Effect of Semi-Aging Heat Treatment on Microstructure and Mechanical Properties of an Inertia Friction Welded Joint of FGH96 Powder Metallurgy Superalloy

Abstract

:1. Introduction

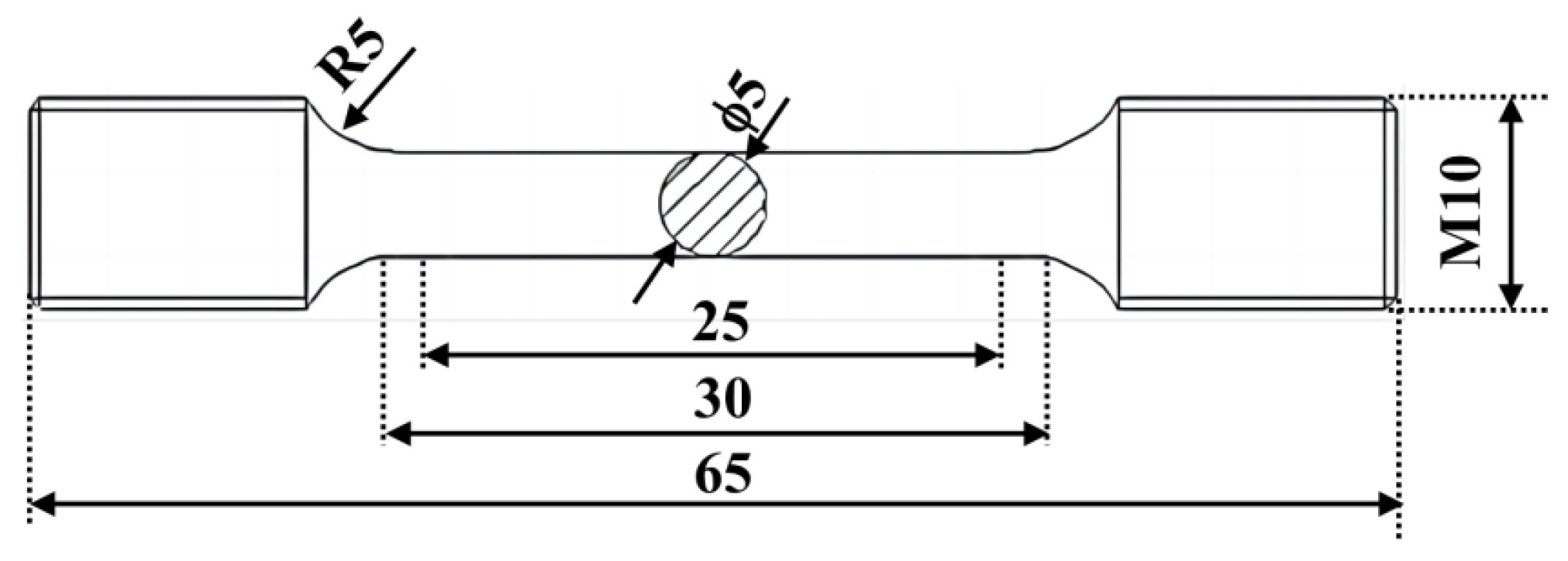

2. Materials and Methods

3. Results and Discussion

3.1. Morphology of Welded Joints

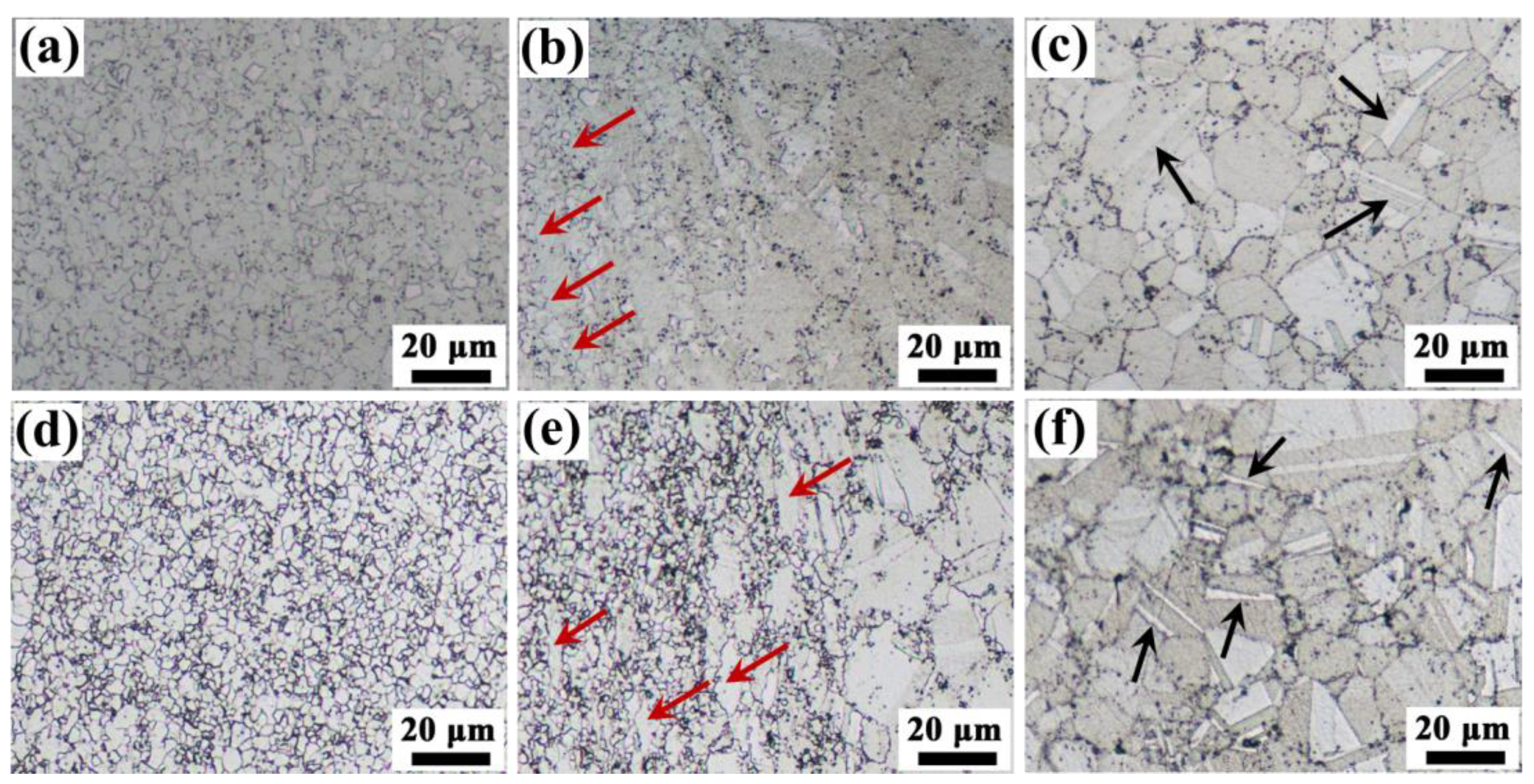

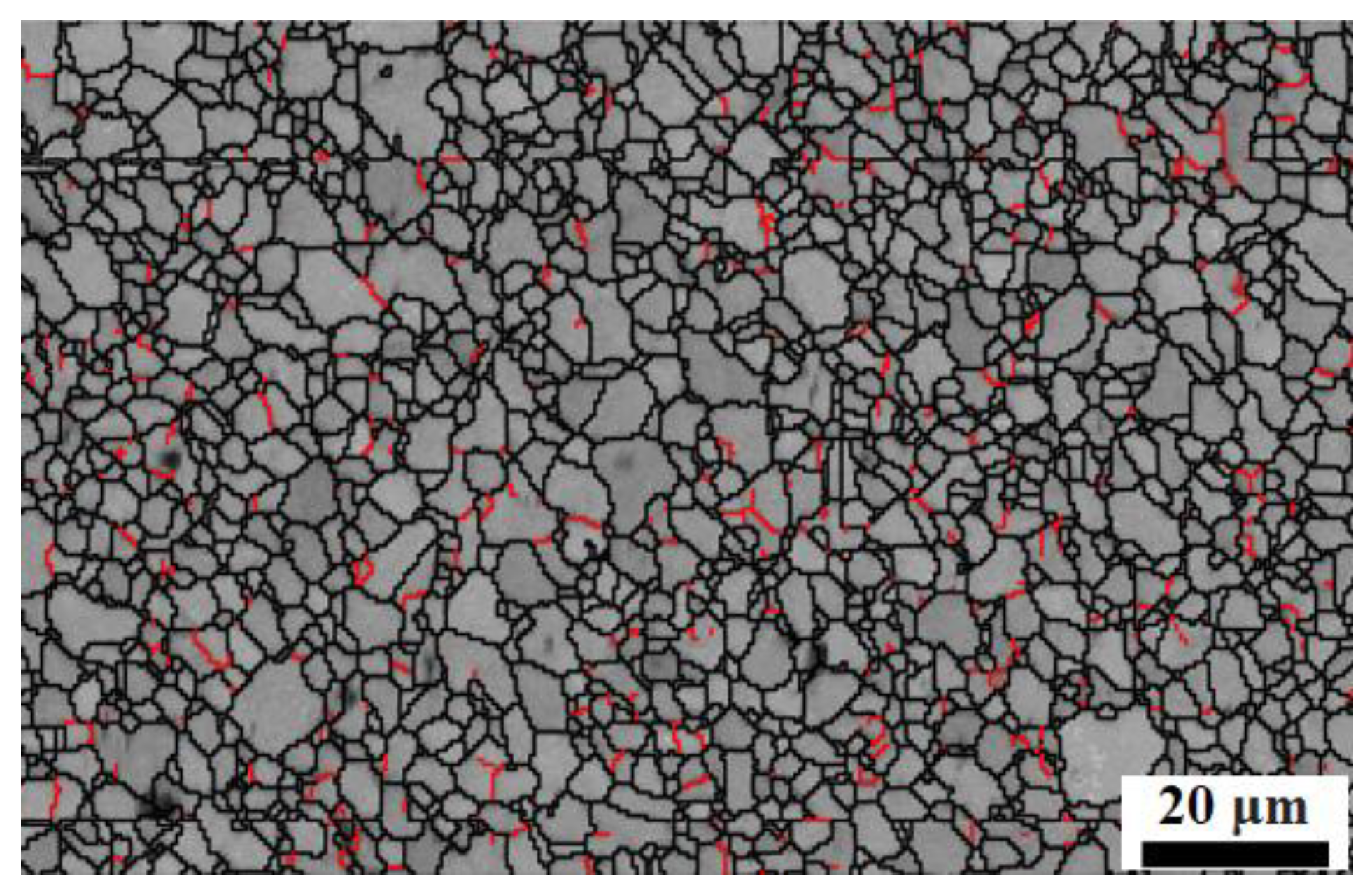

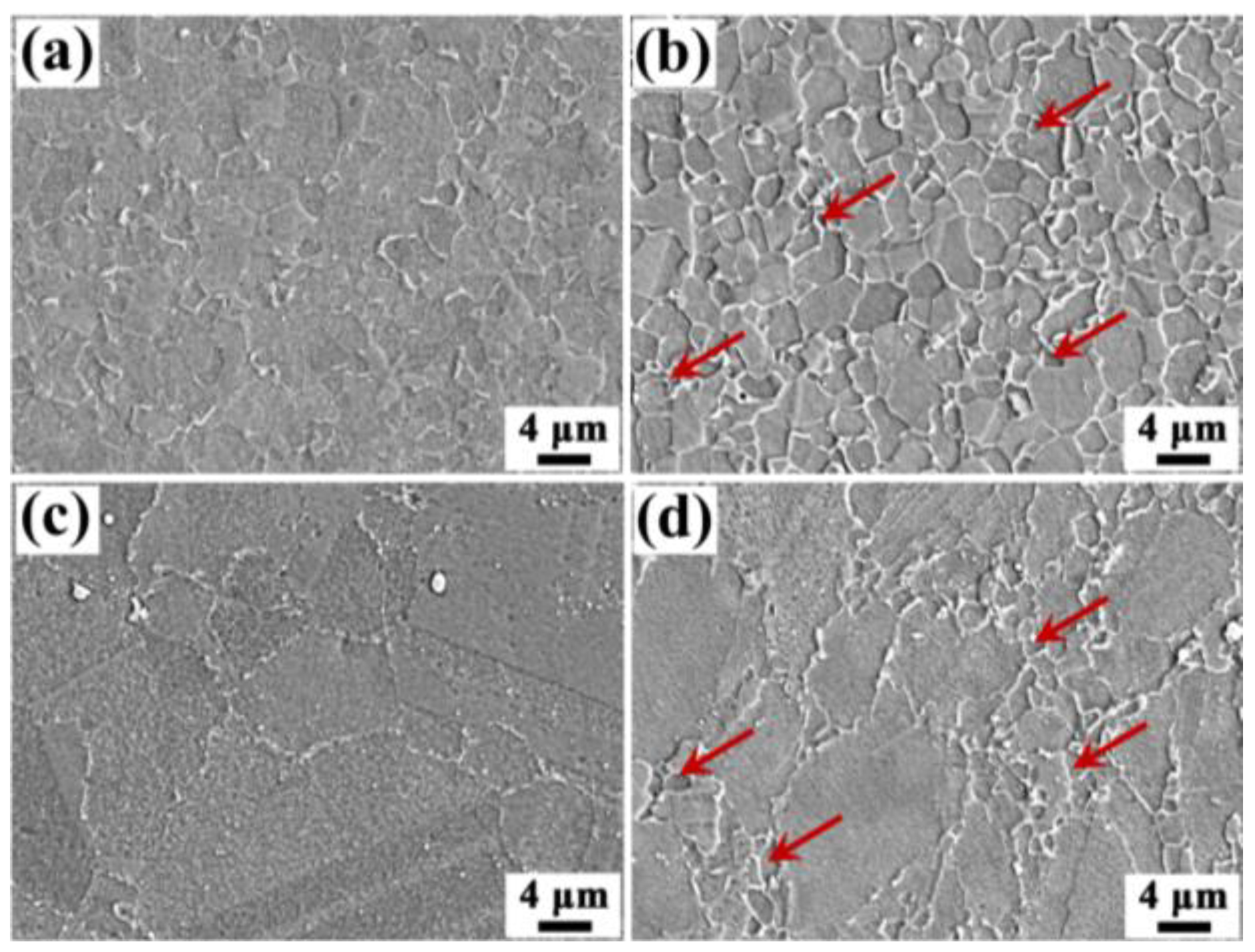

3.2. Microstructure

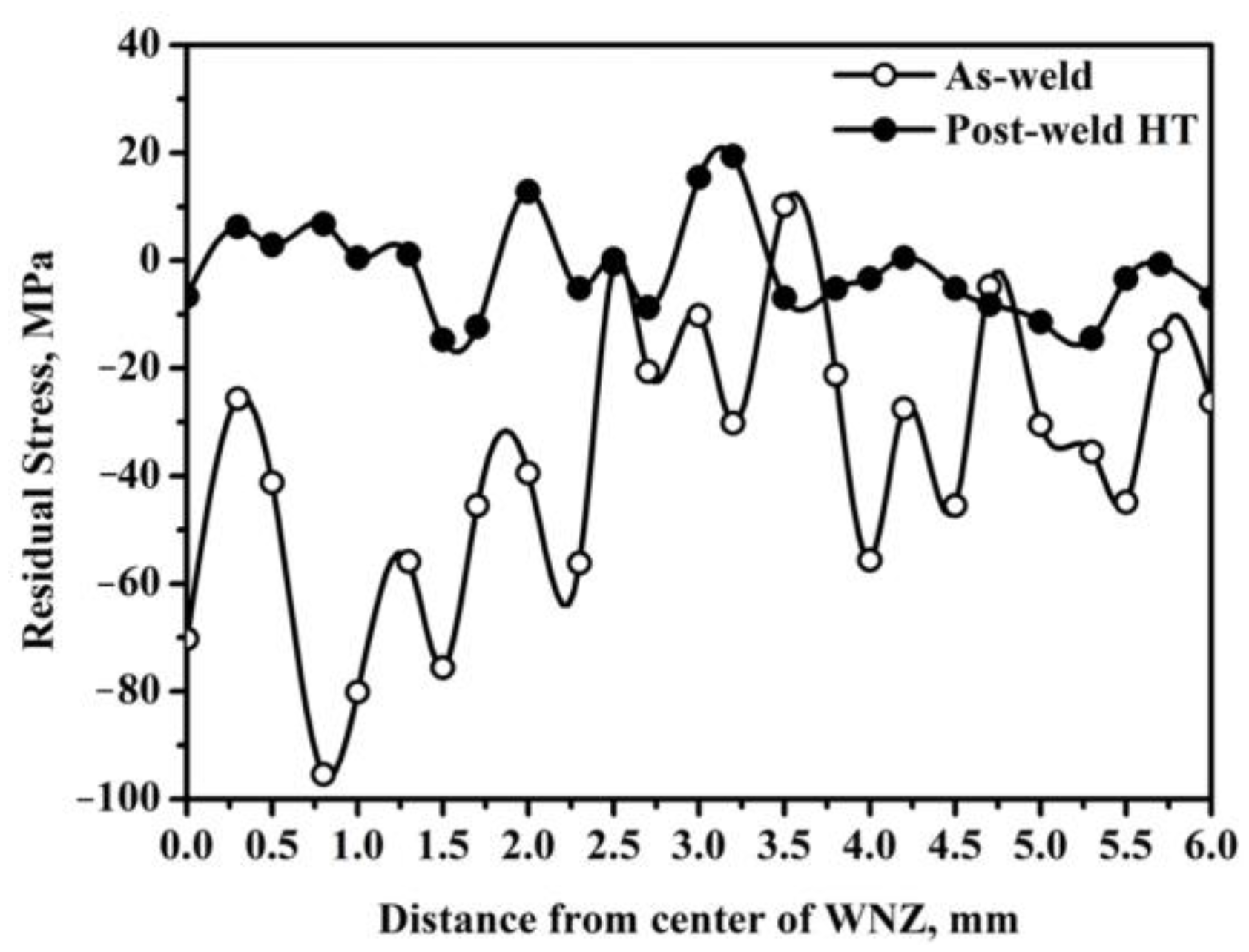

3.3. Distribution of Residual Stress

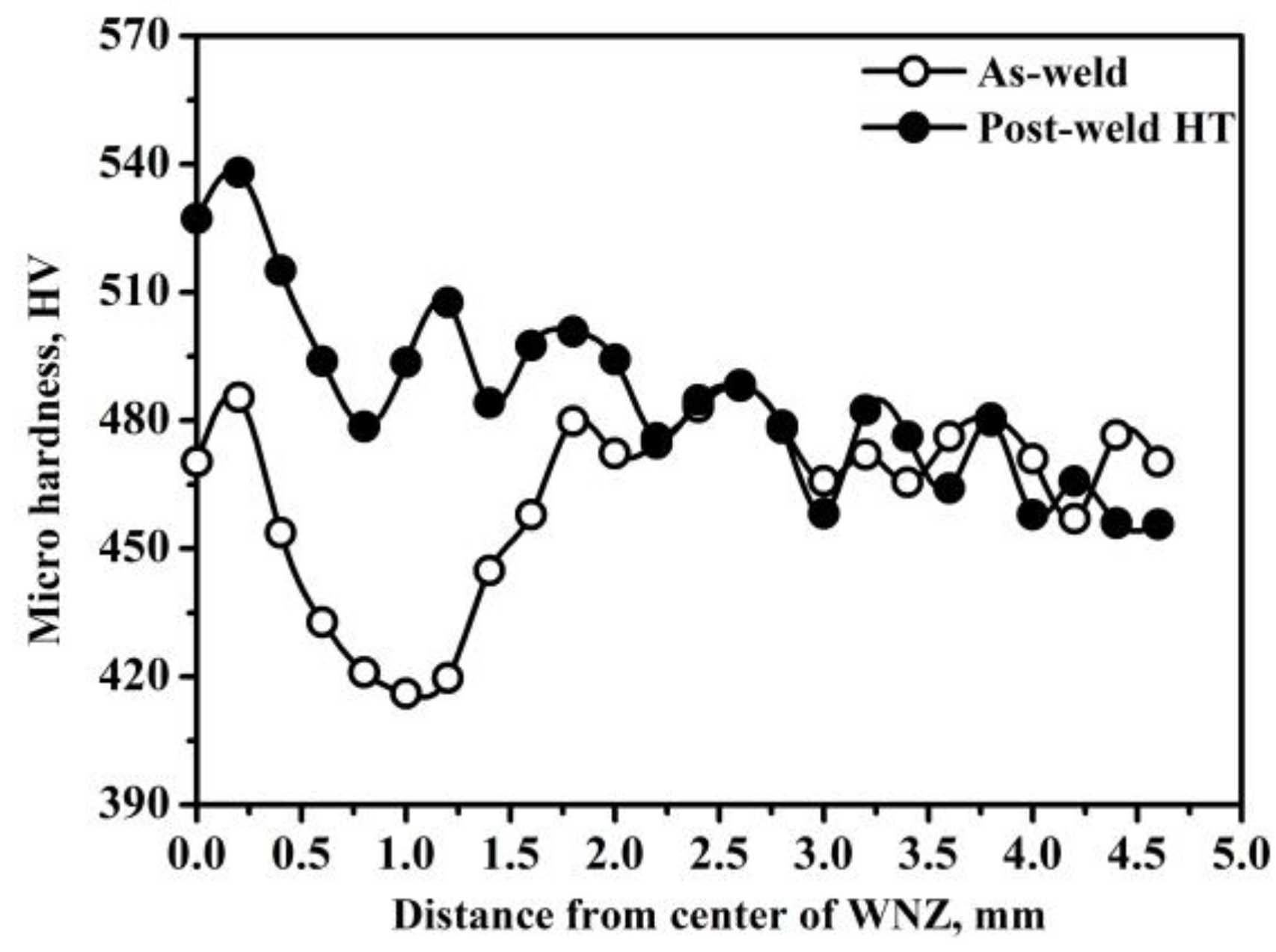

3.4. Distribution of Micro-Hardness

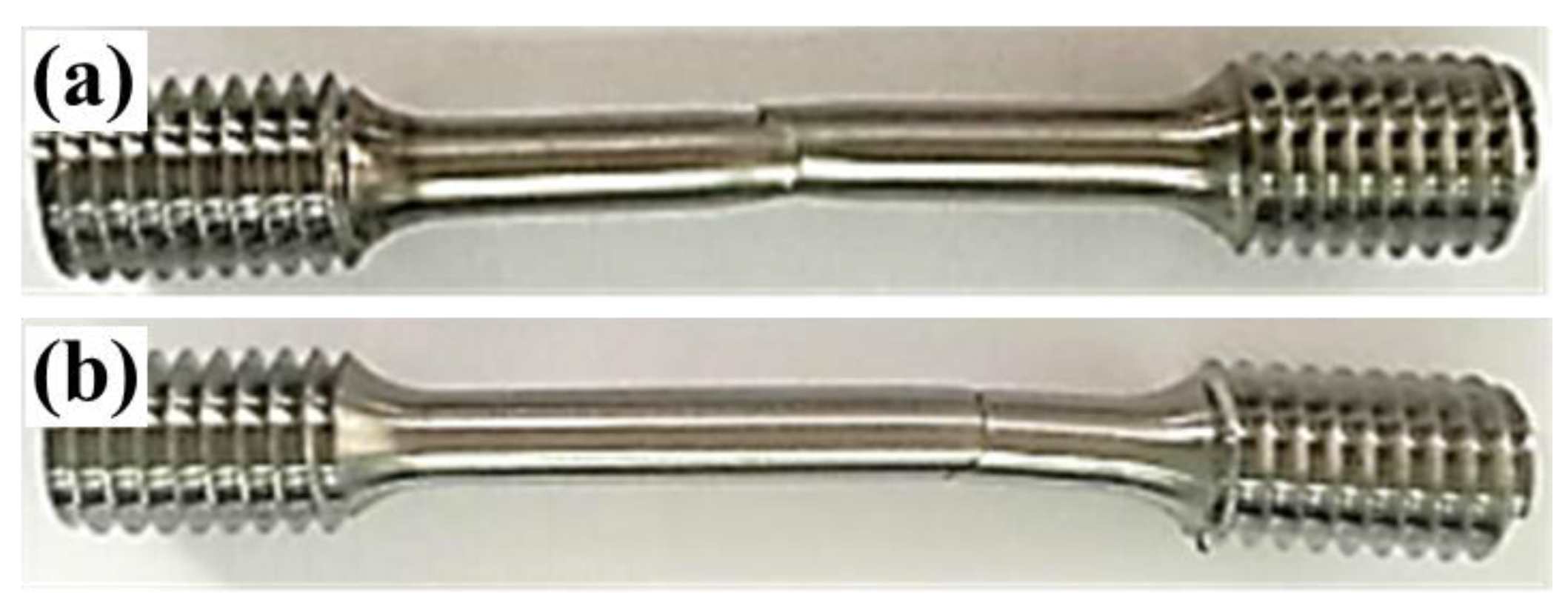

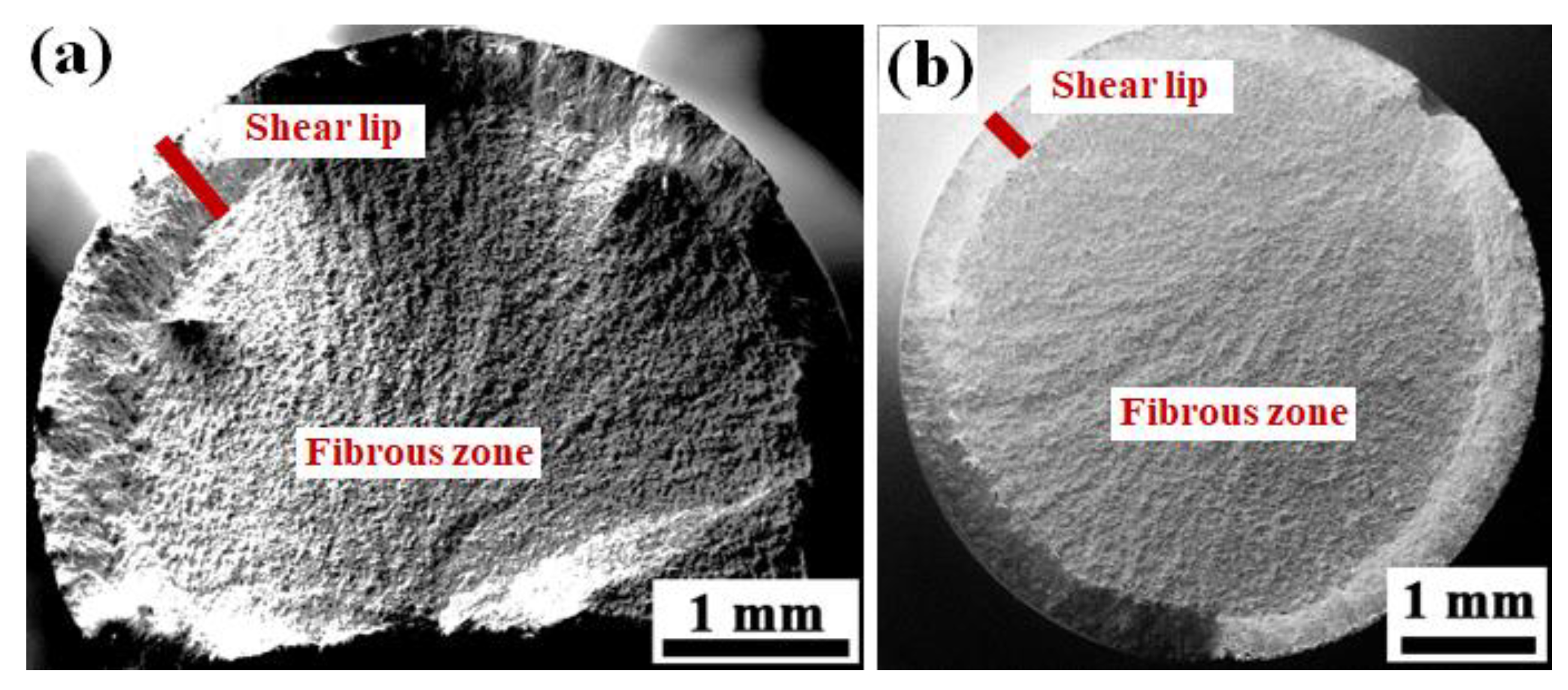

3.5. Mechanical Properties and Failure Behavior

4. Conclusions

- (1)

- After the semi-aging heat treatment, the grain size and grain boundary morphology of the base metal shows no changes. However, the semi-aging heat treatment can further facilitate recrystallization in the WNZ and TZ, which reduces the average grain size in the WNZ from 4.18 μm to 2.88 μm.

- (2)

- A large residual stress of up to −96 MPa existed in the inertia friction welded FGH96 joint. However, semi-aging heat treatment after welding (760 °C, 8 h) can effectively eliminate the residual stress in the WNZ and TZ, making the overall residual stress of the welded sample uniform.

- (3)

- Post-weld semi-aging heat treatment increased the micro-hardness of the WNZ from 470 HV to 530 HV. Meanwhile, post-weld semi-aging heat treatment also increased the room temperature tensile strength, which leads to the failure location relocating to the base metal.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, Y.H.; Wang, M.; Sun, P.W.; Yang, G.; Song, W.J.; Wang, X.F. Effect of solution treatment on microstructure evolution of a powder metallurgy nickel based superalloy with incomplete dynamic recrystallization microstructure. Metals 2023, 13, 239. [Google Scholar] [CrossRef]

- Lin, C.H.; Yu, L.W.; Zeng, J.L.; Wu, H.B.; Guo, X.J.; Liu, J.X.; Zhang, Y.K. Experimental study on FGH95 superalloy turbine disk joint material by oblique laser shock processing. Metals 2021, 11, 1770. [Google Scholar] [CrossRef]

- Xu, Y.M.; Zhang, S.M.; He, T.P.; Liu, X.L.; Chang, X.Y. Prediction of low-cycle crack initiation life of powder superalloy FGH96 with inclusions based on damage mechanics. Trans. Nonferr. Met. Soc. China 2012, 32, 895–907. [Google Scholar] [CrossRef]

- Peng, Z.C.; Zou, J.W.; Wang, X.Q. Microstructural characterization of dislocation movement during creep in powder metallurgy FGH96 superalloy. Mater. Today Commun. 2020, 25, 101361. [Google Scholar] [CrossRef]

- Shi, Y.; Yang, X.G.; Yang, D.D.; Shi, D.Q.; Miao, G.L. Evaluation of the influence of surface crack-like defects on fatigue life for a P/M nickel-based superalloy FGH96. Int. J. Fatigue 2020, 137, 105639. [Google Scholar] [CrossRef]

- Singh, A.R.P.; Nag, S.; Chattopadhyay, S.; Ren, Y.; Tiley, J.; Viswanathan, G.B.; Fraser, H.L.; Banerjee, R. Mechanisms related to different generations of γ′ precipitation during continuous cooling of a nickel base superalloy. Acta Mater. 2013, 61, 280–293. [Google Scholar] [CrossRef]

- Li, L.; Liu, F.R.; Nie, S.J.; Wang, Q.; Zhao, R.X.; Zhang, Y.Z.; Feng, H.Y.; Lin, X. Effect of thermal cycling on grain evolution and micro-segregation in selective laser melting of FGH96 superalloy. Metals 2023, 13, 121. [Google Scholar] [CrossRef]

- Liu, W.; Liu, Z.L.; Zhang, H.; Ruan, J.J.; Huang, H.L.; Zhou, X.; Meng, F.C.; Zhang, S.Z.; Jiang, L. Hot deformation behavior and new grain size model of hot extruded FGH4096 superalloy during hot compression. J. Alloys Compd. 2023, 938, 168574. [Google Scholar] [CrossRef]

- Liu, A.; Zhang, Y.T.; Wang, X.S.; Xu, W.; Zhang, Y.; He, Y.H. Evaluation of the influences of the stress ratio, temperatures, and local microstructure on small fatigue crack propagation behavior of the FGH96 superalloy. Int. J. Fatigue 2023, 171, 107573. [Google Scholar] [CrossRef]

- Xu, Y.M.; Chen, H.; Zhang, S.M.; He, T.P.; Liu, X.R.; Chang, X.Y. An experimental study on low-cycle fatigue crack initiation life prediction of powder superalloy FGH96 based on the Manson-Coffin and damage mechanics methods. Metals 2021, 11, 489. [Google Scholar] [CrossRef]

- Zhang, M.J.; Li, F.G.; Yuan, Z.W.; Li, J.; Wang, S.Y. Effect of heat treatment on the micro-indentation behavior of powder metallurgy nickel based superalloy FGH96. Mater. Design 2013, 49, 705–715. [Google Scholar] [CrossRef]

- Preuss, M.; Withers, P.J.; Pang, J.W.L.; Baxter, G.J. Inertia welding nickel-based auperalloy: Part II. Residual stress characterization. Metall. Mater. Trans. A 2002, 33, 3227–3234. [Google Scholar] [CrossRef]

- Preuss, M.; Withers, P.J.; Pang, J.W.L.; Baxter, G.J. Inertia welding nickel-based superalloy: Part I. Metallurgical characterization. Metall. Mater. Trans. A 2002, 33, 3215–3225. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, W.F.; Zhang, L.W.; Xia, Y.N.; Li, R.Q. The microstructure and gamma prime distributions in inertia friction welded joint of P/M superalloy FGH96. J. Mater. Eng. Perform. 2017, 26, 1581–1588. [Google Scholar] [CrossRef]

- Wang, Z.T.; Huang, S.; Zhang, W.Y.; Zhang, B.J.; Ning, Y.Q. Microstructure characterization and mechanical property of the GH4065A superalloy inertia friction welded joints. Metals 2022, 12, 1390. [Google Scholar] [CrossRef]

- Li, Z.S.; Liu, Z.T.; Chen, D.J.; Mo, F.; Fu, Y.F.; Dai, Y.; Wu, X.; Cong, D.L. Study of microstructure and properties of aluminum/steel inertia radial friction welding. Metals 2022, 12, 2023. [Google Scholar] [CrossRef]

- Attallah, M.M.; Preuss, M. 2-Inertia friction welding (IFW) for aerospace applications. In Woodhead Publishing Series in Welding and Other Joining Technologies, Welding and Joining of Aerospace Materials, 2nd ed.; Chaturvedi, M.C., Ed.; Woodhead Publishing: Winnipeg, MB, Canada, 2012; pp. 21–74. [Google Scholar]

- Raimondi, L.; Bennett, C.J.; Axinte, D.; Gameros, A.; Stevens, P.A. Development of a novel monitoring system for the in-process characterisation of the machine and tooling effects in Inertia Friction Welding (IFW). Mech. Syst. Signal Process. 2021, 156, 107551. [Google Scholar] [CrossRef]

- Cam, G.; Kocak, M. Progress in joining of advanced materials. Int. Mater. Rev. 1998, 43, 1–33. [Google Scholar] [CrossRef]

- Maalekian, M.; Kozeschnik, E.; Brantner, H.P.; Cerjak, H. Comparative analysis of heat generation in friction welding of steel bars. Acta Mater. 2008, 56, 2843–2855. [Google Scholar] [CrossRef]

- Karadge, M.; Grant, B.; Withers, P.J.; Baxter, G.; Preuss, M. Thermal relaxation of residual stresses in nickel-based superalloy inertia friction welds. Metall. Mater. Trans. A 2011, 42, 2301–2311. [Google Scholar] [CrossRef]

- Pang, J.W.L.; Preuss, M.; Withers, P.J.; Baxter, G.J.; Small, C. Effects of tooling on the residual stress distribution in an inertia weld. Mater. Sci. Eng. A 2003, 356, 405–413. [Google Scholar] [CrossRef]

- Yang, J.; Li, J.L.; Jin, F. Effect of welding parameters on high-temperature tensile and fatigue properties of FGH96 inertia friction welded joints. Weld. World 2019, 63, 1033–1053. [Google Scholar] [CrossRef]

- Bennett, C.J.; Hyde, T.H.; Shipway, P.H. A transient finite element analysis of thermoelastic effects during inertia friction welding. Comp. Mater. Sci. 2011, 50, 2592–2598. [Google Scholar] [CrossRef]

- Grant, B.; Preuss, M.; Withers, P.J.; Baxter, G.; Rowlson, M. Finite element process modelling of inertia friction welding advanced nickel-based superalloy. Mater. Sci. Eng. A 2009, 513–514, 366–375. [Google Scholar] [CrossRef]

- Chamanfar, A.; Jahazi, M.; Cormier, J. A review on inertia and linear friction welding of Ni-based superalloys. Metall. Mater. Trans. A 2015, 46, 1639–1669. [Google Scholar] [CrossRef]

- Senkov, O.N.; Mahaffey, D.W.; Semiatin, S.L. A comparison of the inertia friction welding behavior of similar and dissimilar Ni-based superalloys. Metall. Mater. Trans. A 2018, 49, 5428–5444. [Google Scholar] [CrossRef]

- Huang, Z.W.; Li, H.Y.; Baxter, G.; Bray, S.; Bowen, P. Electron microscopy characterization of the weld line zones of an inertia friction welded superalloy. J. Mater. Process. Technol. 2011, 211, 1927–1936. [Google Scholar] [CrossRef]

- Nie, L.F.; Zhang, L.W.; Zhu, Z.; Xu, W. Microstructure evolution modeling of FGH96 superalloy during inertia friction welding process. Finite Elem. Anal. Des. 2014, 80, 63–68. [Google Scholar] [CrossRef]

- Iqbal, N.; Rolph, J.; Moat, R.; Hughes, D.; Hofmann, M.; Kelleher, J.; Baxter, G.; Withers, P.J.; Preuss, M. A comparison of residual stress development in inertia friction welded fine grain and coarse grain nickel-base superalloy. Metall. Mater. Trans. A 2011, 42, 4056–4063. [Google Scholar] [CrossRef]

- Iracheta, O.; Bennett, C.J.; Sun, W. A sensitivity study of parameters affecting residual stress predictions in finite element modelling of the inertia friction welding process. Int. J. Solids Struct. 2015, 71, 180–193. [Google Scholar] [CrossRef]

- Akarapu, S.; Hirth, J.P. Dislocation pile-ups in stress gradients revisited. Acta Mater. 2013, 61, 3621–3629. [Google Scholar] [CrossRef]

- Damodaram, R.; Ganesh Sundara Raman, S.; Satyanarayana, D.V.V.; Madhusudhan Reddy, G.; Prasad Rao, K. Hot tensile and stress rupture behavior of friction welded alloy 718 in different pre-and post-weld heat treatment conditions. Mater. Sci. Eng. A 2014, 612, 414–422. [Google Scholar] [CrossRef]

- Preuss, M.; Withers, P.J.; Baxter, G.J. A comparison of inertia friction welds in three nickel base superalloys. Mater. Sci. Eng. A 2006, 437, 38–45. [Google Scholar] [CrossRef]

- Li, W.Y.; Wang, F.F. Modeling of continuous drive friction welding of mild steel. Mater. Sci. Eng. A 2011, 528, 5921–5926. [Google Scholar] [CrossRef]

- Masoumi, F.; Shahriari, D.; Monajati, H.; Cormier, J.; Flipo, B.C.D.; Devaux, A.; Jahazi, M. Linear friction welding of AD730™ Ni-base superalloy: Process-microstructure-property interactions. Mater. Design 2019, 183, 108117. [Google Scholar] [CrossRef]

- Tabaie, S.; Rézaï-Aria, F.; Flipo, B.C.D.; Jahazi, M. Grain size and misorientation evolution in linear friction welding of additively manufactured IN718 to forged superalloy AD730™. Mater. Charact. 2021, 171, 110766. [Google Scholar] [CrossRef]

| C | Cr | Co | Mo | W | Al | Ti | Nb | Ni |

|---|---|---|---|---|---|---|---|---|

| 0.02~0.05 | 15.50~16.50 | 12.50~13.50 | 3.80~4.20 | 3.80~4.20 | 2.00~2.40 | 3.50~3.90 | 0.60~1.00 | Bal. |

| Target Material | Voltage, KV | Current, mA | Diffraction Crystal Face | 2Ɵ |

|---|---|---|---|---|

| Mn | 20 | 4 | (311) | 152–162 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, X.; Zhu, G.; Tan, Q.; Sun, B. Effect of Semi-Aging Heat Treatment on Microstructure and Mechanical Properties of an Inertia Friction Welded Joint of FGH96 Powder Metallurgy Superalloy. Metals 2023, 13, 632. https://doi.org/10.3390/met13030632

Han X, Zhu G, Tan Q, Sun B. Effect of Semi-Aging Heat Treatment on Microstructure and Mechanical Properties of an Inertia Friction Welded Joint of FGH96 Powder Metallurgy Superalloy. Metals. 2023; 13(3):632. https://doi.org/10.3390/met13030632

Chicago/Turabian StyleHan, Xiufeng, Guoliang Zhu, Qingbiao Tan, and Baode Sun. 2023. "Effect of Semi-Aging Heat Treatment on Microstructure and Mechanical Properties of an Inertia Friction Welded Joint of FGH96 Powder Metallurgy Superalloy" Metals 13, no. 3: 632. https://doi.org/10.3390/met13030632

APA StyleHan, X., Zhu, G., Tan, Q., & Sun, B. (2023). Effect of Semi-Aging Heat Treatment on Microstructure and Mechanical Properties of an Inertia Friction Welded Joint of FGH96 Powder Metallurgy Superalloy. Metals, 13(3), 632. https://doi.org/10.3390/met13030632