Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries

Abstract

:1. Introduction

2. Material and Methods

2.1. Material

2.2. Methods: Cell Characterisation

2.3. Methods Processing and Evaluation

2.4. Calculations

3. Results and Discussion

3.1. Cell Characterisation

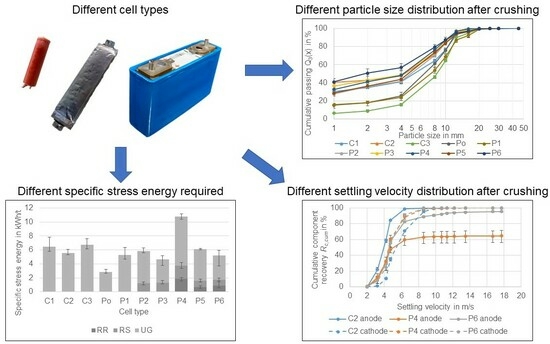

3.2. Specific Stress Energy

3.3. Particle Size Distribution of the Crushing Product after Drying

3.4. Air Classification Products

3.5. Mass Recovery of Products

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Neef, C.; Schmaltz, T.; Thielmann, A. Recycling von Lithium-Ionen Batterien: Chancen und Herausforderungen für den Maschinen- und Anlagenbau; Fraunhofer-Institut für System- und Innovationsforschung ISI: Karlsruhe, Germany, 2021. [Google Scholar]

- Council of the European Union. Proposal for a Regulation of the European Parliament and of the Council Concerning Batteries and Waste Batteries, Repealing Directive 2006/66/EC and Amending Regulation (EU) No 2019/1020—Letter to the Chair of the European Parliament Committee on the Environment, Public Health and Food Safety (ENVI). 2023. Available online: https://data.consilium.europa.eu/doc/document/ST-5469-2023-INIT/en/pdf (accessed on 10 November 2023).

- Woehrle, T. Lithium-ion cell. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 101–112. [Google Scholar]

- Weber, C.J.; Roth, M. Separators. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 75–88. [Google Scholar]

- Shi, C.; Dai, J.; Shen, X.; Peng, L.; Li, C.; Wang, X.; Zhang, P. A high-temperature stable ceramic-coated separator prepared with polyimide binder/Al2O3 particles for lithium-ion batteries. J. Membr. Sci. 2016, 517, 91–99. [Google Scholar] [CrossRef]

- Link, S.; Neef, C.; Wicke, T. Trends in Automotive Battery Cell Design: A Statistical Analysis of Empirical Data. Batteries 2023, 9, 261. [Google Scholar] [CrossRef]

- Wurm, C.; Öttinger, O.; Wittkämper, S.; Zauter, R.; Vuorilehto, K. Anode materials for lithium-ion batteries. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 43–58. [Google Scholar]

- Vuorilehto, K. Materials and function. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 21–28. [Google Scholar]

- Thackeray, M.M. Manganese oxides for lithium batteries. Prog. Solid State Chem. 1997, 25, 1–71. [Google Scholar] [CrossRef]

- Nam, G.W.; Park, N.-Y.; Park, K.-J.; Yang, J.; Liu, J.; Yoon, C.S.; Sun, Y.-K. Capacity Fading of Ni-Rich NCA Cathodes: Effect of Microcracking Extent. ACS Energy Lett. 2019, 4, 2995–3001. [Google Scholar] [CrossRef]

- Graf, C. Cathode materials for lithium-ion batteries. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 29–41. [Google Scholar]

- Hartnig, C.; Schmidt, M. Electrolytes and conducting salts. In Lithium-Ion Batteries: Basics and Applications; Korthauer, R., Ed.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 59–74. [Google Scholar]

- Meutzner, F.; de Vivanco, M.U. Electrolytes—Technology review. In Proceedings of the AIP Conference Proceedings, Boise, ID, USA, 20–25 July 2014; p. 185. [Google Scholar]

- Wuschke, L. Mechanische Aufbereitung von Lithium-Ionen-Batteriezellen; TU Bergakademie Freiberg: Freiberg, Germany, 2018. [Google Scholar]

- Diekmann, J.; Sander, S.; Sellin, G.; Petermann, M.; Kwade, A. Crushing of Battery Modules and Cells. In Recycling of Lithium-Ion Batteries: The LithoRec Way; Kwade, A., Diekmann, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 127–138. [Google Scholar]

- Windisch-Kern, S.; Gerold, E.; Nigl, T.; Jandric, A.; Altendorfer, M.; Rutrecht, B.; Scherhaufer, S.; Raupenstrauch, H.; Pomberger, R.; Antrekowitsch, H.; et al. Recycling chains for lithium-ion batteries: A critical examination of current challenges, opportunities and process dependencies. Waste Manag. 2022, 138, 125–139. [Google Scholar] [CrossRef] [PubMed]

- Hauck, D.; Kurrat, M. Overdischarging Lithium-Ion Batteries. In Recycling of Lithium-Ion Batteries: The LithoRec Way; Kwade, A., Diekmann, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 53–81. [Google Scholar]

- Stehmann, F.; Bradtmöller, C.; Scholl, S. Separation of the Electrolyte—Thermal Drying. In Recycling of Lithium-Ion Batteries: The LithoRec Way; Kwade, A., Diekmann, J., Eds.; Springer: Berlin/Heidelberg, Germany, 2018; pp. 139–154. [Google Scholar]

- Vanderbruggen, A.; Sygusch, J.; Rudolph, M.; Serna-Guerrero, R. A contribution to understanding the flotation behavior of lithium metal oxides and spheroidized graphite for lithium-ion battery recycling. Colloids Surf. A Physicochem. Eng. Asp. 2021, 626, 127111. [Google Scholar] [CrossRef]

- Salces, A.M.; Bremerstein, I.; Rudolph, M.; Vanderbruggen, A. Joint recovery of graphite and lithium metal oxides from spent lithium-ion batteries using froth flotation and investigation on process water re-use. Miner. Eng. 2022, 184, 107670. [Google Scholar] [CrossRef]

- Wang, X.-T.; Gu, Z.-Y.; Ang, E.H.; Zhao, X.-X.; Wu, X.-L.; Liu, Y. Prospects for managing end-of-life lithium-ion batteries: Present and future. Interdiciplinary Mater. 2022, 1, 417–433. [Google Scholar] [CrossRef]

- Doose, S.M.; Julian, K.; Michalowski, P.; Kwade, A. Challenges in Ecofriendly Battery Recycling and Closed Material Cycles: A Perspective on Future Lithium Battery Generations. Metals 2021, 11, 291. [Google Scholar] [CrossRef]

- Velázquez-Martínez, O.; Valio, J.; Santasalo-Aarnio, A.; Reuter, M.; Serna-Guerrero, R. A Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 2019, 5, 68. [Google Scholar] [CrossRef]

- Kaya, M. State-of-the-art lithium-ion battery recycling technologies. Circ. Econ. 2022, 1, 100015. [Google Scholar] [CrossRef]

- Kaas, A.; Mütze, T.; Peuker, U.A. Review on Zigzag Air Classifier. Processes 2022, 10, 764. [Google Scholar] [CrossRef]

- Lyon, T.; Mütze, T.; Peuker, U.A. Decoating of Electrode Foils from EOL Lithium-Ion Batteries by Electrohydraulic Fragmentation. Metals 2022, 12, 209. [Google Scholar] [CrossRef]

- Pinegar, H.; Smith, Y.R. End-of-Life Lithium-Ion Battery Component Mechanical Liberation and Separation. JOM 2019, 71, 4447–4456. [Google Scholar] [CrossRef]

- Wilke, C.; Kaas, A.; Peuker, U.A. Supplementary Information to the Publication “Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries”; Technische Universität Dresden: Dresden, Germany, 2023. [Google Scholar] [CrossRef]

- Woldt, D. Zerkleinerung nicht-sproeder Stoffe in Rotorscheren und -reissern. Freib. Forschungshefte 2005, 887, 173. [Google Scholar]

- Kaas, A.; Wilke, C.; Vanderbruggen, A.; Peuker, U.A. Influence of different discharge levels on the mechanical recycling efficiency of lithium-ion batteries. Waste Manag. 2023, 172, 1–10. [Google Scholar] [CrossRef]

- Diekmann, J.; Hanisch, C.; Froböse, L.; Schälicke, G.; Loellhoeffel, T.; Fölster, A.-S.; Kwade, A. Ecological Recycling of Lithium-Ion Batteries from Electric Vehicles with Focus on Mechanical Processes. J. Electrochem. Soc. 2016, 164, A6184–A6191. [Google Scholar] [CrossRef]

| Indication | C1 | C2 | C3 | Po | P1 | P2 | P3 | P4 | P5 | P6 |

|---|---|---|---|---|---|---|---|---|---|---|

| Cell type | Cylindric | Cylindric | Cylindric | Pouch | Prismatic | Prismatic | Prismatic | Prismatic | Prismatic | Prismatic |

| Chemistry | LCO | NCA | LFP | LCO | NMC 111 | NMC 111 | NMC 433 | LMO + NMC | LMO + NMC | NMC 111 |

| Voltage in V | n.a. | 3.6 | 3.3 | 3.7 | n.a. | n.a. | n.a. | n.a. | 3.93 | 3.68 |

| Capacity in Ah | n.a. | 5 | 4 | 5 | n.a. | 20 | 37 | 50 | 60 | 94 |

| Casing material | Steel | Steel | Aluminium | Aluminium | Aluminium | Aluminium | Aluminium | Steel | Aluminium | Aluminium |

| Casing thickness in mm | 0.4 | 0.4 | 0.6 | 0.1 | 0.5 | 0.9 | 0.8 | 0.8 | 0.9 | 0.9 |

| Number of windings | 1 | 1 | 1 | Stacked | 1 | 2 | 2 | 2 | 4 | 4 |

| Cell length in mm | - | - | - | 140 | 120 | 173 | 148 | 173 | 173 | 173 |

| Cell width in mm | - | - | - | 9.5 | 12.5 | 19 | 26.5 | 45 | 45 | 45 |

| Cell height in mm | 65 | 70 | 118 | 42 | 85 | 87 | 91 | 100 | 125 | 125 |

| Cell diameter in mm | 18 | 21 | 32 | - | - | - | - | - | - | - |

| Cell weight in g | 44 | 68 | 197 | 196 | 270 | 663 | 794 | 1706 | 1830 | 2035 |

| Cells per experiment | 9 | 6 | 2 | 2 | 2 | 1 | 1 | 1 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wilke, C.; Kaas, A.; Peuker, U.A. Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries. Metals 2023, 13, 1901. https://doi.org/10.3390/met13111901

Wilke C, Kaas A, Peuker UA. Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries. Metals. 2023; 13(11):1901. https://doi.org/10.3390/met13111901

Chicago/Turabian StyleWilke, Christian, Alexandra Kaas, and Urs Alexander Peuker. 2023. "Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries" Metals 13, no. 11: 1901. https://doi.org/10.3390/met13111901

APA StyleWilke, C., Kaas, A., & Peuker, U. A. (2023). Influence of the Cell Type on the Physical Processes of the Mechanical Recycling of Automotive Lithium-Ion Batteries. Metals, 13(11), 1901. https://doi.org/10.3390/met13111901