Detonation Spraying of Ni-Based Composite Coatings Reinforced by High-Entropy Intermetallic Particles

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparing Composite Powder

2.2. DS Process

2.3. Characterization

3. Results and Discussion

4. Conclusions

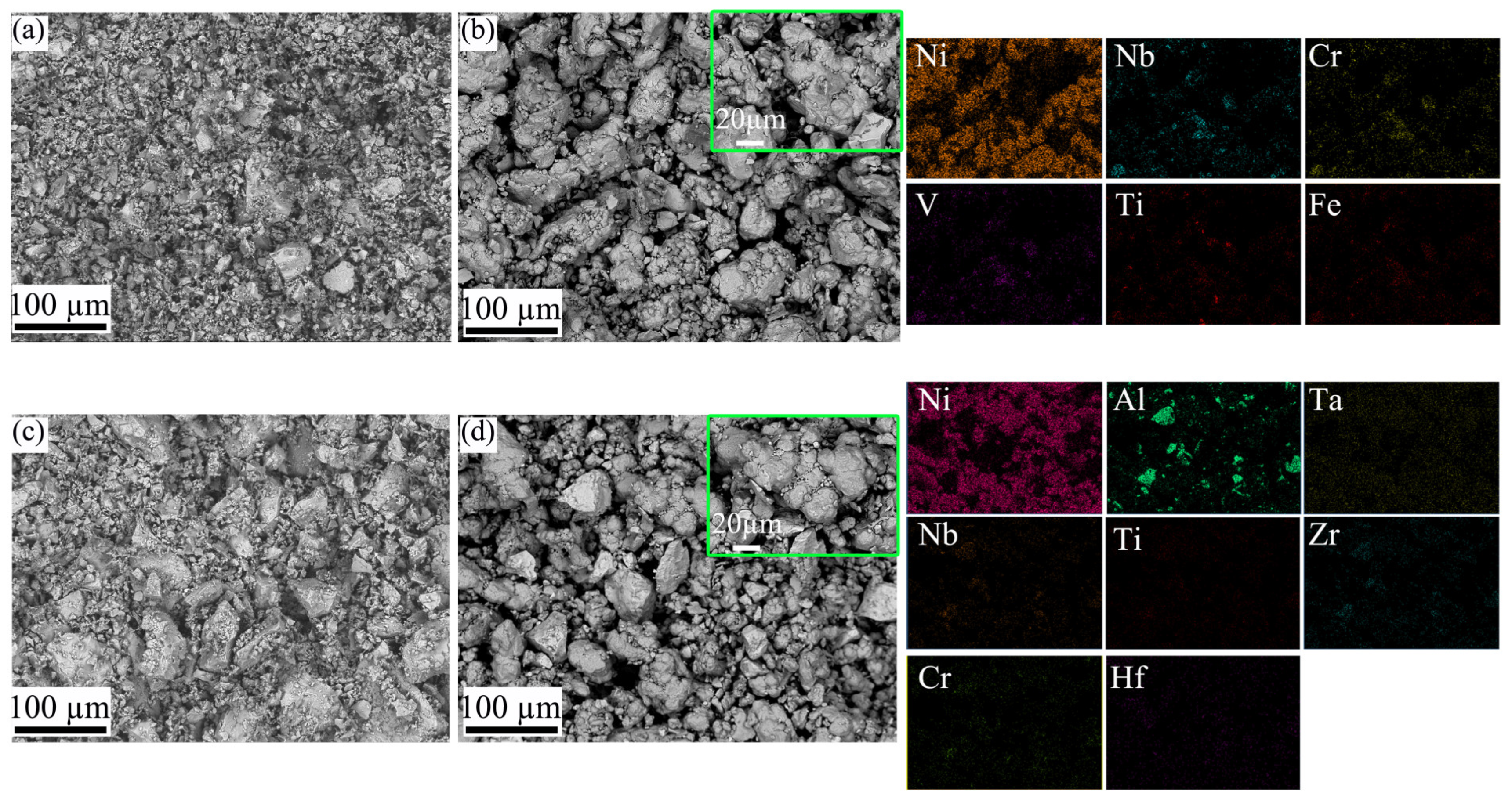

- The FeNiCrV-TiNb and Al3(TiZrNbCrHfTa) HEIC powders, prepared by melting techniques followed by crushing and ball milling, indicated a single hexagonal C14 Laves phase and a tetragonal D022-type phase along with some minor CrTi and Cr5Al8 phases, respectively.

- The sprayed Ni-7wt.% FeNiCrV-TiNb and Ni-7wt.% Al3(TiZrNbCrHfTa) composite coatings exhibited the same crystal structure as the corresponding powder mixtures, indicating suitable thermal stability during the DS process.

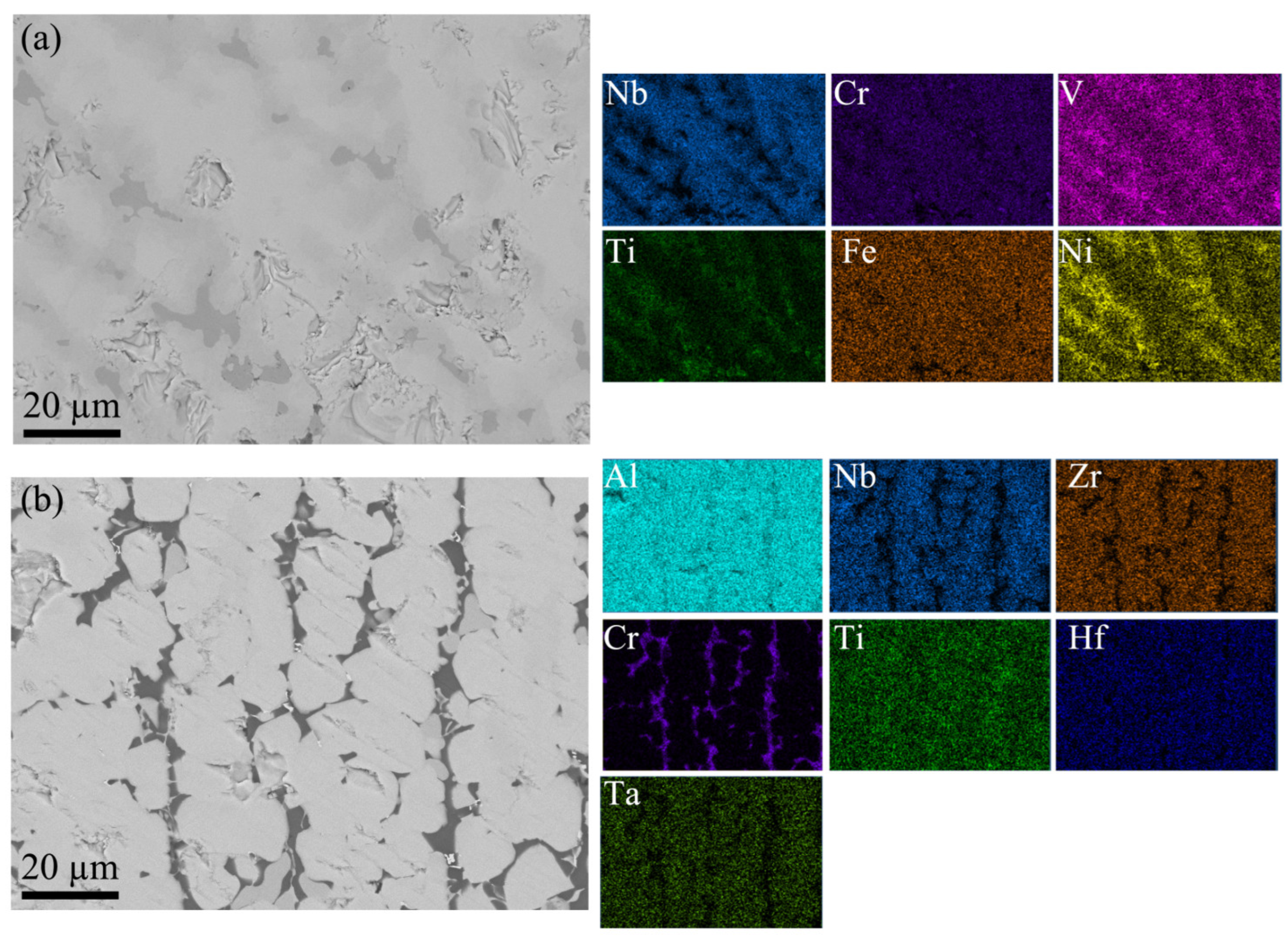

- Both composite coatings exhibited a dense lamellar microstructure consisting of Ni layers with HEIC particles embedded in them.

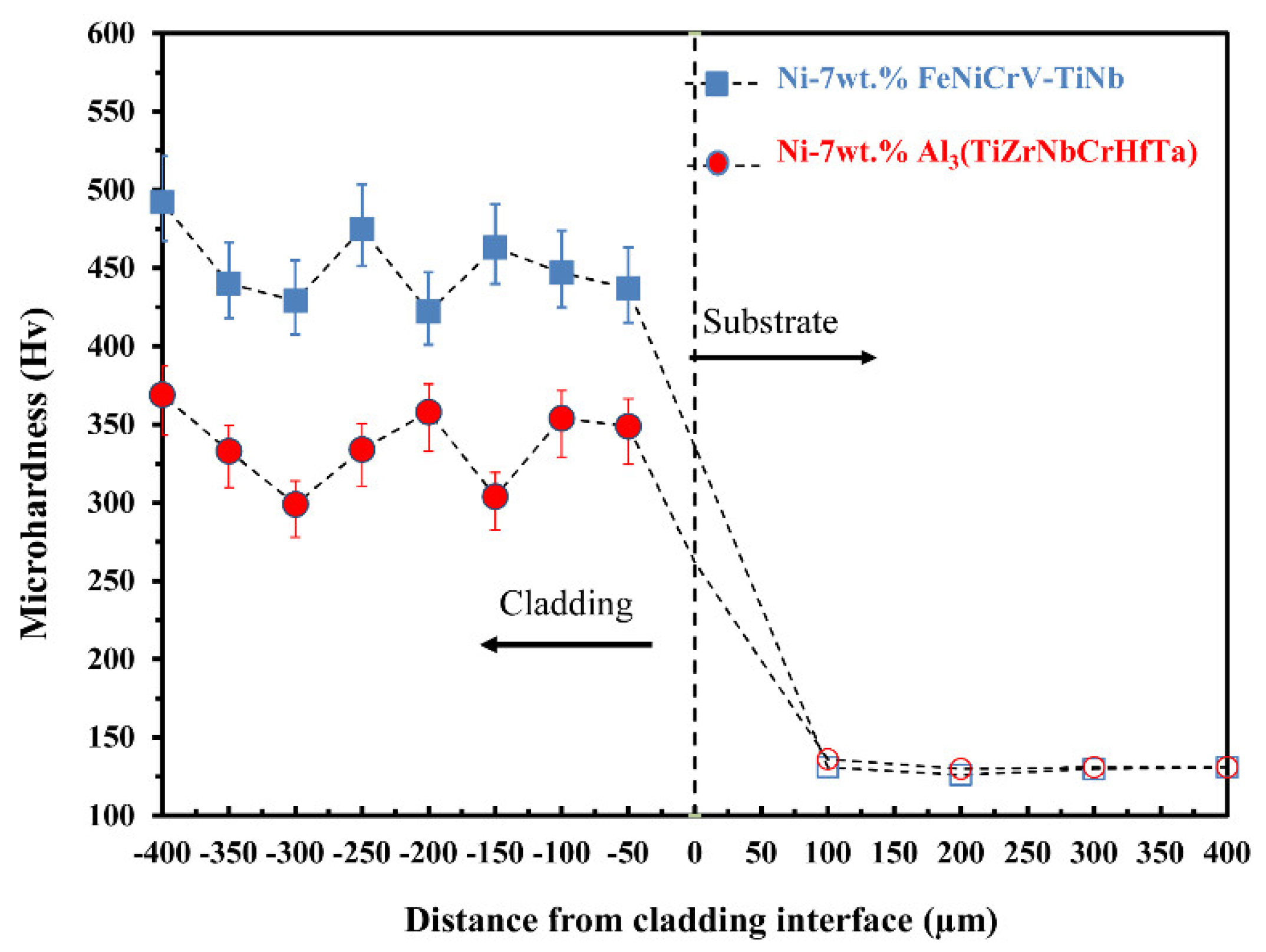

- Ni-7wt.% FeNiCrV-TiNb exhibited higher microhardness (450 HV) than Ni-7wt.% Al3(TiZrNbCrHfTa) (338 HV), which could be attributed to the higher microhardness of its reinforcement particles.

- HEICs are introduced as novel reinforcement particles for fabricating a wide range of metal matrix composites, especially for working at high temperatures.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, J.-L.; Cheng, Y.-H.; Chen, Y.-X.; Liang, X.-B. Composition design and preparation process of refractory high-entropy alloys: A review. Int. J. Refract. Met. Hard Mater. 2022, 105, 105836. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Fereidonnejad, R.; Cabot, A. Semi-ordered high entropy materials: The case of high entropy intermetallic compounds. J. Alloys Compd. 2023, 960, 170802. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Mikhailov, D.; Sudarikov, M.; Fereidonnejad, R.; Cabot, A.; Trofimov, E. Segregation mediated design of single-phase refractory medium and high entropy intermetallic compounds with complete suppression of pest oxidation. J. Alloys Compd. 2022, 927, 167102. [Google Scholar] [CrossRef]

- Trofimov, E.; Moghaddam, A.O.; Litvinyuk, K.; Mikhailov, D. Microsegregation in high-entropy intermetallic compounds. J. Alloys Compd. 2023, 934, 168021. [Google Scholar] [CrossRef]

- Yin, L.; Guo, Y.; Guo, X. Cocktail effect on RT5-type (R = rare earth, T = 3d transition metal) high entropy intermetallic compounds. J. Magn. Magn. Mater. 2022, 563, 169883. [Google Scholar] [CrossRef]

- Yin, L.; Guo, X.; Guo, Y.; Hui, Y.; Lu, S. Valence electron structures and thermal and magnetic properties of RCo5 (R = light rare earth) intermetallic compounds with medium-and high-entropy design at R site. J. Alloys Compd. 2023, 965, 171357. [Google Scholar] [CrossRef]

- Yang, T.; Cao, B.; Zhang, T.; Zhao, Y.; Liu, W.; Kong, H.; Luan, J.; Kai, J.; Kuo, W.; Liu, C. Chemically complex intermetallic alloys: A new frontier for innovative structural materials. Mater. Today 2022, 52, 161–174. [Google Scholar] [CrossRef]

- Wang, H.; He, Q.-F.; Yang, Y. High-entropy intermetallics: From alloy design to structural and functional properties. Rare Met. 2022, 41, 1989–2001. [Google Scholar] [CrossRef]

- Liu, J.; Wang, X.; Singh, A.P.; Xu, H.; Kong, F.; Yang, F. The Evolution of Intermetallic Compounds in High-Entropy Alloys: From the Secondary Phase to the Main Phase. Metals 2021, 11, 2054. [Google Scholar] [CrossRef]

- Yao, K.; Liu, L.; Ren, J.; Guo, Y.; Liu, Y.; Cao, Y.; Feng, R.; Wu, F.; Qi, J.; Luo, J. High-entropy intermetallic compound with ultra-high strength and thermal stability. Scr. Mater. 2021, 194, 113674. [Google Scholar] [CrossRef]

- Li, H.; Yang, W.; Ma, Y.; Kong, F.; Wan, Y.; Chen, C.; Liu, H.; Li, H.; Inoue, A. Plastic TiZrHfCoNiCu High Entropy Alloy Via Stable B2 Phase. J. Alloys Compd. 2023, 935, 167897. [Google Scholar] [CrossRef]

- He, Q.; Wang, J.; Chen, H.; Ding, Z.; Zhou, Z.; Xiong, L.; Luan, J.; Pelletier, J.; Qiao, J.; Wang, Q. A highly distorted ultraelastic chemically complex Elinvar alloy. Nature 2022, 602, 251–257. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Chen, S.; Jia, Y.; Hu, Z.; Huang, H.; Yang, Z.; Dong, A.; Zhu, G.; Wang, D.; Shu, D. FCC-L12 ordering transformation in equimolar FeCoNiV multi-principal element alloy. Mater. Des. 2019, 168, 107648. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zheng, M.; Zhang, X.; Yang, X.; Gu, J. In situ EBSD/DIC-based investigation of deformation and fracture mechanism in FCC-and L12-structured FeCoNiV high-entropy alloys. Int. J. Plast. 2022, 152, 103247. [Google Scholar] [CrossRef]

- Ye, Z.; Li, C.; Zheng, M.; Zhang, X.; Yang, X.; Wang, Q.; Gu, J. Realizing superior strength-ductility combination in dual-phase AlFeCoNiV high-entropy alloy through composition and microstructure design. Mater. Res. Lett. 2022, 10, 736–743. [Google Scholar] [CrossRef]

- Park, H.J.; Na, Y.S.; Hong, S.H.; Kim, J.T.; Kim, Y.S.; Lim, K.R.; Park, J.M.; Kim, K.B. Phase evolution, microstructure and mechanical properties of equi-atomic substituted TiZrHfNiCu and TiZrHfNiCuM (M = Co, Nb) high-entropy alloys. Met. Mater. Int. 2016, 22, 551–556. [Google Scholar] [CrossRef]

- Yadav, T.; Mukhopadhyay, S.; Mishra, S.; Mukhopadhyay, N.; Srivastava, O. Synthesis of a single phase of high-entropy Laves intermetallics in the Ti–Zr–V–Cr–Ni equiatomic alloy. Philos. Mag. Lett. 2017, 97, 494–503. [Google Scholar] [CrossRef]

- Sharma, A. High entropy alloy coatings and technology. Coatings 2021, 11, 372. [Google Scholar] [CrossRef]

- Han, P.; Wang, W.; Liu, Z.; Zhang, T.; Liu, Q.; Guan, X.; Qiao, K.; Ye, D.; Cai, J.; Xie, Y. Modification of cold-sprayed high-entropy alloy particles reinforced aluminum matrix composites via friction stir processing. J. Alloys Compd. 2022, 907, 164426. [Google Scholar] [CrossRef]

- Zou, Y.; Qiu, Z.; Huang, C.; Zeng, D.; Lupoi, R.; Zhang, N.; Yin, S. Microstructure and tribological properties of Al2O3 reinforced FeCoNiCrMn high entropy alloy composite coatings by cold spray. Surf. Coat. Technol. 2022, 434, 128205. [Google Scholar] [CrossRef]

- Peng, Y.; Zhang, W.; Li, T.; Zhang, M.; Liu, B.; Liu, Y.; Wang, L.; Hu, S. Effect of WC content on microstructures and mechanical properties of FeCoCrNi high-entropy alloy/WC composite coatings by plasma cladding. Surf. Coat. Technol. 2020, 385, 125326. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, C.; Zhang, S.; Zhang, J.; Chen, J.; Liu, Y. Fabrication and wear behavior of TiC reinforced FeCoCrAlCu-based high entropy alloy coatings by laser surface alloying. Mater. Chem. Phys. 2020, 255, 123571. [Google Scholar] [CrossRef]

- Gong, N.; Meng, T.L.; Cao, J.; Wang, Y.; Karyappa, R.; Ivan Tan, C.K.; Suwardi, A.; Zhu, Q.; Ngo, A.C.Y.; Misra, K.P. Laser-cladding of high entropy alloy coatings: An overview. Mater. Technol. 2023, 38, 2151696. [Google Scholar] [CrossRef]

- Samoilova, O.; Shaburova, N.; Samodurova, M.; Pashkeev, K.; Ostovari Moghaddam, A.; Trofimov, E. Microstructure and Wear Behavior of Al0.25CoCrFeNiSi0.6 High-Entropy Alloy Coating Deposited on Stainless Steel by Detonation Spraying. J. Therm. Spray Technol. 2023, 32, 1220–1229. [Google Scholar] [CrossRef]

- Wu, Z.-X.; He, M.-J.; Feng, C.-S.; Wang, T.-L.; Lin, M.-Z.; Liao, W.-B. Effects of Annealing on the Microstructures and Wear Resistance of CoCrFeNiMn High-Entropy Alloy Coatings. J. Therm. Spray Technol. 2022, 31, 1244–1251. [Google Scholar] [CrossRef]

- Zhao, P.; Zhu, J.; Yang, K.; Li, M.; Shao, G.; Lu, H.; Ma, Z.; Wang, H.; He, J. Outstanding wear resistance of plasma sprayed high-entropy monoboride composite coating by inducing phase structural cooperative mechanism. Appl. Surf. Sci. 2023, 616, 156516. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Abdollahzadeh, A.; Samodurova, M.; Shaburova, N.; Mikhailov, D.; Fereidonnejad, R.; Zhivulin, V.; Trofimov, E. Novel high entropy intermetallic compounds: Synthesis and detonation spraying. Intermetallics 2022, 146, 107591. [Google Scholar] [CrossRef]

- Moghaddam, A.O.; Mikhailov, D.; Fereidonnejad, R.; Shaburova, N.; Vinnik, D.; Uchaev, D.; Bai, F.-Q.; Janas, D.; Trofimov, E. Phase formation, microhardness and magnetic properties of FeNiCrV-TiNb,(NiCoFeCuMn) 3 (AlTi) and (FeNiCoCrMn)(MoCr) high entropy intermetallic compounds. J. Alloys Compd. 2022, 912, 165195. [Google Scholar] [CrossRef]

- Rakhadilov, B.; Buytkenov, D.; Kakimzhanov, D.; Kozhanova, R.; Bektasova, G. The effect of detonation spraying on the phase composition and hardness of Al2O3 coatings. Eurasian J. Phys. Funct. Mater. 2020, 4, 160–166. [Google Scholar] [CrossRef]

- Liao, W.-B.; Wu, Z.-X.; Lu, W.; He, M.; Wang, T.; Guo, Z.; Huang, J. Microstructures and mechanical properties of CoCrFeNiMn high-entropy alloy coatings by detonation spraying. Intermetallics 2021, 132, 107138. [Google Scholar] [CrossRef]

- Lai, L.; Gan, M.; Wang, J.; Chen, L.; Liang, X.; Feng, J.; Chong, X. New class of high-entropy rare-earth niobates with high thermal expansion and oxygen insulation. J. Am. Ceram. Soc. 2023, 106, 4343–4357. [Google Scholar] [CrossRef]

- Zhou, L.; Li, F.; Liu, J.-X.; Hu, Q.; Bao, W.; Wu, Y.; Cao, X.; Xu, F.; Zhang, G.-J. High-entropy thermal barrier coating of rare-earth zirconate: A case study on (La0.2Nd0.2Sm0.2Eu0.2Gd0.2) 2Zr2O7 prepared by atmospheric plasma spraying. J. Eur. Ceram. Soc. 2020, 40, 5731–5739. [Google Scholar] [CrossRef]

- Chen, H.; Zhao, Z.; Xiang, H.; Dai, F.-Z.; Xu, W.; Sun, K.; Liu, J.; Zhou, Y. High entropy (Y0.2Yb0.2Lu0.2Eu0.2Er0.2) 3Al5O12: A novel high temperature stable thermal barrier material. J. Mater. Sci. Technol. 2020, 48, 57–62. [Google Scholar] [CrossRef]

- Li, Z.; Zheng, J.; Zhang, W.; Zheng, Y.; Zhao, W.; Xue, L.; Yang, F.; Chen, H. A promising high-entropy thermal barrier material with the formula (Y0.2Dy0.2Ho0.2Er0.2Yb0.2) 3Al5O12. Materials 2022, 15, 8079. [Google Scholar] [CrossRef]

| EDS Chemical Composition (at. %) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| HEICs | Al | Ni | Cr | Fe | V | Ti | Nb | Zr | Hf | Ta | Porosity (%) | |

| FeNiCrV-TiNb | Powder | - | 16.49 | 17.75 | 16.98 | 16.48 | 15.63 | 16.67 | - | - | - | - |

| DS | - | 90.58 | 1.91 | 1.94 | 1.88 | 1.63 | 2.06 | - | - | - | 0.5 | |

| Al3(TiZrNb-CrHfTa) | Powder | 73.22 | - | 3.94 | - | - | 4.15 | 4.64 | 4.22 | 5.08 | 4.77 | - |

| DS | 8.21 | 88.40 | 0.40 | - | - | 0.44 | 0.63 | 0.58 | 0.49 | 0.85 | 0.65 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moghaddam, A.O.; Shaburova, N.; Naseri, M.; Latfulina, Y.; Samodurova, M.; Krymsky, V.; Litvinyuk, K.; Trofimov, E. Detonation Spraying of Ni-Based Composite Coatings Reinforced by High-Entropy Intermetallic Particles. Metals 2023, 13, 1807. https://doi.org/10.3390/met13111807

Moghaddam AO, Shaburova N, Naseri M, Latfulina Y, Samodurova M, Krymsky V, Litvinyuk K, Trofimov E. Detonation Spraying of Ni-Based Composite Coatings Reinforced by High-Entropy Intermetallic Particles. Metals. 2023; 13(11):1807. https://doi.org/10.3390/met13111807

Chicago/Turabian StyleMoghaddam, Ahmad Ostovari, Nataliya Shaburova, Majid Naseri, Yulia Latfulina, Marina Samodurova, Valerii Krymsky, Ksenia Litvinyuk, and Evgeny Trofimov. 2023. "Detonation Spraying of Ni-Based Composite Coatings Reinforced by High-Entropy Intermetallic Particles" Metals 13, no. 11: 1807. https://doi.org/10.3390/met13111807

APA StyleMoghaddam, A. O., Shaburova, N., Naseri, M., Latfulina, Y., Samodurova, M., Krymsky, V., Litvinyuk, K., & Trofimov, E. (2023). Detonation Spraying of Ni-Based Composite Coatings Reinforced by High-Entropy Intermetallic Particles. Metals, 13(11), 1807. https://doi.org/10.3390/met13111807