Process Technology for Diffusion Welding with Cyclically Pulsative Joining Forces

Abstract

:1. Introduction

2. State of the Art

2.1. Fundamentals of Diffusion Welding

2.2. Recipient Design

2.3. Conclusions from the State of the Art and Objectives

- Reduction of the machining effort of joining the surfaces in advance.

- 2.

- Reduction of the welding time up to the replacement of the welding time by a frequency-based test criterion.

- 3.

- Adjustment of more favourable material properties through the frequency-superimposed application of force, and reduction of the phase thicknesses.

- Testing of materials and compounds in reactive environments through inert atmosphere or vacuum;

- Material and component testing under operating conditions, including temperature up to approx. 1000 °C, mechanical load in the compression and tensile range (static and dynamic), various inert ambient media;

- Reduction of the required measures for joining surface preparation by facilitated approximation of the surfaces to each other on an atomic level;

- Joining of materials in the pressure threshold range (welding pressure) up to 100 kN at characteristic frequencies up to 150 Hz and a variable number of load cycles;

- Enhancement of the factor frequency shift or frequency monitoring for non-destructive characterisation of the welded joint during the joining process and qualification of a joining time adapted to the process condition.

3. Experimental Methods

3.1. Concept of Technical Implementation

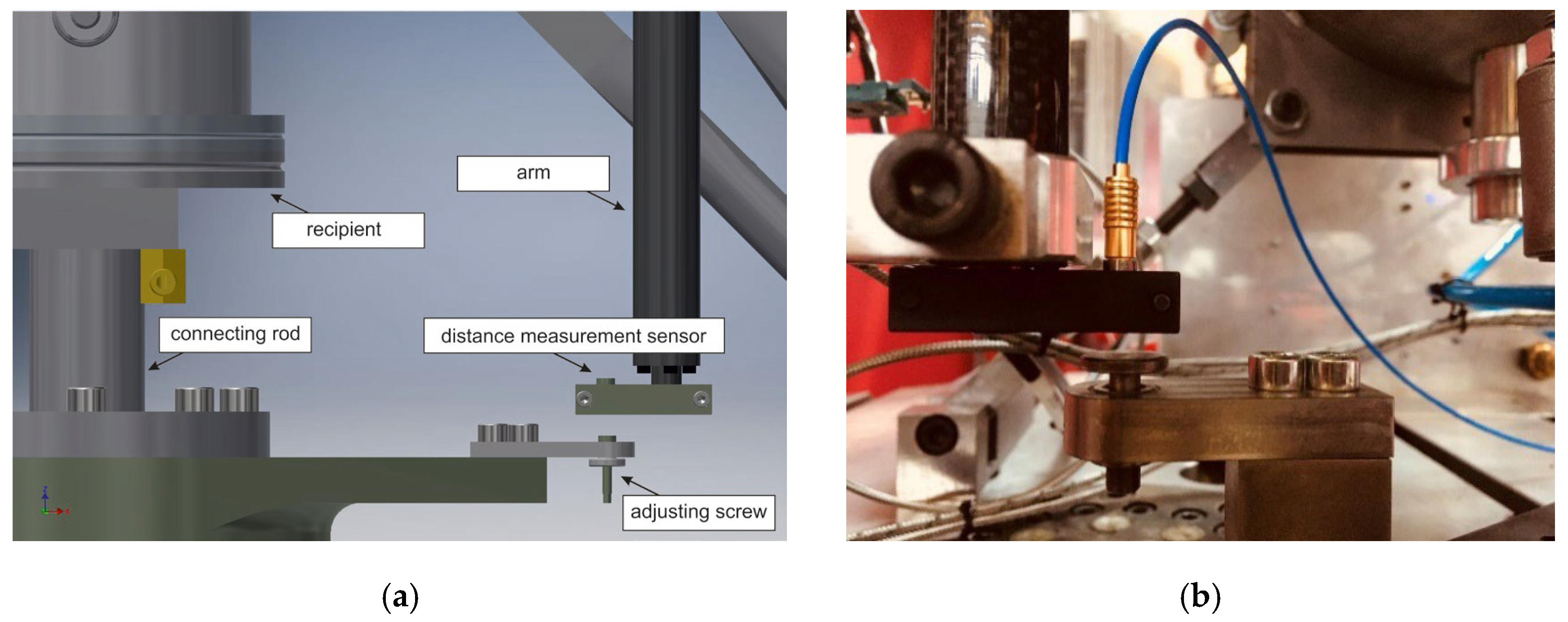

3.2. Construction

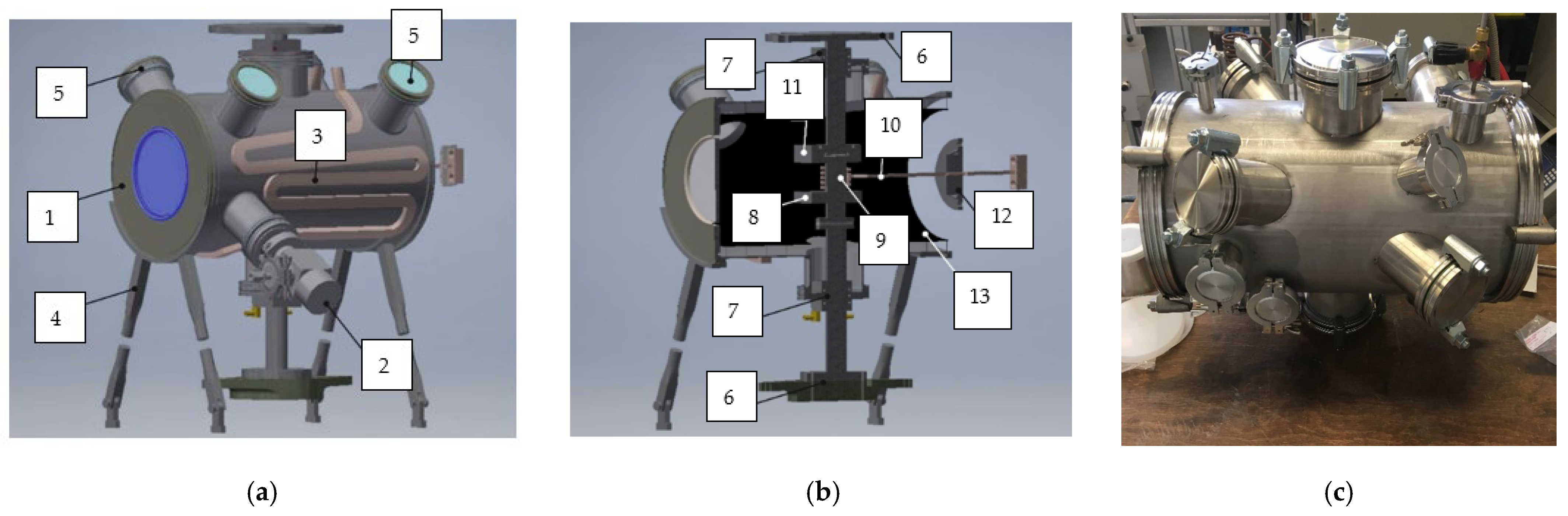

3.2.1. Vacuum Chamber—The Recipient

3.2.2. Sample Heating System

3.2.3. Control of the System

- With and without heating;

- Under vacuum or inert gas atmosphere;

- According to the type of pressure control (force- or distance-controlled).

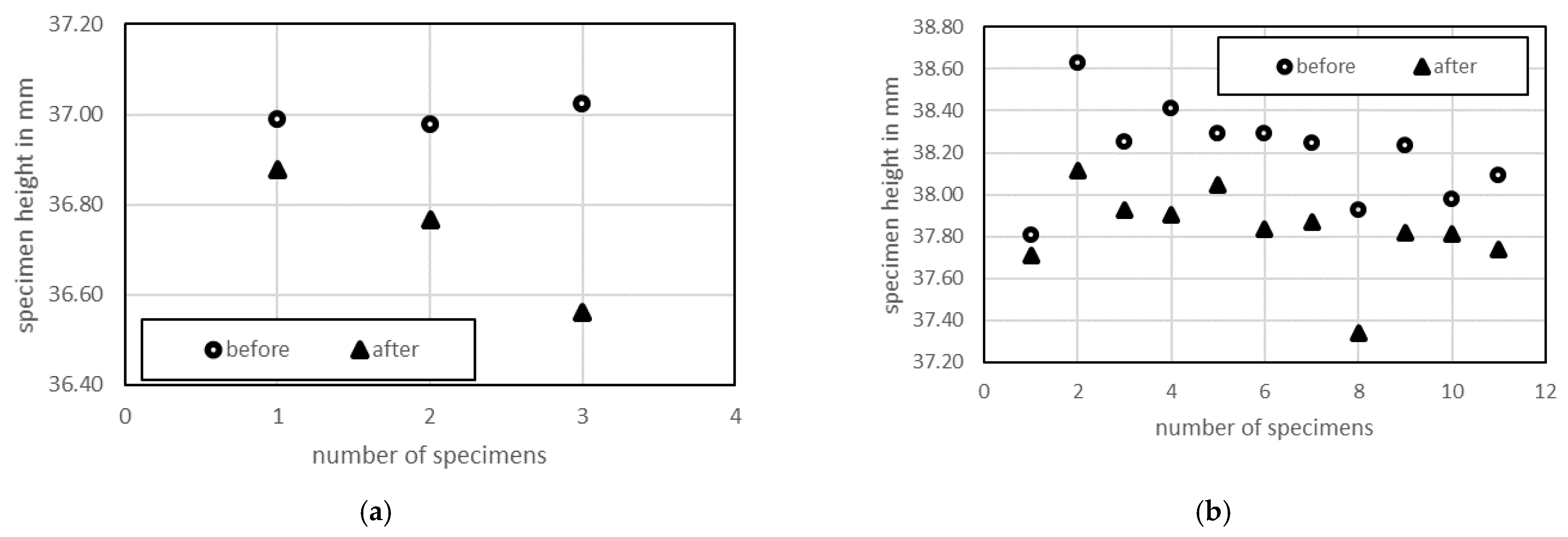

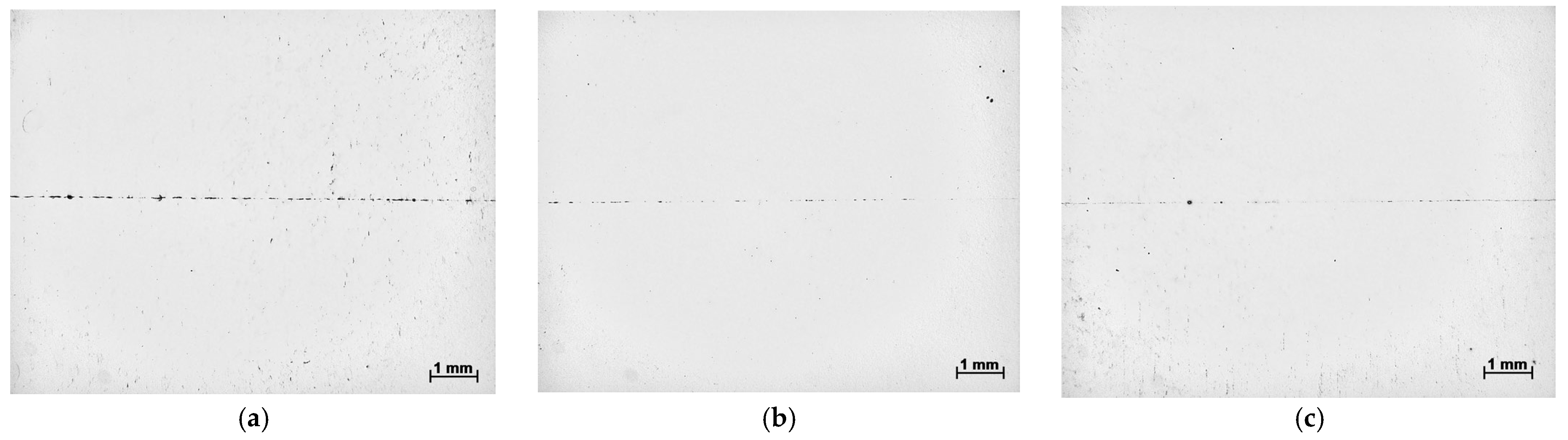

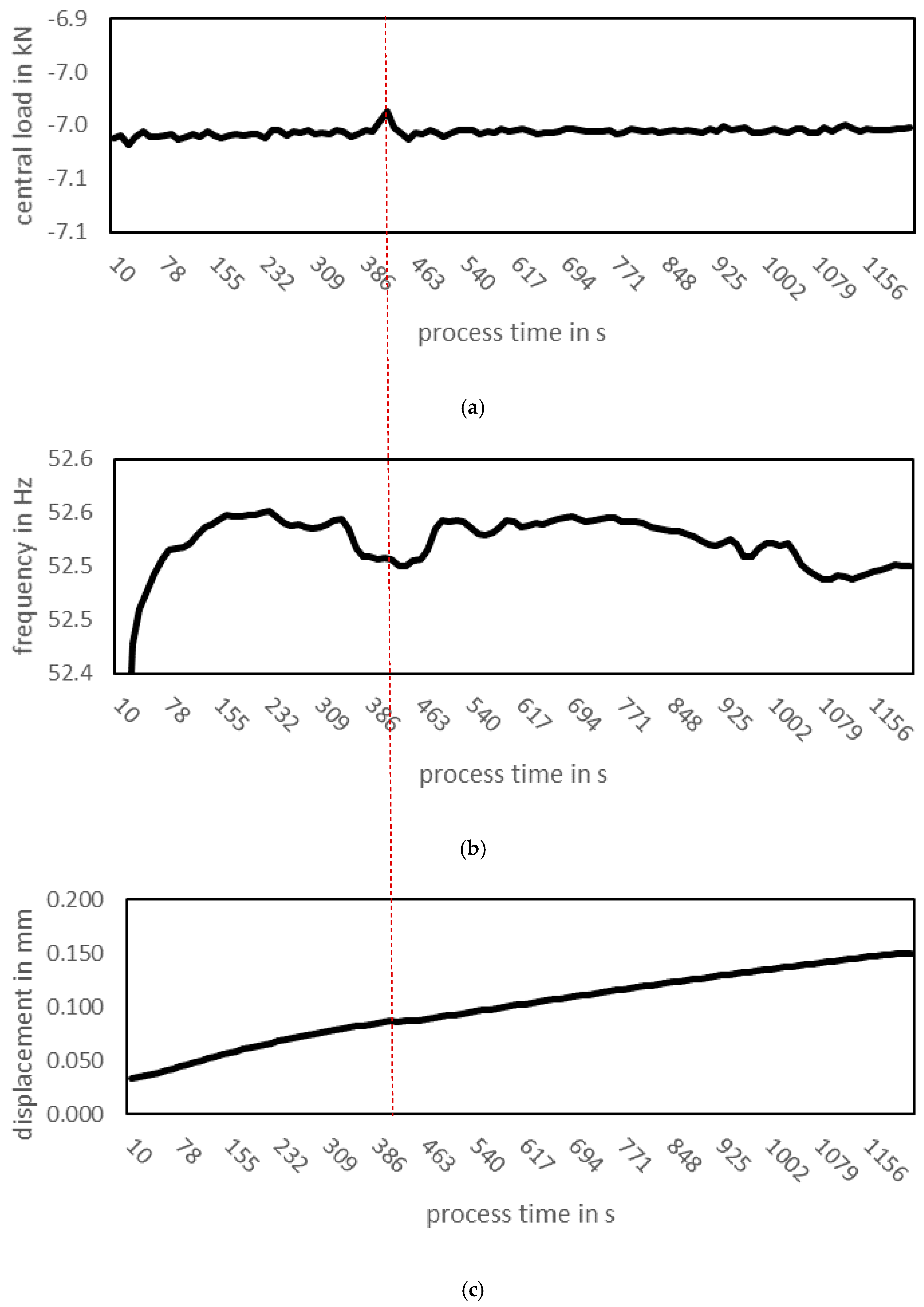

4. Results—Benchmarking Samples

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Matthes, K.-J.; Richter, E. (Eds.) Schweißtechnik–Schweißen von Metallischen Konstruktionswerkstoffen; Fachbuchverlag Leipzig: Leipzig, Germany, 2002. [Google Scholar]

- Akca, E.; Gürsel, A. The importance of interlayers in diffusion welding-A review. Period. Eng. Nat. Sci. (PEN) 2015, 3, 2. [Google Scholar] [CrossRef]

- Günther, W.-D.; Mehlhorn, H.; Wiesner, P. Diffusionsschweißen; Verlag Technik Berlin: Berlin, Germany, 1978. [Google Scholar]

- Basuki, W.W. Optimierung der Diffusionsschweißparameter von Hastelloy® C-22® zur Herstellung von Mikrowärmetauschern; Forschungszentrum Karlsruhe GmbH: Karlsruhe, Germany, 2008. [Google Scholar]

- Kolukisa, S. The effect of the welding temperature on the weldability in diffusion welding of martensitic (AISI 420) stainless steel with ductile (spheroidal graphite-nodular) cast iron. J. Mater. Process. Technol. 2007, 186, 33–36. [Google Scholar] [CrossRef]

- Ben-Haroush, M.; Mittelman, B.; Priel, R.S.E. The Influence of Time, Atmosphere and Surface Roughness on the Interface Strength and Microstructure of AA6061–AA1050 Diffusion Bonded Components. Materials 2023, 16, 769. [Google Scholar] [CrossRef] [PubMed]

- DIN EN ISO 21920-2; Geometrische Produktspezifikation (GPS)–Oberflächenbeschaffenheit: Profile–Teil 2: Begriffe und Kenngrößen für die Oberflächenbeschaffenheit. Deutsches Institut für Normung e. V.: Berlin, Germany, 2022.

- Dwivedi, G.S.D.K. Effect of pressure pulsation on bond interface characteristics of 409 ferritic stainless steel diffusion bonds. Vacuum 2017, 146, 152–158. [Google Scholar]

- Dwivedi, G.S.D.K. Diffusion bonding of 304 austenitic stainless-steel using pressure pulses. Mater. Today Proc. 2021, 44, 2135–2141. [Google Scholar]

- Dahms, S. Diffusionsschweißen von Werkstoffen Mit Unterschiedlichen Eigenschaften. Ph.D. Thesis, Tallin University of Technology, Tallin, Estonia, 2011. [Google Scholar]

- Jafarian, M.; Khodabandeh, A.; Manafi, S. Evaluation of diffusion welding of 6061 aluminum and AZ31 magnesium alloys without using an interlayer. Mater. Des. 2015, 65, 160–164. [Google Scholar] [CrossRef]

- Hafizi, M.; Kasiri-Asgarani, M.; Naalchian, M.; Bakhsheshi-Rad, H.R.; Berto, F. The Effect of Holding Time on Dissimilar Transient Liquid-Phase-Bonded Properties of Super-Ferritic Stainless Steel 446 to Martensitic Stainless Steel 410 Using a Nickel-Based Interlayer. Micromachines 2022, 13, 1801. [Google Scholar] [CrossRef] [PubMed]

- Shi, H.; Qiao, S.; Qui, R.; Yu, X.Z.H. Effect of Welding Time on the Joining Phenomena of Diffusion Welded Joint between Aluminum Alloy and Stainless Steel. Mater. Manuf. Process. 2012, 27, 1366–1369. [Google Scholar] [CrossRef]

- Chisabas, R.S.S.; Zabala, J.P.O.; Cantor, D.F.; Loureiro, G.; Lino, C.O. Development of a Thermal-Vacuum Chamber for testing in Small Satellites. In Proceedings of the 47th International Conference on Environmental Systems, Charleston, SC, USA, 16–20 July 2017. [Google Scholar]

- Eisfelder, J.E. Konstruktive Betrachtungen zum Diffusionsschweißen Mit Dynamisch Modulierter Prozesskraft. Ph.D. Thesis, Fakultät für Maschinenbau TU Chemnitz, Chemnitz, Germany, 2021. [Google Scholar]

- Awiszus, B.; Bast, J.; Dürr, H.; Matthes, K.-J. (Eds.) Grundlagen der Fertigungstechnik, 2nd ed.; Fachbuchverlag Leipzig: München, Germany, 2005. [Google Scholar]

- Zhu, L.; Wu, J.; Liu, Z.; Ma, J. Design of Electron Beam Welding Vacuum Chamber for Collar Rings in CFETR Windows. J. Fusion Energy 2017, 36, 127–133. [Google Scholar] [CrossRef]

- Cooper, N.; Coles, L.A.; Everton, S.; Maskey, I.; Campion, R.P.; Madkhaly, S.; Morley, C.; O’Shea, J.; Evans, W.; Saint, R.; et al. Additively manufactured ultra-high vacuum chamber for portable quantum technologies. Addit. Manuf. 2021, 40, 101898. [Google Scholar] [CrossRef]

- Jayaram, S.G.E. Design and construction of a low-cost economical thermal vacuum chamber for spacecraft environmental testing. J. Eng. Des. Technol. 2011, 9, 47–62. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, S.; Yoon, S.; Seon, J.; Jin, H.; Lee, D.; Lin, R.P. Construction of a Thermal Vacuum Chamber for Environment Test of Triple CubeSat Mission TRIO-CINEMA. J. Astron. Space Sci. 2013, 30, 335–344. [Google Scholar] [CrossRef] [Green Version]

- “3.2.2 Dichtungswerkstoffe,” Pfeiffer Vacuum GmbH. Available online: https://www.pfeiffer-vacuum.com/de/know-how/mechanische-komponenten-im-vakuum/werkstoffe/dichtungswerkstoffe/elastomerdichtungen/ (accessed on 1 September 2022).

- DIN 28404; Vakuumtechnik, Flansche-Maße. Deutsches Institut für Normung e.V.: Berlin, Germany, 1986.

- Yang, J.; Chen, R.D.H.; Guo, J.; Han, J.; Fu, H. Thermal characteristics of induction heating in cold crucible used for directional solidification. Appl. Therm. Eng. 2013, 59, 69–76. [Google Scholar] [CrossRef]

- Yang, Y.; Wang, X.L.S. Thermal characteristics of induction heating with stepped diameter mold during two-phase zone continuous casting high-strength aluminum alloys. Int. J. Heat Mass Transf. 2020, 152, 119479. [Google Scholar] [CrossRef]

- DIN EN 1593; Dichtheitsprüfung–Blasenprüfverfahren. Deutsches Institut für Normung e.V.: Berlin, Germany, 1999.

- Stahlhandel Gröditz GmbH. 1.7225 (42CrMo4 vergütet)|1.7227 (42CrMoS4) Werkstoffdatenblatt. Available online: https://www.stahlportal.com/lagervorrat/17225-42crmo4-verguetet-17227-42crmos4/ (accessed on 30 September 2022).

- Stahlhandel Gröditz GmbH. 1.0503 (C45)|1.1730 C45U Werkstoffdatenblatt. Available online: https://www.stahlportal.com/lagervorrat/10503-c45-11730-c45u/ (accessed on 30 September 2022).

- Yuan, X.J.; Sheng, G.M.; Qin, B.; Zhou, W.Z.H.B. Impulse pressuring diffusion bonding of titanium alloy to stainless steel. Mater. Charact. 2008, 59, 930–936. [Google Scholar] [CrossRef]

- Guangmin, L.J.S. Diffusion Bonding of TiC Cermet to Stainless Steel Using Impulse Pressuring with Ti-Nb Interlayer. Rare Met. Mater. Eng. 2017, 46, 882–887. [Google Scholar]

| Description 0 = 1 = | Heating without with | Atmosphere Vacuum Shield Gas | Pressure Control Strength-Regulated Travel-Regulated |

|---|---|---|---|

| scenario A 1 scenario A 2 | 1 | 0 | 0 |

| 1 | 0 | 1 | |

| scenario B 1 scenario B 2 | 0 | 0 | 0 |

| 0 | 0 | 1 | |

| scenario C 1 scenario C 2 | 1 | 1 | 0 |

| 1 | 1 | 1 | |

| scenario D 1 scenario D 2 | 0 | 1 | 0 |

| 0 | 1 | 1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

John, B.; Letsch, H.; Wölck, J.; Hess, M.; Hensel, J. Process Technology for Diffusion Welding with Cyclically Pulsative Joining Forces. Metals 2023, 13, 547. https://doi.org/10.3390/met13030547

John B, Letsch H, Wölck J, Hess M, Hensel J. Process Technology for Diffusion Welding with Cyclically Pulsative Joining Forces. Metals. 2023; 13(3):547. https://doi.org/10.3390/met13030547

Chicago/Turabian StyleJohn, Björn, Holger Letsch, Johannes Wölck, Marcel Hess, and Jonas Hensel. 2023. "Process Technology for Diffusion Welding with Cyclically Pulsative Joining Forces" Metals 13, no. 3: 547. https://doi.org/10.3390/met13030547

APA StyleJohn, B., Letsch, H., Wölck, J., Hess, M., & Hensel, J. (2023). Process Technology for Diffusion Welding with Cyclically Pulsative Joining Forces. Metals, 13(3), 547. https://doi.org/10.3390/met13030547