scholar] [CrossRef]

- Akopyan, T.K.; Belov, N.A.; Aleshchenko, A.S.; Galkin, S.P.; Gamin, Y.V.; Gorshenkov, M.V.; Cheverikin, V.V.; Shurkin, P.K. Formation of the gradient microstructure of a new Al alloy based on the Al-Zn-Mg-Fe-Ni system processed by radial-shear rolling. Mater. Sci. Eng. A 2019, 746, 134–144. [Google Scholar] [CrossRef]

- Derevyagina, L.S.; Gordienko, A.I.; Pochivalov, Y.I.; Smirnova, A.S. Modification of the Structure of Low-Carbon Pipe Steel by Helical Rolling, and the Increase in Its Strength and Cold Resistance. Phys. Met. Metallogr. 2018, 119, 83–91. [Google Scholar] [CrossRef]

- Panin, S.; Vlasov, I.; Maksimov, P.; Moiseenko, D.; Maruschak, P.; Yakovlev, A.; Schmauder, S.; Berto, F. Increasing Fatigue Life of 09Mn2Si Steel by Helical Rolling: Theoretical–Experimental Study on Governing Role of Grain Boundaries. Materials 2020, 13, 4531. [Google Scholar] [CrossRef]

- Panin, S.; Vlasov, I.; Moiseenko, D.; Maksimov, P.; Maruschak, P.; Yakovlev, A.; Gomorova, J.; Mishin, I.; Schmauder, S. Increasing Low-Temperature Toughness of 09Mn2Si Steel through Lamellar Structuring by Helical Rolling. Metals 2021, 11, 352. [Google Scholar] [CrossRef]

- Bogatov, A.A.; Panov, E.I. Effect of Stress-strain State during Helical Rolling on Metal and Alloy Structure and Ductility. Metallurgist 2013, 57, 434–441. [Google Scholar] [CrossRef]

- Lezhnev, S.N.; Naizabekov, A.B.; Volokitina, I.E.; Panin, E.A.; Kuis, D.V. Recycling of stainless steel bar scrap by radial-shear rolling to obtain an ultrafine-grained gradient structure. Litiyo Metall. (Foundry Prod. Metall.) 2021, 2, 61–67. [Google Scholar] [CrossRef]

- Zhuchin, V.N.; Potapov, I.N.; Aleksandrovich, A.I.; Akhmedshin, R.I.; Kharitonov, E.A.; Dereviashkin, V.P.; Zimin, V.Y. Moscow Steel and Alloys Institute (Elektrostal Branch), Assignee. Sample for the Research of Stress-Strain State. Soviet Union Patent SU 946707, 4 February 1981. [Google Scholar]

- Vorontsov, V.K.; Polukhin, P.I.; Belevitin, V.A.; Brinza, V.V. Experimental Methods of Mechanics of Deformable Solids (Technological Challenges of Metal Forming); Metallurgia: Moscow, Russia, 1990; 480p, ISBN 5-229-00175-5. (In Russian) [Google Scholar]

- Belevitin, V.A. Design and Improvement of Methods of Experimental Mechanics for Metal Forming Technological Processes Optimization; Ufalei Metallurgical Engineering Plant: Verkhniy Ufalei City, Russia, 1997. (In Russian) [Google Scholar]

- Watanabe, T.; Komatu, S.; Yanagisawa, A.; Konuma, S. Development of flux and filler metal for brazing magnesium alloy AZ31B. Yosetsu Gakkai Ronbunshu/Q. J. JPN Weld. 2004, 22, 163–167. [Google Scholar]

- Skripalenko, M.M.; Romantsev, B.A.; Kaputkina, L.M.; Galkin, S.P.; Skripalenko, M.N.; Cheverikin, V.V. Study of transient and steady-state stages during two-high and three-high screw rolling of a 12kh18n10t steel workpiece. Metallurgist 2019, 63, 366–375. [Google Scholar] [CrossRef]

- Skripalenko, M.M.; Galkin, S.P.; Karpov, B.V.; Romantsev, B.A.; Kaputkina, L.M.; Danilin, A.V.; Skripalenko, M.N.; Patrin, P.V. Forming features and properties of titanium alloy billets after radial-shear rolling. Materials 2019, 12, 3179. [Google Scholar] [CrossRef] [PubMed]

- Surikova, N.S.; Vlasov, I.V.; Derevyagina, L.S.; Gordienko, A.I.; Narkevich, N.A. Influence of cross-screw rolling modes on mechanical properties and fracture toughness of Pipe Steel. Izv. Ferr. Metall. 2021, 64, 28–37. [Google Scholar] [CrossRef]

- Bikmukhametova, A.; Galieva, E.; Valeev, I.; Klassman, E.; Musabirov, I.; Valitov, V. The influence of radial shear rolling on the structure and properties of 58ni-cr-Mo-B-al-Cu Superalloy. Lett. Mater. 2021, 11, 566–570. [Google Scholar] [CrossRef]

- Stefanik, A.; Szota, P.; Mróz, S.; Wachowski, M. Changes in the properties in bimodal Mg alloy bars obtained for various deformation patterns in the RSR rolling process. Materials 2022, 15, 954. [Google Scholar] [CrossRef]

- Shaposhnikov, M.A. Mechanical Testing of Metals; Gosudarstvennoe Nauchno-Tehnicheskoe Mashinostroitelnoy Literature: Moscow-Leningrad, Russia, 1951; p. 385. (In Russian) [Google Scholar]

- McLean, D. Mechanical Properties of Metals, 1st ed.; Wiley: New York, NY, USA, 1962; p. 407. [Google Scholar]

- Nikulin, A.N. Screw Rolling. Stresses and Strains; Metallurgizdat: Moscow, Russia, 2015; ISBN 978-5-902194-82-8. (In Russian) [Google Scholar]

- Skripalenko, M.M.; Rogachev, S.O.; Romantsev, B.A.; Galkin, S.P.; Kaputkina, L.M.; Skripalenko, M.N.; Danilin, A.V.; Fadeev, V.A. Creation of 3D model of stainless-steel billet’s grain after three-high screw rolling. Materials 2022, 15, 995. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skripalenko, M.M.; Rogachev, S.O.; Bazhenov, V.E.; Romantsev, B.A.; Skripalenko, M.N.; Karpov, B.V.; Titov, A.Y.; Koltygin, A.V.; Danilin, A.V. Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles. Metals 2023, 13, 1671. https://doi.org/10.3390/met13101671

Skripalenko MM, Rogachev SO, Bazhenov VE, Romantsev BA, Skripalenko MN, Karpov BV, Titov AY, Koltygin AV, Danilin AV. Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles. Metals. 2023; 13(10):1671. https://doi.org/10.3390/met13101671

Chicago/Turabian StyleSkripalenko, Mikhail M., Stanislav O. Rogachev, Viacheslav E. Bazhenov, Boris A. Romantsev, Mikhail N. Skripalenko, Boris V. Karpov, Andrey Yu. Titov, Andrey V. Koltygin, and Andrei V. Danilin. 2023. "Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles" Metals 13, no. 10: 1671. https://doi.org/10.3390/met13101671

APA StyleSkripalenko, M. M., Rogachev, S. O., Bazhenov, V. E., Romantsev, B. A., Skripalenko, M. N., Karpov, B. V., Titov, A. Y., Koltygin, A. V., & Danilin, A. V. (2023). Research of Three-High Screw Rolling of Aluminum Billets with Copper Inserts at Different Rolls Feed Angles. Metals, 13(10), 1671. https://doi.org/10.3390/met13101671