Influence of Specimen Diameter for Titanium Grade 1 on SHPB Tests and Its Verification Using FEM

Abstract

1. Introduction

2. Experimental Work

2.1. SHPB Apparatus and Theory

2.2. Wave Impedance in the SHPB Test

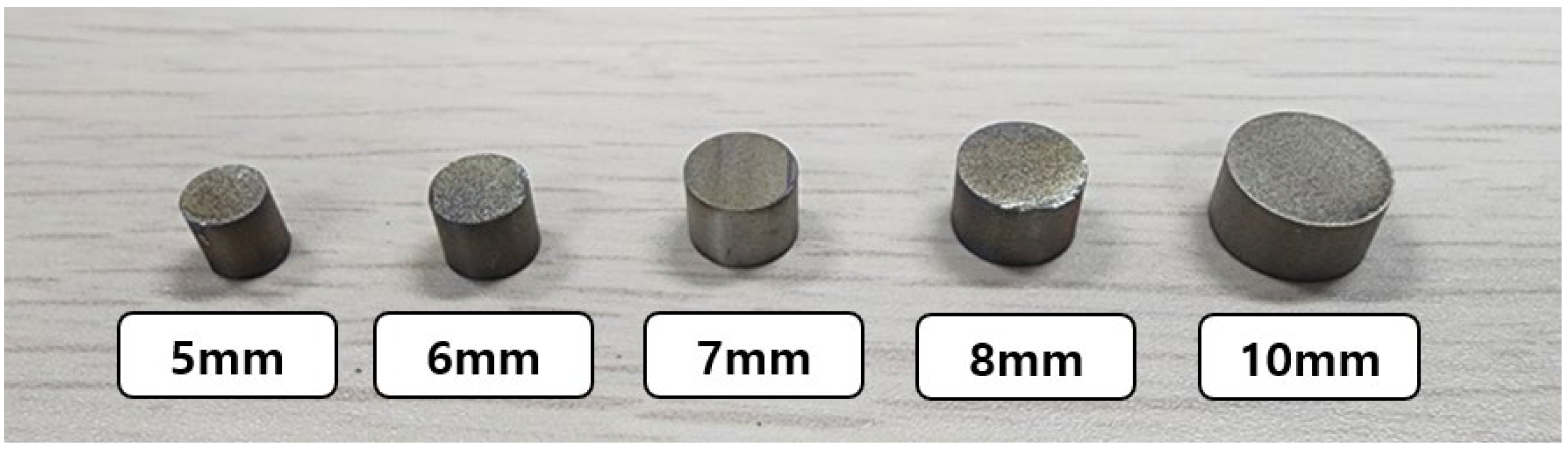

2.3. Specimen Dimensions

3. Experimental Results

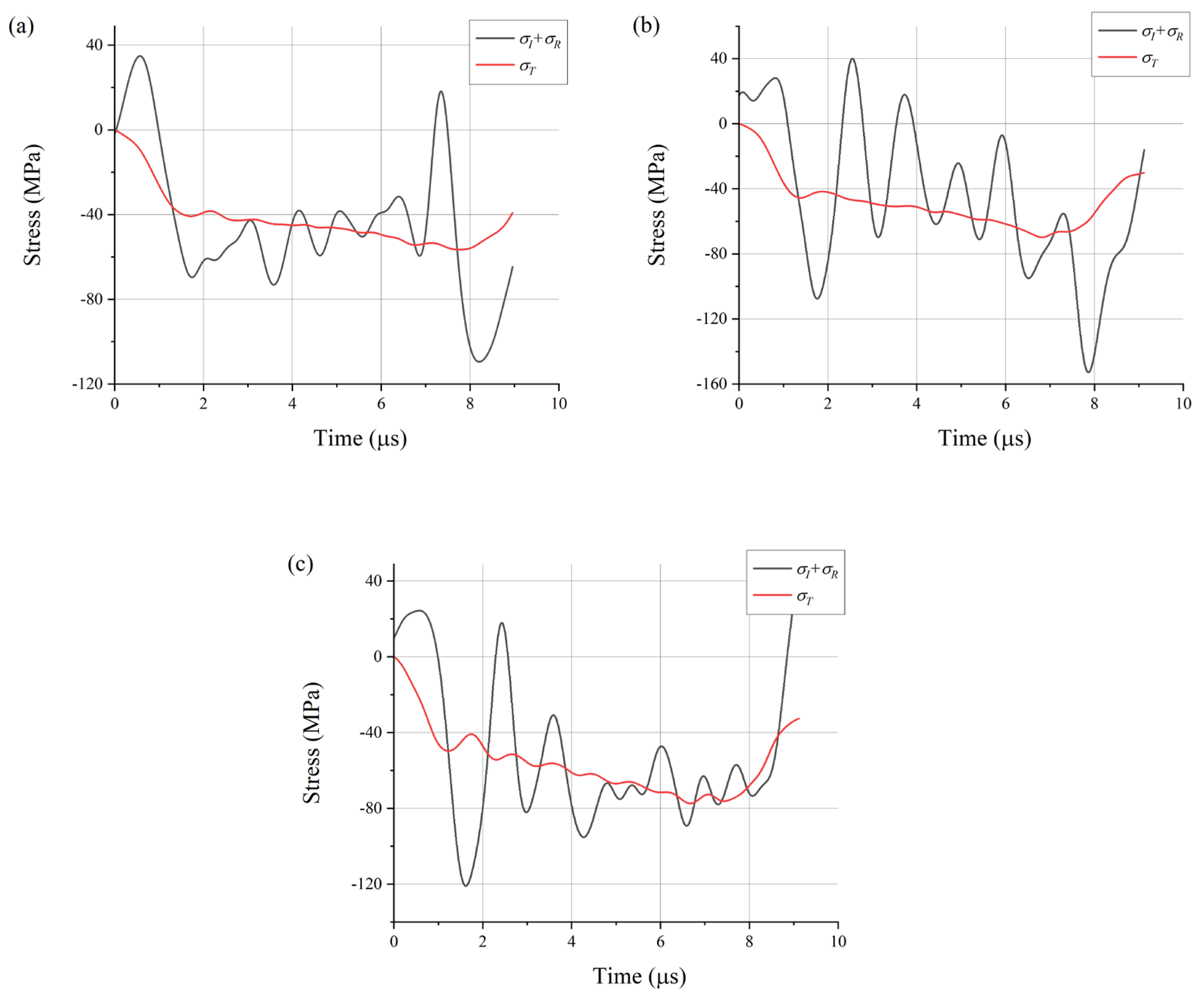

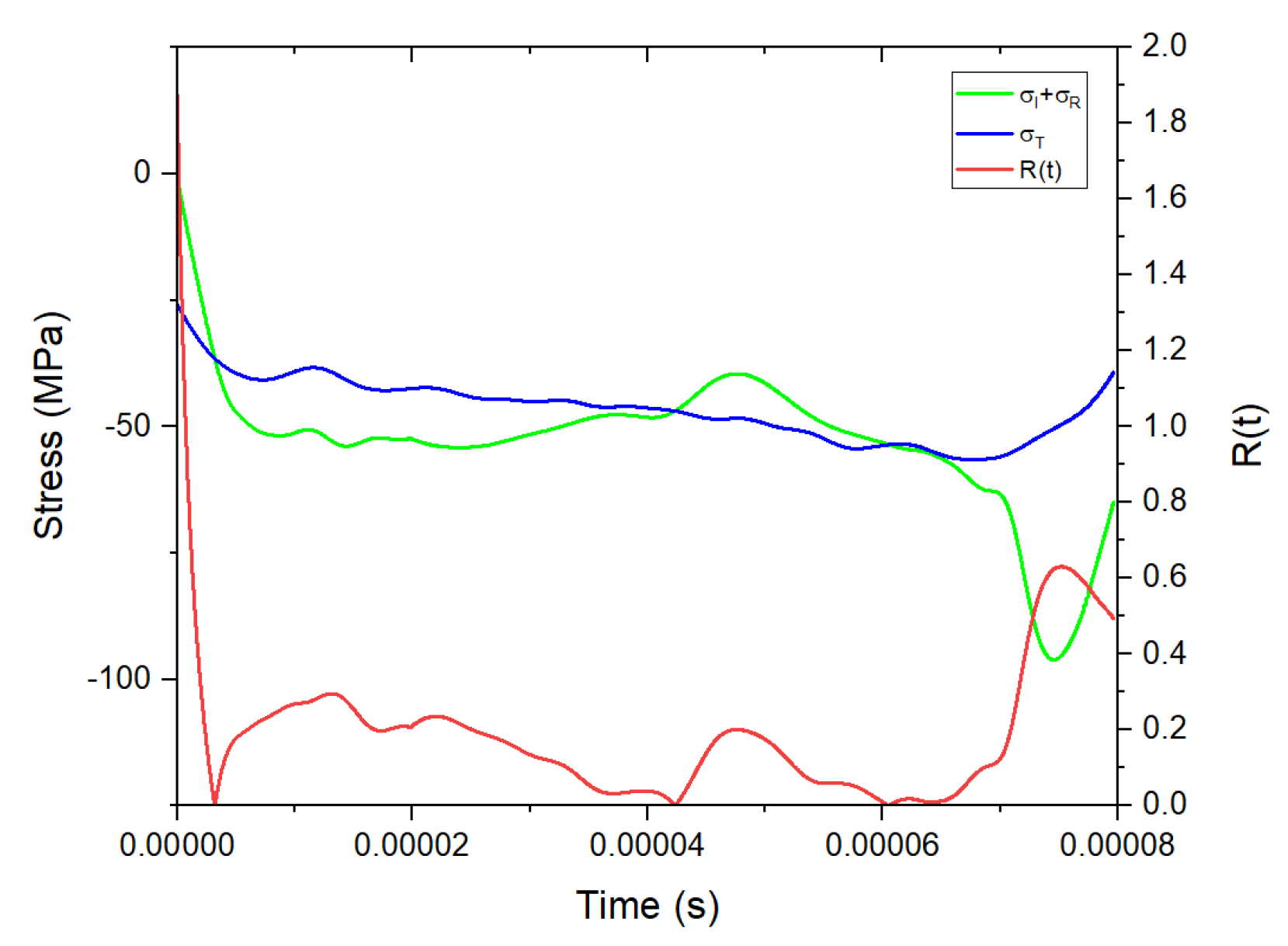

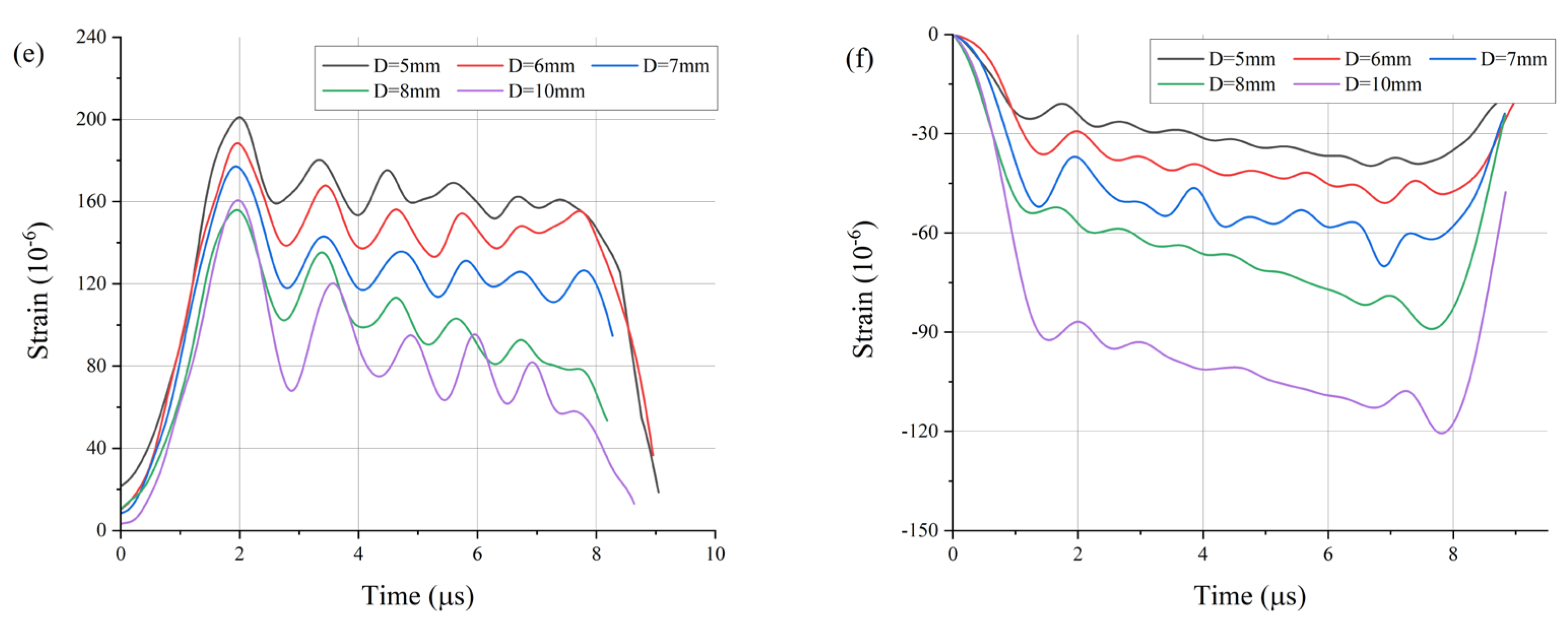

3.1. Equilibrium Check

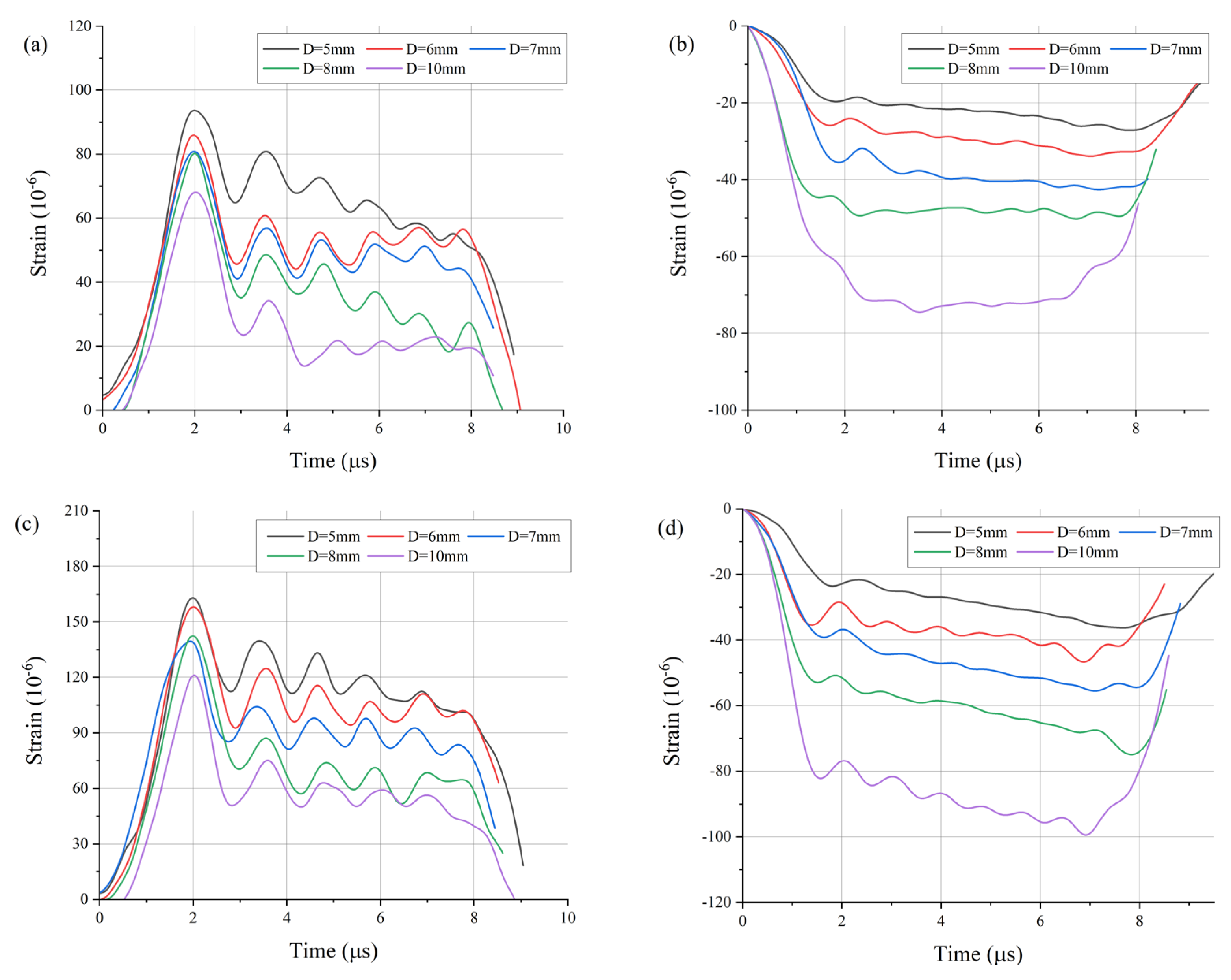

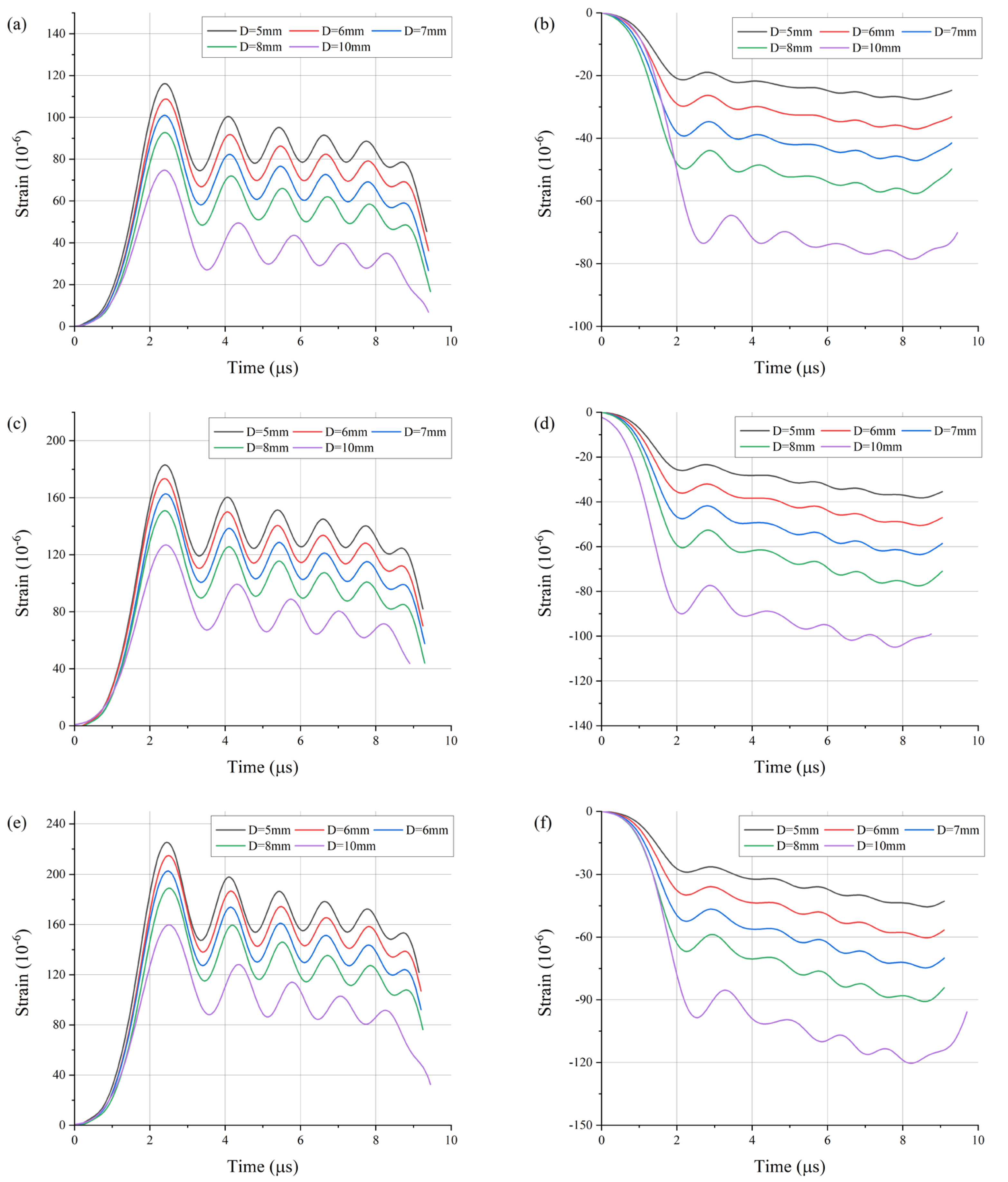

3.2. The Experimental Results of Reflected and Transmitted Pulses

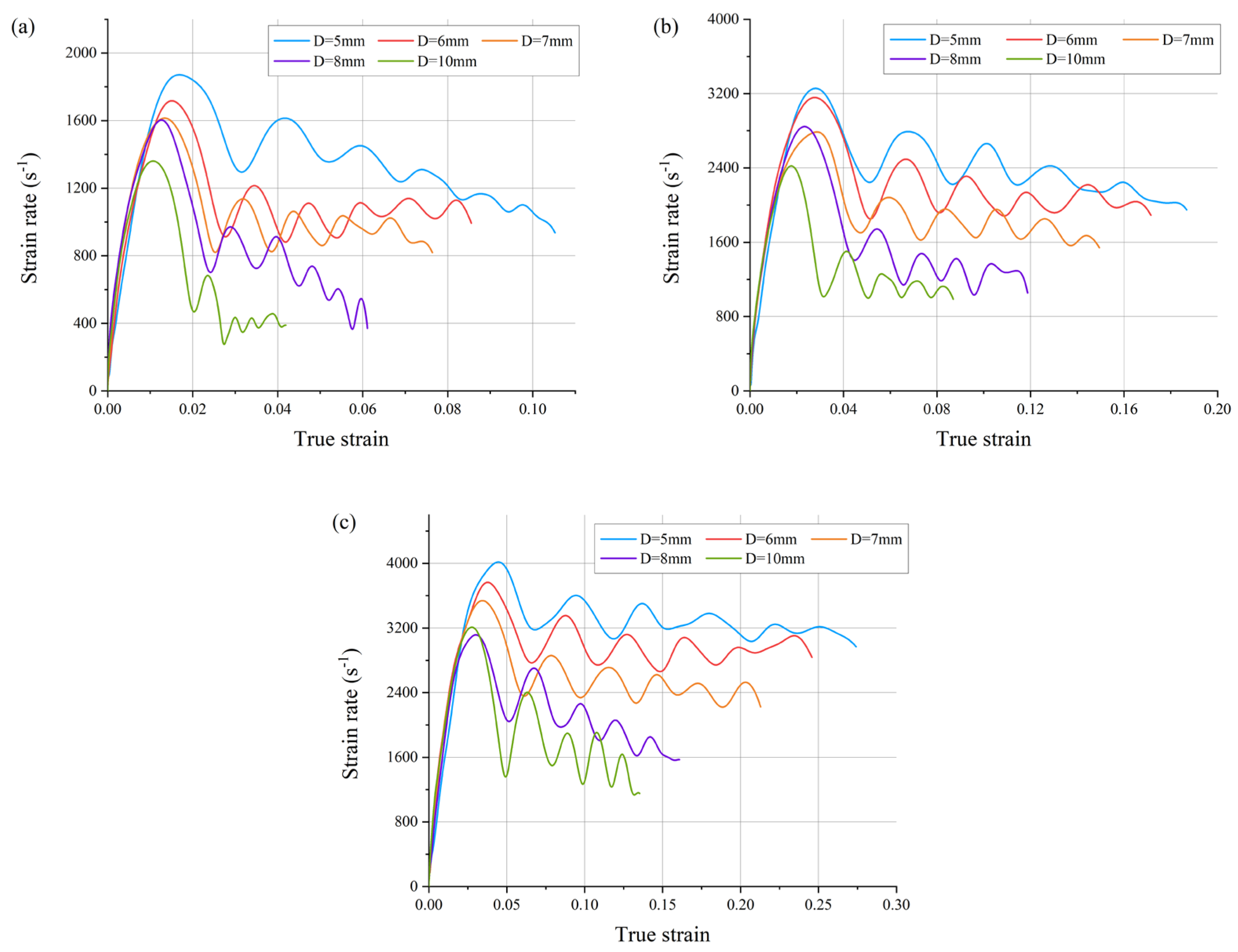

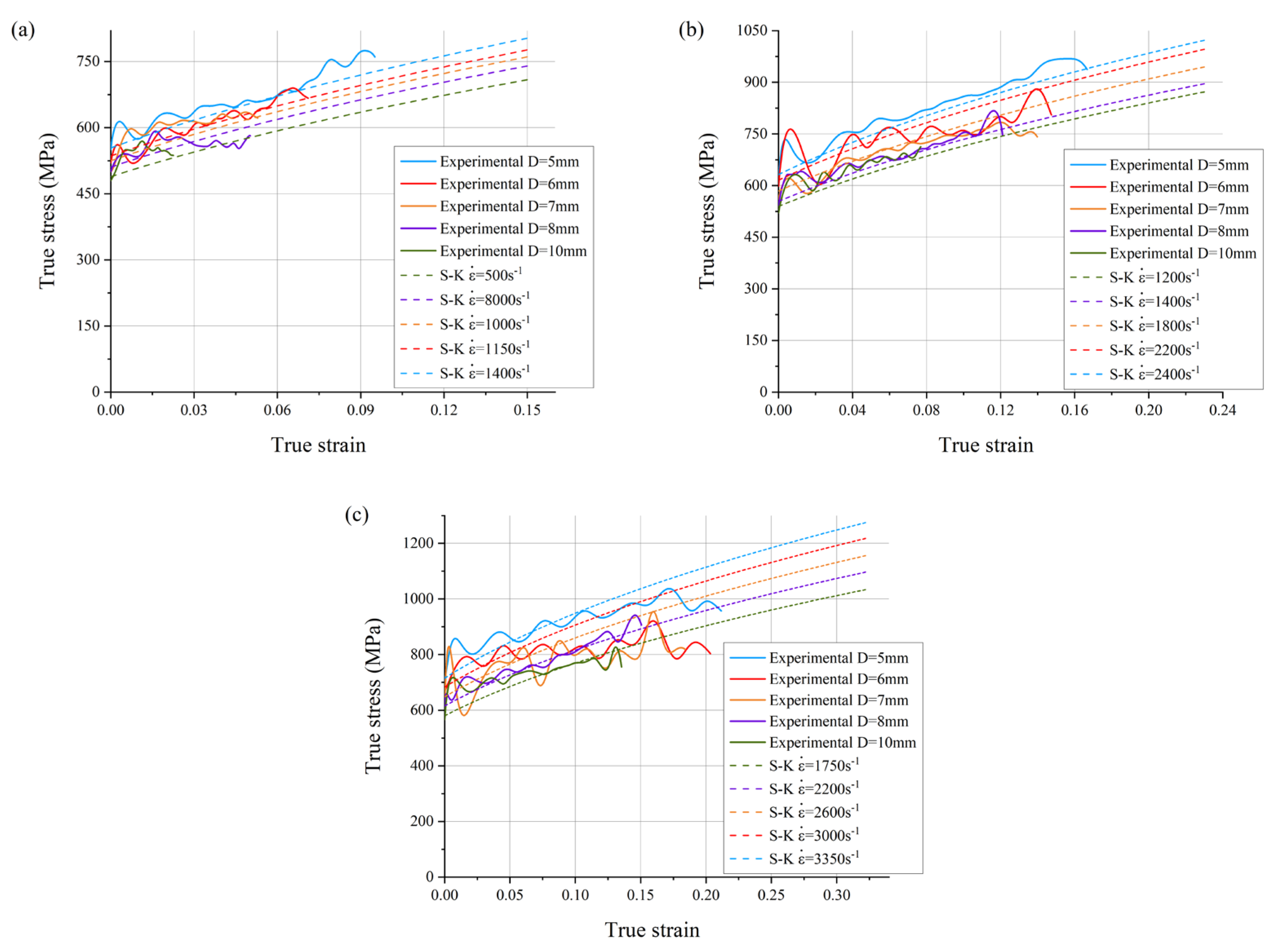

3.3. Acquisition of Dynamic Compression Material Properties in an Experiment

4. Numerical Analysis

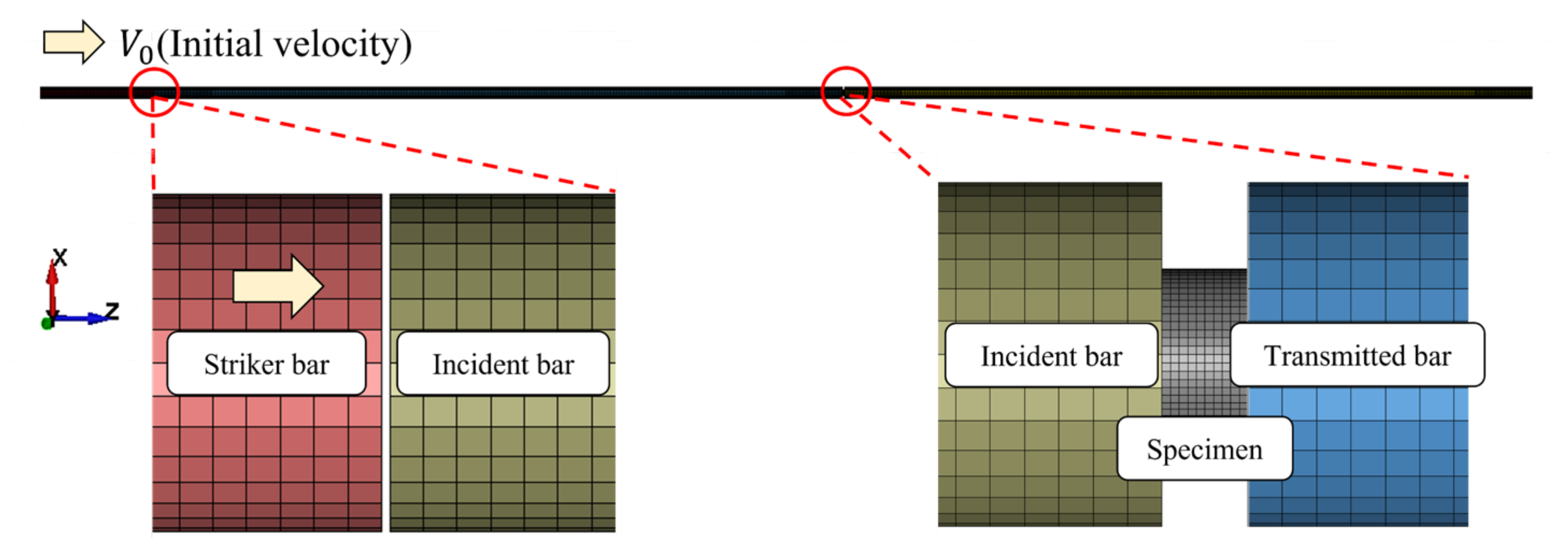

4.1. Finite Element Model

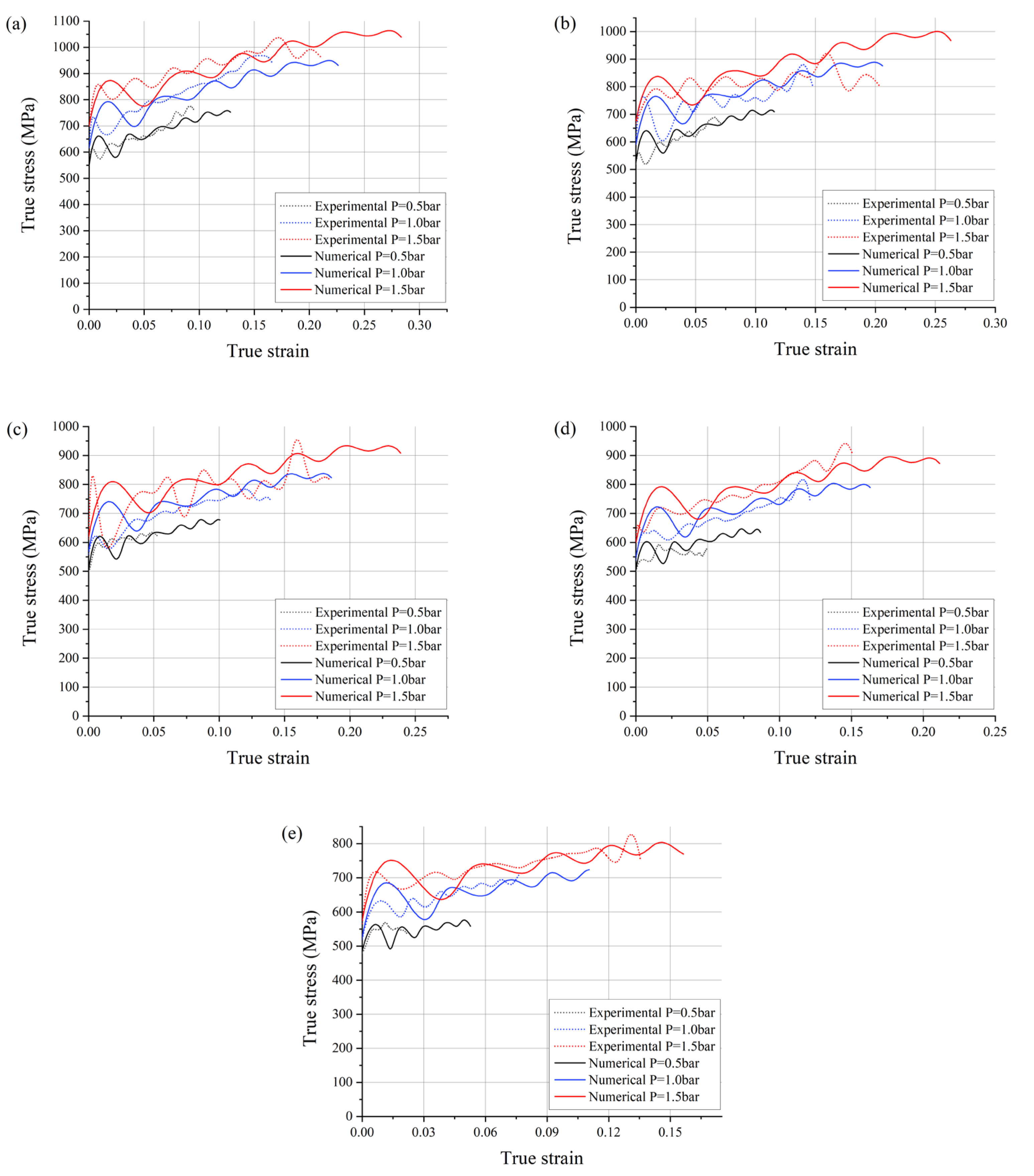

4.2. FEM Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Khan, A.S.; Suh, Y.S.; Kazmi, R. Quasi-static and dynamic loading responses and constitutive modeling of titanium alloys. Int. J. Plast. 2004, 20, 2233–2248. [Google Scholar] [CrossRef]

- Khan, A.S.; Baig, M.; Choi, S.H.; Yang, H.S.; Sun, X. Quasi-static and dynamic responses of advanced high strength steels Experiments and modeling. Int. J. Plast. 2012, 30–31, 1–17. [Google Scholar] [CrossRef]

- Huh, H.; Lim, J.H.; Park, S.H. High Speed tensile test of steel sheets for the stress-strain curve at the intermediate strain rate. Int. J. Automot. Technol. 2009, 10, 195–204. [Google Scholar] [CrossRef]

- Lu, F.; Lin, Y.; Wang, X.; Lu, L.; Chen, R. A theoretical analysis about the influence of interfacial friction in SHPB tests. Int. J. Impact Eng. 2015, 79, 95–101. [Google Scholar] [CrossRef]

- Lifshitz, J.M.; Leber, H. Data processing in the split hopkinson pressure bar tests. Int. J. Impact Eng. 1994, 15, 723–733. [Google Scholar] [CrossRef]

- Meng, H.; Li, Q.M. Correlation between the accuracy of a SHPB test and the stress uniformity based on numerical experiments. Int. J. Impact Eng. 2003, 28, 537–555. [Google Scholar] [CrossRef]

- Mousawi, M.M.; Reid, S.R.; Deans, W.F. The use of the split Hopkinson pressure bar techniques in high strain rate materials testing. Inst. Mech. Eng. 1997, 211, 273–292. [Google Scholar]

- Chen, W.; Song, B. Split Hopkinson (Kolsky) Bar: Design, Testing and Applications; Springer: New York, NY, USA; Heidelberg, Germany, 2011. [Google Scholar]

- Nicholas, T. Tensile testing of materials at high rates of strain. Exp. Mech. 1981, 21, 177–185. [Google Scholar] [CrossRef]

- Cadoni, E.; Dotta, M.; Forni, D.; Kaufmann, H. Effects of strain rate on mechanical properties in tension of a commercial aluminium alloy used in armour applications. Procedia Struct. Integr. 2016, 2, 986–993. [Google Scholar] [CrossRef][Green Version]

- Xu, W.F.; Huang, X.C.; Hao, Z.M.; Wang, Y.; Xia, Y.M. Effect of the geometric shapes of specimens on impact tensile tests. J. Zhejiang Univ. Sci. A 2010, 11, 817–821. [Google Scholar] [CrossRef]

- Naik, N.K.; Perla, Y. Mechanical behavior of acrylic under high strain rate tensile loading. Polym. Test. 2008, 27, 504–512. [Google Scholar] [CrossRef]

- Hopkinson, B. A method of measuring the pressure produced in the detonation of high explosives or by the impact of bullets. Philos. Trans. R. Soc. Lond. Ser. A 1914, 213, 437–456. [Google Scholar]

- Kolsky, H. An investigation of the mechanical properties of materials at very high rates of loading. Proc. Phys. Soc. Lond. Sect. B 1949, 62, 676–700. [Google Scholar] [CrossRef]

- He, A.; Xi, G.; Zhang, H.; Wang, X. A comparative study on Johnson-Cook, modified Johnson-Cook and Arrhenius-type constitutive models to predict the high temperature flow stress in 20CrMo alloy steel. Mater. Des. 2013, 52, 677–685. [Google Scholar] [CrossRef]

- Berkovic, L.; Chabotier, A.; Coghe, F.; Rabet, L. Constitutive equations of a ballistic steel alloy as a function of temperature. EPJ Web Conf. 2012, 26, 04017. [Google Scholar] [CrossRef]

- Dehgahi, S.; Pirgazi, H.; Sanjari, M.; Seraj, P.; Odeshi, A.; Kestens, L.A.I.; Mohammadi, M. Effect of building direction on high strain-rate compressive behavior of heat-treated LPBF-maraging steels using Split Hopkinson pressure bar apparatus. Mater. Sci. Eng. 2022, 835, 142653. [Google Scholar] [CrossRef]

- Li, H.; Li, F.; Zhang, R.; Zhi, X. High strain rate experiments and constitutive model for Q390D steel. J. Constr. Steel Res. 2023, 206, 107933. [Google Scholar] [CrossRef]

- Li, M.; Hao, H.; Cui, J.; Hao, Y. Numerical investigation of the failure mechanism of cubic concrete specimens in SHPB tests. Def. Technol. 2022, 18, 1–11. [Google Scholar] [CrossRef]

- Shubham; Yerramalli, C.S.; Sumant, C.; Prusty, R.K.; Ray, B.C. Finite element modelling and experimentation of plain weave glass/epoxy composites under high strain-rate compression loading for estimation of Johnson-Cook model parameters. Int. J. Impact Eng. 2022, 167, 104262. [Google Scholar] [CrossRef]

- Li, X.; Kim, J.; Roy, A.; Ayvar-Soberanis, S. High temperature and strain-rate response of AA2124-SiC metal matrix composites. Mater. Sci. Eng. A 2022, 856, 144014. [Google Scholar] [CrossRef]

- Li, P.; Yuan, K.; Guo, W.; Wang, R.; Chen, L.; Gao, M.; Du, P. Dynamic compressive behavior of a single crystal nickel-base superalloy at ultra-high temperature: Mechanism investigation with a modified electric synchronous SHPB technique. J. Mater. Res. Technol. 2022, 18, 637–657. [Google Scholar] [CrossRef]

- Li, X.; Wei, Z.; Wang, X.; Yang, L.; Hao, X.; Wang, M.; Guo, M.; Guo, J. Effect of cryogenic temperatures on the mechanical behavior and deformation mechanism of AISI 316H stainless steel. J. Mater. Res. Technol. 2023, 22, 3375–3386. [Google Scholar] [CrossRef]

- Gu, X.; Zhang, Q.; Huang, D.; Yv, Y. Wave dispersion analysis and simulation method for concrete SHPB test in peridynamics. Eng. Fract. Mech. 2016, 160, 124–137. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, J.; Ou, X.; Meng, L.; Yao, X. Dynamic mechanical properties and failure mechanism of magnesium aluminum spinel based on experiments and peridynamic simulations. J. Eur. Ceram. Soc. 2023, 43, 7581–7598. [Google Scholar] [CrossRef]

- Kariem, M.A.; Santiago, R.C.; Govender, R.; Shu, D.W.; Ruan, D.; Nurick, G.; Alves, M.; Lu, G.; Langdon, G.S. Round-Robin test of split Hopkinson pressure bar. Int. J. Impact Eng. 2019, 126, 62–75. [Google Scholar] [CrossRef]

- Kariem, M.A.; Ruan, D.; Beynon, J.H.; Prabowo, D.A. Mini Round-Robin Test on the Split Hopkinson Pressure Bar. J. Test Eval. 2018, 46, 457–468. [Google Scholar] [CrossRef]

- Pankow, M.; Attard, C.; Waas, A.M. Specimen size and shape effect in split Hopkinson pressure bar testing. J. Strain Anal. Eng. Des. 2009, 44, 689–698. [Google Scholar] [CrossRef]

- Wang, Q.Z.; Zhang, S.; Xie, H.P. Rock Dynamic Fracture Toughness Tested with Holed-Cracked Flattened Brazilian Discs Diametrically Impacted by SHPB and its Size Effect. Exp. Mech. 2010, 50, 877–885. [Google Scholar] [CrossRef]

- Shin, H.H.; Kim, J.B. A Phenomenological Constitutive Equation to Describe Various Flow Stress Behaviors of Materials in Wide Strain Rate and Temperature Regimes. Am. Soc. Mech. Eng. 2010, 132, 021009. [Google Scholar] [CrossRef]

- An, W.J.; Woo, M.A.; Noh, H.K.; Kang, B.S.; Kim, J. Design and Fabrication of Split Hopkinson Pressure Bar for Acquisition of Dynamic Material Property of Al6061-T6. J. Korean Soc. Precis. Eng. 2015, 33, 587–594. [Google Scholar] [CrossRef]

- Frew, D.J.; Forrestal, M.J.; Chen, W. Pulse Shaping Techniques for Testing Elastic-plastic Materials with a Split Hopkinson Pressure Bar. Exp. Mech. 2005, 45, 186–195. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Frew, D.J.; Forrestal, M.J. Dynamic Compression Testing of Soft Materials. J. Appl. Mech. 2002, 69, 214–223. [Google Scholar] [CrossRef]

- Othman, R. The Kolsky-Hopkinson Bar Machine: Selected Topics; Springer International Publishing: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Gorham, D.A. Specimen inertia in high strain-rate compression. J. Phys. Appl. Phys. 1989, 22, 1888–1893. [Google Scholar] [CrossRef]

- Hockly, M.; Siviour, C.R. Specimen Inertia in high strain rate tensile testing. EPJ Web Conf. 2015, 94, 01050. [Google Scholar] [CrossRef]

- Rodríguez, J.; Cortés, R.; Martínez, M.A.; Sánchez-Gálvez, V.; Navarro, C. Numerical study of the specimen size effect in the split Hopkinson pressure bar tests. J. Mater. Sci. 1995, 30, 4720–4725. [Google Scholar] [CrossRef]

- Sharpe, W.N.; Hoge, K.G. Specimen strain measurement in the split-Hopkinson-pressure-bar experiment. Exp. Mech. 1972, 12, 570–574. [Google Scholar] [CrossRef]

- Davies, E.D.H.; Hunter, S.C. The dynamic compression testing of solids by the method of the split Hopkinson pressure bar. J. Mech. Phys. Solids 1963, 11, 155–179. [Google Scholar] [CrossRef]

- Ren, L.; Yu, X.; He, Y.; Wang, K.; Yao, H. Numerical investigation of lateral inertia effect in dynamic impact testing of UHPC using a Split-Hopkinson pressure bar. Constr. Build. Mater. 2020, 246, 118483. [Google Scholar] [CrossRef]

- Pei, P.; Pei, Z.; Tang, Z. Numerical and Theoretical Analysis of the Inertia Effects and Interfacial Friction in SHPB Test Systems. Materials 2020, 13, 4809. [Google Scholar] [CrossRef]

- Iwamoto, T.; Yokoyama, T. Effects of radial inertia and end friction in specimen geometry in split Hopkinson pressure bar tests: A computational study. Mech. Mater. 2012, 51, 97–109. [Google Scholar] [CrossRef]

| Length (mm) | Diameter (mm) | |

|---|---|---|

| Striker bar | 200 | 20 |

| Incident bar | 1200 | 20 |

| Transmitted bar | 1200 | 20 |

| SNCM439 | |

|---|---|

| Density | 7850 kg/m3 |

| Young’s modulus | 196 GPa |

| Poisson’s ratio | 0.3 |

| Yield strength | 1550 MPa |

| Specimen | Diameter (mm) | Thickness (mm) | Slenderness Ratio |

|---|---|---|---|

| Case 1 | 5 | 5 | 1.0 |

| Case 2 | 6 | 5 | 0.83 |

| Case 3 | 7 | 5 | 0.71 |

| Case 4 | 8 | 5 | 0.63 |

| Case 5 | 10 | 5 | 0.5 |

| (a) P = 0.5 | |||||

| Diameter (mm) | 5 | 6 | 7 | 8 | 10 |

| (%) | ±12.0 | ±1.3 | ±0.95 | ±0.98 | ±4.5 |

| (b) P = 1.0 | |||||

| Diameter (mm) | 5 | 6 | 7 | 8 | 10 |

| (%) | ±12.2 | ±0.5 | ±26.8 | ±9.6 | ±6.5 |

| (c) P = 1.5 | |||||

| Diameter (mm) | 5 | 6 | 7 | 8 | 10 |

| (%) | ±6.0 | ±2.4 | ±16.8 | ±4.4 | ±0.29 |

| A (MPa) | B (MPa) | C | D | E |

|---|---|---|---|---|

| 410.15 | 794 | 1.6 | 0.014 | 0.0000083 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, Y.-B.; Park, B.; Kim, J. Influence of Specimen Diameter for Titanium Grade 1 on SHPB Tests and Its Verification Using FEM. Metals 2023, 13, 1941. https://doi.org/10.3390/met13121941

Kim Y-B, Park B, Kim J. Influence of Specimen Diameter for Titanium Grade 1 on SHPB Tests and Its Verification Using FEM. Metals. 2023; 13(12):1941. https://doi.org/10.3390/met13121941

Chicago/Turabian StyleKim, Yeon-Bok, ByeongJin Park, and Jeong Kim. 2023. "Influence of Specimen Diameter for Titanium Grade 1 on SHPB Tests and Its Verification Using FEM" Metals 13, no. 12: 1941. https://doi.org/10.3390/met13121941

APA StyleKim, Y.-B., Park, B., & Kim, J. (2023). Influence of Specimen Diameter for Titanium Grade 1 on SHPB Tests and Its Verification Using FEM. Metals, 13(12), 1941. https://doi.org/10.3390/met13121941