The Structural and Mechanical Properties of CrAlTiN-Si Nanostructured Coatings Deposited by the Means of High-Power Impulse Magnetron Sputtering

Abstract

:1. Introduction

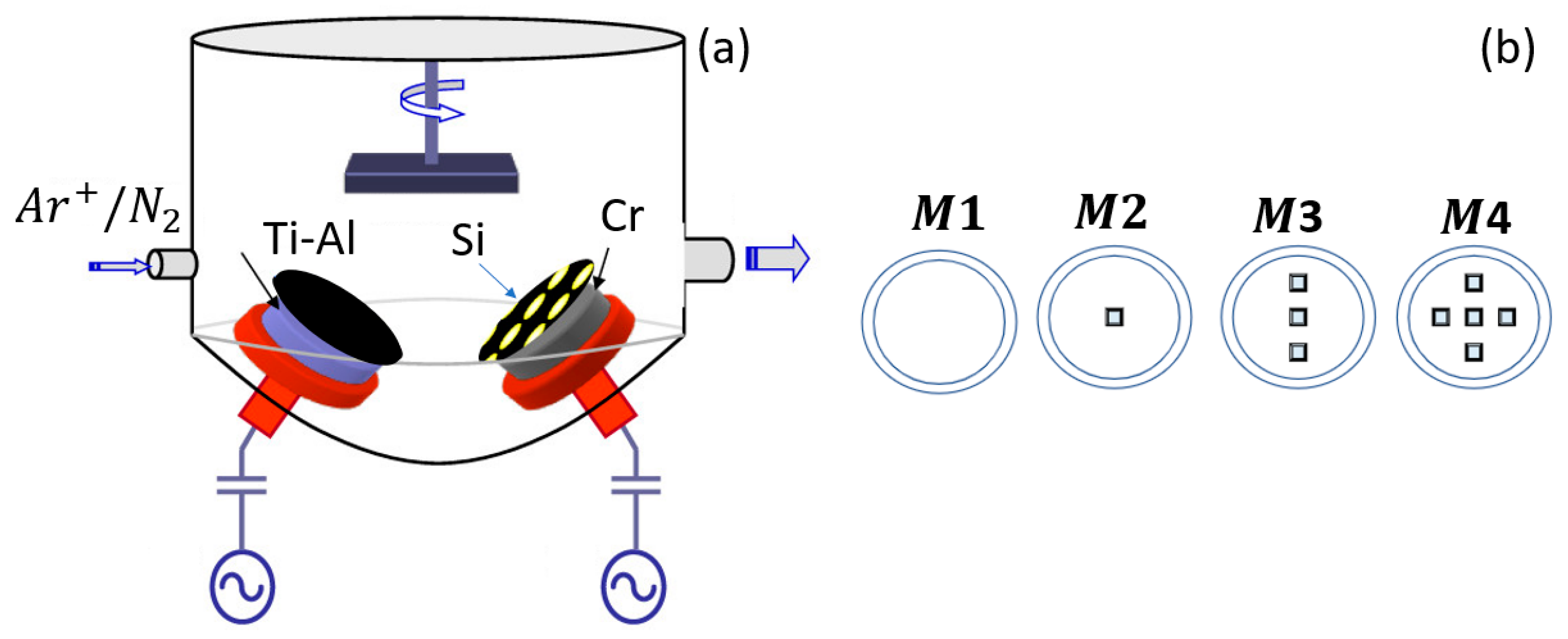

2. Materials and Methods

2.1. Coating Deposition

2.2. Coating Characterization

3. Results

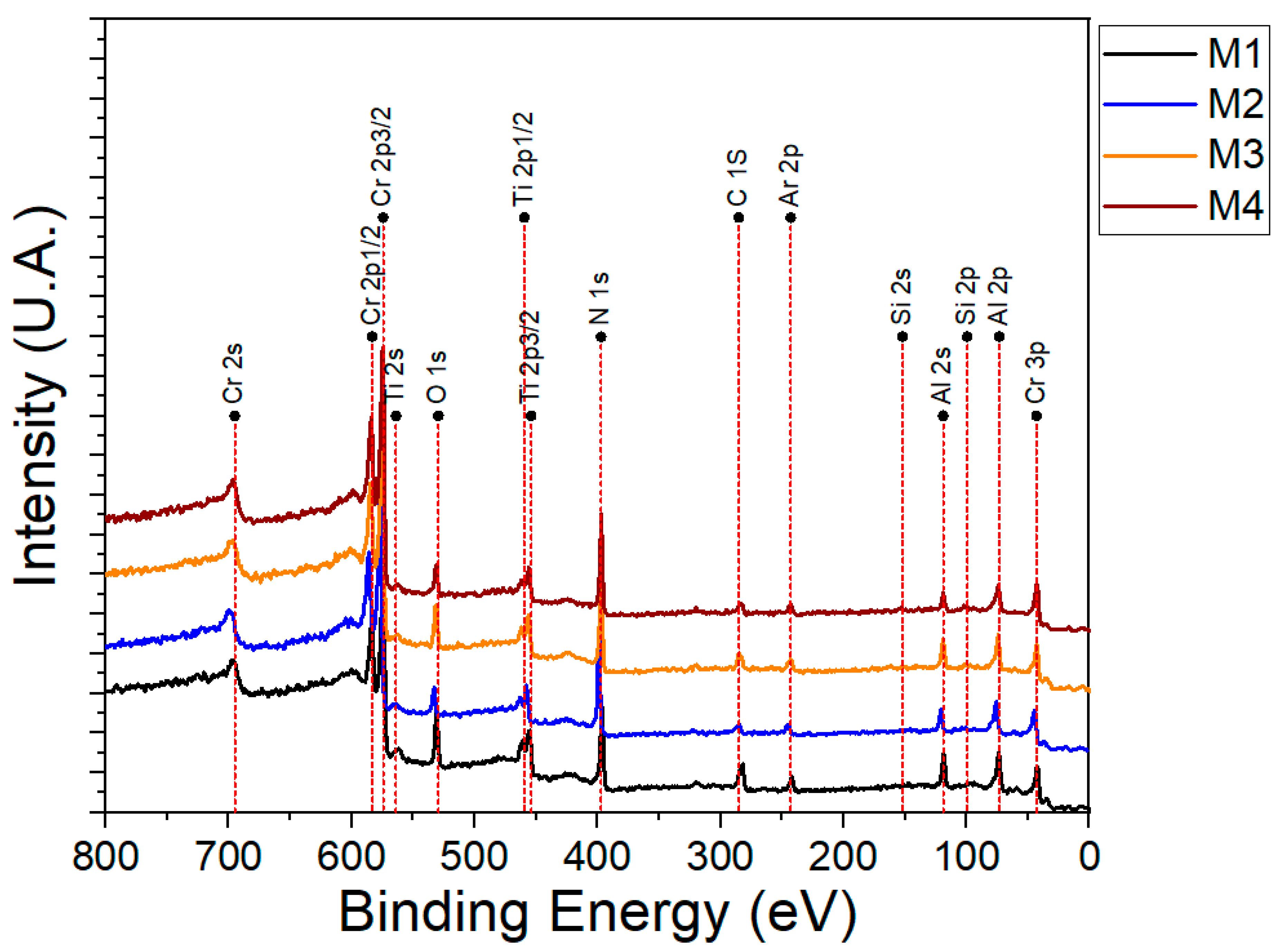

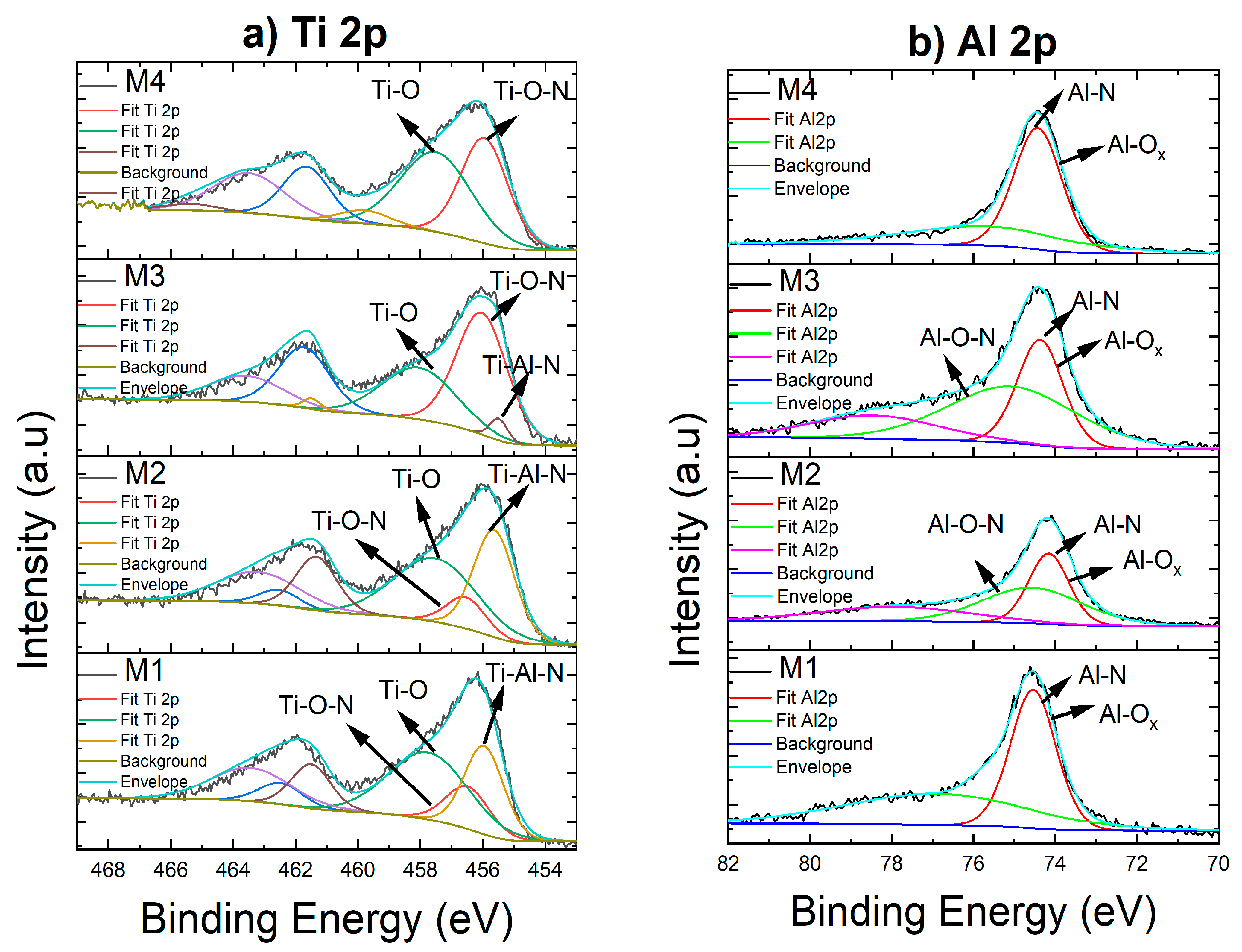

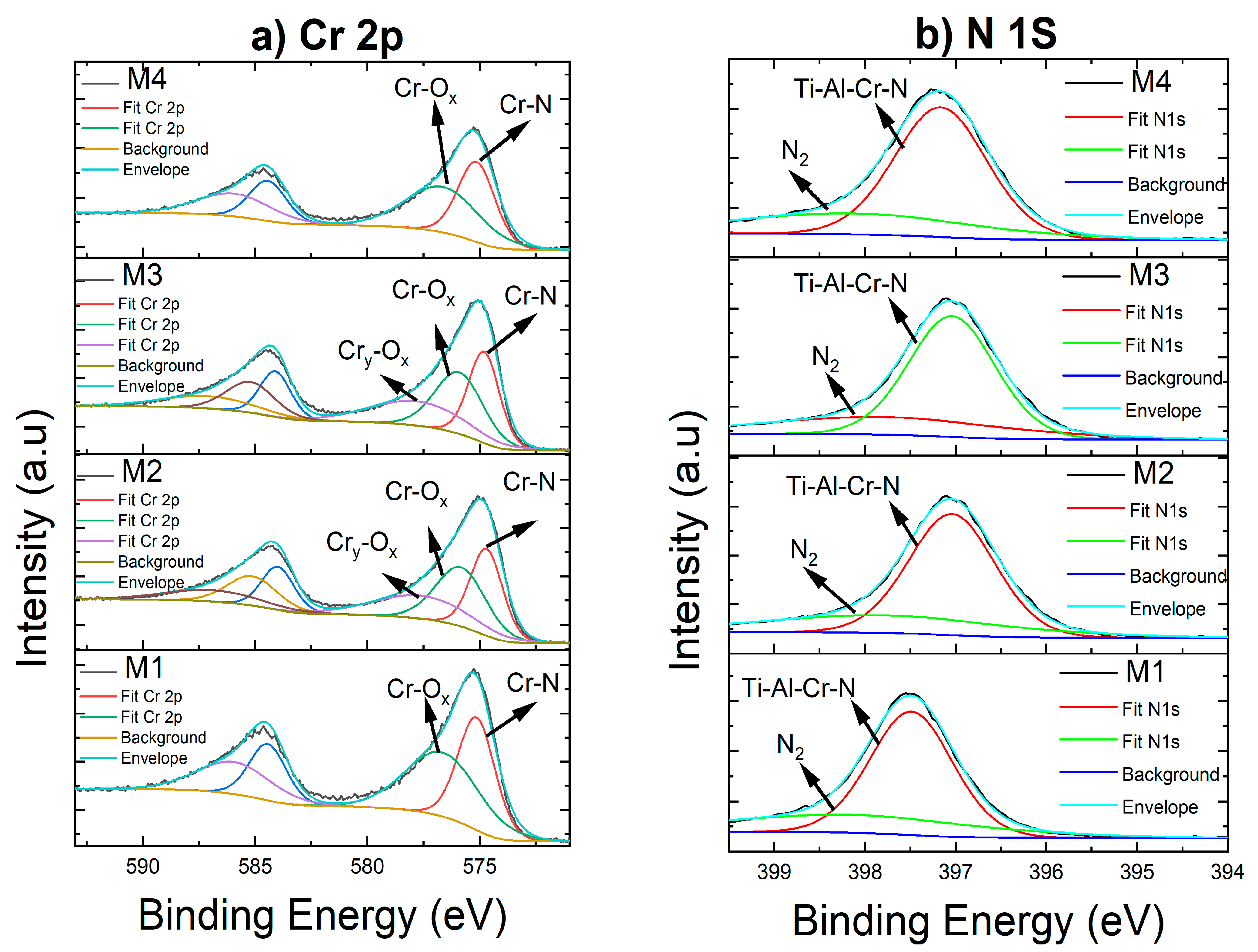

3.1. Chemical Composition

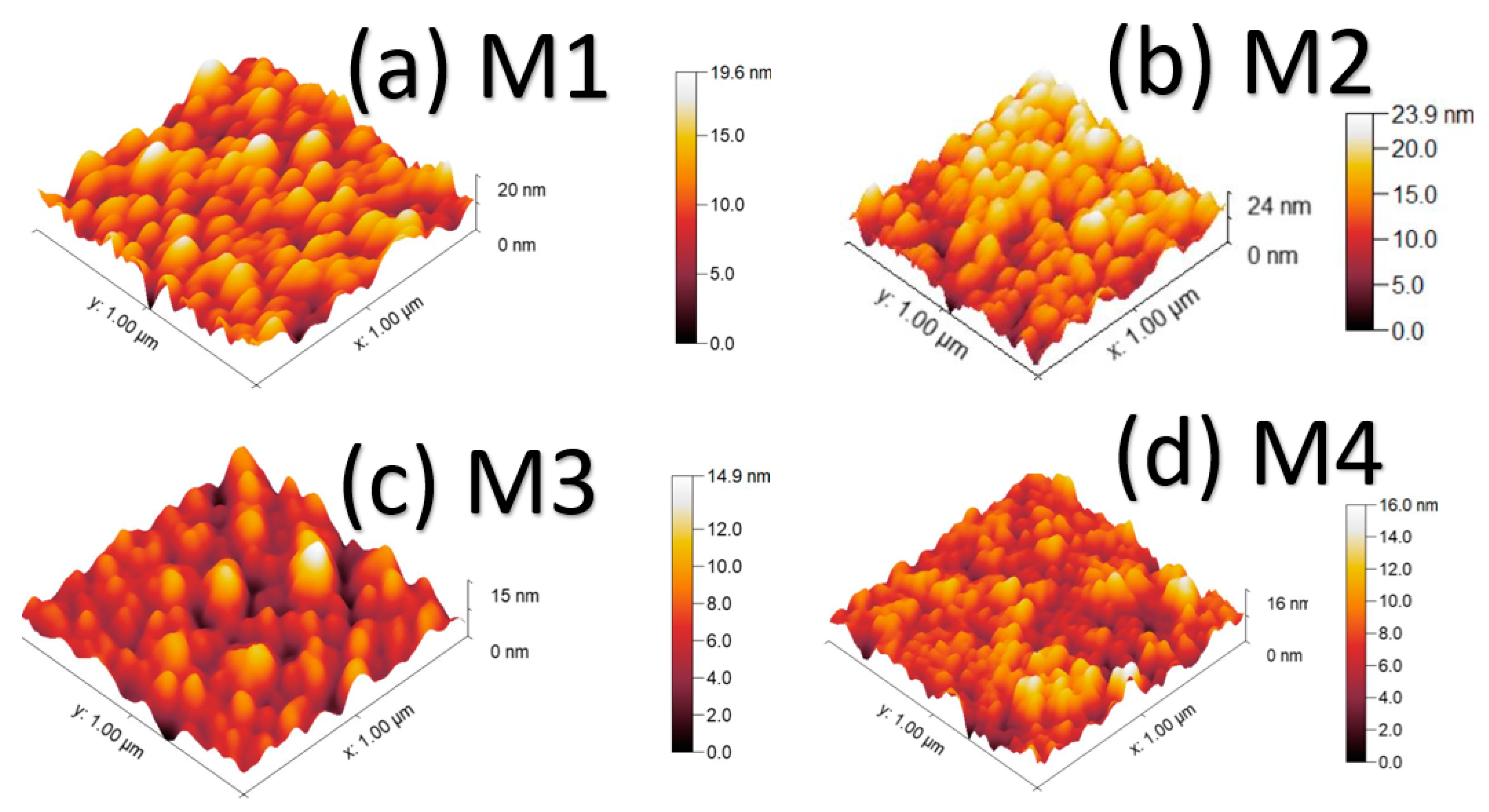

3.2. Morphological Characterization

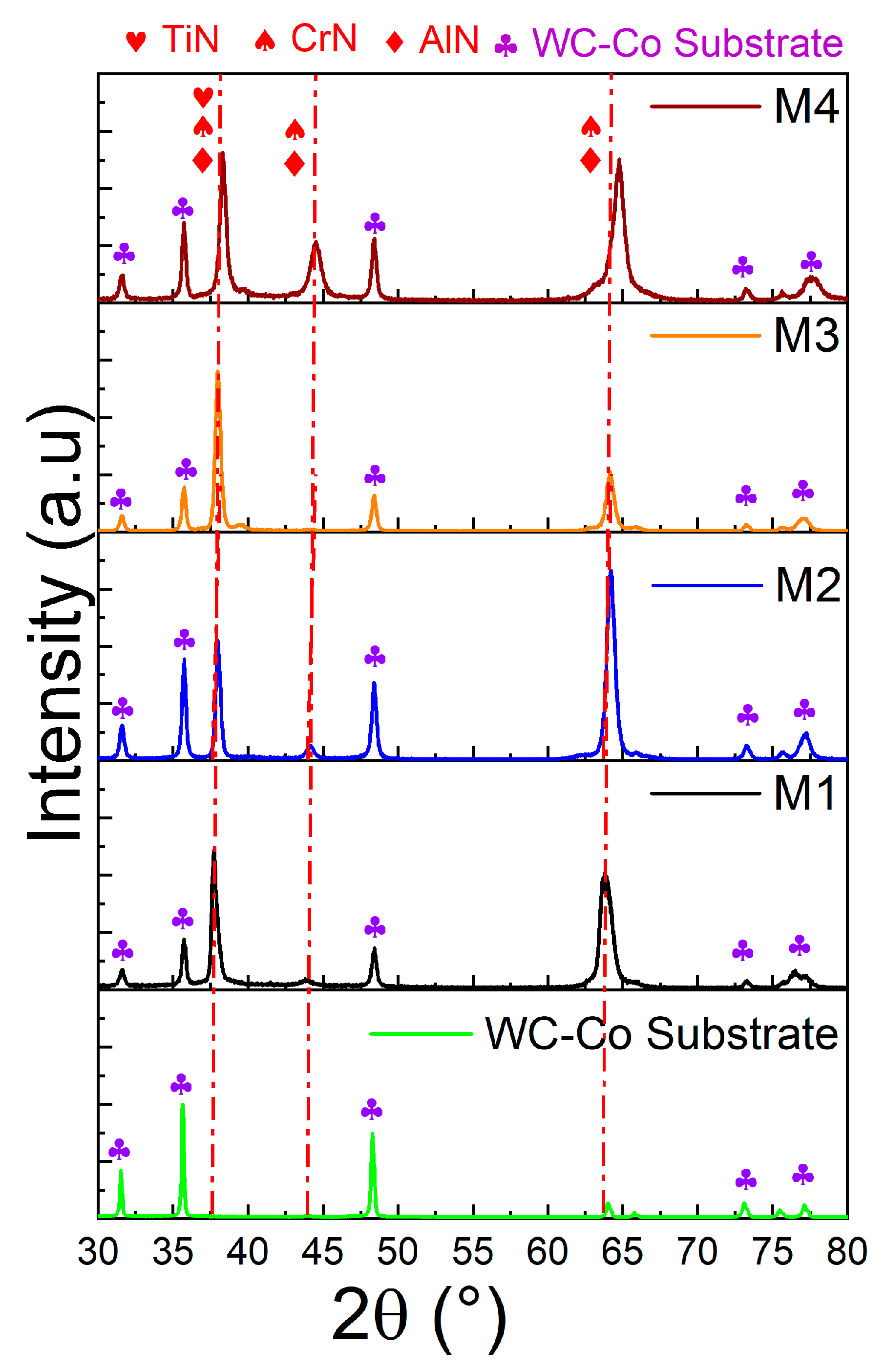

3.3. Structural Characterization

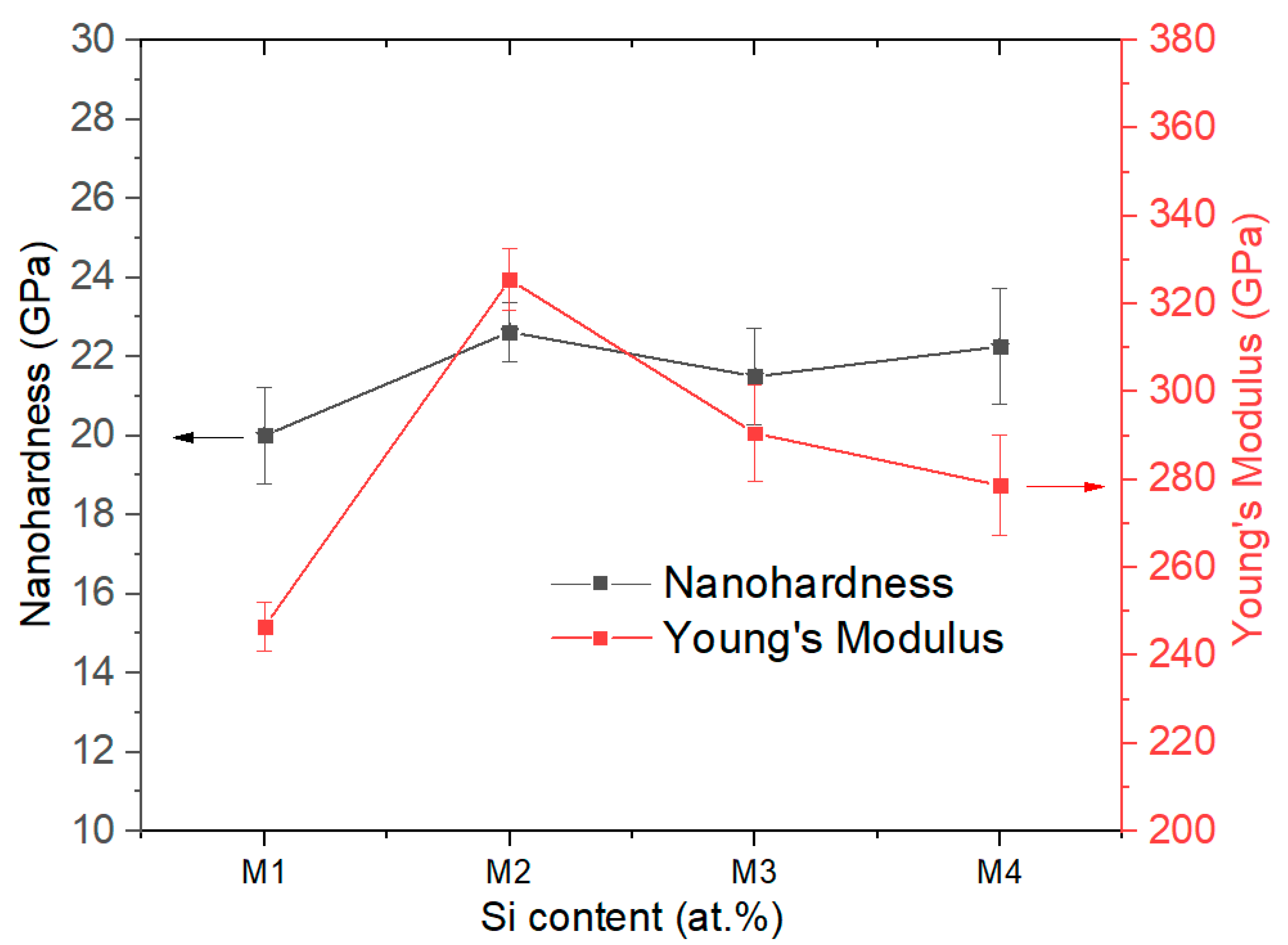

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Von Fieandt, L.; Larsson, T.; Lindahl, E.; Bäcke, O.; Boman, M. Chemical Vapor Deposition of TiN on Transition Metal Substrates. Surf. Coat. Technol. 2018, 334, 373–383. [Google Scholar] [CrossRef]

- Das, K.; Sen, S.; Joseph, A.; Ghosh, A.; Rane, R.; Biswas, K.; Mukherjee, S.; Ghosh, M. Investigation on the Effects of Pretreatment on the Surface Characteristics of Duplex Plasma-Treated AISI P20 Tool Steel. Materialia 2023, 27, 101679. [Google Scholar] [CrossRef]

- Beake, B.D.; Bird, A.; Isern, L.; Endrino, J.L.; Jiang, F. Elevated Temperature Micro-Impact Testing of TiAlSiN Coatings Produced by Physical Vapour Deposition. Thin Solid Film. 2019, 688, 137358. [Google Scholar] [CrossRef]

- Alhafian, M.R.; Chemin, J.B.; Valle, N.; El Adib, B.; Penoy, M.; Bourgeois, L.; Ghanbaja, J.; Barrirero, J.; Soldera, F.; Mücklich, F.; et al. Study of the Oxidation Mechanism at High Temperature of Nanofiber Textured AlTiCrN Coatings Produced by Physical Vapor Deposition Using High-Resolution Characterization Techniques. Corros. Sci. 2022, 201, 110226. [Google Scholar] [CrossRef]

- Beake, B.D.; Isern, L.; Endrino, J.L.; Fox-Rabinovich, G.S. Micro-Impact Testing of AlTiN and TiAlCrN Coatings. Wear 2019, 418–419, 102–110. [Google Scholar] [CrossRef]

- Fox-Rabinovich, G.S.; Kovalev, A.I.; Aguirre, M.H.; Beake, B.D.; Yamamoto, K.; Veldhuis, S.C.; Endrino, J.L.; Wainstein, D.L.; Rashkovskiy, A.Y. Design and Performance of AlTiN and TiAlCrN PVD Coatings for Machining of Hard to Cut Materials. Surf. Coat. Technol. 2009, 204, 489–496. [Google Scholar] [CrossRef]

- Guo, D.; Yu, D.; Zhang, P.; Song, W.; Zhang, B.; Peng, K. Laminar Plasma Jet Surface Hardening of P20 Mold Steel: Analysis on the Wear and Corrosion Behaviors. Surf. Coat. Technol. 2021, 415, 127129. [Google Scholar] [CrossRef]

- Yan, G.; Lu, S.; Zhang, M.; Wang, J.; Yang, X.; Zhang, Z.; Gu, J.; Li, C. Wear and Corrosion Behavior of P20 Steel Surface Modified by Gas Nitriding with Laser Surface Engineering. Appl. Surf. Sci. 2020, 530, 147306. [Google Scholar] [CrossRef]

- Shakerin, S.; Sanjari, M.; Pirgazi, H.; Amirkhiz, B.S.; Mohammadi, M. On the Bending of MS1-P20 Hybrid Steels Additively Manufactured Using Laser Powder Bed Fusion. Materialia 2022, 24, 101501. [Google Scholar] [CrossRef]

- Danek, M.; Fernandes, F.; Cavaleiro, A.; Polcar, T. Influence of Cr Additions on the Structure and Oxidation Resistance of Multilayered TiAlCrN Films. Surf. Coat. Technol. 2017, 313, 158–167. [Google Scholar] [CrossRef]

- Fernandes, F.; Danek, M.; Polcar, T.; Cavaleiro, A. Tribological and Cutting Performance of TiAlCrN Films with Different Cr Contents Deposited with Multilayered Structure. Tribol. Int. 2018, 119, 345–353. [Google Scholar] [CrossRef]

- Kovalev, A.I.; Wainstein, D.L.; Rashkovskiy, A.Y.; Fox-Rabinovich, G.S.; Yamamoto, K.; Veldhuis, S.; Aguirre, M.; Beake, B.D. Impact of Al and Cr Alloying in TiN-Based PVD Coatings on Cutting Performance during Machining of Hard to Cut Materials. Vacuum 2009, 84, 184–187. [Google Scholar] [CrossRef]

- Chen, J.T.; Wang, J.; Zhang, F.; Zhang, G.A.; Fan, X.Y.; Wu, Z.G.; Yan, P.X. Characterization and Temperature Controlling Property of TiAlN Coatings Deposited by Reactive Magnetron Co-Sputtering. J. Alloys Compd. 2009, 472, 91–96. [Google Scholar] [CrossRef]

- Liew, W.Y.H.; Lim, H.P.; Melvin, G.J.H.; Dayou, J.; Jiang, Z.T. Thermal Stability, Mechanical Properties, and Tribological Performance of TiAlXN Coatings: Understanding the Effects of Alloying Additions. J. Mater. Res. Technol. 2022, 17, 961–1012. [Google Scholar] [CrossRef]

- Lim, H.P.; Jiang, Z.T.; Melvin, G.J.H.; Nayan, N.; Chee, F.P.; Soon, C.F.; Hassan, N.; Liew, W.Y.H. A Systematic Investigation of the Tribological Behaviour of Oxides Formed on AlSiTiN, CrAlTiN, and CrAlSiTiN Coatings. Wear 2023, 512–513, 204552. [Google Scholar] [CrossRef]

- Huang, B.; Liu, L.T.; Du, H.M.; Chen, Q.; Liang, D.D.; Zhang, E.G.; Zhou, Q. Effect of Nitrogen Flow Rate on the Microstructure, Mechanical and Tribological Properties of CrAlTiN Coatings Prepared by Arc Ion Plating. Vacuum 2022, 204, 111336. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Carlet, M. HPPMS TiAlCrSiN—Influence of Substrate Bias and Pulse Frequency on Cutting Performance. Surf. Coat. Technol. 2020, 397, 126056. [Google Scholar] [CrossRef]

- Chen, H.; Zheng, B.C.; Li, Y.G.; Wu, Z.L.; Lei, M.K. Flexible Hard TiAlSiN Nanocomposite Coatings Deposited by Modulated Pulsed Power Magnetron Sputtering with Controllable Peak Power. Thin Solid Film. 2019, 669, 377–386. [Google Scholar] [CrossRef]

- Chen, W.; Wu, W.; Huang, Y.; Wu, D.; Li, B.; Wang, C.; Wang, Y.; Li, S.Y. Influence of Annealing on Microstructures and Mechanical Properties of Arc-Deposited AlCrTiSiN Coating. Surf. Coat. Technol. 2021, 421, 127470. [Google Scholar] [CrossRef]

- Fuentes, G.G.; Almandoz, E.; Pierrugues, R.; Martínez, R.; Rodríguez, R.J.; Caro, J.; Vilaseca, M. High Temperature Tribological Characterisation of TiAlSiN Coatings Produced by Cathodic Arc Evaporation. Surf. Coat. Technol. 2010, 205, 1368–1373. [Google Scholar] [CrossRef]

- Kuo, Y.C.; Wang, C.J.; Lee, J.W. The Microstructure and Mechanical Properties Evaluation of CrTiAlSiN Coatings: Effects of Silicon Content. Thin Solid Film. 2017, 638, 220–229. [Google Scholar] [CrossRef]

- Cao, F.; Munroe, P.; Zhou, Z.; Xie, Z. Mechanically Robust TiAlSiN Coatings Prepared by Pulsed-DC Magnetron Sputtering System: Scratch Response and Tribological Performance. Thin Solid Film. 2018, 645, 222–230. [Google Scholar] [CrossRef]

- Zhang, D.; Zuo, X.; Wang, Z.; Li, H.; Chen, R.; Wang, A.; Ke, P. Comparative Study on Protective Properties of CrN Coatings on the ABS Substrate by DCMS and HiPIMS Techniques. Surf. Coat. Technol. 2020, 394, 125890. [Google Scholar] [CrossRef]

- Gui, B.; Zhou, H.; Zheng, J.; Liu, X.; Feng, X.; Zhang, Y.; Yang, L. Microstructure and Properties of TiAlCrN Ceramic Coatings Deposited by Hybrid HiPIMS/DC Magnetron Co-Sputtering. Ceram. Int. 2021, 47, 8175–8183. [Google Scholar] [CrossRef]

- Xu, Y.X.; Riedl, H.; Holec, D.; Chen, L.; Du, Y.; Mayrhofer, P.H. Thermal Stability and Oxidation Resistance of Sputtered Ti-Al-Cr-N Hard Coatings. Surf. Coat. Technol. 2017, 324, 48–56. [Google Scholar] [CrossRef]

- Vanegas, P.H.S.; Calderon, V.S.; Alfonso, O.J.E.; Olaya, F.J.J.; Ferreira, P.J.; Carvalho, S. Influence of Silicon on the Microstructure and the Chemical Properties of Nanostructured ZrN-Si Coatings Deposited by Means of Pulsed-DC Reactive Magnetron Sputtering. Appl. Surf. Sci. 2019, 481, 1249–1259. [Google Scholar] [CrossRef]

- Lin, C.H.; Duh, J.G.; Yeh, J.W. Multi-Component Nitride Coatings Derived from Ti–Al–Cr–Si–V Target in RF Magnetron Sputter. Surf. Coat. Technol. 2007, 201, 6304–6308. [Google Scholar] [CrossRef]

- Daniel, R.; Musil, J. Novel Nanocomposite Coatings: Advances and Industrial Applications, 1st ed.; CRC Press: Boca Raton, FL, USA, 2013; ISBN 9789814411189. [Google Scholar]

- Zhou, B.; Wang, Y.; Liu, Z.; Zhi, J.; Sun, H.; Wang, Y.; Wu, Y.; Hei, H.; Yu, S. Effect of Modulation Ratio on Microstructure and Tribological Properties of TiAlN/TiAlCN Multilayer Coatings Prepared by Multi-Excitation Source Plasma. Vacuum 2023, 211, 111917. [Google Scholar] [CrossRef]

- Cao, H.S.; Liu, F.J.; Hao, L.I.; Luo, W.Z.; Qi, F.G.; Lu, L.W.; Nie, Z.H.; Ouyang, X.P. Effect of Bias Voltage on Microstructure, Mechanical and Tribological Properties of TiAlN Coatings. Trans. Nonferrous Met. Soc. China 2022, 32, 3596–3609. [Google Scholar] [CrossRef]

- Miletić, A.; Panjan, P.; Čekada, M.; Kovačević, L.; Terek, P.; Kovač, J.; Dražič, G.; Škorić, B. Nanolayer CrAlN/TiSiN Coating Designed for Tribological Applications. Ceram. Int. 2021, 47, 2022–2033. [Google Scholar] [CrossRef]

- Zhang, L.; Shen, Y.Q.; Zhao, Y.M.; Chen, S.N.; Ouyang, X.; Zhang, X.; Liang, H.; Liao, B.; Chen, L. Structure Control of High-Quality TiAlN Monolithic and TiAlN/TiAl Multilayer Coatings Based on Filtered Cathodic Vacuum Arc Technique. Surf. Interfaces 2023, 38, 102836. [Google Scholar] [CrossRef]

- Polcar, T.; Cavaleiro, A. High Temperature Properties of CrAlN, CrAlSiN and AlCrSiN Coatings—Structure and Oxidation. Mater. Chem. Phys. 2011, 129, 195–201. [Google Scholar] [CrossRef]

- Chang, L.C.; Sung, M.C.; Chen, Y.I. Effects of Bias Voltage and Substrate Temperature on the Mechanical Properties and Oxidation Behavior of CrSiN Films. Vacuum 2021, 194, 110580. [Google Scholar] [CrossRef]

- Wu, J.; He, N.; Li, H.; Liu, X.; Ji, L.; Huang, X.; Chen, J. Deposition and Characterization of TiAlSiN Coatings Prepared by Hybrid PVD Coating System. Surf. Interface Anal. 2015, 47, 184–191. [Google Scholar] [CrossRef]

- Cavaleiro, D.; Carvalho, S.; Cavaleiro, A.; Fernandes, F. TiSiN(Ag) Films Deposited by HiPIMS Working in DOMS Mode: Effect of Ag Content on Structure, Mechanical Properties and Thermal Stability. Appl. Surf. Sci. 2019, 478, 426–434. [Google Scholar] [CrossRef]

- Chang, L.C.; Liu, Y.H.; Chen, Y.I. Mechanical Properties and Oxidation Behavior of Cr-Si-N Coatings. Coatings 2019, 9, 528. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Carlet, M. Nanocomposite (Ti,Al,Cr,Si)N HPPMS Coatings for High Performance Cutting Tools. Surf. Coat. Technol. 2019, 378, 124857. [Google Scholar] [CrossRef]

- Vanegas, H.S.; Alfonso, J.E.; Olaya, J.J. Effect of Si Content on Functional Behavior of Nanostructured Coatings of Zr-Si-N. Mater. Res. Express 2019, 6, 115076. [Google Scholar] [CrossRef]

- Bobzin, K.; Brögelmann, T.; Kruppe, N.C.; Carlet, M. Wear Behavior and Thermal Stability of HPPMS (Al,Ti,Cr,Si)ON, (Al,Ti,Cr,Si)N and (Ti,Al,Cr,Si)N Coatings for Cutting Tools. Surf. Coat. Technol. 2020, 385, 125370. [Google Scholar] [CrossRef]

- Macías, H.A.; Yate, L.; Coy, L.E.; Olaya, J.J.; Aperador, W. Effect of Nitrogen Flow Ratio on Microstructure, Mechanical and Tribological Properties of TiWSiN × Thin Film Deposited by Magnetron Co-Sputtering. Appl. Surf. Sci. 2018, 456, 445–456. [Google Scholar] [CrossRef]

| Sample | Target | U (V) | I (mA) | Ipk(A) | Frequency (Hz) | Pulse Width (µs) |

|---|---|---|---|---|---|---|

| (CrTiAlSi) N | Cr, Si | 651 | 300.125 | 34 | 500 | 60 |

| Ti, Al | 749.75 | 390.25 | 45.25 | 500 | 60 |

| Sample | Si Pellets | Titanium (at.%) | Aluminum (at.%) | Chromium (at.%) | Silicon (at.%) | Nitrogen (at.%) |

|---|---|---|---|---|---|---|

| M1 | 0.0 | 7.1 | 16.7 | 34.9 | 0.0 | 41.3 |

| M2 | 1.0 | 6.3 | 15.7 | 34.2 | 0.1 | 43.7 |

| M3 | 3.0 | 6.3 | 16.6 | 31.2 | 1.0 | 44.9 |

| M4 | 5.0 | 6.2 | 17.2 | 30.1 | 1.9 | 44.6 |

| Element | M1 (at.%) | M2 (at.%) | M3 (at.%) | M4 (at.%) |

|---|---|---|---|---|

| Ti | 5.7 | 4.6 | 5.0 | 4.4 |

| Al | 26.5 | 27.1 | 22.8 | 23.4 |

| Cr | 21.3 | 29.6 | 27.0 | 33.4 |

| N | 21.2 | 26.4 | 25.0 | 25.6 |

| Si | -- | -- | -- | 1.5 |

| C | 14.4 | 6.3 | 10.6 | 6.0 |

| O | 9.4 | 4.8 | 7.9 | 5.7 |

| Ar | 1.5 | 1.2 | 1.7 | -- |

| Sample | Si (at.%) | Ra (nm) | D (nm) |

|---|---|---|---|

| M1 | 0.0 | 2.0 ± 0.2 | 1273.0 |

| M2 | 0.1 | 2.0 ± 0.2 | 893.2 |

| M3 | 1.0 | 1.2 ± 0.2 | 669.9 |

| M4 | 1.9 | 1.0 ± 0.1 | 598.2 |

| Sample | Si Content (at. %) | 2θ (°) | FWHM (°) | Lattice Parameter (nm) | Crystalline Size (nm) |

|---|---|---|---|---|---|

| M1 | 0.0 | 37.8 | 0.439 | 0.412 | 20.0 |

| M2 | 0.1 | 37.8 | 0.416 | 0.412 | 21.1 |

| M3 | 1.0 | 38.0 | 0.373 | 0.410 | 23.5 |

| M4 | 1.9 | 38.3 | 0.509 | 0.413 | 17.2 |

| Sample | Si (at.%) | Nano-Hardness (GPa) | Young’s Modulus (GPa) | H/E (×10−2) | (×10−1 GPa) |

|---|---|---|---|---|---|

| M1 | 0.0 | 20.0 ± 1.2 | 246.6 ± 5.5 | 8.11 | 1.32 |

| M2 | 0.1 | 22.6 ± 0.7 | 325.5 ± 7.0 | 6.95 | 1.09 |

| M3 | 1.0 | 21.5 ± 1.2 | 290.6 ± 11.1 | 7.40 | 1.18 |

| M4 | 1.9 | 22.2 ± 1.5 | 278.7 ± 11.4 | 7.98 | 1.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ordóñez Jiménez, A.F.; Vanegas, H.S.; Moreno, C.M.; Olaya, J.J.; Pineda, Y. The Structural and Mechanical Properties of CrAlTiN-Si Nanostructured Coatings Deposited by the Means of High-Power Impulse Magnetron Sputtering. Metals 2023, 13, 1691. https://doi.org/10.3390/met13101691

Ordóñez Jiménez AF, Vanegas HS, Moreno CM, Olaya JJ, Pineda Y. The Structural and Mechanical Properties of CrAlTiN-Si Nanostructured Coatings Deposited by the Means of High-Power Impulse Magnetron Sputtering. Metals. 2023; 13(10):1691. https://doi.org/10.3390/met13101691

Chicago/Turabian StyleOrdóñez Jiménez, Andrés Felipe, Henry Samir Vanegas, Carlos Mauricio Moreno, Jhon Jairo Olaya, and Yaneth Pineda. 2023. "The Structural and Mechanical Properties of CrAlTiN-Si Nanostructured Coatings Deposited by the Means of High-Power Impulse Magnetron Sputtering" Metals 13, no. 10: 1691. https://doi.org/10.3390/met13101691

APA StyleOrdóñez Jiménez, A. F., Vanegas, H. S., Moreno, C. M., Olaya, J. J., & Pineda, Y. (2023). The Structural and Mechanical Properties of CrAlTiN-Si Nanostructured Coatings Deposited by the Means of High-Power Impulse Magnetron Sputtering. Metals, 13(10), 1691. https://doi.org/10.3390/met13101691