Study of Machined Surface Quality of AZ31B Magnesium Alloy by End Milling

Abstract

:1. Introduction

2. Experimental Procedure

2.1. Experimental Material

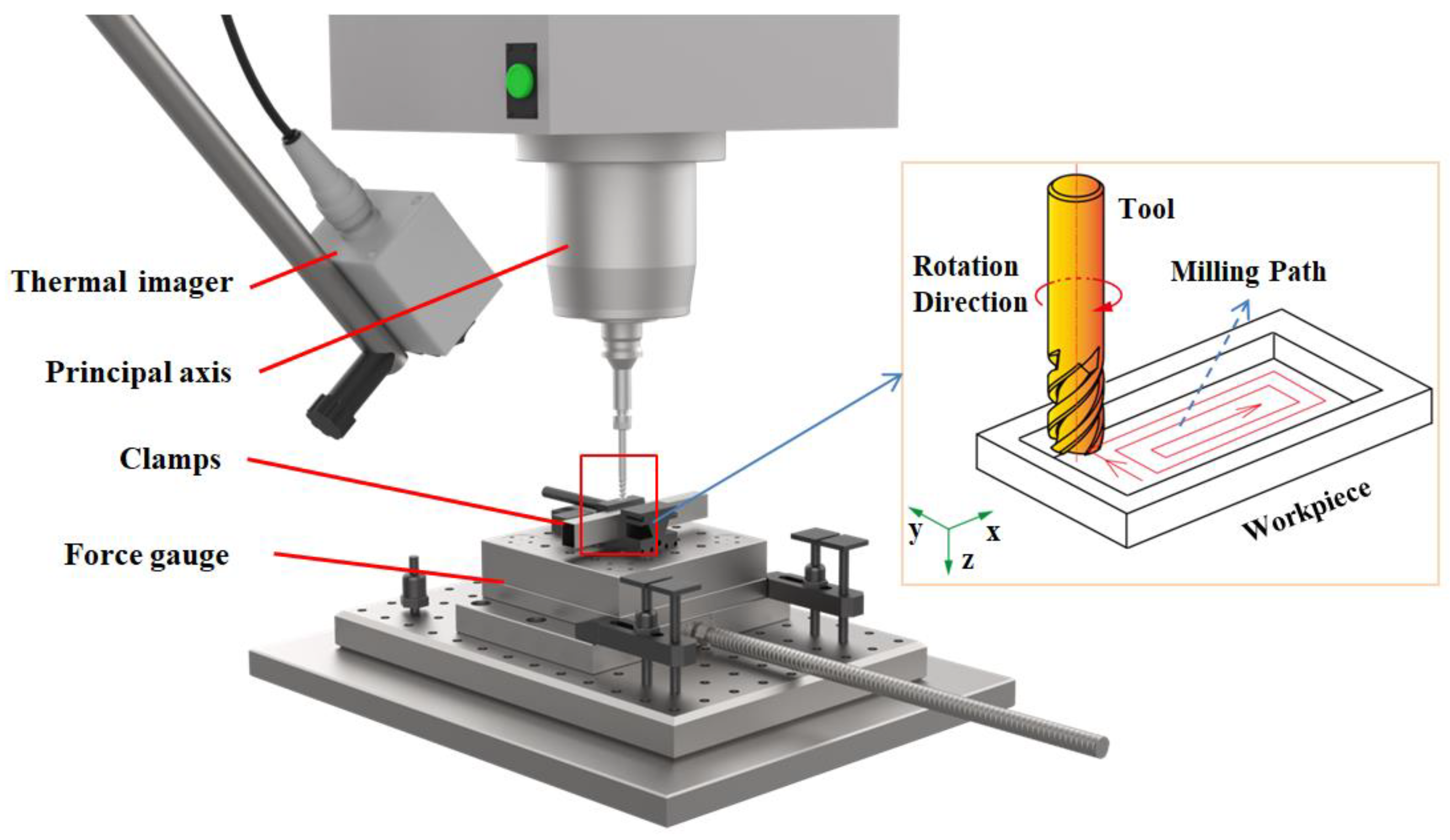

2.2. Milling Test

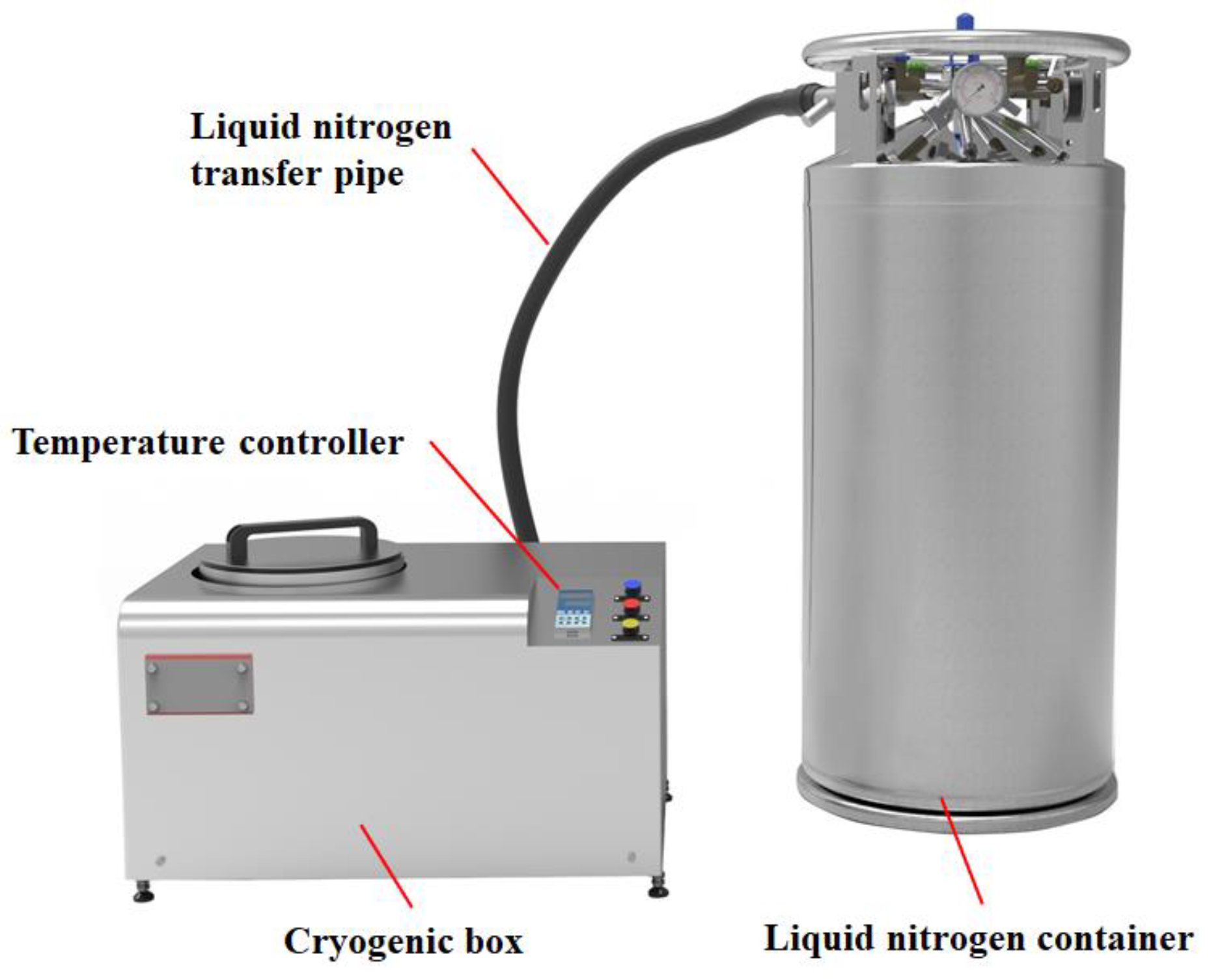

2.3. Heat Treatment Test

3. Experimental Results and Analysis

3.1. Analysis of the Influence of Milling Process and Stress-Relief Annealing Treatment on Surface Quality

3.1.1. Surface Residual Stress Analysis

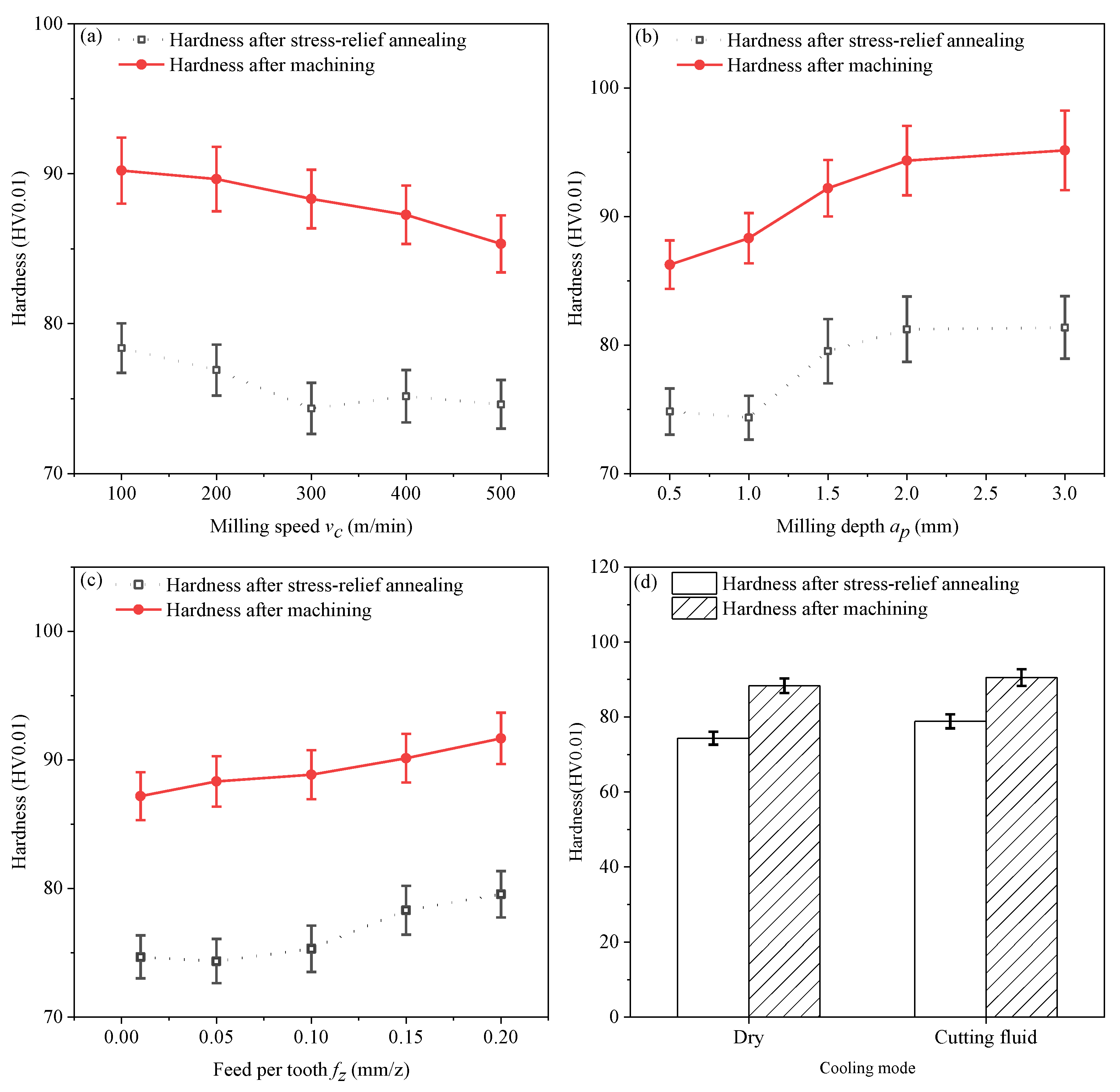

3.1.2. Surface Hardness Analysis

3.1.3. Surface Roughness Analysis

3.2. Analysis of the Influence of Milling Process and Cryogenic Treatment on Surface Quality

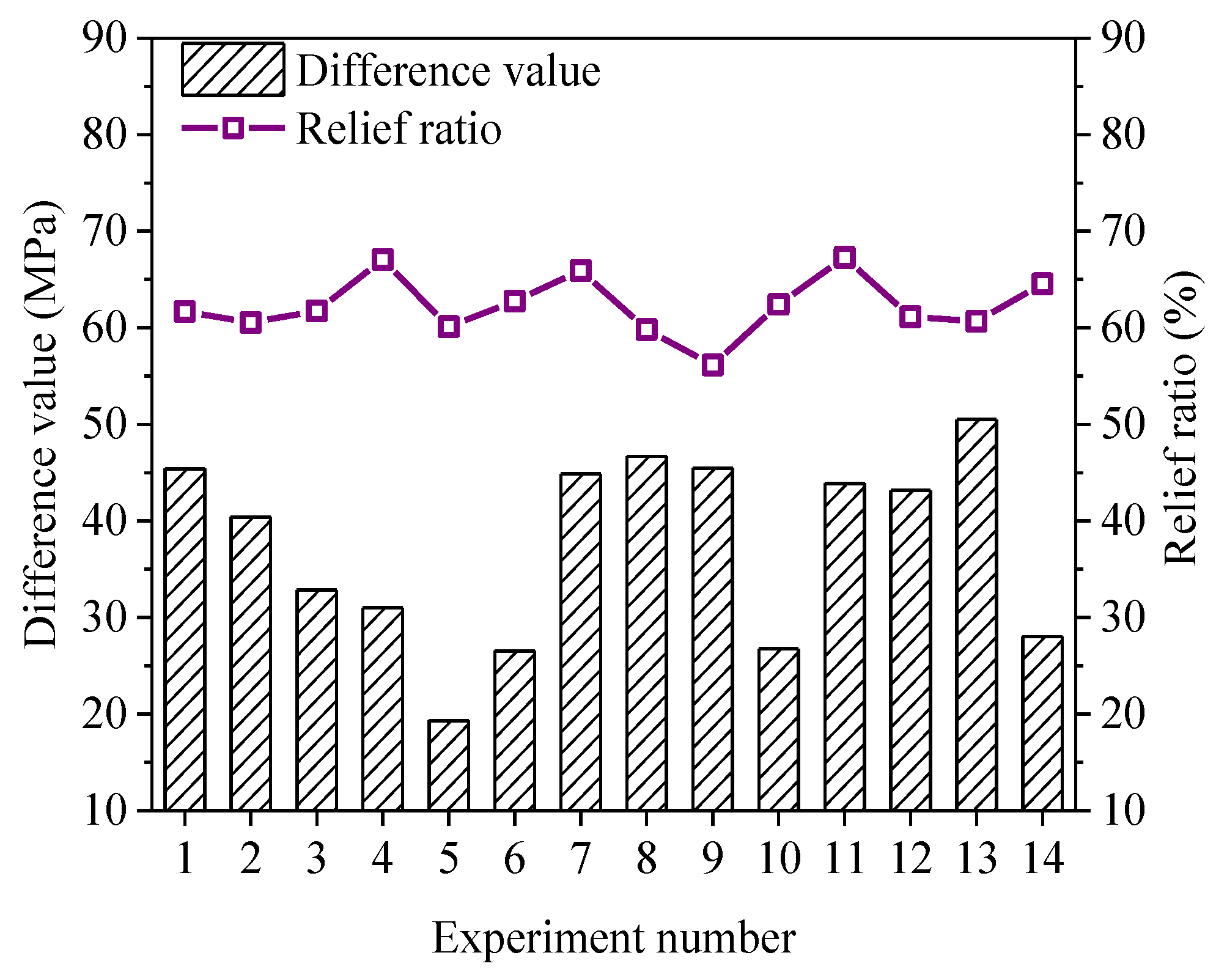

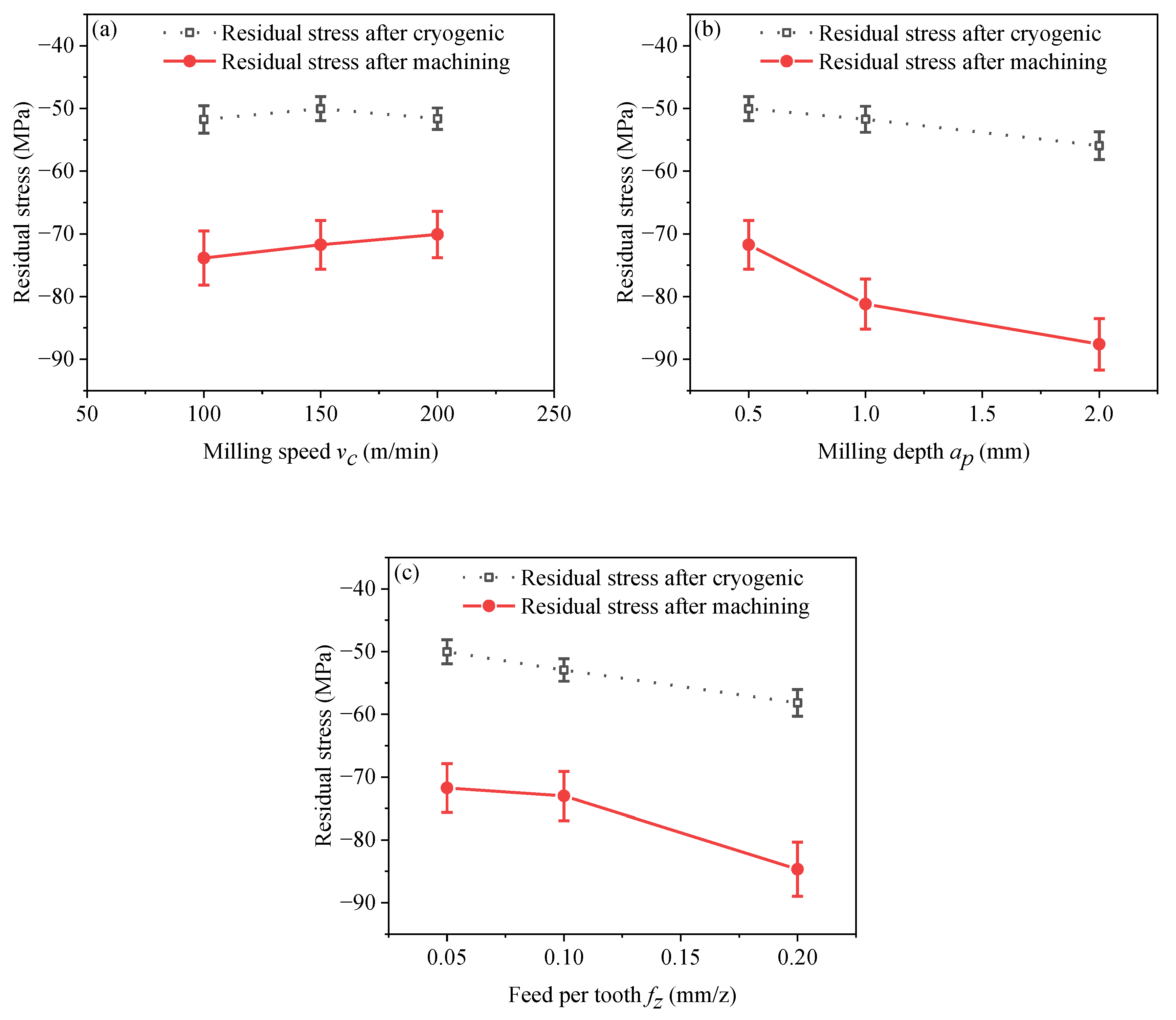

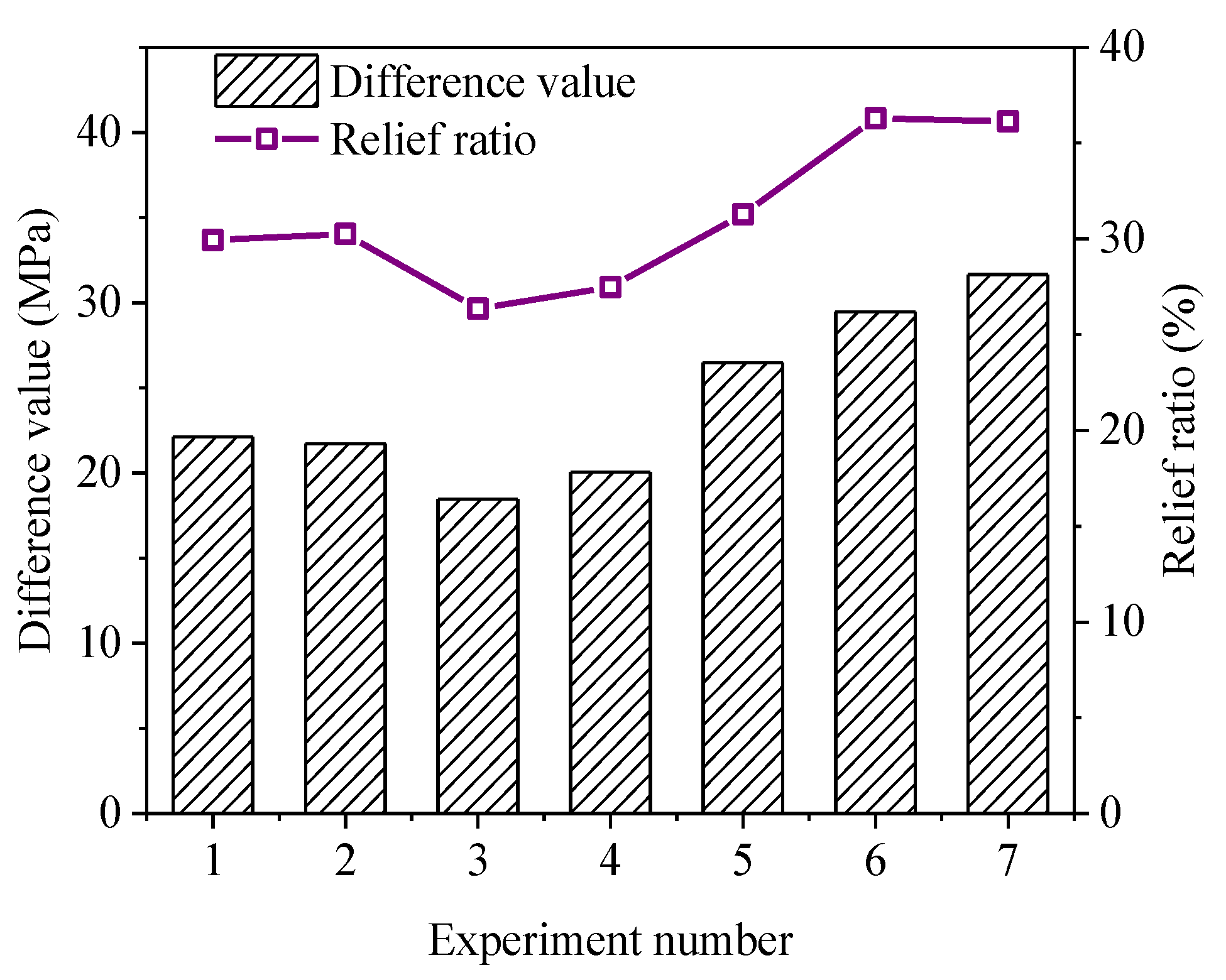

3.2.1. Surface Residual Stress Analysis

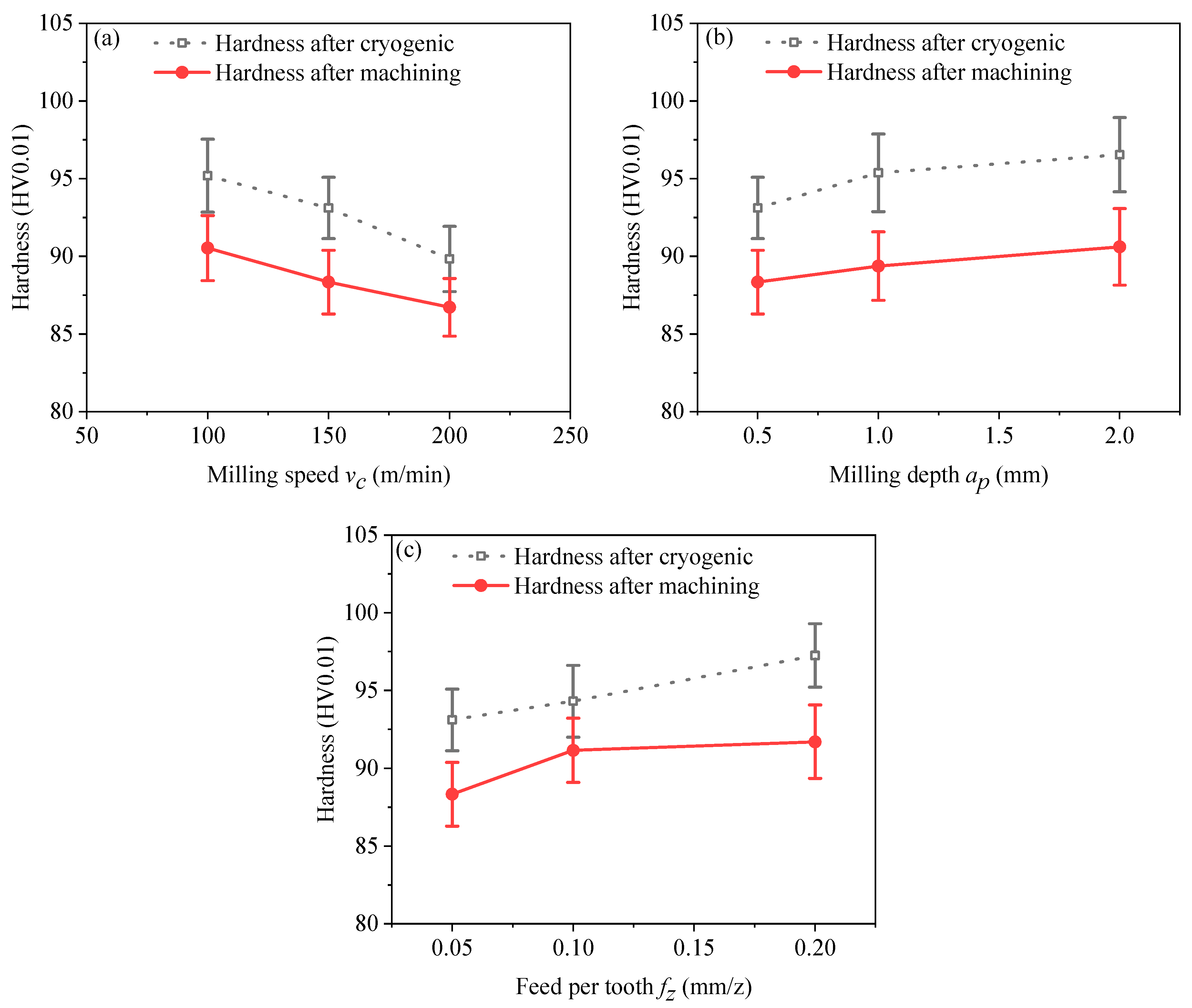

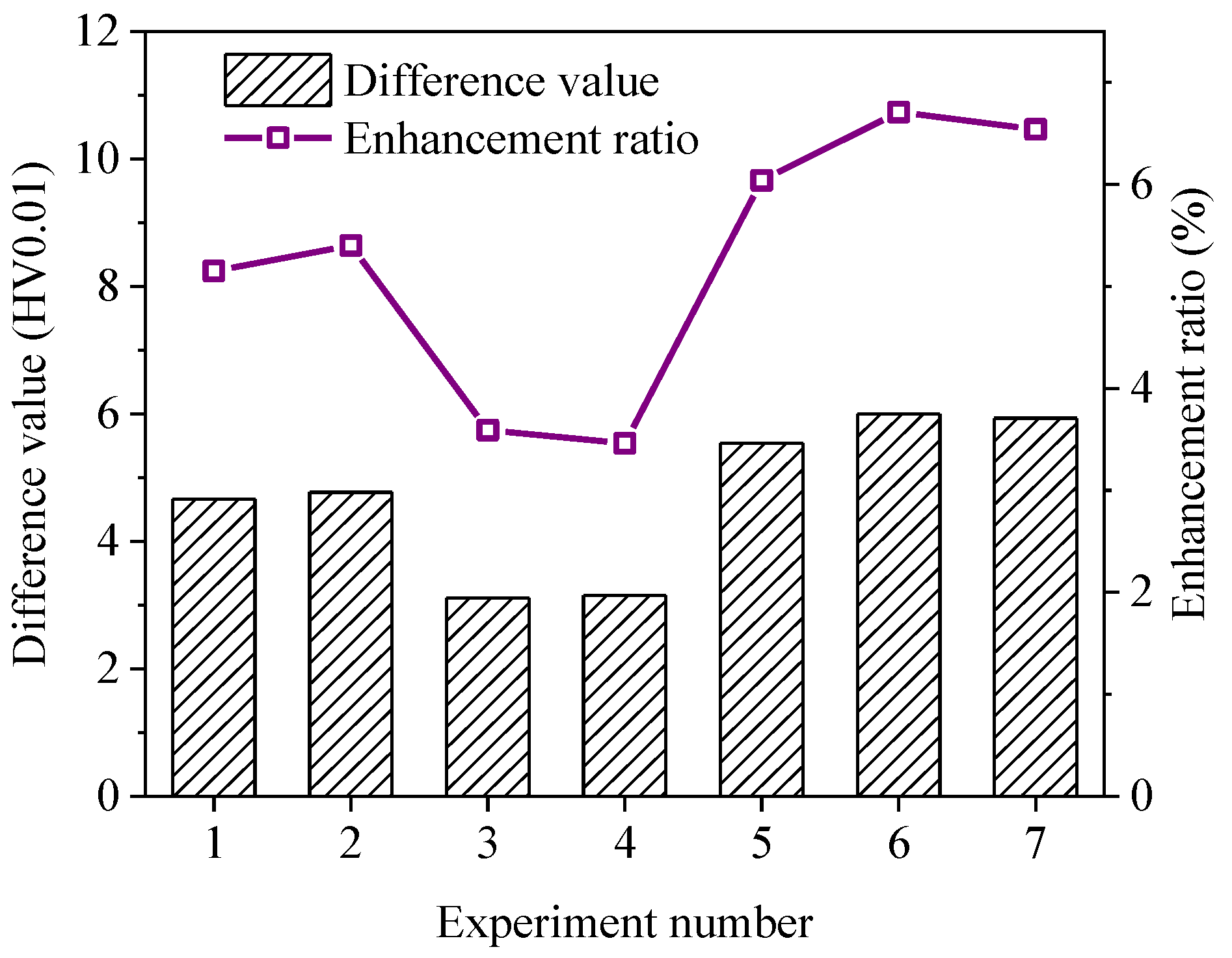

3.2.2. Surface Hardness Analysis

4. Conclusions

- (1)

- The law of the influence of the milling parameters on the surface quality of AZ31B magnesium alloy frame parts was obtained. The surface residual compressive stress, hardness, and roughness of the frame parts decreased with the increase in the milling speed and increased as the depth of cut and the feed per tooth increased. Using cutting fluid in the milling process can decrease the surface residual stress and roughness of the frame parts but increase the surface hardness.

- (2)

- Both stress-relief annealing and cryogenic treatment can reduce the surface residual stress and homogenize the residual stress distribution of the frame parts within the selected milling parameters. The relief ratio of the residual stress on the milled magnesium alloy surface varied from 56.14% to 67.29% after the stress-relief annealing treatment. The relief ratio of the residual stress on the surface of the workpiece varied from 26.35% to 36.29% by the cryogenic treatment. Therefore, the stress-relief annealing treatment is more effective than the cryogenic treatment in relieving the surface residual stresses.

- (3)

- Stress-relief annealing resulted in a reduction in the hardness of the machined surface of the magnesium alloy in a range of about 12.54–15.82%. The cryogenic treatment enhanced the hardness of the machined surface of the magnesium alloy, and the increase rate ranged from 3.46% to 6.71%.

- (4)

- After comprehensively evaluating the various effects of milling parameters on surface residual stress and surface hardness, it can be concluded that different milling parameters and heat treatment methods can be combined to meet different machining requirements. Within the selected range of milling parameters, higher milling speed, such as 500 m/min, can effectively reduce surface residual stress, although it may cause a slight decrease in hardness. The implementation of cutting fluid can enhance the overall surface quality. A smaller cutting depth and feed per tooth, such as 0.5 mm and 0.01 mm/z, are advantageous for obtaining a smaller surface residual stress and surface roughness, which is beneficial for achieving good surface quality. If machining standards necessitate higher surface hardness, further processing of framework components can be conducted through cryogenic treatment. This not only enhances surface hardness but also mitigates surface residual stress. In the absence of stringent hardness requirements, stress-relief annealing can also be employed for the heat treatment of framework components, further reducing the residual surface stress in the workpiece.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhu, Z.; Xi, X.; Xu, X.; Cai, Y. Digital Twin-driven machining process for thin-walled part manufacturing. J. Manuf. Syst. 2021, 59, 453–466. [Google Scholar] [CrossRef]

- Gobivel, K.; Sekar, K.V. Influence of cutting parameters on end milling of magnesium alloy AZ31B. Mater. Today Proc. 2022, 62, 933–937. [Google Scholar] [CrossRef]

- Hu, X.D.; Wu, G.J.; Liu, G.B.; Li, J. Key Technologies for CNC Milling of Thin walled Magnesium Alloy Parts. Met. Process. (Cold Work.) 2019, S2, 90–92. [Google Scholar]

- Khajehzadeh, M.; Boostanipour, O.; Razfar, M.R. Finite element simulation and experimental investigation of residual stresses in ultrasonic assisted turning. Ultrasonics 2022, 108, 106208. [Google Scholar] [CrossRef] [PubMed]

- Li, W.; Wang, L.; Yu, G.; Wang, D. Time-varying dynamics updating method for chatter prediction in thin-walled part milling process. Mech. Syst. Signal Process. 2021, 159, 107840. [Google Scholar] [CrossRef]

- Yue, C.; Zhang, J.; Liu, X.; Chen, Z.; Liang, S.Y.; Wang, L. Research progress on machining deformation of thin-walled parts during milling process. Chin. J. Aronaut. 2022, 43, 106–131. [Google Scholar]

- Waseem, A.; Ismail, L.; Steven, Y. Prediction and control of residual stress-based distortions in the machining of aerospace parts: A review. J. Manuf. Process. 2022, 76, 106–122. [Google Scholar] [CrossRef]

- Liang, X.; Liu, Z.; Wang, B.; Hou, X. Modeling of plastic deformation induced by thermo-mechanical stresses considering tool flank wear in high-speed machining Ti-6Al-4V. Int. J. Mech. Sci. 2018, 140, 1–12. [Google Scholar] [CrossRef]

- Wang, H.; Estrin, Y.; Fu, H.; Song, G.; Zúberová, Z. The effect of pre-processing and grain structure on the bio-corrosion and fatigue resistance of magnesium alloy AZ31. Wiley-VCH Verlag. 2007, 9, 967–972. [Google Scholar] [CrossRef]

- Ding, Y.-L.; Wang, J.-G.; Zhao, M.; Ju, D.-Y. Effect of annealing temperature on joints of diffusion bonded Mg/Al alloys. Trans. Nonferrous Met. Soc. China 2018, 28, 251–258. [Google Scholar] [CrossRef]

- Asl, K.M.; Tari, A.; Khomamizadeh, F. Effect of deep cryogenic treatment on microstructure, creep and wear behaviors of AZ91 magnesium alloy. Msea 2009, 523, 27–31. [Google Scholar] [CrossRef]

- Liu, Y.; Shao, S.; Xu, C.S.; Zeng, X.S.; Yang, X.J. Effect of cryogenic treatment on the microstructure and mechanical properties of Mg–1.5Zn–0.15Gd magnesium alloy. Msea 2013, 588, 76–81. [Google Scholar] [CrossRef]

- Jose, C.O.; António, C.B.; Maria, J.M. Residual Stresses Induced by Dry and Cryogenic Cooling during Machining of AZ31B Magnesium Alloy. Adv. Mat. Res. 2014, 3278, 658–663. [Google Scholar]

- Li, B.; Jiang, X.; Yang, J.; Liang, S.Y. Effects of depth of cut on the redistribution of residual stress and distortion during the milling of thin-walled part. J. Mater. Process Technol. 2015, 216, 223–233. [Google Scholar] [CrossRef]

- Zhou, K.; Jiao, X.L.; Zhang, H.; Sun, H. Numerical control milling experiment and optimization of 5083 aluminum magnesium alloy thin-walled parts. Equip. Manuf. Technol. 2018, 9, 116–120 + 127. [Google Scholar]

- Wang, R.J.; Du, M.X.; Zhang, P.C. The Effect of Milling Process Parameters on the Surface Quality of AZ31B Magnesium Alloy. Trans. Mater. Heat Treat. 2022, 43, 151–160. [Google Scholar]

- Lian, Y.; Ji, P.; Zhang, J.; Yuan, X.; Xu, W.; Zhao, Y.; Mo, J.; Zheng, L.; Dou, S. Effect of homogenization annealing on internal residual stress distribution and texture in ME21 magnesium alloy extruded plates. J. Magnes. Alloy 2019, 7, 186–192. [Google Scholar] [CrossRef]

- Niu, X.; Huang, Y.; Yan, X.; Chen, Z.; Yuan, R.; Zhang, H.; Tang, L. Optimization of Cryogenic Treatment Parameters for the Minimum Residual Stress. J. Mater. Eng. Perform. 2021, 30, 9038–9047. [Google Scholar] [CrossRef]

- Marwan, A.M.; Ali, H.A.; Jamal, J.D. Influence of cryogenic treatment on hardness, tensile properties, and microstructure of aluminum alloy AA6061. Mater. Today Proc. 2022, 60, 2157–2161. [Google Scholar] [CrossRef]

- Navas, V.G.; Gonzalo, O.; Bengoetxea, I. Effect of cutting parameters in the surface residual stresses generated by turning in AISI 4340 steel. Int. J. Mach. Tools Manuf. 2012, 61, 48–57. [Google Scholar] [CrossRef]

- Mahdi, M.; Zhang, L.C. Residual stresses in ground components caused by coupled thermal and mechanical plastic deformation. J. Mater. Process Technol. 1999, 95, 238–245. [Google Scholar] [CrossRef]

- Li, L.; Chang, H.; Wang, M.; Zuo, D.W.; He, L. Temperature measurement in high speed milling Ti6Al4V. Key Eng. Mater. 2004, 259–260, 804–808. [Google Scholar] [CrossRef]

- Wang, C.; Ding, F.; Tang, D.; Zheng, L.; Li, S.; Xie, Y. Modeling and simulation of the high-speed milling of hardened steel SKD11 (62 HRC) based on SHPB technology. Int. J. Mach. Tools Manuf. 2016, 108, 13–26. [Google Scholar] [CrossRef]

- Fan, L.; Yan, P.; Chen, S.Q.; Chen, H.; Jiao, L.; Qiu, T.Y.; Wang, X.B. Low temperature cutting performance and process parameter optimization of magnesium alloy. J. Harbin Inst. Technol. 2022, 54, 53–63 + 69. [Google Scholar]

- Sun, S.L.; Zhao, J.; Yuan, W.J.; Xi, W.; Zhao, C. GH4169 Study on Surface work hardening of GH4169 Nickel Base Superalloy. Tools Technol. 2016, 50, 24–27. [Google Scholar]

- Wojciechowski, S.; Krajewska-Śpiewak, J.; Maruda, R.; Krolczyk, G.; Nieslony, P.; Wieczorowski, M.; Gawlik, J. Study on ploughing phenomena in tool flank face—Workpiece interface including tool wear effect during ball-end milling. Tribol. Int. 2023, 181, 108313, ISSN 0301-679X. [Google Scholar] [CrossRef]

- Zhou, J.; Shu, L.S. Effect of high-speed milling parameters on surface roughness and residual stress of nickel based laser cladding alloy. Tools Technol. 2022, 56, 45–48. [Google Scholar]

- Tian, Z.Q.; Wei, K.X.; Wei, W.; Du, Q.B.; Hu, J. Microstructure and Mechanical Properties of Cryogenic Aluminum Silicon Alloy. Metal. Heat Treat. 2017, 42, 54–58. [Google Scholar]

- Huang, Y.; Yan, X.; Niu, X.; Chen, Q.; Yuan, R.; Zhang, H.; Yao, Y.; Fan, J. Effects of Deep and Shallow Cryogenic Treatment on Surface Residual Stress of 2A12 Aluminum Alloy Thick Plate. Hot Work. Technol. 2022, 51, 152–154 + 157. [Google Scholar] [CrossRef]

- Rao, C.; Zhou, M.; Lan, Y.; Xu, W. Effect of deep cryogenic treatment on microstructure and mechanical properties of AZ91 magnesium alloy. Light Alloy Fabr. Technol. 2021, 49, 66–71. [Google Scholar] [CrossRef]

| Al | Zn | Mn | Be | Cu | Ca | Si | Fe | Mg |

|---|---|---|---|---|---|---|---|---|

| 3.19 | 0.81 | 0.334 | 0.1 | 0.05 | 0.04 | 0.02 | 0.005 | Bal. |

| Mechanical Property | Symbol | Unit | Numerical Value |

|---|---|---|---|

| Melting point | T | °C | 630 |

| Density | ρ | g/cm3 | 1.77 |

| Vickers hardness | HV | HV0.01 | 83 |

| Strength limit | σb | MPa | 255 |

| Yield limit | σs | MPa | 155 |

| Elongation at break | σh | - | 21% |

| Young’s modulus | E | GPa | 45 |

| Compressive yield strength | σcy | MPa | 110 |

| Poisson’s ratio | μ | - | 0.35 |

| Shear modulus | G | GPa | 17.0 |

| Shear strength | σc | MPa | 145 |

| Specific heat capacity | Cp | J/kg/°C | 1013 |

| Thermal conductivity | λ | W/m/°C | 78.9 |

| Radiation | Mn-kα |

|---|---|

| Voltage and current | 20 kV, 4 mA |

| Collimator diameter (mm) | 5 |

| X-ray elastic | (1/2) S2 = 29.32 × 10−6 |

| constants (MPa−1) | S1 = −6.59 × 10−6 |

| Bragg angle 2θ (deg) | 151.06, (hkl) = (203) |

| Number of ψ angles | 30 |

| Number | Milling Speed vc/m·min−1 | Milling Depth ap/mm | Feed Rate per Tooth fz/mm·z−1 | Cooling Mode |

|---|---|---|---|---|

| 1 | 100 | 1 | 0.05 | Dry |

| 2 | 200 | 1 | 0.05 | Dry |

| 3 | 300 | 1 | 0.05 | Dry |

| 4 | 400 | 1 | 0.05 | Dry |

| 5 | 500 | 1 | 0.05 | Dry |

| 6 | 300 | 0.5 | 0.05 | Dry |

| 7 | 300 | 1.5 | 0.05 | Dry |

| 8 | 300 | 2 | 0.05 | Dry |

| 9 | 300 | 3 | 0.05 | Dry |

| 10 | 300 | 1 | 0.01 | Dry |

| 11 | 300 | 1 | 0.1 | Dry |

| 12 | 300 | 1 | 0.15 | Dry |

| 13 | 300 | 1 | 0.2 | Dry |

| 14 | 300 | 1 | 0.05 | Cutting fluid |

| Number | Milling Speed, vc/m·min−1 | Milling Depth, ap/mm | Feed Rate per Tooth, fz/mm·z−1 | Cryogenic Temperature, T/°C | Cryogenic Time, t/h |

|---|---|---|---|---|---|

| 1 | 100 | 0.5 | 0.05 | −195 | 2 |

| 2 | 150 | 0.5 | 0.05 | −195 | 2 |

| 3 | 200 | 0.5 | 0.05 | −120 | 2 |

| 4 | 150 | 0.5 | 0.1 | −120 | 2 |

| 5 | 150 | 0.5 | 0.2 | −195 | 8 |

| 6 | 150 | 1 | 0.05 | −195 | 8 |

| 7 | 150 | 2 | 0.05 | −195 | 8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, P.; Huang, Y.; Wang, R.; Ohashi, K. Study of Machined Surface Quality of AZ31B Magnesium Alloy by End Milling. Metals 2023, 13, 1712. https://doi.org/10.3390/met13101712

Zhang P, Huang Y, Wang R, Ohashi K. Study of Machined Surface Quality of AZ31B Magnesium Alloy by End Milling. Metals. 2023; 13(10):1712. https://doi.org/10.3390/met13101712

Chicago/Turabian StyleZhang, Pengchong, Yang Huang, Rongjun Wang, and Kazuhito Ohashi. 2023. "Study of Machined Surface Quality of AZ31B Magnesium Alloy by End Milling" Metals 13, no. 10: 1712. https://doi.org/10.3390/met13101712

APA StyleZhang, P., Huang, Y., Wang, R., & Ohashi, K. (2023). Study of Machined Surface Quality of AZ31B Magnesium Alloy by End Milling. Metals, 13(10), 1712. https://doi.org/10.3390/met13101712