Deposition of Superconducting Nb3Sn Coatings Using Multiple Magnetron Sputtering Techniques

Abstract

:1. Introduction

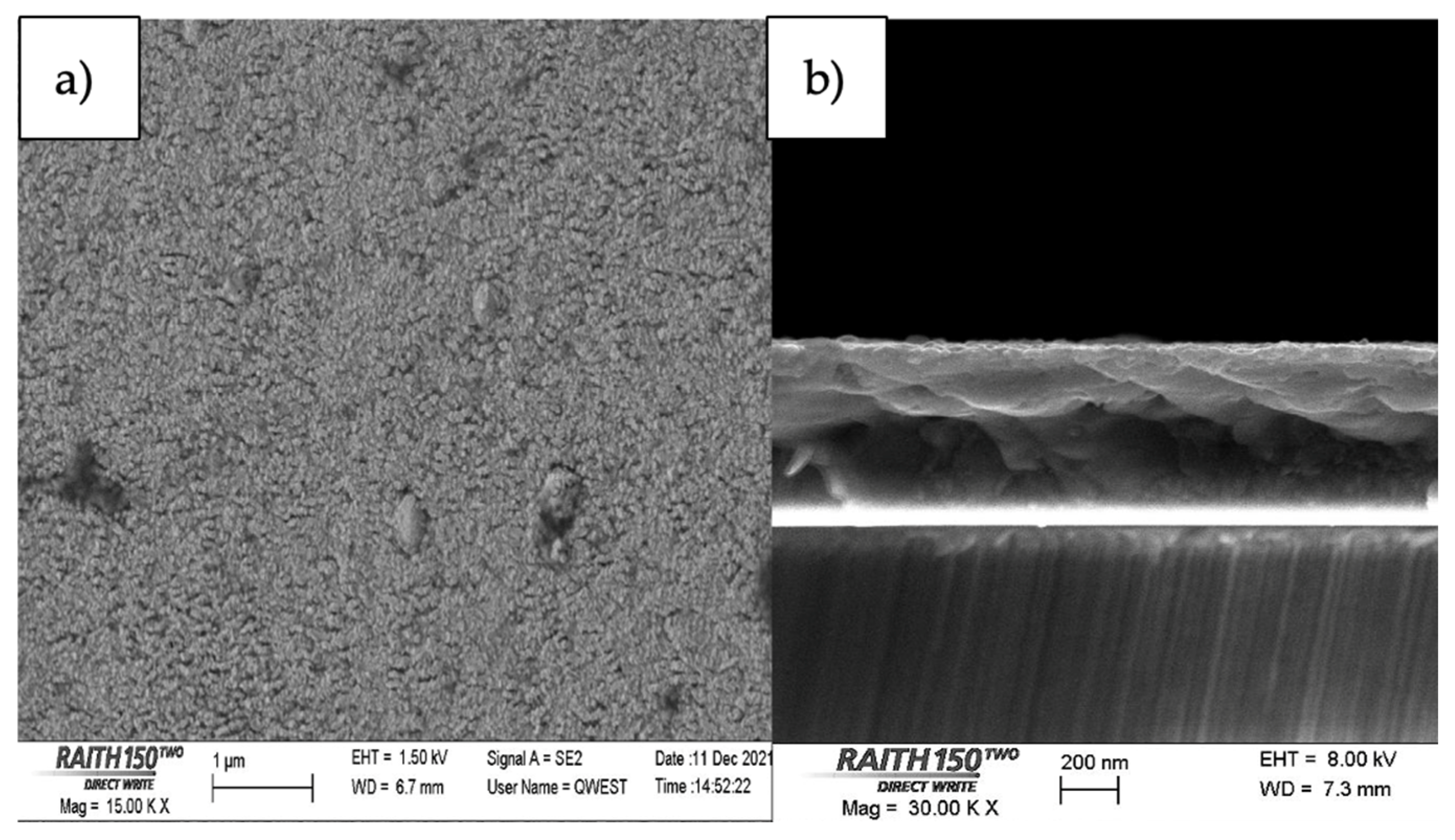

2. Materials and Methods

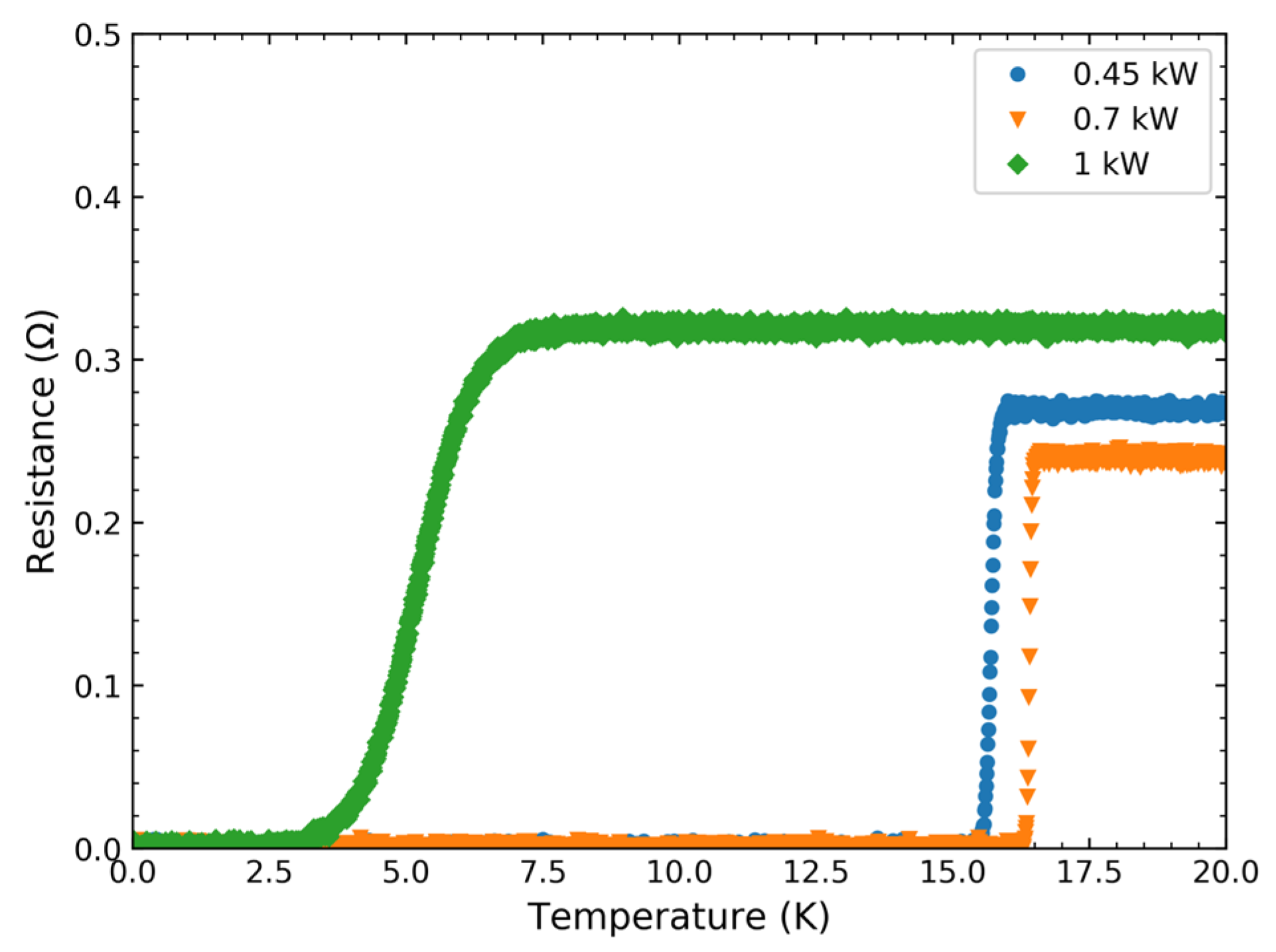

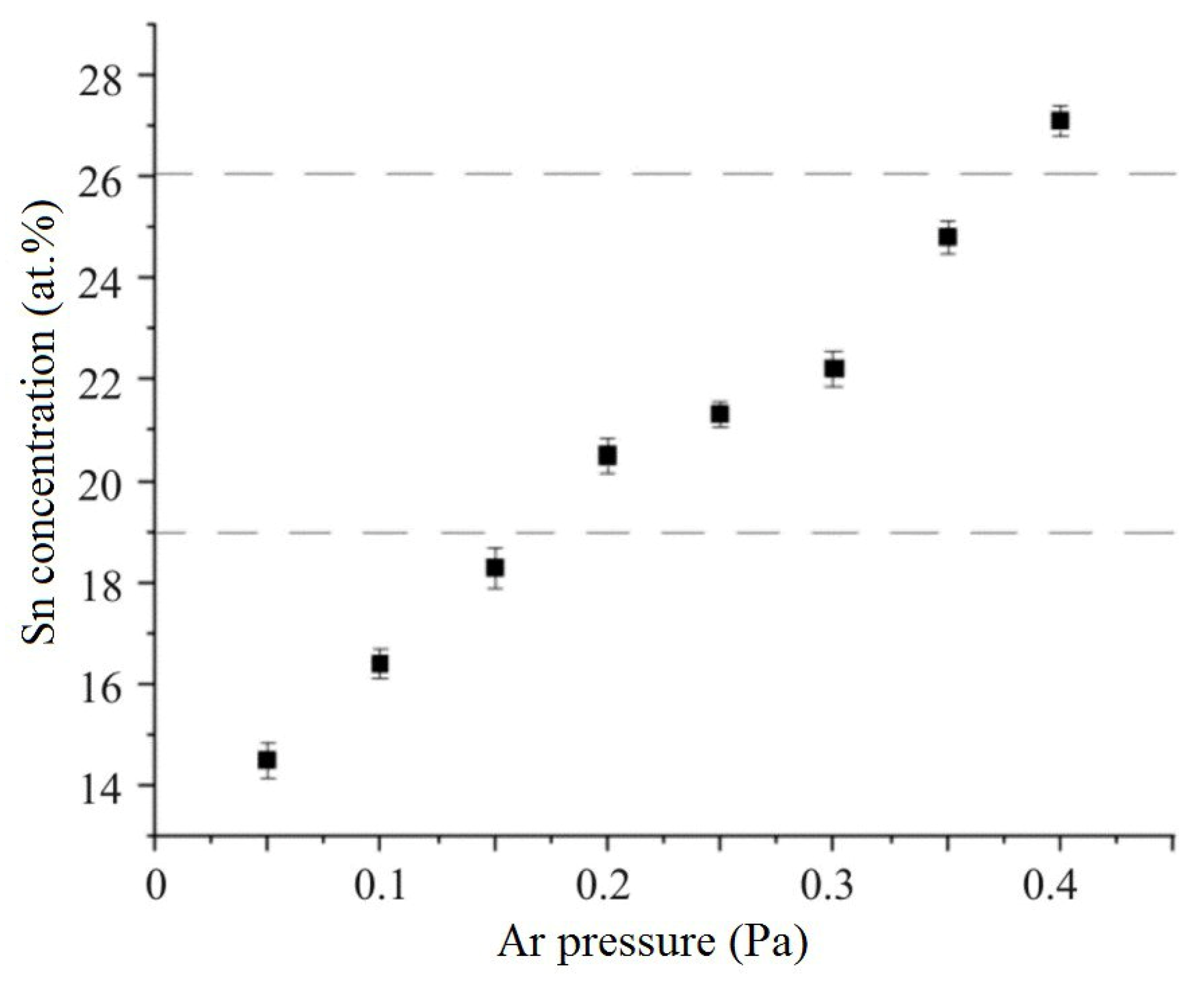

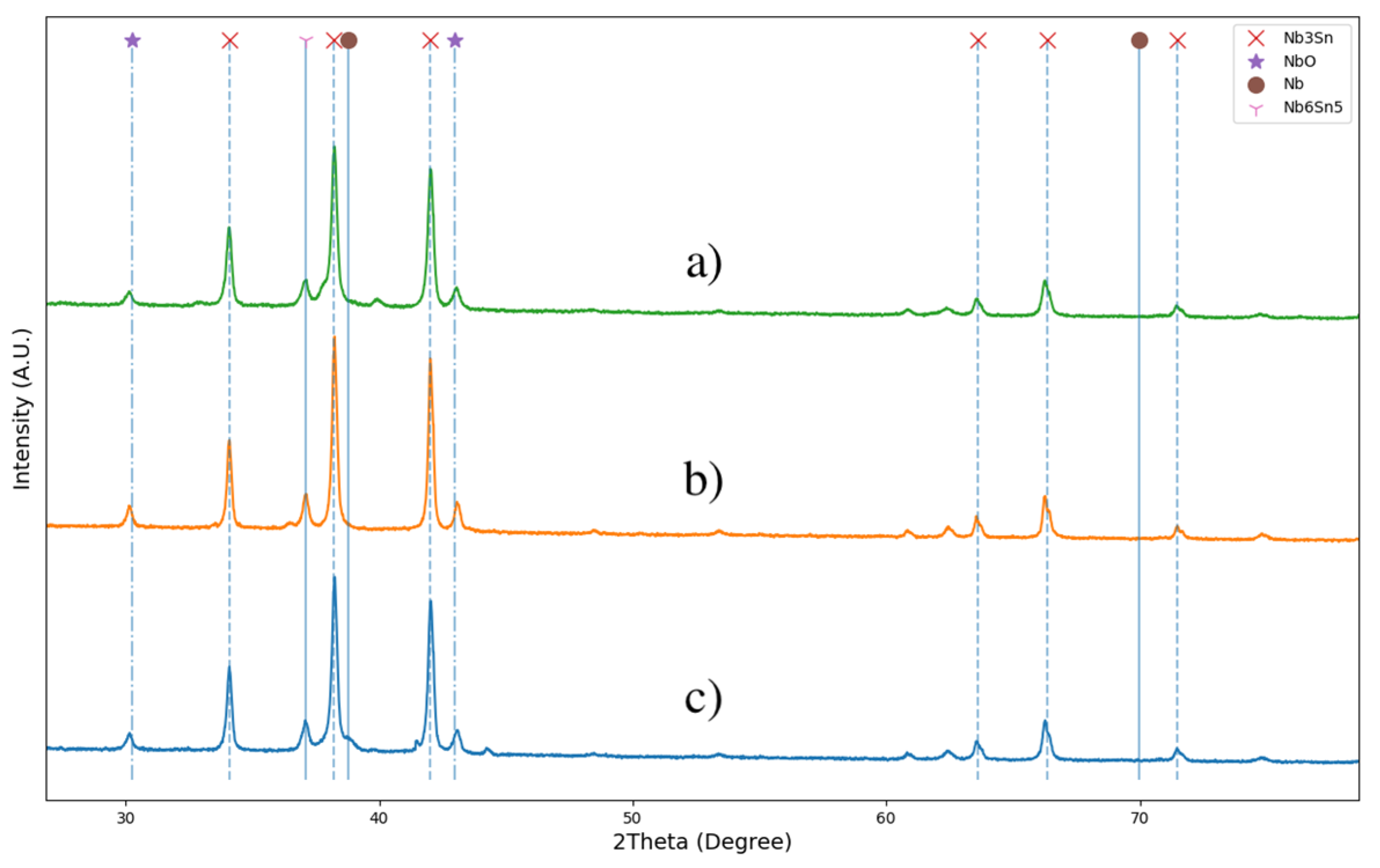

3. Results and Discussion

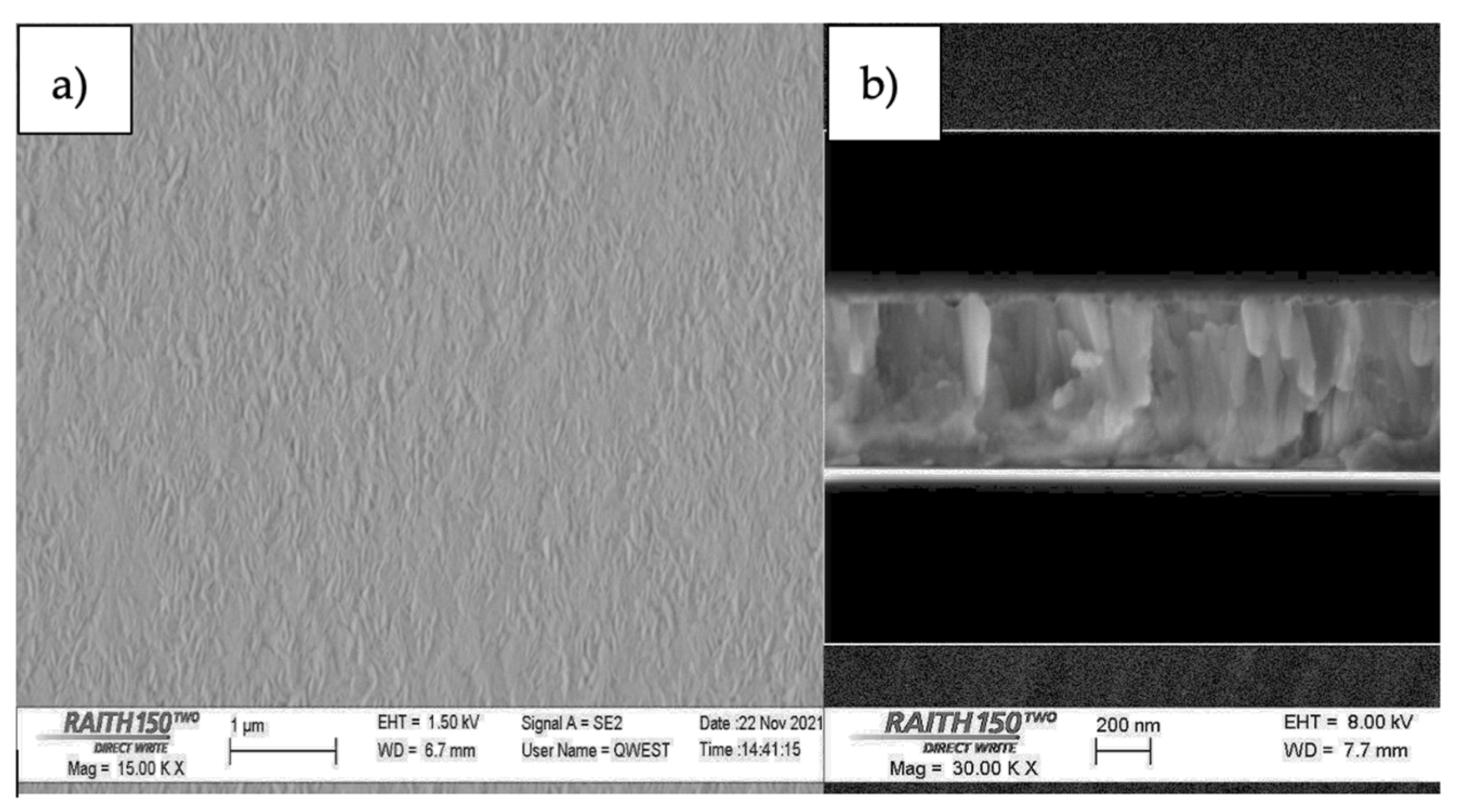

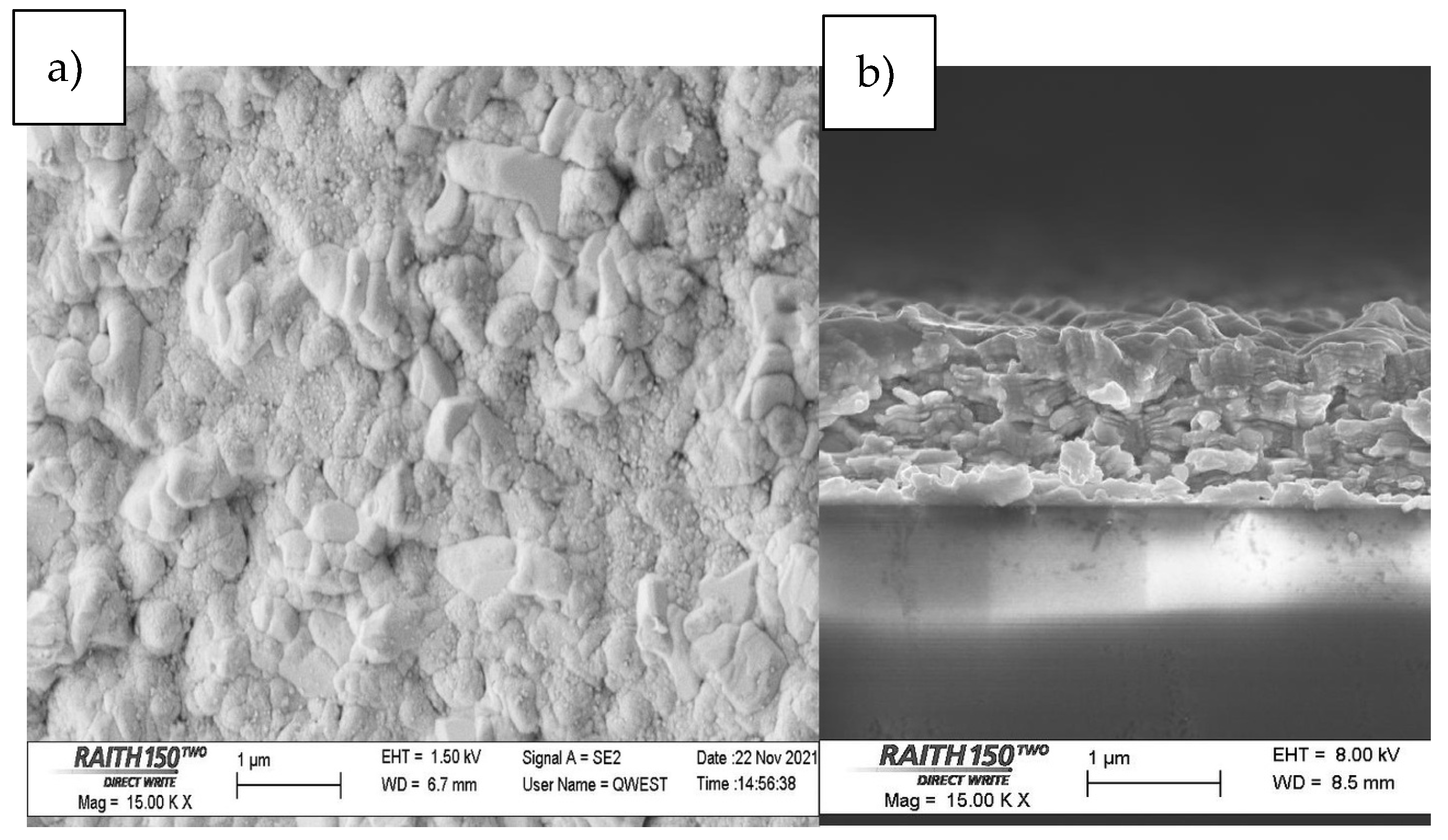

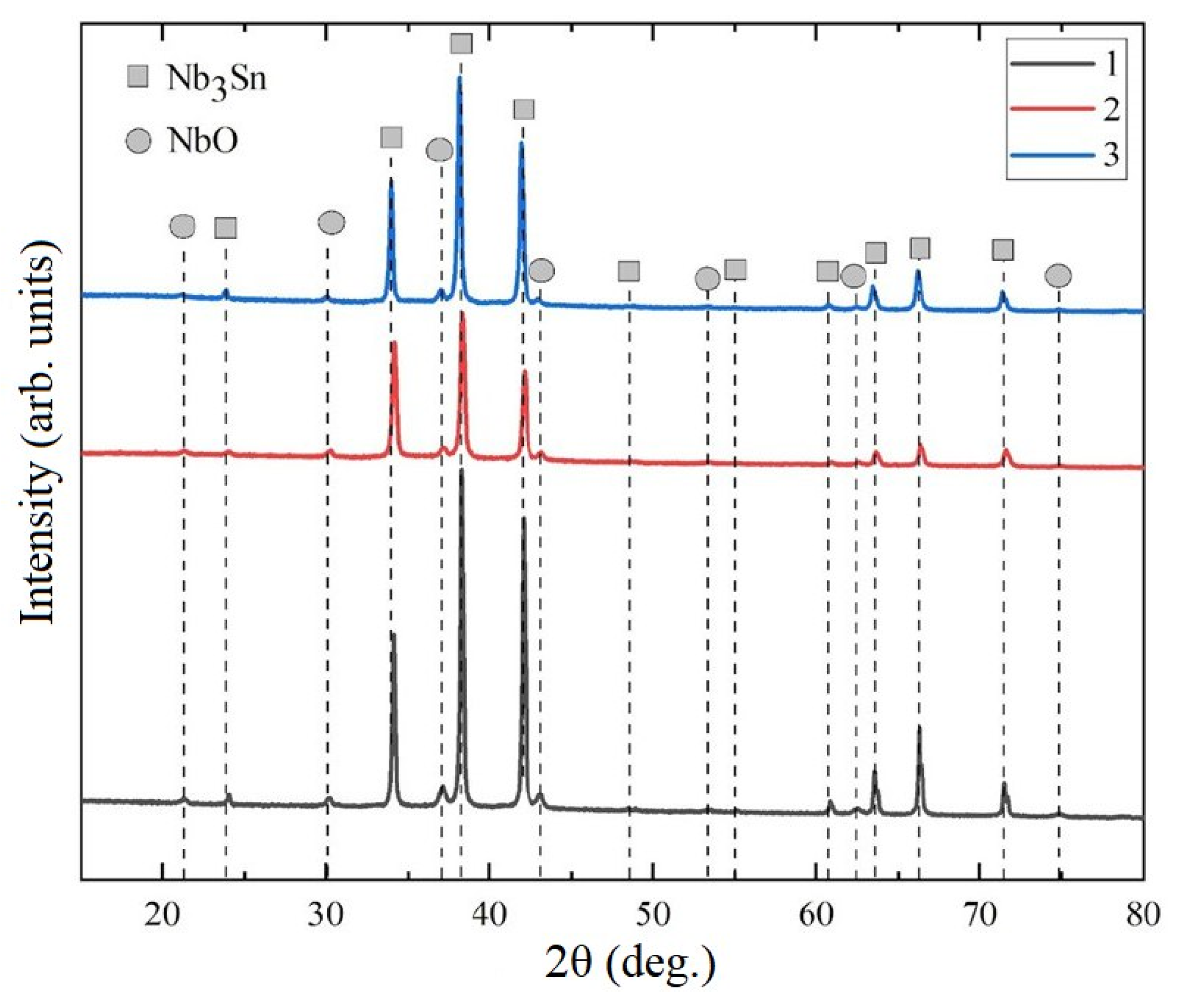

3.1. Co-Evaporation of Nb and Sn and Multilayer Coatings

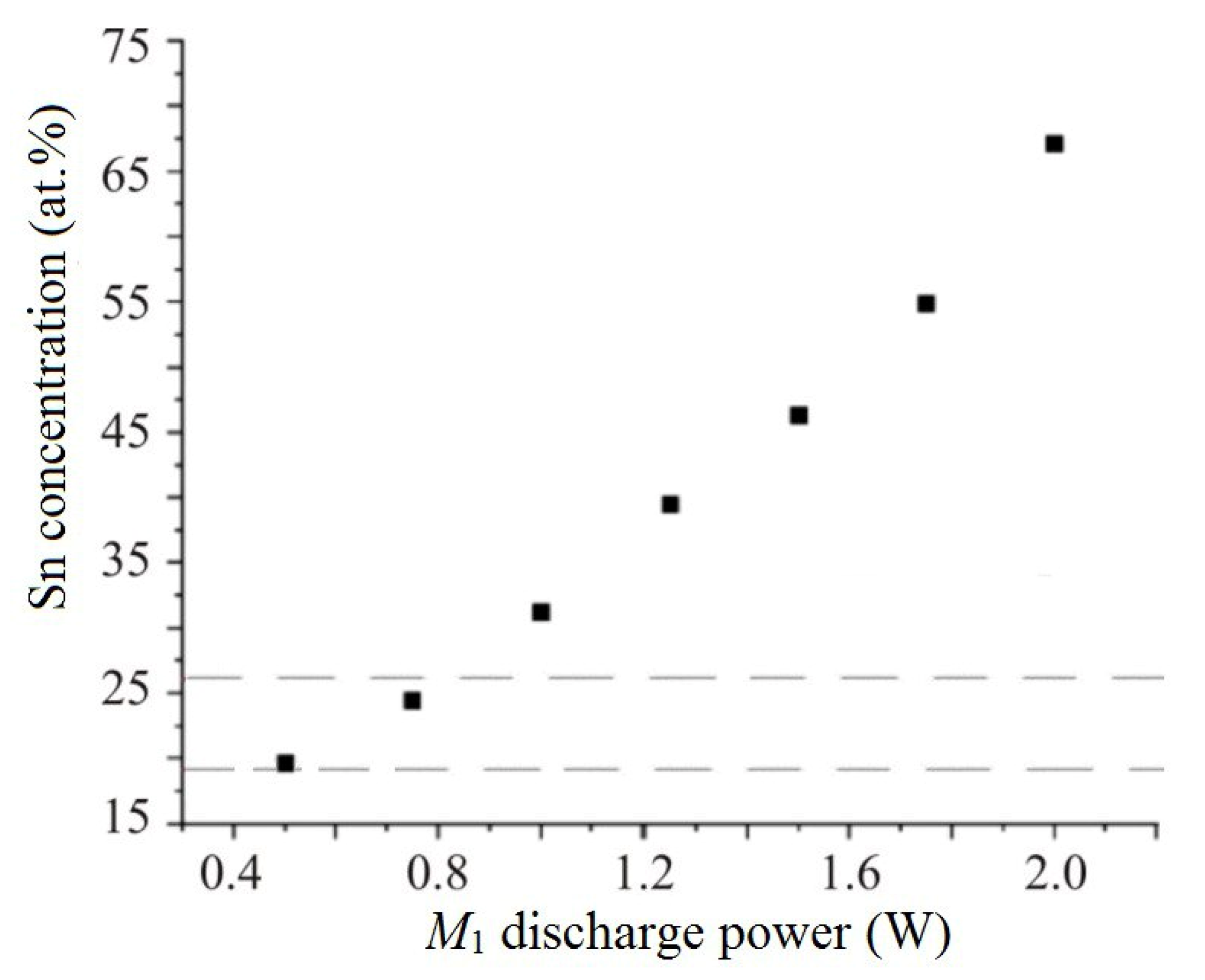

3.2. Deposition for a Stoichiometric Target

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Posen, S.; Lee, J.; Seidman, D.N.; Romanenko, A.; Tennis, B.; Melnychuk, O.S.; Sergatskov, D.A. Advances in Nb3Sn superconducting radiofrequency cavities towards first practical accelerator applications. Supercond. Sci. Technol. 2021, 34, 025007. [Google Scholar] [CrossRef]

- Posen, S.; Hall, D.L. Nb3Sn superconducting radiofrequency cavities: Fabrication, results, properties, and prospects. Supercond. Sci. Technol. 2017, 30, 033004. [Google Scholar] [CrossRef]

- Pudasaini, U.; Eremeev, G.; Reece, C.E.; Tuggle, J.; Kelley, M. Initial growth of tin on niobium for vapor diffusion coating of Nb3Sn. Supercond. Sci. Technol. 2018, 32, 045008. [Google Scholar] [CrossRef]

- Tan, W.; Ma, R.; Pan, H.; Zhao, H.; He, X.; Chen, X.; Zhao, C.; Lu, X. The observation of tin islands in Nb3Sn thin films deposited by magnetron sputtering. Phys. C Supercond. Its Appl. 2020, 576, 1353667. [Google Scholar] [CrossRef]

- Xiao, L.; Lu, X.; Yang, Z.; Tan, W.; Yang, Y.; Zhu, L.; Xie, D. Annealing study on the properties of Cu-based Nb3Sn films under argon pressures for SRF applications. Phys. C Supercond. Its Appl. 2021, 586, 1353894. [Google Scholar] [CrossRef]

- Grassellino, A.; Romanenko, A.; Sergatskov, D.; Melnychuk, O.; Trenikhina, Y.; Crawford, A.; Rowe, A.; Wong, M.; Khabiboulline, T.; Barkov, F. Nitrogen and argon doping of niobium for superconducting radio frequency cavities: A pathway to highly efficient accelerating structures. Supercond. Sci. Technol. 2013, 26, 102001. [Google Scholar] [CrossRef]

- Sharma, R.G. Review on the fabrication techniques of A-15 superconductors. Cryogenics 1987, 27, 361–378. [Google Scholar] [CrossRef]

- Godeke, A. A review of the properties of Nb3Sn and their variation with A15 composition, morphology and strain state. Supercond. Sci. Technol. 2006, 19, R68. [Google Scholar] [CrossRef]

- Hillenbrand, B.; Martens, H.; Pfister, H.; Schnitzke, K.; Uzel, Y. Superconducting Nb3Sn cavities with high microwave qualities. IEEE Trans. Magn. 1977, 13, 378–491. [Google Scholar] [CrossRef]

- Sun, Z.; Ge, M.; Maniscalco, J.T.; Arrieta, V.; McNeal, S.R.; Liepe, M.U. Electrochemical Polishing of Chemical Vapor Deposited Niobium Thin Films. arXiv 2023, arXiv:2301.00788. [Google Scholar] [CrossRef]

- Agatsuma, K.; Tateishi, H.; Arai, K.; Saitoh, T.; Nakagawa, M. Nb3Sn thin films made by RF magnetron sputtering process with a reacted Nb3Sn powder target. IEEE Trans. Magn. 1996, 32, 2925–2928. [Google Scholar] [CrossRef]

- Kampwirth, R.; Hafstrom, J.; Wu, C. Application of high rate magnetron sputtering to the fabrication of A-15 compounds. IEEE Trans. Magn. 1977, 13, 315–318. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Pudasaini, U.; Eremeev, G.V.; Elsayed-Ali, H.E. Fabrication of superconducting Nb3Sn film by Co-sputtering. Vacuum 2023, 212, 112019. [Google Scholar] [CrossRef]

- Ilyina, E.A.; Rosaz, G.; Descarrega, J.B.; Vollenberg, W.; Lunt, A.J.G.; Leaux, F.; Calatroni, S.; Venturini-Delsolaro, W.; Taborelli, M. Development of sputtered Nb3Sn films on copper substrates for superconducting radiofrequency applications. Supercond. Sci. Technol. 2019, 32, 035002. [Google Scholar] [CrossRef]

- Koblischka, M.R.; Pust, L.; Chang, C.-S.; Hauet, T.; Koblischka-Veneva, A. The Paramagnetic Meissner Effect (PME) in Metallic Superconductors. Metals 2023, 13, 1140. [Google Scholar] [CrossRef]

- Shakel, M.S.; Elsayed-Ali, H.E.; Eremeev, G.; Pudasaini, U.; Valente-Feliciano, A.M. First Results from Nb3Sn Coatings of 2.6 GHz Nb SRF Cavities Using DC Cylindrical Magnetron Sputtering System. arXiv 2023, arXiv:2307.08806. [Google Scholar]

- Deambrosis, S.M. 6 GHz Cavities: A Method to Test A15 Intermetallic Compounds Rf Properties; Universita Degli Studi di Padova: Padova, Italy, 2008. [Google Scholar]

- Allen, L.; Beasley, M.; Hammond, R.; Turneaure, J. RF surface resistance of high-Tcsuperconducting A15 thin films. IEEE Trans. Magn. 1983, 19, 1003–1006. [Google Scholar] [CrossRef]

- Carta, G.; Rossetto, G.; Zanella, P.; Crociani, L. Attempts to deposit Nb3Sn by MO-CVD. In Proceedings of the International Workshop on Thin Films and New Ideas for Pushing the Limits of RF Superconductivity, LNL, Legnaro, Italy, 9–12 October 2006. [Google Scholar]

- Rossi, A.A.; Deambrosis, S.M.; Stark, S. A15 Nb3Sn Films by Multilayer Sputtering & Review of SRF Tests. In Proceedings of the Proceedings of SRF 2009, Berlin, Germany, 20–25 September 2009; pp. 149–154. [Google Scholar]

- Le Febvrier, A.; Landalv, L.; Liersch, T.; Sandmark, D.; Sandstrom, P.; Eklund, P. An upgraded ultra-high vacuum magnetron-sputtering system for high-versatility and software-controlled deposition. Vacuum 2021, 187, 110137. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Pudasaini, U.; Charles, E. Properties of Nb3Sn films fabricated by magnetron sputtering from a single target. Appl. Surf. Sci. 2021, 541, 148528. [Google Scholar] [CrossRef]

- Sayeed, M.N.; Eremeev, G.V.; Owen, P.; Reece, C.; Elsayed-Ali, H.E. Microstructural and superconducting radiofrequency properties of multilayer sequentially sputtered Nb3Sn films. IEEE Trans. Appl. Supercond. 2021, 31, 1–4. [Google Scholar] [CrossRef]

- Zhu, L.; Lu, X.; Yang, Z.; Tan, W.; Yang, Y.; Xiao, L.; Xie, D. Study on preparation of Nb3Sn films by bronze route. Phys. C Supercond. Its Appl. 2022, 601, 1354113. [Google Scholar] [CrossRef]

- Shakel, S.; Sayeed, N.; Eremeev, G.V.; Valente-Feliciano, A.-M.; Pudasaini, U.; Elsayed-Ali, H.E. Commissioning of a two-target DC cylindrical magnetron sputter coater for depositing Nb3Sn film on Nb superconducting radiofrequency cavities. Vacuum 2023, 217, 112563. [Google Scholar] [CrossRef]

- Vandenberg, J.; Gurvitch, M.; Hamm, R.; Hong, M.; Rowell, J. New phase formation and superconductivity in reactively diffused Nb3Sn multilayer films. IEEE Trans. Magn. 1985, 21, 819–822. [Google Scholar] [CrossRef]

- Xiao, L.; Lu, X.; Xie, D.; Tan, W.; Yang, Y.; Zhu, L. The Technical Study of Nb3Sn Film Deposition on Copper by HiPIMS. In Proceedings of the 19th International Conference on RF Superconductivity, SRF2019, Dresden, Germany, 30 June–5 July 2019; pp. 846–847. [Google Scholar]

- Sayeed, N.; Pudasaini, U.; Reece, C.E.; Eremeev, G.V.; Elsayed-Ali, H.E. Effect of substrate temperature on the growth of Nb3Sn film on Nb by multilayer sputtering. Thin Solid Film. 2022, 763, 139569. [Google Scholar] [CrossRef]

- Valizadeh, R.; Hannah, A.N.; Aliasghari, S.; Malyshev, O.B.; Stenning, G.B.G.; Turner, D.; Dawson, K.; Dahnak, V.R. PVD Deposition of Nb3Sn thin film on copper substrate from an alloy Nb3Sn target. In Proceedings of the IPAC’19, Melbourne, Australia, 19–24 May 2019; pp. 2818–2821. [Google Scholar]

- Aliasghari, S.; Avcu, E.; Skeldon, P.; Valizadeh, R.; Mingo, B. Abrasion resistance of a Nb3Sn magnetron-sputtered coating on copper substrates for radio frequency superconducting cavities. Mater. Des. 2023, 231, 112030. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yurjev, Y.; Savelev, A.; Yurjeva, A.; Kazimirov, A.; Kharisova, A. Deposition of Superconducting Nb3Sn Coatings Using Multiple Magnetron Sputtering Techniques. Metals 2023, 13, 1730. https://doi.org/10.3390/met13101730

Yurjev Y, Savelev A, Yurjeva A, Kazimirov A, Kharisova A. Deposition of Superconducting Nb3Sn Coatings Using Multiple Magnetron Sputtering Techniques. Metals. 2023; 13(10):1730. https://doi.org/10.3390/met13101730

Chicago/Turabian StyleYurjev, Yuriy, Aleksandr Savelev, Alena Yurjeva, Artem Kazimirov, and Anastasiia Kharisova. 2023. "Deposition of Superconducting Nb3Sn Coatings Using Multiple Magnetron Sputtering Techniques" Metals 13, no. 10: 1730. https://doi.org/10.3390/met13101730