Designing Quaternary and Quinary Refractory-Based High-Entropy Alloys: Statistical Analysis of Their Lattice Distortion, Mechanical, and Thermal Properties

Abstract

:1. Introduction

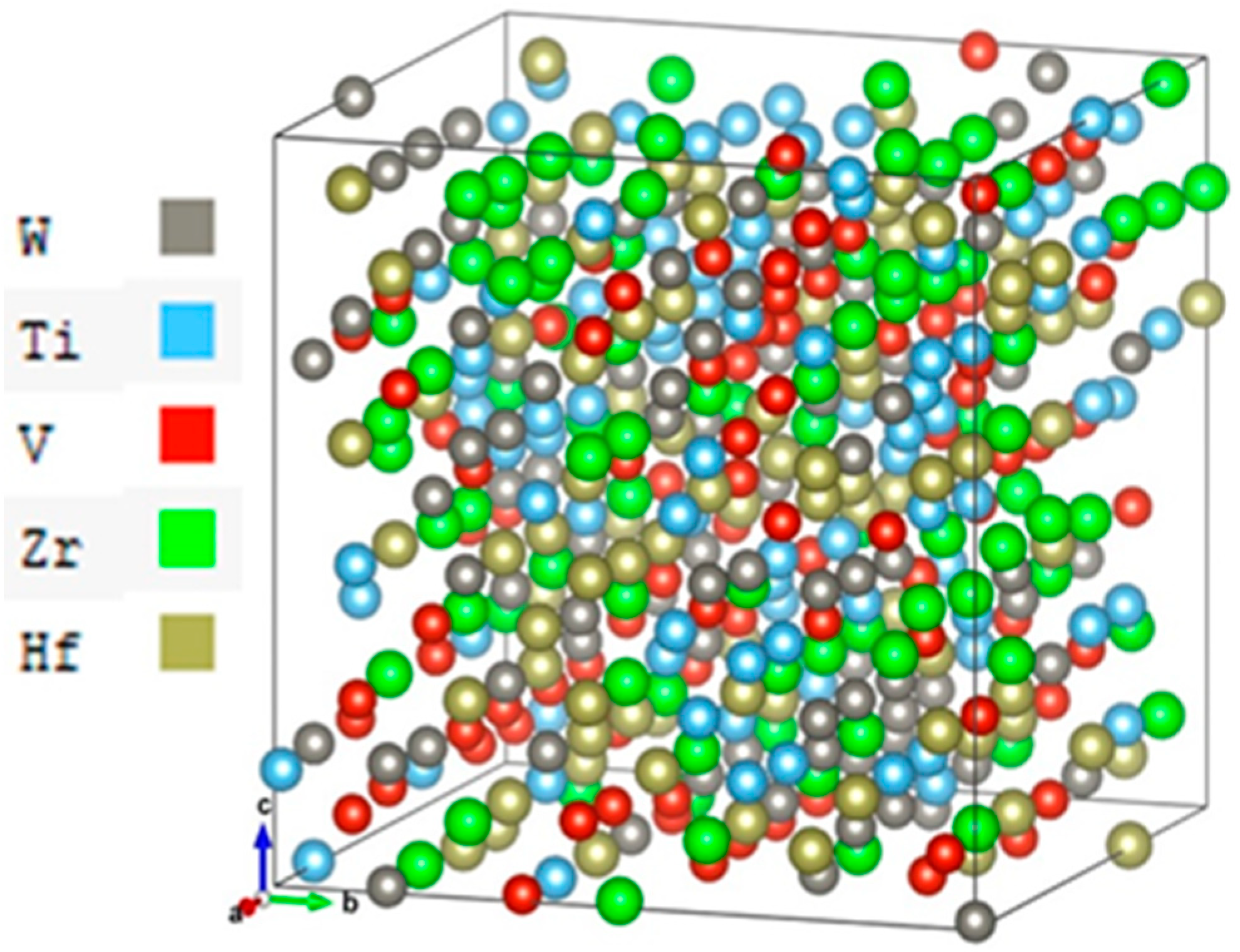

2. Computational Modeling and Method

2.1. Optimization and Mechanical Properties

2.2. Electronic Structure

3. Results and Discussion

3.1. Electronic Structure

3.2. Interatomic Bonding and Lattice Distortion

3.3. Mechanical Properties

3.4. Thermal Properties

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, Y.L.; Lin, S.J.; Chen, S.K. High-Entropy Alloys—A New Era of Exploitation. Mater. Sci. Forum 2007, 560, 1–9. [Google Scholar] [CrossRef]

- Zhu, H.; Zhao, T.; Zhang, B.; An, Z.; Mao, S.; Wang, G.; Han, X.; Lu, X.; Zhang, J.; Zhou, X. Entropy Engineered Cubic N-Type AgBiSe2 Alloy with High Thermoelectric Performance in Fully Extended Operating Temperature Range. Adv. Energy Mater. 2021, 11, 2003304. [Google Scholar] [CrossRef]

- Sun, L.; Cava, R.J. High-Entropy Alloy Superconductors: Status, Opportunities, and Challenges. Phys. Rev. Mater. 2019, 3, 090301. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy Design Strategies and Future Trends in High-Entropy Alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Dąbrowa, J.; Zajusz, M.; Kucza, W.; Cieślak, G.; Berent, K.; Czeppe, T.; Kulik, T.; Danielewski, M. Demystifying the Sluggish Diffusion Effect in High Entropy Alloys. J. Alloys Compd. 2019, 783, 193–207. [Google Scholar] [CrossRef]

- Jiang, B.; Yu, Y.; Cui, J.; Liu, X.; Xie, L.; Liao, J.; Zhang, Q.; Huang, Y.; Ning, S.; Jia, B.; et al. High-Entropy-Stabilized Chalcogenides with High Thermoelectric Performance. Science 2021, 371, 830–834. [Google Scholar] [CrossRef]

- Jiang, B.; Wang, W.; Liu, S.; Wang, Y.; Wang, C.; Chen, Y.; Xie, L.; Huang, M.; He, J. High Figure-of-Merit and Power Generation in High-Entropy GeTe-Based Thermoelectrics. Science 2022, 377, 208–213. [Google Scholar] [CrossRef]

- Waseem, O.A.; Ryu, H.J. Combinatorial Synthesis and Analysis of AlxTayVz-Cr20Mo20Nb20Ti20Zr10 and Al10CrMoxNbTiZr10 Refractory High-Entropy Alloys: Oxidation Behavior. J. Alloys Compd. 2020, 828, 154427. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, H.; Fan, Y.; Zhang, W.; Wei, R.; Wang, T.; Zhang, T.; Li, F. A Novel Ultrafine-Grained High Entropy Alloy with Excellent Combination of Mechanical and Soft Magnetic Properties. J. Magn. Magn. Mater. 2020, 502, 166513. [Google Scholar] [CrossRef]

- Granberg, F.; Nordlund, K.; Ullah, M.W.; Jin, K.; Lu, C.; Bei, H.; Wang, L.M.; Djurabekova, F.; Weber, W.J.; Zhang, Y. Mechanism of Radiation Damage Reduction in Equiatomic Multicomponent Single Phase Alloys. Phys. Rev. Lett. 2016, 116, 135504. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Egami, T.; Weber, W.J. Dissipation of Radiation Energy in Concentrated Solid-Solution Alloys: Unique Defect Properties and Microstructural Evolution. MRS Bull. 2019, 44, 798–811. [Google Scholar] [CrossRef]

- Zhang, Y.; Stocks, G.M.; Jin, K.; Lu, C.; Bei, H.; Sales, B.C.; Wang, L.; Béland, L.K.; Stoller, R.E.; Samolyuk, G.D.; et al. Influence of Chemical Disorder on Energy Dissipation and Defect Evolution in Concentrated Solid Solution Alloys. Nat. Commun. 2015, 6, 8736. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Niu, L.; Chen, N.; Jin, K.; Yang, T.; Xiu, P.; Zhang, Y.; Gao, F.; Bei, H.; Shi, S.; et al. Enhancing Radiation Tolerance by Controlling Defect Mobility and Migration Pathways in Multicomponent Single-Phase Alloys. Nat. Commun. 2016, 7, 13564. [Google Scholar] [CrossRef]

- Ikeda, Y.; Grabowski, B.; Körmann, F. Ab Initio Phase Stabilities and Mechanical Properties of Multicomponent Alloys: A Comprehensive Review for High Entropy Alloys and Compositionally Complex Alloys. Mater. Charact. 2019, 147, 464–511. [Google Scholar] [CrossRef]

- El-Atwani, O.; Li, N.; Li, M.; Devaraj, A.; Baldwin, J.K.S.; Schneider, M.M.; Sobieraj, D.; Wróbel, J.S.; Nguyen-Manh, D.; Maloy, S.A.; et al. Outstanding Radiation Resistance of Tungsten-Based High-Entropy Alloys. Sci. Adv. 2019, 5, eaav2002. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, Y.J.; Lin, J.P.; Chen, G.L.; Liaw, P.K. Solid-Solution Phase Formation Rules for Multi-Component Alloys. Adv. Eng. Mater. 2008, 10, 534–538. [Google Scholar] [CrossRef]

- Takeuchi, A.; Inoue, A. Quantitative Evaluation of Critical Cooling Rate for Metallic Glasses. Mater. Sci. Eng. A 2001, 304–306, 446–451. [Google Scholar] [CrossRef]

- Guo, S.; Ng, C.; Lu, J.; Liu, C.T. Effect of Valence Electron Concentration on Stability of Fcc or Bcc Phase in High Entropy Alloys. J. Appl. Phys. 2011, 109, 103505. [Google Scholar] [CrossRef]

- Wu, Z.; Bei, H.; Otto, F.; Pharr, G.M.; George, E.P. Recovery, Recrystallization, Grain Growth and Phase Stability of a Family of FCC-Structured Multi-Component Equiatomic Solid Solution Alloys. Intermetallics 2014, 46, 131–140. [Google Scholar] [CrossRef]

- Senkov, O.N.; Wilks, G.B.; Miracle, D.B.; Chuang, C.P.; Liaw, P.K. Refractory High-Entropy Alloys. Intermetallics 2010, 18, 1758–1765. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Miracle, D.B.; Woodward, C.F. Microstructure and Room Temperature Properties of a High-Entropy TaNbHfZrTi Alloy. J. Alloys Compd. 2011, 509, 6043–6048. [Google Scholar] [CrossRef]

- Senkov, O.N.; Scott, J.M.; Senkova, S.V.; Meisenkothen, F.; Miracle, D.B.; Woodward, C.F. Microstructure and Elevated Temperature Properties of a Refractory TaNbHfZrTi Alloy. J. Mater. Sci. 2012, 47, 4062–4074. [Google Scholar] [CrossRef]

- Senkov, O.N.; Woodward, C.F. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy. Mater. Sci. Eng. A 2011, 529, 311–320. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Woodward, C.; Miracle, D.B. Low-Density, Refractory Multi-Principal Element Alloys of the Cr-Nb-Ti-V-Zr System: Microstructure and Phase Analysis. Acta Mater. 2013, 61, 1545–1557. [Google Scholar] [CrossRef]

- Senkov, O.N.; Senkova, S.V.; Miracle, D.B.; Woodward, C. Mechanical Properties of Low-Density, Refractory Multi-Principal Element Alloys of the Cr-Nb-Ti-V-Zr System. Mater. Sci. Eng. A 2013, 565, 51–62. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Liaw, P.K. Alloy Design and Properties Optimization of High-Entropy Alloys. Jom 2012, 64, 830–838. [Google Scholar] [CrossRef]

- Gao, M.C.; Alman, D.E. Searching for Next Single-Phase High-Entropy Alloy Compositions. Entropy 2013, 15, 4504–4519. [Google Scholar] [CrossRef]

- Tian, F.; Wang, D.; Shen, J.; Wang, Y. An Ab Initio Investgation of Ideal Tensile and Shear Strength of TiVNbMo High-Entropy Alloy. Mater. Lett. 2016, 166, 271–275. [Google Scholar] [CrossRef]

- Fazakas, E.; Zadorozhnyy, V.; Varga, L.K.; Inoue, A.; Louzguine-Luzgin, D.V.; Tian, F.; Vitos, L. Experimental and Theoretical Study of Ti20Zr20Hf 20Nb20X20 (X = v or Cr) Refractory High-Entropy Alloys. Int. J. Refract. Met. Hard Mater. 2014, 47, 131–138. [Google Scholar] [CrossRef]

- Huhn, W. Thermodynamics from First Principles: Prediction of Phase Diagrams and Materials Properties Using Density Functional Theory. Ph.D. Thesis, Carnegie Mellon University, Pittsburgh, PA, USA, 2014. [Google Scholar]

- Toda-Caraballo, I.; Wróbel, J.S.; Dudarev, S.L.; Nguyen-Manh, D.; Rivera-Díaz-Del-Castillo, P.E.J. Interatomic Spacing Distribution in Multicomponent Alloys. Acta Mater. 2015, 97, 156–169. [Google Scholar] [CrossRef]

- Gao, M.C.; Zhang, B.; Yang, S.; Guo, S.M. Senary Refractory High-Entropy Alloy HfNbTaTiVZr. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2016, 47, 3333–3345. [Google Scholar] [CrossRef]

- Li, X.; Tian, F.; Schönecker, S.; Zhao, J.; Vitos, L. Ab Initio-Predicted Micro-Mechanical Performance of Refractory High-Entropy Alloys. Sci. Rep. 2015, 5, 12334. [Google Scholar] [CrossRef] [PubMed]

- Körmann, F.; Sluiter, M.H.F. Interplay between Lattice Distortions, Vibrations and Phase Stability in NbMoTaW High Entropy Alloys. Entropy 2016, 18, 403. [Google Scholar] [CrossRef]

- Tian, L.Y.; Wang, G.; Harris, J.S.; Irving, D.L.; Zhao, J.; Vitos, L. Alloying Effect on the Elastic Properties of Refractory High-Entropy Alloys. Mater. Des. 2017, 114, 243–252. [Google Scholar] [CrossRef]

- Feng, B.; Widom, M. Elastic Stability and Lattice Distortion of Refractory High Entropy Alloys. Mater. Chem. Phys. 2018, 210, 309–314. [Google Scholar] [CrossRef]

- Song, H.; Tian, F.; Hu, Q.M.; Vitos, L.; Wang, Y.; Shen, J.; Chen, N. Local Lattice Distortion in High-Entropy Alloys. Phys. Rev. Mater. 2017, 1, 023404. [Google Scholar] [CrossRef]

- Ge, H.; Tian, F.; Wang, Y. Elastic and Thermal Properties of Refractory High-Entropy Alloys from First-Principles Calculations. Comput. Mater. Sci. 2017, 128, 185–190. [Google Scholar] [CrossRef]

- He, J.; Tritt, T.M. Advances in Thermoelectric Materials Research: Looking Back and Moving Forward. Science 2017, 357, eaak9997. [Google Scholar] [CrossRef]

- Wu, Y.; Chen, Z.; Nan, P.; Chen, L.; Wu, Y.; Chen, Z.; Nan, P.; Xiong, F.; Lin, S.; Zhang, X.; et al. Lattice Strain Advances Thermoelectrics Lattice Strain Advances Thermoelectrics. Joule 2019, 3, 1276–1288. [Google Scholar] [CrossRef]

- Shafeie, S.; Guo, S.; Hu, Q.; Fahlquist, H.; Erhart, P.; Palmqvist, A. High-Entropy Alloys as High-Temperature Thermoelectric Materials. J. Appl. Phys. 2015, 118, 184905. [Google Scholar] [CrossRef]

- Fan, Z.; Wang, H.; Wu, Y.; Liu, X.J.; Lu, Z.P. Thermoelectric High-Entropy Alloys with Low Lattice Thermal Conductivity. RSC Adv. 2016, 6, 52164–52170. [Google Scholar] [CrossRef]

- Lee, J.I.; Oh, H.S.; Park, E.S. Manipulation of σy/κ Ratio in Single Phase FCC Solid-Solutions. Appl. Phys. Lett. 2016, 109, 061906. [Google Scholar] [CrossRef]

- Dutta, B.; Ghosh, S. Vibrational Properties of NixPt1−x Alloys: An Understanding from Ab Initio Calculations. J. Appl. Phys. 2011, 109, 053714. [Google Scholar] [CrossRef]

- Grånäs, O.; Dutta, B.; Ghosh, S.; Sanyal, B. A New First Principles Approach to Calculate Phonon Spectra of Disordered Alloys. J. Phys. Condens. Matter 2012, 24, 015402. [Google Scholar] [CrossRef] [PubMed]

- Dutta, B.; Bisht, K.; Ghosh, S. Ab Initio Calculation of Phonon Dispersions in Size-Mismatched Disordered Alloys. Phys. Rev. B-Condens. Matter Mater. Phys. 2010, 82, 134207. [Google Scholar] [CrossRef]

- Alam, A.; Ghosh, S.; Mookerjee, A. Phonons in Disordered Alloys: Comparison between Augmented-Space-Based Approximations for Configuration Averaging to Integration from First Principles. Phys. Rev. B-Condens. Matter Mater. Phys. 2007, 75, 134202. [Google Scholar] [CrossRef]

- Chouhan, R.K.; Alam, A.; Ghosh, S.; Mookerjee, A. Interplay of Force Constants in the Lattice Dynamics of Disordered Alloys: An Ab Initio Study. Phys. Rev. B-Condens. Matter Mater. Phys. 2014, 89, 060201. [Google Scholar] [CrossRef]

- Wang, Y.; Zacherl, C.L.; Shang, S.; Chen, L.Q.; Liu, Z.K. Phonon Dispersions in Random Alloys: A Method Based on Special Quasi-Random Structure Force Constants. J. Phys. Condens. Matter 2011, 23, 485403. [Google Scholar] [CrossRef]

- Tian, F. A Review of Solid-Solution Models of High-Entropy Alloys Based on Ab Initio Calculations. Front. Mater. 2017, 4, 36. [Google Scholar] [CrossRef]

- Zunger, A.; Wei, S.H.; Ferreira, L.G.; Bernard, J.E. Special Quasirandom Structures. Phys. Rev. Lett. 1990, 65, 353. [Google Scholar] [CrossRef]

- King, D.J.M.; Burr, P.A.; Obbard, E.G.; Middleburgh, S.C. DFT Study of the Hexagonal High-Entropy Alloy Fission Product System. J. Nucl. Mater. 2017, 488, 70–74. [Google Scholar] [CrossRef]

- Soven, P. Coherent-Potential Model of Substitutional Disordered Alloys. Phys. Rev. 1967, 156, 809–813. [Google Scholar] [CrossRef]

- Bellaiche, L.; Vanderbilt, D. Virtual Crystal Approximation Revisited: Application to Dielectric and Piezoelectric Properties of Perovskites. Phys. Rev. B-Condens. Matter Mater. Phys. 2000, 61, 7877–7882. [Google Scholar] [CrossRef]

- Ching, W.Y.; San, S.; Brechtl, J.; Sakidja, R.; Zhang, M.; Liaw, P.K. Fundamental Electronic Structure and Multiatomic Bonding in 13 Biocompatible High-Entropy Alloys. npj Comput. Mater. 2020, 6, 45. [Google Scholar] [CrossRef]

- Dharmawardhana, C.C.; Misra, A.; Ching, W.Y. Quantum Mechanical Metric for Internal Cohesion in Cement Crystals. Sci. Rep. 2014, 4, 7332. [Google Scholar] [CrossRef] [PubMed]

- Kresse, G. Efficient Iterative Schemes for Ab Initio Total-Energy Calculations Using a Plane-Wave Basis Se. Phys. Rev. B 1996, 54, 11169. [Google Scholar] [CrossRef] [PubMed]

- Kresse, G. Ab Initio Molecular Dynamics for Liquid Metals. Phys. Rev. B 1993, 47, 558. [Google Scholar] [CrossRef]

- Reuss, A. Berechnung Der Fließgrenze von Mischkristallen Auf Grund Der Plastizitätsbedingung Für Einkristalle. ZAMM-J. Appl. Math. Mech./Zeitschrift für Angewandte Mathematik und Mechanik 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. 1952, 65, 349. [Google Scholar] [CrossRef]

- Bao, L.; Kong, Z.; Qu, D.; Duan, Y. Revealing the Elastic Properties and Anisotropies of Mg2X(X = Si, Ge and Sn) with Different Structures from a First-Principles Calculation. Mater. Today Commun. 2020, 24, 101337. [Google Scholar] [CrossRef]

- Mo, Y.; Rulis, P.; Ching, W.Y. Electronic Structure and Optical Conductivities of 20 MAX-Phase Compounds. Phys. Rev. B-Condens. Matter Mater. Phys. 2012, 86, 165122. [Google Scholar] [CrossRef]

- Ching, W.Y.; Yoshiya, M.; Adhikari, P.; Rulis, P.; Ikuhara, Y.; Tanaka, I. First-Principles Study in an Inter-Granular Glassy Film Model of Silicon Nitride. J. Am. Ceram. Soc. 2018, 101, 2673–2688. [Google Scholar] [CrossRef]

- Mulliken, R.S. Electronic Population Analysis on LCAO-MO Molecular Wave Functions. I. J. Chem. Phys. 1955, 23, 1833–1840. [Google Scholar] [CrossRef]

- Hasan, S.; Adhikari, P.; Baral, K.; Ching, W.Y. Conspicuous Interatomic Bonding in Chalcogenide Crystals and Implications on Electronic, Optical, and Elastic Properties. AIP Adv. 2020, 10, 075216. [Google Scholar] [CrossRef]

- Hasan, S.; Baral, K.; Li, N.; Ching, W.Y. Structural and Physical Properties of 99 Complex Bulk Chalcogenides Crystals Using First-Principles Calculations. Sci. Rep. 2021, 11, 9921. [Google Scholar] [CrossRef] [PubMed]

- Hasan, S.; Rulis, P.; Ching, W. First-Principles Calculations of the Structural, Electronic, Optical, and Mechanical Properties of 21 Pyrophosphate Crystals. Crystals 2022, 12, 1139. [Google Scholar] [CrossRef]

- Hunca, B.; Dharmawardhana, C.; Sakidja, R.; Ching, W.Y. Ab Initio Calculations of Thermomechanical Properties and Electronic Structure of Vitreloy Zr41.2Ti13.8Cu12.5Ni10Be22.5. Phys. Rev. B 2016, 94, 144207. [Google Scholar] [CrossRef]

- Poudel, L.; Twarock, R.; Steinmetz, N.F.; Podgornik, R.; Ching, W.Y. Impact of Hydrogen Bonding in the Binding Site between Capsid Protein and MS2 Bacteriophage SsRNA. J. Phys. Chem. B 2017, 121, 6321–6330. [Google Scholar] [CrossRef]

- Adhikari, P.; Li, N.; Shin, M.; Steinmetz, N.F.; Twarock, R.; Podgornik, R.; Ching, W.Y. Intra- And Intermolecular Atomic-Scale Interactions in the Receptor Binding Domain of SARS-CoV-2 Spike Protein: Implication for ACE2 Receptor Binding. Phys. Chem. Chem. Phys. 2020, 22, 18272–18283. [Google Scholar] [CrossRef] [PubMed]

- San, S.; Tong, Y.; Bei, H.; Kombaiah, B.; Zhang, Y.; Ching, W.Y. First-Principles Calculation of Lattice Distortions in Four Single Phase High Entropy Alloys with Experimental Validation. Mater. Des. 2021, 209, 110071. [Google Scholar] [CrossRef]

- Bérardan, D.; Franger, S.; Dragoe, D.; Meena, A.K.; Dragoe, N. Colossal Dielectric Constant in High Entropy Oxides. Phys. Status Solidi-Rapid Res. Lett. 2016, 10, 328–333. [Google Scholar] [CrossRef]

- Yao, H.; Ouyang, L.; Ching, W.Y. Ab Initio Calculation of Elastic Constants of Ceramic Crystals. J. Am. Ceram. Soc. 2007, 90, 3194–3204. [Google Scholar] [CrossRef]

- Deng, H. Theoretical Prediction of the Structural, Electronic, Mechanical and Thermodynamic Properties of the Binary α-As2Te3 and β-As2Te3. J. Alloys Compd. 2015, 656, 695–701. [Google Scholar] [CrossRef]

- Tian, Y.; Xu, B.; Zhao, Z. Microscopic Theory of Hardness and Design of Novel Superhard Crystals. Int. J. Refract. Met. Hard Mater. 2012, 33, 93–106. [Google Scholar] [CrossRef]

- Pugh, S.F. Relations between the Elastic Moduli and the Plastic Properties of Polycrystalline Pure Metals. Lond. Edinb. Dublin Philos. Mag. J. Sci. 1954, 45, 823–843. [Google Scholar] [CrossRef]

- Ali, M.A.; Hossain, M.A.; Rayhan, M.A.; Hossain, M.M.; Uddin, M.M.; Roknuzzaman, M.; Ostrikov, K.; Islam, A.K.; Naqib, S.H. First-Principles Study of Elastic, Electronic, Optical and Thermoelectric Properties of Newly Synthesized K2Cu2GeS4 Chalcogenide. J. Alloys Compd. 2019, 781, 37–46. [Google Scholar] [CrossRef]

- Heciri, D.; Belkhir, H.; Belghit, R.; Bouhafs, B.; Khenata, R.; Ahmed, R.; Bouhemadou, A.; Ouahrani, T.; Wang, X.; Bin Omran, S. Insight into the Structural, Elastic and Electronic Properties of Tetragonal Inter-Alkali Metal Chalcogenides CsNaX (X = S, Se, and Te) from First-Principles Calculations. Mater. Chem. Phys. 2019, 221, 125–137. [Google Scholar] [CrossRef]

- Mouhat, F.; Coudert, F.X. Necessary and Sufficient Elastic Stability Conditions in Various Crystal Systems. Phys. Rev. B-Condens. Matter Mater. Phys. 2014, 90, 224104. [Google Scholar] [CrossRef]

- Thakur, V.; Pagare, G. Theoretical Calculations of Elastic, Mechanical and Thermal Properties of REPt3 (RE = Sc, Y and Lu) Intermetallic Compounds Based on DFT. Indian J. Phys. 2018, 92, 1503–1513. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, W.; Gan, G.-Y.; Shi, X.-F.; Tang, B.-Y. Structural, Mechanical and Electronic Properties of (TaNbHfTiZr)C High Entropy Carbide under Pressure: Ab Initio Investigation. Phys. B Phys. Condens. Matter 2018, 550, 163–170. [Google Scholar] [CrossRef]

- Yang, A.; Bao, L.; Peng, M.; Duan, Y. Explorations of Elastic Anisotropies and Thermal Properties of the Hexagonal TMSi2 (TM = Cr, Mo, W) Silicides from First-Principles Calculations. Mater. Today Commun. 2021, 27, 102474. [Google Scholar] [CrossRef]

- Ma, H.; Zhang, X.; Wang, F. First-Principles Study of the Lattice Vibration, Elastic Anisotropy and Thermodynamical Properties of Tantalum Silicide with the Different Crystal Structures. Vacuum 2021, 191, 110410. [Google Scholar] [CrossRef]

- Senkov, O.N.; Miracle, D.B.; Chaput, K.J.; Couzinie, J.P. Development and Exploration of Refractory High Entropy Alloys—A Review. J. Mater. Res. 2018, 33, 3092–3128. [Google Scholar] [CrossRef]

- Li, X.Y.; Zhang, H.P.; Lan, S.; Abernathy, D.L.; Otomo, T.; Wang, F.W.; Ren, Y.; Li, M.Z.; Wang, X.L. Observation of High-Frequency Transverse Phonons in Metallic Glasses. Phys. Rev. Lett. 2020, 124, 225902. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Clarke, D.R.; Fuierer, P.A. Anisotropic Thermal Conductivity of the Aurivillus Phase, Bismuth Titanate (Bi4Ti3O12): A Natural Nanostructured Superlattice. Appl. Phys. Lett. 2008, 93, 102907. [Google Scholar] [CrossRef]

- Clarke, D.R. Materials Selections Guidelines for Low Thermal Conductivity Thermal Barrier Coatings. Surf. Coatings Technol. [CrossRef]

- Cahill, D.G.; Watson, S.K.; Pohl, R.O. Lower Limit to the Thermal Conductivity of Disordered Crystals. Phys. Rev. B 1992, 46, 6131–6140. [Google Scholar] [CrossRef]

- Morelli, D.T.; Slack, G.A. High Lattice Thermal Conductivity Solids. In High Thermal Conductivity Materials; Springer: New York, NY, USA, 2006; pp. 37–68. [Google Scholar] [CrossRef]

- Murphy, K.F. Strain Effects on Thermal Conductivity of Nanostructured Silicon by Raman Piezothermography. Doctoral Dissertation, University of Pennsylvania, Philadelphia, PA, USA, 2014. [Google Scholar]

- Bhowmick, S. Effect of Strain on the Thermal Conductivity of Solids. J. Chem. Phys. 2006, 125, 164513. [Google Scholar] [CrossRef]

- Knura, R.; Parashchuk, T. Origins of Low Lattice Thermal Conductivity of Pb1 − x Snx Te Alloys for Thermoelectric Applications. Dalton Trans. 2021, 50, 4323–4334. [Google Scholar] [CrossRef]

- Jia, T.; Chen, G.; Zhang, Y. Lattice Thermal Conductivity Evaluated Using Elastic Properties. Phys. Rev. B 2017, 95, 155206. [Google Scholar] [CrossRef]

- Brugger, K. Generalized Griineisen Parameters in the Anisotropic Debye Model. Phys. Rev. 1965, 137, A1826. [Google Scholar] [CrossRef]

- Malhotra, A.; Maldovan, M. Impact of Phonon Surface Scattering on Thermal Energy Distribution of Si and SiGe Nanowires. Sci. Rep. 2016, 6, 25818. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Shao, L.; Fan, T.W.; Duan, J.M.; Chen, X.T.; Tang, B.Y. Elastic and thermodynamic properties of high entropy carbide (HfTaZrTi)C and (HfTaZrNb)C from ab initio investigation. Ceram. Int. 2020, 46, 15104–15112. [Google Scholar] [CrossRef]

- Boudiaf, K.; Bouhemadou, A.; Boudrifa, O.; Haddadi, K.; Saoud, F.S.; Khenata, R.; Al-Douri, Y.; Bin-Omran, S.; Ghebouli, M.A. Structural, Elastic, Electronic and Optical Properties of LaOAgS-Type Silver Fluoride Chalcogenides: First-Principles Study. J. Electron. Mater. 2017, 46, 4539–4556. [Google Scholar] [CrossRef]

- Guo, F.; Zhou, X.; Li, G.; Huang, X.; Xue, L.; Liu, D.; Jiang, D. Structural, mechanical, electronic and thermodynamic properties of cubic TiC compounds under different pressures: A first-principles study. Solid State Commun. 2020, 311, 113856. [Google Scholar] [CrossRef]

- Anderson, O.L. A simplified method for calculating the Debye temperature from elastic constants. J. Phys. Chem. Solids 1963, 24, 909–917. [Google Scholar] [CrossRef]

- Wachter, P.; Filzmoser, M.; Rebizant, J. Electronic and elastic properties of the light actinide tellurides. Phys. B Condens. Matter 2001, 293, 199–223. [Google Scholar] [CrossRef]

- Fine, M.E.; Brown, L.D.; Marcus, H.L. Elastic constants versus melting temperature in metals. Scr. Metall. 1984, 18, 951–956. [Google Scholar] [CrossRef]

- Benkaddour, K.; Chahed, A.; Amar, A.; Rozale, H.; Lakdja, A.; Benhelal, O.; Sayede, A. First-principles study of structural, elastic, thermodynamic, electronic and magnetic properties for the quaternary Heusler alloys CoRuFeZ (Z = Si, Ge, Sn). J. Alloys Compd. 2016, 687, 211–220. [Google Scholar] [CrossRef]

- Liu, S.Y.; Zhang, S.; Liu, S.; Li, D.J.; Li, Y.; Wang, S. Phase stability, mechanical properties and melting points of high-entropy quaternary metal carbides from first-principles. J. Eur. Ceram. Soc. 2021, 41, 267–6274. [Google Scholar] [CrossRef]

- Clarke, D.R.; Levi, C.G. Materials design for the next generation thermal barrier coatings. Annu. Rev. Mater. Res. 2003, 33, 383–417. [Google Scholar] [CrossRef]

- Cahill, D.G.; Ford, W.K.; Goodson, K.E.; Mahan, G.D.; Majumdar, A.; Maris, H.J.; Merlin, R.; Phillpot, S.R. Nanoscale thermal transport. J. Appl. Phys. 2003, 93, 793–818. [Google Scholar] [CrossRef]

- Morelli, D.T.; Heremans, J.P. Thermal conductivity of germanium, silicon, and carbon nitrides. Appl. Phys. Lett. 2002, 81, 5126–5128. [Google Scholar] [CrossRef]

- Toberer, E.S.; Zevalkink, A.; Snyder, G.J. Phonon engineering through crystal chemistry. J. Mater. Chem. 2011, 21, 15843–15852. [Google Scholar] [CrossRef]

- Arab, F.; Sahraoui, F.A.; Haddadi, K.; Bouhemadou, A.; Louail, L. Phase stability, mechanical and thermodynamic properties of orthorhombic and trigonal MgSiN 2: An ab initio study. Phase Transitions 2016, 89, 480–513. [Google Scholar] [CrossRef]

- Naher, M.I.; Afzal, M.A.; Naqib, S.H. A comprehensive DFT based insights into the physical properties of tetragonal superconducting Mo5PB2. Results Phys. 2021, 28, 104612. [Google Scholar] [CrossRef]

| Models | a(Å) | b(Å) | c(Å) | Vol (Å3) | NN (Å) | SNN (Å) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| M1 | WTiVZrHf 1 | 19.871 | 19.915 | 19.794 | 90.327 | 90.329 | 89.885 | 7832.808 | 2.867 | 3.310 |

| M2 | HfMoTiWZr 1 | 19.91 | 19.987 | 19.889 | 90.174 | 90.232 | 89.945 | 7914.625 | 2.876 | 3.321 |

| M3 | MoTaTiV 2 | 19.015 | 19.015 | 18.988 | 89.928 | 90.14 | 90.056 | 6865.245 | 2.743 | 3.168 |

| M4 | MoTaTiVZr 1 | 19.589 | 19.507 | 19.487 | 90.164 | 90.355 | 89.943 | 7446.129 | 2.819 | 3.255 |

| M5 | WTaCrV 2 | 18.53 | 18.542 | 18.543 | 89.74 | 89.823 | 89.903 | 6370.888 | 2.676 | 3.09 |

| M6 | MoNbTaW 2 | 19.387 | 19.388 | 19.388 | 89.997 | 90.065 | 89.901 | 7287.275 | 2.742 | 3.878 |

| M7 | TiZrHfW 2 | 20.252 | 20.338 | 20.269 | 90.129 | 90.067 | 90.175 | 8348.226 | 2.928 | 3.381 |

| M8 | TiZrNbMoTa 1 | 19.844 | 19.857 | 19.875 | 89.903 | 89.918 | 90.103 | 7831.877 | 2.866 | 3.31 |

| M9 | NbTaTiV 2 | 19.288 | 19.325 | 19.290 | 90.060 | 90.058 | 90.16 | 7189.958 | 2.786 | 3.217 |

| M10 | TiVNbHf 2 | 19.711 | 19.72 | 19.628 | 89.843 | 89.583 | 90.268 | 7628.582 | 2.841 | 3.281 |

| M11 | Ti0.38V0.15Nb0.23Hf0.24 2 | 19.821 | 19.788 | 19.792 | 90.06 | 89.941 | 90.29 | 7762.676 | 2.858 | 3.300 |

| M12 | TiZrHfVNb 1 | 20.136 | 20.113 | 20.014 | 89.94 | 90.011 | 89.869 | 8105.873 | 2.899 | 3.348 |

| Models | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | M12 | VEC | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Ti | PC | −0.26 | −0.16 | 0.07 | −0.03 | -- | -- | −0.32 | −0.09 | −0.12 | −0.26 | −0.24 | −0.31 | 4 |

| Q* | 4.26 | 4.16 | 3.93 | 4.03 | -- | -- | 4.32 | 4.09 | 4.12 | 4.26 | 4.24 | 4.31 | ||

| V | PC | −0.24 | -- | 0.01 | −0.06 | 0.08 | -- | -- | -- | −0.12 | −0.25 | −0.23 | −0.28 | 5 |

| Q* | 5.24 | -- | 4.99 | 5.06 | 4.92 | -- | -- | -- | 5.12 | 5.25 | 5.23 | 5.28 | ||

| Cr | PC | -- | -- | -- | -- | −0.71 | -- | -- | -- | -- | -- | -- | -- | 6 |

| Q* | -- | -- | -- | -- | 6.71 | -- | -- | -- | -- | -- | -- | -- | ||

| Zr | PC | 0.24 | 0.31 | 0.38 | -- | -- | 0.19 | 0.32 | -- | -- | -- | 0.18 | 4 | |

| Q* | 3.76 | 3.69 | 3.62 | -- | -- | 3.81 | 3.68 | -- | -- | -- | 3.82 | |||

| Nb | PC | -- | -- | -- | -- | -- | 0.32 | -- | 0.21 | 0.22 | 0.09 | 0.09 | 0.02 | 5 |

| Q* | -- | -- | -- | -- | -- | 4.68 | -- | 4.79 | 4.78 | 4.91 | 4.91 | 4.98 | ||

| Mo | PC | -- | −0.55 | −0.31 | −0.41 | −0.43 | -- | −0.46 | -- | -- | -- | -- | 6 | |

| Q* | -- | 6.55 | 6.31 | 6.41 | 6.43 | -- | 6.46 | -- | -- | -- | -- | |||

| Hf | PC | 0.45 | 0.53 | -- | -- | -- | -- | 0.41 | -- | -- | 0.41 | 0.44 | 0.39 | 4 |

| Q* | 3.55 | 3.47 | -- | -- | -- | -- | 3.59 | -- | -- | 3.59 | 3.56 | 3.61 | ||

| Ta | PC | -- | -- | 0.23 | 0.12 | 0.35 | 0.08 | -- | 0.02 | 0.03 | -- | -- | -- | 5 |

| Q* | -- | -- | 4.77 | 4.88 | 4.65 | 4.92 | -- | 4.98 | 4.97 | -- | -- | -- | ||

| W | PC | −0.2 | −0.12 | -- | -- | 0.28 | 0.02 | −0.28 | -- | -- | -- | -- | -- | 6 |

| Q* | 6.2 | 6.12 | -- | -- | 5.72 | 5.98 | 6.28 | -- | -- | -- | -- | -- | ||

| or | 4.6 | 4.8 | 5.0 | 4.8 | 5.5 | 5.5 | 4.5 | 4.8 | 4.75 | 4.5 | 4.5 | 4.4 | ||

| Model | C11 | C12 | C44 | K | G | E | Hv | CP: C12–C44 | η | G/K | TBOD | AZ |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| M1 | 170.71 | 107.04 | 37.11 | 128.24 | 34.86 | 95.88 | 2.59 | 69.93 | 0.375 | 0.272 | 0.041 | 1.166 |

| M2 | 201.82 | 114.19 | 38.84 | 143.37 | 40.73 | 111.63 | 3.04 | 75.35 | 0.370 | 0.284 | 0.042 | 0.887 |

| M3 | 258.38 | 139.11 | 31.43 | 178.46 | 40.72 | 113.51 | 2.37 | 107.67 | 0.394 | 0.228 | 0.055 | 0.527 |

| M4 | 201.89 | 116.36 | 32.02 | 144.84 | 35.92 | 99.53 | 2.38 | 84.34 | 0.386 | 0.248 | 0.047 | 0.749 |

| M5 | 376.99 | 159.09 | 48.63 | 230.47 | 67.53 | 184.57 | 4.50 | 110.47 | 0.367 | 0.293 | 0.057 | 0.446 |

| M6 | 389.28 | 159.94 | 49.61 | 234.94 | 69.88 | 190.73 | 4.69 | 110.33 | 0.365 | 0.297 | 0.051 | 0.433 |

| M7 | 164.35 | 102.72 | 44.12 | 123.22 | 38.20 | 103.88 | 3.20 | 58.60 | 0.360 | 0.310 | 0.038 | 1.432 |

| M8 | 201.18 | 118.75 | 33.52 | 146.21 | 36.38 | 100.77 | 2.41 | 85.23 | 0.385 | 0.249 | 0.042 | 0.813 |

| M9 | 200.66 | 136.46 | 24.30 | 157.83 | 27.15 | 77.03 | 1.29 | 112.16 | 0.419 | 0.172 | 0.048 | 0.757 |

| M10 | 165.92 | 110.54 | 28.56 | 128.99 | 28.17 | 78.78 | 1.73 | 81.98 | 0.398 | 0.218 | 0.040 | 1.031 |

| M11 | 159.86 | 105.79 | 32.62 | 123.81 | 30.24 | 83.89 | 2.07 | 73.17 | 0.387 | 0.244 | 0.040 | 1.207 |

| M12 | 151.23 | 99.48 | 30.62 | 116.72 | 28.61 | 79.34 | 2.00 | 68.86 | 0.387 | 0.245 | 0.036 | 1.183 |

| Model | ρ (Kg/m3) | νl (m/s) | νs (m/s) | νm (m/s) | ΘD (K) | Tmelt (K) |

|---|---|---|---|---|---|---|

| M1 | 11,709.54 | 3862.68 | 1725.29 | 1946.48 | 231.60 | 1561.88 |

| M2 | 12,533.18 | 3971.51 | 1802.80 | 2032.49 | 241.00 | 1745.76 |

| M3 | 11,358.89 | 4526.66 | 1893.26 | 2141.44 | 266.25 | 2080.01 |

| M4 | 10,412.46 | 4302.30 | 1857.34 | 2098.35 | 253.92 | 1746.15 |

| M5 | 15,238.36 | 4586.22 | 2105.19 | 2372.21 | 302.38 | 2781.03 |

| M6 | 15,769.33 | 4561.45 | 2105.10 | 2371.51 | 289.05 | 2853.66 |

| M7 | 12,466.75 | 3737.64 | 1750.56 | 1970.71 | 229.56 | 1524.32 |

| M8 | 10,790.15 | 4247.93 | 1836.06 | 2074.22 | 246.82 | 1741.94 |

| M9 | 10,758.12 | 4246.85 | 1588.55 | 1802.85 | 220.72 | 1738.88 |

| M10 | 10,071.86 | 4066.47 | 1672.39 | 1892.72 | 227.19 | 1533.59 |

| M11 | 9629.90 | 4128.41 | 1772.07 | 2002.46 | 238.98 | 1497.77 |

| M12 | 9453.01 | 4047.57 | 1739.70 | 1965.78 | 231.23 | 1446.77 |

| Model | Clarke Model κmin (W·m−1·K−1) | Cahill Model κmin (W·m−1·K−1) | Slack Model κL (W·m−1·K−1) | Mixed Model κL (W·m−1·K−1) | γα | α (×10−5) | λdom (Å) |

|---|---|---|---|---|---|---|---|

| M1 | 0.54897 | 0.49659 | 0.69331 | 0.73710 | 2.361 | 4.59 | 0.815 |

| M2 | 0.56862 | 0.50962 | 0.88163 | 0.91413 | 2.311 | 3.93 | 0.851 |

| M3 | 0.66220 | 0.62294 | 0.76401 | 0.79356 | 2.556 | 3.93 | 0.897 |

| M4 | 0.61351 | 0.56618 | 0.70941 | 0.75364 | 2.464 | 4.45 | 0.879 |

| M5 | 0.76628 | 0.68246 | 1.75668 | 1.63648 | 2.276 | 2.37 | 0.994 |

| M6 | 0.70012 | 0.62166 | 1.84346 | 1.76763 | 2.260 | 2.29 | 0.993 |

| M7 | 0.53075 | 0.46744 | 0.87195 | 0.91217 | 2.213 | 4.19 | 0.825 |

| M8 | 0.58636 | 0.54074 | 0.71212 | 0.76133 | 2.460 | 4.40 | 0.869 |

| M9 | 0.54351 | 0.54905 | 0.34487 | 0.41132 | 2.860 | 5.89 | 0.755 |

| M10 | 0.54606 | 0.51904 | 0.45064 | 0.51310 | 2.604 | 5.68 | 0.793 |

| M11 | 0.56966 | 0.52752 | 0.56240 | 0.62115 | 2.481 | 5.29 | 0.839 |

| M12 | 0.54328 | 0.50271 | 0.52396 | 0.58808 | 2.477 | 5.59 | 0.823 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

San, S.; Hasan, S.; Adhikari, P.; Ching, W.-Y. Designing Quaternary and Quinary Refractory-Based High-Entropy Alloys: Statistical Analysis of Their Lattice Distortion, Mechanical, and Thermal Properties. Metals 2023, 13, 1953. https://doi.org/10.3390/met13121953

San S, Hasan S, Adhikari P, Ching W-Y. Designing Quaternary and Quinary Refractory-Based High-Entropy Alloys: Statistical Analysis of Their Lattice Distortion, Mechanical, and Thermal Properties. Metals. 2023; 13(12):1953. https://doi.org/10.3390/met13121953

Chicago/Turabian StyleSan, Saro, Sahib Hasan, Puja Adhikari, and Wai-Yim Ching. 2023. "Designing Quaternary and Quinary Refractory-Based High-Entropy Alloys: Statistical Analysis of Their Lattice Distortion, Mechanical, and Thermal Properties" Metals 13, no. 12: 1953. https://doi.org/10.3390/met13121953

APA StyleSan, S., Hasan, S., Adhikari, P., & Ching, W.-Y. (2023). Designing Quaternary and Quinary Refractory-Based High-Entropy Alloys: Statistical Analysis of Their Lattice Distortion, Mechanical, and Thermal Properties. Metals, 13(12), 1953. https://doi.org/10.3390/met13121953