Microstructure and Superelasticity of Cu–Sn Shape-Memory Microwires by Glass-Coated Melt Spinning

Abstract

:1. Introduction

2. Experimental

3. Results

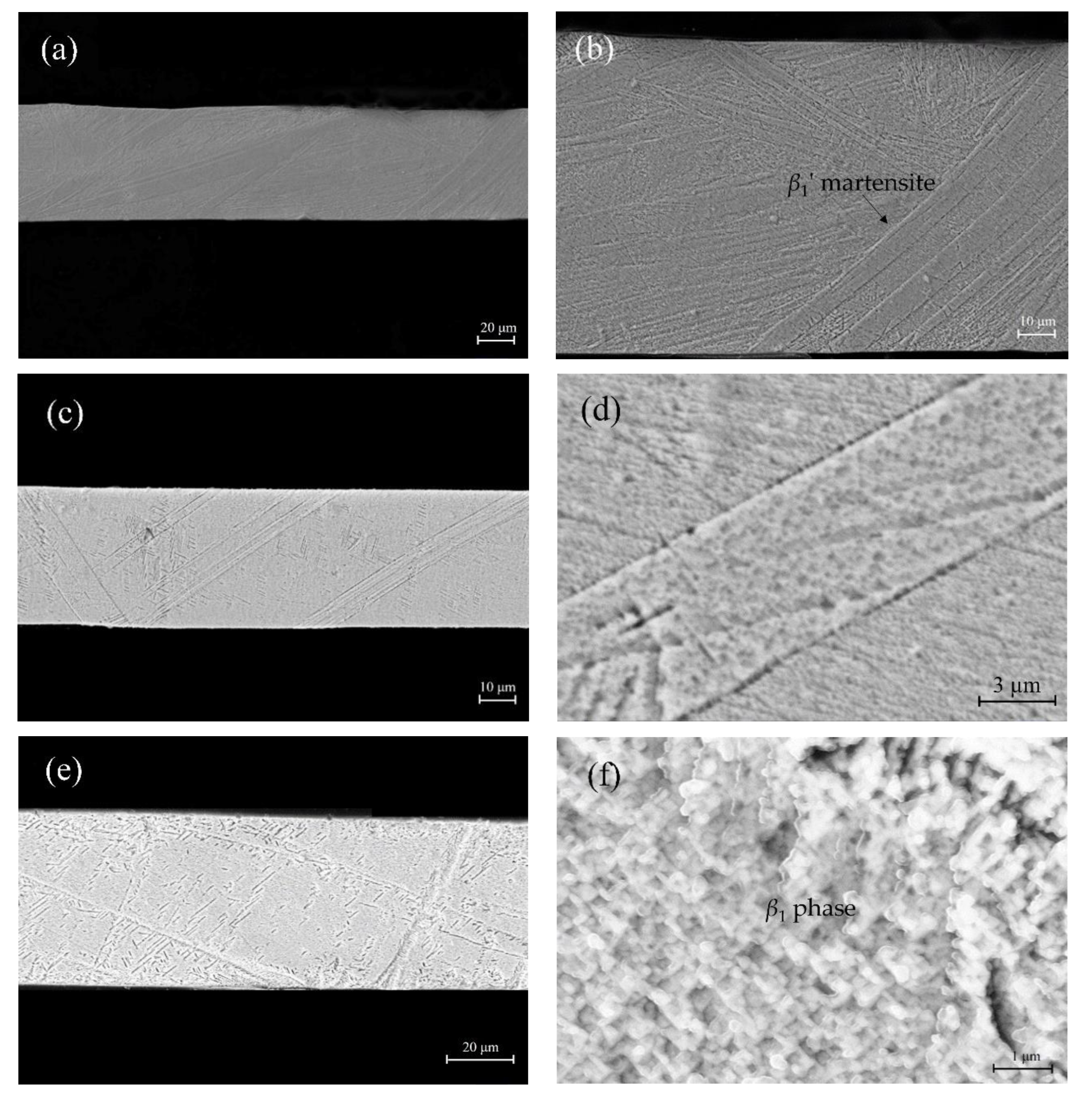

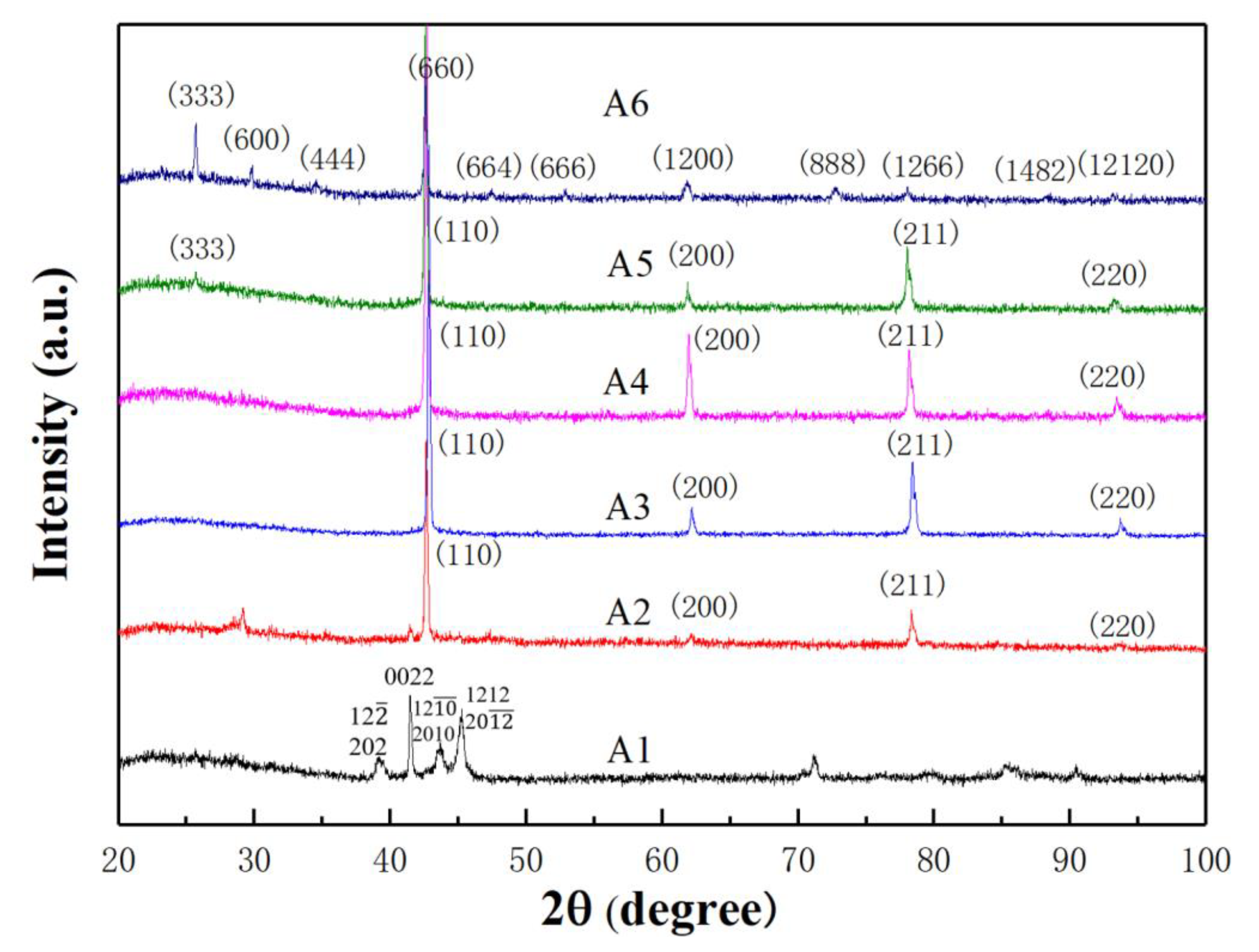

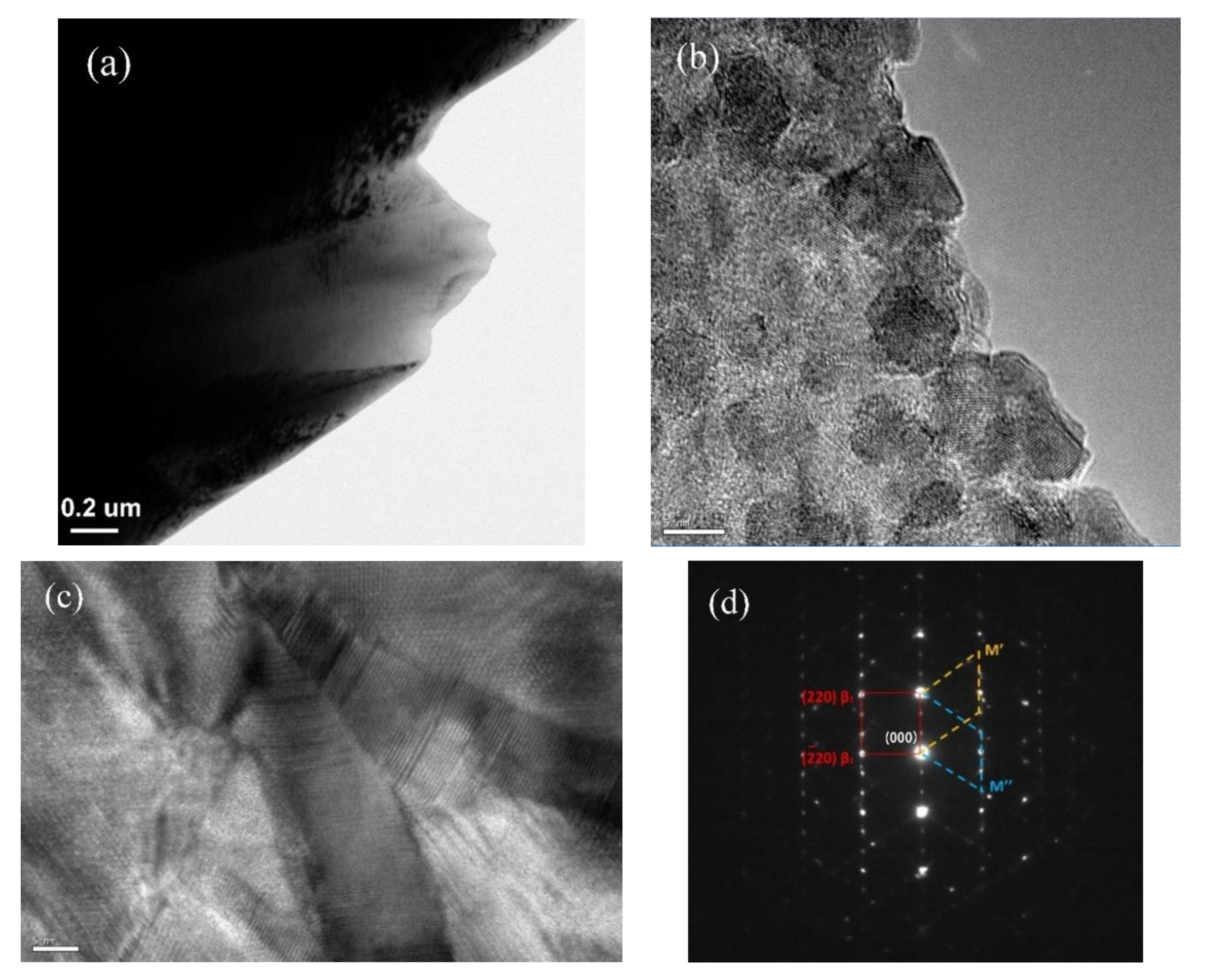

3.1. Effect of Sn Content on the Phase Composition and Microstructure of Cu–Sn Microwires

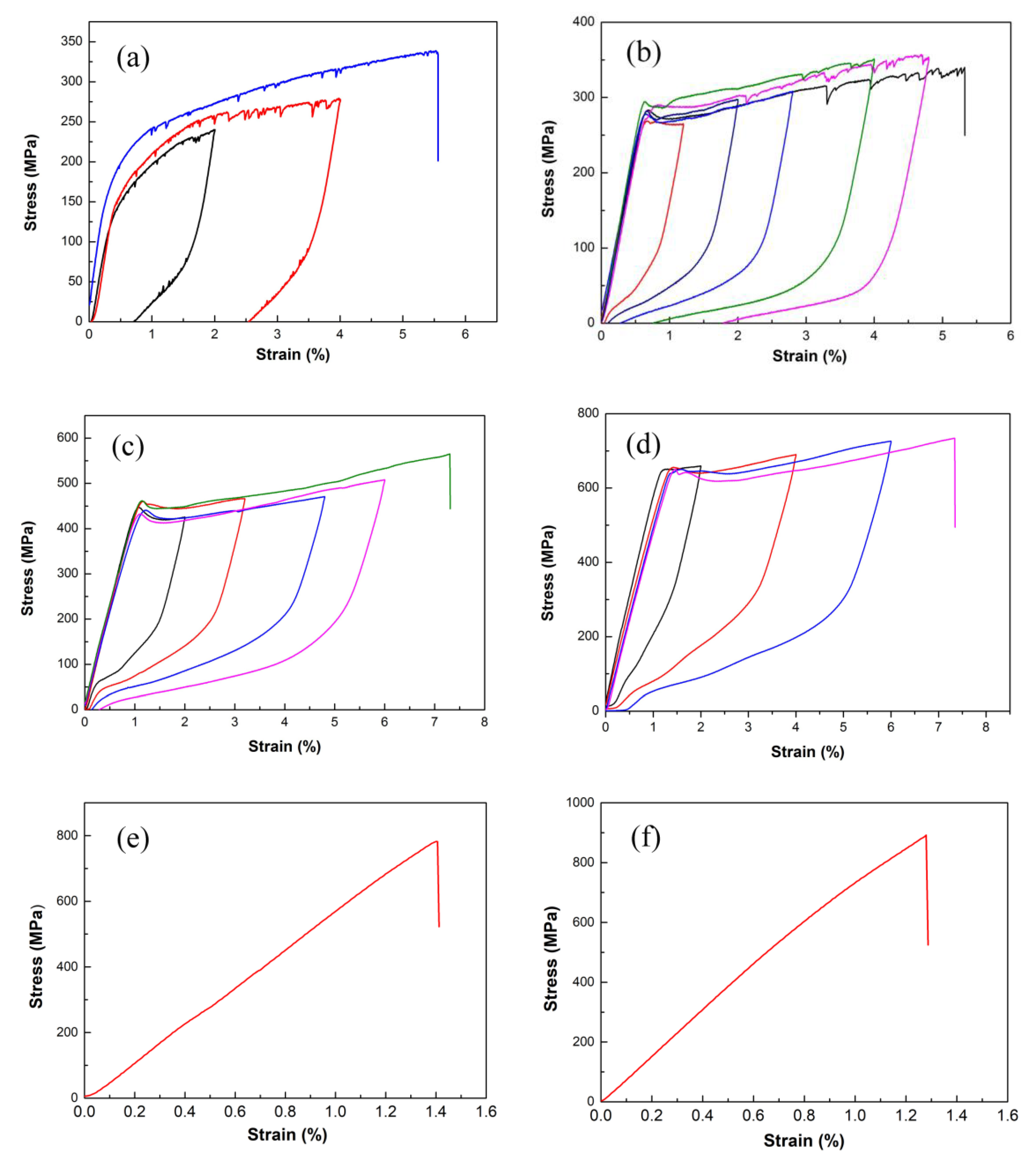

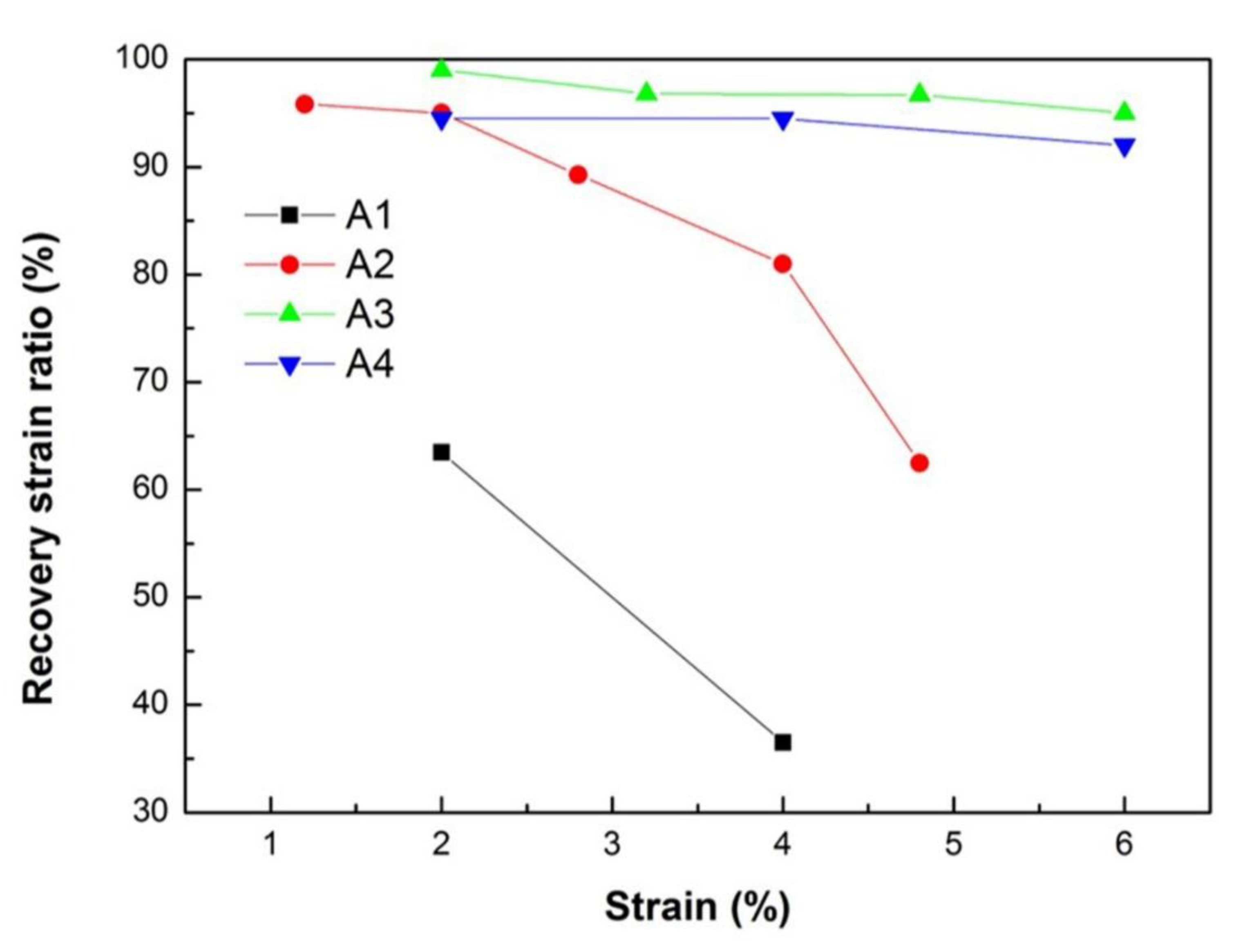

3.2. Effect of Sn Content on the Superelasticity of Cu–Sn Microwires

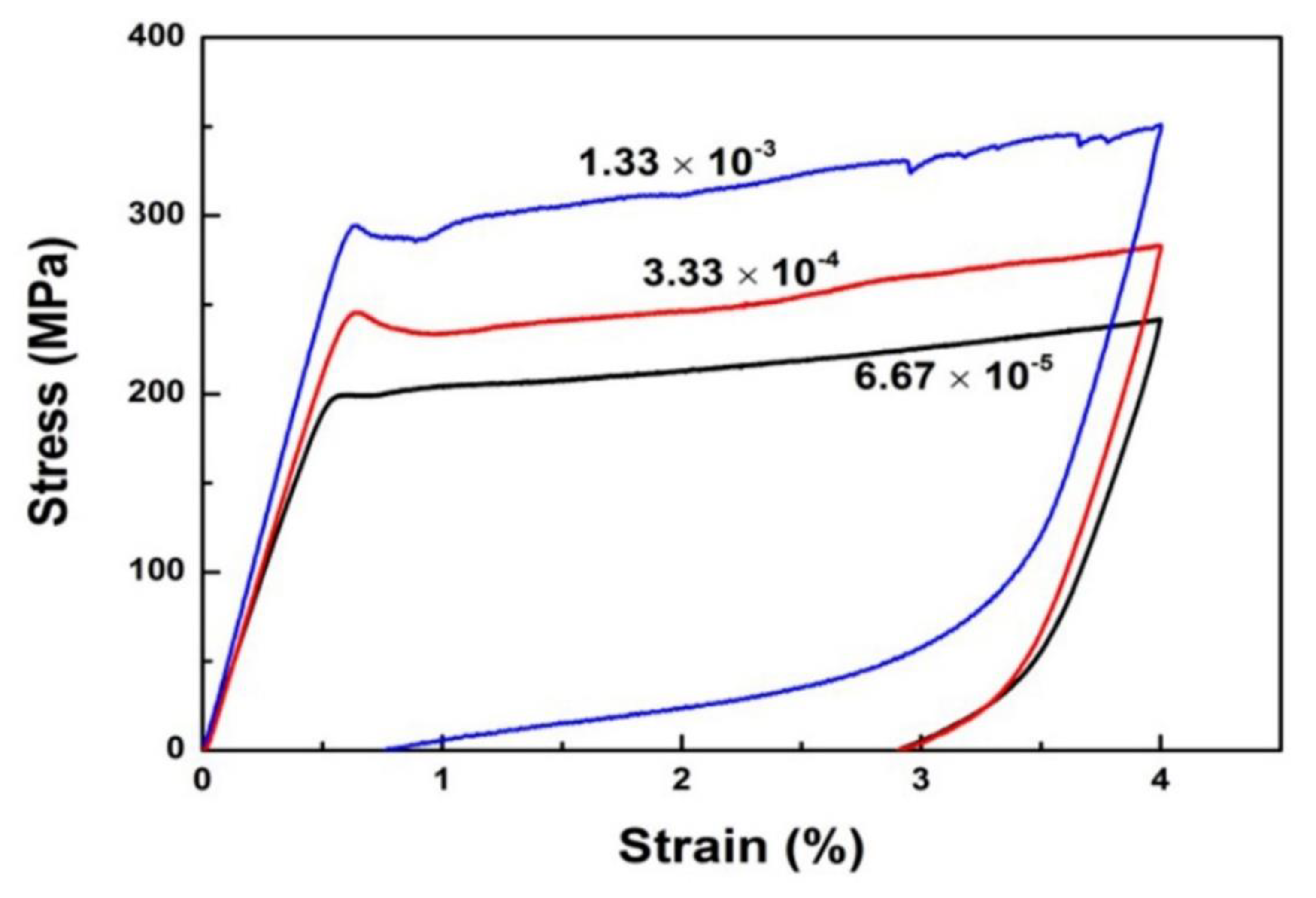

3.3. Effect of Strain Rate on the Superelasticity of Cu–Sn Microwires

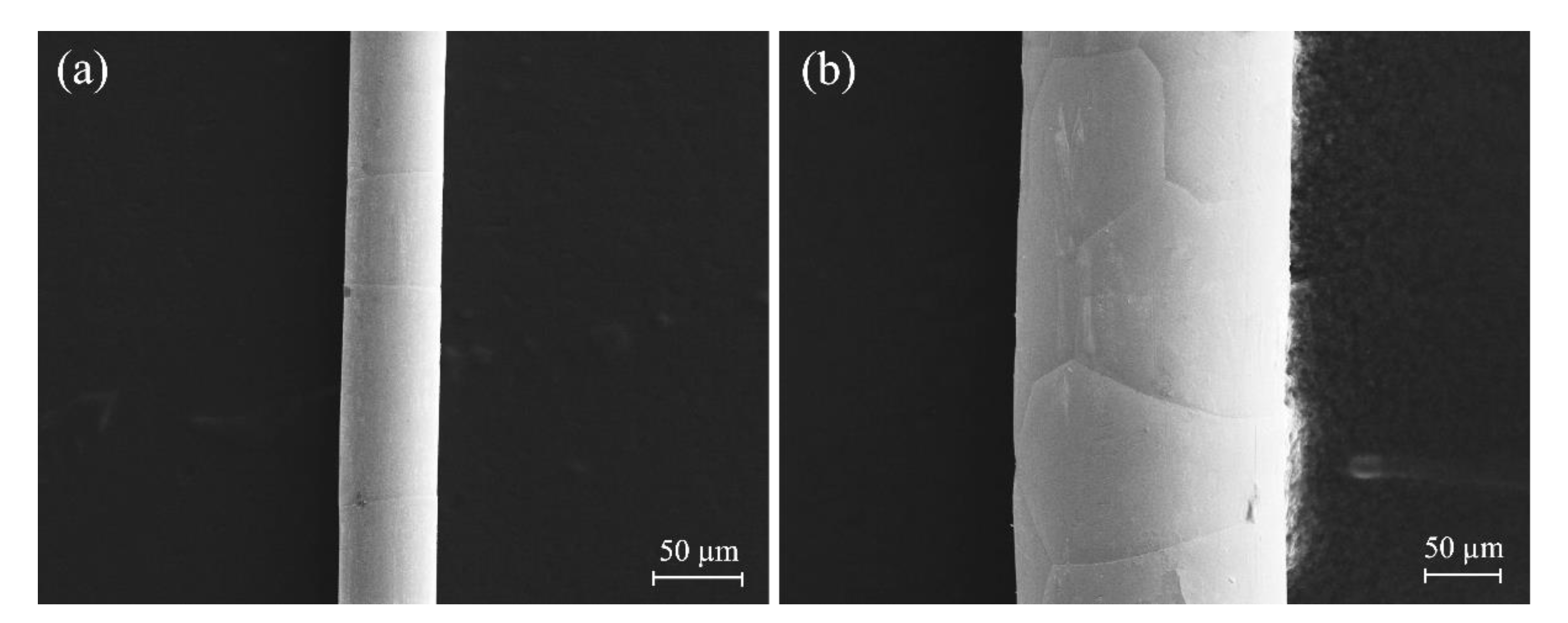

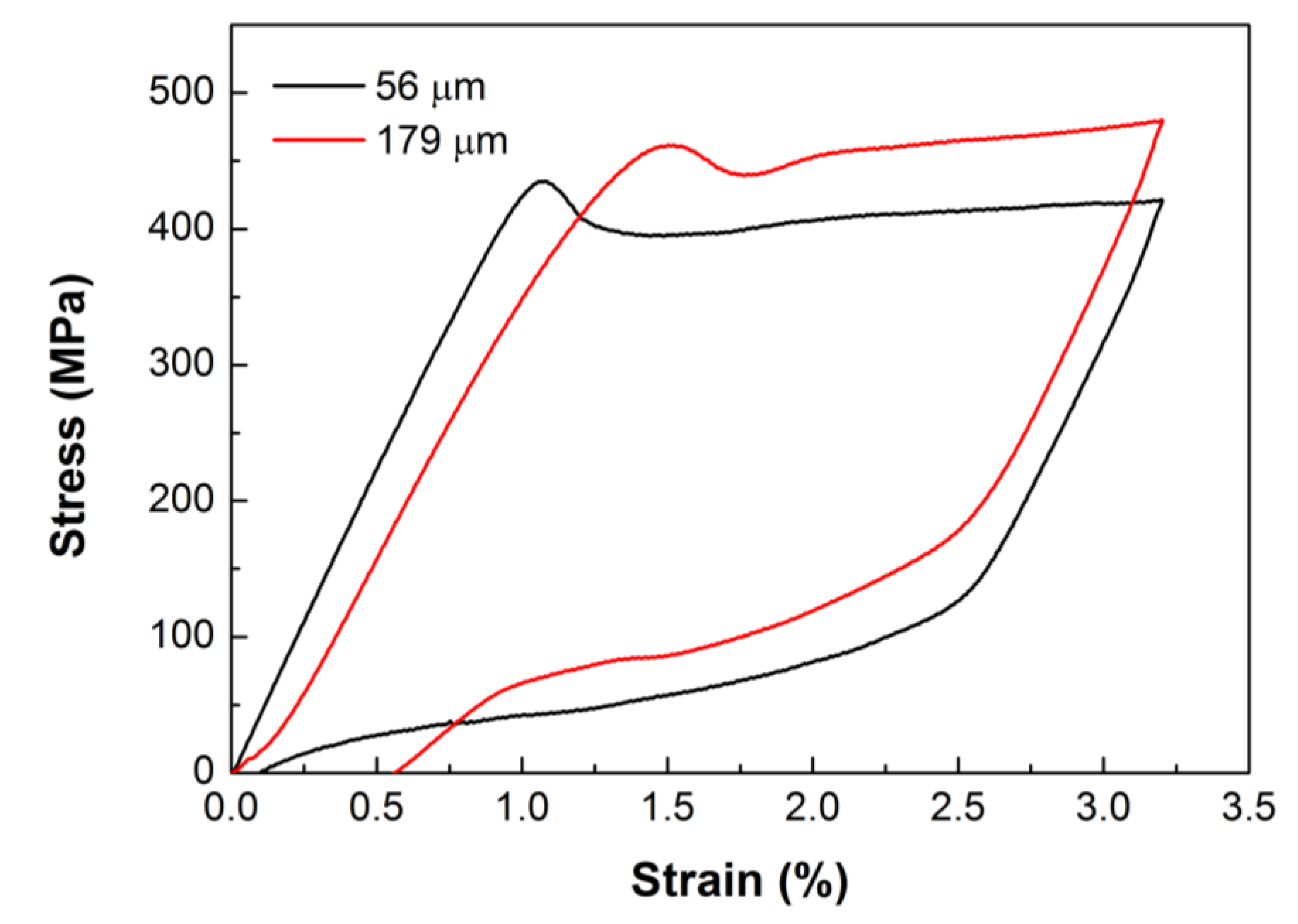

3.4. Superelastic Effect of Bamboo-like Grain Structured Cu–Sn Microwires

4. Discussion

5. Conclusions

- (1)

- Cu–Sn microwires with a diameter of 10–200 µm were fabricated successfully by the glass-coated melt spinning method. For the high cooling rate, the grain size of as-cast Cu–Sn microwires could be refined to the scale of micrometers. The phase in the as-cast microwires gradually transforms from martensite to austenite with Sn content increasing from 14.0 at.% to 16.5 at.%. When the Sn content exceeds 16.5 at.%, a highly ordered intermetallic phase, δ, is formed.

- (2)

- Microwires with Sn content of 16 at.% (A3) and 16.5 at.% (A4) show excellent superelasticity. The fracture stress, σf, and the critical stress for stress-induced martensitic transformation, σMs, increases with Sn content increases. Strain rate has a significant influence on the superelasticity of microwires. The higher the strain rate, the better the superelasticity of the microwires.

- (3)

- A bamboo-grained structure was formed in the Cu–Sn microwire with a Sn content of 16 at.% (A3) by annealing at 750 °C for 5 h before quenching in water. Due to the unconfined free surfaces and absence of triple junctions, the bamboo-like grain structure also shows excellent superelasticity. The results show that two opposite strategies of refining the grain size to the micrometer level or increasing the grain size to the one dimensional size of the specimen are both effective in improving the superelasticity of the Cu–Sn alloy.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ölander, A. An electrochemical inverstigation of solid cadmium-gold alloys. J. Am. Chem. Soc. 1932, 56, 3819–3833. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- Chluba, C.; Ge, W.W.; Miranda, R.L.; Strobel, J.; Kienle, L.; Quandt, E.; Wuttig, M. Ultralow-fatigue shape memory alloy films. Science 2015, 348, 1004–1107. [Google Scholar] [CrossRef] [PubMed]

- Kainuma, R.; Imana, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef] [PubMed]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. A lightweight shape-memory magnesium alloy. Science 2016, 353, 368–370. [Google Scholar] [CrossRef] [PubMed]

- Hou, H.; Simsek, E.; Ma, T.; Johnson, N.S.; Qian, S.; Cissé, C.; Stasak, D.; Al Hasan, N.; Zhou, L.; Hwang, Y.; et al. Fatigue-resistant high-performance elastocaloric materials made by additive manufacturing. Science 2019, 366, 1116–1121. [Google Scholar] [CrossRef] [PubMed]

- Qian, S.; Catalini, D.; Muehlbauer, J.; Liu, B.; Mevada, H.; Hou, H.; Hwang, Y.; Radermacher, R.; Takeuchi, I. High-performance multimode elastocaloric cooling system. Science 2023, 380, 722–727. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Fang, S.; Xiao, Y.; Gao, E.; Jiang, N.; Li, Y.; Mou, L.; Shen, Y.; Zhao, W.; Li, S.; et al. Torsional refrigeration by twisted, coiled, and supercoiled fibers. Science 2019, 366, 216–221. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhou, W.; Shi, Y.; Yang, X.; Bai, Y.; Li, L.; Wang, S.; Li, T.; Feng, S.; Zhang, T. Superelastic alloy based electrical interconnects for highly stretchable electronics. Npj Flex. Electron. 2022, 6, 8. [Google Scholar] [CrossRef]

- Curtis, S.M.; Gugat, J.L.; Bumke, L.; Duygu, D.; Seigner, L.; Schmadel, D.; Lazarus, N.S.; Quandt, E. Thin-film superelastic alloys for stretchable electronics. Shape Mem. Superelast. 2023, 9, 35–49. [Google Scholar] [CrossRef]

- Lovey, F.C.; Torra, V. Shape memory in Cu-based alloys: Phenomenological behavior at the mesoscale level and interaction of martensitic transformation with structural defects in Cu-Zn-Al. Prog. Mater. Sci. 1999, 44, 189–289. [Google Scholar] [CrossRef]

- Shimizu, K.; Otsuka, K.; Wayman, C.M.; Nakai, K.; Sakamoto, H. Superelasticity effects and stress-induced martensitic transformation in Cu-Al-Ni alloys. Acta Metall. 1976, 24, 207–226. [Google Scholar]

- Qiao, L.; Rimoli, J.J.; Chen, Y.; Schuh, C.A.; Radovitzky, R. Nonlocal superelastic model of size-dependent hardening and dissipation in single crystal Cu-Al-Ni shape memory alloys. Phys. Rev. Lett. 2011, 106, 085504. [Google Scholar] [CrossRef] [PubMed]

- Horikawa, H.; Ichinose, S.; Morii, K.; Miyazaki, S.; Otsuka, K. Orientation dependence of β1→β1′ stress-induced martensitic transformation in a Cu-Al-Ni alloy. Metall. Trans. A 1988, 19A, 915–923. [Google Scholar] [CrossRef]

- Miyazaki, S.; Kawai, T.; Otsuka, K. On the origin of intergranular fracture in β phase shape memory alloys. Scr. Metall. 1982, 16, 431–436. [Google Scholar] [CrossRef]

- Omori, T.; Kusama, T.; Kawata, S.; Ohnuma, I.; Sutou, Y.; Araki, Y.; Ishida, K.; Kainuma, R. Abnormal grain growth induced by cyclic heat treatment. Science 2013, 341, 1500–1502. [Google Scholar] [CrossRef] [PubMed]

- Kusama, T.; Omori, T.; Saito, T.; Kise, S.; Tanaka, T.; Araki, Y.; Kainuma, R. Ultra-large single crystals by abnormal grain growth. Nat. Commun. 2017, 8, 1–9. [Google Scholar] [CrossRef]

- Ueland, S.M.; Schuh, C.A. Superelasticity and fatigue in oligocrystalline shape memory alloy microwires. Acta Mater. 2012, 60, 282–292. [Google Scholar] [CrossRef]

- Ueland, S.M.; Chen, Y.; Schuh, C.A. Oligocrystalline Shape memory alloys. Adv. Funct. Mater. 2012, 22, 2094–2099. [Google Scholar] [CrossRef]

- Tuncer, N.; Schuh, C.A. Melt-cast microfibers of Cu-based shape memory alloy adopt a favorable texture for superelasticity. Scr. Mater. 2016, 117, 46–50. [Google Scholar] [CrossRef]

- Font, J.; Cesari, E.; Muntasell, J.; Pons, J. Thermomechanical cycling in Cu-Al-Ni-based melt-spun shape-memory ribbons. Mater. Sci. Eng. A 2003, 354, 207–211. [Google Scholar] [CrossRef]

- Ochin, P.; Dezellus, A.; Plaindoux, P.; Pons, J.; Vermaut, P.; Portier, R.; Cesari, E. Shape memory thin round wires produced by the in rotating water melt-spinning technique. Acta Mater. 2006, 54, 1877–1885. [Google Scholar] [CrossRef]

- Ceylan, M.; Zengin, R. Shape memory properties and oxidation behaviour of a rapidly liquid quenched Cu–Sn alloy. J. Mater. Process Tech. 2000, 97, 148–152. [Google Scholar] [CrossRef]

- Kamal, M. Mechanical properties of rapidly solidified of Cu-Sn shape memory alloys. Radiat. Eff. Defects Solids 2006, 161, 189–191. [Google Scholar] [CrossRef]

- Li, D.S.; Rong, Q.G.; Zhu, Y. The shape memory effect (SME) of liquid rapidly quenched (LRQ) Cu-Sn alloys. In Rapidly Quenched Metals; Elsevier Science Publishers B.V.: North-Holland, the Netherlands, 1985; pp. 1425–1428. [Google Scholar]

- Zhao, Y.Y.; Li, H.; Wang, Y.S.; Zhang, Y.; Liaw, P.K. Shape memory and superelasticity in amorphous/nanocrystalline Cu-15.0 atomic percent (at.%) Sn wires. Adv. Eng. Mater. 2014, 16, 40–44. [Google Scholar] [CrossRef]

- Zhao, Y.Y.; Li, H.; Hao, H.Y.; Li, M.; Zhang, Y.; Liaw, P.K. Microwires fabricated by glass-coated melt spinning. Rev. Sci. Instrum. 2013, 84, 075102. [Google Scholar] [CrossRef] [PubMed]

- Larin, V.S.; Torcunov, A.V.; Zhukov, A.; González, J.; Vazquez, M.; Panina, L. Preparation and properties of glass-coated microwires. J. Magn. Magn. Mater. 2002, 249, 39–45. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, J.F.; Zhai, Q. Rapid dendritiv growth in melt-spun Cu-Sn alloys. Chin. J. Nonferrous Met. 2007, 17, 1521–1526. [Google Scholar]

- Bondt, M.D.; Deruyttere, A. Pearlite and bainite formation in a Cu-16.5 at.% Sn alloy. Acta Metall. 1967, 15, 993–1005. [Google Scholar] [CrossRef]

- Saunders, N.; Miodownlk, A.P. The Cu-Sn (Copper-Tin) System. Bull. Alloy Phase Diagr. 1990, 11, 279–285. [Google Scholar] [CrossRef]

- Kennon, N.F.; Miller, T.M. Martensitic transformations in β1 Cu-Sn alloy. Trans. JIM 1972, 13, 322–326. [Google Scholar] [CrossRef]

- Fürtauer, S.; Li, D.; Cupid, D.; Flandorfer, H. The Cu-Sn phase diagram, Part I: New experimental results. Intermetallics 2013, 34, 142–147. [Google Scholar] [CrossRef] [PubMed]

- Shimizu, K.I.; Sakamoto, H.; Otsuka, K. On the crystal structure of the banded martensite in Cu-24.5 wt% Sn alloy. Trans. JIM 1975, 16, 581–590. [Google Scholar] [CrossRef]

- Kuwano, N.; Wayman, C.M. Precipitation Processes in a β-Phase Cu-15 at.% Sn Shape Memory Alloy. Trans. JIM 1983, 24, 499–503. [Google Scholar] [CrossRef]

- Jani, J.M.; Leary, M.A. Subic and M.A. Gibson. A review of shape memory alloy research, applications and opportunities. Mater. Design 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Juan, J.M.S.; Nό, M.L.; Schuh, C.A. Superelasticity and shape memory in micro- and nanometer-scale pillars. Adv. Mater. 2008, 20, 272–278. [Google Scholar] [CrossRef]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic effect in polycrystalline ferrous alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef]

- Kato, H.; Miura, S. Thermodynamical analysis of the stress-induced martensitic transformation in Cu-15.0 at.% Sn alloy single crystals. Acta Metall. Mater. 1995, 43, 351–360. [Google Scholar] [CrossRef]

- Zeller, S.; Gnauk, J. Shape memory behavior of Cu-Al wires produced by horizontal in-rotating-liquid-spinning. Mater. Sci. Eng. A 2008, 481–482, 562–566. [Google Scholar] [CrossRef]

- Miura, S.; Morita, Y.; Nakanishi, N. Superplasticity and Shape Memory Effect in Cu-Sn Alloys. In Shape Memory Effect in Alloys; Perkins, J., Ed.; Plenum Press: New York, NY, USA, 1976; pp. 389–405. [Google Scholar]

- Kato, H.; Hirata, N.; Miura, S. Effects of aging on pseudoelastic behaviour in Cu-15.0 at.% Sn alloy single crystals. Acta Metall. 1995, 43, 361–369. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Yamauchi, K.; Ono, N.; Kainuma, R.; Ishida, K. Effect of grain size and texture on pseudoelasticity in Cu-Al-Mn-based shape memory wire. Acta Mater. 2005, 53, 4121–4133. [Google Scholar] [CrossRef]

- Sutou, Y.; Omori, T.; Kainuma, R.; Ishida, K. Grain size dependence of pseudoelasticity in polycrystalline Cu-Al-Mn-based shape memory sheets. Acta Mater. 2013, 61, 3842–3850. [Google Scholar] [CrossRef]

| Composition | A1 | A2 | A3 | A4 | A5 | A6 |

|---|---|---|---|---|---|---|

| Cu (at.%) | 86 | 85.5 | 84 | 83.5 | 82.5 | 81.5 |

| Sn (at.%) | 14 | 14.5 | 16 | 16.5 | 17.5 | 18.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Bai, Y.; Li, T.; Zhang, Y. Microstructure and Superelasticity of Cu–Sn Shape-Memory Microwires by Glass-Coated Melt Spinning. Metals 2023, 13, 1852. https://doi.org/10.3390/met13111852

Zhao Y, Bai Y, Li T, Zhang Y. Microstructure and Superelasticity of Cu–Sn Shape-Memory Microwires by Glass-Coated Melt Spinning. Metals. 2023; 13(11):1852. https://doi.org/10.3390/met13111852

Chicago/Turabian StyleZhao, Yangyong, Yuanyuan Bai, Tie Li, and Yong Zhang. 2023. "Microstructure and Superelasticity of Cu–Sn Shape-Memory Microwires by Glass-Coated Melt Spinning" Metals 13, no. 11: 1852. https://doi.org/10.3390/met13111852

APA StyleZhao, Y., Bai, Y., Li, T., & Zhang, Y. (2023). Microstructure and Superelasticity of Cu–Sn Shape-Memory Microwires by Glass-Coated Melt Spinning. Metals, 13(11), 1852. https://doi.org/10.3390/met13111852